Drive shaft HONDA CR-V 2000 RD1-RD3 / 1.G Owner's Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 448 of 1395

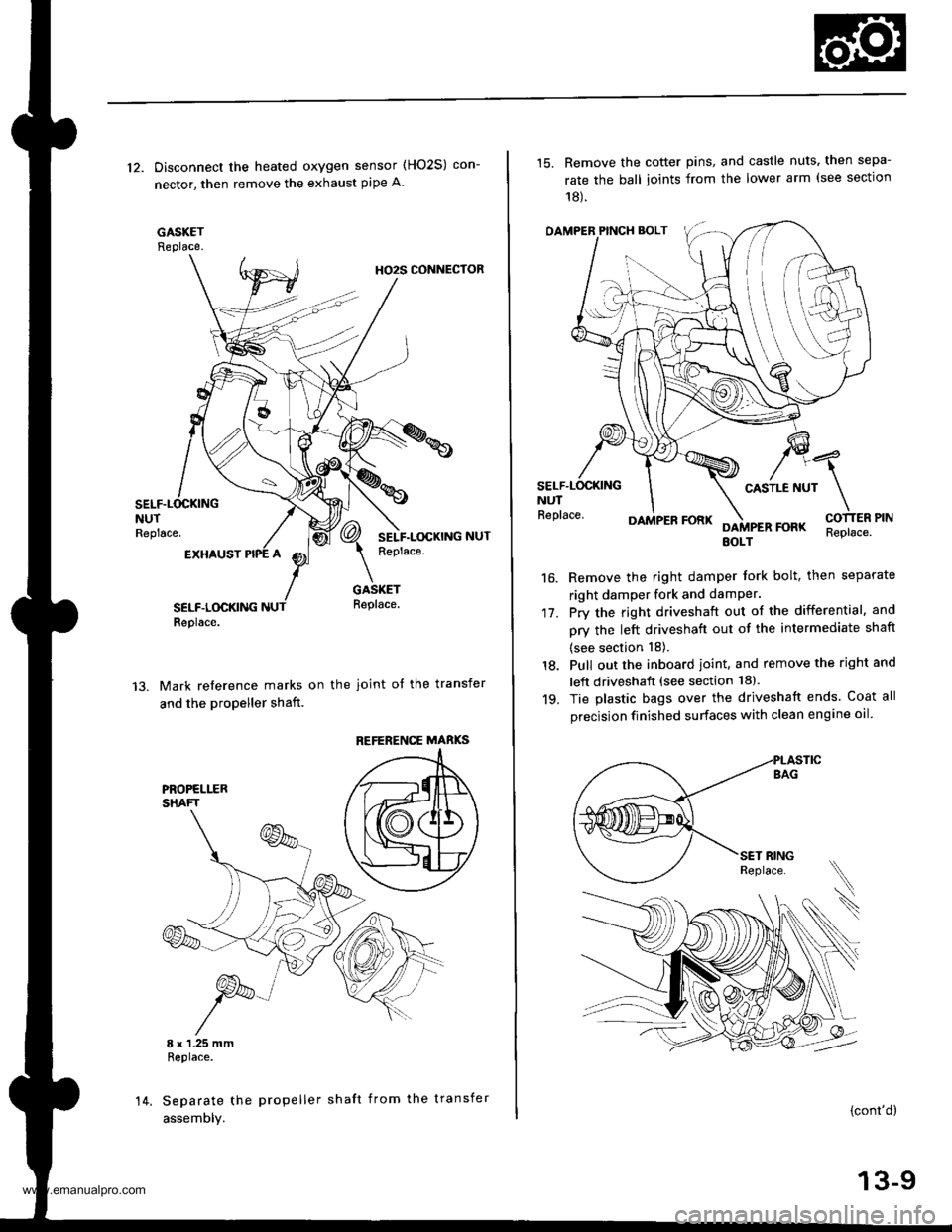

12. Disconnect the heated oxygen sensor (HO2S) con-

nector, then remove the exhaust pipe A.

GASKETReplace.

HO2S CONNECTOR

NUTReplace.

EXHAUST

SELF.LOCKINGReplace.

GASKETReplace.

Mark reference marks on the joint of the transfer

and the propeller shaft.

8 x 1.25 mmReplace.

Separate the propeller shaft from the transfer

assemDly.

REFERENCE MABKS

14.

15. Remove the cotter pins, and castle nuts. then sepa-

rate the ball ioints from the lower arm (see sectlon

18).

OAMPER PINCH BOLT

CASTLE NUTNUTReplace.

17.

16.

DAMPER FORKFOFKEOLTReplace.

Remove the right damper tork bolt, then separate

right damper fork and damPer.

Pry the right driveshaft out of the differential, and

pry the left driveshaft out of the intermediate shaft

(see section 18).

Pull out the inboard ioint, and remove the right and

left driveshaft (see section 18).

Tie plastic bags over the driveshatt ends. Coat all

precision finished surfaces with clean engine oil

18.

19.

