Fault HONDA CR-V 1999 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 88 of 1395

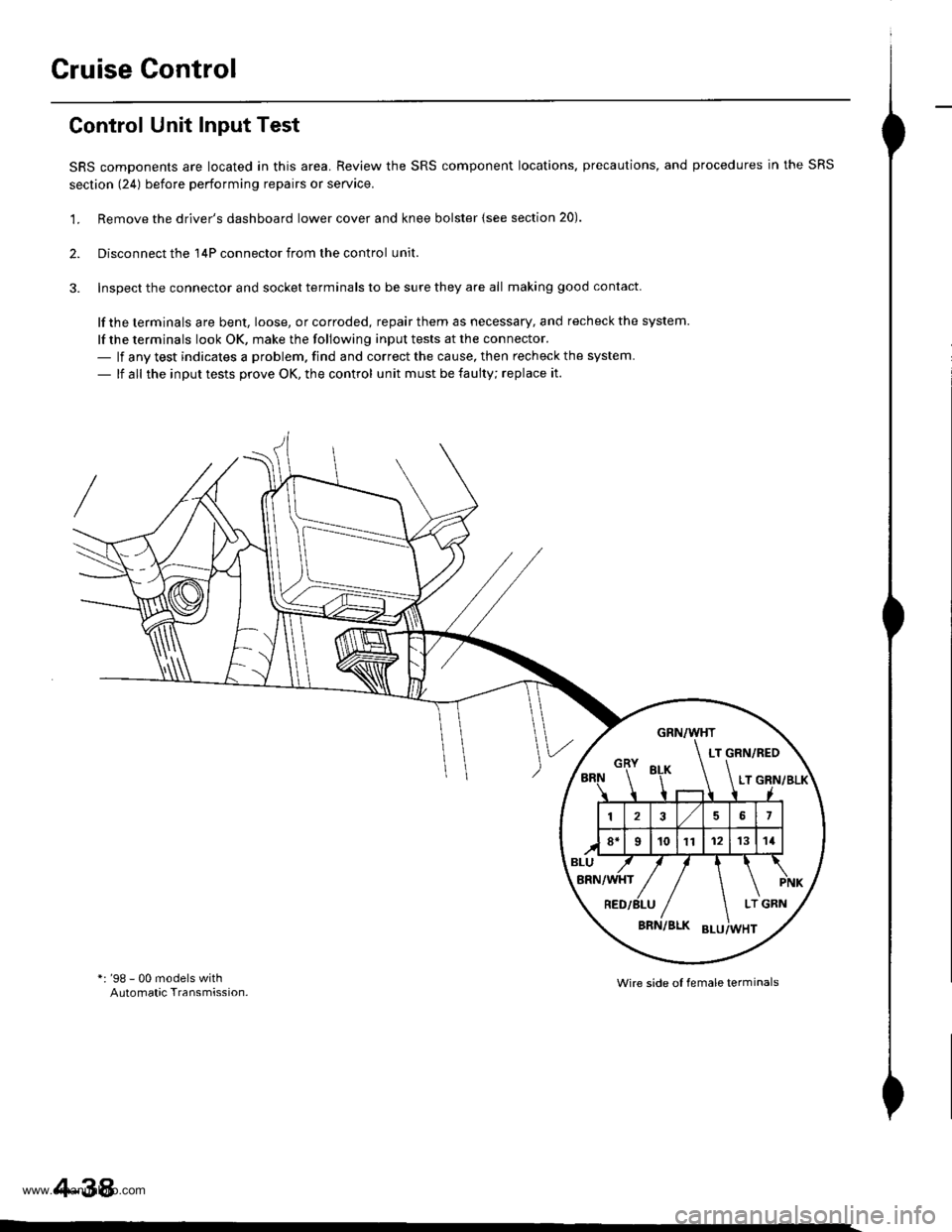

Cruise Control

Control Unit Input Test

SRS components are located in this area. Review the SRS component locations. precautions, and procedures in the SRS

section (241 before performing repairs or seryice.

'1. Remove the driver's dashboard lower cover and knee bolster {see section 20).

2. Disconnect the 'l4P connector from the control unit.

3. Inspect the connector and socket terminals to be sure they are all making good contact

lf the terminals are bent, loose, or corroded, repair them as necessary, and recheck the system.

lf the terminals look OK, make the following input tests at the connector.- lf any test indicates a problem. find and correct the cause, then recheck the system.

- lf all the input tests prove OK, the control unit must be faulty; replace it.

