shaft HONDA CR-V 2000 RD1-RD3 / 1.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 67 of 1395

e

o

I'

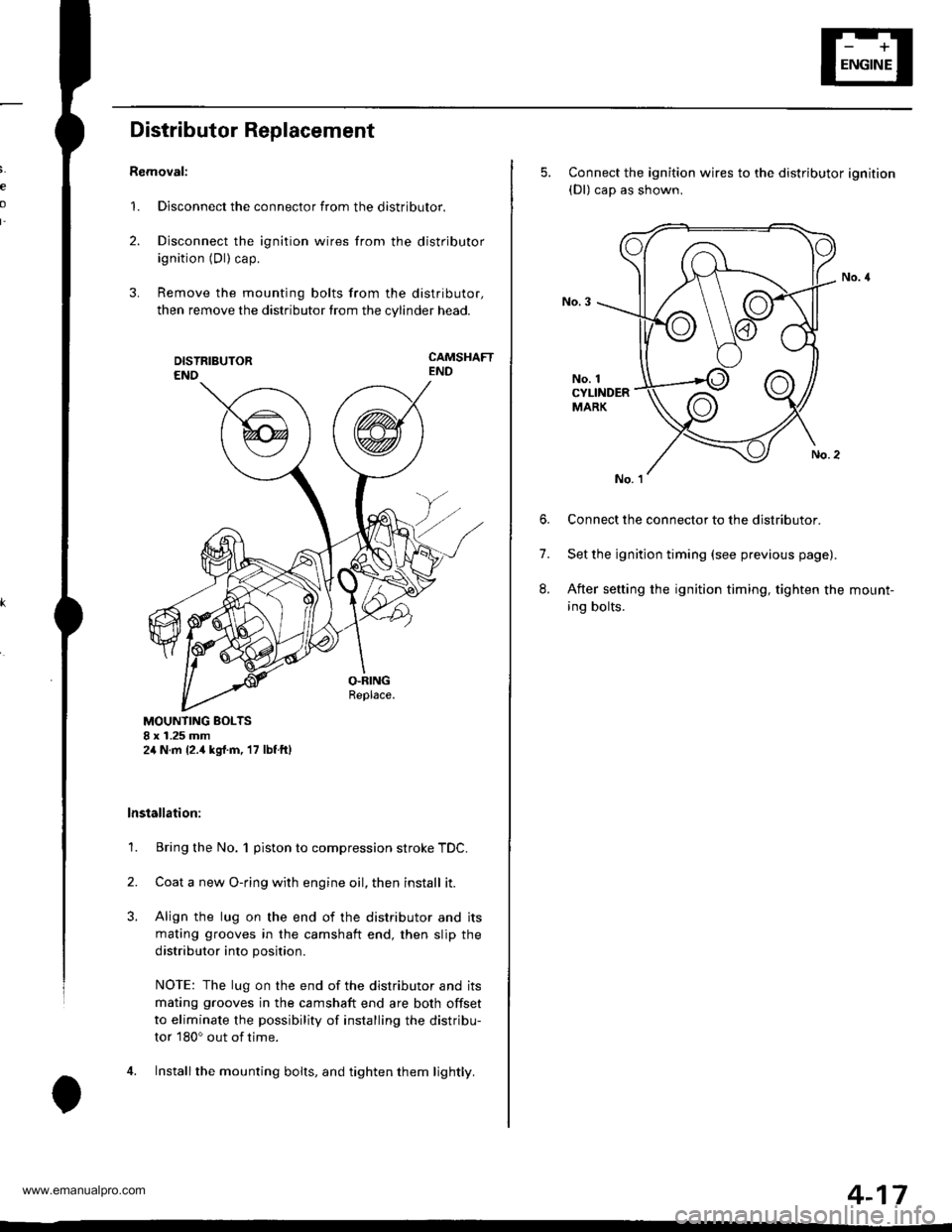

Distributor Replacement

Removal:

1. Disconnect the connector from the distributor.

2. Disconnect the ignition wires from the distributor

ignition (Dl) cap.

3. Remove the mounting bolts from the distributor,

then remove the distributor from the cylinder head.

CAMSHAFTEND

MOUNTING BOLTS8 x 1.25 mm2,1N.m {2.,1kgrf.m, 17 lbf ftl

lnstallation:

1. Bring the No. 1 piston to compression stroke TDC.

2. Coata new O-ring with engine oil, then install it.

3. Align the lug on the end of the distributor and its

mating grooves in the camshaft end, then slip the

distributor into position.

NOTE: The lug on the end of the distributor and its

mating grooves in the camshaft end are both offset

to eliminate the possibility of installing the distribu-

tor 180o out of time.

4. Installthe mounting bolts, and tighten them lightly.

5. Connect the ignition wires to the distributor ignition(Dl) cap as shown,

No. 1CYLINDERMARK

6. Connect the connector to the distributor.

7. Set the ignition timing (see previous page).

8. After setting the ignition timing, tighten the mount-

ing bolts.