\

{cont'd}

13-9

www.emanualpro.com

Page 474 of 1395

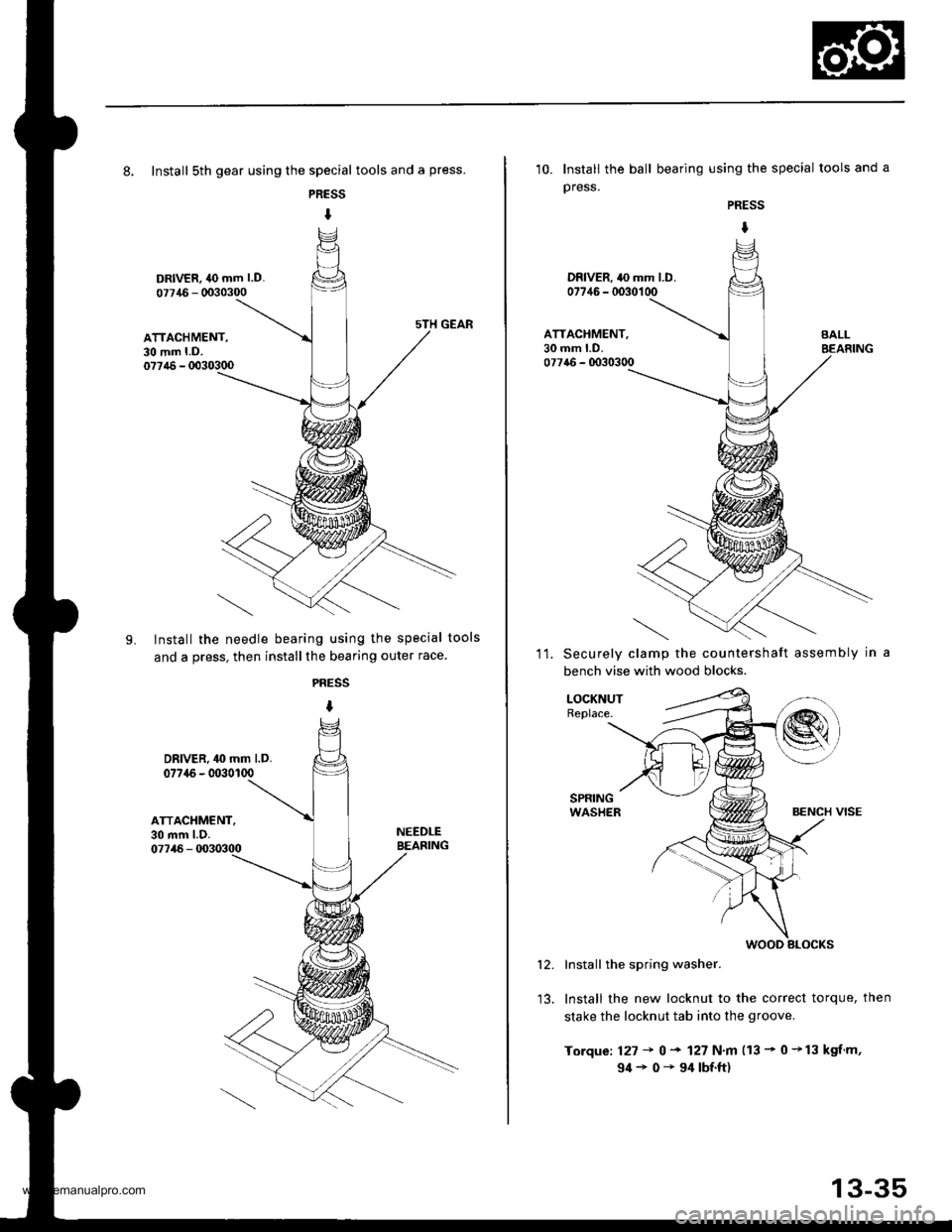

8. Install sth gear using the special tools and a press.

PRESS

I

DRIVER, 40 mm l.D.

07715 - 0030300

ATTACHMENT,30 mm LD.077,16 - 0030300

LInstall the needle bearing using the special tools

and a press, then installthe bearing outer race

PRESS

I

DRIVER. 40 mm l.D.077{6 - 0030100

ATTACHMENT,30 mm l.D.07746 - 0030300

NEEDLEBEASING

10. Install the ball bearing using the special tools and a

press.

PRESS

I

DRIVER. 40 mm LD.07746 - 0030100

ATTACHMENT,30 mm LD.077a6 - 0030300

11.Securely clamp the countershaft assembly in

bench vise with wood blocks.

LOCKNUTReplace.

Install the spring washer.

Install the new locknut to the correct torque, then

stake the locknut tab into the groove.