*: '98 - 00 models withAutomatic Transmission.Wire side ol female terminals

4-38

www.emanualpro.com

Page 89 of 1395

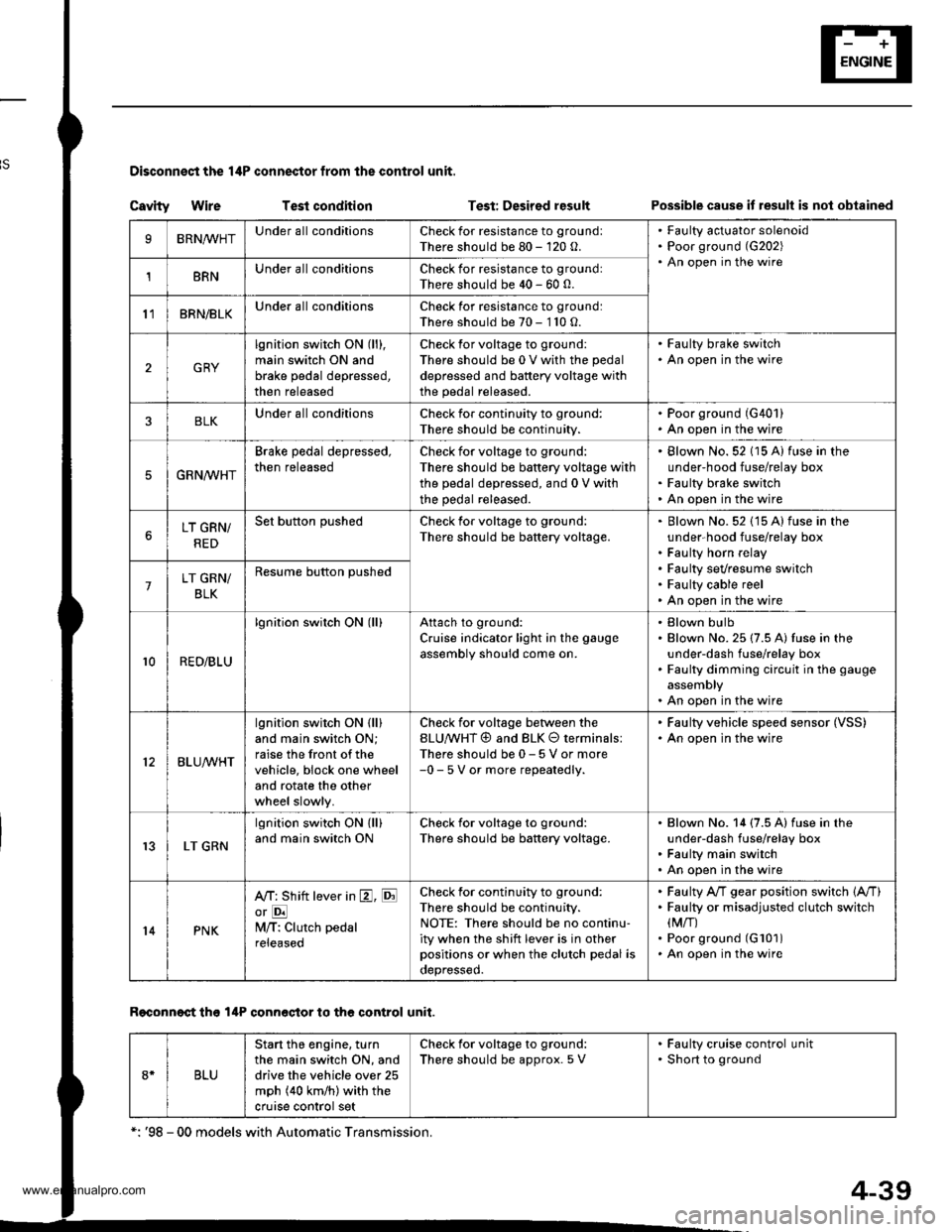

Disconnest the lilP connector from the control unit.

Csvity WireTest condition

R€conn€ct tho 14P connGctor to the control unit.

Test: Desired resultPossible cause it result is not obtained

BRNAr'VHTUnder all conditionsCheck for resistance to groundl

There should be 80 - 120 o.

Faulty actuator solenoid

Poor ground (G202)

An open in the wire1BRNUnder all conditionsCheck for resistance to groundl

There should be 40 - 60 0.

11BRN/BLKUnder all conditionsCheck for resistance to ground:

There should be 70 - 110 O.

2GRY

lgnition switch ON (ll),

main switch ON and

brake pedal depressed,

then released

Check for voltage to ground:

There should be 0 V with the pedal

depressed and battery voltage with

the pedal released.

. Faulty brake switch. An open in the wire

BLKUnder all conditionsCheck for continuity to ground:

There should be continuity.

. Poor ground (G401). An open in the wire

5GRNMHT

Brake pedal depressed,

then released

Check for voltage to ground:

There should be battery voltage with

the pedal depressed, and 0 V with

the pedal released.

Blown No.52 1'15 Alfuse in the

under-hood fuse/relay box

Faulty brake switch

An open in the wire

LT GRN/

RED

Set button pushedCheck for voltage to ground:

There should be battery voltage.Blown No. 52 {'15 A} fuse in the

under-hood fuse/relay box

Faulty horn relay

Faulty sevresume switch

Faulty cable reel

An open in the wire7LT GRN/

BLK

Resume button pushed

10RED/BLU

lgnition switch ON lll)Attach to ground:

Cruise indicator light in the gauge

assembly should come on.

Elown bulbBlown No. 25 (7.5 A) tuse in theunder-dash fuse/relay box

Faulty dimming circuit in the gauge

assembly

An open in the wire

ELU^r'r'HT

lgnitjon switch ON {ll}and main switch ON;

raise the front of the

vehicle, block one wheel

and rotate the other

wheel slowly.

Check for voltage between the

ELUA/VHT @ and BLK O terminalsl

There should be 0 - 5 V or more-0 - 5 V or more repeatedly.

Faulty vehicle speed sensor (VSS)

An open in the wire

r3LT GRN

lgnition switch ON {ll}and main switch ONCheck for voltage to ground:

There should be battery voltage.

Blown No. 14 (7.5 A) fuse in theunder-dash fuse/relay box

Faulty main switch

An open in the wire

l4PNK

A'/T: Shift lever in E, EotE

lvl/T: Clutch pedal

releaseo

Check for continuity to ground:

There should be continuity.NOTE: There should be no continu-

ity when the shift lever is in otherpositions or when the clutch pedal is

oepresseo.

Faulty A/f gear position switch 1A,/TlFaulty or misadjusted clutch switch

fi{/r)Poor ground (G101)

An open in the wire

BLU

Start tho engine. turnthe main switch ON, anddrive the vehicle over 25

mph (40 km/h)with the

crurse control set

Check for voltage to ground:

There should be approx.5 V

. Faulty cruise control unit. Shod to ground

*: '98 - 00 models with Automatic Transmission.

