Drive shaft HONDA CR-V 2000 RD1-RD3 / 1.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 179 of 1395

1.

2.

3.

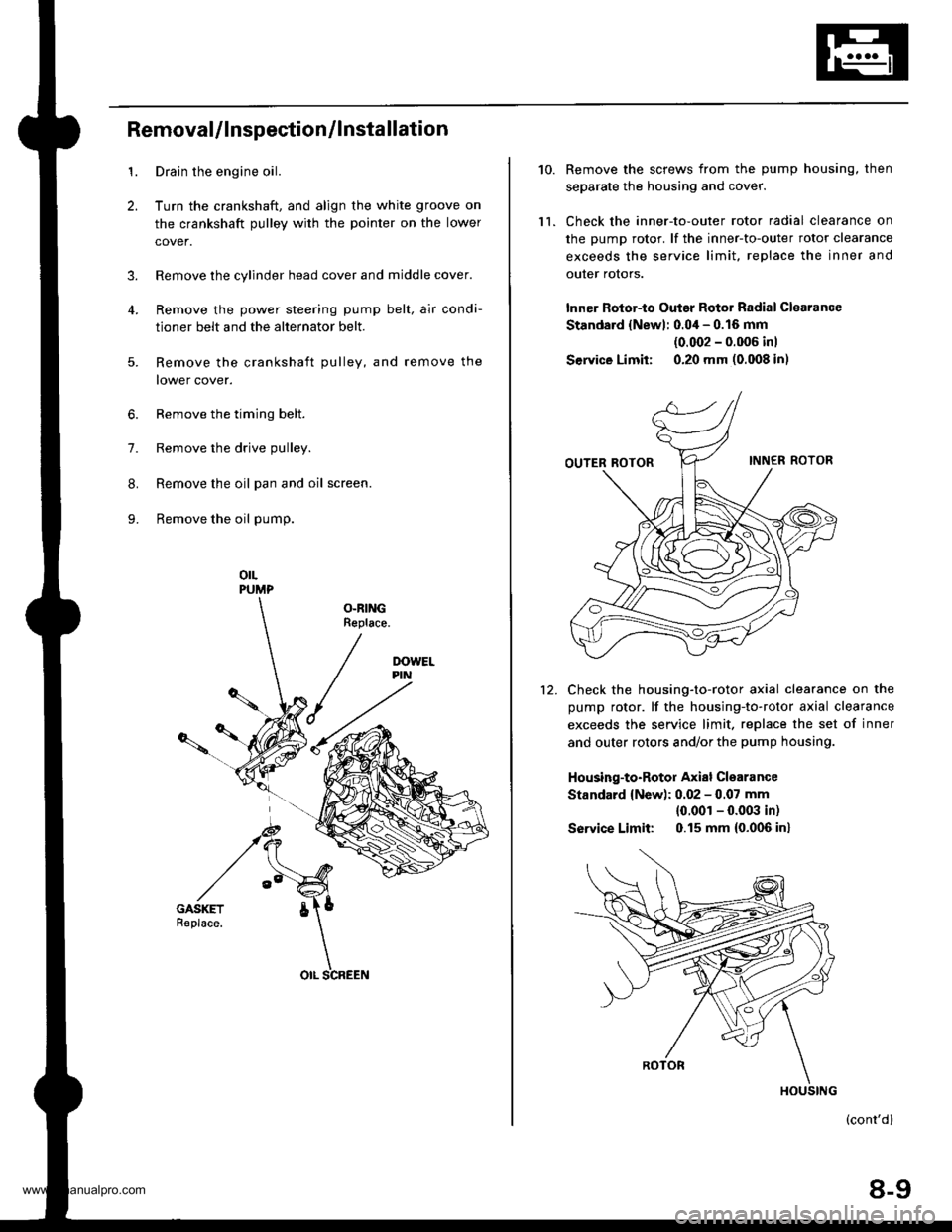

RemovaUlnspection/lnstallation

Drain the engine oil.

Turn the crankshaft, and align the white groove on

the crankshaft pulley with the pointer on the lower

cover.

Remove the cylinder head cover and middle cover.

Remove the power steering pump belt, air condi-

tioner belt and the alternator belt.

Remove the crankshaft pulley, and remove the

lower cover.

6. Remove the timing belt.

7. Remove the drive pulley.

8. Remove the oil pan and oil screen.

9. Remove the oil pump.

orLPUMP

OLRINGReplace.

5.

OIL SCREEN

10.

ll.

Remove the screws from the pump housing, then

separate the housing and cover.

Check the inner-to-outer rotor radial clearance on

the pump rotor. lf the inner-to-outer rotor clearance

exceeds the service limit. replace the inner and

outer rotors.

lnner Rotor-to Outar Rotor Radial Clearance

Standard {Newl: 0.04 - 0.16 mm

{0.002 - 0.006 inl

Service Limit: 0.20 mm (0.008 in)

Check the housing-to-rotor axial clearance on the

pump rotor. lf the housing-to-rotor axial clearance

exceeds the service limit. replace the set of inner

and outer rotors and/or the pump housing.

Housing-to-Rotor Axial Clearance

Standard {New): 0.02 - 0.07 mm

{0.001 - 0.003 in)

So|'�ice Limit: 0.15 mm (0.006 inl

(cont'd)