4-17

www.emanualpro.com

Page 83 of 1395

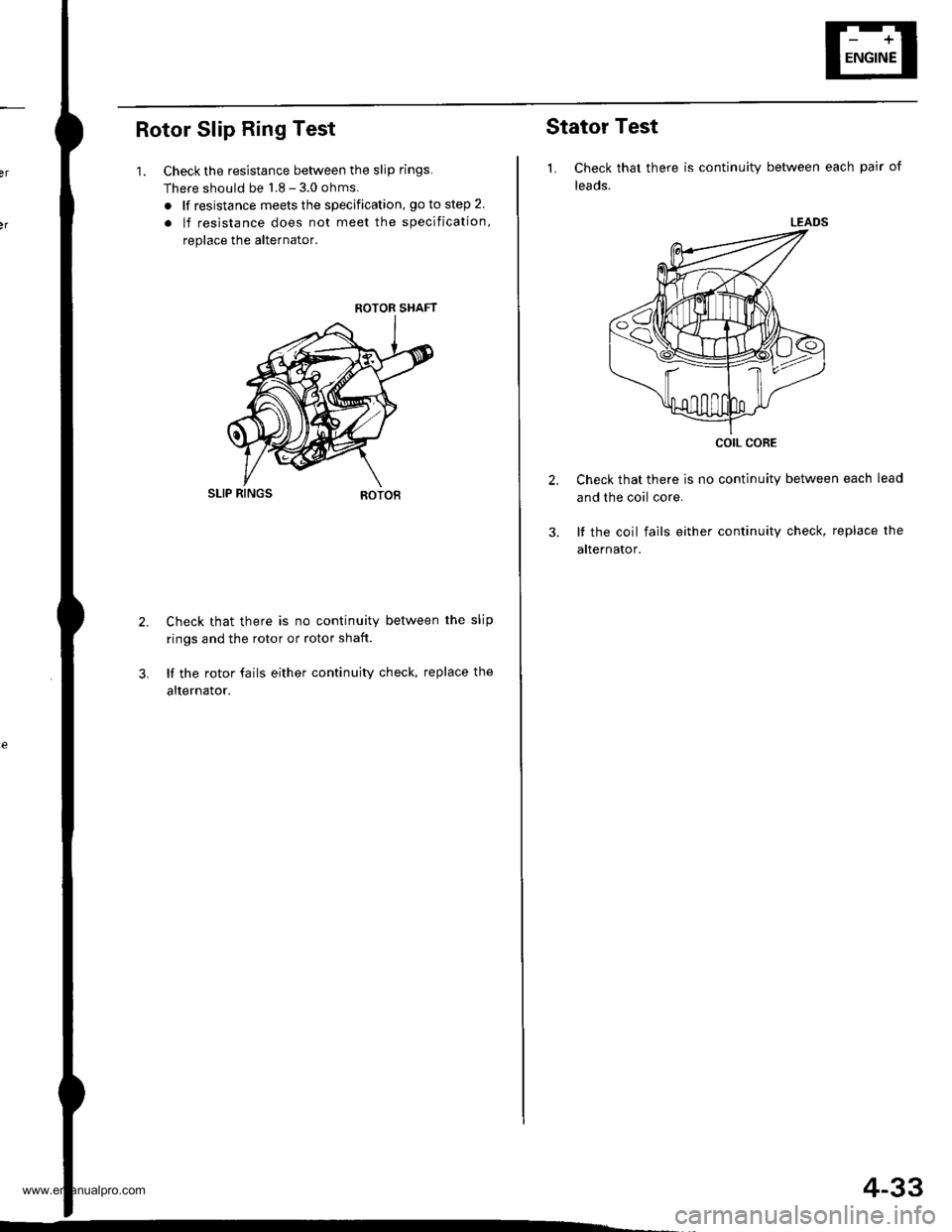

Rotor Slip Ring Test

1. Check the resistance between the slip rings.

There should be 1.8 - 3.0 ohms.

. lf resistance meets the specification, go to step 2

. lf resistance does not meet the specification,

replace the alternator.

SLIP RINGS

Check that there is no continuity between the slip

rings and the rotor or rotor shaft.

lf the rotor fails either continuity check, replace the

alternator.

ROTOR SHAFT

4-33

Stator Test

1. Check that there is continuity between each pair of

leads.

Check that there is no continuity between each lead

and the coil core.

It the coil fails either continuity check, replace the

alternator.