4-39

www.emanualpro.com

Page 331 of 1395

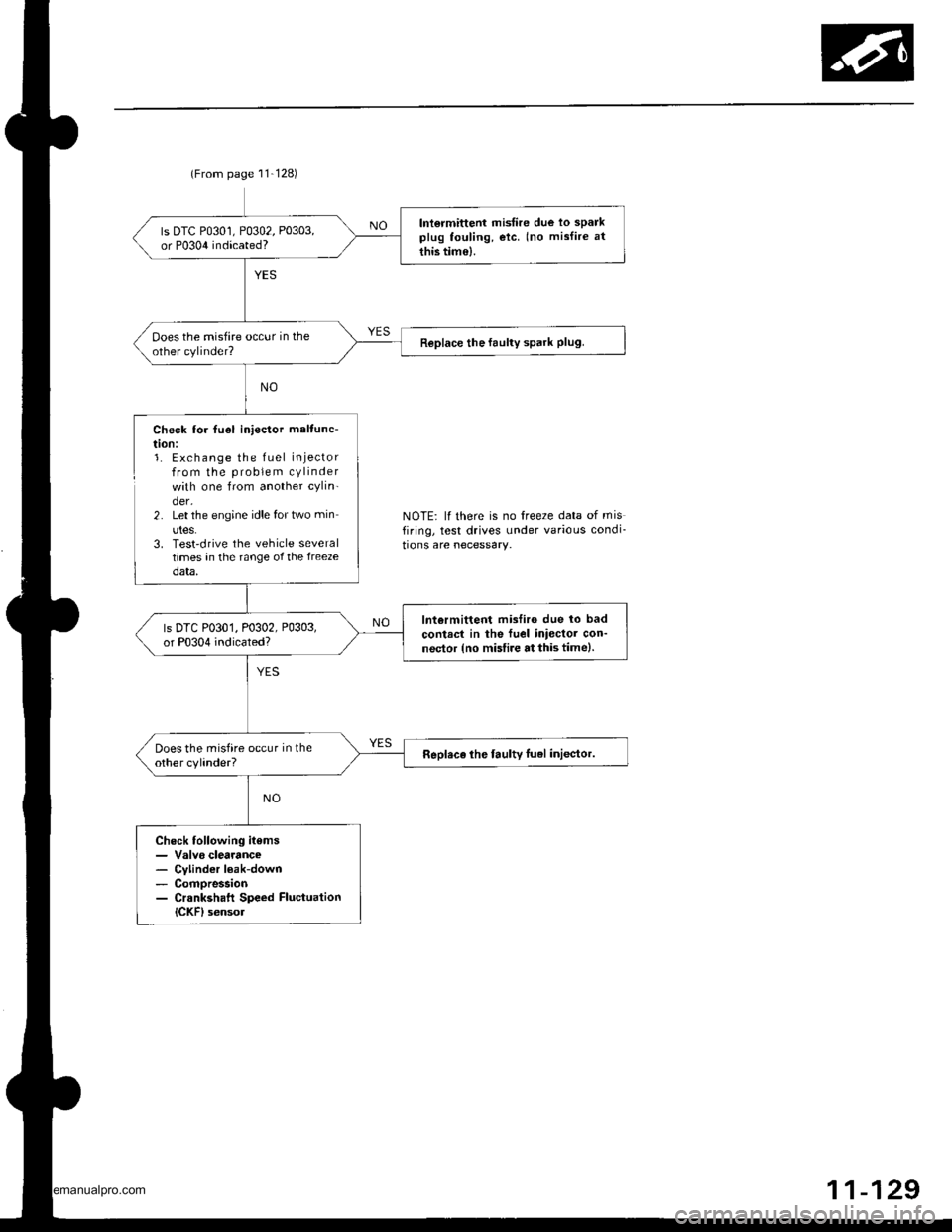

(From page 11-128)

lntormittent misfire due lo sparkplug fouling, etc. (no mislire at

this tim€).

ls DTC P0301, P0302, P0303,or P0304 indicated?

ooes the misfire occur in theother cylinder?Replace the faulty spark Plug.

Check lor fuel iniector maltunc-

t|on:1. Exchange the fuel injectorfrom the problem cylinderwith one from another cylin-der.2. Let the engine idle for two min

utes.3. Test'drive the vehicle severaltimes in the range of the freezedata,

lntermittent misfiro due lo bad

contrct in the fuel iniector con-nector {no misfire at this time).

ls DTC P0301, P0302, P0303,or P0304 indicated?

Does the misfire occur in theother cylinder?Replace lhe faulty luel inlector.

Check following items- Valvo clearance- Cvlinder l€ak-down- Compression- Crsnkshaft Speed FluctuationICKF) sensol

NOTE: lf there is no freeze data of misfiring, test drives under various condi_

tions are necessary.

11-129

www.emanualpro.com

Page 352 of 1395

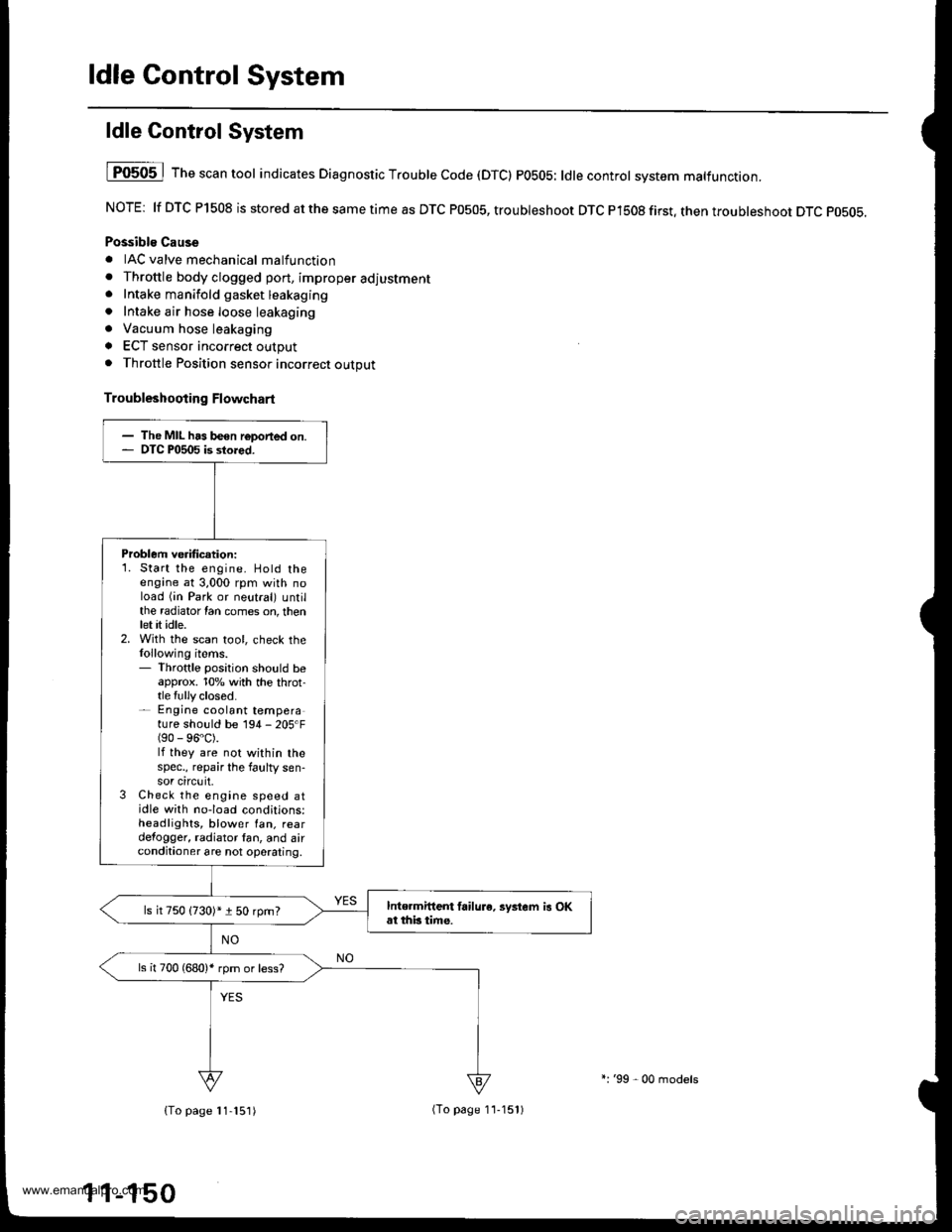

ldle Control System

ldle Control System

I P0505 | The scan tool indicates Diagnostic T.ouble Code (DTCI PO5O5: ldlecontrol svstem mattunction.

NOTE: lf DTC P1508 is stored at the same time as DTC P0505, troubleshoot DTC P1508 first. then troubleshoot DTC p0505.

Possibls Cause

. IAC valve mechanical malfunction. Throttle body clogged port, improper adlustment. Intake manifold gasket leakaging. Intake air hose loose leakaging. Vacuum hose leakaging

a ECT sensor incorrect output. Throttle Position sensor incorrect output

Troubleshooting Flowchart

The MIL has been reDorted on.DTC P0505 is sto.ed.