8-9

HOUSING

www.emanualpro.com

Page 270 of 1395

Troubleshooting

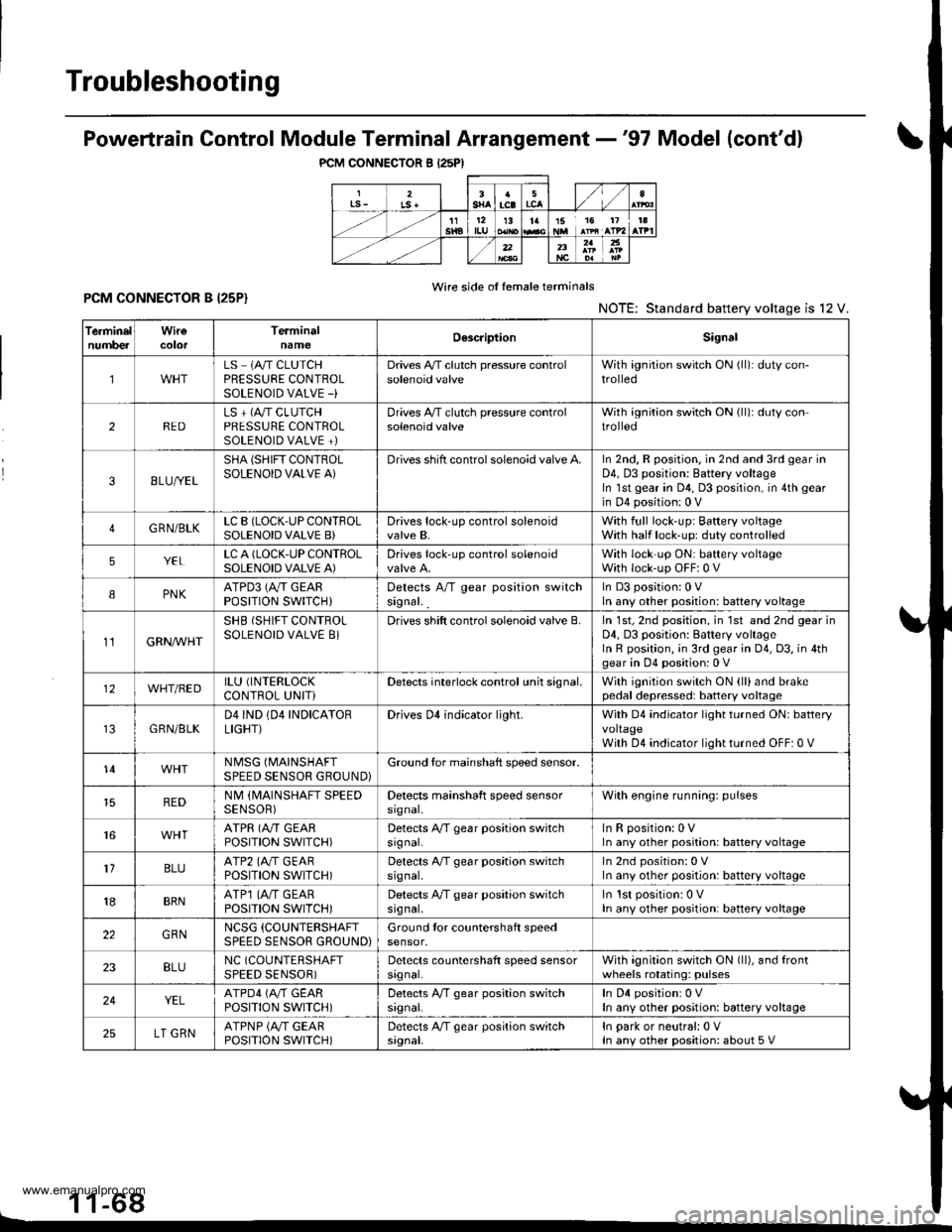

PCM CONNECTOR B I25PI

Powertrain Control Module Terminal Arrangement -'97 Model (cont'dl

Wire side of female terminalsPCM CONNECTOR B I25P}NOTE: Standard battery voltage is l2 V.

1 1-68L

TerminelnumbercolorTerminalnameOescriptionSignal

1LS 1A/T CLUTCHPRESSURE CONTROLSOLENOID VALVE -)

Drives A,/T clutch pressure controlsolenoid valveWith ignition switch ON (ll): duty con-trolled

2REDLS + (A"/T CLUTCHPRESSURE CONTROLSOLENOID VALVE +)

Drives A,/T clutch pressure controlsolenoid valveWith ignition switch ON (ll)r duty controlled

38LU//EL

SHA (SHIFT CONTROLSOLENOID VALVE A)Drives shift control solenoid valve A.In 2nd, R position. in 2nd and 3rd gear inD4, D3 position: Battery voltageIn lst gear in D4, D3 position, in 4th gear

in D4 position: 0 V

4GRN/BLKLC B (LOCK-UP CONTFOLSOLENOID VALVE B)Drives lock-up control solenoidvalve B,With full lock-up; Baftery voltageWith half lock-up: duty controlled

5YELLC A (LOCK.UP CONTROLSOLENOID VALVE A)Drives lock-up control solenoidWith lock'up ON: battery voltageWith lock-up OFF:0 V

IPNKATPD3 (Ay'T GEARPOSITION SWITCH}Detects A/T gear position switchsignal. _

In D3 position:0 Vln any other position: battery voltage

11GRN/VVHT

SHB (SHIFT CONTROLSOLENOID VALVE 8}Drives shift control solenoid valve B.In 1st, 2nd position, in 1st and 2nd gear inD4, D3 position: Battery voltageIn R position, ;n 3rd gear in 04, D3, in 4thgear in D4 position: 0 V

12WHT/BEDILU (INTERLOCK

CONTROL UNITiDetects interlock control unh signal.With ignition switch ON (ll)and brakepedal depressed: battery voltage

GRN/BLKD4IND (04 INDICATORLIGHT}Drives Dl indicator light.With D4 indicator light turned ON: batteryvoltageWith D4 indicator light turned OFF: 0 V

14NMSG (MAINSHAFT

SPEED SENSOR GROUND}Ground tor mainshaft speed sensor.

