Clutch pedal HONDA CR-V 1999 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 30 of 1395

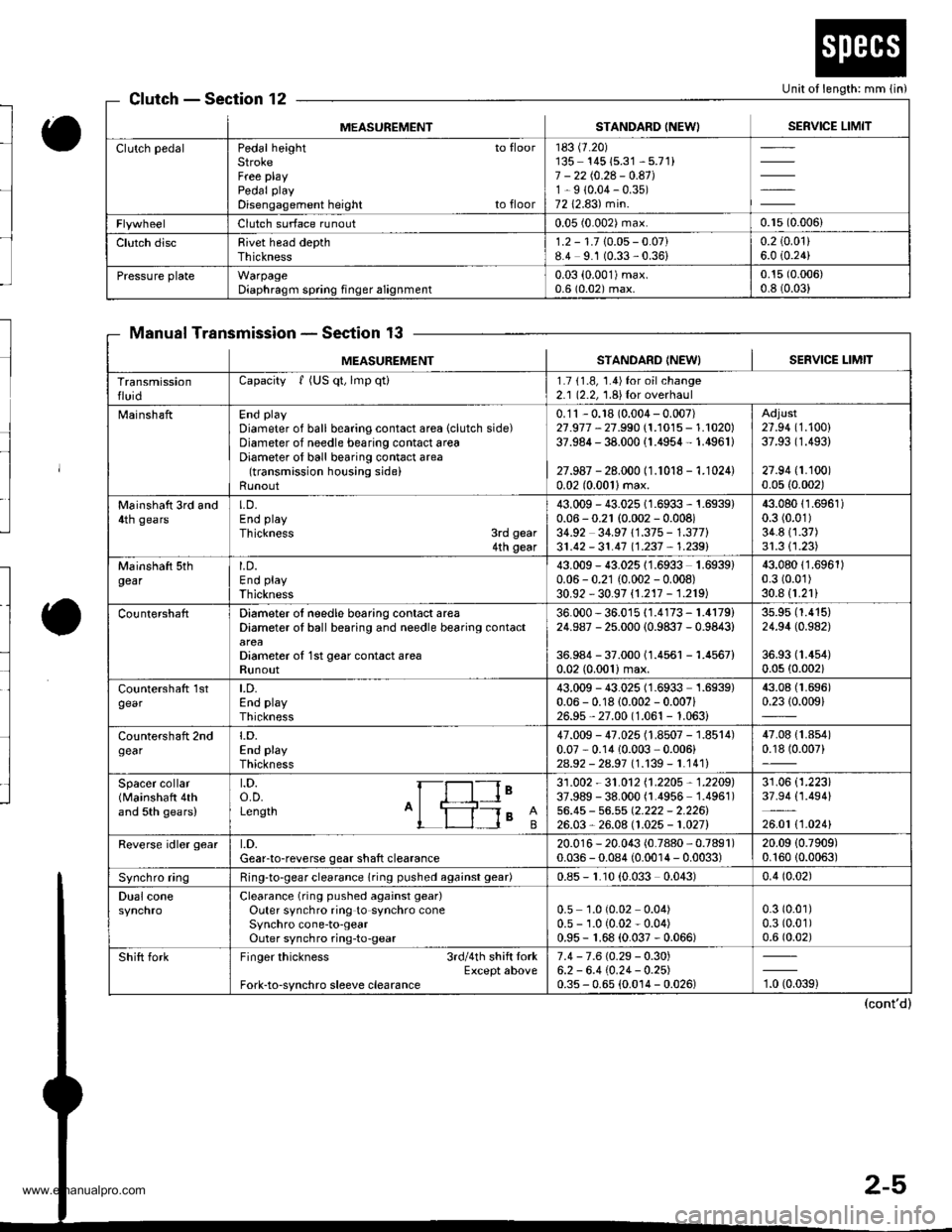

Unit of length: mm lin)ClutchSection 12

Manual TransmissionSection 13

MEASUREMENTSTANDARD INEWISERVICE LIMIT

Clutch pedalPedal height to floorStrokeFree playPedal play

Disengagement height to floor

183 (7.20)

135- 14515.31 - 5.71)7 - 2210.24 - 0.41J1-9 (0.04-0.35)

7212.83) min.

Clutch surface runout0.05 (0.002) max.0.r5 (0.006)

Clutch discRivet head depthThickness1.2 - 1.710.05- 0.07)8.4 9.1 (0.33,0.36)0.2 (0.01)

6.0 i0.24)

Pressure plateWarpageDiaphragm spring finger alignment0.03 (0.001)max.

0.6 (0.02) max.0.15 (0.006)

0.8 (0.03)

MEASUREM€NTSTANDARD INEW} I SERVICE I-IMIT

TransmissionfluidCapacity f (US qt, lmp qti1.7 11.8, 1.4)for oilchange2.1 (2.2, 1.8){or overhaul

MainshaftEnd play

Diameter of ball bearing contact area (clutch side)Diameter of needle bearing contact areaDiameter of ball bearing contact area(transmission housing side)Runout

0.'11 - 0.18 (0.004 - 0.007)27.977 - 27.990 (1.1015 - 1.1020)37.984 - 38.000 (1.4954- 1.4961)

27.987 - 28.000 (1.1018 - 1.1024)0.02 (0.0011max.

Adjust27.94 (1.100)

37.93 (1.493)

27.94 (1.100)

0.05 {0.002)

Mainshatt 3rd and4th gearsLD.End play

Thickness 3rd gear4th gear

43.009 - 43.025 1 1.6933 - 1.6939)0.06 - 0.21 (0.002 - 0.008)34.92 34.97 11.375 - 1.377)31.42 - 31.4'7 11.237 , 1.2391

43.08011.6961)0.3 (0.01)

34.811.37)31.311.23)

Mainshaft sthgearLD.End play

Thickness

43.009 - 43.02511.6933 1.6939)0.06 - 0.21 (0.002 - 0.008)30.92 - 30.97 {1.217 - 1.219)

43.08011.6961)0.3 (0.01)

30.8 (1.21)

CountershaftDiameter ol needle bearing contact areaDiameter oI ball bearing and needle bearing contact

Diameter o{ 1st gear contact areaRunout

36.000 - 36.015 {1.4173 - 1.4179)24.987 - 25.000 (0.9837 - 0.9843)

36.984 - 37.00011.4561 -1.4567)

0.02 (0.001)max.

3s.95 (1.415)

24.94 (0.982)

36.93 (1.4s4)

0.0s (0.002)

countershatt 1stgearLD.End playThickness

43.009 - 43.025 (1.6933 1.6939)0.06 - 0.18 (0.002 - 0.007i26.9s,27.00 (1.061 - 1.063)

43.08 (1.696)

0.2310.009)

Countershaft 2ndgeart.D.End playThickness

47.009 - 47.025 (1.8507 - 1.8514)0.07 - 0.14 10.003 ,0.006)

2As2 - 2a.97 l�1.139-1.1411

47.08 {1.854)0.18 (0.007)

Spacer collar(Mainshaft 4thand 5th gears)

t.D.o.D.Length A'ls I

le31 .002 - 31 .O12 11 .2205 , 1 .2205)37.989 - 38.000 (1.4956 1.4961)56.45 - 56.55 Q.222 - 2.226126.03,26.08 (1.025 - 1.027)

31.06 (1.223)

37.94 (1.494)

26.01 t1 .0241

Reverse idler geart.D.Gear-to-reverse gear shaft clearance20.01 6 - 20.043 (0.7880, 0.7891)0.036 - 0.084 (0.0014 - 0.0033)20.09 (0.7909)

0.16010.0063)

Synchro ringRing-to-gear clearance (ring pushed againsl gear)0.85 - r.10 (0.033 0.043)0.4 (0.02)

Dual coneClearance (ring pushed against gear)