Torque: 127 + 0 + 127 N.m 113 - 0 +13 kgf.m,

94+0-94|bf.ft)

12.

wooD slocKs

13-35

www.emanualpro.com

Page 480 of 1395

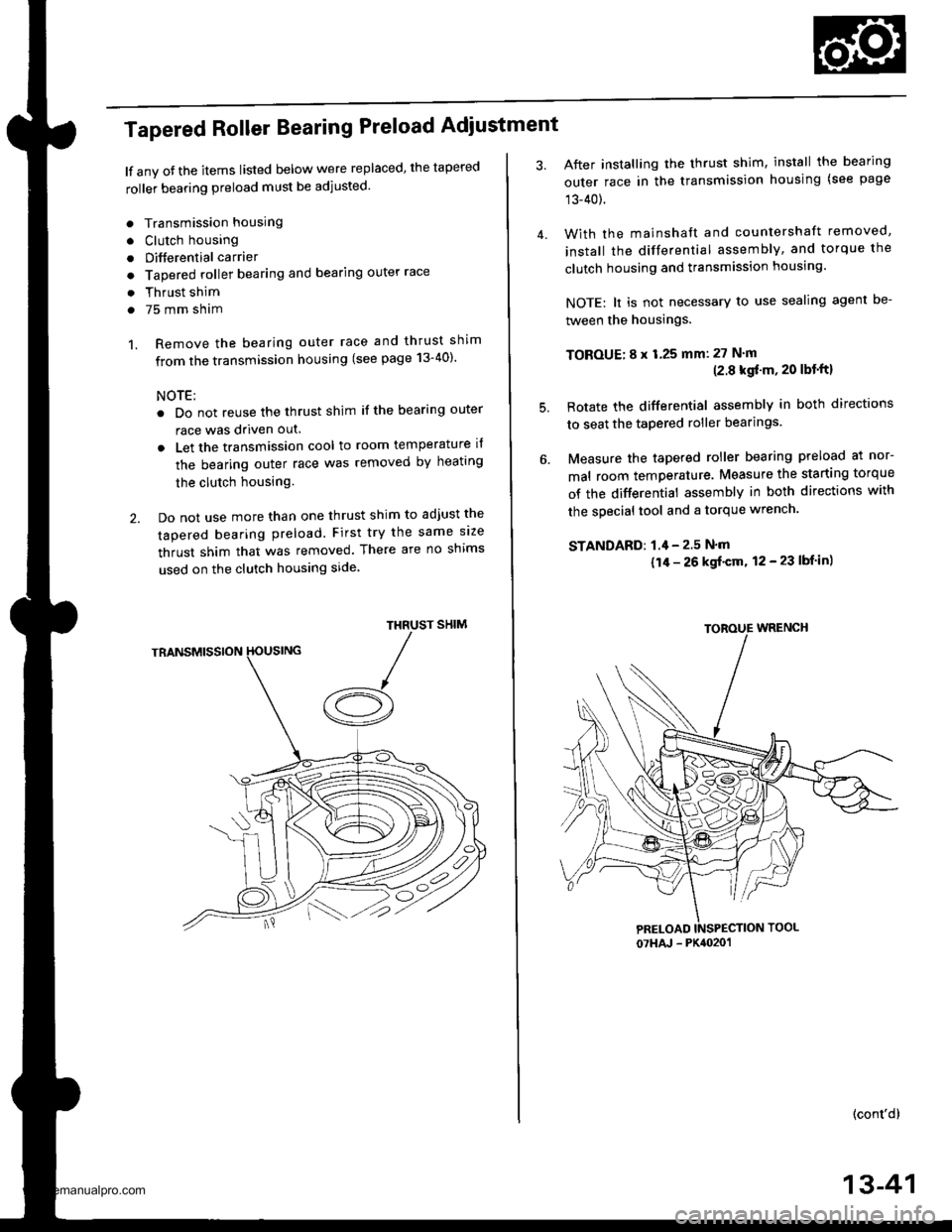

Tapered Roller Bearing Preload Adiustment

lf any oJ the items listed below were replaced, the tapered

roller bearing preload must be adjusted.

. Transmission housing

. Clutch housing

. Differential carrier

o Tapered roller bearing and bearing outer race

. Thrust shim

. 75 mm sham

1. Remove the bearing outer race and thrust shim

from the transmission housing (see page 13-40)'

NOTE:

. Do not reuse the thrust shim if the bearing outer

race was driven out.

. Let the transmission cool to room temperature il

the bearing outer race was removed by heating

the clutch housing.

2. Do not use more than one thrust shim to adjust the

tapered bearing preload. First try the same size

thrust shim that was removed. There are no shims

used on the clutch housing side

SHIMTHRUST

/A

After installing the thrust shim, install the bearing

outer race in the transmission housing (see page

13-40).

With the mainshaft and countershaft removed,

install the differential assembly, and torque the

clutch housing and transmission housing.

NOTE: lt is not necessary to use sealing agent be-

tween the housings.

TOBOUE; 8 x 1.25 mm: 27 N'm(2.8 kgf'm, 20 lbt'ftl

Rotate the differential assembly in both directions

to seat the tapered roller bearings.

Measure the tapered roller bearing preload at nor-

mal room temperature. Measure the starting torque

of the differential assembly in both directions with

the special tool and a torque wrench.

STANDAFD: 1.4 - 2.5 N'm

{1/r - 26 kgf'cm, 12 - 23 lbf in)

(cont'd)

4.

5.