REDNM (MAINSHAFT SPEEDSENSOR)Detects mainshaft speed sensorsrgnal,With engine running: pulses

16ATPR (A"/T GEARPOSITION SWITCH)Detects A/T gear position switchsrgnal.InRposition:0VIn any other position: battery voltage

1'lBLUATP2 (A./T GEARPOSITION SWITCH)Detects A/T gear position switchsrg nal,In 2nd position: 0 VIn any other position: battery voltage

18BRNATP1 (4,,/T GEARPOSTTTON SWTTCH)Detects A/T gear position switchsrg nal,ln lst position: 0 VIn any other position: battery voltage

22GBNNCSG (COUNTERSHAFT

SPEED SENSOR GROUND)Ground tor countershaft speedsensor,

23BLUNC (COUNTERSHAFT

SPEED SENSOR)Detects countershaft speed sensorsrgnal.With agnition switch ON (ll), and lrontwheels rotating: pulses

24YELATPD4 (M GEARPOSITION SWITCH)Detects A,/T gear position switchsrgnal.In D4 positionr 0 VIn any other position: battery voltage

25LT GRNATPNP {A/T GEARPOSITION SWITCH)Detects A/T gear position switchsignal.In park or neutral:0 VIn any other position: about 5 V

www.emanualpro.com

Page 276 of 1395

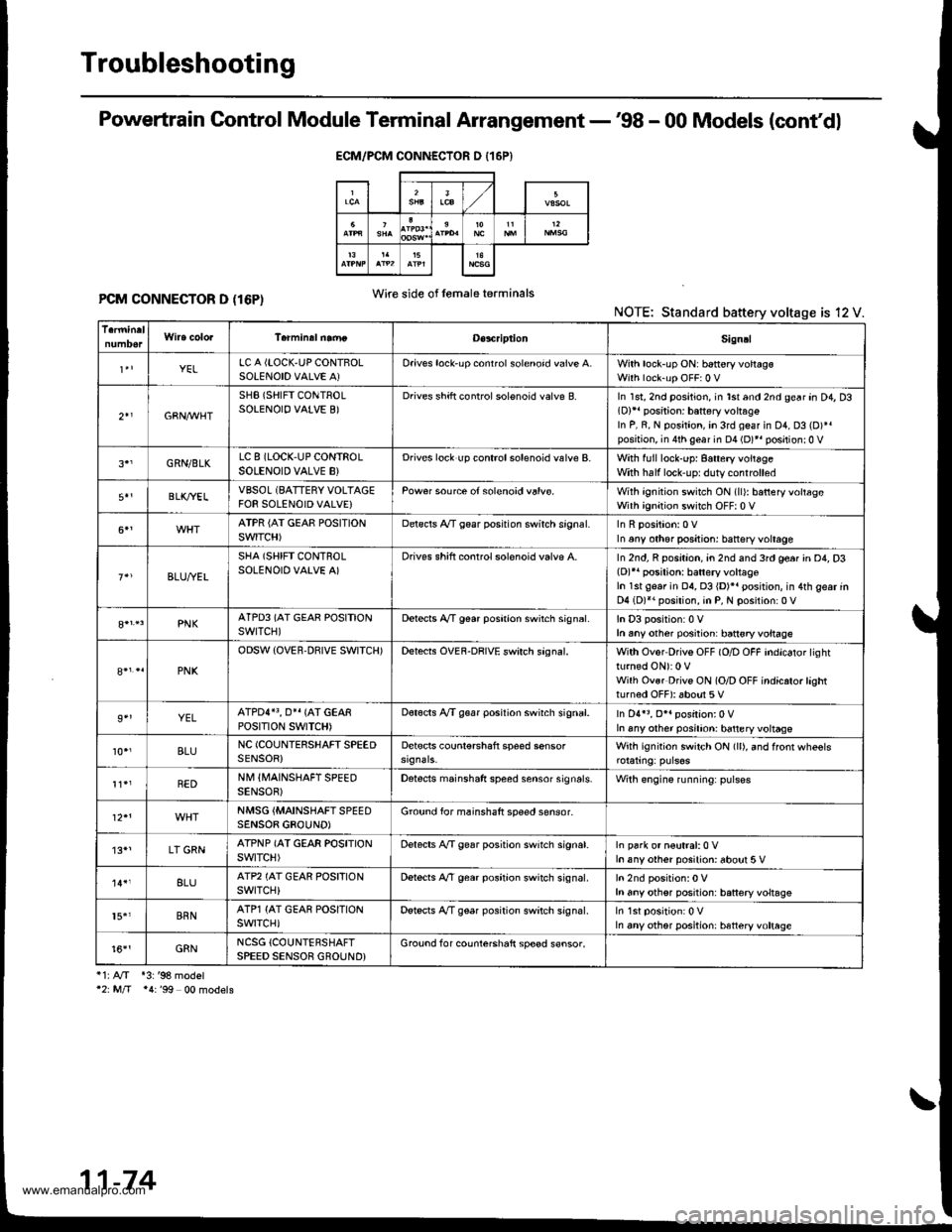

Troubleshooting

Powertrain Control Module Terminal Arrangement -'98 - 00 Models (cont'dl

PCM CONNECTOR D (16P)NOTE: Standard battery voltage is 12 V.

i1:A/T *3:'98 model'2: M/T *4:'99 00 models

ECM/PCM CONNECTOR D {16P}

Wire side of lemaleterminals

D€s4riptionSign!l

YELLC A {LOCK,UP CONTBOLSOLENOID VALVE A)Oriv€s lock'up conrrol solenoid valve A.With lock-up ON: b6ttery voltagsWith lock-up OFF:0 V

2+1GBN,M/HT

SHB (SHIFT CONTROLSOLENOIO VALVE B)Drives shift controlsolenoid valve B.In 1st, 2nd position, in lst and 2nd gear an D4, D3(D)11 position: battery vohag€In P, R, N position, in 3rd geaf in D1, D3 (D)*.position, in 4th gear in D4 (D)*r positionr0 V

GRN/BLKLC 8 (LOCK,UP CONTROLSOLENOID VALVE B}Drives lock up controlsolenoid valve B.With full lock-up: 8attery voitageWith half lock'uprduty controlled

BLK/YELVBSOL (BATTERY VOLTAGEFOR SOLENOID VALVE}Pow€r source of solenoid valvs.With ignition switch ON (ll): batteryvoltageWith ignition switch OFF| 0 V

ATPR {AI GEAE POSITIONSWITCH)Delscls A/T gear posrtion swirch srgnal.In any other positjon: battsry voltage

BLU,ryEL

SHA (SHIFT CONTROLSOLENOID VALVE A)Drives shift conrrol solenoid valvp A.In 2nd, R position, an 2nd and 3rd ge6r in D4, D3(D)r' posilion: batlery voltageIn 1st gear in 04, 03 {D)}. position, in 4th gear inD4 (D)*. position, in P, N position:0 V