Outer synchro ring to synchro coneSynchro cone-to-gearOuter synchro ring-to-gear

0.5 1.0 (0.02 0.04)0.5 - 1.0 (0.02 - 0.04)0.95 - 1.68 (0.037 - 0.066)

0.3 (0.01)

0.3 (0.01)

0.6 (0.02)

Shift forkFinger thickness 3rdl4th shift lorkExcept aboveFork-to-synchro sleeve clearance

7.4 - 7.6 (0.29 - 0.30)6.2 - 6.4 (0.24- 0.2s)0.35 - 0.65 (0.0't4 - 0.026)'t, torag)

www.emanualpro.com

Page 41 of 1395

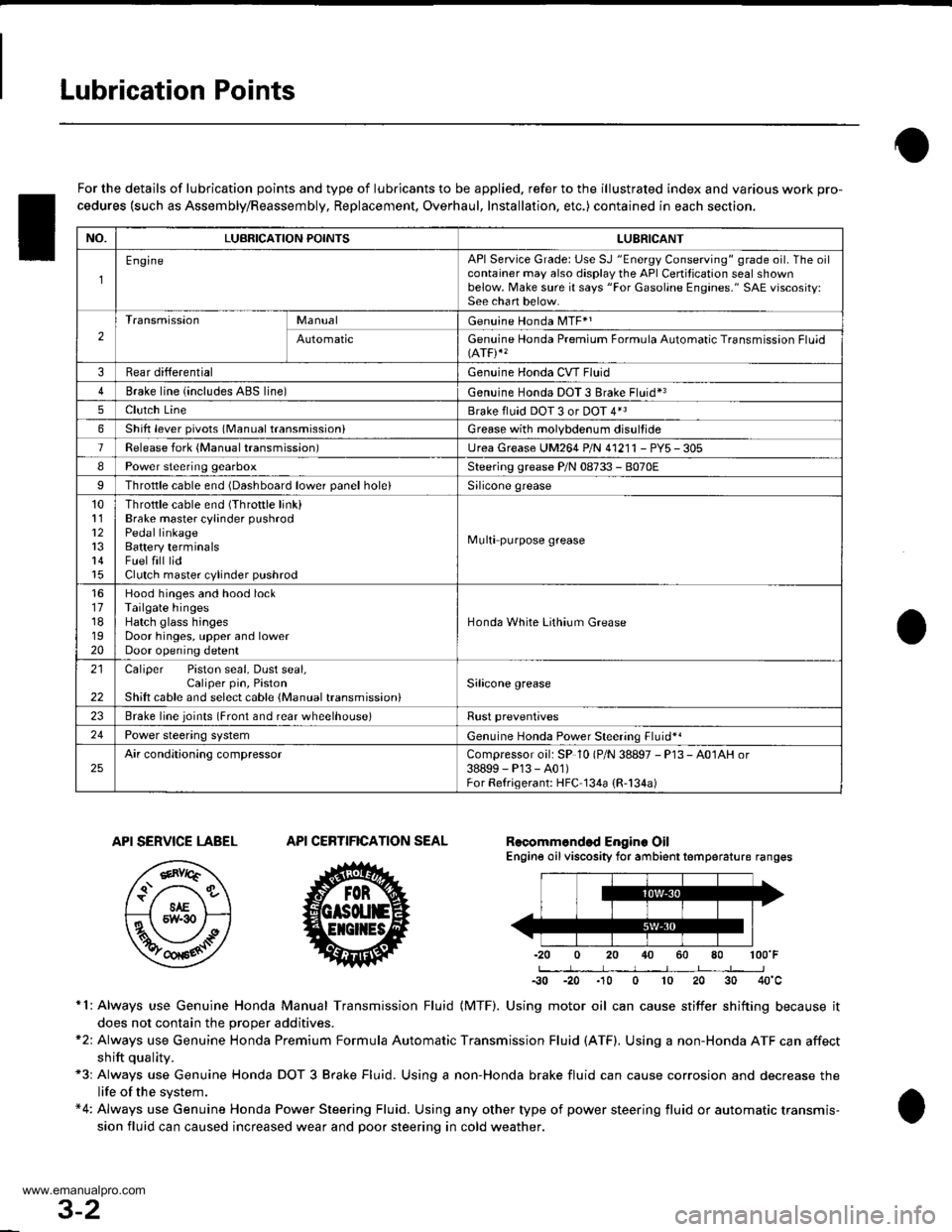

Lubrication Points

For the details of lubrication points and type of lubricants to be applied. refer to the illustrated index and various work pro-

cedures (such as Assembly/Reassembly, Replacement, Overhaul, Installation, etc.) contained in each section.

Recomm6nded Engine OilEngine oil viscosity for ambient temperature ranges

100'F

-30 -20 .10 0 10 20 30 40'c

r1: Always use Genuine Honda Manual Transmission Fluid {MTF). Using motor oil can cause stiffer shifting because it

does not contain the orooer additives.*2: Always use Genuine Honda Premium Formula Automatic Transmission Fluid (ATF). Using a non-Honda ATF can affect

shift qualitv.+3r Always use Genuine Honda DOT 3 Brake Fluid. Using a non-Honda brake fluid can cause corrosion and decrease the

life of the system.*4: Always use Genuine Honda Power Steering Fluid. Using any other type of power steering fluid or automatic transmis-

sion fluid can caused increased wear and poor steering in cold weather.

API SERVICE LABEL

/,.*-G\

/.'z-\e\t/6AE\ll-;-1 5w-30 /---l

w

API CERTIFICATION SEAL

ffi-20 0 20

NO.LUBRICATION POINTSLUBRICANT

EngineAPI Service Grade: Use SJ "Energy Conserving" grade oil. The oilcontainer may also display the API Certitication seal shownbelow. Make sure it says "For Gasoline Engines." SAE vjscosity:See chart below.

2

TransmissionManualGenuine Honda MTF*1

AutomaticGenuine Honda Premium Formula Automatic Transmission Fluid(ATF)*'

3Rear differentialGenuine Honda CVT Fluid

4Brake line (includes ABS line)Genuine Honda DOT 3 Brake Fluid*3

5Clutch LineBrake fluid DOT 3 or DOT 4*3

6Shift lever pivots (Manual transmission)Grease with molybdenum disultide

1Release fork (Manual transmission)LJrea Grease UM264 P/N 4'1211 - PYs - 305

IPower steering gearboxSteering grease P/N 08733 - B070E

Throttle cable end {Dashboard lower panel holelSilicone grease

10l112

14

Throttle cable end (Throttle link)Brake master cylinder pushrodPedal linkageBattery terminalsFuelfill lidClutch master cylinder pushrod

Multi purpose grease

1617181920

Hood hinges and hood lockTailgate hingesHatch glass hingesDoor hinges, upper and lowerDoor opening detent

Honda White Lithium Grease

21

22

Caliper Piston seal, Dust seal,Caliper pin, PistonShilt cable and select cable {Manual transmission)Silicone grease

23Brake line ioints (Front and rear wheelhouse)Rust preventives

24Power steering systemGenuine Honda Power Steering Fluid-.

