shaft HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 14 of 1395

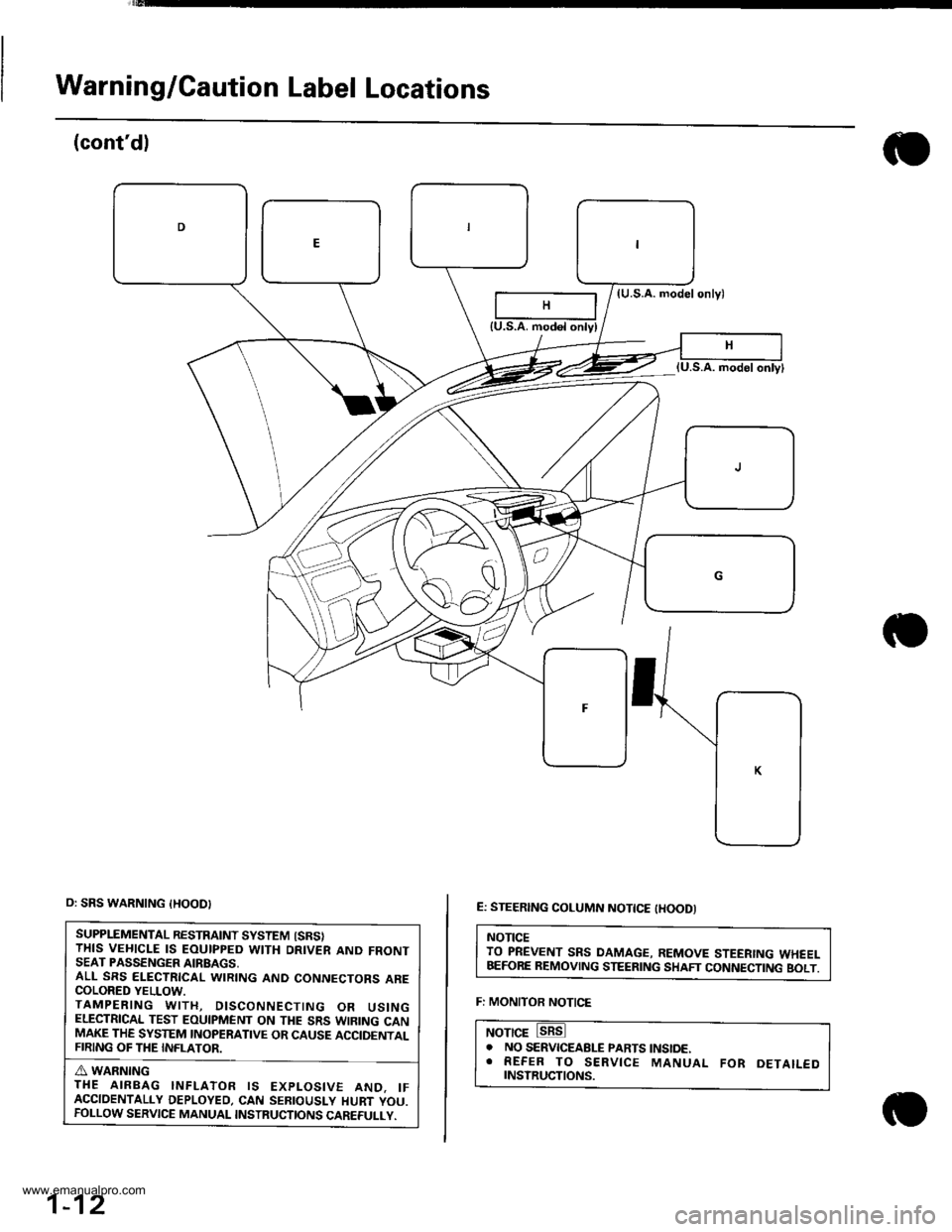

Warning/Caution Label Locations

(cont'dl

(U.S.A. modelonlyl

E: STEERING COLUMN NOTTCE tHOODI

NOTICETO PREVENT SRS DAMAGE, REMOVE STEERING WHEELBEFORE REMOVING STEERING SHAFT CONNECTING BOLT.

F: MONITOR NOTICE

NOTICE. NO SERVICEABLE PARTS tNStoE.. REFER TO SERVICE MANUAL FoR DETAILEDrNsrRucTtoNs.

{U.S.A. modol onlyl

o: SRS WARNING {HOOD}

SUPPLEMENTAL RESTRAINT SYSTEM {SRSITHIS VEHICLE IS EOUIPPED WITH DRIVER AND FRONTSEAT PASSENGER AIRBAGS,ALL SRS ELECTRICAL WIRING AND CONNECTORS ARECOLORED YELLOW.TAMPERING WITH, DISCONNECTING OR USINGELECTRICAL TEST EOUIPMENT ON THE SRS WIRING CANMAKE THE SYSTEM INOPERATIVE OR CAUSE ACCIDENTALFIRING OF THE INFLATOR.

A WARNINGTHE AIRBAG INFLATOR IS EXPLOSIVE AND. IFACCIDENTALLY DEPLOYED, CAN SEBIOUSLY HURT YOU.FOLLOW SERVICE MANUAL INSTRUCTIONS CAREFULLY.

1-12

www.emanualpro.com

Page 27 of 1395

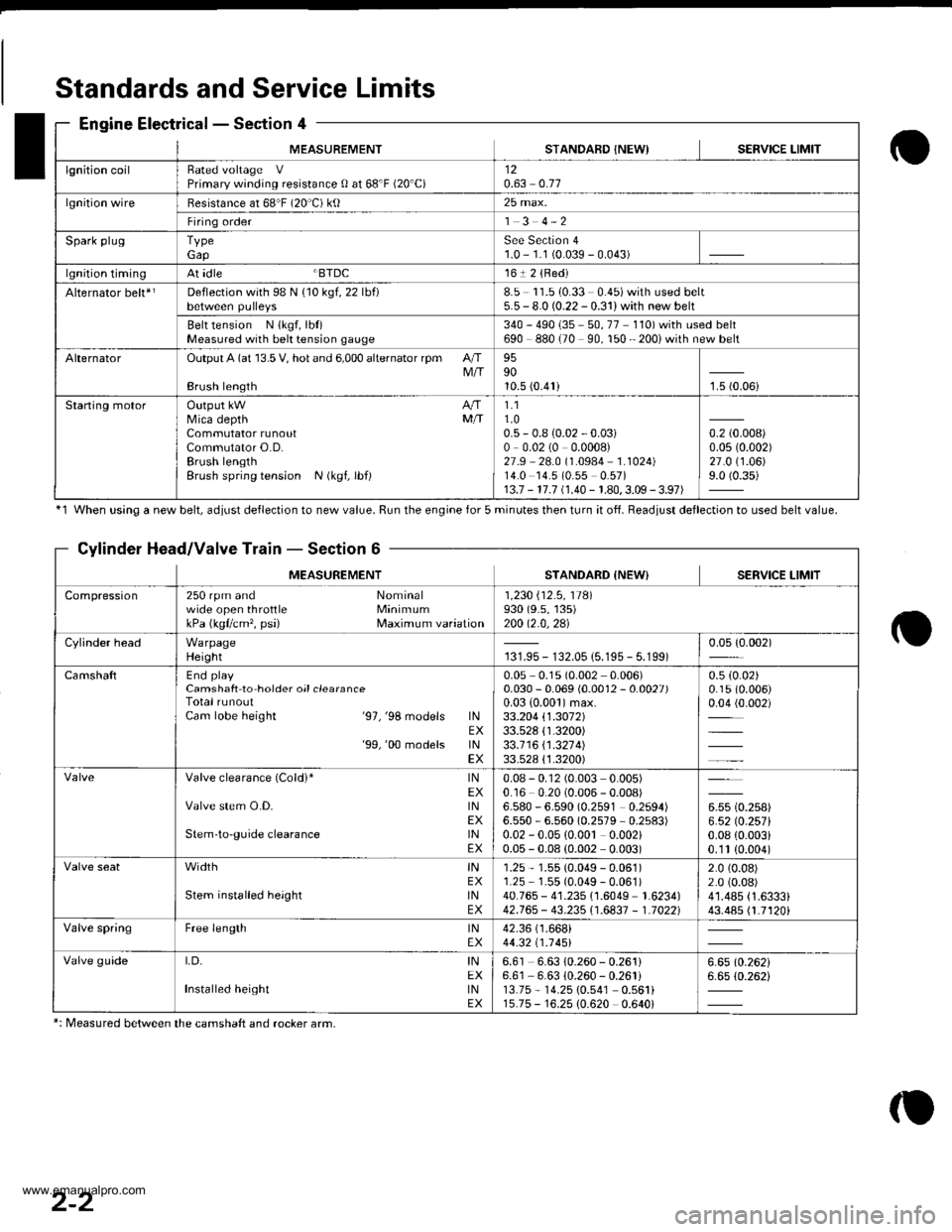

MEASUREMENTSTANDAFD INEWISERVICE LIMIT

lgnition coilRated voltage VPrimary winding resistance 0 at 68'F (20'C)120.63 0.77

lgnition wireBesistance at 68"F (20 C) ktl25 max.