PNKATPD3 (AT GEAR POSITIONswrTcH)Detects A,/T g€ar poshion swirch sign6l.In D3 position:0 Vh any other posiiion: ban€ryvoltage

PNK

ODSW (OVER.DBIVE SWITCH)Detects OVEF-DRIVE swirch sagnal.With Ovor Drivs OFF (O/D OFF indicator lightturned ON): 0 VWilh Ovsr Drivs ON (O/D OFF indicrto.lashtturned OFF): about 5 V

9''YELATPDI}3, O}I {AT GEARPOStTtON SWTTCH)Dot€cts A/T g€ar position swirch signal.In D4r3, O*. position:0 VIn any other posilion: battery voltage

10.,BLUNC (COUNIERSHAFT SPEEDSENSOR)Detscts counl€rshaft speed sensorWith ignition switch ON (ll), and ffonr wheels

REDNM IIVAINSHAFT SPEEDSENSOB)Detects mainshaft speed sensor sign6ls.Wilh engine running: pulses

NMSG {MAINSHAFTSPEEDSENSOB GBOUND)Ground for mainshaft speed sensor-

'13*1LT GRNATPNP (AT GEAR POSITIONswtTcH)Delects A,/T gear position switch signat.In park or n€utral:0 Vh any other posilion: about 5 V

8LUATP2 (AT GEAR POSFIONswrTcH)Dstects A,/T gear position switch signal.h any othsr position: battery voltsgs

15.'BRNATP1 {AT GEAR POSITIONswrTcH)Detscts A/T gear position switch signal.In any other position: htteryvoltage

t6''GRNNCSG {COUNTERSHAFTSPEED SENSOR GROUND}Grouod for counterchaft sp€ed s€nsor.

11-74

www.emanualpro.com

Page 282 of 1395

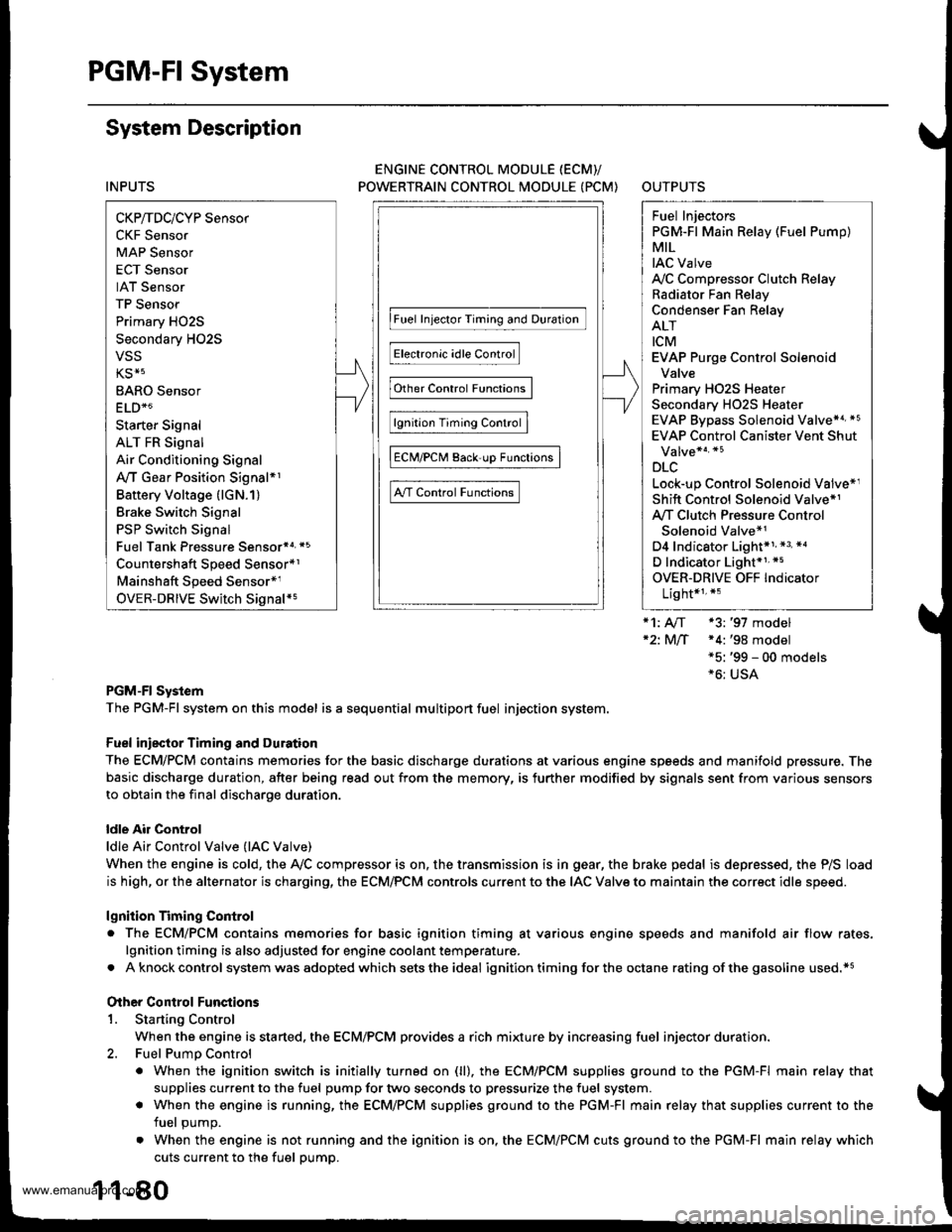

PGM-FI System

System Description

INPUTS

CKP/TDC/CYP Sensor

CKF Sensor

MAP Sensor

ECT Sensor

IAT Sensor

TP Sensor

Primary HO2S

Secondary H02S

vss

KS*5

BARO Sensor

ELD*6

Starter Signal

ALT FR Signal

Air Conditioning Signal

Ay'T Gear Position Signal*1

Baftery Voltage (lGN.1)