Problem verificationi1. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutral) untilthe radiator Ian comes on, thenlet it idle.2. With the scan tool, check thelollowing items.- Throttle position should beapprox. 10% with the throt-tle {ully closed.- Engine coolant temperature shorJld be 194 - 205'F(90 - 96"C).lf they are not within thespec., repair the faulty sen-sor circuit.3 Check the engine speed atidle with no-load conditions:headlights, blower fan. reardefogger, radiator lan, and airconditioner are not operaling,

Inte.mittent failure. syltem is OKat this time.ls it 750 {730)* i 50 rpm?

ls il 700 (680)' rpm or less?

{To page 11-151)(To page 1'l-151)

l:'99 - 00 models

www.emanualpro.com

Page 380 of 1395

Fuel Supply System

System Description

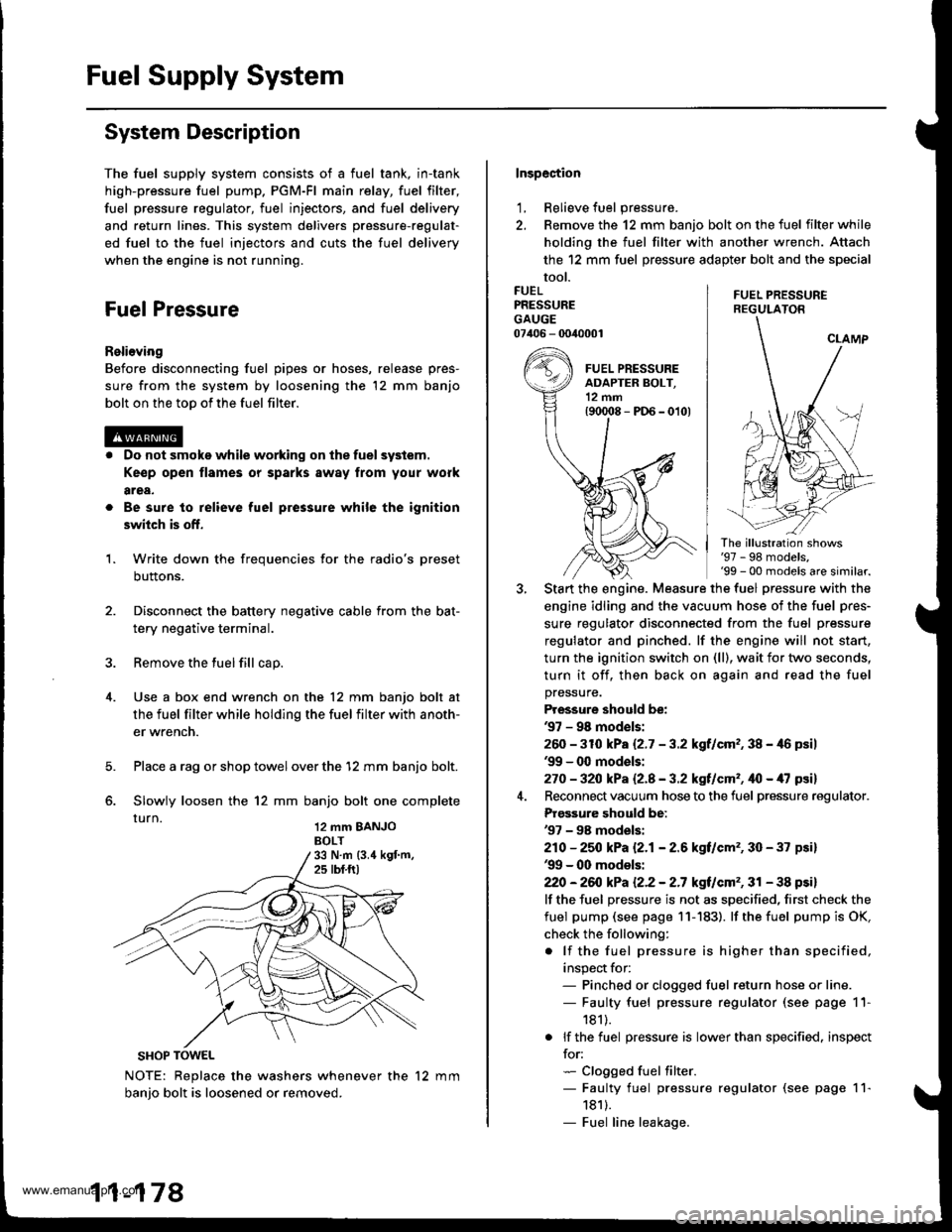

The fuel supply system consists of a fuel tank, in-tank

high-pressure fuel pump. PGM-Fl main relay, fuel filter,

fuel pressure regulator, fuel injectors, and fuel delivery

and return lines. This system delivers pressure-regulat-

ed fuel to the fuel injectors and cuts the fuel delivery

when the engine is not running.

Fuel Pressure

Relieving

Before disconnecting fuel pipes or hoses, release pres-

sure from the system by loosening the 12 mm banjo

bolt on the too of the fuel filter.

Do not smoke while working on the fuel system.

Ke€p open flames or sparks away from your work

area,

Be sure to relieve fuel pressure while the ignition

switch is off.

Write down the frequencies for the radio's preset

buttons.

Disconnect the battery negative cable from the bat-

tery negative terminal.

Remove the fuel fill cap.

Use a box end wrench on the 12 mm banjo bolt at

the fuel filter while holding the fuel filter with anoth-

er wrench.

Place a rag or shop towel over the '12 mm banjo bolt.

Slowly loosen the 12 mm banjo bolt one complete

rurn 12 mm BANJoBOLT

1.

SHOP TOWEL

NOTE: Replace the washers whenever the 12 mm

banio bolt is loosened or removed.

11-178

Inspection

1, Relieve fuel pressure.

2. Remove the 12 mm banjo bolt on the fuel filter while

holding the fuel filter with another wrench. Attach

the 12 mm fuel pressure adapter bolt and the special

tool.

FUEL PRESSUREREGULATON

FUELPRESSUREGAUGE07406 - 0040001

The illustration shows'97 - 98 models,'99 - 00 models are similar.

Start the engine. Measure the fuel pressure with the

engine idling and the vacuum hose of the fuel pres-

sure regulator disconnected from the fuel pressure

regulator and pinched. lf the engine will not start,

turn the ignition switch on (ll), wait for two seconds,

turn it off, then back on again and read the fuel

pressure.

Pressure should be:'97 - 98 mod€ls:

260 -31O kPa 12.7 - 3.2 kgf/cm,, 38 - 46 psil'99 - 0O models:

270 - 32O kPa Q.A - 3.2 kgf/cm'�, ifo - /U psil

Reconnect vacuum hose to the fuel pressure regulator.

