Solenoid HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 701 of 1395

![HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

ai_la2,

(41/4.:4.

\7)

1.0)tl

(3]

t9.1q

oo,ID@,8!Itt\,29

€4

69

aa.21

600toa

04

6!)ent00t.@

ATF FEED PIPE, I x 145 mm

ATF STRAINERSERVO BODYSERVO SEPARATOB PLATESECONDABY VALVE BOOYDOWEL PINSECONDAR HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

ai_la2,

(41/4.:4.

\7)

1.0)tl

(3]

t9.1q

oo,ID@,8!Itt\,29

€4

69

aa.21

600toa

04

6!)ent00t.@

ATF FEED PIPE, I x 145 mm

ATF STRAINERSERVO BODYSERVO SEPARATOB PLATESECONDABY VALVE BOOYDOWEL PINSECONDAR](/img/13/5778/w960_5778-700.png)

ai_la2',

(41/4.:4.

\7)

1.0)tl

(3]

t9.1q

oo,ID@,8!Itt\,29

€4

69

aa.21

600toa

04

6!)ent00t.@

ATF FEED PIPE, I x 145 mm

ATF STRAINERSERVO BODYSERVO SEPARATOB PLATESECONDABY VALVE BOOYDOWEL PINSECONDARY SEPARATOR PLATE

SERVO DETENT BASE ('98 model onlvl

ATF FEED PIPE, 8 x 145 mmATF FEED PIPE.8 x 40 mmATF FEED PIPE,8 x 62 mmATF FEED PIPE, I x 112 mm

ATF FEED PIPE, 8 x 192.5 mm

ATF FEED PIPE, 8 x 105.8 mm

STOP SHAFT BRACKETATF LUERICATION PLATEATF FEED PIPEDOWEL PINLOCK-UP VALVE BODYLOCK-UP SEPARATOR PLATE

REGULATOR VALVE BOOYDOWEL PINCOOLER RELIEF VALVE SPRINGCOOLER BELIEF VALVETOROUE CONVERTER CHECK VALVE SPRING

TOROUE CONVERTER CHECK VALVECONTNOL SHAFTDETENT ARM SPRINGDETENT ARMDETENT ARM SHAFTFILTER Replace.CHECK BALLS1ST ACCUMULATOR CHOKEO-RING Replace.STATOR SHAFTSTOP SHAFTATF FEED PIPE. 8 x 112 mmMAIN VALVE BODYATF PUMP DRIVEN GEAR SHAFTATF PUMP DRIVEN GEAR

MAIN SEPARATOR PLATE

DOWEL PINATF PUMP DRIVE GEARSUCTION PIPE COLLARCOUNTEBSHAFT TOROUE CONVERTER HOUSING

BEARINGATF GUIDE PLATEATF MAGNETTOBOUE CONVERTER HOUSINGOIL SEAL Beplace.MAINSHAFT OIL SEAL Replace.MAINSHAFT TOROUE CONVERTER HOUSING