07HAJ - PK4020'�1

13-41

www.emanualpro.com

Page 484 of 1395

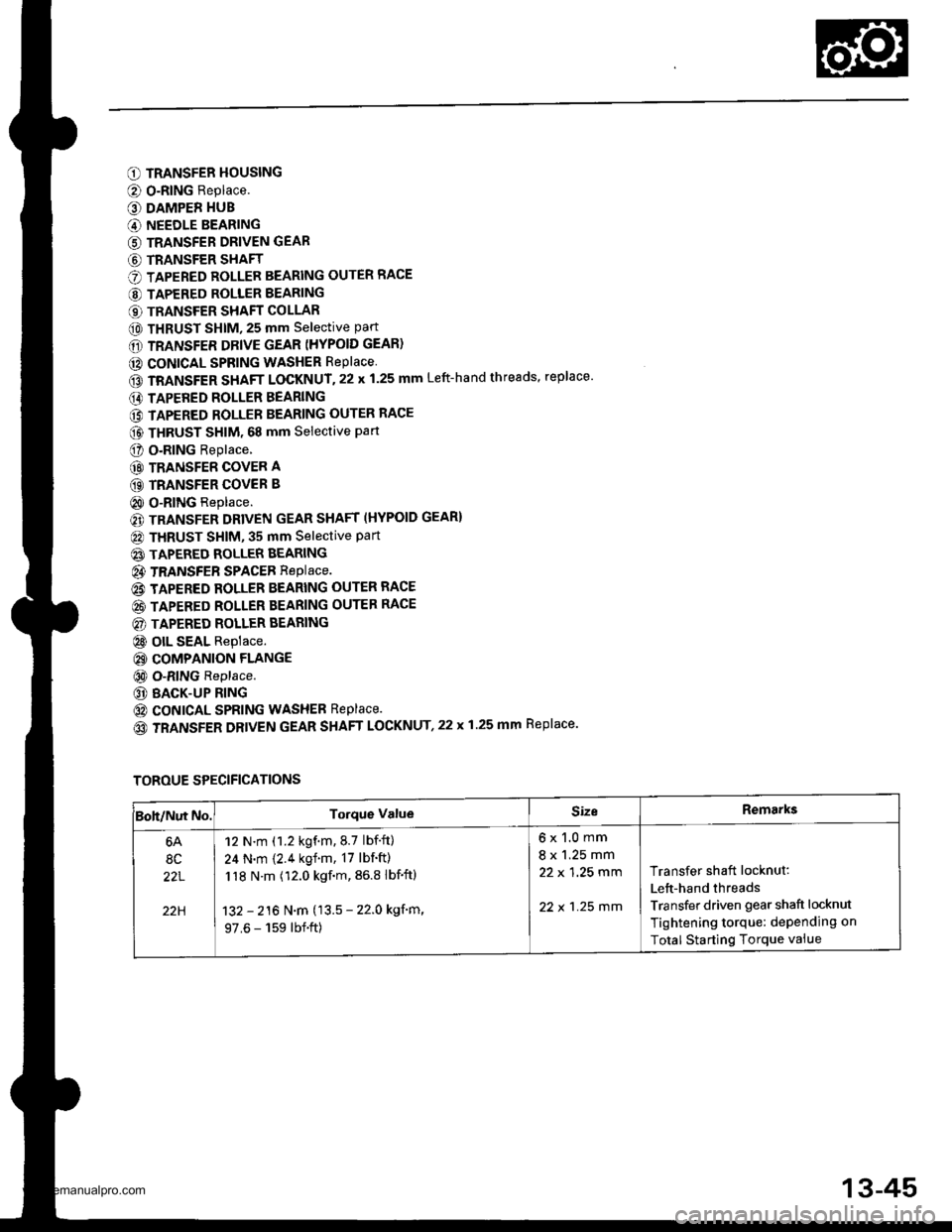

O TRANSFER HOUSING

@ O-RING Replace.

O DAMPER HUB

G) NEEDLE BEARING

G) TRANSFER DRIVEN GEAR

G) TRANSFER SHAFT

O TAPERED ROLLER BEARING OUTER RACE

@ TAPERED ROLLER BEARING

€) TRANSFER SHAFT COLLAR

@ THRUST SHIM, 25 mm selective part

6D TRANSFER DRIVE GEAR (HYPOID GEAR)

@ CONICAL SPRING WASHER RePlace

GD TRANSFER SHAFT LOCKNUT.22 x 1.25 mm Left-hand threads, replace'

E) TAPERED ROLLER BEARING

@ TAPERED ROLLER BEARING OUTER RACE

@ THRUST sHlM. 68 mm selective part

O o.RlNG Replace.

@ TRANSFER COVER A

GD TRANSFER COVER B

@ O-RING Replace.

€) TRANSFER DRIVEN GEAR SHAFT (HYPOID GEAR}

@ THRUST SHIM, 35 mm Selective Part

@ TAPERED ROLLER BEARING

@ TRANSFEB SPACEB RepIace.

@ TAPERED ROLLER BEARING OUTER RACE

@ TAPERED ROLLER BEARING OUTER RACE

@) TAPERED ROLLER BEARING

@ olL SEAL Replace.

@ COMPANION FLANGE

@ O-RING Replace.

@ BACK-UP RING

@ coNtcAL SPRING WASHEB Replace.

(o TRANSFER DRIVEN GEAR SHAFT LOCKNUT,22 x 1.25 mm Replace.