Firing order1 3 4-2

Spark plugTypeGapSee Section 41.0 - 1.1 (0.039 - 0.043)

lgnition timingAt idle BTDC161 2 {Red)

Alternator belt*rDeflection with 98 N {10 kgf, 22 lbf)8.5 11.510.33 0.45)with used belt5.5 - 8.0 (0.22 - 0.31) with new belt

Belt tension N {kgf, lbt)Measured with bek tension gauge340 - 490 {35 - 50, 77 110) with used belt690 880 (70 90, 150 - 200i with new belt

AlternatorOutput A (at 13.5 V, hot and 6,000 alternator rpm AIIM/IBrush length

959010.5 (0.41)1.5 (0.06i

Staning motorOutput kW A/fMica depth MfiCommutator runoutCommutator O.D.Brush lengthBrush spring tension N (kgf, lbf)

1.11.00.5 - 0.8 {0.02 - 0.03)0,0.02 (0 0.0008)27.9 28.0 (1.0984 1.1024)14.0 14.5 (0.55 0.57)13.7 - 17.7 (1.40 - 1.80,3.09 - 3.97)

0.2 (0.008)

0.0s (0.002)

27.0 (1.06)

9.0 (0.35)

Standards and Service Limits

Engine Electrical - Section 4

'1 When using a new belt, ddiust deflection to new value. Run the engine for 5 minutes then turn it of{. Beadiust deflection to used belt value.

Cylinder Head/Valve Train - Section 6

MEASUREMENTSTANDARD {NEW} SERVICE LIMIT

Compression250 rpm and Nominalwide open throttle MinimumkPa (kgflcm'�, psi) Maximum variation

1 ,230 i'12 .5 , 11Al930 (9.s, 135)200 12.0,2al

Cylinder headWarpageHeight131.95 - 132.05 {5.195 - 5.199)0.05 {0.002)

CamshaftEnd playCamshaft to hoider oil clearanceTotal runoutCam lobe height '97,'98 models lNEX'99,'00 models lNEX

0.05 0.1s (0.002 0.006)0.030 - 0.069 (0.0012 - 0.0027)0.03 {0.001)max.33.204 \1.3072133.528 {1.3200)33.1 16 \1 .321 4)33.528 {'1.3200)

0.5 (0.02)

0.15 (0.006)

0.04 (0.002)

Valve clearance (Cold)* lNEXValve stem O.D. lNEXStem'to-guide clearance lNEX

0.08 - 0.12 (0.003 0.005)0.16 0.20 (0.006 - 0.008)6.580 - 6.590 (0.2591 0.2594)6.550 - 6.560 (0.2579 0.2s83)0.02 - 0.05 {0.00t 0.002)0.05 - 0.08 (0.002 0.003)

u* to.rutt6.52lO.257l0.08 {0.003i0.'1t (0.004)

width tNEXStem installed height lNEX

1.25 - 1.55 (0.049 - 0.061)1.25 1.55 (0.049 - 0.061)40.765 - 41.235 {1.6049 1.6234)42.765 - 43.235i'1.6837 - 1.70221

2.0 (0.08)

2.0 (0.08)

41.485 {1.6333}43.485 {1.7120i

Valve springFree length lNEX42.36 (1.668i

44.32 t1 .1 451

Valve guideI,D, INEXInstalled height tNEX

6.61 6.63 10.260 - 0.261)6.61 6.63 {0.260 - 0.261i13.75 - 14.25 10.541 0.561i15.75 - 16.25 {0.620 0.640i

6.6510.26216.65 (0.262i

*: Measured between the camshaft and rocker arm,

2-2

www.emanualpro.com

Page 28 of 1395

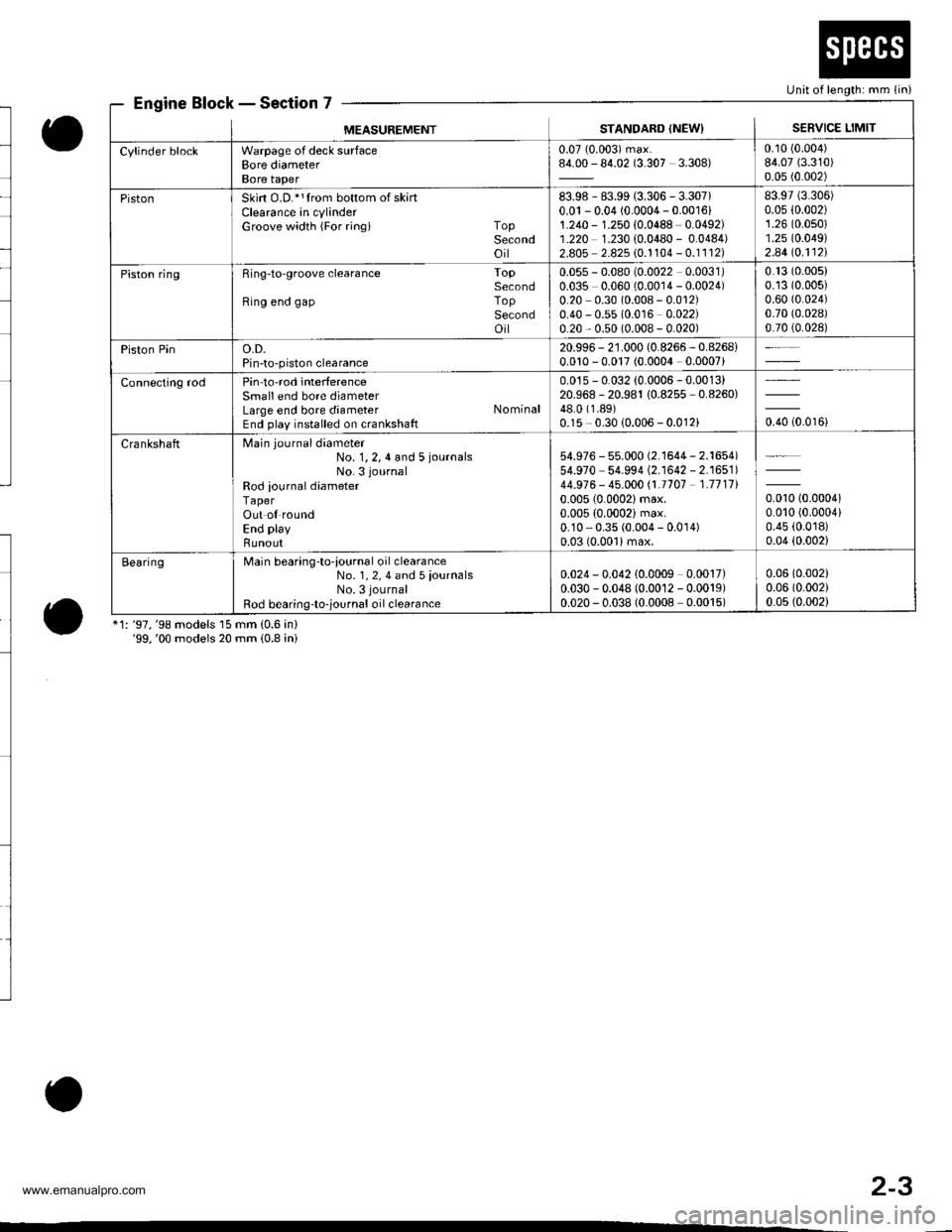

Engine Block - Section 7

o

o*1: '97,'98 models 15 mm (0.6 in)'99,'00 models 20 mm (0.8 ini

Unit of length: mm (in)

MEASUREMENTSTANDARD (NEWISERVICE LIMIT

Cylinder blockWarpage of deck surfaceBore diameterBore taper

0.07 (0.003) max.84.00 - 84.02 (3.307 3.308)0.10 (0.004)