25Air conditioning compressorCompressor oil: SP 10 lP/N 38897 - P13 - A0lAH or38899-P13-A01)For Refrigerant: HFC 134a (R,134a)

3-2

www.emanualpro.com

Page 55 of 1395

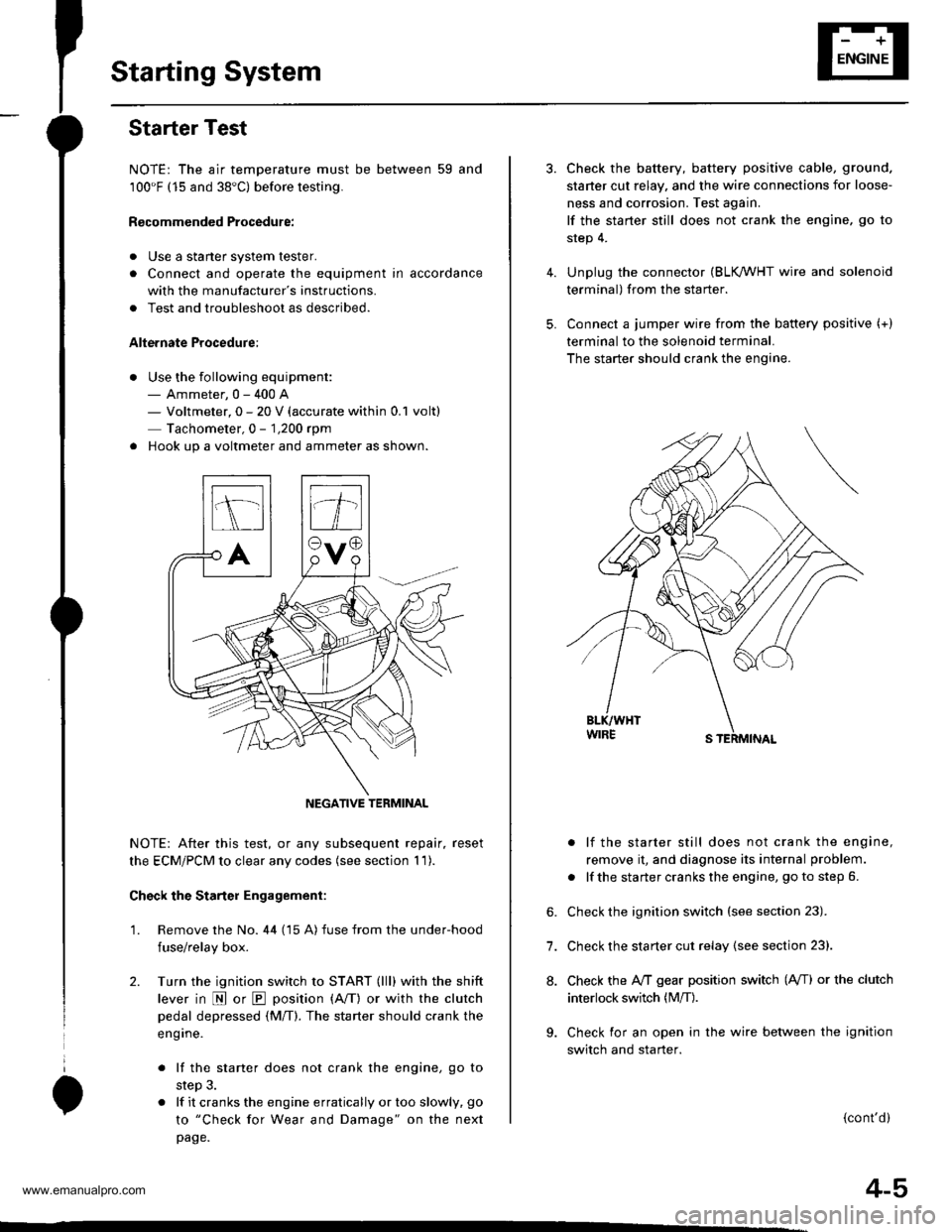

Starting System

Starter Test

NOTE: The air temperature must be between 59 and'100'F (15 and 38"C) before testing.

Recommended Procedure:

. Use a staner system tester.

. Connect and operate the equipment in accordance

with the manufacturer's instructions.

. Test and troubleshoot as described.

Alte.nate Procedure:

. Use the following equipment:- Ammeter, 0 - 400 A- Voltmeter, 0 - 20 V (accurate within 0.1 volt)

Tachometer,0 - 1,200 rpm

. Hook up a voltmeter and ammeter as shown.

NOTE: After this test, or any subsequent repair. reset

the ECM/PCM to clear any codes (see section 1 1).

Check the Starter Engagement:

'1. Remove the No. 44 (15 A) fuse from the under-hood

fuse/relay box.

2. Turn the ignition switch to START (lll) with the shift

lever in E or E position (A/T) or with the clutch

pedal depressed {M/T). The starter should crank the

eng ine.

. lf the starter does not crank the engine, go to

step 3.

. lf it cranks the engine erratically or too slowly, go

to "Check for Wear and Damage" on the next

page.

NEGATIVE TERMINAL

4.

5.

6.

7.

8.

Check the battery, battery positive cable, ground.

staner cut relay, and the wire connections for loose-

ness and corrosion. Test again.

lf the staner still does not crank the engine, go to

step 4.

Unplug the connector (BLK /VHT wire and solenoid

terminal) from the starter.

Connect a jumper wire from the baftery positive (+)

terminal to the solenoid terminal.

The starter should crank the engine.

. lf the starter still does not crank the engine,

remove it, and diagnose its internal problem.

. lf the starter cranks the engine, go to step 6.

Check the ignition switch (see section 23).

Check the starter cut relay {see section 23}.

Check the IVT gear position switch (A/T) or the clutch

interlock switch (M[).

Check for an open in the wire between the ignition

switch and starter.

(cont'd)

4-5

www.emanualpro.com

Page 56 of 1395

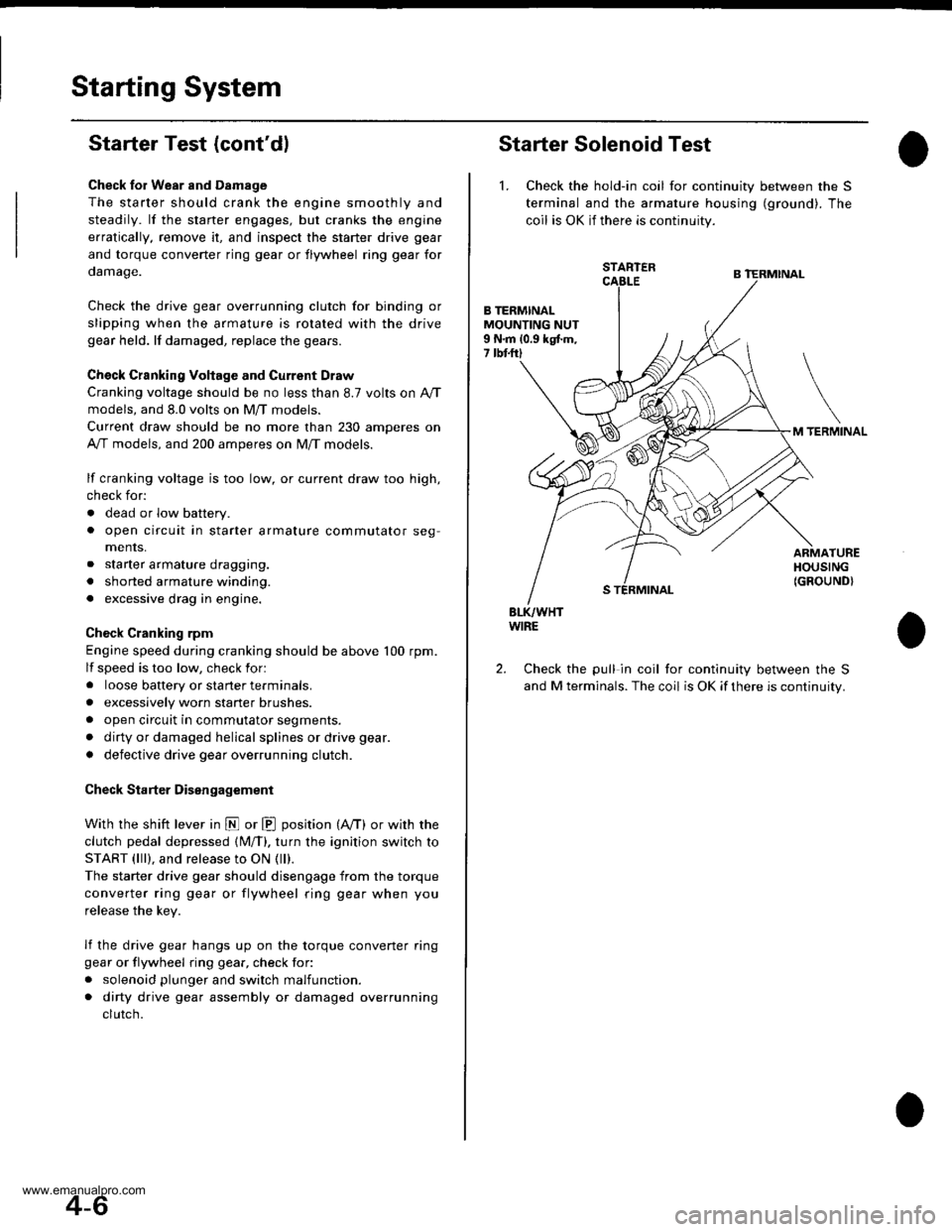

Starting System

Starter Test (cont'dl

Check lor Wear and D8mage

The starter should crank the engine smoothly and

steadily. lf the staner engages, but cranks the engine

erratically, remove it, and inspect the starter drive gear

and torque converter ring gear or flywheel ring gear for

oamage.