Brake Switch Signal

PSP Switch Signal

Fuel Tank Pressuae Sensor*4. *5

Countershaft Speed Sensor*1

Mainshaft Speed Sensor*r

OVER-DRIVE Switch Signal*s

ENGINE CONTROL MODULE (ECM)/

POWERTRAIN CONTROL MODULE (PCM) OUTPUTS

|iuel 1"j""- Th,rhg ""d Drrafr";-l

Et*-.nt"tdt"cont.orl

to,r*,c;;trffi;]

l.----.---:. .Lrgnrnon |lmrng Lonrror I

Ecir/PcM B*k',p Fr""il]

m;"t-ll-r*'io*l

Fuel Injectors

PGM-Fl Main Relay (Fuel Pump)

MIL

IAC Valve

Ay'C Compressor Clutch Relay

Radiator Fan Relay

Condenser Fan Relay

ALT

tcM

EVAP Purge Control Solenoid

Valve

Primary HO2S Heater

Secondary H02S HeaterEVAP Bypass Solenoid Valve*a *5

EVAP Control Canister Vent Shut

DLC

Lock-up Control Solenoid Valve*l

Shift Control Solenoid Valve*1

Ay'T Clutch Pressure Control

Solenoid Valve*1

D4 Indicator Light'1 *3, *a

D Indicator Light,l *5

OVER-DRIVE OFF Indicator

Lighl*t *:

*1: A/T {3:'97 model'2: M/f +4:'98 model*5: '99 - 00 models"6: USA

PGM-Fl System

The PGM-Fl system on this model is a sequential multiport fuel injection system.

Fuel iniecior Timing and Duration

The ECM/PCM contains memories for the basic discharge durations at various engine speeds and manifold pressure. The

basic discharge duration, after being read out from the memory, is further modified by signals sent from various sensors

to obtain the final discharge duration.

ldle Air Control

ldle Air Control Valve (lAC Valve)

When the engine is cold, the Ay'C compressor is on, the transmission is in gear, the brake pedal is depressed, the P/S load

is high, or the alternator is charging, the ECM/PCM controls current to the IAC Valve to maintain the correct idle speed.

lgnition Timing Control

o The ECM/PCM contains memories for basic ionition timing at various engine speeds and manifold air flow rates.

lgnition timing is also adjusted for engine coolant temperature.

. A knock control system was adopted which sets the ideal ig nition timing for the octane rating of the gasoline used.*s

Other Control Funstions

1. Starting Control

When the engine is started. the ECM/PCM provides a rich mixture by increasing fuel injector duration.

2. Fuel Pump Control

. When the ignition switch is initially turned on (ll). the ECMiPCM suppli€s ground to the PGM-FI main relay that

supplies current to the fuel pump for two seconds to pressurize the fuel system.

. When the engine is running, the ECM/PCM supplies ground to the PGM-FI main relay that supplies current to the

fuel oumo.

. When the engine is not running and the ignition is on, the ECM/PCM cuts ground to the PGM-FI main relay which

cuts current to the fuel pump.

1 1-80

www.emanualpro.com

Page 331 of 1395

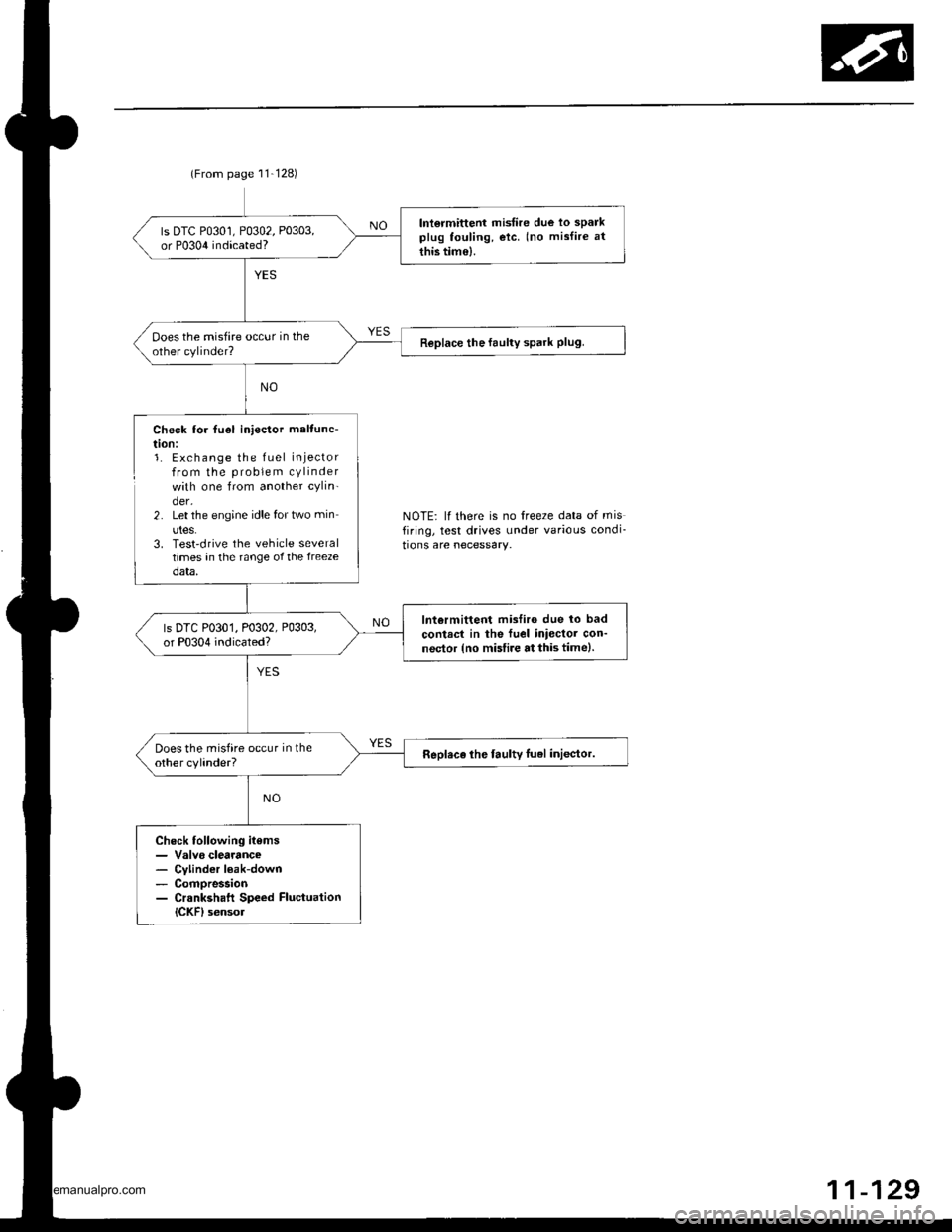

(From page 11-128)

lntormittent misfire due lo sparkplug fouling, etc. (no mislire at

this tim€).

ls DTC P0301, P0302, P0303,or P0304 indicated?

ooes the misfire occur in theother cylinder?Replace the faulty spark Plug.

