Start HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 898 of 1395

't 4.

15.

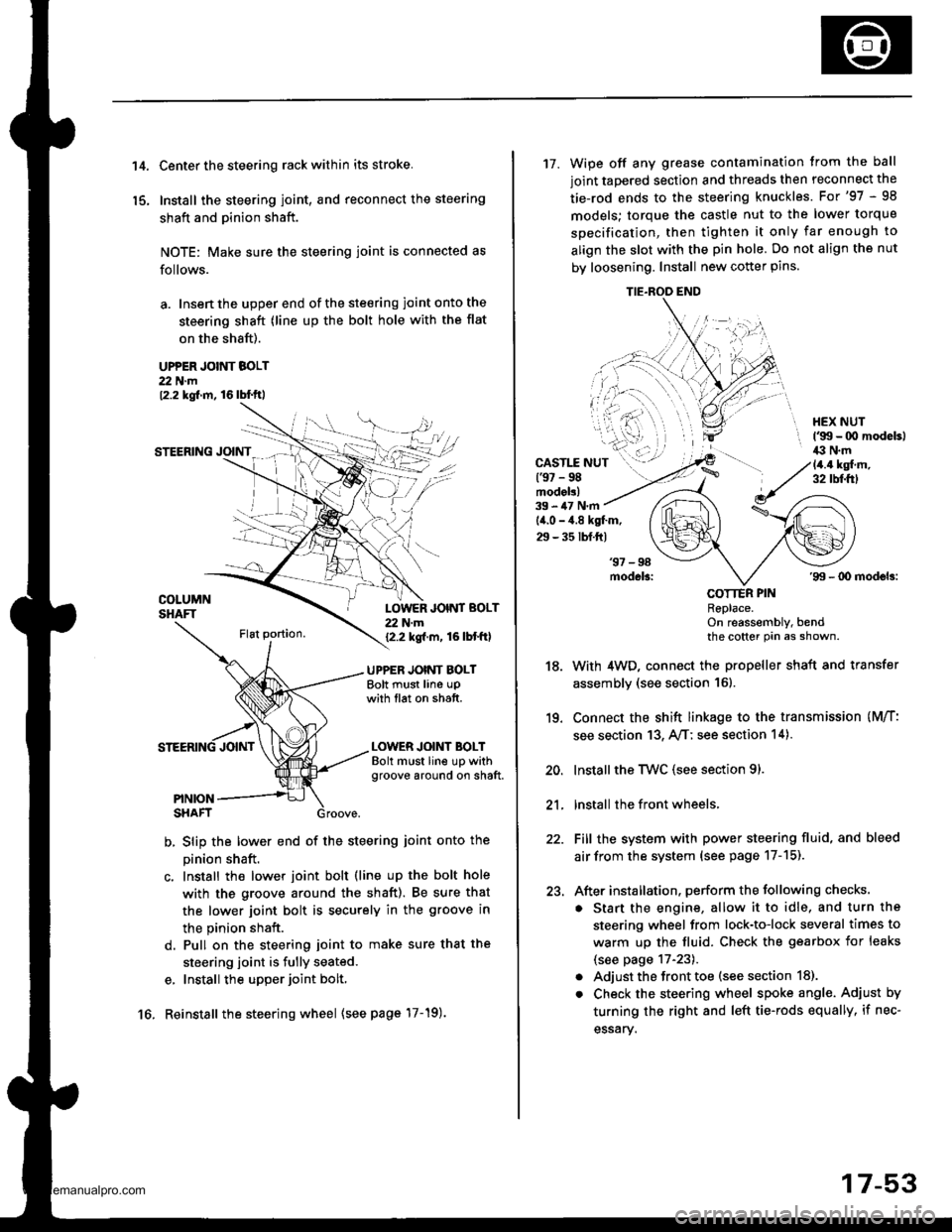

Center the steering rack within its stroke.

Install the steering joint, and reconnect the steering

shaft and pinion shaft.

NOTE: Make sure the steering joint is connected as

follows.

a. Insen the upper end of the steering joint onto the

steering shaft (line up the bolt hole with the flat

on the shaft).

UPPER JOINT BOLT22 N.m12.2 kgf.m, 16lbl.ft,

STEERING JOINT

COLUMNSHAFTLOWER JOINT BOLT22 N.m12.2 kgf.m, 16lbtftl

UPPER JOINT BOLTBolt must line upwith tlat on shatt.

LOWER JOINT BOLTBolt must line up withgroove around on shaft.

PINIONSHAFT

b, Slip the lower end of the steering ioint onto the

pinion shaft.

c. Install the lower joint bolt (line up the bolt hole

with ths groove around the shaft). Be sure that

the lower joint bolt is securely in the groove in

the pinion shaft.

d. Pull on the steering joint to make sure that the

steering joint is fully seated.

e, Install the upper joint bolt,

Reinstall the steering wheel {see page'17-19).16.

17-53

17. Wipe off any grease contamination trom the ball

joint tapered section and threads then reconnect the

tie-rod ends to the steering knuckles. For'97 - 98

models; torque the castle nut to the lower torque

specification, then tighten it only far enough to

align the slot with the pin hole. Do not align the nut

by loosening. Install new cotter pins.

CAST1T NUT(9t - 98modol!)

HEX NUTl'g!t - 00 modeb)il:l N.m14.4 ksl.m,32 tbf.f0

39 - iU N'm

lil.o - 4.8 kgl.m,

29 - 35 tbf.ftl

18.

19.

20.

21.

22.

23.

'99 - lD modeb:

COTTER PINRePlace.on reassembly, bendthe cotter Pin as shown.

With 4WD, connect the propeller shaft and transfer

assembly (see section 16).

Connect the shift linkage to the transmission (M/T:

see section 13, A,/T; see section 14).

Installthe Twc (see section 91.

lnstall the front wheels,

Fill the system with power steering fluid, and bleed

air from the system (see page 17-15).

After installation. perform the following checks.

. Start the engine, allow it to idle, and turn the

steering wheel from lock-to-lock several times to

warm up the fluid. Check the gearbox for leaks

(see page 17-23).

. Adjust the front toe (s€e section 18).

. Check the steering wheel spoke angl€. Adjust by

turning the right and left tie-rods equally, if nec-

essary.