TOROUE SPECIFICATIONS

Boh/Nut No.Torque ValueSizeRemarks

6A

8C

22L

22H

12 N.m (1.2 kgf.m.8.7 lbf.ft)

24 N.m {2.4 kgf.m, 17 lbf'ft)

118 N.m (12.0 kgf.m, 86.8 lbf'ftl

132 - 216 N.m (13.5 - 22.0 kgf'm,

97.6 - 159 lbf.ft)

6x1.0mm

8 x 1.25 mm

22 x 1 ,25 mm

22 x 1 .25 mm

Transfer shaft locknut:

Lett-hand threads

Transfer driven gear shaft locknut

Tightening torque: dePending on

Total Starting Torque vaiue

13-45

www.emanualpro.com

Page 486 of 1395

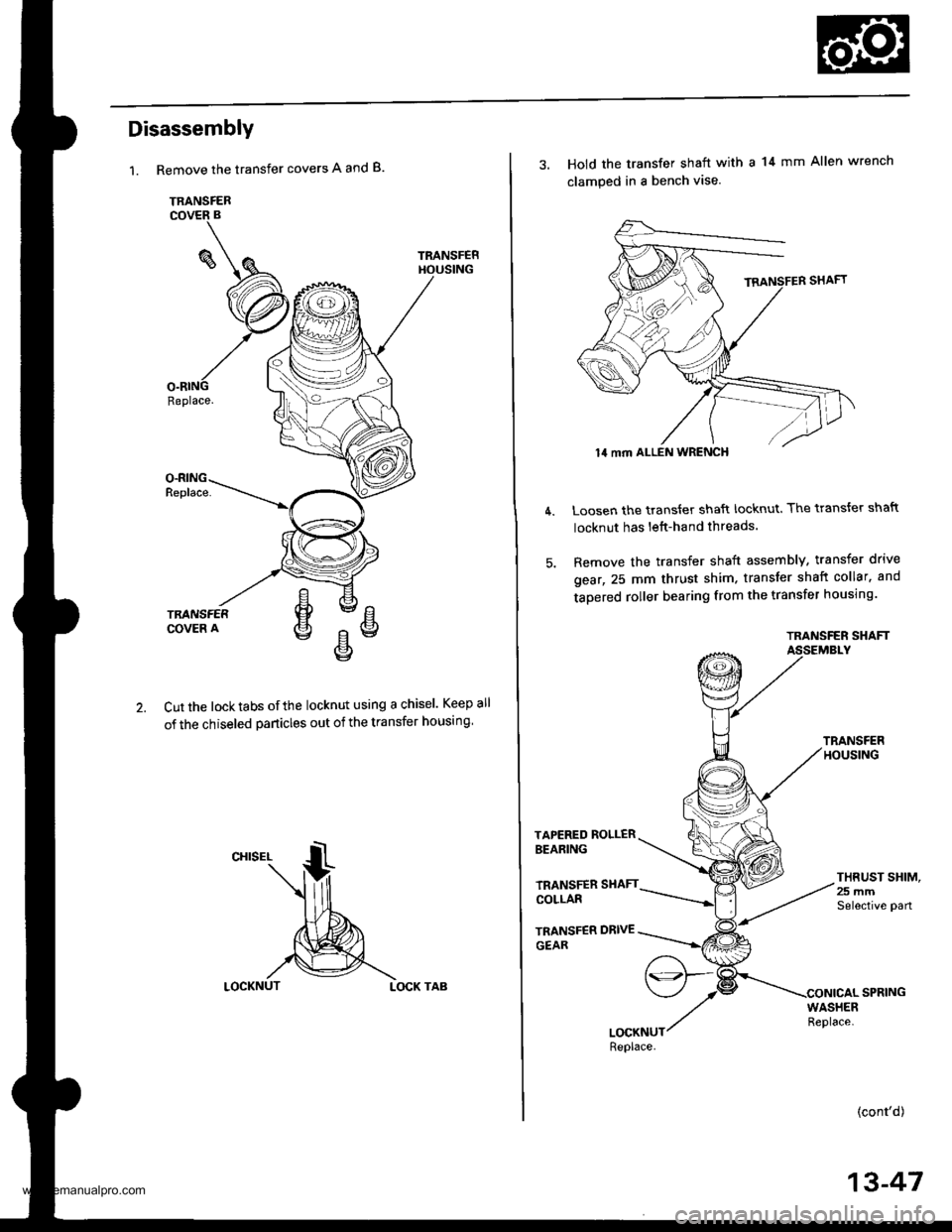

Disassembly

1.Remove the transfer covers A and B.

TRANSFER

TRANSFEF

Replace.

Cut the locktabs ofthe locknut using a chisel. Keep

of the chiseled particles out of the transfer housing

LOCKNUTLOCK TAB

atl

3. Hold the transfer shaft with a 14 mm Allen wrench

clamped in a bench vise.

Loosen the transter shaft locknut. The transfer shaft

locknut has lett-hand threads.

Remove the transfer shaft assembly, transfer drive

gear,25 mm thrust shim. transfer shaft collar. and

tapered roller bearing from the transfer housing.