Prgs3ure should be:'97 - 98 models:

210 - 25O kPa 12.1- 2.6 kgf/cm'�, 30 - 37 psi)'99 - 00 models:

22O -26iJ kPa 12.2 - 2.7 kgt/cm'�, 31 - 38 psi)

lf the fuel pressure is not as specified, first check the

fuel pump (see page 11- 183). lf the fuel pump is OK,

check the following:

. lf the fuel pressure is higher than specified,

inspect for:- Pinched or clogged fuel return hose or line.- Faulty fuel pressure regulator (see page 11-

181).

. lf the fuel pressure is lower than specified. inspect

for:- Clogged fuel filter.- Faulty fuel pressure regulator (see page 11-

1811.- Fuel line leakage.

www.emanualpro.com

Page 388 of 1395

Fuel Supply System

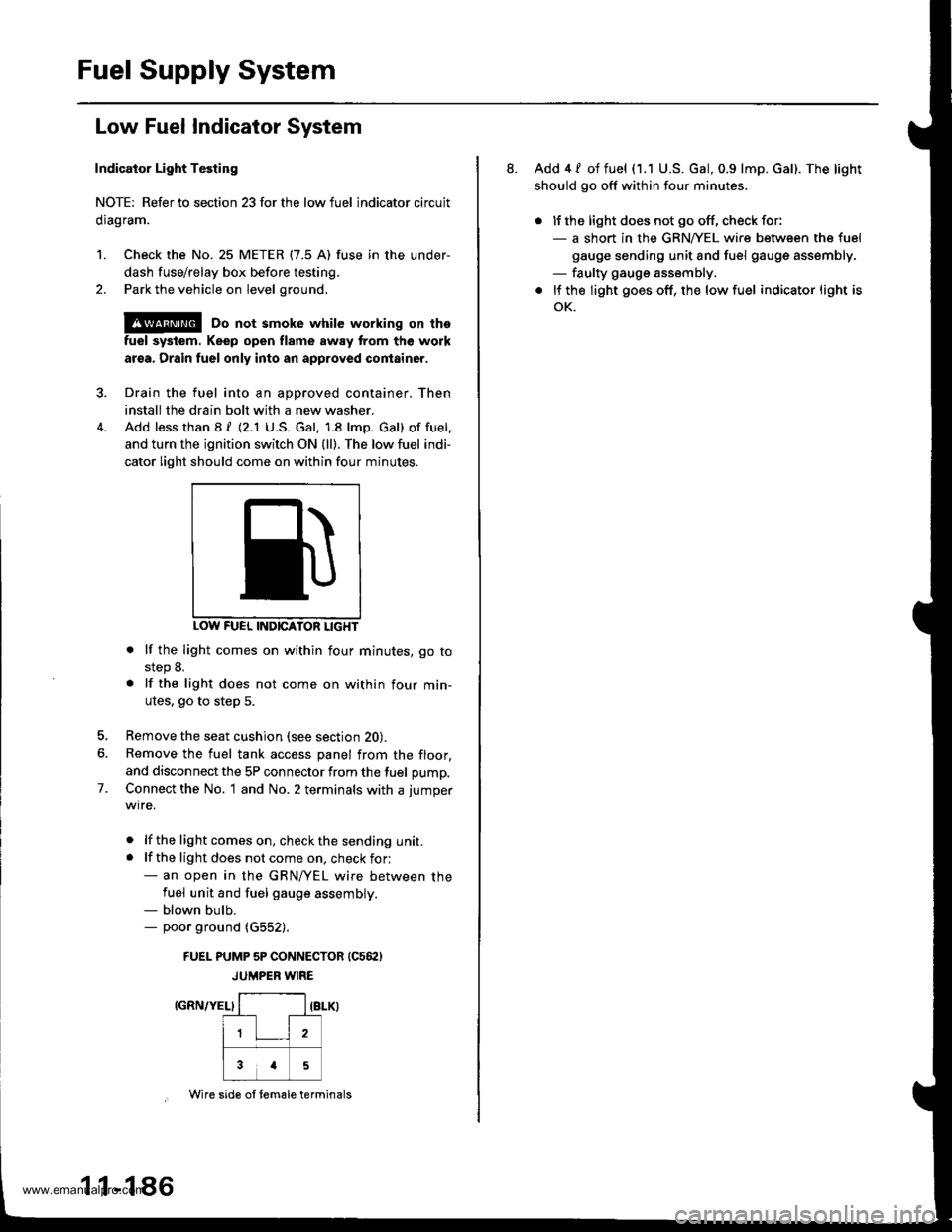

Low Fuel Indicator System

Indicator Light Testing

NOTE: Refer to section 23forthe lowfuel lndicator circuit

clragram.

1. Check the No. 25 METER (7.5 A) fuse in the under-

dash fuse/relay box before testing.

2. Park the vehicle on level ground.

@ Do not smoke while working on the

fuel system. Keep open flame away trom the work

aroa. Drain fuel only into an approved container.

Drain the fuel into an aoDroved container. Then

install the drain bolt with a new washer.

Add less than 8 f (2.1 U.S. Gal. 1.8 lmp. Gal) of fuel,

and turn the ignition switch ON {ll). The low fuel indi-

cator light should come on within four minutes.

INDICATON LIGHT

. lf the light comes on within four minutes, go tostep 8.

. lf the light does not come on within four min-

utes. go to step 5.

Remove the seat cushion (see section 20).

Remove the fuel tank access panel from the floor,

and disconnect the 5P connector from the fuel pump,

Connect the No. 1 and No. 2 terminals with a jumper

wire.

. lf the lightcomeson, checkthe sending unit.. lf the light does not come on, check for:- an open in the GRN/yEL wire between thefuel unit and fuel gauge assembly.- blown bulb.- poor ground (G552).

FUEI- PUMP 5P CONNECTOR (C562)

JUMPER WIRE

IGRN/YEL}

7.

1 1-1 86

Wire sid€ ol tem€le terminals

8. Add 4 / of fuel (1.1 U.S. Gal, 0.9 lmp. Gal). The light

should go off within four minutes.

. lJ the light does not go off, check for:- a short in the GRNA/EL wire between the fuel

gauge sending unit and fuel gauge assembly.- faulty gauge assembly.