Check the drive gear overrunning clutch for binding or

slipping when the armature is rotated with the drive

gear held. lf damaged, replace the gears.

Check Cranking Voltage and Current Draw

Cranking voltage should be no less than 8.7 volts on Ay'T

models, and 8.0 volts on M/T moders.

Current draw should be no more than 230 amperes on

A,/T models, and 200 amperes on M/T models.

lf cranking voltage is too low, or current draw too high,

check for:

. dead or low battery.

a open circuit in starter armature commutator seg,

ments.

. starter armature dragging.

. shorted armature winding.

. excessive drag in engine.

Check Cranking rpm

Engine speed during cranking should be above 100 rpm.

lf speed is too low, check for:

a loose baftery or starter terminals.

. excesslvely worn staner brushes

. open circuit in commutator segments.

. dirty or damaged helical splines or drive gear.

a defective drive gear overrunning clutch.

Check Starter Disengagement

With the shift lever in @ or @ position (A,iT) or with the

clutch pedal depressed {M/T). turn the ignition switch to

START (lll). and release to ON (ll).

The starter drive gear should disengage from the torque

converter ring gear or flywheel ring gear when you

release the key.

lf the drive gear hangs up on the torque converter ring

gear or flywheel ring gear, check for

. solenoid plunger and switch malfunction.

. dirty drive gear assembly or damaged overrunning

clutch.

Starter Solenoid Test

1. Check the hold-in coil for continuity between the S

terminal and lhe armature housing (ground). The

coil is OK if there is continuity.

STARTER

B TERMINALMOUNTING NUT9 N.m 10.9 kgtm,7 tbtftl

TERMINAL

ARMATUREHOUSING(GROUND}

BLK/WHTWIRE

Check the pull in coil for continuity between the S

and M terminals. The coil is OK if there is continuity.

2.

4-6

www.emanualpro.com

Page 86 of 1395

Gruise Control

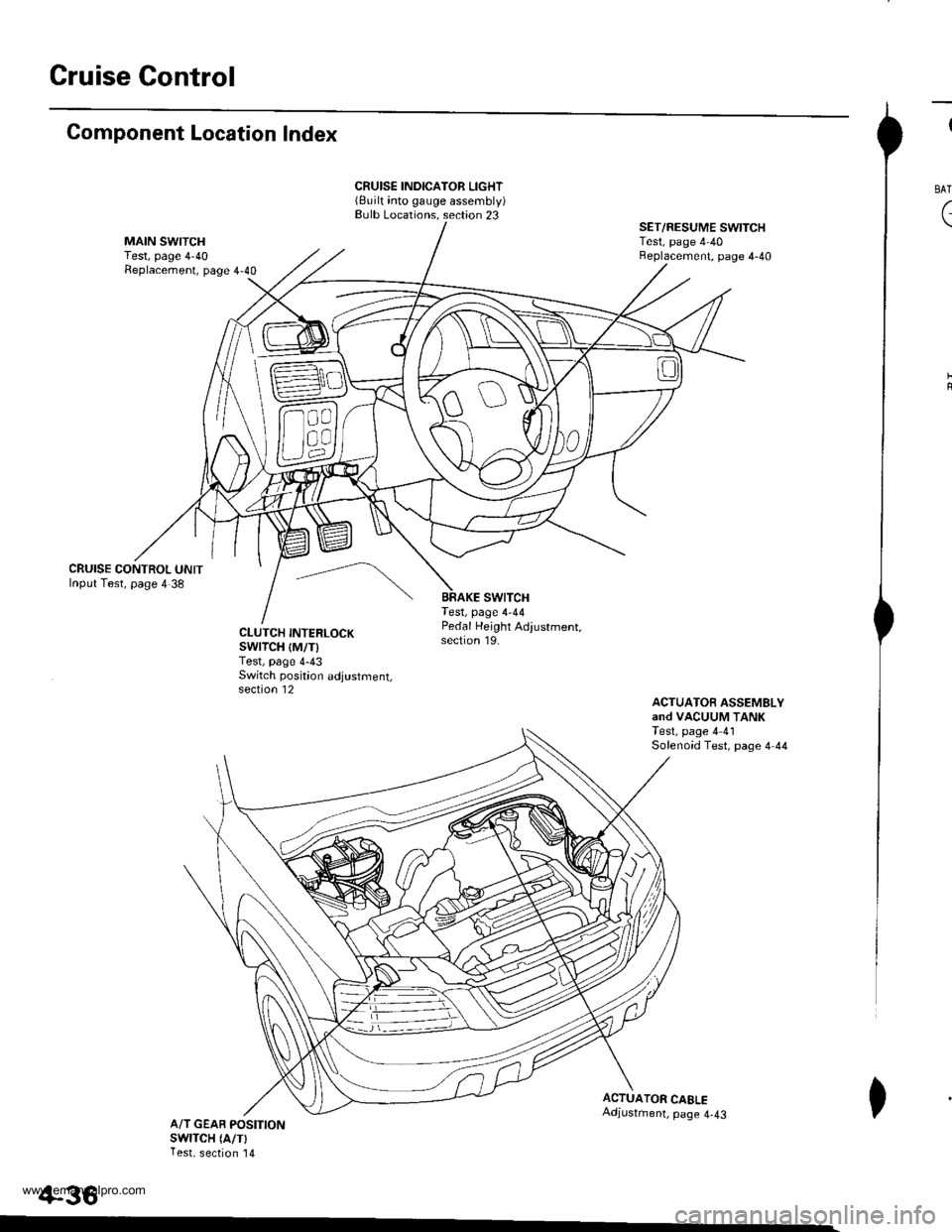

Component Location Index

CRUISE CONTROL UNITInput Test, page 4 38

CRUISE INDICATOR LIGHT(Built into gauge assembly)Bulb Locations. section 23

swtTcHTest, page 4-44

SET/RESUME SWITCHTest, page 4 40Beplacement, page 4-40

ACTUATOfi ASSEMBLYand VACUUM TANKTest, page 4 41Solenoid Test, page 4 44

CLUTCH INTERLOCKswrTcH {M/T)Test, page 4-43Switch poskion adjustment,section 12

Pedal Height Adjustment,section 19.