84.07 (3.310)

0.05 (0.002)

PistonSkirt O.D.*1trom bottom of skartClearance in cylinderGroove width {For ringi TopSecondoil

83.98 - 83.99 (3.306 - 3.307)0.01 - 0.04 (0.0004 - 0.001611.240 - 1.250 {0.0488 - 0.0492)1.220 1.230 {0.0480 - 0.0484)2.805 2.825 10.1104 - 0.1112)

83.97 (3.306)

0.05 {0.002)1.26 (0.0s0)

1.25 (0.049)

2.44lo.112l

Piston ringRing-to'groove clearance ToPSecondRing end gap ToPSecondoil

0.055 - 0.080 (0.0022 0.0031)0.035 0.060 (0.0014 - 0.0024)0.20 0.30 (0.008 - 0.012)0.40 - 0.55 (0.016 0.022)0.20 - 0.50 (0.008 - 0.020)

0.13 (0.005)

0.13 (0.005)

0.60 (0.024)

0.70 (0.028)

0.70 (0.028)

Piston Pino.D.Pin-to-piston clearance

20.996 - 21.000 (0.8266 - 0.8268i0.010 - 0.017 (0.0004 - 0.0007)

Connecting rodPin-to-rod interferenceSmall end bore diameterLarge end bore diameter NominalEnd play installed on crankshaft

0.015 - 0.032 (0.0006 - 0.0013)20.968 -20.981 10.8255 -0.8260)

48.0 (1.89)

0.15 - 0.30 {0.006 - 0.012ioro to.oroi

CrankshaftMain journaldiameter

No. 1,2,4 and 5 iournalsNo. 3 journal

Rod iournal diameterTaperOut ol roundEnd play

Bunout

54.976 - 55.000 (2.'�l644 - 2.1654)54.970 54.994 (2.1642 - 2.1651)44.976 - 45.000 /.1.1707 - 1.711110.005 (0.0002)max.

0.005 (0.0002) max.0.10 - 0.35 (0.004 - 0.0 r 4)0.03 (0.001)max.

0.010 (0.00041

0.010 (0.0004)

0.45 (0.0r8)

0.04 (0.002)

BearingMain bearing-to-iournal oil clearanceNo. 1, 2, 4 and 5 iournalsNo. 3 journal

Rod bearing-to-,ournal oil clearance

0.024 - 0.042 10.0009 0.0017)0.030 - 0.048 (0.0012 - 0.0019)0.020 - 0.038 (0.0008 0.0015)

0.06 (0.002)

0.06 (0.002)

0.05 (0.002)

o

2-3

www.emanualpro.com

Page 30 of 1395

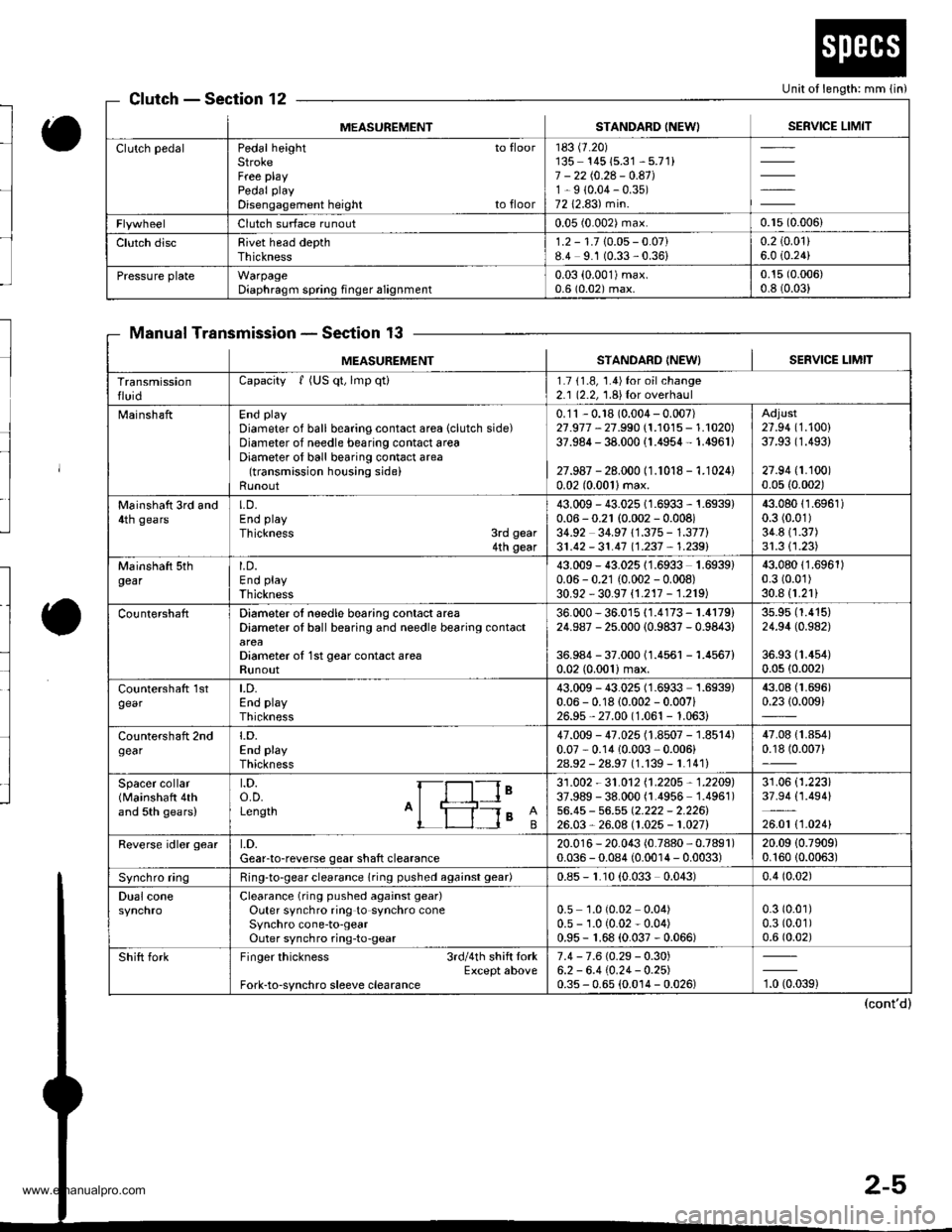

Unit of length: mm lin)ClutchSection 12

Manual TransmissionSection 13

MEASUREMENTSTANDARD INEWISERVICE LIMIT

Clutch pedalPedal height to floorStrokeFree playPedal play

Disengagement height to floor

183 (7.20)

135- 14515.31 - 5.71)7 - 2210.24 - 0.41J1-9 (0.04-0.35)

7212.83) min.

Clutch surface runout0.05 (0.002) max.0.r5 (0.006)

Clutch discRivet head depthThickness1.2 - 1.710.05- 0.07)8.4 9.1 (0.33,0.36)0.2 (0.01)

6.0 i0.24)

Pressure plateWarpageDiaphragm spring finger alignment0.03 (0.001)max.

0.6 (0.02) max.0.15 (0.006)

0.8 (0.03)

MEASUREM€NTSTANDARD INEW} I SERVICE I-IMIT

TransmissionfluidCapacity f (US qt, lmp qti1.7 11.8, 1.4)for oilchange2.1 (2.2, 1.8){or overhaul

MainshaftEnd play

Diameter of ball bearing contact area (clutch side)Diameter of needle bearing contact areaDiameter of ball bearing contact area(transmission housing side)Runout

0.'11 - 0.18 (0.004 - 0.007)27.977 - 27.990 (1.1015 - 1.1020)37.984 - 38.000 (1.4954- 1.4961)

27.987 - 28.000 (1.1018 - 1.1024)0.02 (0.0011max.

Adjust27.94 (1.100)

37.93 (1.493)

27.94 (1.100)

0.05 {0.002)

Mainshatt 3rd and4th gearsLD.End play

Thickness 3rd gear4th gear

43.009 - 43.025 1 1.6933 - 1.6939)0.06 - 0.21 (0.002 - 0.008)34.92 34.97 11.375 - 1.377)31.42 - 31.4'7 11.237 , 1.2391

43.08011.6961)0.3 (0.01)

34.811.37)31.311.23)

Mainshaft sthgearLD.End play

Thickness

43.009 - 43.02511.6933 1.6939)0.06 - 0.21 (0.002 - 0.008)30.92 - 30.97 {1.217 - 1.219)

43.08011.6961)0.3 (0.01)

30.8 (1.21)

CountershaftDiameter ol needle bearing contact areaDiameter oI ball bearing and needle bearing contact

Diameter o{ 1st gear contact areaRunout

36.000 - 36.015 {1.4173 - 1.4179)24.987 - 25.000 (0.9837 - 0.9843)

36.984 - 37.00011.4561 -1.4567)

0.02 (0.001)max.