BEARINGLOCK.UP CONTROL SOLENOID VALVE A/B

FILTER/GASKET Replace.LOCK-UP CONTROL SOLENOID VALVE A/B

ASSEMELY

i4ll(4d

@@.!!l

art)@@@@li]t

TOROUE SPECIFICATIONS

Bolt/Nut No.Torque ValueSizeRemarks

12 N.m (1.2 kgim,8.7 lbf'tt)6x1.0mm

14-185

www.emanualpro.com

Page 778 of 1395

Transmission

Installation (cont'dl

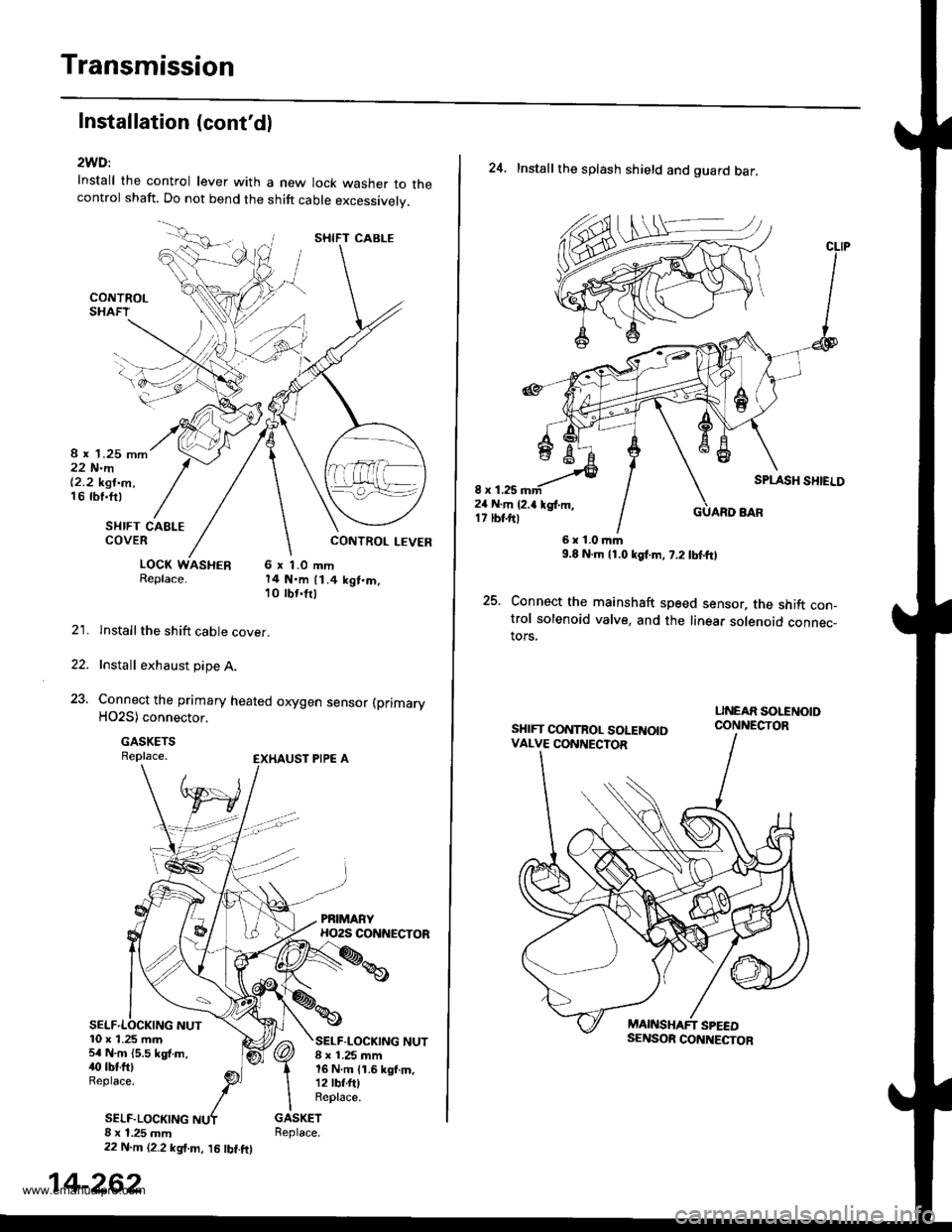

2WD:

Install the control lever with a new lock washer to thecontrol shaft. Do not bend the shift cable excessivelv.

8 r 1.25 mm22 N.m|'2.2 kgt.m,16 rbf.ft)

SI{IFT CAELECOVER

LOCK WASHER 6 x 1.0 mmReplace. 14 N.m 11.4 kgt.m,10 tbr.frl

lnstallthe shift cable cover.

Install exhaust pipe A.

Connect the primary heated orygen sensor (primary

HO2S) connector.

GASKETSReplace.

22.

23.

10 x 1.25 m.n5r N.m {5.5 kgf.m,40 tbtftlReplace.

SELF.LOCKING

SELF-LOCKING NUT8 ! 1.25 mm16 N.m {1.6 kgf.m,12 lbf.fttReplace.

8 x 1.25 mm22 N.m {2,2 kgt.m, l5 lbt.ftl

SHIFT CABLE

14-262

24. Installthe splash shield and guard bar,

8 x 1.2524 N.m {2.a kgl.m,17 tbt.ftl

SPLASH SHIELD

GUARO BAR

25.

6r1.0|r|m9.8 N.m l1.0lgf.m, 7.2 tbtftl

Connect the mainshaft speed sensor, the shift con-trol solenoid valve, and the linear solenoid connec_tors,

SHIFT CONTROL SOLENOIDVALVE CONNECTOR

www.emanualpro.com

Page 779 of 1395

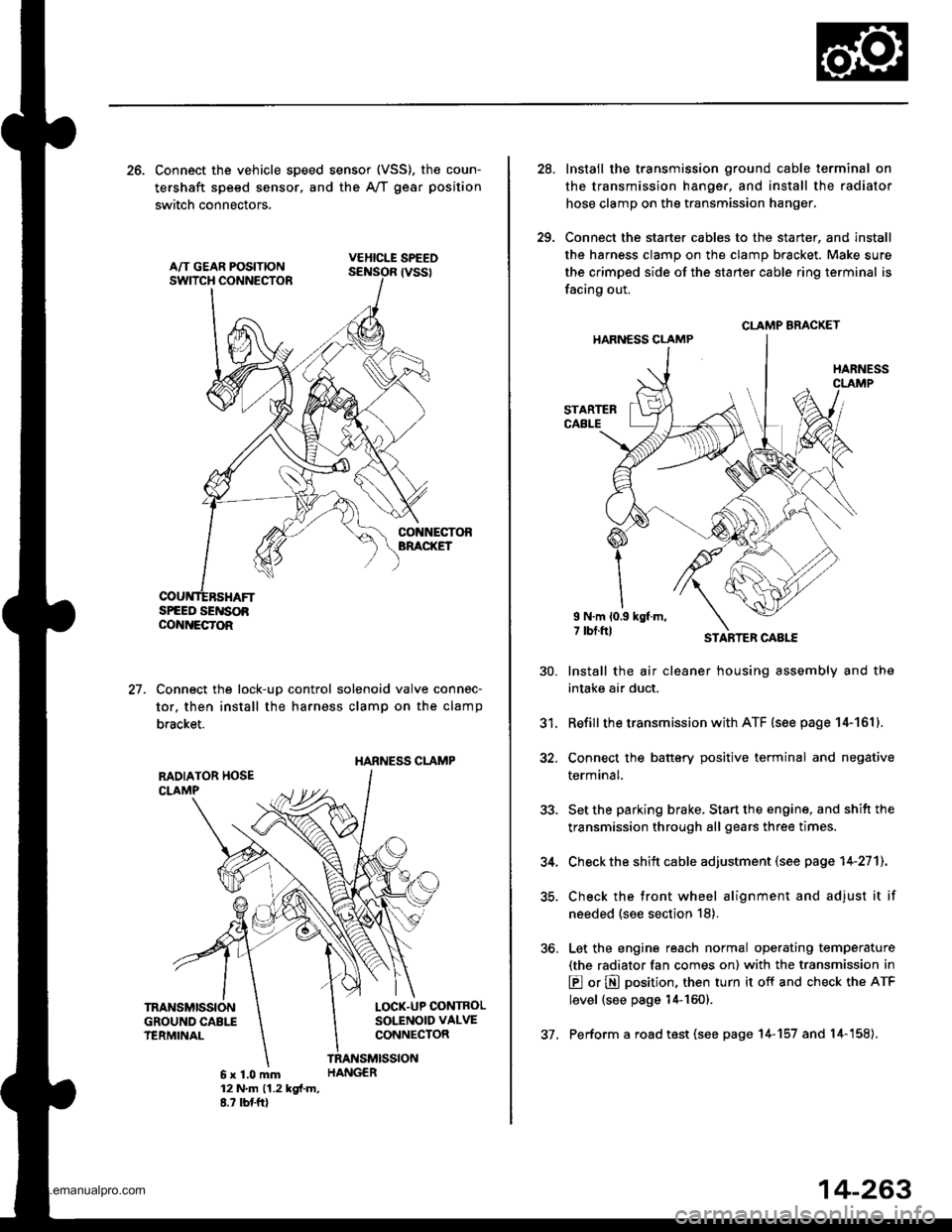

26. Connect the vehicle speed sensor (VSS). the coun-

tershaft speed sensor. and the A,/T gear position

switch connectors,

VEHICLE SPEEO

SPEED SENSOACO'{NECTOR

Connect the lock-up control solenoid valve connec-

tor, then install the harness clamp on the clamp

bracket.