ACTUATOR CAELEAdjustment, page 4-43A/T GEAB POSITIONswlTcH (A/TlTest, section '14

+36

I

BAT

(

I

www.emanualpro.com

Page 89 of 1395

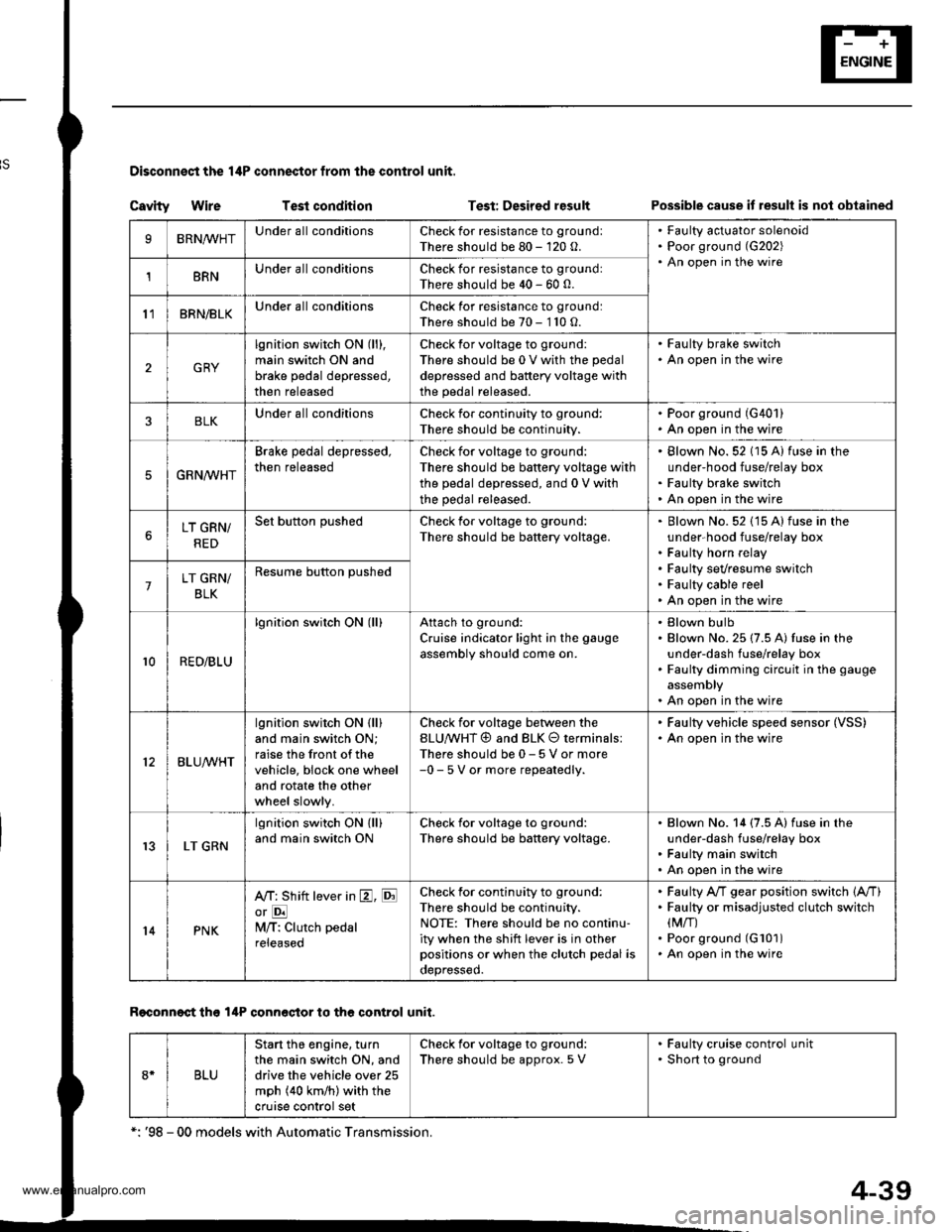

Disconnest the lilP connector from the control unit.

Csvity WireTest condition

R€conn€ct tho 14P connGctor to the control unit.

Test: Desired resultPossible cause it result is not obtained

BRNAr'VHTUnder all conditionsCheck for resistance to groundl

There should be 80 - 120 o.

Faulty actuator solenoid

Poor ground (G202)

An open in the wire1BRNUnder all conditionsCheck for resistance to groundl

There should be 40 - 60 0.

11BRN/BLKUnder all conditionsCheck for resistance to ground:

There should be 70 - 110 O.

2GRY

lgnition switch ON (ll),

main switch ON and

brake pedal depressed,

then released

Check for voltage to ground:

There should be 0 V with the pedal

depressed and battery voltage with

the pedal released.

. Faulty brake switch. An open in the wire

BLKUnder all conditionsCheck for continuity to ground:

There should be continuity.

. Poor ground (G401). An open in the wire

5GRNMHT

Brake pedal depressed,

then released

Check for voltage to ground:

There should be battery voltage with

the pedal depressed, and 0 V with

the pedal released.

Blown No.52 1'15 Alfuse in the

under-hood fuse/relay box

Faulty brake switch

An open in the wire

LT GRN/

RED

Set button pushedCheck for voltage to ground:

There should be battery voltage.Blown No. 52 {'15 A} fuse in the

under-hood fuse/relay box

Faulty horn relay

Faulty sevresume switch

Faulty cable reel

An open in the wire7LT GRN/

BLK

Resume button pushed

10RED/BLU

lgnition switch ON lll)Attach to ground:

Cruise indicator light in the gauge

assembly should come on.

Elown bulbBlown No. 25 (7.5 A) tuse in theunder-dash fuse/relay box

Faulty dimming circuit in the gauge

assembly

An open in the wire

ELU^r'r'HT

lgnitjon switch ON {ll}and main switch ON;

raise the front of the

vehicle, block one wheel

and rotate the other

wheel slowly.

Check for voltage between the

ELUA/VHT @ and BLK O terminalsl

There should be 0 - 5 V or more-0 - 5 V or more repeatedly.

Faulty vehicle speed sensor (VSS)

An open in the wire

r3LT GRN

lgnition switch ON {ll}and main switch ONCheck for voltage to ground:

There should be battery voltage.

Blown No. 14 (7.5 A) fuse in theunder-dash fuse/relay box

Faulty main switch

An open in the wire

l4PNK

A'/T: Shift lever in E, EotE

lvl/T: Clutch pedal

releaseo

Check for continuity to ground:

There should be continuity.NOTE: There should be no continu-

ity when the shift lever is in otherpositions or when the clutch pedal is

oepresseo.

Faulty A/f gear position switch 1A,/TlFaulty or misadjusted clutch switch

fi{/r)Poor ground (G101)

An open in the wire

BLU

Start tho engine. turnthe main switch ON, anddrive the vehicle over 25

mph (40 km/h)with the

crurse control set

Check for voltage to ground:

There should be approx.5 V

. Faulty cruise control unit. Shod to ground

*: '98 - 00 models with Automatic Transmission.