TIE.ROO END

www.emanualpro.com

Page 931 of 1395

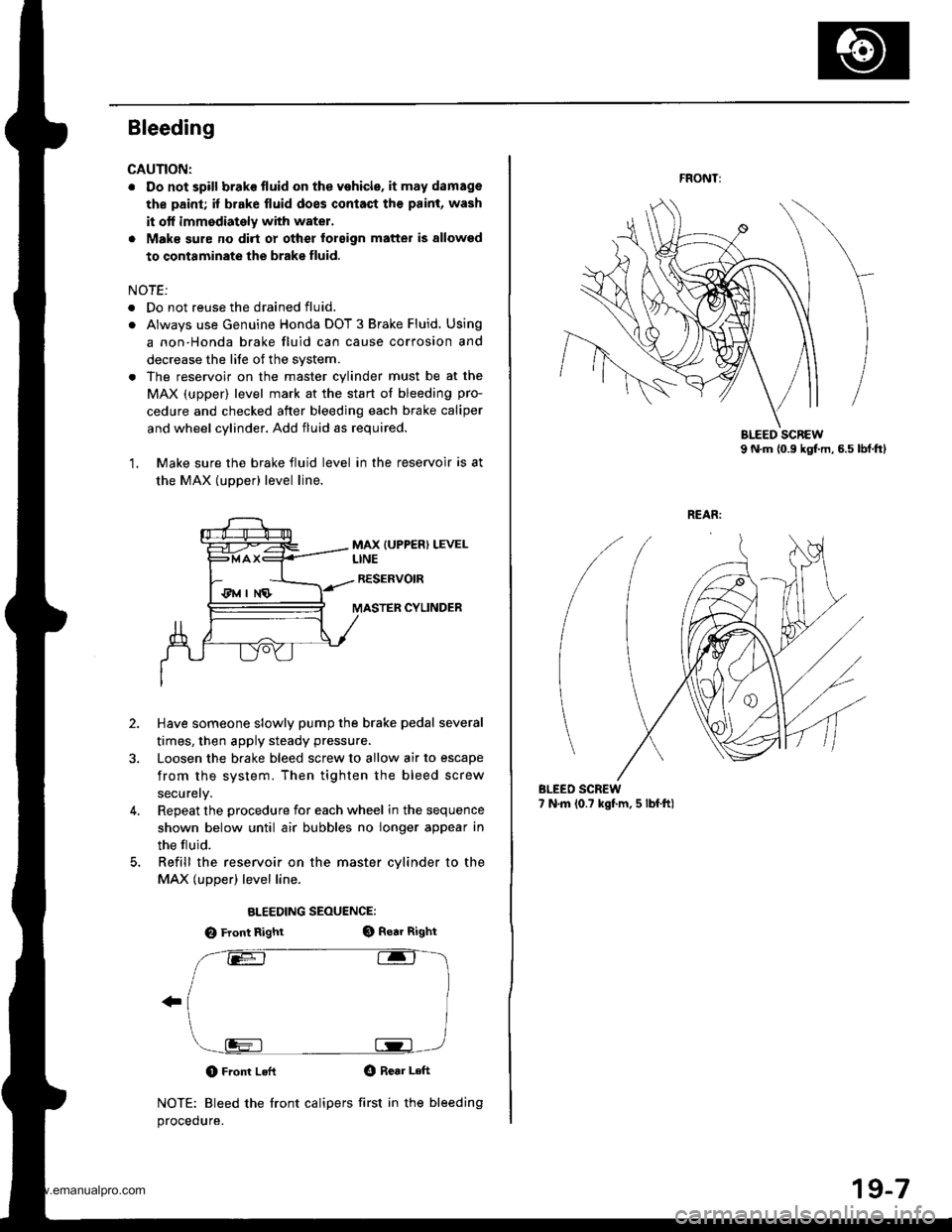

Bleeding

CAUNON:

. Do not spill brake tluid on the vehicle. it may damage

the paint; if brake fluid does contaqt th€ paint, wash

it otf immodiately with water.

. Maks sure no dirt oy other forsign matter is allowsd

to contaminate the brake fluid.

NOTE:

. Do not reuse the drained fluid.

. Always use Genuine Honda DOT 3 Brake Fluid. Using

a non-Honda brake fluid can cause corrosion and

decrease the life of the svstem.

. The reservoir on the master cylinder must be at the

MAX (upper) level mark at the start of bleeding pro-

cedure and checked after bleeding each brake caliper

and wheel cylinder. Add fluid as required.

1, Make sure the brake fluid level in the reservoir is at

the MAX (uDDer) level line.

MAX {UPPER) LEVELLINE

RESERVOIR

MASTER CYLINDER

2.

3.

Have someone slowly pump the brake pedal several

times, then apply steady pressu.e.

Loosen the brake bleed screw to allow air to escape

from the system. Then tighten the bleed screw

securely.

Repeat the procedure for each wheel in the sequence

shown below until air bubbles no longer appear in

the tluid.

Refill the reservoir on the master cvlinder to the

MAX (upper) level line.

ALEEDING SEOUENCE:

O Front RightGt Rear Right

O Front LeflO Rear Left

NOTE: Bleed the front calipers first in the bleeding

procedure.

4.

FRONT:

BLEEO SCREW7 N.m (0.? kgf.m, 5 lbf.ftl

19-7

www.emanualpro.com

Page 939 of 1395

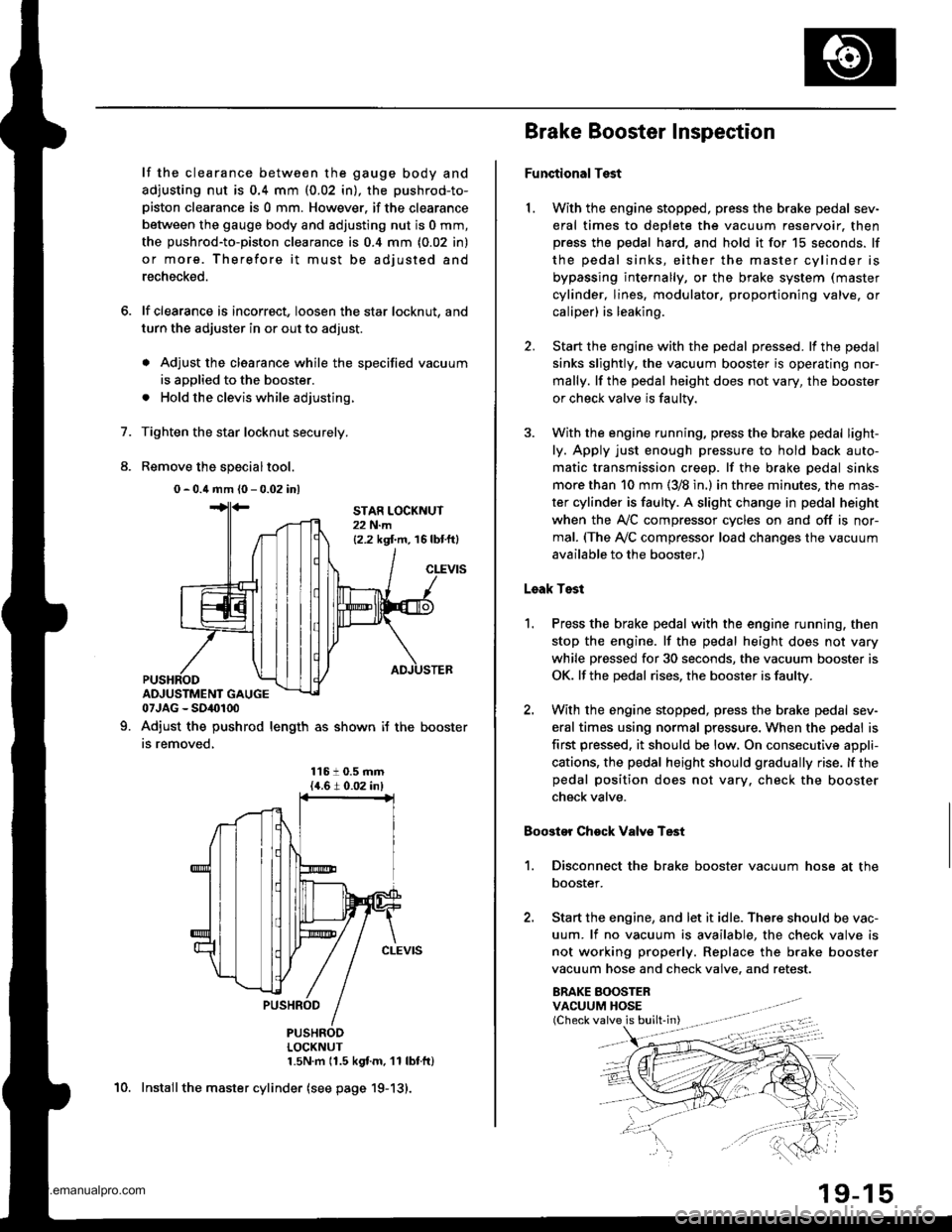

6.

7.

8.

lf the clearance between the gauge body and

adjusting nut is 0.4 mm (0.02 in), the pushrod-to-

piston clearance is 0 mm. However. if the clearance

between the gauge body and adjusting nut is 0 mm,

the pushrod-to-piston clearance is 0.4 mm (0.02 in)

or more. Therefore it must be adjusted and

recheck€d.

lf clearance is incorrect, loosen the star locknut, and

turn the adjuster in or out to adjust.

. Adjust the clearance while the specified vacuum

is applied to the booster.

. Hold the clevis while adjusting.

Tighten the star locknut securely.

Remove the special tool.

0 - 0.4 mm (0 - 0.02 inl

Adjust the pushrod length as shown if the

is removed,

booster

11610.5 mm{4.6 t 0.02 inl

PUSHRODLOCKNUT1.5N.m 11.5 kgf.m. '11 lbtfl)

Install the master cylinder (see page 19-13).

9.

STAR LOCKNUT22 N.m12.2 kgt m. 16 lbtftl

10.

(Check valve is built-in)

Brake Booster Inspection

FunctionalTest

1. With the engine stopped, press the brake pedal sev-

eral times to deplete the vacuum reservoir. thenpress the pedal hard, and hold it for 15 seconds. lf

the pedal sinks, either the master cylinder is

bypassing internally, or the brake system (master

cylinder, lines, modulator, proportioning valve. or

caliper) is leaking.

2. Start the engine with the pedal pressed. lf the pedal

sinks slightly. the vacuum booster is operating nor-

mally. lf the pedal height does not vary, the booster

or check valve is faultv.

3. With the engine running, press the brake pedal light-

ly. Apply just enough pressure to hold back auto-

matic transmission creep. lf the brake pedal sinks

more than 10 mm (3/8 in.) in three minutes, the mas-

ter cylinder is faulty. A slight change in pedal height

when the Ay'C compressor cycles on and off is nor-

mal. (The Ay'C compressor load changes the vacuum

available to the booster.)

Leak Test

1.Press the brake pedal with the engine running, then

stop the engine. lf the pedal height does not vary

while pressed for 30 seconds, the vacuum booster is

OK. lf the pedal rises, the booster is faulty.

With the engine stopped, press the brake pedal sev-

eral times using normal pressure. When the pedal is

first pressed. it should be low, On consecutive appli-

cations, the pedal height should gradually rise. lf thepedal position does not vary. check the booster

check valve.

Boostor Chock Valve Test

1. Disconnect the brake booster vacuum hose at the

booster.

2. Start the engine, and let it idle. There should be vac-

uum. lf no vacuum is available, the check valve is

not working properly. Replace the brake booster

vacuum hose and check valve. and retest.

ERAKE BOOSTERVACUUM HOSE

www.emanualpro.com

Page 953 of 1395

Anti-lock Brake System (ABS)

Features/Gonstruction (cont'd)