LEADS

corL coRE

www.emanualpro.com

Page 84 of 1395

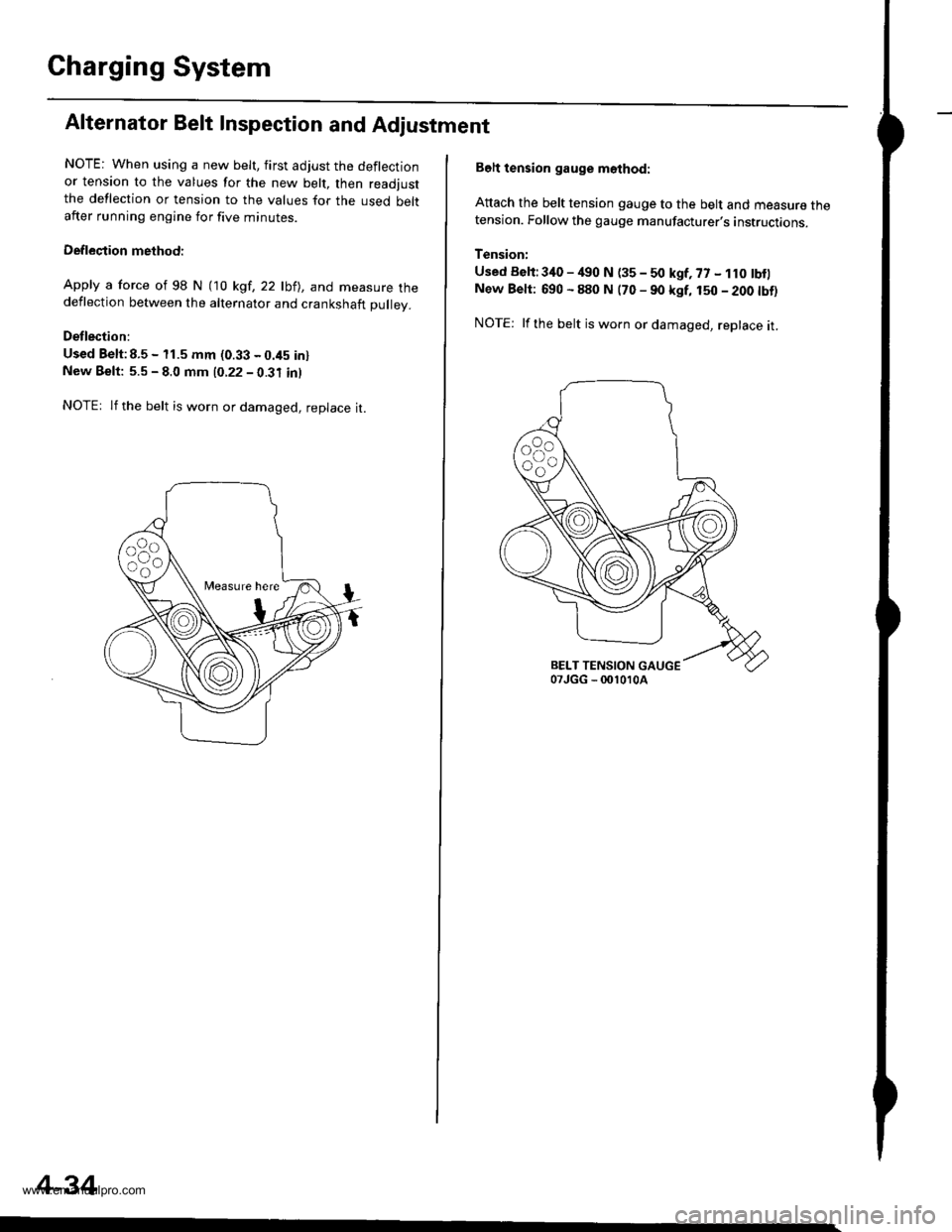

Charging System

Alternator Belt Inspection and Adjustment

NOTE: When using a new belt, first adjust the deflectionor tension to the values for the new belt, then readjustthe deflection or tension to the values for the used beltafter running engine for five minutes.

Deflection methodi

Apply a force of 98 N (10 kgt,22lbll, and measure thedeflection between the alternator and crankshaft pulley.

Detlection:

Used Belt:8.5 - 11.5 mm (0.33 - 0.45 inlNew Beft: 5.5 - 8.0 mm 10.22 - 0.31 inl

NOTEr lf the belt is worn or damaged, replace it.

Measure here

4-34

Belt tension gauge m6thod:

Attach the belt tension gauge to the belt and measure thetension. Follow the gauge manufacturer's instructions.

Tension:

Used Belt:340 - /€0 N (35 - 50 kgf, 77 - 1r0 tbf)New Belt: 690 - 880 N (70 - 90 kgf, 150 - 200 tbt)

NOTE: lfthe belt is worn or damaged, replace it.

www.emanualpro.com

Page 104 of 1395

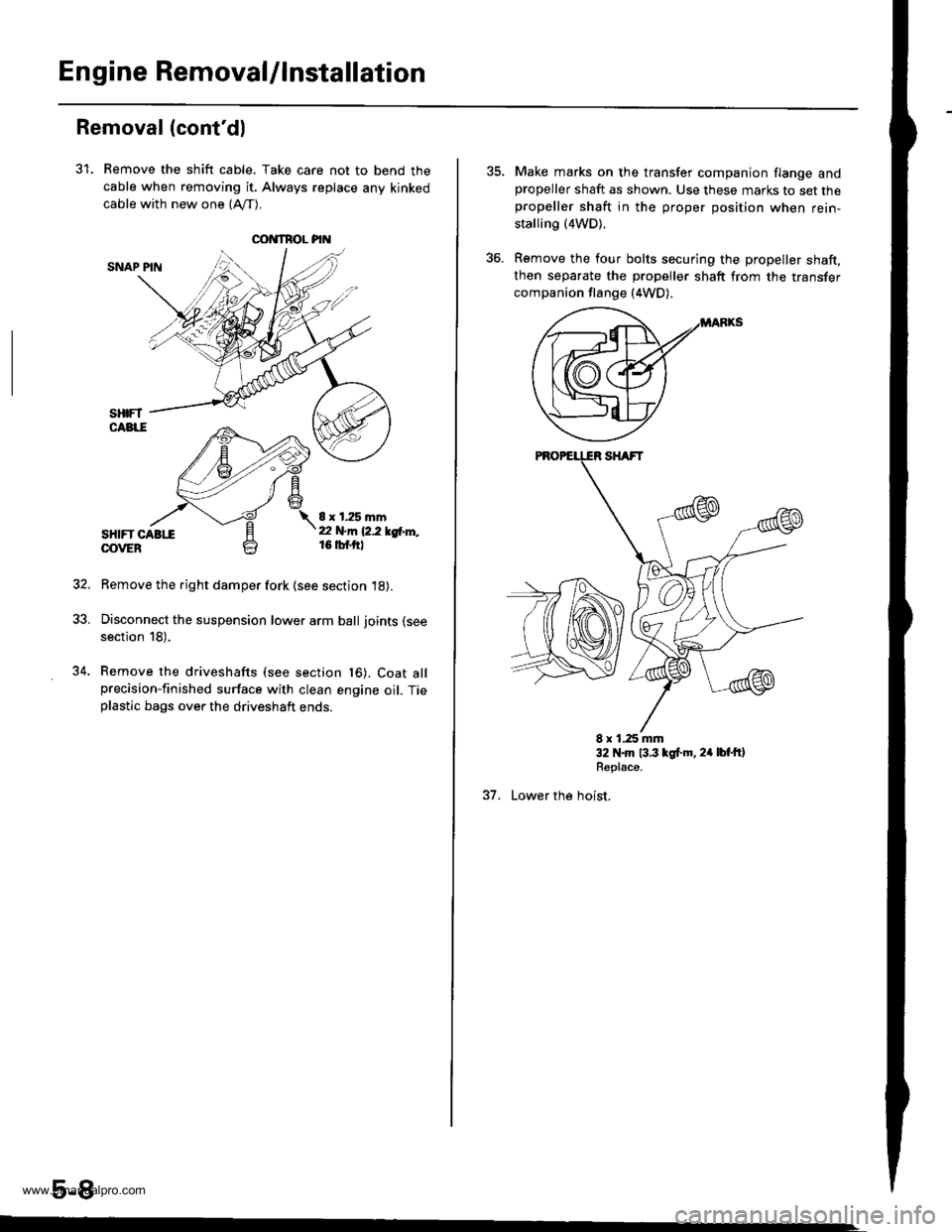

Engine RemovaUlnstallation

OOI{TROL PI

Removal (cont'dl

31. Remove the shift cable. Take care not to bend the

cable when removing it. Always replace any kinked

cable with new one (Afl-).

SNAP PIN

sHtFT CABttOOVEB

8 x 1.25 mmt2 N.m 12.2 lgtr'l'',,16 tbf.ftl

Remove the right damper fork (see section 18).