4-39

www.emanualpro.com

Page 93 of 1395

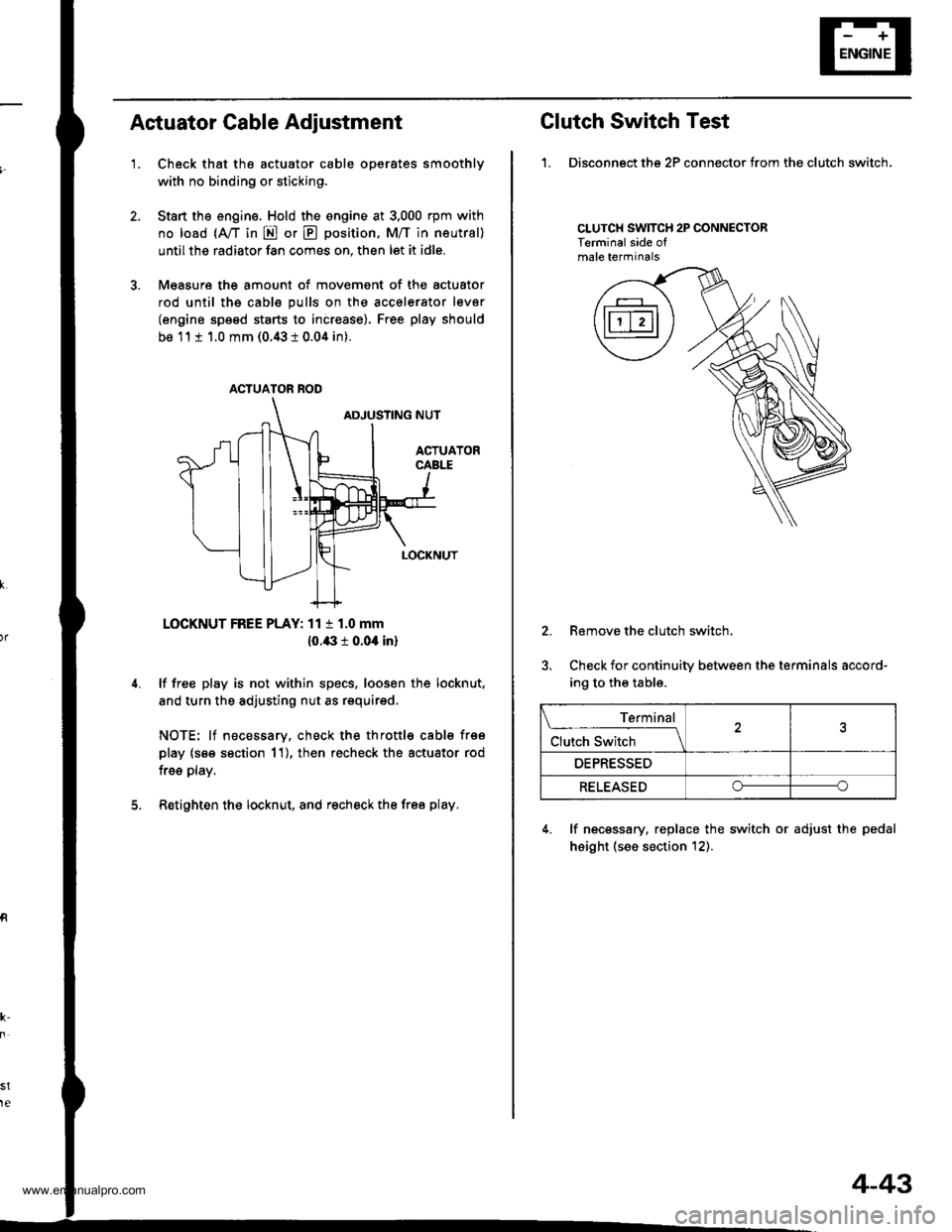

Actuator Cable Adiustment

'1.Check that the actuator cable operates smoothly

with no binding or sticking.

Start the engine. Hold the engine at 3,000 rpm with

no load (A,/T in E or E position, M/T in neutral)

until the radiator fan comes on, then let it idle.

Measure the amount of movement of the actuator

rod until ths cable pulls on the accelerator lever

(engine speed starts to increase). Free play should

be 11 t 1.0 mm (0.43 i 0.04 in).

LOCKNUT FREE PLAY: 11 t 1.0 mm

10.43 r 0.04 in)

lf free play is not within specs, loosen the locknut,

and turn the adjusting nut as requirsd,

NOTE: lf necessary, check the throttl€ cable frso

play (s€e section 11), then recheck the actuator rod

free play.

Retighten the locknut, and recheck the free play.

st

te

ACTUATOR ROD

Clutch Switch Test

1. Disconngct ths 2P connector from the clutch switch.

CLUTCH SWITCH 2P CONNECTORTerminalside ofmale terminals

2.

5.

Remove the clutch switch,

Check for continuity between the terminals accord-

ing to the table.

4. lf necessary, replace the switch or adjust the pedal

height (see section t2).

Terminal

Clutch Switch \

OEPRESSED

RELEASEDoo

4-43

www.emanualpro.com

Page 102 of 1395

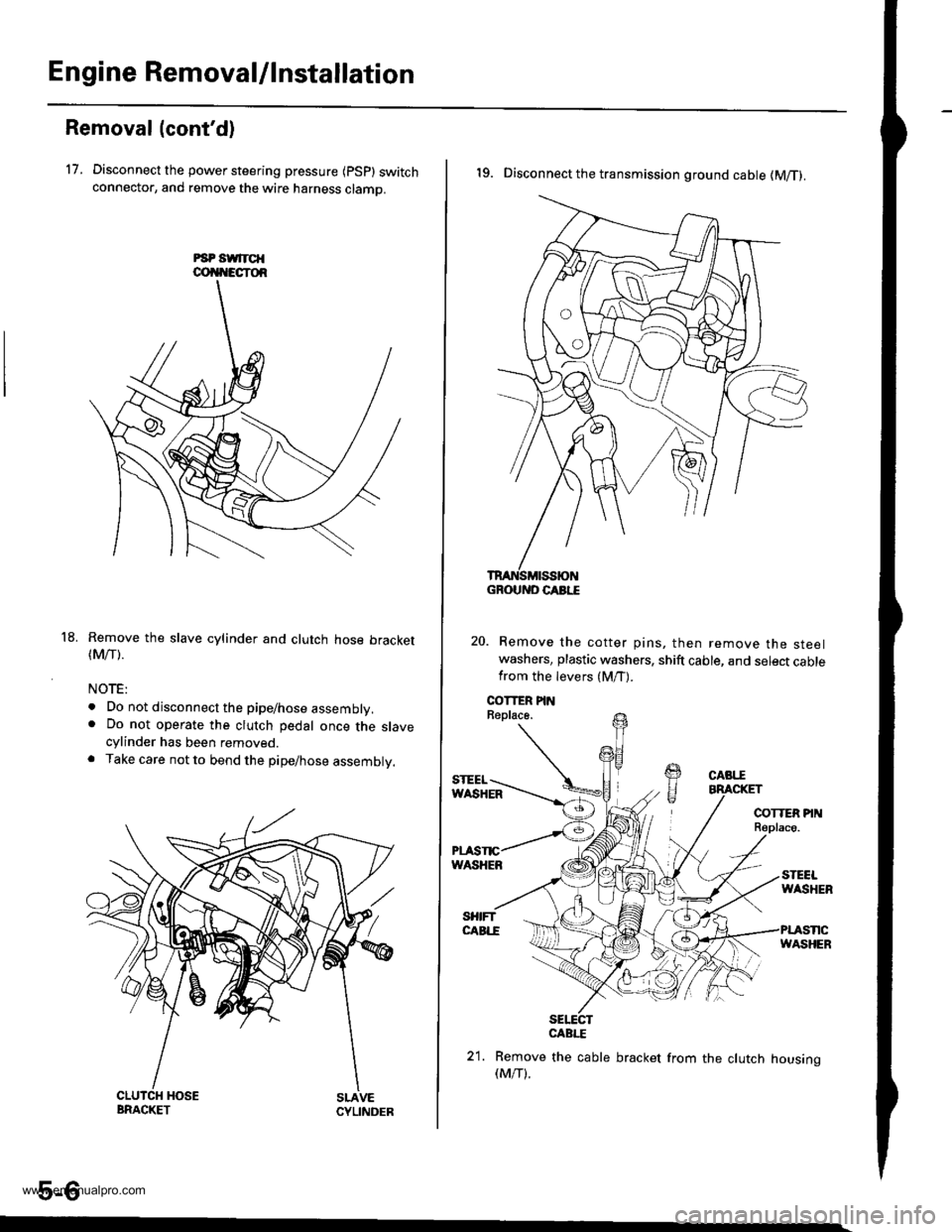

Engine Removal/lnstallation

Removal (cont'd)

17. Disconnect the power steering pressure {psp} switchconnector, and remove the wire harness clamo.

Remove the slave cylinder and clutch hose bracket(Mrr).

NOTE:

. Do not disconnect the pipe/hose assembly.. Do not operate the clutch pedal once the slavecylinder has been removed.. Take care not to bend the pipe/hose assembly.

5-6

18.