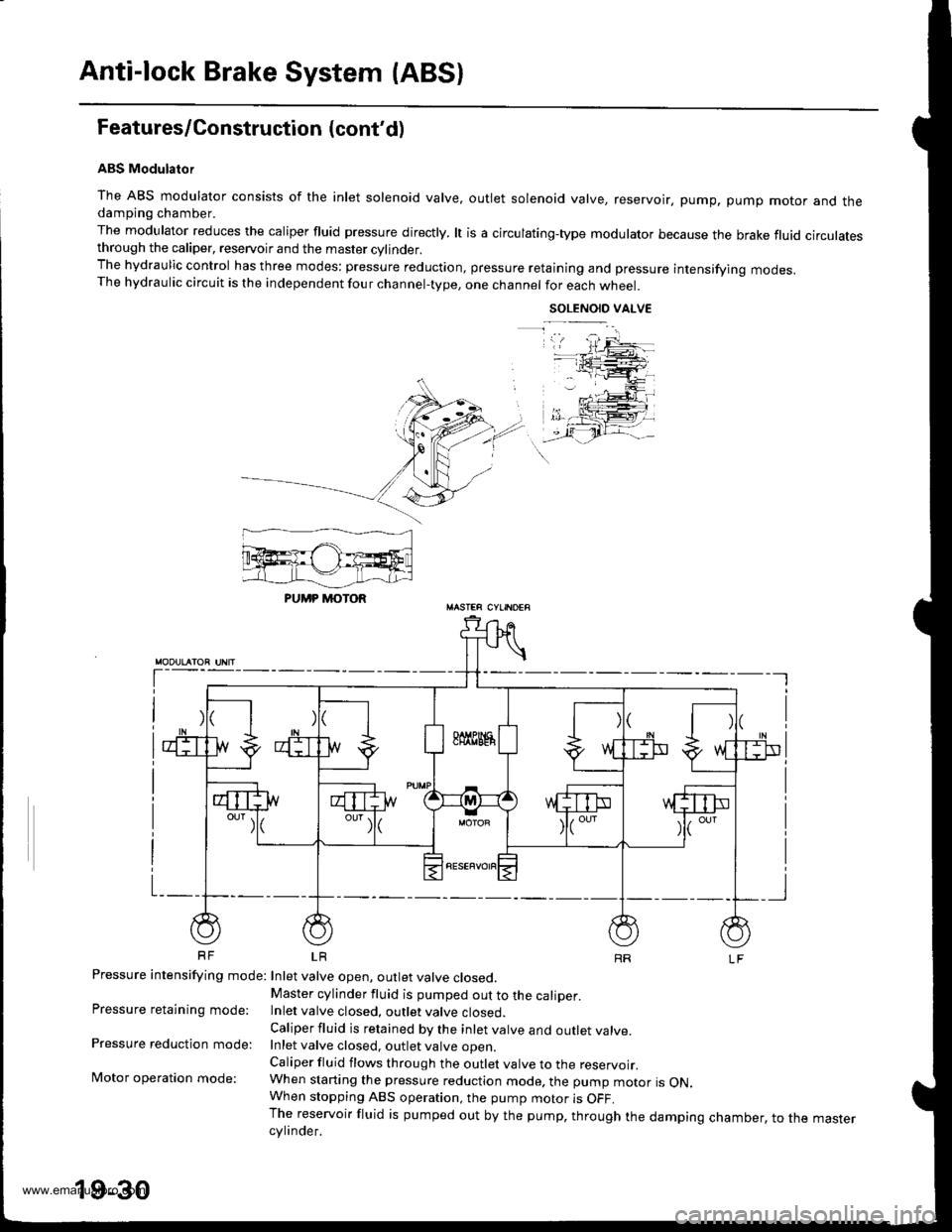

ABS Modulator

The ABS modulator consists of the inlet solenoid valve, outlet solenoid valve, reservoir, pump, pump motor and thedampjng chamber.

The modulator reduces the caliper fluid pressure directly. lt is a circulating-type modulator because the brake fluid circulatesthrough the caliper, reservoir and the master cylinder.The hydraulic control has three modes: pressure reduction, pressure retaining and pressure intensifying modes.The hydraulic circuit is the independent four channel-type, one channel for each wheel.

SOLENOID VALVE

t-

Pressure intensifying mode: Inlet valve open, outlet valve closed,

Pressure retaining mode:

Pressure reduction mode:

Motor operation mode:

Master cylinder fluid is pumped out to the caliper.Inlet valve closed, outlet valve closed.

Caliper fluid is retained by the inlet valve and outlet valve.Inlet valve closed, outlet valve ooen

Caliper fluid flows through the outlet valve to the reservoir.When starting the pressure reduction mode. the pump motor is ON.When stopping ABS operation, the pump motor is OFF.The reservoir fluid is pumped out by the pump, through the damping chamber, to the mastercylinder.

PUMP MOTOR

19-30

www.emanualpro.com

Page 954 of 1395

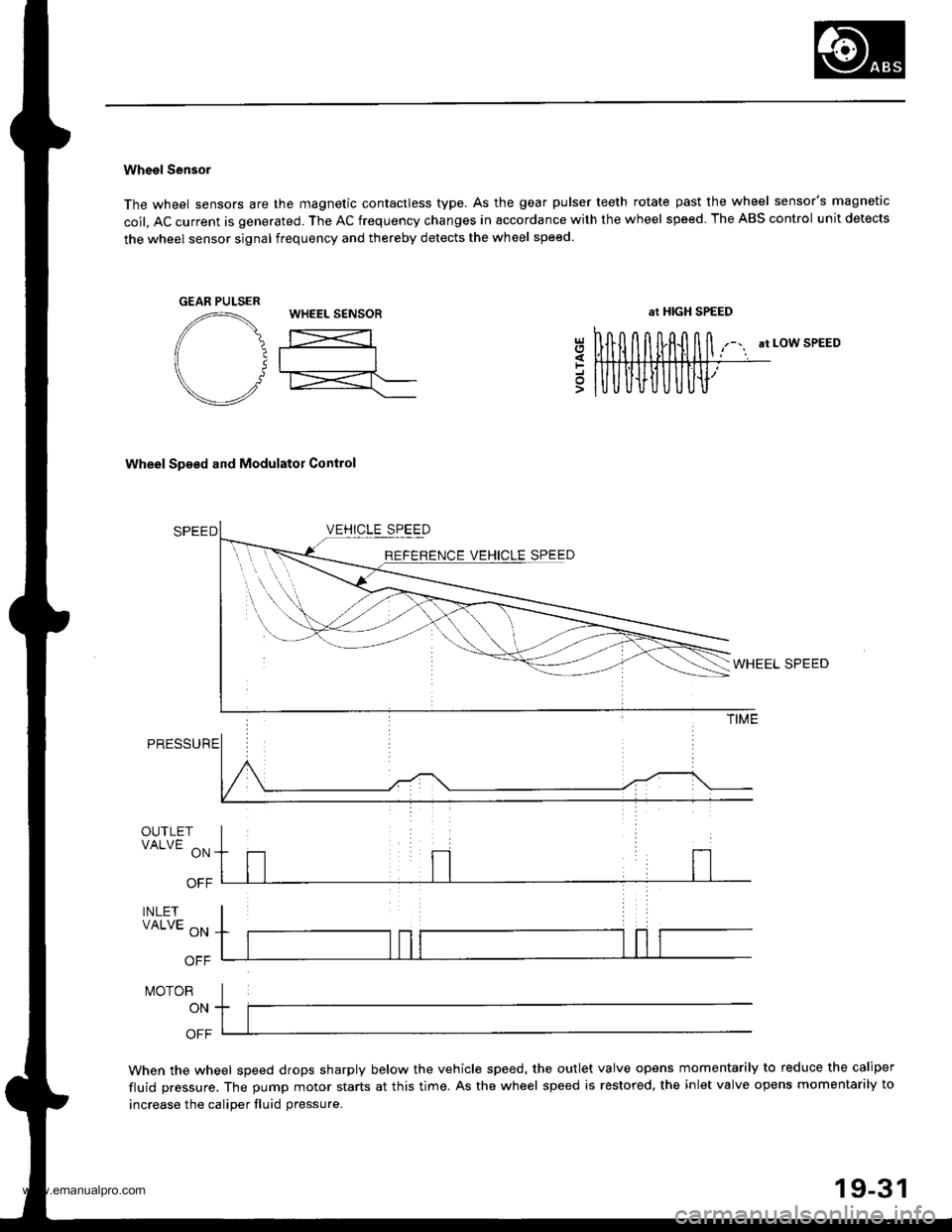

Wheel Sensor

The wheel sensors are the magnetic contactless type. As the gear pulser teeth rotate past the wheel sensor's magnetic

coil, AC current is generated. The AC frequency changes in accordance with the wheel speed. The ABS control unit detects

the wheel sensor signal frequency and thereby detects the wheel speed

at LOW SPEED

wheel Sp€od and Modulatot Control

VEHICLE SPEED

VEHICLE SPEED

WHEEL SPEED

PRESSU

OUTLETVALVE ON

OFF

INLETVALVE ON

OFF

MOTOR

ON

OFF

When the wheel speed drops sharply below the vehicle speed, the outlet valve opens momentarily to reduce the caliper

fluid pressure. The pump motor starts at this time. As the wheel speed is restored. the inlet valve opens momentarily to

increase the caliDer fluid oressure.