Disconnect the suspension lower arm ball joints (see

section 18),

Remove the driveshafts (see section t6). Coat allprecision-finished surface with clean engine oil. Tieplastic bags over the driveshaft ends.

5-8

34.

Make marks on the transfer companion flange andpropeller shaft as shown. Use these marks to set thepropeller shaft in the proper position when rein-

stalling (4WD).

Remove the four bolts securing the propeller shaft,then separate the propeller shaft from the transfer

companion flange (4WD).

E x 1.25 mm32 N.m 13.3 lgt.m, 24 lbt'ftlRepl€ce.

37. Lower the hoist,

www.emanualpro.com

Page 112 of 1395

Engine Removal/lnstallo cton

Installation (cont'd)

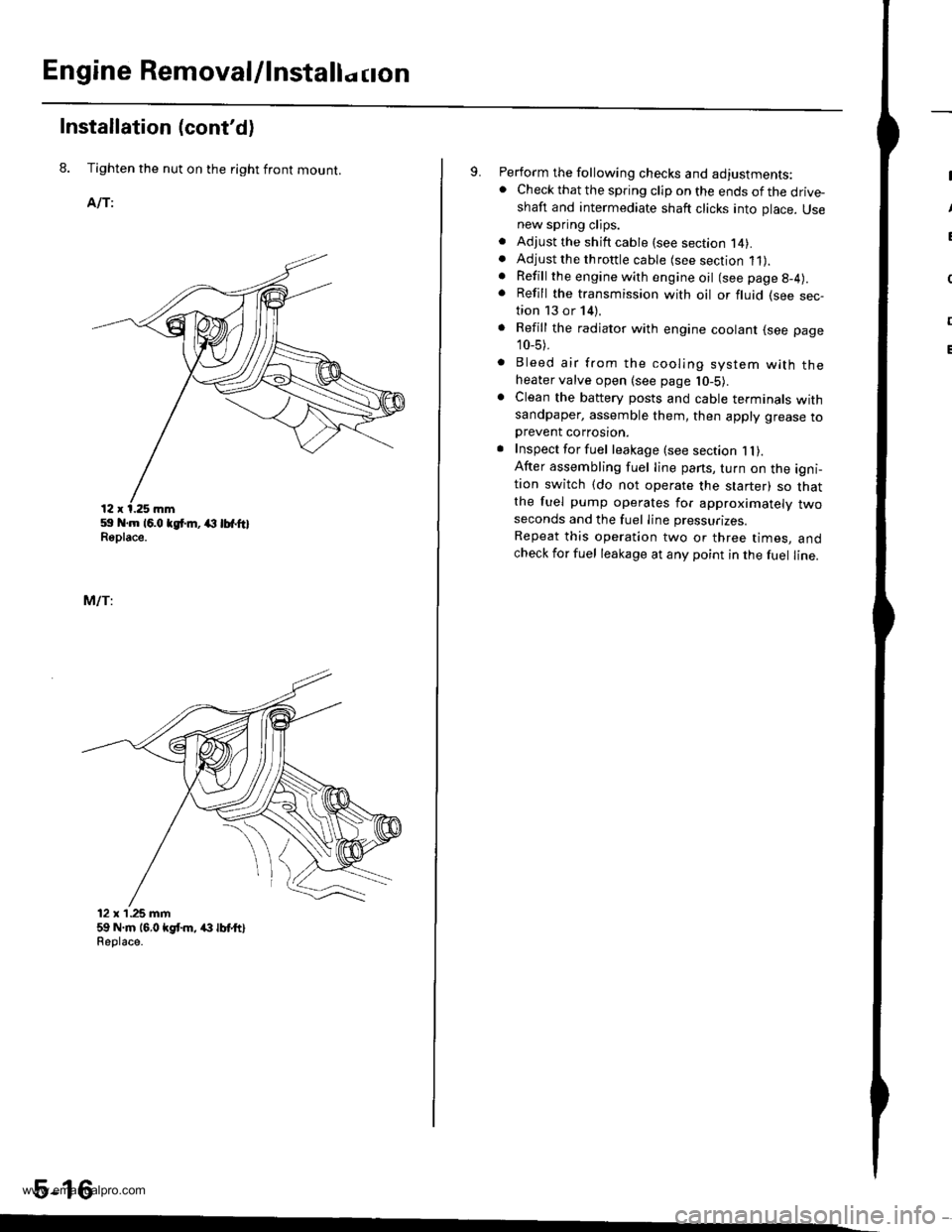

8. Tighten the nut on the right front mount.

AlTi

59 .m 16.0 tgt m, (l lbfftlReplace.

MlTi

12 x'1.25 mm59 N.m 16,0 kgt m, /(} lbt ttlReolace.

5-16

9. Perform the following checks and adjustments:. Check that the spring clip on the ends of the drive-shaft and intermediate shaft clicks into place. Usenew spring clips.. Adjust the shift cable (see section l4).. Adjust the throttle cable (see section 11).. Refill the engine with engine oil (see page g-4).

. Refill the transmission with oil or fluid (see sec-tion 13 or 14).

. Refill the radiator with engine coolant (see page

10_5).

. Bleed air from the cooling system with theheater valve open (see page l0-5).. Clean the battery posts and cable terminals withsandpaper, assemble them, then apply grease toDrevent corrosron.. Inspect for fuel leakage (see section 1l).After assembling fuel line pans, turn on the igni-tion switch (do not operate the starter) so thatthe fuel pump operates for approximately twoseconds and the fuel Iine pressurizes.