Check lor fuel iniector maltunc-

t|on:1. Exchange the fuel injectorfrom the problem cylinderwith one from another cylin-der.2. Let the engine idle for two min

utes.3. Test'drive the vehicle severaltimes in the range of the freezedata,

lntermittent misfiro due lo bad

contrct in the fuel iniector con-nector {no misfire at this time).

ls DTC P0301, P0302, P0303,or P0304 indicated?

Does the misfire occur in theother cylinder?Replace lhe faulty luel inlector.

Check following items- Valvo clearance- Cvlinder l€ak-down- Compression- Crsnkshaft Speed FluctuationICKF) sensol

NOTE: lf there is no freeze data of misfiring, test drives under various condi_

tions are necessary.

11-129

www.emanualpro.com

Page 427 of 1395

Transaxle

Clutch ...........12-1

Manual Transmission ............................ 13-1

Automatic Transmission .................. ..... 1 4-1

Differential ... 15-1

Driveshafts ... 16-1

www.emanualpro.com

Page 429 of 1395

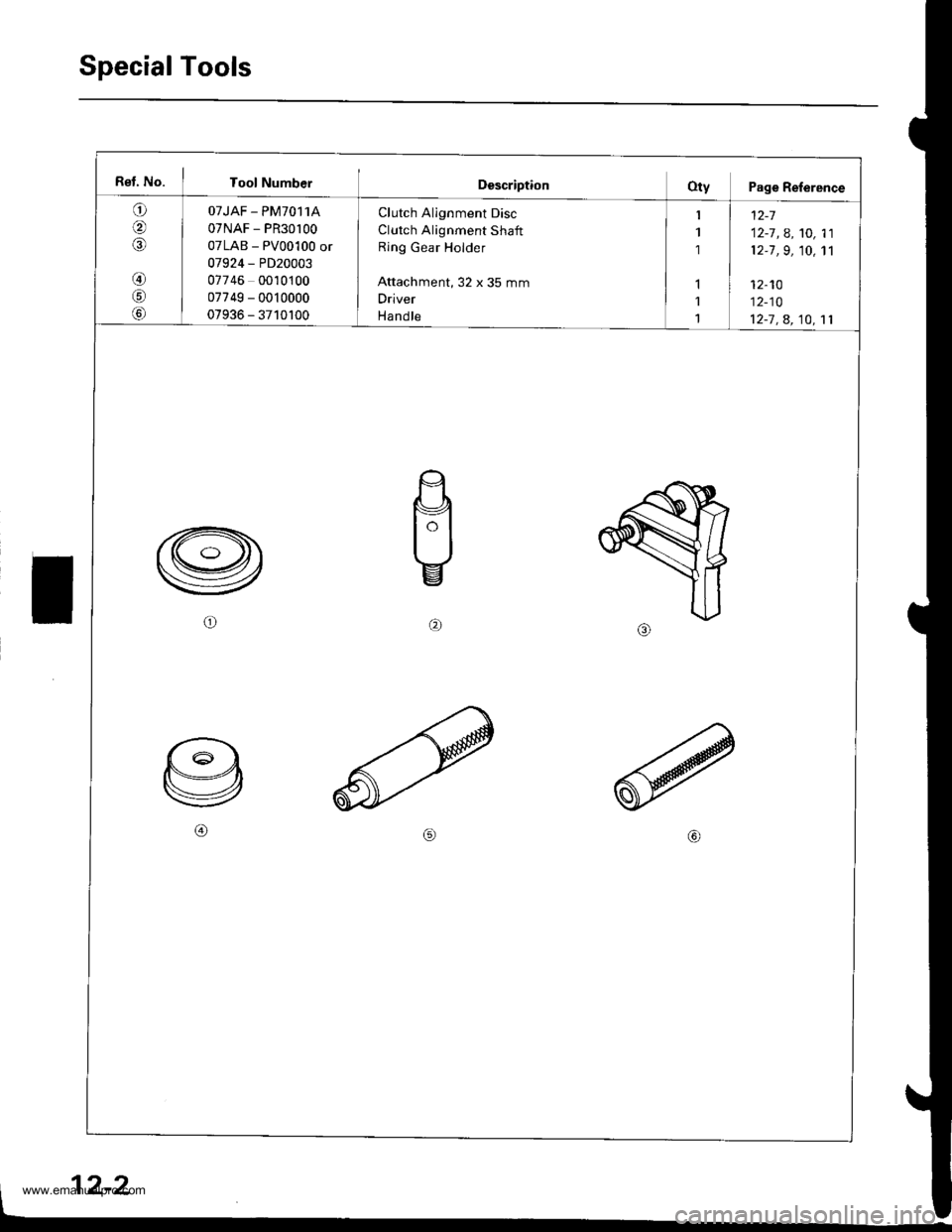

Special Tools

Rel. No. I Tool NumberDescriptionOty Page Reference

a

IA

@

!c,

Lo,

OTJAF - PM70,I1A

07NAF - PR30l00

07LAB - PV00100 or

07924 - PD20003

07746 0010100

07749 - 0010000

07936 - 3710100

Clutch Alignment Disc

Clutch Alignment Shaft

Ring Gear Holder

Attachment, 32 x 35 mm

Driver

Ha nd le

1 | t2-7

1 12-7 , A, '�t0, 11

1 12-7 ,9, 10, 1'l

I1 I 12-10

1 12-10

1 12-7 , a, 10, 11

b)