. lf the light goes off, the low fuel indicator light is

oK.

www.emanualpro.com

Page 580 of 1395

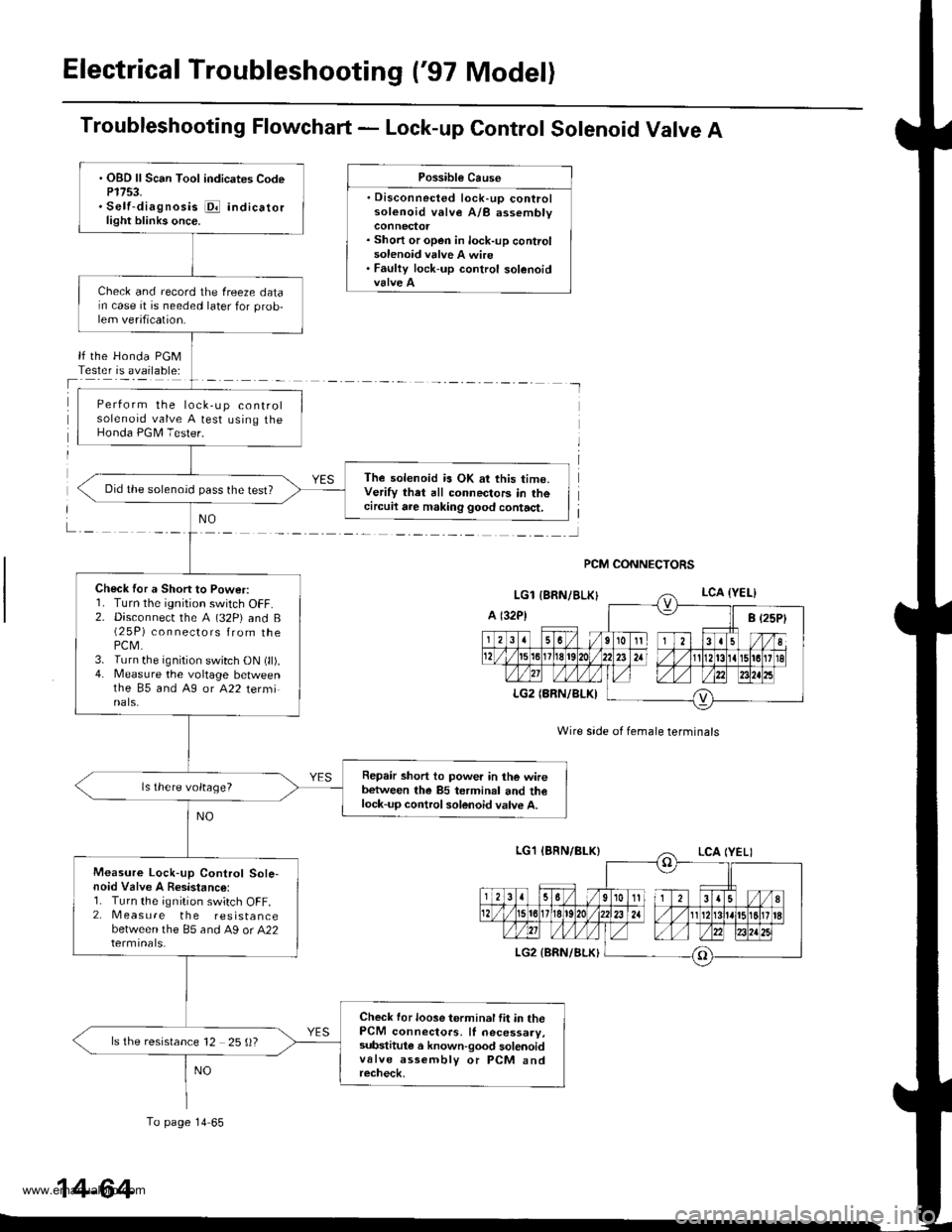

Electrical Troubleshooting ('97 Model)

Troubleshooting Flowchart - Lock-up Control Solenoid Valve A

Possible Cause

. Disconnected lock-up controlsolenoid valve A/B assembly

. Short or open in lock-up controlsolenoid valve A wire. Faulty lock-up control solenoid

lf the Honda PGMTester is available:

NO

Wire side of female terminals

PCM CONNECTORS

. OBD ll Scan Tool indicates CodeP1753.. Self-diagnosis i@ indicatorlight blinks once.

Check and record the freeze datarn case it is needed later for prob-lem verification.

Perform the lock,up controlsolenoid valve A test using theHonda PGM Tester.

The solenoid is OK at this time.Verify that all connectors in thecircuil are making good contact,

Did the solenoid pass the test?

Check for a Short to Power:r. I urn rne tgntUon swttch ut-f.2. Disconnecr the A (32P) and B(2 5P) connectors from thePCM.3. Turn the ignition switch ON (ll).4. Measure the voltage betweenthe 85 and A9 or A22 terminals.

Repair short to power in the wirebetween the 85 terminal and thelock-up control solenoid valve A.

ls there voltage?

Measure Lock-up Control Sole-noid Valve A Resistance:1. Turn the ignition switch OFF.2. Measure the resistancebetween the 85 and A9 or A22

Check for loose terminal fit in thePCM connectors, ll necessary,substitule a known-good solenoidvalve assembly or PCM andrecheck,

ls the resistance 12 25 ()?