Repeat this operation two or three times, andcheck for fuel leakage at any point in the fuel line.

www.emanualpro.com

Page 114 of 1395

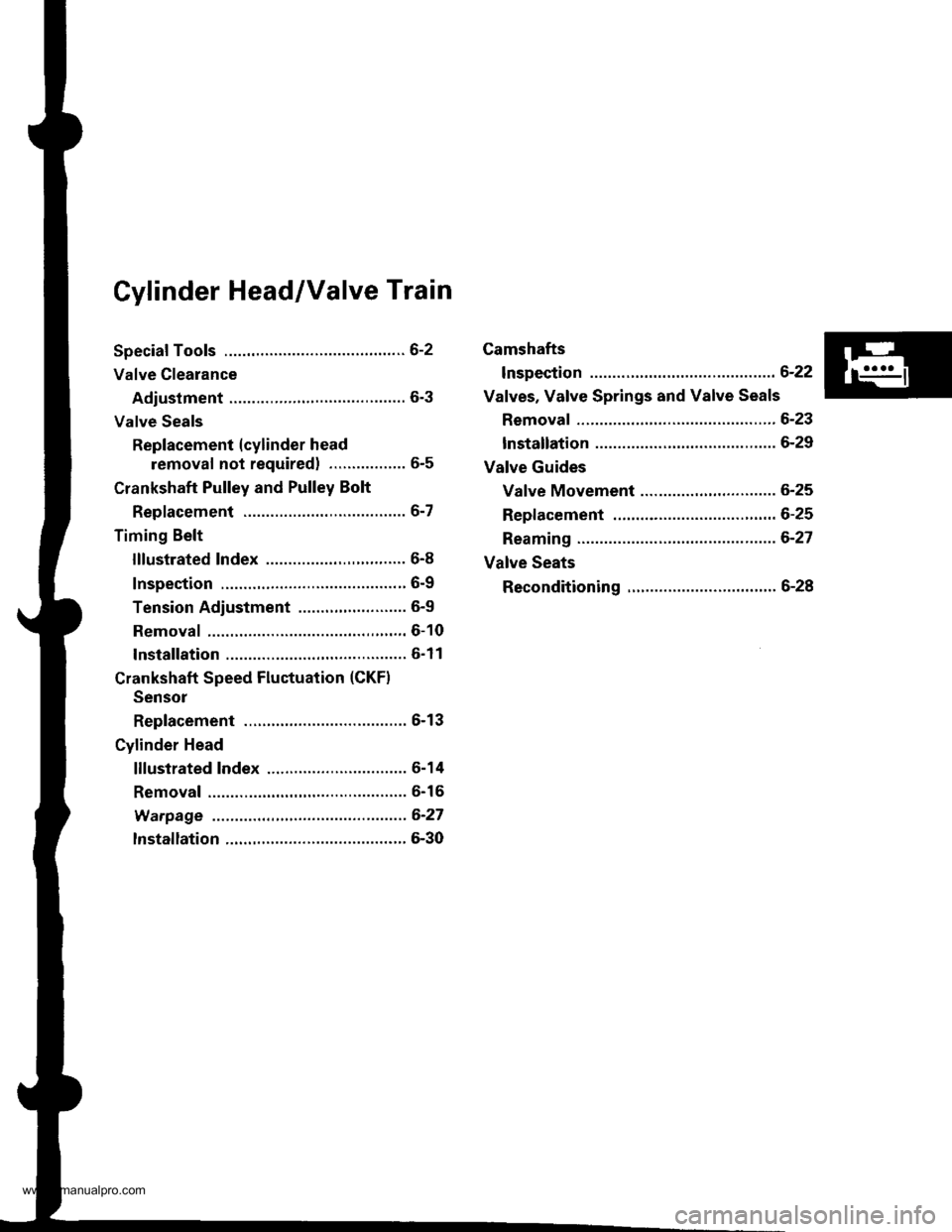

Cylinder Head/Valve Train

Speciaf Tools .............6-2

Valve Clearance

Adiustment ............6-3

Valve Seals

Replacement (cylinder head

removal not requiredl ................. 6-5

Crankshaft Pulley and Pulley Bolt

Replacement .........6-7

Timing Belt

I llustrated lndex ............................... 6-8

Inspection ............., 6-9

Tension Adjustment ........................ 6-9

Removal ...........,..... 6-10

lnstallation .............6-11

Crankshaft Speed Fluctuation (CKFI

Sensor

Replacement .........6-13

Cylinder Head

lllustrated lndex ............................... 6-14

Removal .................6-16

Warpage ................6-27

lnstallation ............. 6-30

Camshafts

lnspection ..............6-22

Valves, Valve Springs and Valve Seals

Removal ................, 6-23

lnstallation ............. 6-29

Valve Guides

Valve Movement ............,,,,.,............ 6-25

Replacement .........6-25

Reaming .................6-27

Valve Seats

Reconditioning ......6-28

www.emanualpro.com

Page 117 of 1395

Valve Clearancev

Adjustment (cont'dl

6. Tighten the locknut, and check the clearance agajn.

Repeat the adjustment if necessary.