HARNESS CI-AMP

27.

RADIATOR HOSECLAMP

TRANSMISSIONGROUND CAB1ITERMINAL

LOCK-UP OONTROLSOLENOID VALVECONNECTOR

6x1.0mm12 N'm (1.2 kgi.m,8.? tbtftl

28.

29.

Instail the transmission ground cable terminal on

the transmission hanger, and install the radiator

hose clamp on the transmission hanger,

Connect the starter cables to the starter, and install

the harness clamD on the clamD bracket. Make sure

the crimped side of the starter cable ring terminal is

facing out.

STARTEBCABLE

STARTER CAAtf,

Install the air cleaner housing assembly and the

intake air duct.

Refill the transmission with ATF (see page 14-161).

Connect the battery positive terminal and negative

terminal.

Set the parking brake, Start the engine, and shift the

transmission through all gears three times.

Check the shift cable adjustment (see page 14-271]-.

Check the tront wheel alignment and adjust it if

needed (see section 18).

Let the engine reach normal operating temperature

(the radiator fan comes on) with the transmission in

E or N position, then turn it off and check the ATF

level {see page 14-160).

Perform a road test (see page 14-157 and 14-158).

30.

31.

34.

CLAMP BRACKET

37.

14-263

www.emanualpro.com

Page 783 of 1395

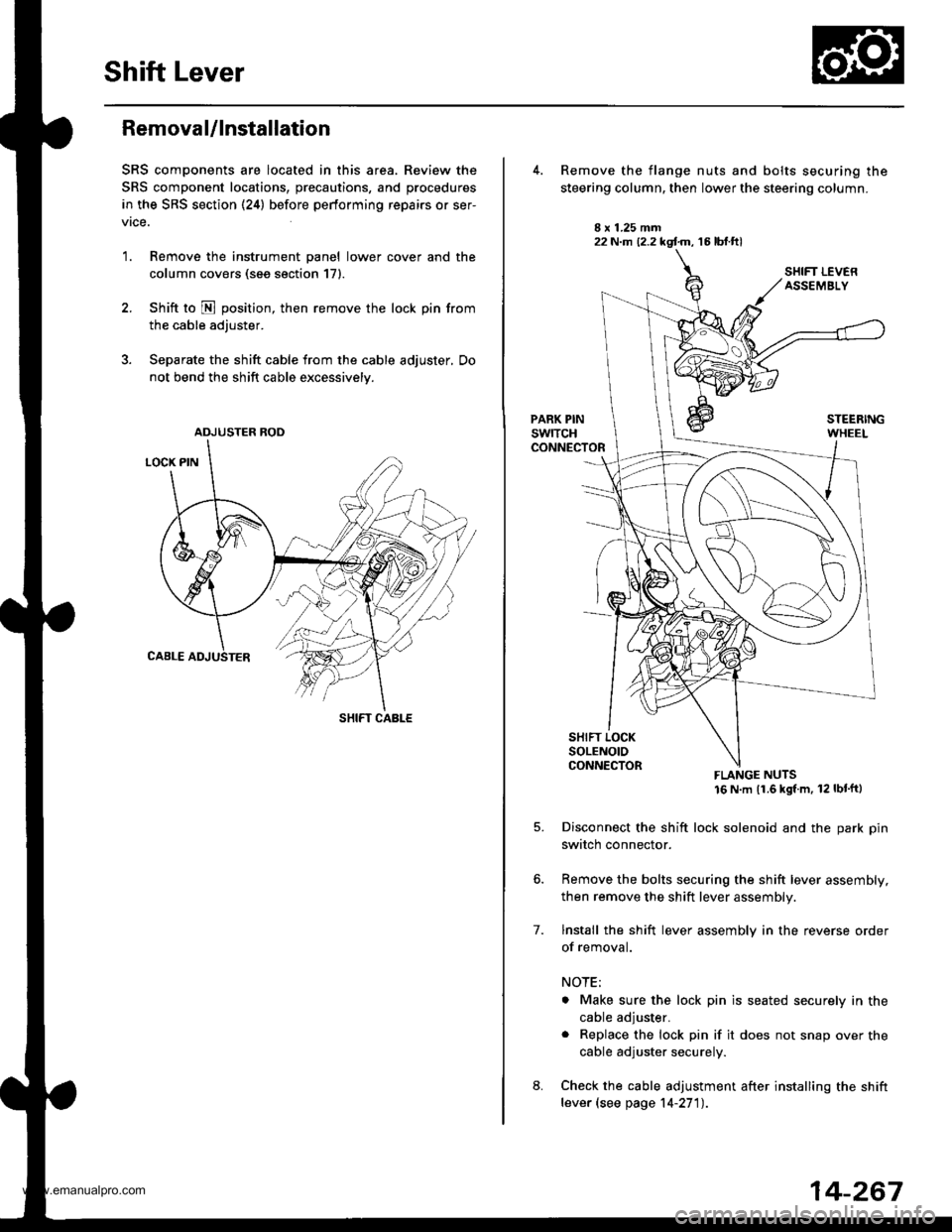

Shift Lever

Removal/lnstallation

SRS components are located in this area. Review the

SRS component locations, precautions, and procedures

in the SRS section (24) before performing repairs or ser-

vrce.

1. Remove the instrument panel lower cover and the

column covers (see section 171.

2. Shift to N position, then remove the lock pin from

the cable adjuster.

3. Separate the shift cable from the cable adjuster, Do

not bend the shift cable excessively.