To page 14 65

14-64

www.emanualpro.com

Page 582 of 1395

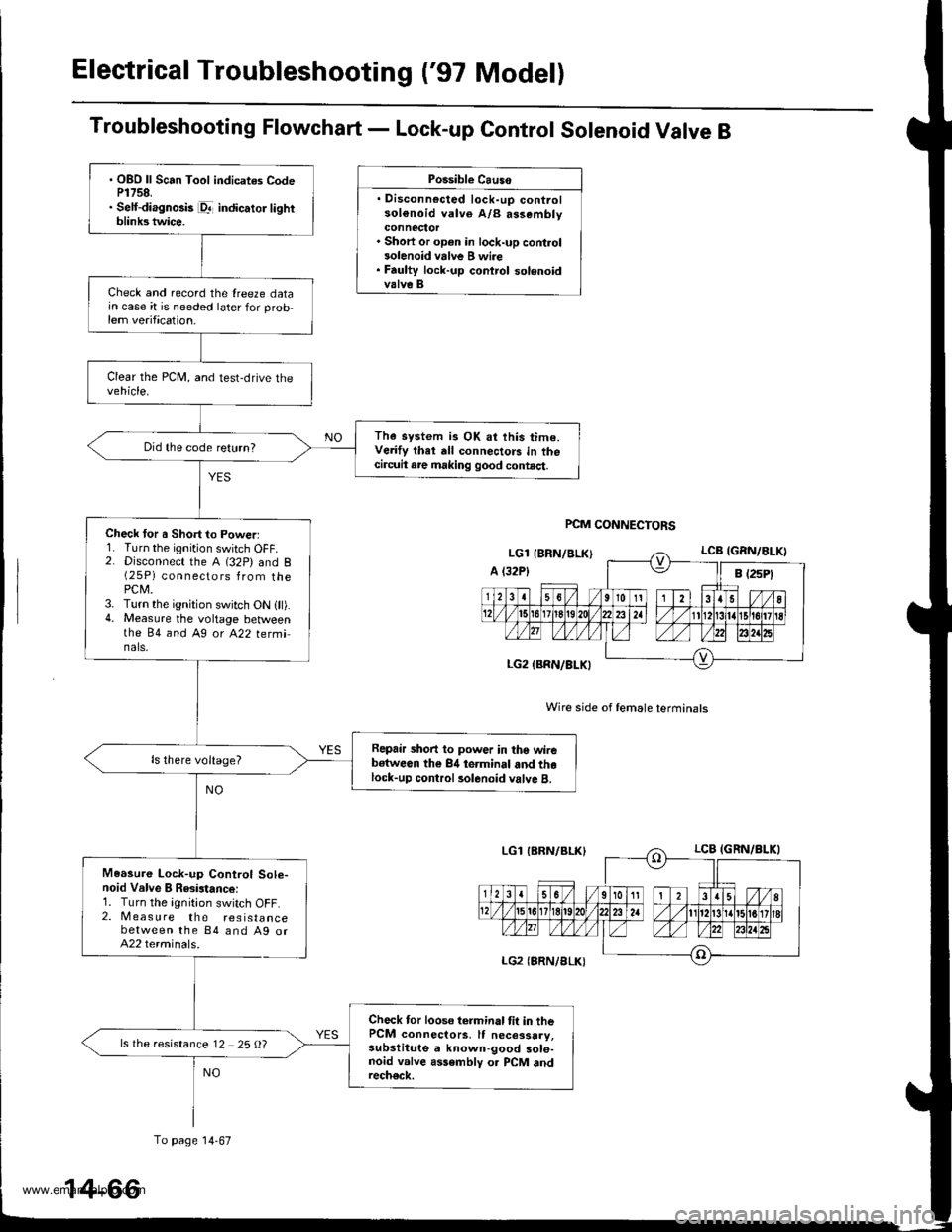

Electrical Troubleshooting ('97 Model)

Troubleshooting Flowchart - Lock-up Control Solenoid Valve B

Possible Causo

. Disconnocted lock-up controlsol€noid valve A/B assembly

. Short or op€n in lock-up control3olenoid vrlve B wi.e. Faulty lock-up control solenoidvalve B

Wire side of female terminals

PCM CONNECTORS

. OBO ll Scan Tool indicates CodeP1758.. Self-diagnosis pr- indicator lightblink3 twice.

Check and record the {reeze datajn case it is needed later for prob,lem verification.

The system is OK at this time.Verify thet dll connectors in thecircuit are making good contact.

Did the code return?

Check tor a Short to Powerl1. Turn the ignition switch OFF.2. Disconnect the A (32P) and B(25P) connectors from thePCM.3. Turn the ignition switch ON {ll).4. Measure the voltage betweenthe 84 and Ag ot A22 tetminals,

Repair short to power in tho wirebstween the 84 terminal and thelock-up control rolenoid valve B.

Measure Lock-up Control Sole-noid Valve B Resistance:1. Turn the ignition switch OFF.2. Measure the resistancebetween the 84 and Ag orA22 terminals.

Check tor loose terminal tit in thePCM connectors, It necessary,subslitute a known-good sole-noid valve assembly o. PCM andrech€ck.

ls the resistance 12 25 O?

To page 14-67

14-66

www.emanualpro.com

Page 584 of 1395

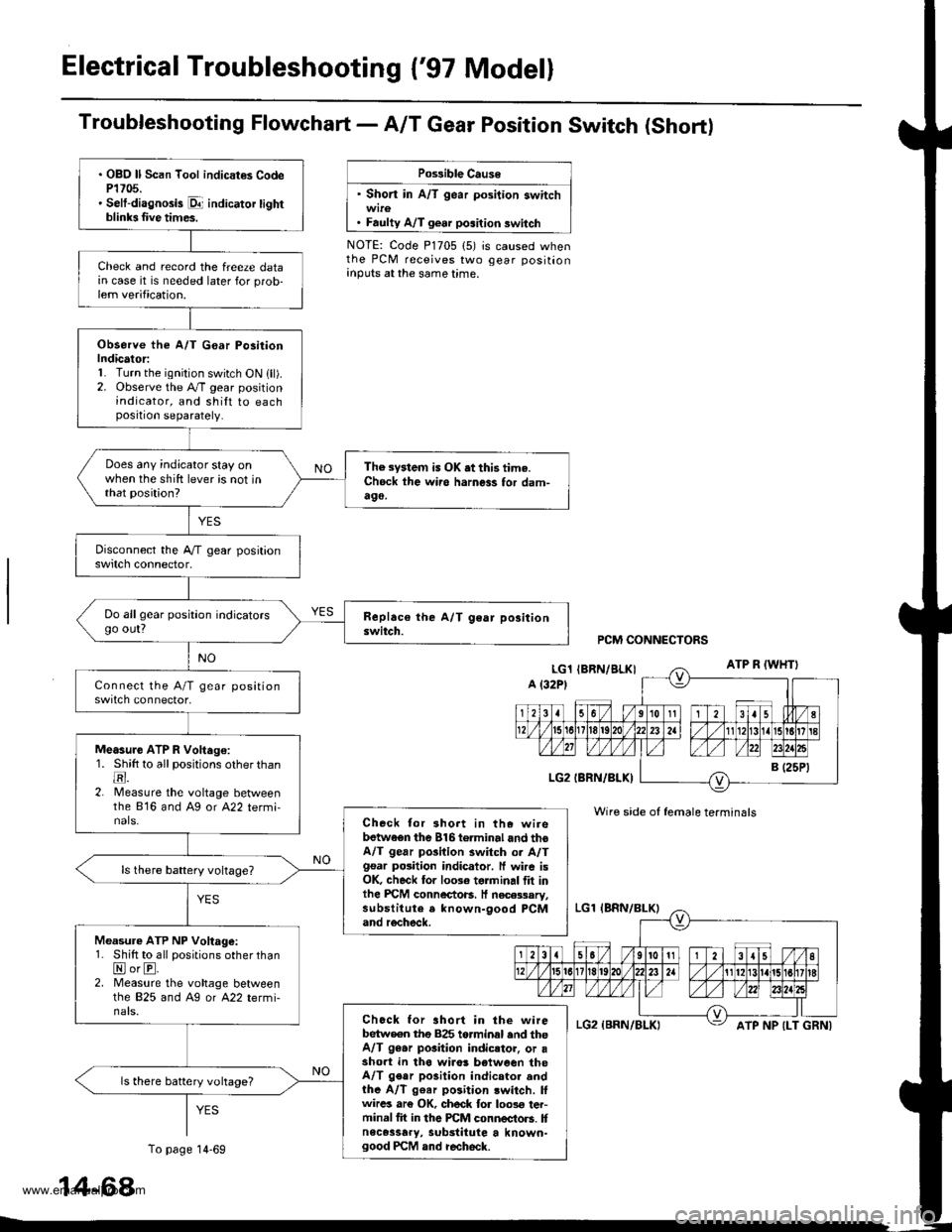

Electrical Troubleshooting {'97 Model}

Troubfeshooting Flowchart- AIT Gear Position Switch (Short)

Po$ible Cause

' Short in A/T gear position switch

. Faulty A/T gear position switch

NOTE: Code P1705 (5) is caused whenthe PCM receives two gear positionanputs at the same time.