F

GEAR PULSER

19-31

www.emanualpro.com

Page 959 of 1395

Troubleshooting Precautions

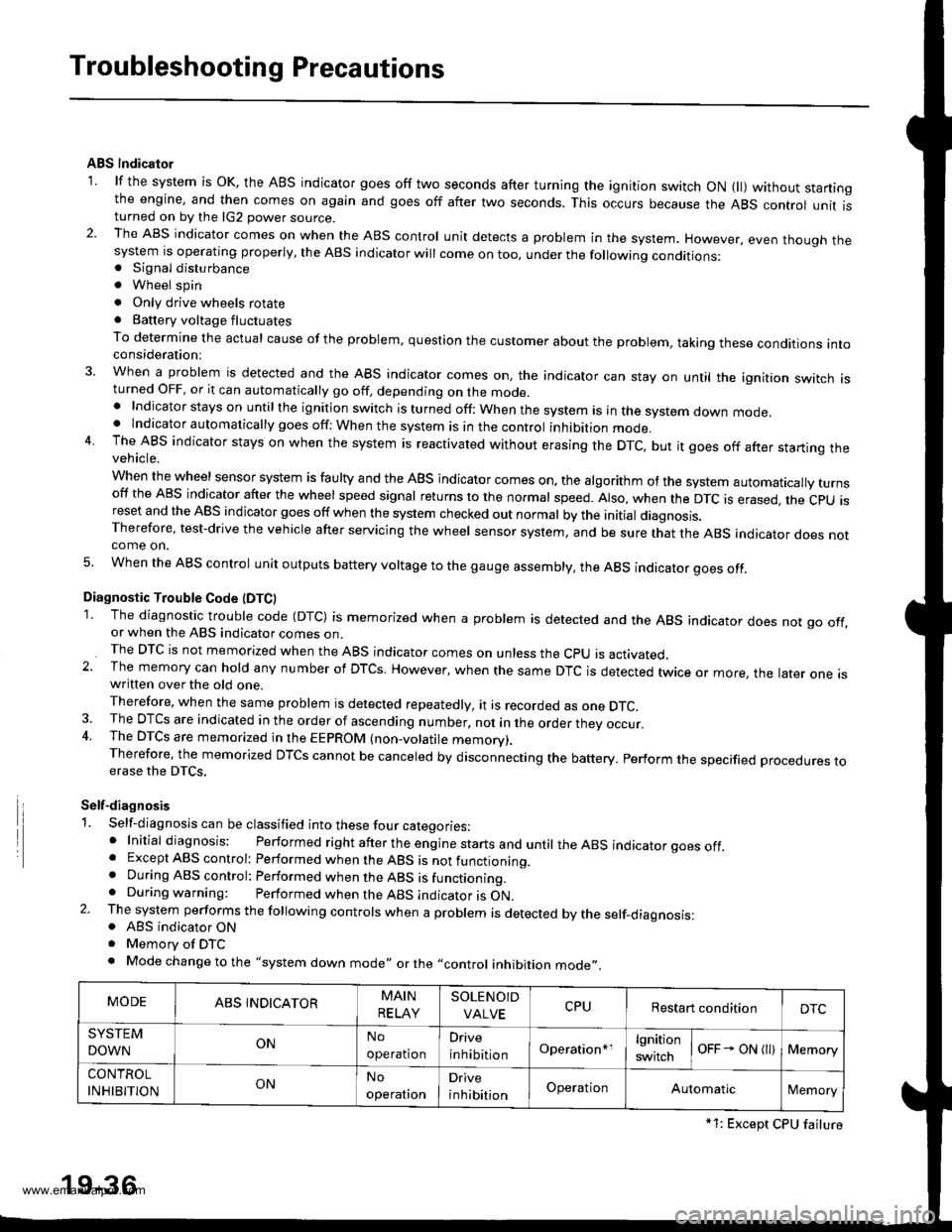

ABS lndicalor

1 lf the system is oK, the ABS indicator goes off two seconds after turning the ignition switch oN 1l) wathout staningthe engine, and then comes on again and goes off after two seconds. This occurs because the ABS control unit isturned on by the lG2 power source.2. The ABS indicator comes on when the ABS control unit detects a problem in the system. However, even thouoh thesystem is operating properly, the ABs indicator will come on too, under the following conditions:. Signal disturbance

. Wheel spin

. Only drive wheels rotate. Battery voltage fluctuates

To determine the actual cause of the problem, question the customer about the problem, taking these conditions intoconsideration:

3 When a problem is detected and the ABS indicator comes on, the indicator can stay on until the ignition switch isturned OFF, or it can automatically go off, depending on the mode.. Indicator stays on untilthe ignition switch is turned off: When the system is in the system down mode.. Indicator automatically goes off: When the system is in the control inhibition mode.4 The ABS indicator stays on when the system is reactivated without erasing the DTC, but it goes off after starting thevehicle.

When the wheel sensor system is faulty and the ABS indicator comes on. the algorithm of the system automatically turnsoff the ABS indicator after the wheel speed signal returns to the normal speed. Also, when the DTc is erased, the cpu isreset and the ABS indicator goes off when the system checked out normal by the initial diagnosis.Therefore, test-drive the vehicle after servicing the wheel sensor system. and be sure that the ABS indicator does notcome on.

5 When the ABS control unit outputs battery voltage to the gauge assembly, the ABS indicator ooes off.

Diagnostic Trouble Code (DTCI

1. The diagnostic trouble code (DTc) is memorized when a problem is detected and the ABS indicator does not go off,or when the ABS indicator comes on.The DTc is not memorized when the ABS indicator comes on unress the cpu is activated,2 The memory can hold any number of DTCs. However, when the same DTc is detected twice or more, the tater one iswritten over the old one.

Therefore, when the same problem is detected repeatedly, it is recorded as one DTC.3. The DTCs are indicated in the order of ascending number, not in the order they occur.4. The DTCS are memorized in the EEPROM (non-volatile memorv).Therefore, the memorized DTcs cannot be canceled by disconnecting the battery. perform the specified procedures toerase the DTCS.

Self-diagnosis

1. Self-diagnosis can be classified into these four categories:' Initial diagnosis: Performed right after the eng ine starts and untir theABS indicator goes off.. Except ABS control: Performed when the ABS is not functioning.. During ABS control: Performed when the ABS is functioning.. During warning: Performed when the ABS indicator is ON.2. The system performs the fo|owing contrors when a probrem is detected by the serf-diagnosis:. ABS indicator ON. Memorv of DTC. Mode changetothe "system down mode,, or the ,,control inhibition mode,,.