TRANSFER SHAFTASSEMBLY

TAPERED ROLLERBEARING

TRANSFER SHAFTCOLLAR

TRANSFER DRIVE

GEAR

THRUST SHIM,25 mmSelective pan

(cont'd)

14 mm ALLEN WRENCH

13-47

www.emanualpro.com

Page 487 of 1395

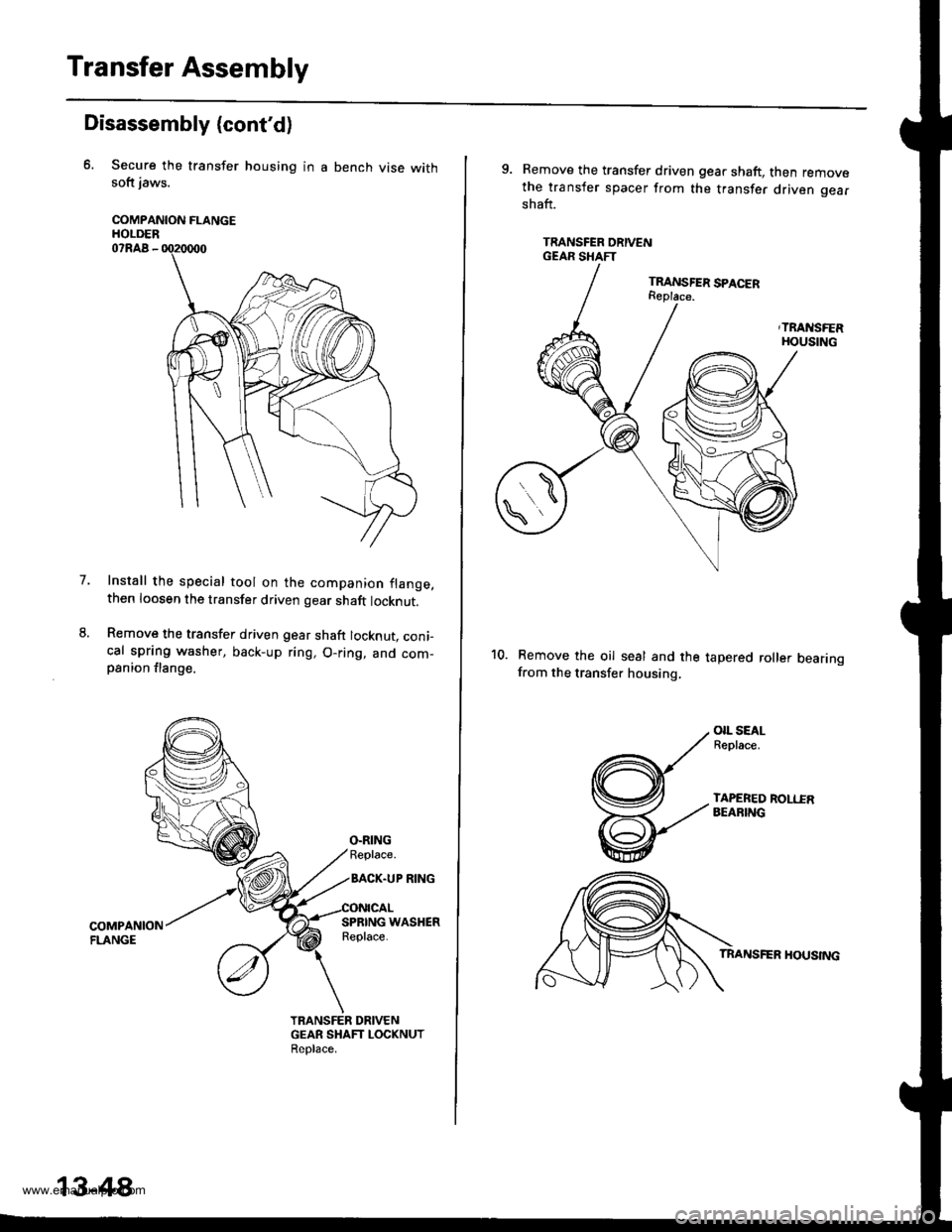

Transfer Assembly

Disassembly (cont'd)

Secure the transfer housing in a bench vise withsoft jaws.

COMPANION FLANGEHOLDER07RAA -

Install the special tool on the companion flange,then loosen the transfer driven gear shaft locknut.

Remove the transfer driven gear shaft locknut, coni-cal spring washer, back-up ring, O-ring, and com-psnion flange.

7.

TRANSFER DRIVENGEAR SHAFT LOCKNUTReolace,

13-48

9. Remove the transfer driven gear shaft, then removethe transfer spacer from the transfer driven gearshaft.

TRANSFER ORIVENGEAR SHAFT

Remove the oil seal and the tapered roller bearingfrom the transfer housing,

OIL SEALReplace.