2-2

www.emanualpro.com

Page 437 of 1395

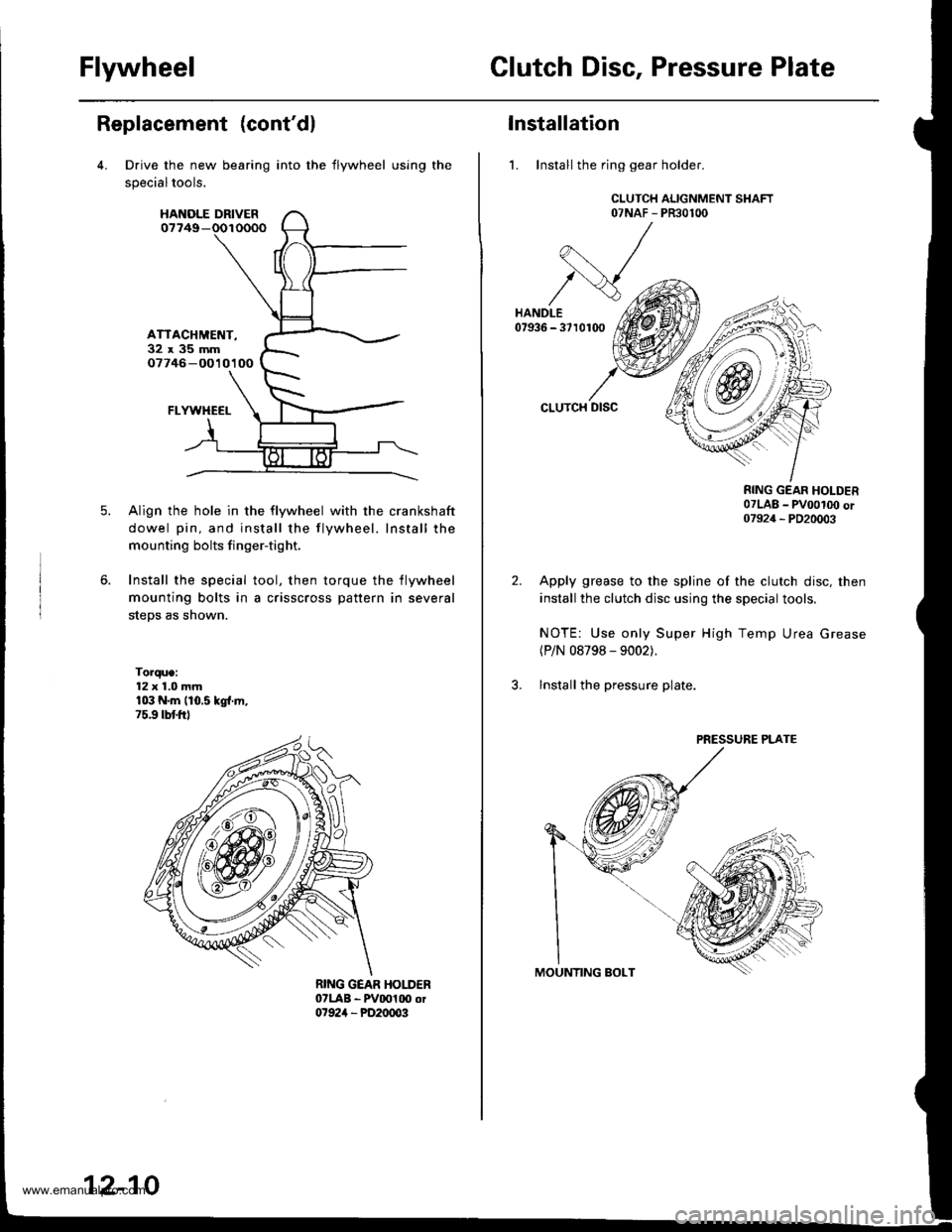

FlywheelClutch Disc, Pressure Plate

Replacement (cont'dl

Drive the new bearing

specialtools.

HANOLE DRIVER07749-

ATTACHMET{T-32x35mm07746 -O010100

FLYWHECI-

Align the hole in the flywheel with the crankshaft

dowel pin, and install the flywheel. Install the

mounting bolts finger-tight.

Install the special tool, then torque the flywheel

mounting bolts in a crisscross pattern in several

steps as shown.

Torque:12 x 1.0 mmr03 N.m (10.5 kgl.ln,75.9 tbtftl

into the flywheel using the

12-10

Installation

1. Install the ring gear holder.

CLUTCH ALIGNMENT SHAFT07NAF - PR30100

CLUTCH DISC

RING GEAR HOLDER07LAB _ pvoot(x) or07924 _ PD20003

Apply grease to the spline of the clutch disc, then

install the clutch disc using the special tools.

NOTE: Use only Super High Temp Urea Grease(P/N 08798 - 9002).

lnstall the pressure plate.

PRESSURE PLATE

www.emanualpro.com

Page 440 of 1395

Manual Transmission

Diff€rential

lndex ...................... ......... 13-38

Backlash Inspestion ..,....,.,.....................,......, 13-38

Final Driven Gear Replacement .................... 13-39

Tapered Roller BearingReplacement ............. 13-39

Bearing Outer Race Replacement ......,.,........ 13-i10

Tapered Roller Bearing PreloadAdiustment ............... 13-il1

Oil Seal Reolacement .................................... 13-/l:}

Transfer Assembly

lllustrated Index ............. 13-il4

Inspection ..,....,.,......,...... 13-46

Disassembly ................... 13-47

Transfer Drive Gear BearingReplacement ...,..................,....................... 13-ilg

Transfer Driven Gear Shaft BearingReplacement .............................................. 13-ilg

Transfer Shaft Disassembly/Reassembly .............. 13-50

Transler Cover A Bearing Outer RaceRep1acement.........,.,.,..........,....,...,.........,., 13-50

Transter Housing Bearing Outer RaceReD1acement.............................................. 13-51