. OBO ll Scan Tool indicat€s CodeP1705.' Selt-diagnosis p1- indicator tightblinb Iive times.

Check and record the freeze datain case it is needed later for prob-lem verification.

Observe the A/T G€ar Po3itionIndicator:1. Turn the ignition switch ON lll).2. Observe the A./T gear positionindicator, and shilt to eachposition separately.

Does any indicator stay onwhen the shift lever is not inthat position?

The system is OK .t this time.Ch6ck ihe wii6 harness for dam-490,

Do allgear position indicatorsgo out?

Measure ATP R Voltago:1. Shitt to all positions other thantr.2. lMeasure the voltage betweenthe 816 and Ag or A22 termi-nals.Check tor 3hort in the wirebetwaen the 816torminal and thoA/T gear pGilion switch or A/Tgsar posiiion indicator. ff wire isOK, check for 10036 torminal flt inlhe PICM connectoB. It necessary,substitute a known-9ood PCMand recheck.

Measure ATP NP Voltage:1. Shift to all positions other thanNorE.2. Measure the vohage betweenlhe 825 and Ag or A22 termi-nals.Chock for ahort in the wirebetw€en tho 825 torminal end theA/T 96.r pGition indicstor, or asho.t in tha wiro! b€tween theA/T gear po3ition indicator andthe A/T g€ar position lwitch. lfwircs ar€ OK, ch6ck for loos€ ter-minal fit in the PCM connectors. Itnece3sary, substitute a known-good PCM and recheck.

ls there battery vohage?

PCM CONNECTORS

Wire side of female terminals

ATP NP {LT GRNI

14-68

To page 14-69

www.emanualpro.com

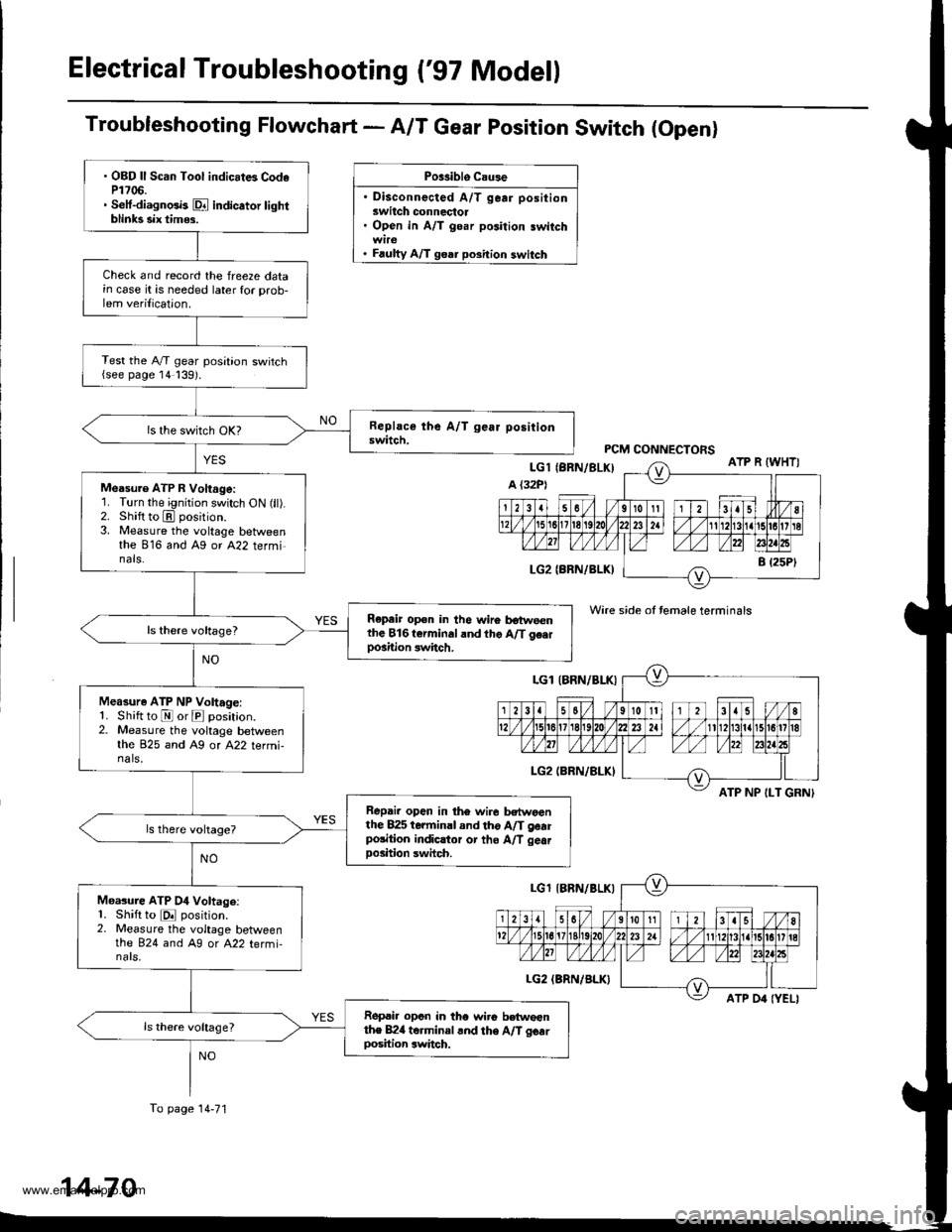

Page 586 of 1395

Electrical Troubleshooting ('97 Model)

Troubleshooting Flowchart - A/T Gear position Switch (Openl

Po$iblo C.u3e

. Disconnected A/T gear positionswitch connectol. Open in A/T goar position switch

. Faulty A/T goar position switch

Wire side ot temale terminals

ATP NP ILT GRNI

. OBD ll Scan Tool indicat6 CodeP1706.. Setf-diagnGb Dl indicator tightblinks six tim$.

Check and record the freeze datain case it is needed later for prob-lem verilication.

Test the A,/T gear position switch{see page 14139).

Measu.e ATP R Voltage:'1. Turn the ignition switch ON (ll).2. Shift to E position.3. Measure the voltage betweenthe 816 and Ag or A22 termi-nals.

Repeir op€n in the wire botweenthe 816t€rminaland the A/T g€.rpo3ition switch.

Measure ATP NP Voltage:1. Shift to E or E position.2. Measure the voltage betweenthe 825 and A9 or A22 termi-na ls,

Repai. open in th6 wir6 bctwoanthe 825 terminal and tho A/T gearpolition indicltor or tho A/T gea.Doshion swhch.

Moasure ATP 04 Voltage:1. Shift to E position.2. Measure the voltage betweenthe 824 and A9 or A22 termi-nars,

Ropai. opcn in tho wiro betwoenthe B24 torminal .nd the A/T gcarDosition switch.

To page 14-71

14-70

www.emanualpro.com