TAPEREO ROLIIRAEARING

TRANSFER HOUSING

www.emanualpro.com

Page 488 of 1395

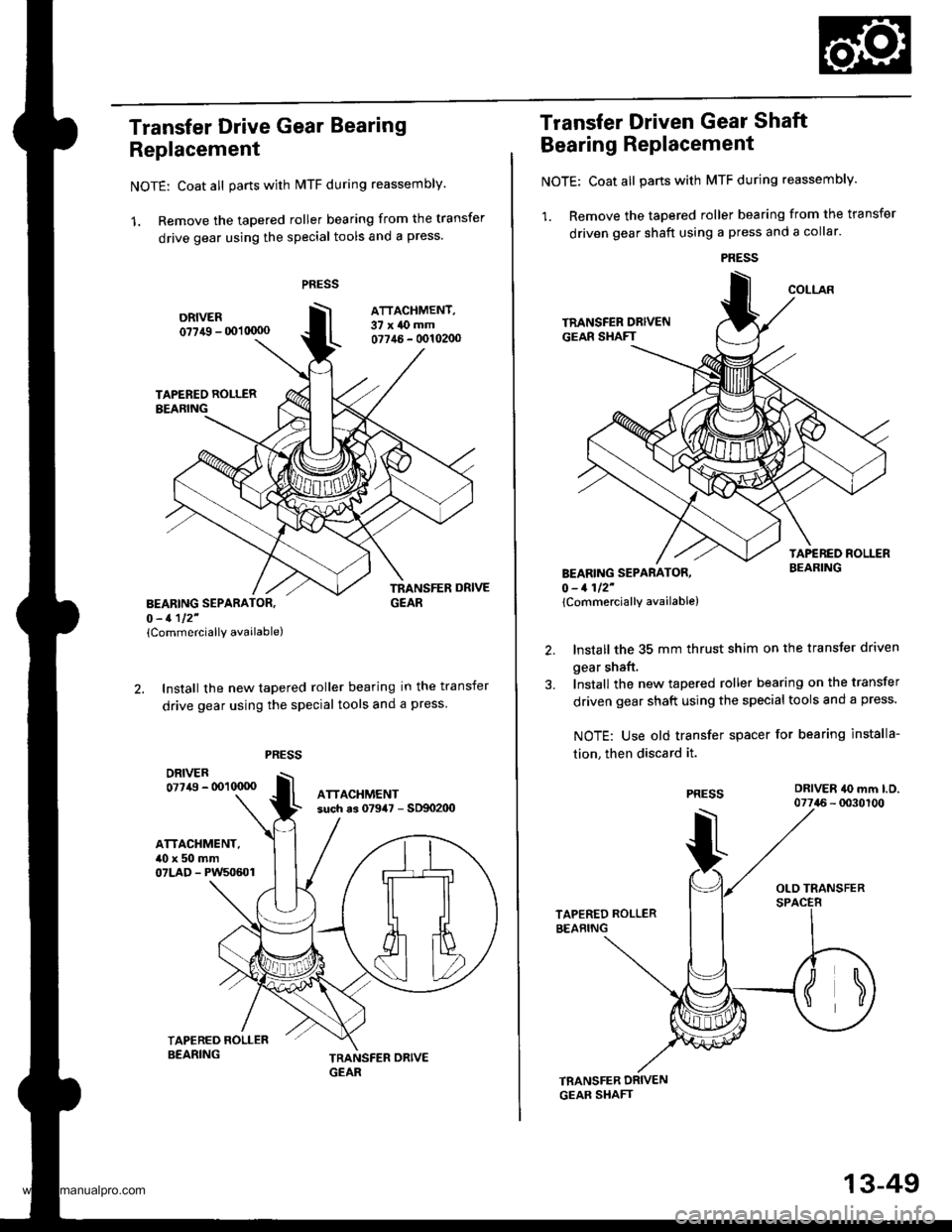

Transfer Drive Gear Bearing

Replacement

NOTE: Coat all parts with MTF during reassembly.

1. Remove the tapered roller bearing from the transfer

drive gear using the special tools and a press.

BEARING SEPARATOR, GEARo - 1112"

{Commercially available)

Install the new tapered roller bearing in the transfer

drive gear using the special tools and a press

ATTACHMENT,40x50mm07LAD - PW5lr601

ATTACHMENT,37x/Omm07746 - 0010200

Transfer Driven Gear Shaft

Bearing Replacement

NOTE: Coat all parts with MTF during reassembly.

1. Remove the taDered roller bearing from the transfer

driven gear shaft using a press and a collar.

BEARING SEPARATOR,0 - 1112'

lCommercially available)

lnstall the 35 mm thrust shim on the transter driven

gear shaft.

Install the new tapered roller bearing on the transfer

driven gear shaft using the special tools and a press.

NOTE: Use old transfer spacer for bearing installa-

tion, then discard it.