3s.95 (1.415)

24.94 (0.982)

36.93 (1.4s4)

0.0s (0.002)

countershatt 1stgearLD.End playThickness

43.009 - 43.025 (1.6933 1.6939)0.06 - 0.18 (0.002 - 0.007i26.9s,27.00 (1.061 - 1.063)

43.08 (1.696)

0.2310.009)

Countershaft 2ndgeart.D.End playThickness

47.009 - 47.025 (1.8507 - 1.8514)0.07 - 0.14 10.003 ,0.006)

2As2 - 2a.97 l�1.139-1.1411

47.08 {1.854)0.18 (0.007)

Spacer collar(Mainshaft 4thand 5th gears)

t.D.o.D.Length A'ls I

le31 .002 - 31 .O12 11 .2205 , 1 .2205)37.989 - 38.000 (1.4956 1.4961)56.45 - 56.55 Q.222 - 2.226126.03,26.08 (1.025 - 1.027)

31.06 (1.223)

37.94 (1.494)

26.01 t1 .0241

Reverse idler geart.D.Gear-to-reverse gear shaft clearance20.01 6 - 20.043 (0.7880, 0.7891)0.036 - 0.084 (0.0014 - 0.0033)20.09 (0.7909)

0.16010.0063)

Synchro ringRing-to-gear clearance (ring pushed againsl gear)0.85 - r.10 (0.033 0.043)0.4 (0.02)

Dual coneClearance (ring pushed against gear)

Outer synchro ring to synchro coneSynchro cone-to-gearOuter synchro ring-to-gear

0.5 1.0 (0.02 0.04)0.5 - 1.0 (0.02 - 0.04)0.95 - 1.68 (0.037 - 0.066)

0.3 (0.01)

0.3 (0.01)

0.6 (0.02)

Shift forkFinger thickness 3rdl4th shift lorkExcept aboveFork-to-synchro sleeve clearance

7.4 - 7.6 (0.29 - 0.30)6.2 - 6.4 (0.24- 0.2s)0.35 - 0.65 (0.0't4 - 0.026)'t, torag)

www.emanualpro.com

Page 31 of 1395

Standards and Service Limits

Manual Transmission {cont'd} - Section 13

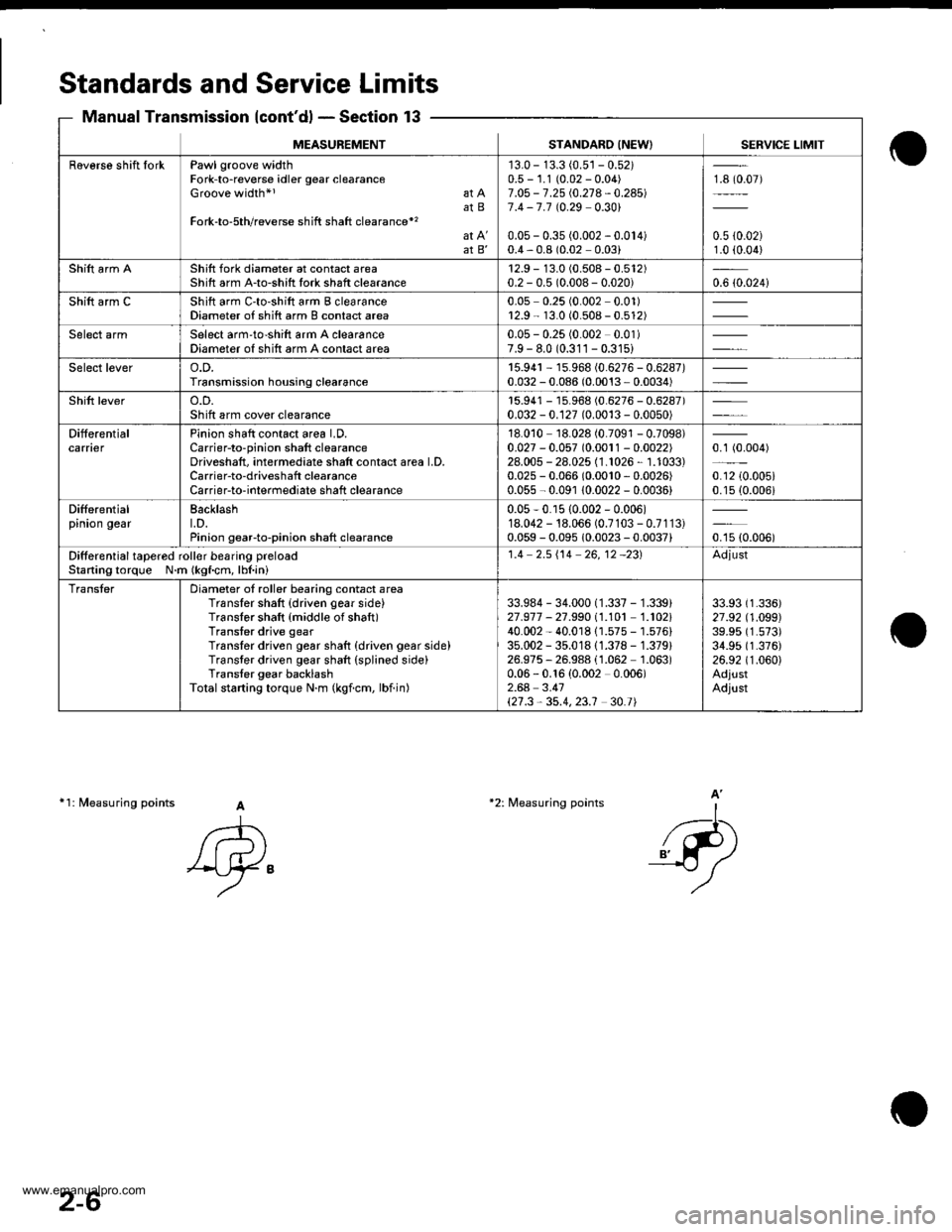

11: fuleasuring points A

A

'Ay"

-l-...

_{-P)

A'*2: Measuring points

MEASUREMENTSTANDARO INEW) SERVICE LIMIT

Raverse shift IorkPawl groove widthFork-to-reverse idler gear clearanceGroove width*l at AatBFork-to-5th/reverse shift shaft clearance*'�

at B'

'13.0 - 13.3 (0.5'�j - 0.52)0.5 - 1.1 (0.02 - 0.04)7.O5 - 7.25 i.0.21 4 - 0.24517.4 -7.7 t0.29 0.301

0.05 - 0.35 (0.002 - 0.014)0.4,0.8 (0.02 0.03)

18 (0.07)

0.5 {0.02)1.0 (0.04)

Shift arm AShift fork diameter at contact areaShift arm A-to-shitt tork shaft clearance12.9 - 13.0 (0.508 - 0.512)0.2 - 0.5 (0.008- 0.020)0.6 {0.024i

Shift arm CShift arm C'to-shift arm B clearanceDiameter of shift arm B contact area0.05 0.25 (0.002 0.01)r2.9 - 13.0 (0.508 - 0.512)

Select armSelect arm'to-shift arm A clearanceDiameter of shift arm A contact area0.05 - 0.25 (0.002 0.01)7.9 - 8.0 (0.311 - 0.31s)

Select levero.D.Transmission housing clearance15.94r - 15.968 (0.6276 - 0.6287)0.032 - 0.086 (0.0013 - 0.0034)

Shift levero.D.Sh ift arm cover clearancer5.941 - 15.968 (0.6276 - 0.6287)0.032 - 0.127 (0.0013 - 0.0050)

DifferentialcarnerPinion shaft contact area LD.Carrier-to-pinion shaft clearanceDriveshaft, intermediate shatt contact area LD,Carrier-to-driveshaft clearanceCarrierto-interrnediate shaft clearance

18.010 18.028 (0.7091 - 0.7098)0.027 - 0.057 (0.0011 - 0.0022)28.005 - 28.025 (1.1026, 1.1033)0.025 - 0.066 (0.0010,0.0026)