ADJUSTER ROD

SHIFT CABLE

22 N.m (2.2 kgf.m, 16 lbt.ftl

7.

Remove the flange nuts and bolts securing the

steering column, then lower the steering column.

FLANGE NUTS16 N m (1.6 kgl m, 12 lbt'ftl

Disconnect the shift lock solenoid and the park pin

switch connector.

Remove the bolts securing the shift lever assembly,

then remove the shift lever assembly.

lnstall the shift lever assembly in the reverse order

of removal.

NOTE;

. Make sure the lock pin is seated securely in the

cable adjuster.

. Replace the lock pin if it does not snap over the

cable adjuster securely.

Check the cable adjustment after installing the shift

lever (see page 14-27'l).

14-267

www.emanualpro.com

Page 784 of 1395

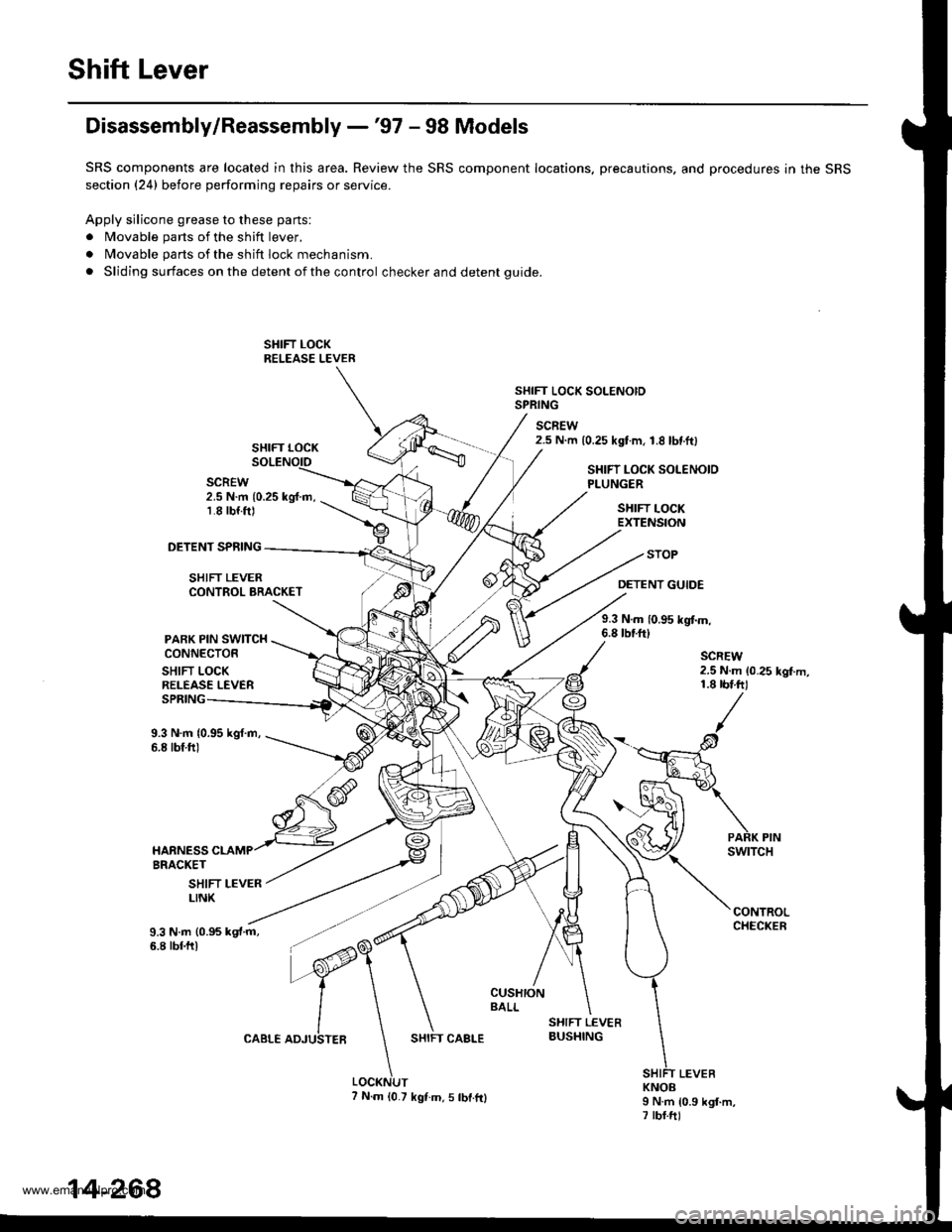

Shift Lever

Disassembly/Reassembly -'97 - 98 Models

SRS components are located in this area. Review the SRS component locations. precautions. and procedures in the SRS

section (24) before performing repairs or service.

Apply silicone grease to these parts'

. Movable parts of the shift lever,

. Movable parts of the shift lock mechanism.

. Sliding surfaces on the detent of the control checker and detent guide.

SHIFT LOCK SOLENOIDSPRING

SCREW

SHIFT LOCK2.5 N.m {0.25 kgtm, 1.8 lbtftl

SCREW2.5 N.m {0.25 kg{.m,1.8 rbf.ft)