MODEABS INDICATORMAIN

RELAY

SOLENOID

VALVECPURestart conditionDTC

SYSTEM

DOWNONNo

operation

Drive

inhibitionOperation*rlgnition

switchoFF - ON l)Memory

CONTROL

INHIBITIONONNo

operal|on

Drive

inhibitionOperationAutomaticlMemory

*1: Except CPU failure

19-36

www.emanualpro.com

Page 960 of 1395

Kickback'1. The motor operates when the ABS is functioning. and the fluid in the reservoir is forced out to the master cylinder,

causing kickback at the brake pedal.

2. The ABS control unit operates the solenoid valve when the brake pedal is released after the initial diagnosis You may

hear the solenoid valve operate at this time, but it is normal

Pumo Motol

1. The pump motor operates when the ABS is functioning

2. The ABS control unit checks the pump motor operation during acceleration. You may hear the motor operate at this

time, but it is normal.

Brake Fluid Replacement/Ail Bleeding

L Brake fluid replacement and air bleeding procedures are the same as for vehicles without ABS To ease bleeding, start

with the front wheels.

Troubleshooting

1. The troubleshooting flowchart procedures assume that the cause of the problem is still present and the ABS indicator

is still on. Following the flowchart when the ABS indicator does not come on can result in incorrect diagnosis.

2. Ouestion the customer about the conditions when the problem occurred, and try to reproduce the same conditions

for troubleshooting.

Self-diagnosis is made at various times such as the initial diagnosis, except ABS control, during ABS control, during

acceleration, during the specified vehicle speed, etc. Therefore, the symptom canngt be checked unless the check

conditions match with the problem conditjons

3. When the ABS jndicator does not come on during the test-drive. but troubleshooting is performed based on the DTC,

check lor loose connectors, poor contact of the terminals, etc., before you start troubleshooting.

4. After troubleshooting, erase the DTC and test-drive the vehicle. Be sure the ABS indicator does not come on.

5. The connector illustratjons show the female terminals with a single outline and the male terminals with a double out-

l ne.

ABS Function Test

To simulate ABS operation and activate the solenoid valves and pump, use the Honda PGM Tester.

Connect the PGM Tester to the 16P Data Link Connector (DLC). When the System Select menu is displayed, select the ABS

Test Mode menu, and follow the tester's prompts.

19-37

www.emanualpro.com

Page 961 of 1395

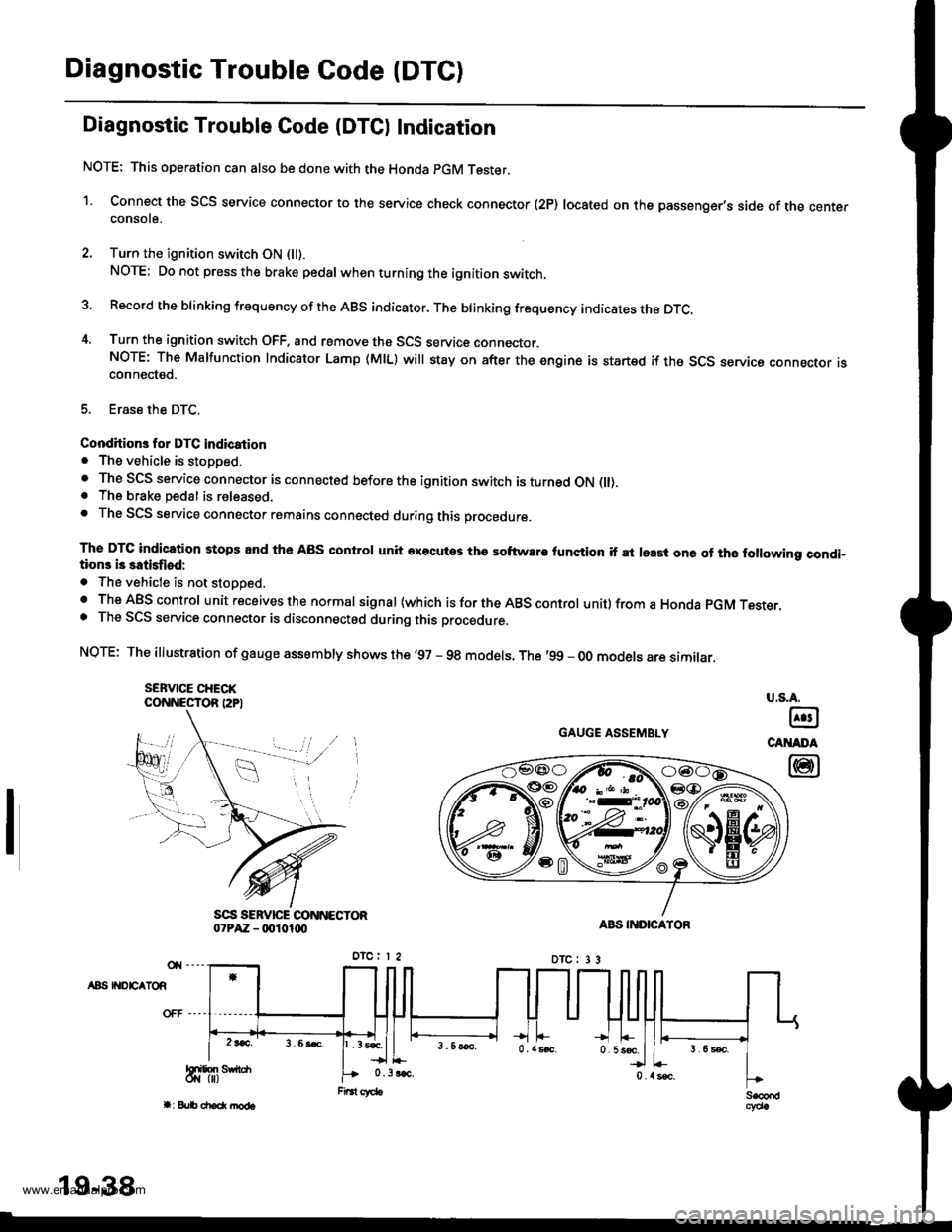

Diagnostic Trouble Code (DTC)

Diagnostic Trouble Gode IDTCI Indication

NOTE: This operation can also be done with the Honda pGM Tester.

1. Connect the SCS service connector to the service check connector (2P) located on the passenger's side of the centerconsote.

2. Turn the ignition switch ON (ll).

NOTE; Do not press the brake pedal whenturningthe ignition switch.

3 Record the blinking frequency of the ABS indicator. The brinking frequency indicates the DTc.

4. Turn the ignition switch OFF. and remove the SCS service connector.NOTE: The Malfunction Indicator Lamp (MlL) will stay on after the engine is startsd if the SCS seryica connecror rsconnected.

5. Erase the DTC.

Conditions for DTC indication. The vehicle is stopped.. The SCS service connector is connected before the ignition switch is turned ON flt).. The brake pedal is released.. The SCS service connector remains connected during this procedure.