GAUGE

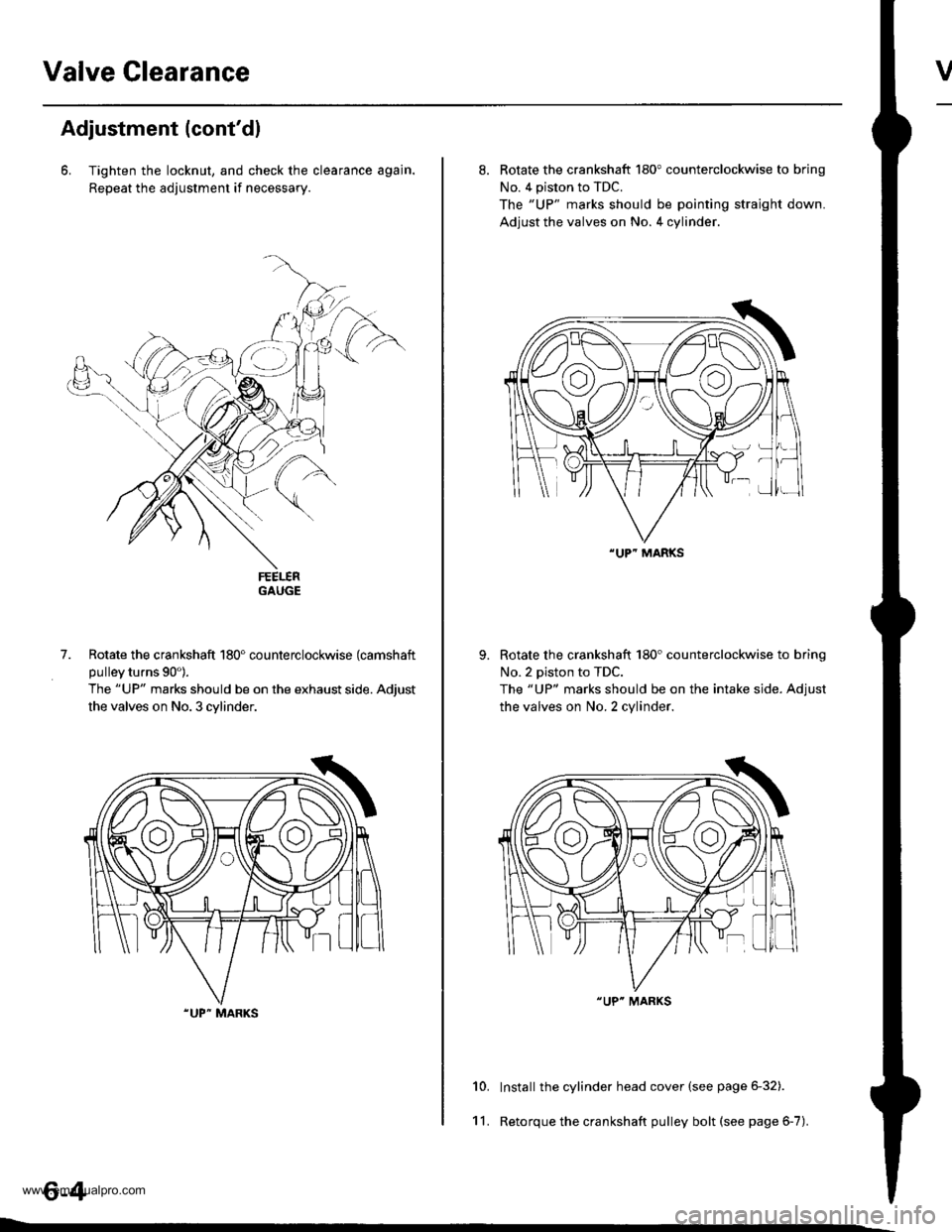

Rotate the crankshaft 180" counterclockwise (camshaft

pulley turns 90').

The "UP" marks should be on the exhaust side. Adjust

the valves on No. 3 cylinder.

.UP" MARKS

7.

8. Rotate the crankshaft 180" counterclockwise to brinq

No. 4 piston to TDC.

The "UP" marks should be pointing straight down.

Adjust the valves on No. 4 cylinder.

Rotate the crankshaft 180'counterclockwise to brino

No.2 piston to TDC.

The "UP" marks should be on the intake side. Adiust

the valves on No. 2 cylinder.

Install the cylinder head cover (see page 6-32).

Retorque the crankshaft pulley bolt (see page 6-7).

10.

11.

"UP" MARKS

"UP" MARKS

www.emanualpro.com

Page 118 of 1395

Valve Seals

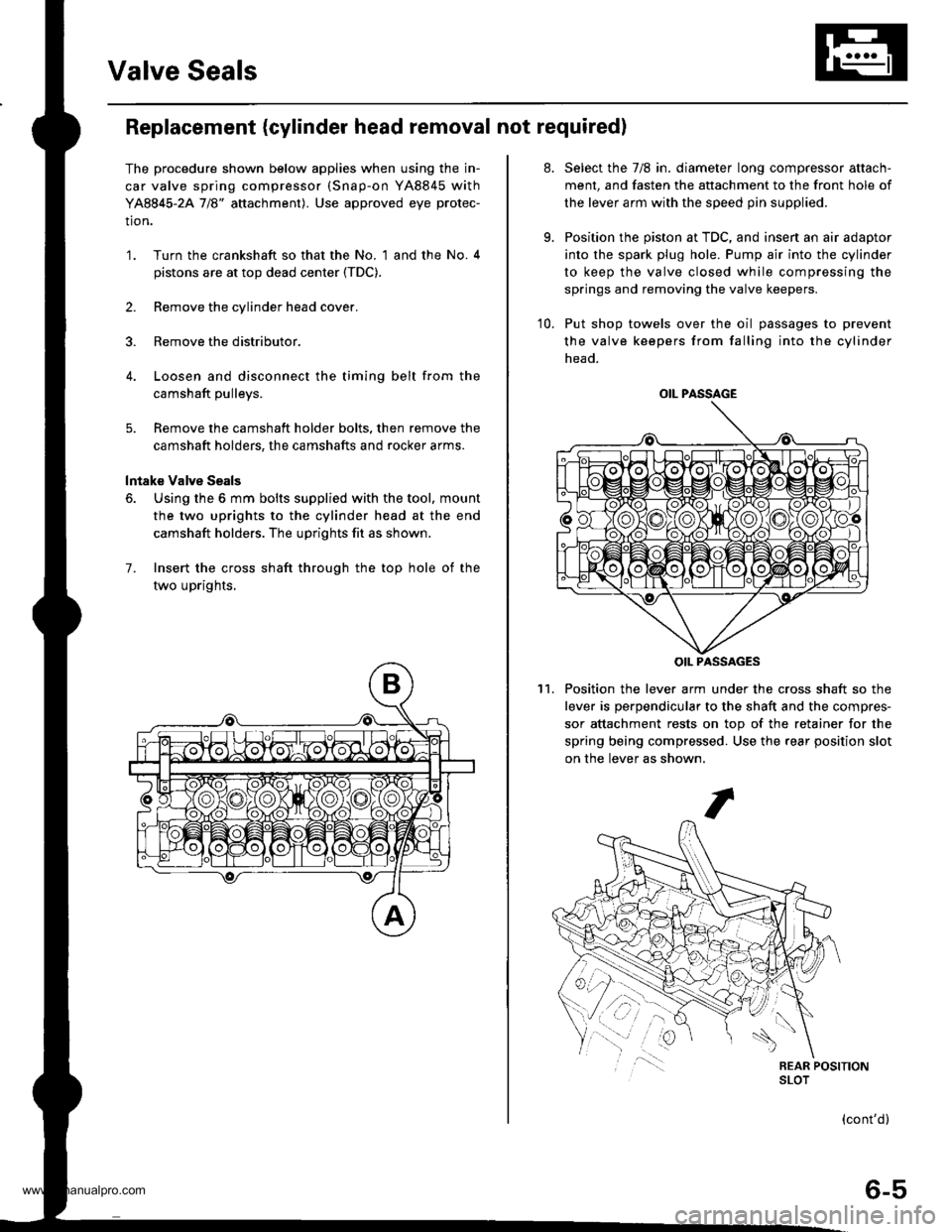

Replacement (cylinder head removal not required)

The procedure shown below applies when using the in-

car valve spring compressor (Snap-on YA8845 with

YA8845-2A 7/8" auachment). Use approved eye protec-

tion.