0.055 - 0.091 10.0022 - 0.0036)

0.1 (0.004)

0.12 {0.005i0.15 (0.006i

Differentialpinion gearBacklasht.D.Pinion gearto-pinion shaft clearance

0.05-0.r5 {0.002 - 0.006)18.042 - 18.066 (0.7103 - 0.7113)0.059 - 0.095 10.0023 - 0.0037)oru ro.ooor

Ditferential tapered roll€r besring preloacStaning torque N.m (kgf.cm, lbl.ini

1.4 2.5i'14 26,12 -231Adjust

TransterDiameter of roller bearing contact areaTransler shaft {driven gear side}Translor shaft {middle of shaft)Transter drive gearTranslor driven gear shaft {driven gear side)Transter driven gear shaft (splined side)Trans{er gear backlashTotalstarting torque N.m (kgicm, lbiin)

33.984 - 34.000 (1.337 - 1.339)21.977 - 27.99011.101 1.102140.002 - 40.01811.575 - 1.576)35.002 - 35.01811.378 - 1.379)26.975, 26.988 (1.062 1.063)0.06 - 0.16 {0.002 0.006)2.64 3.41\21.3,35.4,23.1 30.t|

33.93 (1.336)

27 .92 (1 .O99)39.95 (1.573)

34.95 (1.376)

26.92 (1.060)

AdjustAdjust

2-6

www.emanualpro.com

Page 33 of 1395

Standards and ServiceLimits

Section 14Automatic Transmission (cont'd)-

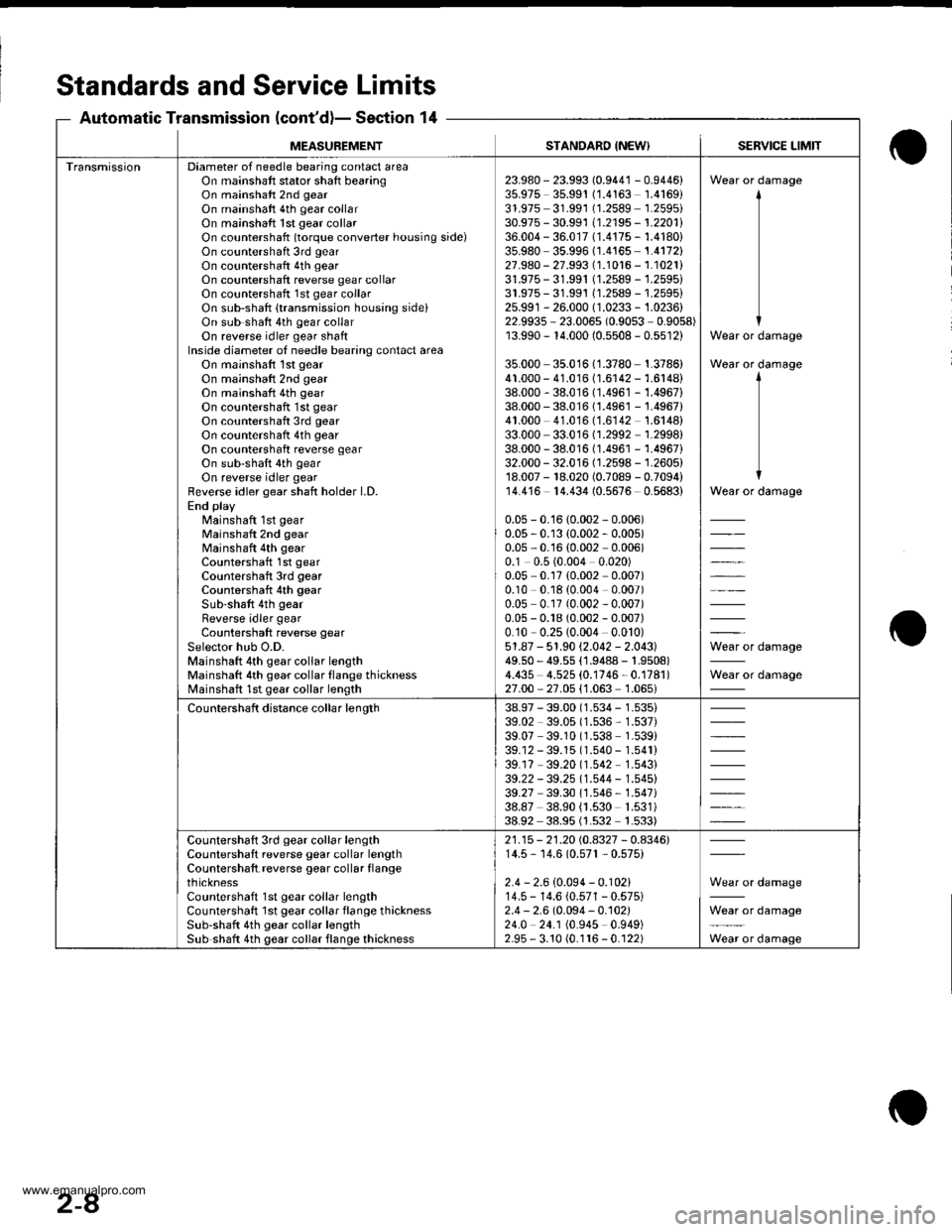

MEASUBEMENTSTANDARD {NEW}SERVICE LIMIT

TransmissionDiameter of needle bearing contact areaOn mainshaft stator shaft bearingOn mainshaft 2nd gear

On mainshaft 4th gear collarOn mainshaft 1st gear collarOn countershatt (torque converter housing side)On countershaft 3rd gear

On countershaft 4th gearOn countershaft reverse gear collarOn countershaft 1st gear collarOn sub-shaft {transmission housing sideiOn sub shaft 4th gear collarOn reverse idler gear shaftInside diameter of needle bearing contact areaOn mainshaft 1st gear

On mainshaft 2nd gearOn mainshaft 4th gear

On countershaft 1st gear

On countershaft 3rd gear

On countershaft 4th gear

On countershaft reverse gearOn sub-shaft 4th gear

On reverse idler gearfleverse idler gear shaft holder l.D.End playMainshaft 1st gearMainshaft 2nd gearMainshaft 4th gearCountershaft 1st gearCountershaft 3rd gearCountershaft 4th gear

Sub-shaft 4th gear

Reverse idler gearCountershaft reverse gear

Selector hub O.D.Mainshaft 4th gear collar lengthMainshaft 4th gear collar flange thicknessMainshaft 1st gear collar length

23.980- 23.993 (0.9441 - 0.9446)35.975 35.99'! (1.4163 1.4169)31.975 31.991 (1.2589 1.2595i30.975 - 30.991 11.2195 - 1.2201l'36.004 - 36.017 (1.4175 - 1.4180)35.980 35.996 (1.4165 1.4172)27.980 - 27.993 (1.1016 - 1.1021i31.975- 31.991 (1.2589 -'�j.2595i

31.975- 31.991 (1.2589 - 1.2595)25.991 - 26.000 (1.0233 - 1.0236)22.9935 - 23.006s (0.9053 0.9058)13.990 - r4.000 (0.5508 - 0.5512)

35.000 35.016 (1.3780 1.3786)41.000 - 41.016 (1.6142 - 1.6148)38.000 - 38.016 (1.4961 -'�1.4967)

38.000 - 38.016 (1.496'1 - 1.4967)41.000 41.016 (1.6142 1.6148)33.000 - 33.016 (1.2992 1.2998)38.000 - 38.016 (1.4961 - 1.4967)32.000 - 32.016 (1.2598 - 1.2605)18.007 - 18.020 (0.7089 - 0.7094)14.416 14.434 (0.5676 0.5683)

0.05 - 0.16 {0.002 - 0.006)0.05 - 0.13 (0.002 - 0.005)0.05,0.'16 (0.002 0.006)0.1 0.5 (0.004 0.020)0.05 0.17 {0.002 0.007)0.10 0.18 (0.004 0.007)0.0s 0.17 (0.002 - 0.007)0.05 - 0.18 (0.002 - 0.007)0.10,0.25(0.004 0.010)51.87 - 51.90 (2.042 - 2.043)49.50 - 49.55 (1.9488 - |.9508)4.435 4.525 (0.1746-0.1781)

27.00,27.05 {1.063'1.065i

Wear or damage

Wear or damage

Wear or damage

Wear or damage

il*=lo'. d"'.n"n"