The DTC indication stops and the ABS control unit axecutos tha softwaro lunction if at least one of tho following condi-tions i3 satisfiod:

. The vehicle is not stoooed.. The ABS control unit receives the normal signal (which is for the ABS control unit) from a Honda pGM Tesrer.. The SCS service connector is disconnectod during this procedure.

NQTE: The illustration of gauge assembly shows the '97 - 98 models. The '99 - oo models are similar.

SEFVICE CHECKCONNESTOR I2P}

GAUGE ASSEMBLY

A8S II{DEATOR

u.s.A.

@

CANADA

@

19-38

www.emanualpro.com

Page 968 of 1395

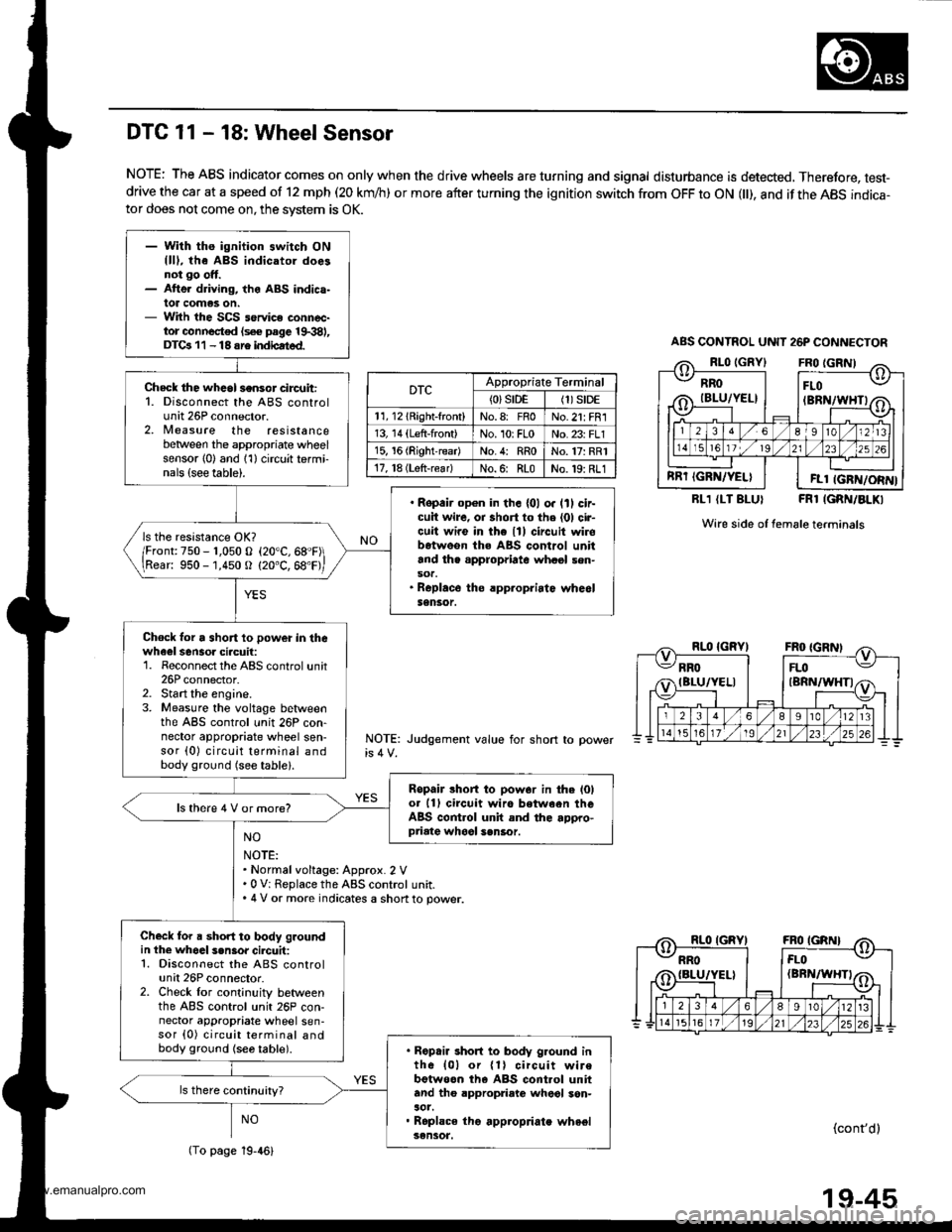

- With ths ignition switch ONllll, the ABS indicatol doesnot go ott.- Atte. driving, the ABS indica-lot comas on.- With the SCS service connec-tor connocted (s€€ page 19.381,DTGr 11 - 18 sre indbated.

Check the whcol sensor circuit:1. Disconnect the ABS controlunit 26P connector.2, Nleasure the resistancebetween the appropriate wheelsensor l0) and 1'l) circuit termi-nals {see table).

. Ropair op€n in th. {01 o. lll cir-cuit wire, oa short to the (01 cir-cuit wire in the lll circuit wirobetweon the ABS control unitand th. appropriate whasl sen-sot.. Roplace the rpp.opriatc whe6lSensor.

ls the resistance OK?

/Fronr:750 - r,050 o (20"C,68"F\

\Rear: 950 -'1,450 O (20"C, 68'F,

Chock lor a short 10 power in thewheel sensoa ciacuil:1. Reconnect the ABS control unit26P connector.2. Start the engine.3. Measure the voltage betlveenthe ABS control unit 26P con-nector appropriate wheel sen-sor (0) circuit terminal andbody ground (see table).

Ropair lhort to pow.r in the l0lot 11) circuit wiro between theABS control unit and the appro-priate whool sen6or.

ls there 4 V or more?

Check for a short to body groundin the whoal s.n3or cilcuit:1. Disconnect the ABS controlunit 26P connector.2. Check lor cont;nuity betweenthe ABS control unit 26P con-nector appropriate wheel sen-sor {0) circuit terminal andbody ground {se6 table).. Ropair short to body g.ound inth6 {01 or {1} circuit wirebotweon th6 ABS cont.ol unitand tho appropriato wheol son-aot.. Roplace tho appropriate wheelsensot.

DTC 11 - 18: Wheel Sensor

NOTE: The ABS indicator comes on only when the drive wheels are turning and signal disturbance is detected, Therefore, test-drive the car at a speed of 12 mph (20 km/h) or more after turning the ignition switch from OFF to ON l), and if the ABS indica-tor does not come on, the svstem is OK.

RLl (LT BLUI FRl IGRN/BLKI

Wire side of female terminals

NOTE: Judgement value for short

NO

NOTE:. Normalvoltage: Approx. 2 V.0 V: Replace the ABS control unit.. 4 V or more indicates a shon to power.