1. Turn the crankshaft so that the No. 1 and the No. 4

pistons are at top dead center (TDC).

2. Remove the cylinder head cover.

3. Remove the distributor.

4. Loosen and disconnect the timing belt from the

camshaft pulleys.

5. Remove the camshaft holder bolts. then remove the

camshaft holders, the camshafts and rocker arms.

lntake Valve Seals

6. Using the 6 mm bolts supplied with the tool, mount

the two uprights to the cylinder head at the end

camshaft holders. The uprights fit as shown.

7. Insert the cross shaft through the top hole of the

two uprights,

at.

9.

Select the 7/8 in. diameter long compressor attach-

ment, and fasten the attachment to the front hole of

the lever arm with the speed pin supplied.

Position the piston at TDC, and insen an air adaptor

into the spark plug hole. Pump air into the cylinder

to keep the valve closed while compressing the

springs and removing the valve keepers.

10. Put shop towels over the oil passages to prevent

the valve keepers from falling into the cylinder

head.

Position the lever arm under the cross shaft so the

lever is perpendicular to the shaft and the compres-

sor attachment rests on top of the retainer for the

spring being compressed. Use the rear position slot

on the lever as shown,

't1.

OIL PASSAGE

OIL PASSAGES

(cont'd)

6-5

www.emanualpro.com

Page 119 of 1395

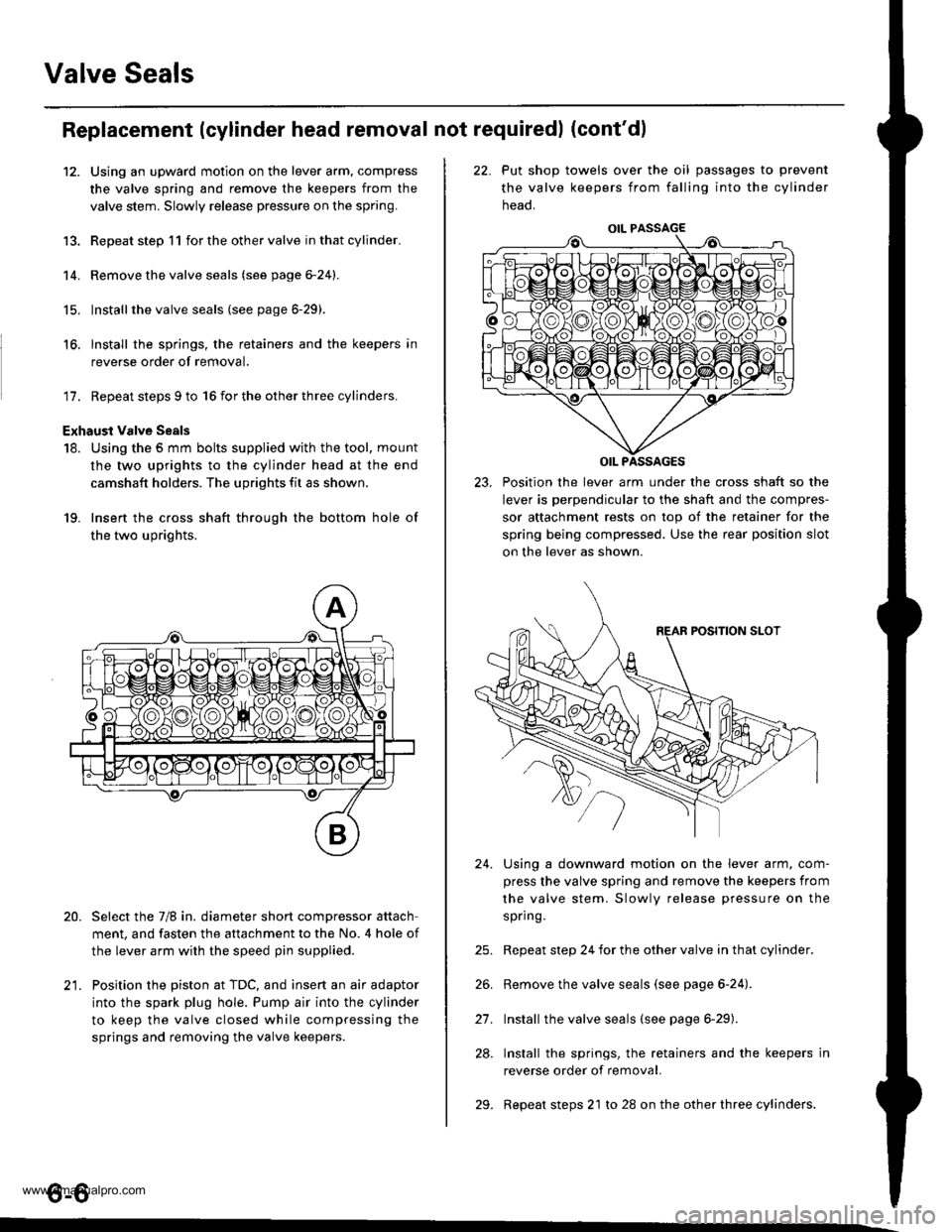

Valve Seals

12.

Replacement (cylinder head removal not requiredl (cont'dl

Using an upward motion on the lever arm, compress

the valve spring and remove the keepers from the

valve stem. Slowly release pressure on the spring.

Repeat step 11 for the other valve in that cylinder.

Remove the valve seals (see page 6-24).