SHIFT LOCK SOLENOIDPLUNGER

SHIFT LOCKEXTENSION

DETENT SPFING

SHIFT LEVER

PARK PIN SWITCHCONNECTOR

SHIFT LOCKRELEASE LEVER

CONTROL BRACKET

STOP

DETENT GUIDE

9.3 N.m 10.95 kgtm,6.8 tbrft)

SPRING

9.3 N.m {0.95 kgf.m,6.8 tbf.ftl

SHIFT LEVERLINK

9.3 N.m (0.95 kgt.m,6.8 tbf.ftl

SHIFT CAALE

KNOBI N.m 10.9 kgt.m,7 rbf.ftl

14-268

7 N.m {0.7 kgf.m.5 tbt.fr}

www.emanualpro.com

Page 785 of 1395

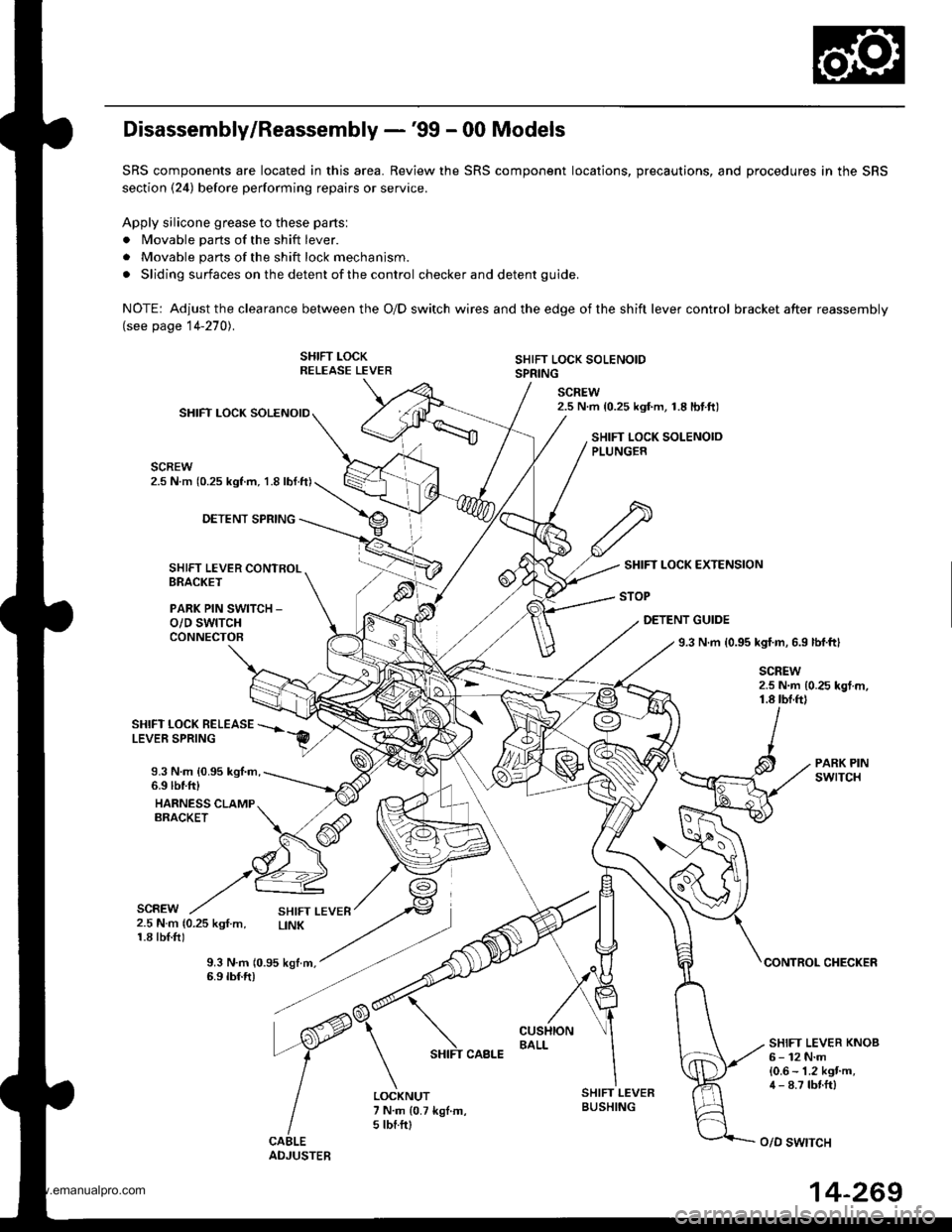

Disassembly/Reassembly -'99 - 00 Models

SRS components are located in this area. Review the SRS component locations, precautions, and procedures in the SRS

section (24) before performing repairs or service.

Apply silicone grease to these parts:

. Movable parts of the shift lever.

. Movable parts of the shift lock mechanism.

. Sliding surfaces on the detent of the control checker and detent guide.

NOTE: Adjustthe clearance between the O/D switch wires and the edge ofthe shift lever control bracket after reassembly(see page 14-270).

SHIFT LOCKRELEASE LEVERSHIFT LOCK SOLENOIDSPRING

SCREW2.5 N.m {0.25 kgf.m, 1.8lbtft)SHIFT LOCK SOLENOID

SCREW2.5 N.m (0.25 kgl.m, 1.8 lbl.ft)

SHIFT LOCK SOLENOIOPLUNGER

DETENT SPRING

SHIFT LEVER CONTROLBRACKET

PARK PIN SWITCH _

o/D swtTcHCONNECTOB

SHIFT LOCK EXTENSION

STOP

DETENT GUIDE

9.3 N.m {0.95 kgf.m, 6.9 lbl.ftl

SCREW2.5 N.m {0.25 kgt m,1.8 tbf.ftl

SHIFT LOCK BELEASELEVER SPRING

9.3 N.m {0.95 kgl.m,6.9 lbtfr)

HARNESS CLAMPERACKET

PARK PINswrTcH

SCREW2.5 N.m {0.25 kgf.m,1.8 tbl.f0

9.3 N.m 10.95 kgtm,6.9 tbf.ft)CONTROL CHECKER

SHIFT LEVER KNOB6- 12 N.m{0.6 - 1.2 kgt'm,4 - 8.7 tbnft)LOCKNUT7 N.m {0.7 kgl.m,5 tbf.ftl

SHIFT LEVERBUSHING

o/D swtTcH

14-269

www.emanualpro.com

Page 948 of 1395

Anti-lock Brake System (ABSI,'97 - 00 Models

Special Tools ............. 19-26

Component Locations ......................... 19-27

Anti-lock Brake System (ABS)