NO(cont'dl

ABS CONTNOL UNIT 26P CONNECTOR

RROIBLU/YEL}

RRT IGRN/YELI

FLO(BRN/WHTI

FLl IGFN/ORN}

DTCAppropriate Terminal

{0}srDE(1)S|DE

11, l2lRight-front)No.8: FnoNo.21: FR1

13, 14 (Left-front)No. 10rFLoNo. 23: FLl

15, 16 (RightreadNo.4: RRoNo.17: RR1

17, l8 (Lsft-rear)No.6: RLoNo.19: RL1

(To page 19-46)

19-45

www.emanualpro.com

Page 970 of 1395

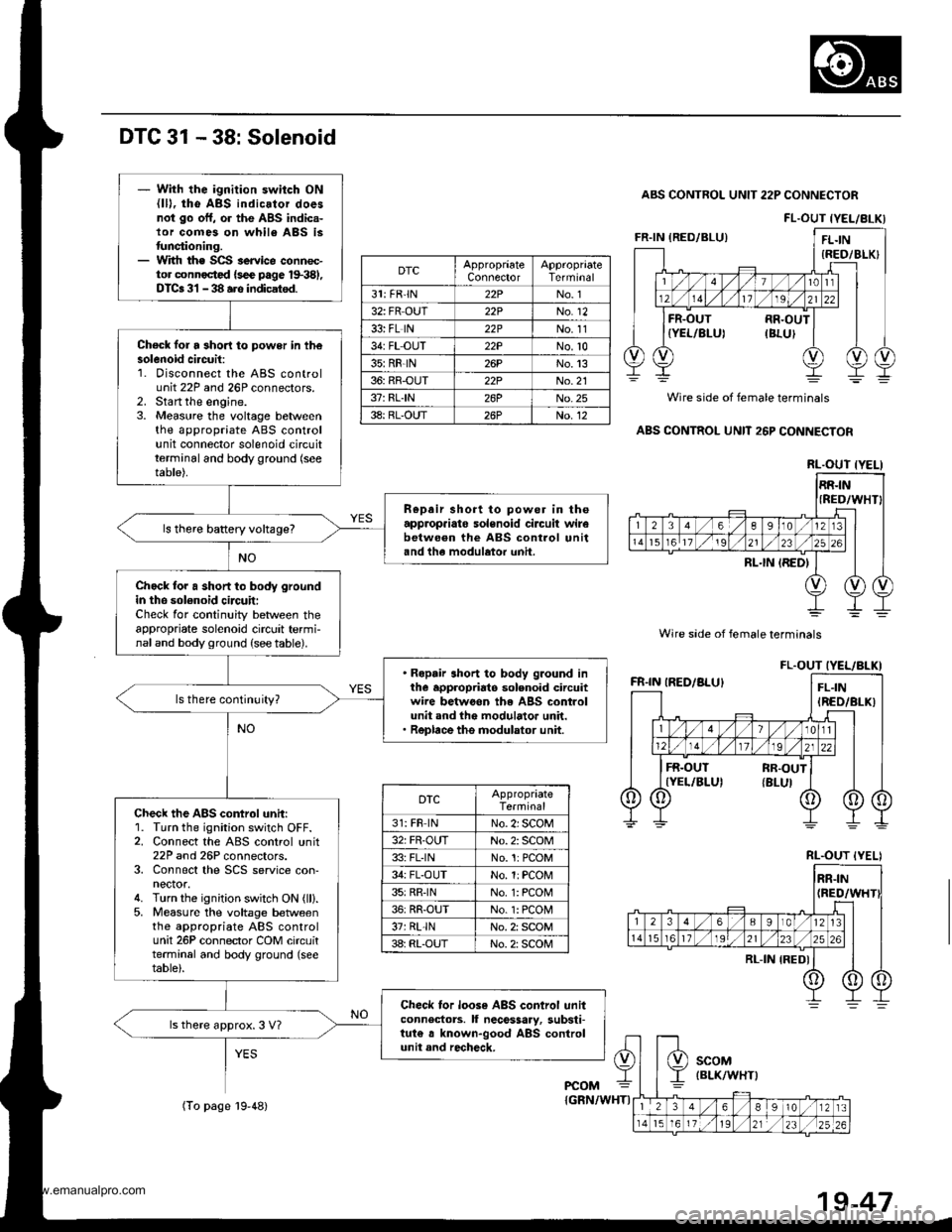

DTC 31 - 38: Solenoid

ABS CONTROL UNIT 22P CONNECTOR

Wire sade of female terminals

Wire side of female terminals

ABS CONTROL UNIT 26P CONNECTOR

FL.OUT IYEL/8LKI

DTCAppropraateConnectorTerminal

31: FR'lN22PNo. 1

32: FR OUT22PNo. 12

33: FL lN22PNo. 11

34: FL OUT22PNo.10

35:RR-lN26PNo.13

36: RR-OUT22PNo.21

37: RLIN26PNo.25

38: RL-OUT26PNo. 12

RL.OUT {YELI

FL.OUT IYEL/BLKI

DTCAppropriateTerminal

31: FR lNNo. 2i SCOM

32: FR-OUTNo. 2: SCOM

33: FLINNo.1:PCOM

34: FL-OUTNo. 1:PCOM

35:RRINNo. 1: PCON4

36: RR-OUTNo. 1: PCON4

37rRL-lNNo. 2: SCOM

3a: RL-OUTNo. 2: SCOM

RL.OUT {YELI

- With the ignition switch ON{lD, tho ABS indicator doesnot go off, or the ABS indic.-lor comes on whil6 ABS istunctioning.- With th€ SCS service connoc-tor connoctcd {sce page 1$381,DTCa 31 - 38 ars indicatsd.

Check for a 3hori to power in th€solenoid ci.cuit:1. Disconnect the ABS controluntr tlr ano zbr connectors_2. Start the engine.3. Measure the voltage betweenthe appropriate ABS controlunit connector solenoid circuitterminal and body ground (see

table).

R€pair short to power in theapprop.iato solenoid circuit wirebetwe€n the ABS control unitand the modulator unh.

ls there baRery voltage?

Chock for a short to body groundin the sol€noid circuit:Check for continuity between theappropriate solenoid circuit termi-naland body ground (see table).

. Ropair short to body ground inthe appropriato solenoid circuitwire betwoon the ABS controlunit and the modulator unit.. Replace the modulator unit.

ls there continuity?

Check the ABS control unit:1. Turn the ignition switch OFF.2. Connect the ABS control unit22P and 26P connectors.3. Connect the SCS service con-nector.4. Turn the ignition switch ON (ll).5, Measure the voltage betweenthe appropriate ABS controlunit 26P connector COM circuitterminal and body ground (seetable).

Check tor loose ABS control unitconnectors. ll nece$ary, substi-tut€ a known-good ABS controlunit and recheck.

ls there approx. 3 V7

PCOM

(To page l9-48){GRN/WHTI

19-47

www.emanualpro.com