Reassembly ..-............,... 13-52

Mainshaft Bearing/Oil Seal

Beplacement .................. 13-62

Countershaft Bearing

Replacement .,,.,.,., ..,...... 13-63

Mainshaft Thrust Clearance

Adiustment .................... 13-6,1

Transmission Assembly

Reassembly .,.,.,.,..,.,....,., 13-67

fnstaffation .,.,.............,... 13-72

Gearshift Mechanism

Overhaul ................ .........13-17

www.emanualpro.com

Page 441 of 1395

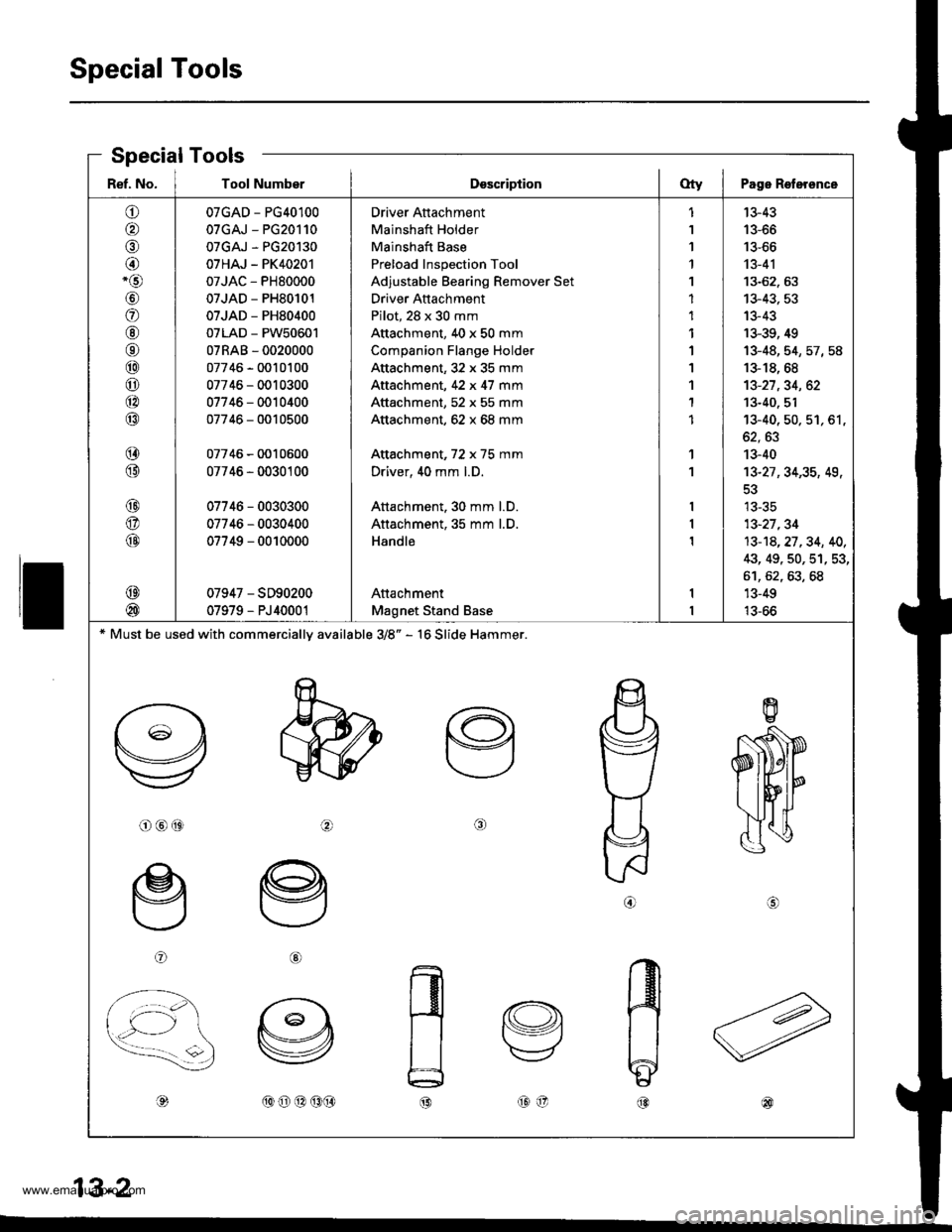

Special Tools

ll

Ref. No. I Tool NumberDsscriptionOty I Page Roterence

o

o,6)

@-o

\9'

a

@6r

@

o

@

@

@

@

@

@

@

@

@

07GAD - PG40100

07GAJ - PG20110

07GAJ - PG20130

07HAJ - PK40201

07JAC - PH80000

07JAD - PH80101

07JAD - PH80400

07LAD - PW50601

07RAB - 0020000

07746 - 0010100

07746 - 0010300

07746 - 0010400

07746 - 0010500

07746 - 0010600

07746 - 0030100

07746 - 0030300

07746 - 0030400

07749 - 0010000

07947 - SD90200

07979 - PJ40001

Driver Attachment

Mainshaft Holder

Mainshaft Base

Preload Inspection Tool

Adjustable Bearing Remover Set

Driver Attachment

Pilot, 28 x 30 mm

Attachment, 40 x 50 mm

Companion Flange Holder

Attachment,32 x 35 mm

Attachment, 42 x 47 mm

Attachment, 52 x 55 mm

Attachment, 62 x 68 mm

Attachment, 72 x 75 mm

Driver, 40 mm l.D.

Attachment. 30 mm l.D.

Attachment, 35 mm l.D.

Handle

Attachment

Magnet Stand Base

1

1

1'l

1

1

1

1

1

1'I

1

1

1

1

13-43

13-66

13-66

13-41

13-62. 63

13-43, 53

13-43

13-39, 49

13-48,54,57,58

13-18, 68

13-27,34, 62

13-40. 51't3-40, 50. 51, 61,

oz, oJ

13-40

13-27 ,34,35, 49,

tJ-5C

13-27,34

13-14,27.34, 40,

43, 49, 50, 51, 53,

61,62,63,68'13-49

13-66

* Must be used with commercially available 3/8" - 16 Slide Hammer.

o@(9ta\

oG)

,d,(oo@(9(}@o@

.A IAa 5-z

Special Tools

www.emanualpro.com