Wear or damage

Countershaft distance collar length38.97 - 39.00 (1.534 - 1.535)39.02 39.05 (1.536, 1.537)39.07 39.10 (1.538 1.539)39.12 - 39.15 (1.540 - 1.541)39.17 - 39.20 (1.542 * 1.543)39.22 - 39.25 11.544 - 1.545)39.27 39.30 1'1.546 - 1.547i38.87 38.90 {1.530 1.531)38.92 38.95 (1.s32 1.533)

Countershaft 3rd gear collar lengthCountershaft reverse gear collar lengthCountershaft reverse gear collar flangethicknessCountershaft 1st gear collar lengthCountershaft lst gear collar flange thicknessSub-shaft 4th gear collar lengthSub shatt 4th gear collar flange thickness

21.15 - 21.20 rc.4327 - 0.4346)14.5, 14.6 (0.57't , 0.575)

2.4 - 2.6 (0.094 - 0.102)14.5 - 14.6 (0.571 - 0.575)2.4 - 2.6 (0.094 - 0.102)24.0 24.1 (0.945 0.949)2.95 - 3.10 (0.116 - 0.122)

Wear or damage

Wear or damage

Wear or damage

2-8

www.emanualpro.com

Page 34 of 1395

2-9

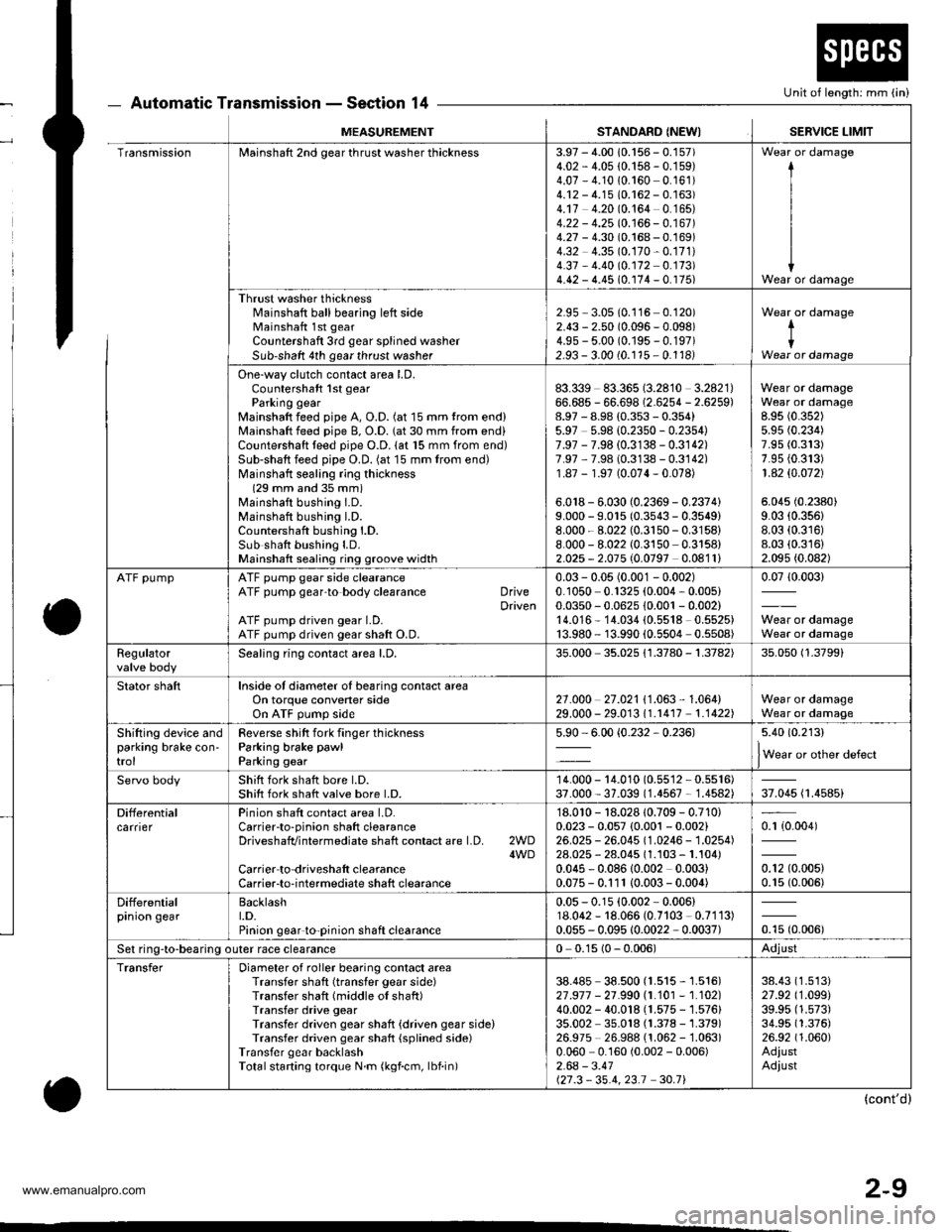

Automatic Transmission - Section 14

o

Unit of length: mm (in)

o

MEASUREMENTSTANDARD (NEWISERVICE LIMIT

TransmissionMainshaft 2nd gear thrust washer thickness3.97 - 4.00 10.156 - 0.157)4.02 - 4.05 {0.158 - 0.159)4.07 - 4.1010.160 0.161)4.12 - 4.15 (0.162 - 0.163)4.17 4.20 (0.164 0.165)4.22 - 4.25 10.166 - 0.167 )4.27 - 4.30 (0.168 - 0.169)4.32 4.35 (0.170-0.171)

4.37 - 4.40 (0.172 0.173)4.42 - 4.45 (0.174 - 0. r75)

I

I

IWear or damage

Thrust washer thicknessl'rainshaft ball bearing left sideMainshaft 1st gear

Countershaft 3rd gear splined washerSub-shaft 4th gear thrust washer

2.95 3.05 (0.116 0.120)2.43 - 2.50 (0.096 - 0.098)4.9s - 5.00 (0.195 - 0.197)2.93 - 3.00 (0.115 - 0.1181

Wear or damage

tIWear or damage

One-way clutch contact area LD.Countershaft 1st gearParking gearMainshaft feed pipe A, O.D. (at 15 mm trom end)Mainshaft feed pipe B, O.D. (at 30 mm from end)Countershaft teed pipe O.D. lat 15 mm from end)Sub-shaft feed pipe O.D. (at 15 mm from end)Mainshatt sealing ring thickness(29 mm and 35 mm)Mainshaft bushing I.D.Mainshaft bushing l.D.Countershaft bushing l.D.Sub shatt bushing LD.Mainshaft sealing ring groove width

83.339 83.365 (3.2810 3.2821)66.685 - 66.698 (2.6254 - 2.6259)8.97 - 8.98 (0.353 - 0.354)5.97 5.98 {0.2350 - 0.2354)7.97 - 7.98 (0.3138 - 0.3142)7.97 ,7.98 (0.3138 - 0.3142)1.87 - 1.97 (0.074-0.078)

6.018 - 6.030 (0.2369 - 0.2374)9.000 - 9.015 (0.3543 - 0.3549)8.000 - 8.022 (0.3150-0.3158)

8.000 - 8.022 (0.3150 0.3158)2.025 - 2.075 (0.0797 0.0811)

Wear or damageWear or damage8.95 (0.352)

5.95 (0.234)

7.95 (0.313)

7.95 {0.313)1 .42 $.O72)

5.045 (0.2380)

9.03 (0.356)

8.03 (0.316)

8.03 (0.316)

2.095 (0.082)

ATF pumpATF pump gear side clearanceATF pump gear'to body clearance DriveDrivenATF pump driven gear LD.ATF pump driven gear shaft O.D.