19. Disconnect the transmission ground cable (M/T).

Remove the cotter pins, then remove the steelwashers, plastic washers, shift cable, and select cablefrom the levers (M/T).

sElEcrCABI."E

21. Remove the cable bracket from the clutch housing(M/T).

GROUND CABI."E

www.emanualpro.com

Page 270 of 1395

Troubleshooting

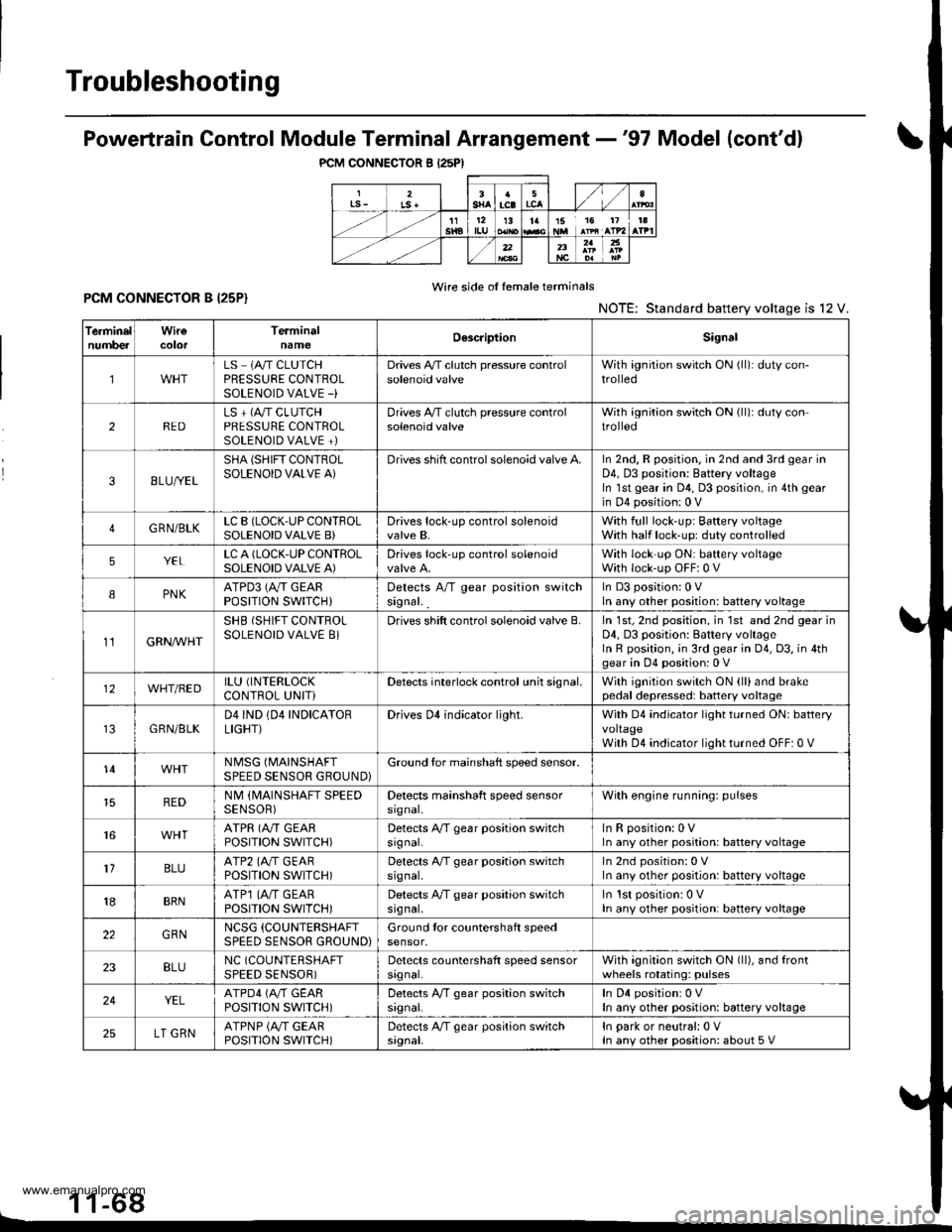

PCM CONNECTOR B I25PI

Powertrain Control Module Terminal Arrangement -'97 Model (cont'dl

Wire side of female terminalsPCM CONNECTOR B I25P}NOTE: Standard battery voltage is l2 V.

1 1-68L

TerminelnumbercolorTerminalnameOescriptionSignal

1LS 1A/T CLUTCHPRESSURE CONTROLSOLENOID VALVE -)

Drives A,/T clutch pressure controlsolenoid valveWith ignition switch ON (ll): duty con-trolled

2REDLS + (A"/T CLUTCHPRESSURE CONTROLSOLENOID VALVE +)

Drives A,/T clutch pressure controlsolenoid valveWith ignition switch ON (ll)r duty controlled

38LU//EL

SHA (SHIFT CONTROLSOLENOID VALVE A)Drives shift control solenoid valve A.In 2nd, R position. in 2nd and 3rd gear inD4, D3 position: Battery voltageIn lst gear in D4, D3 position, in 4th gear

in D4 position: 0 V

4GRN/BLKLC B (LOCK-UP CONTFOLSOLENOID VALVE B)Drives lock-up control solenoidvalve B,With full lock-up; Baftery voltageWith half lock-up: duty controlled

5YELLC A (LOCK.UP CONTROLSOLENOID VALVE A)Drives lock-up control solenoidWith lock'up ON: battery voltageWith lock-up OFF:0 V

IPNKATPD3 (Ay'T GEARPOSITION SWITCH}Detects A/T gear position switchsignal. _

In D3 position:0 Vln any other position: battery voltage

11GRN/VVHT

SHB (SHIFT CONTROLSOLENOID VALVE 8}Drives shift control solenoid valve B.In 1st, 2nd position, in 1st and 2nd gear inD4, D3 position: Battery voltageIn R position, ;n 3rd gear in 04, D3, in 4thgear in D4 position: 0 V

12WHT/BEDILU (INTERLOCK

CONTROL UNITiDetects interlock control unh signal.With ignition switch ON (ll)and brakepedal depressed: battery voltage

GRN/BLKD4IND (04 INDICATORLIGHT}Drives Dl indicator light.With D4 indicator light turned ON: batteryvoltageWith D4 indicator light turned OFF: 0 V

14NMSG (MAINSHAFT

SPEED SENSOR GROUND}Ground tor mainshaft speed sensor.

REDNM (MAINSHAFT SPEEDSENSOR)Detects mainshaft speed sensorsrgnal,With engine running: pulses

16ATPR (A"/T GEARPOSITION SWITCH)Detects A/T gear position switchsrgnal.InRposition:0VIn any other position: battery voltage

1'lBLUATP2 (A./T GEARPOSITION SWITCH)Detects A/T gear position switchsrg nal,In 2nd position: 0 VIn any other position: battery voltage

18BRNATP1 (4,,/T GEARPOSTTTON SWTTCH)Detects A/T gear position switchsrg nal,ln lst position: 0 VIn any other position: battery voltage

22GBNNCSG (COUNTERSHAFT

SPEED SENSOR GROUND)Ground tor countershaft speedsensor,

23BLUNC (COUNTERSHAFT

SPEED SENSOR)Detects countershaft speed sensorsrgnal.With agnition switch ON (ll), and lrontwheels rotating: pulses

24YELATPD4 (M GEARPOSITION SWITCH)Detects A,/T gear position switchsrgnal.In D4 positionr 0 VIn any other position: battery voltage