Features/Construction ............. ......, 19-2A

Circuit Diagram ......... 19-32

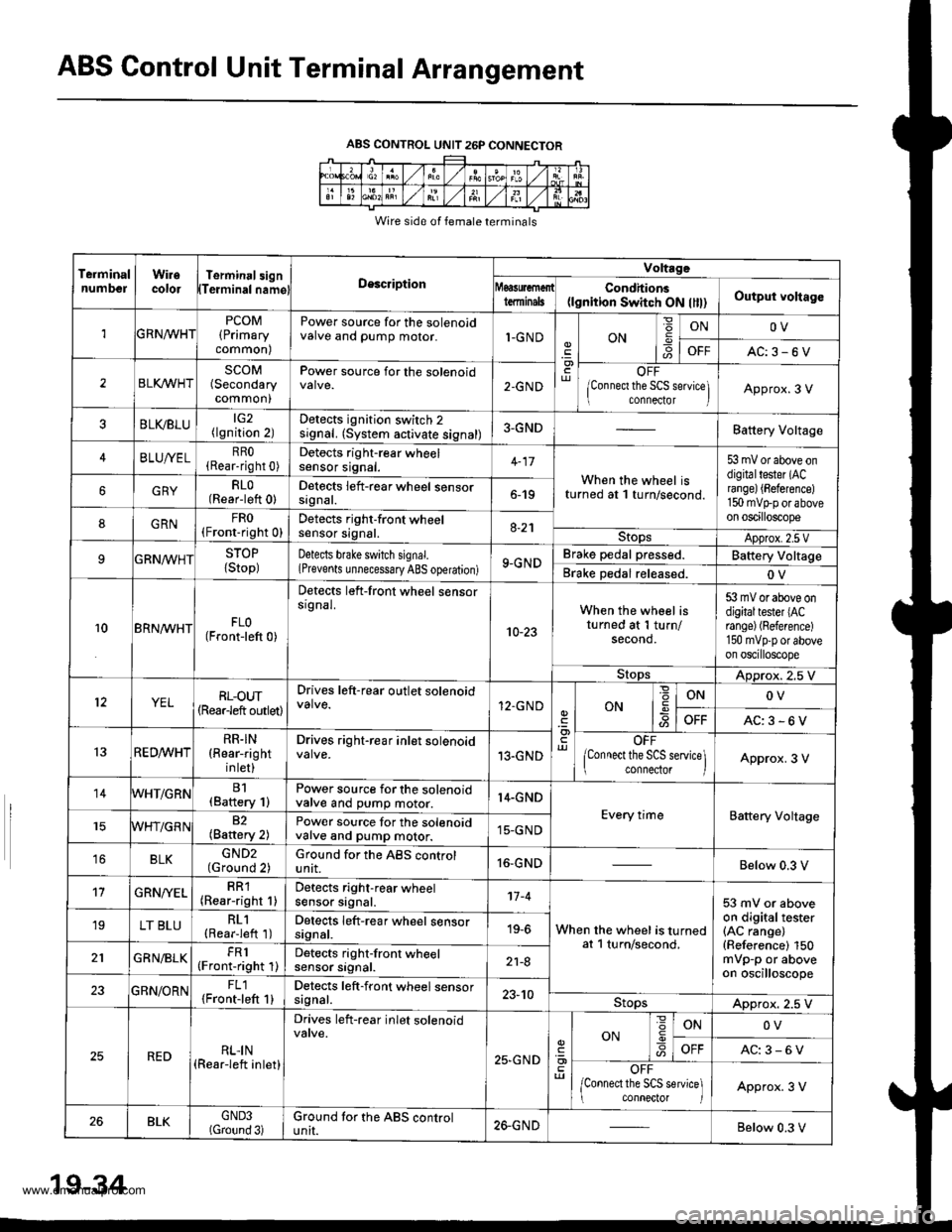

ABS Control Unit Terminal

Arrangement ......... 19-34

Troubleshooting Precautions ............. 19-36

Diagnostic Trouble Gode (DTC)

Diagnostic Trouble Code (DTC)

Indication (SCS Model ................ 19-38

DTG Erasure (MES Mode) ............... 19-39

Troubleshooting lndex .................... 19-40

Troubleshooting

ABS Indicator Light Does Not

Come On ............ 19-41

ABS Indicator Light Does Not

Go Off (No DTC) ........................... 19-43

DTC 1r - 18:

Wheel Sensor .... 19-45

DTC 31 - 38:

Solenoid ............. 19-47

DTC 51 - 53:

ABS Pump Motor ......................... 19-49

DTC 54:

Main Relay ......... 19-52

DTC 61:

lgnition Voltage ........................... 19-54

DTC 81:

Central Processing Unit (CPU) .... 19-55

Modulator Unit

Removal/lnstallation ....................... 19-56

ABS Control Unit

Replacement ..,...... 19-57

Pulsers/Wheel Sensors

Inspection .............. 19-57

Wheel Sensor Replacement ............ 19-58

www.emanualpro.com

Page 952 of 1395

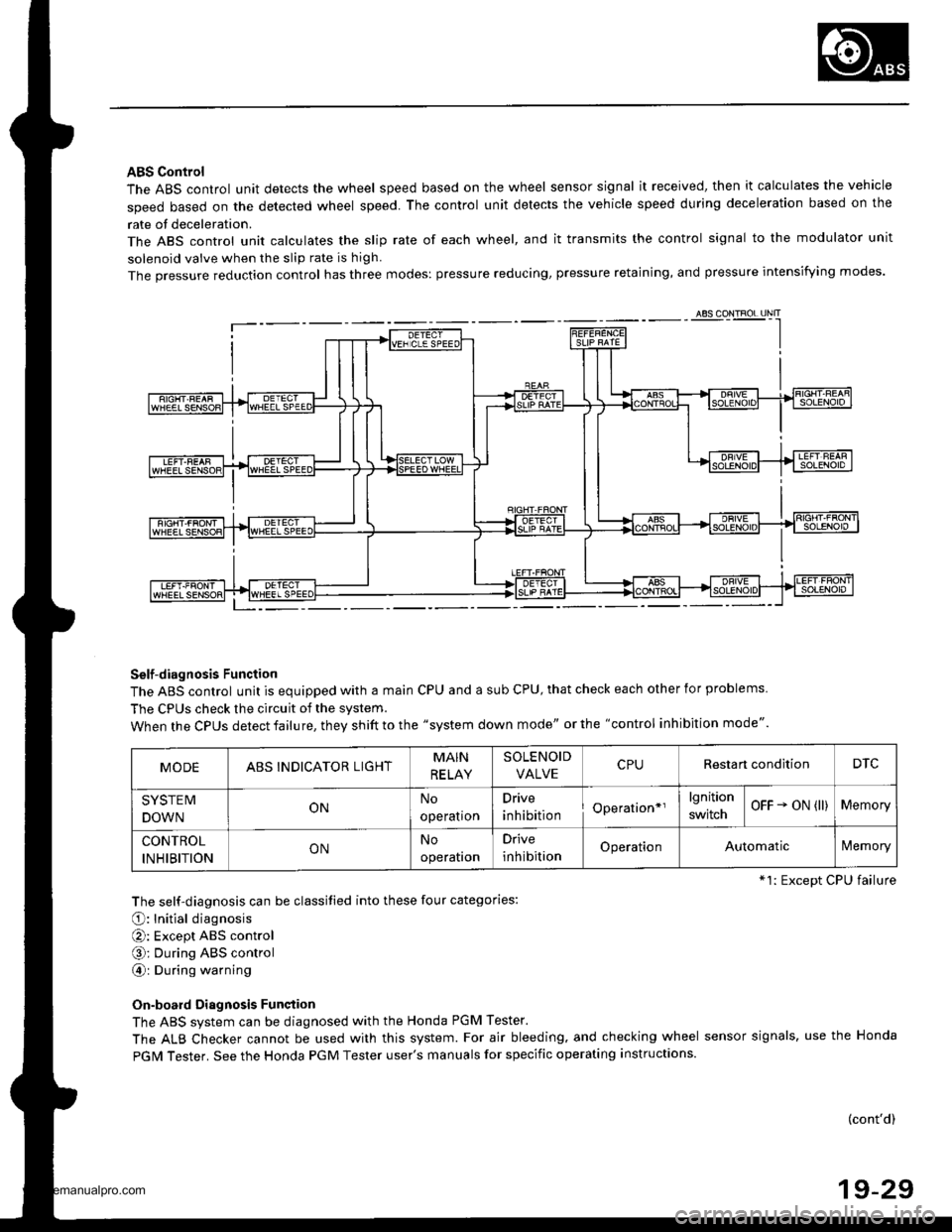

ABS Control

The ABS control unit detects the wheel speed based on the wheel sensor signal it received, then it calculates the vehicle

speed based on the detected wheel speed. The control unit detects the vehicle speed during deceleration based on the

rate of deceleration.

The ABS control unit calculates the slip rate of each wheel, and it transmits the control signal to the modulator unit

solenoid valve when the slip rate is high

The pressure reduction control has three modes: pressure reducing, pressure retaining, and pressure intensi{ying modes.

Self-diagnosis Function

The ABS control unit is equipped with a main cPU and a sub cPU, that check each other for problems.

The CPUs check the circuit of the system.

When the CPUS detect failure, they shift to the "system down mode" or the "control inhibition mode".

The self-diagnosis can be classitied into these four categories:

O: Initial diagnosis

O: Except ABS control

O; During ABS control

@: During warning

On-board Diagnosis Function

The ABS system can be diagnosed with the Honda PGM Tester.

The ALB Checker cannot be used with this system. For air bleeding. and checking wheel sensor signals, use the Honda

PGIM Tester. See the Honda PGM Tester user's manuals for specific operating instructions.

(cont'd)