0.03 - 0.05 (0.001 - 0.002)0.1050 0.1325 (0.004, 0.005)0.0350 - 0.0625 10.001 - 0.002)14.016* 14.034 (0.5518 0.5525)13.980 - 13.990 {0.5504 0.5508)

0.0710.003)

Wear or damageWear or damage

Regulatorvalve bodySealing ring contact area l.D,35.000 35.025 {1.3780 - 1.3782)35.050 (1.3799)

Stator shaftInside of diameter oI bearing contact areaOn torque convener sideOn ATF pump side2't .o00 27 .021 I '1 .063 , 1 .064)29.000 - 29.01311.r417 1.1422)Wear or damageWear or damage

Shifting device andparking brake con'trol

Reverse shitt fork finger thicknessParking brake pawl

Parking gear

5.90 - 6.00 {0.232,0.236)5.40 (0.213)

lWear or other defect

Servo bodyShift fork shatt bore l.D.Shift fork shatt valve bore l.D.14.000 - 14.010 (0.55'�l2 - 0.5516)37.000 - 37.039 (1.4567 - 1.4582)37.045 (1.4585)

DifferentialcarrierPinion shaft contact area LD.Carrierto-pinion shaft clearanceDriveshafvintermediate shaft contact are l.D. 2WD4WDCarrier to driveshalt clearanceCarrier-to-intermediate shaft clearance

'18.010 - 18.028 10.709 - 0.710)0.023 - 0.057 {0.001 - 0.002}26.025 - 26.045 (1.0246 - 1.0254)28.025 - 28.045 (1.103 - 1.104)0.045 - 0.08610.002 0.003)0.075 - 0.111 10.003- 0.004)

0.r {0.004)

0.12 (0.005)

0.15 (0.006)

Differentialprnron gearBacklasht.D.Pinion gear'to-pinion shaft clearance

0.05 - 0.15 (0.002 - 0.006)18.062 - 18.066 (0.7103 - 0.7113)0.055 - 0.095 10.0022 - 0.0037)otu to.oout

Set ring-to-bearing outer race clearance0 0.15 (0 - 0.006)Adjust

TransferDiameter of roller bearing contact areaTransfer shaft (transfer gear side)Transfer shaft (middle of shaft)Transfer drive gearTransfer driven gear shaft {driven gear side)Transfer driven gear shaft {splined side)Transfer gear backlashTotalstarting torque N.m (kgf.cm, lbf.in)

38.485 38.500 (1.515 - 1.516)27 .917 - 21 .990 |.1.101 - 1.102)40.002 - 40.018 (1.575 - 1.576)35.002 35.018 (1.378 - 1.379)26.975 26.988 (1.062 -'�l.063)

0.060 0.160 (0.002 - 0.006)2.64 - 3.41127.3 - 35.4,23.1 30.71

38.43 (1.513)

27.92 (1.099)

39.95 (1.573)

34.95 (1.376)

26.92 (1.060)

AdiustAdiust

(cont'd)

www.emanualpro.com

Page 59 of 1395

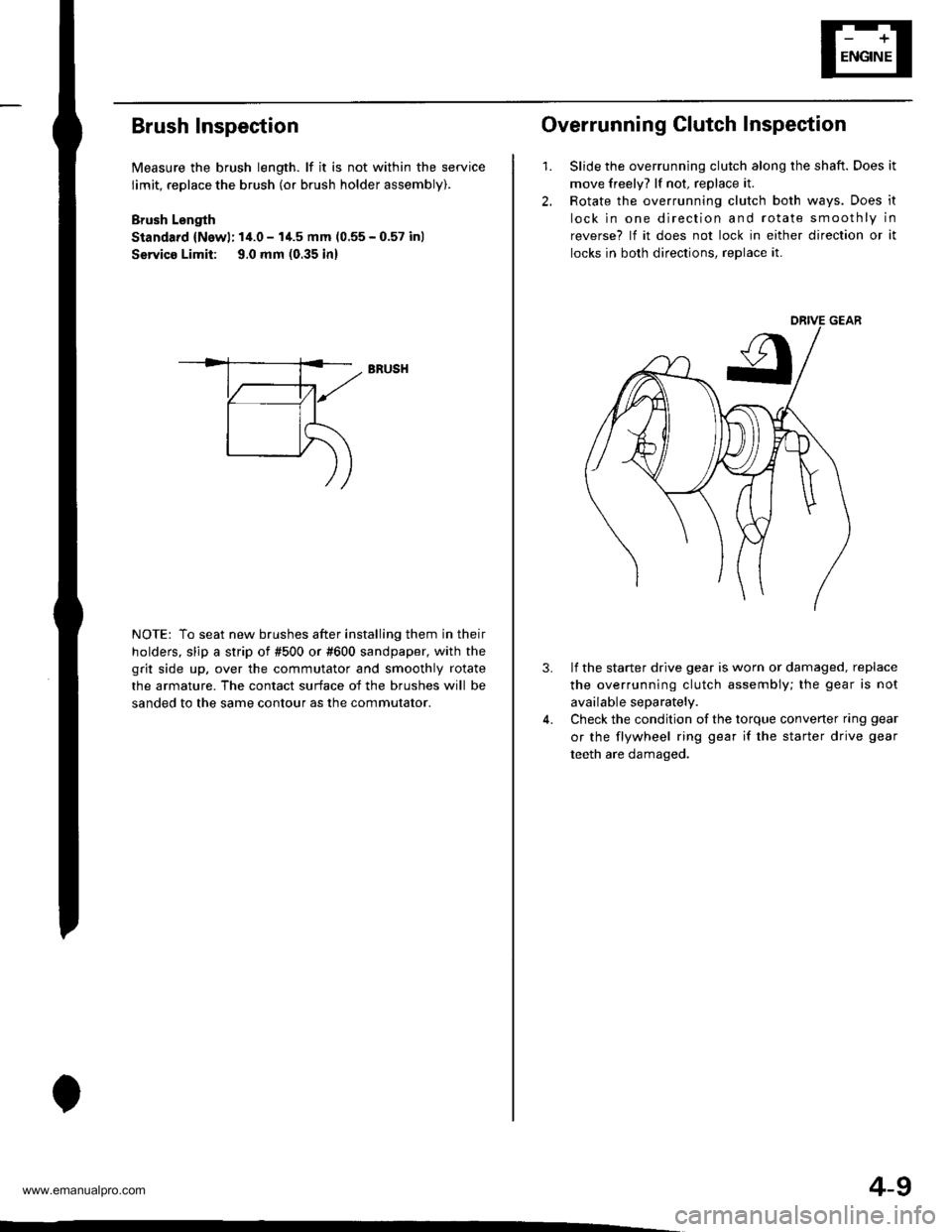

Brush Inspection

Measure the brush length. lf it is not within the service

limit, replace the brush (or brush holder assembly).

Brush Lsngth

Standard {Newl: 14.0 - I'1.5 mm (0.55 - 0.57 inl

Servico Limit: 9.0 mm (0.35 in)

NOTE: To seat new brushes after installing them in their

holders. slip a strip of #500 or #600 sandpaper, with the

grit side up, over the commutator and smoothly rotate

the armature. The contact surface of the brushes will be

sanded to the same contour as the commutator.

BRUSH

4-9

2.

1.

Overrunning Clutch Inspection

Slide the overrunning clutch along the shaft. Does it

move freely? lf not, replace it.

Rotate the overrunning clutch both ways. Does it

lock in one direction and rotate smoothly in

reverse? lf it does not lock in either direction or it

locks in both directions, reDlace it.

3.lf the starter drive gear is worn or damaged, replace

the overrunning clutch assembly; the gear is not

available separately.

Check the condition of the torque converter ring gear

or the flywheel ring gear if the starter drive gear

teeth are damaged.