25LT GRNATPNP {A/T GEARPOSITION SWITCH)Detects A/T gear position switchsignal.In park or neutral:0 VIn any other position: about 5 V

www.emanualpro.com

Page 273 of 1395

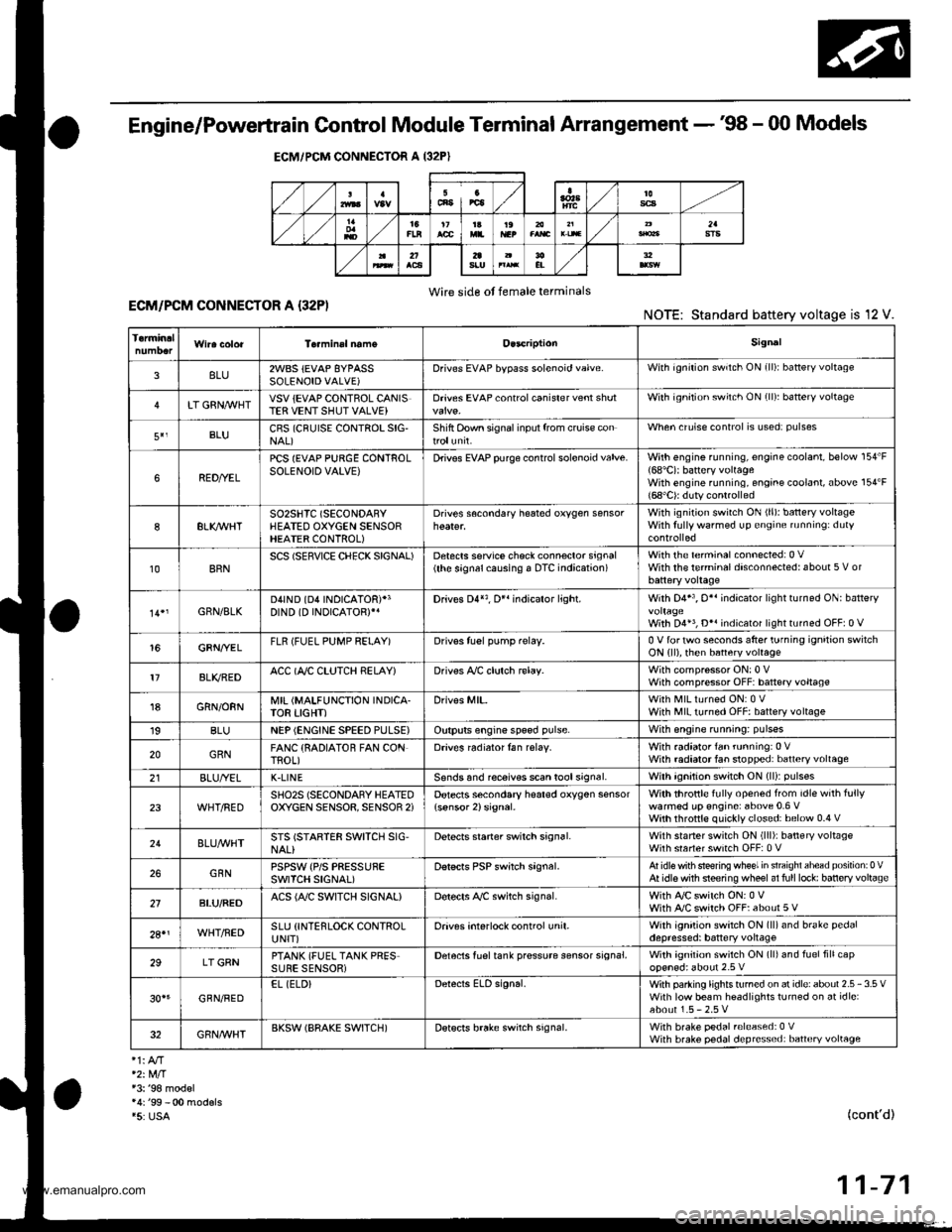

Engine/Powertrain Control Module Terminal Arrangement - 38 - 00 Models

ECM/PCM CONNECTOR A (32P}

,/./5aIsca

,/ l,/t5ItsTs

n2ls!uCI

Wire side ot female terminalsECM/FCM CONNECTOR A {32P)NOTE: Standard baftery voltage is '12 V.

D93criptionSignal

3BLU2WBS {EVAP BYPASSSOLENOID VALVE)Drives EVAP bvoass solonoid valve.With ignirion switch ON {ll)r battery voltage

LT GRNMHTVSV {EVAP CONTROL CANISTEB VENT SHUT VALVE)D.ives EVAP controlcanisler vent shutWith ig^ition switch ON (ll): battery voltage

5',BLUCRS (CRUISE CONTROL SIG'NAL)Shift Oown signalinputfrcm cruise conWhen cruise control is used: pulses

6RED/YEL

PCS (EVAP PURGE CONTROLSOLENOID VALVE)Drives EVAP purge controlsolonoid valve.With engins running, engine coolant, below 154'F(68'C)r battery voltageWith engine running, engine coolant, above 154"F{6a'C}r duty conl.olled

8ELIOWHTSO2SHTC (SECONDARVHEATED OXYGEN SENSORHEATER CONTROL)

Drives sacondary heated oxygen sensorWith ignition switch ON (ll): banery voltageWith fully warmed up engine running: duty

10BRNSCS (SERVICE CHECX SIGNAL)Detects seNics check conneclor signal(he signalcausing a DTC indicatjon)with rhe lerminal connected:0 vWith the rerminaldisconnectedrabout 5 v or

l4'rGRN/8LKD4IND (D4INDICATOR)+3DIND (D INDICATORTIDrives D4*3. Dr'indicaior light.W,rh 04' , O" indrcator light turned O batter,

With D4*3, D*. indicator light turned OFFr0 V

16GRNI/ELFLR (FUEL PUMP RELAY)Drivss fusl pump relay.0 V for iwo seconds after ru'nin9 ign'lion swilchON lll), then banery voltage

17AL|(/REDACC (I/C CLUTCH RELAY}Drives l,/C clurch rclay.With compressor ONr0 VWith compressor OFF: battery voltage

18GRN/ORNMIL (MALFUNCTION INDICA.TOR LIGHT)Driv€s MlL.With MlLturned ON:0 VWith MIL turned OFF: battery voltage

19BLUNEP (ENGINE SPEED PULSE)Outputs engine spsed pulse.With sngine runnin9: pulses

20GRNFANC {RADIATOR FAN CONTROL)Drives r6diator fan rslay.With radaator fan running:0 VWith radaatorfan stopped: battery vollage

218LU/t/ELK-LINESends and receiv€s scan toolsignal.With ignition switch ON (ll): p'rlses

23WHT/REDSHO2S (SECONDARY HEATEDOXYGEN SENSOR. SENSOR 2iDetects secondary h€at€d oxygen sensorWith throttle fully opened from idle wilh fullywalmed up engine: above 0.6 Vwith rhrottle quickly closed: below 0-4 V

21BLU/WHTSTS (STARTER SWITCH SIG,NAL}Dotocts srarter switch signal.Whh staner switch ON (lll): batlery voltageWith srarter switch OFF: 0 V

26GBNPSPSW {P/S PsESSUFESWITCH SIGNAL)Detecrs PSP switch signal.At idle with steeing wh€el in stBighl ahead position: 0 VAt idls with nee ng wheel al full lockr banory voltage

2fBLU/BEOACS (Ir'C SWTCH SIGNAL}D€tects ly'C switch signal.With Ay'C switch ON:0 VWith l/C swil€h OFF: about 5 V

2A'\WHT/NEDSLU {INTERLOCK CONTROLUNIT)Orives interlock control unil.With ignilion switch ON (ll)and brake pedaldepressed: battery vohage

29LT GRNPTANK (FUEL TANK PRES'SURE SENSOR)Detocts fueltank pressure sensor signal.With agnition switch ON (ll) and fuel fill capopensd; about 2.5 v

GBN/FEDEL (ELD}Detects ELD signal.Wirh paaing rightstumed on at idle:about 2.5 - 3.5 VWith low beam headlights tumed on at idle:about 1.5-2.5V

GRN/WHTBKSW (BRAKE SWTTCH)Dst€cts brake switch signal.Wirh brake pedal released:0 VWith brake pedal depressed: battery vollage

13: '98 modsl

15: USA(cont'd)

11-71

www.emanualpro.com