19-29

ABS CONTROL I-INIT

MODEABSINDICATOR LIGHTMAIN

RE LAY

SOLENOID

VALVERestan conditionDTC

SYSTEM

DOWNONNo

operatron

Drive

inhibitionOperation*rlgnition

switchOFF - oN (ll)Memory

CONTROL

INHIBITIONONNo

operaton

Drive

inhibitionOperationAutomaticlVemory

*1: Except CPU failure

www.emanualpro.com

Page 953 of 1395

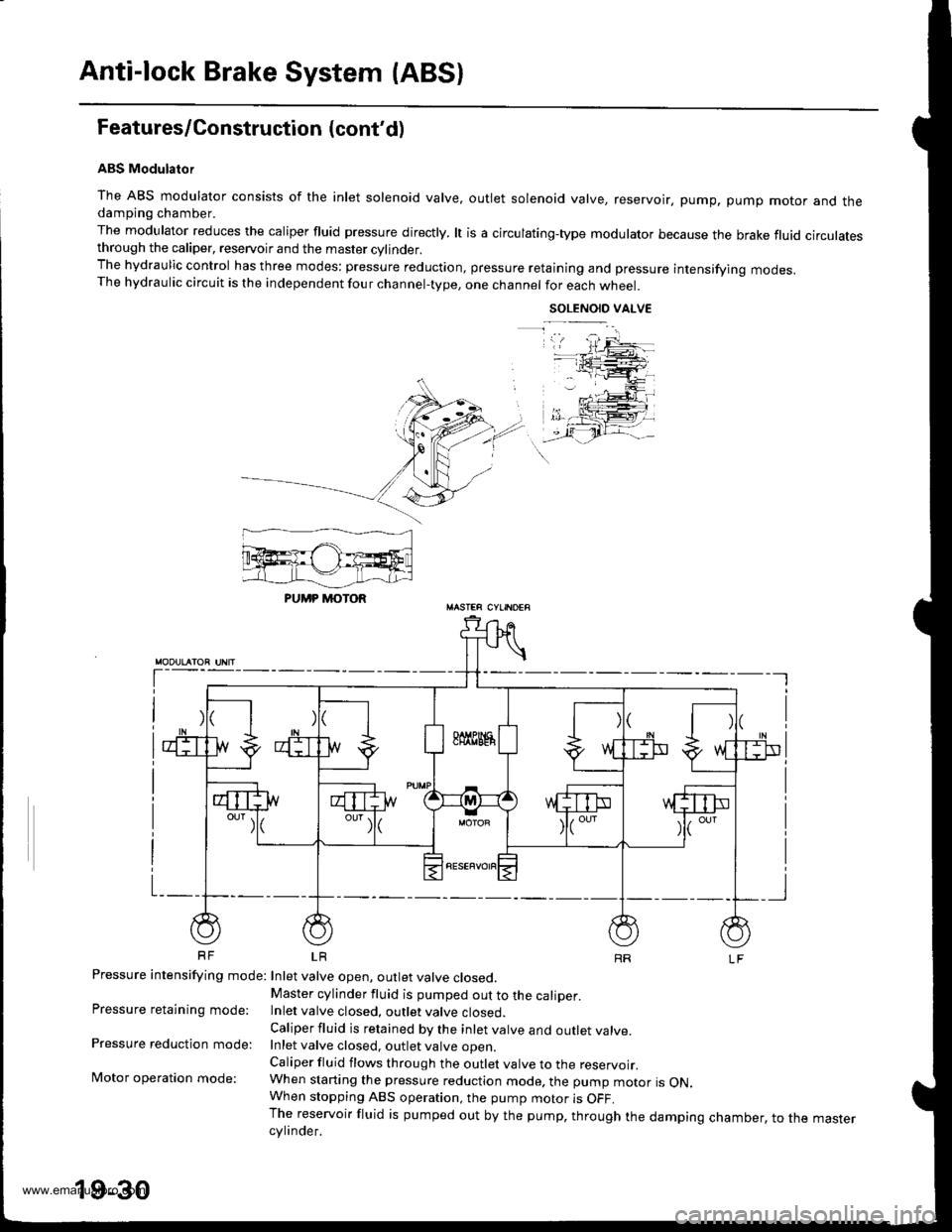

Anti-lock Brake System (ABS)

Features/Gonstruction (cont'd)

ABS Modulator

The ABS modulator consists of the inlet solenoid valve, outlet solenoid valve, reservoir, pump, pump motor and thedampjng chamber.

The modulator reduces the caliper fluid pressure directly. lt is a circulating-type modulator because the brake fluid circulatesthrough the caliper, reservoir and the master cylinder.The hydraulic control has three modes: pressure reduction, pressure retaining and pressure intensifying modes.The hydraulic circuit is the independent four channel-type, one channel for each wheel.

SOLENOID VALVE

t-

Pressure intensifying mode: Inlet valve open, outlet valve closed,

Pressure retaining mode:

Pressure reduction mode:

Motor operation mode:

Master cylinder fluid is pumped out to the caliper.Inlet valve closed, outlet valve closed.

Caliper fluid is retained by the inlet valve and outlet valve.Inlet valve closed, outlet valve ooen

Caliper fluid flows through the outlet valve to the reservoir.When starting the pressure reduction mode. the pump motor is ON.When stopping ABS operation, the pump motor is OFF.The reservoir fluid is pumped out by the pump, through the damping chamber, to the mastercylinder.

PUMP MOTOR

19-30

www.emanualpro.com

Page 957 of 1395

ABS Control Unit Terminal Arrangement

ABS CONTROL UNIT 26P CONNECTOR

Wire side of female terminals

TeiminalnumbelWiiecolorTerminal3ignTeiminalnamglDescription

Voltrge

tdminalsCondhions(lgnition Switch ON llll)Output voltago

1GRNn/VHTPCOM(Primary

common)

Power source for the solenoidvalve and pump motor.1-GNDON6

ONOV

OFFAC:3-6V

2BLI(WHTSCOM(Secondary

common)

Power source for the solenoid2-GNDOFF

lConnect the SCS seNice] connector IApprox.3 V

BLVBLU(lgnition 2)Detects ignition switch 2signal. (System activate signal)3-GNDBattery Voltage

4BLUA/ELRRO(Rear-right 0)Detocts right-rear wheelsensor srgnat.When the wheel isturned at 1 turn/second.

53 mV or above ondigitaltester (ACrange) {Beference)150 mvtrp or aboveon oscilloscope

GRYRLO(Rear-left 0)Detects left-rear wheel sensorsrgnat.6-19

8GRNFRO(Fronr-right 0)Detects right-front wheelsensor signal.8-21StopsApprox.2.5 VSTOP

{Stop)Detects bfake switch signal.(Prevents unnecessary ABS operation)9-GNDBrake pedal pressed.Battery Voltage

Brake Dedal released.OV

10BRN^/VHTFLO(Front-left 0)

Detects left-front wheel sensorsrgnal.

10-23

When the wheel isturned at 1 turn/second.

53 mV or above ondigitaltester lACrange) (Reference)

150 mvpp or aboveon oscilloscope

StopsADprox. 2.5 V

YELRL-oUT(Rearleft outlet)

Drives left-rear outlet solenoid12.GNDONONOV

OFFAC:3-6V

13RED^/vHTRR.IN(Rear-right

inlet)

Drives right-rear inlet solenoid13.GNDOFF

lConnect the SCS service\ connector IApprox. 3 V

14WHT/GRNB1(Baftery 1)Power source for the solenoidvalve and pump motor.14.GND

Every timeBattery Voltage82(Battery 2)Power source for the solenoidvalve and pump motor.15-GND

16BLKGND2(Ground 2)Ground for the ABS controlunit.16-GNDBelow 0.3 V

't7GRN/YELRR1(Rear-right 1)Detects right-rear wheelsensor signal.'t7 -4

When the wheel is turnedat l turn/second,

53 mV or aboveon digitaltester(AC range)(Reference) 150mVp-p or aboveon oscilloscope

19LT BLURL1(Rearieft 1)Detects left-rear wheel sensorsignal.19-6

GRN/BLKFR1(Front-right 1)Detects right-front wheelsensor srgnat.21-8

23GBN/ORNFL1{Front-left 1}Detects left-front wheel sensorsagnal.23-10StopsApprox. 2.5 V

REDRLI N(Rear-left inlet)

Drives left-rear inlet solenoid

25,GND

ON

=

-9ONOV

AC:3-6V

OFF

/Connect the SCS service] conneclor IApprox. 3 V

26BLKGND3(Gtound 3)Ground tor the ABS controluntI.26-GNDBelow 0.3 V

19-34

www.emanualpro.com