www.emanualpro.com

Page 61 of 1395

I

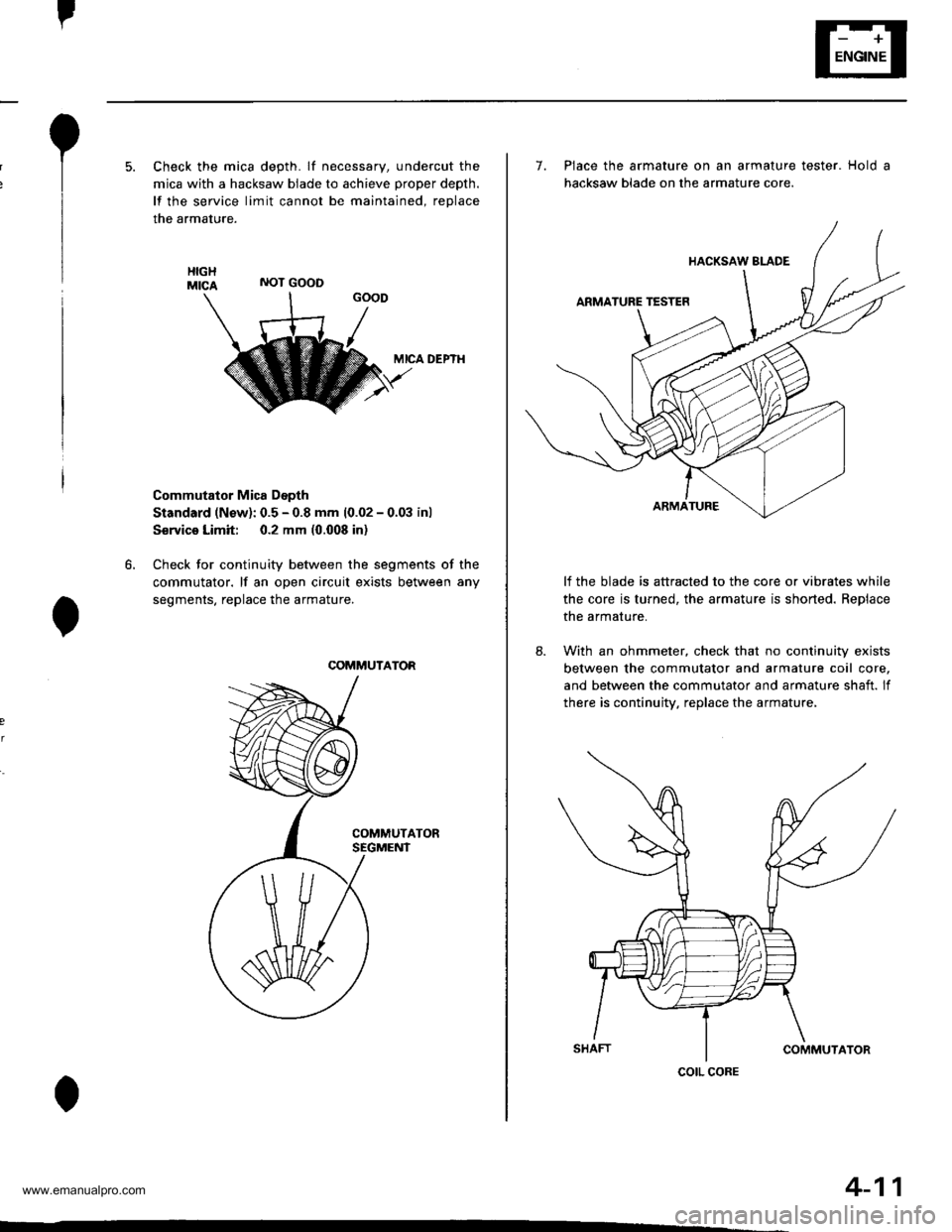

NOT GOOD

5. Check the mica depth. lf necessary, undercut the

mica with a hacksaw blade to achieve proper depth.

lf the service limit cannot be maintained, reDlace

the armature.

MICA DEPTI{

Commutator Mica Depth

Standard (Nsw): 0.5 - 0.8 mm 10.02 - 0.03 inl

Servico Limit: 0.2 mm (0.008 in)

Check for continuity between the segments of the

commutator. lf an open circuit exists between any

segments. replace the armature.

6.

COMMUTATOR

4-11

7. Place the armature on an armature tester. Hold a

hacksaw blade on the armature core.

lf the blade is attracted to the core or vibrates while

the core is turned. the armature is shorted. Replace

the armature.

8. With an ohmmeter, check that no continuity exists

between the commutator and armature coil core,

and between the commutator and armature shaft. lf

there is continuity. replace the armature,

cotL coRE

www.emanualpro.com

Page 66 of 1395

lgnition System

5.

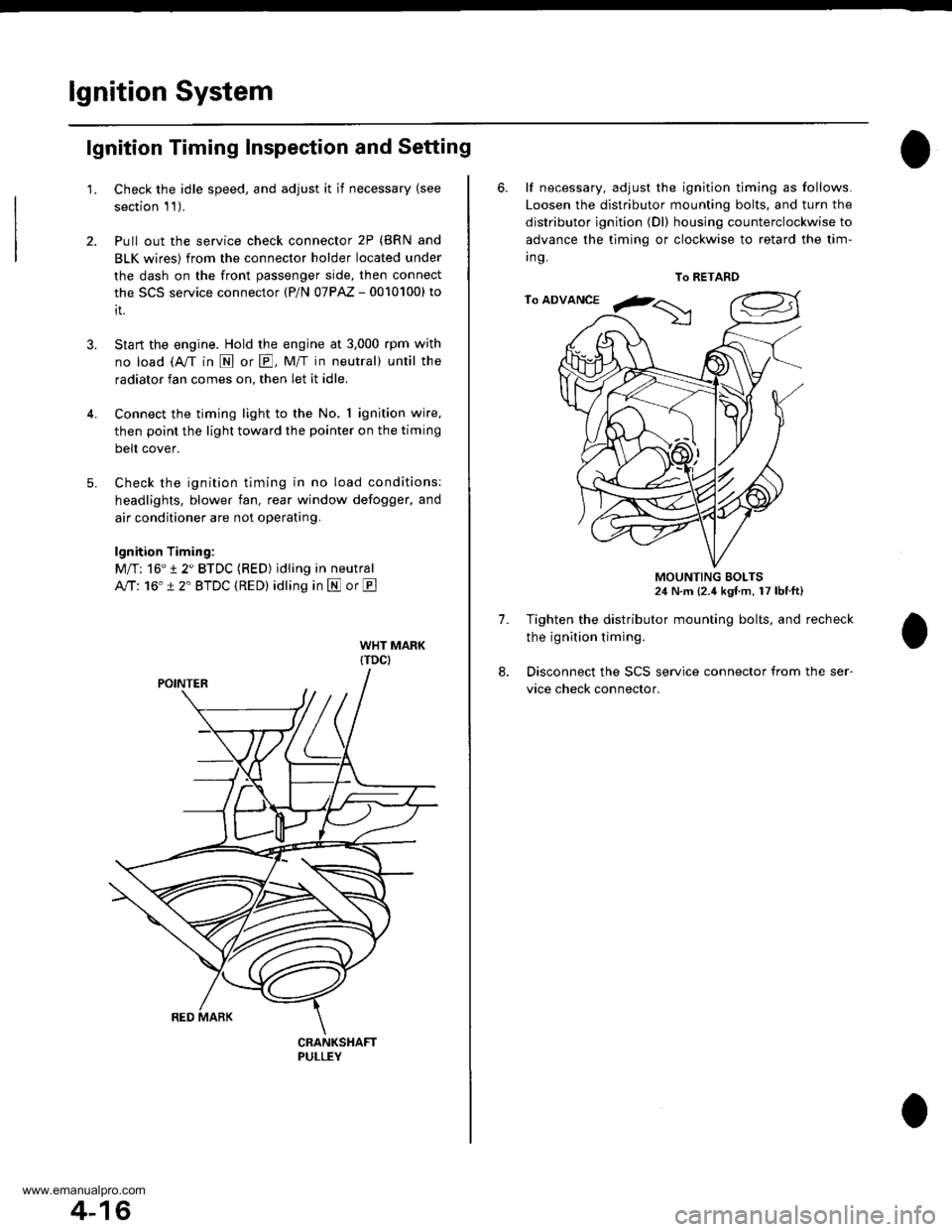

lgnition Timing Inspection and Setting

2.

1.Check the idle speed, and adjust it if necessary (see

section 1 1).

Pull out the service check connector 2P (BRN and

BLK wires) from the connector holder located under

the dash on the front passenger side, then connect

the scs service connector (P/N 07PAz - 0010100) to

it.

Start the engine. Hold the engine at 3,000 rpm with

no load (A/T in N or E, Mff in neutral) until the

radiator fan comes on, then let it idle.

Connect the timing light to the No. I ignition wire,

then point the light toward the pointer on the timing

belt cover.

Check the ignition timing in no load conditions:

headlights, blower fan, rear window defogger, and

air conditioner are not operating.

lgnition Timing:

M/T: 16" 12" BTDC (RED) idling in neutral

AlTt'16" !2" BTDC (RED) idling in E or E

CRANKSHAFTPULLEY

4-16

6. lf necessary, adjust the ignition timing as follows.

Loosen the distributor mounting bolts, and turn the

distributor ignition (Dl) housing counterclockwise to

advance the timing or clockwise to retard the tim-

t no,

7.

8.

MOUNTING BOLTS24 N.m {2.4 kgf m, 17 lbtft}

Tighten the distributor mounting bolts, and recheck

the ignition timing.

Disconnect the SCS service connector from the ser-

vice check connector.

To RETARD

www.emanualpro.com