Installthe valve seals (see page 6-29).

lnstall the springs, the retainers and the keepers in

reverse order of removal.

'17. Repeat steps 9 to 16 for the other three cylinders.

Exhaust valve Seals

18. Using the 5 mm bolts supplied with the tool, mount

the two uprights to the cylinder head at the end

camshaft holders. The uprights fit as shown.

19. Insert the cross shaft through the bottom hole of

the two uprights.

Select the 7/8 in. diameter short compressor attach

ment, and fasten the attachment to the No. 4 hole of

the lever arm with the speed pin supplied.

Position the piston at TDC, and insert an air adaptor

into the spark plug hole. Pump air into the cylinder

to keep the valve closed while compressing the

springs and removing the valve keepers.

13.

14.

15.

16.

20.

t1

22. Put shop towels over the oil passages to prevent

the valve keepers from falling into the cylinder

neao.

23. Position the lever arm under the cross shaft so the

lever is perpendicular to the shaft and the compres-

sor attachment rests on top of the retainer for the

spring being compressed. Use the rear position slot

on the lever as shown.

Using a downward motion on the lever arm, com-

press the valve spring and remove the keepers from

the valve stem. Slowly release pressure on the

spring.

Repeat step 24 for the other valve in that cylinder.

Remove the valve seals (see page 6-24).

Install the valve seals (see page 6-29).

Install the springs, the retainers and the keepers in

reverse order of removal.

Repeat steps 21 to 28 on the other three cylinders.

24.

21.

28.

29.

o-o

www.emanualpro.com

Page 120 of 1395

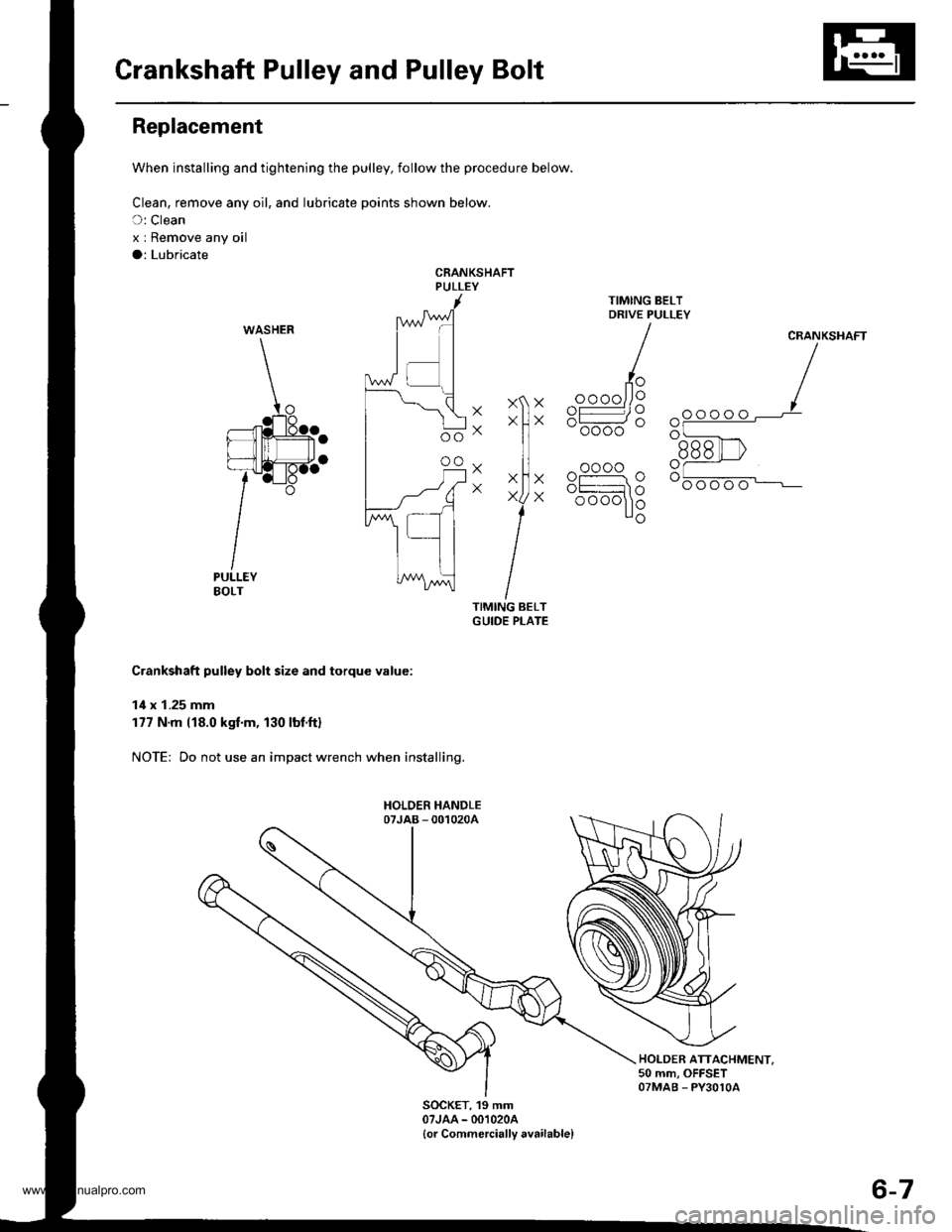

Crankshaft Pulley and Pulley Bolt

Replacement

When installing and tightening the pulley, follow the procedure below.

Clean, remove any oil, and lubricate points shown below.

C: Clean

x I Remove any oil

a: Lubricate

CRANKSHAFTPULLEY

XXX

Xo

X

X

X

X

CRANKSHAFT

oooo

- oooo

oooo

oooo

Crankshaft pulley bolt size and torque value:

14 x 1.25 mm

177 N'm (18.0 kgf.m, 130 lbt.ftl

NOTE: Do not use an impact wrench when installing.

HOLDER ATTACHMENT.50 mm, OFFSETOTMAB - PY3OlOA

SOCKET, 19 mm07JAA - 001020A

{or Commercially available}

WASHER

^ oooo

6r.

Ro".

6-7

www.emanualpro.com