DRIVER 40 mm l.D.07746 - 0030r00

13-49

www.emanualpro.com

Page 489 of 1395

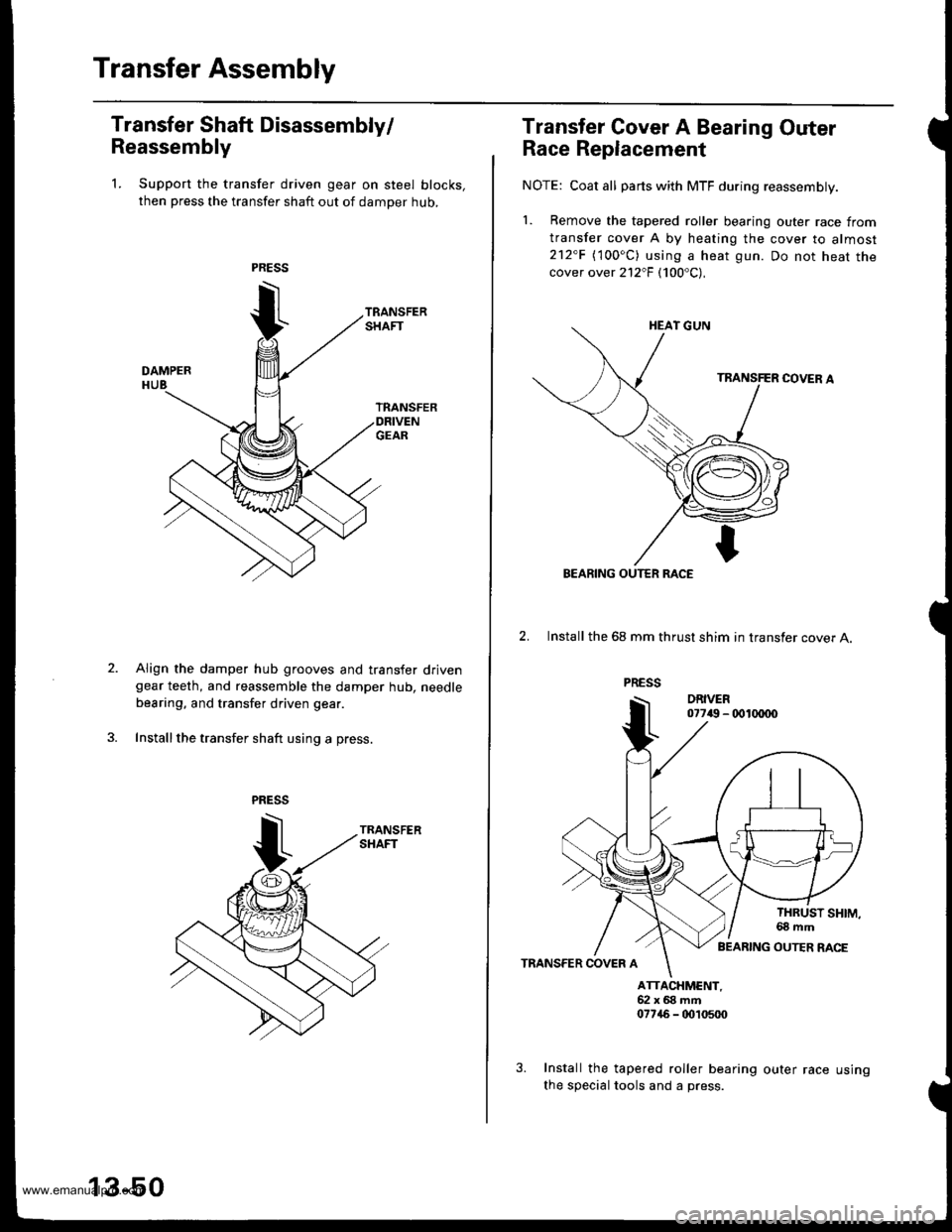

Transfer Assembly

Transfer Shaft Disassembly/

Reassembly

1. Support the transfer driven gear on steel blocks,

then press the transfer shaft out of damper hub,

Align the damper hub grooves and transfer drivengear teeth, and reassemble the damper hub. needle

bearing, and transfer driven gear.

Install the transfer shaft using a press.

13-50

us Ing

Transfer Gover A Bearing Outer

Race Replacement

NOTE: Coat all parts with MTF during reassembly.

1. Bemove the tapered roller bearing outer race from

transfer cover A by heating the cover to almost212"F (100oC) using a heat gun. Do not heat thecover over 212"F (100'C),

2. Install the 68 mm thrust shim in transfer cover A.

TRANSFER COVER A

ATTACXMCNT,52x68mft07746 - tD,t0500

Install the tapered roller bearing outer race

the special tools and a press.

BEARING OUTER RACE

BEARING OUTER RACE

www.emanualpro.com

Page 491 of 1395

Transfer Assembly

Reassembly

Note these items during reassembly:. While reassembling the transfer assembly:- Check and adjust the transfer gear tooth contact.- Measure and adjust the transfer gear backlash.- Check and adjust the tapered roller bearing start-Ing rorque.

. Coat all parts with MTF during reassembly.. Replace the tapered roller bearing and the bearingouter race as a set if either part is replaced.. Replace the transfer drive gear and the transfer dri-ven gear shaft as a set if either part is replaced,

Outline of Assembly

1.Select the 35 mm thrust shim.

Perform this procedure if the transler driven gear

shaft or the tapered roller bearing on the transferdriven gear shaft is replaced.

Preassemble the parts to check and adjust transfergear backlash and transfer gear tooth contact.

Disassemble the parts, then assemble the transferdriven gear shaft and its related parts.

4. Measure and adjust the staning torque of the trans-fer driven gear shaft tapered roller bearing.

5. Assemble the transfer shaft and jts related parts.

6. Measure and adjust the total starting torque.

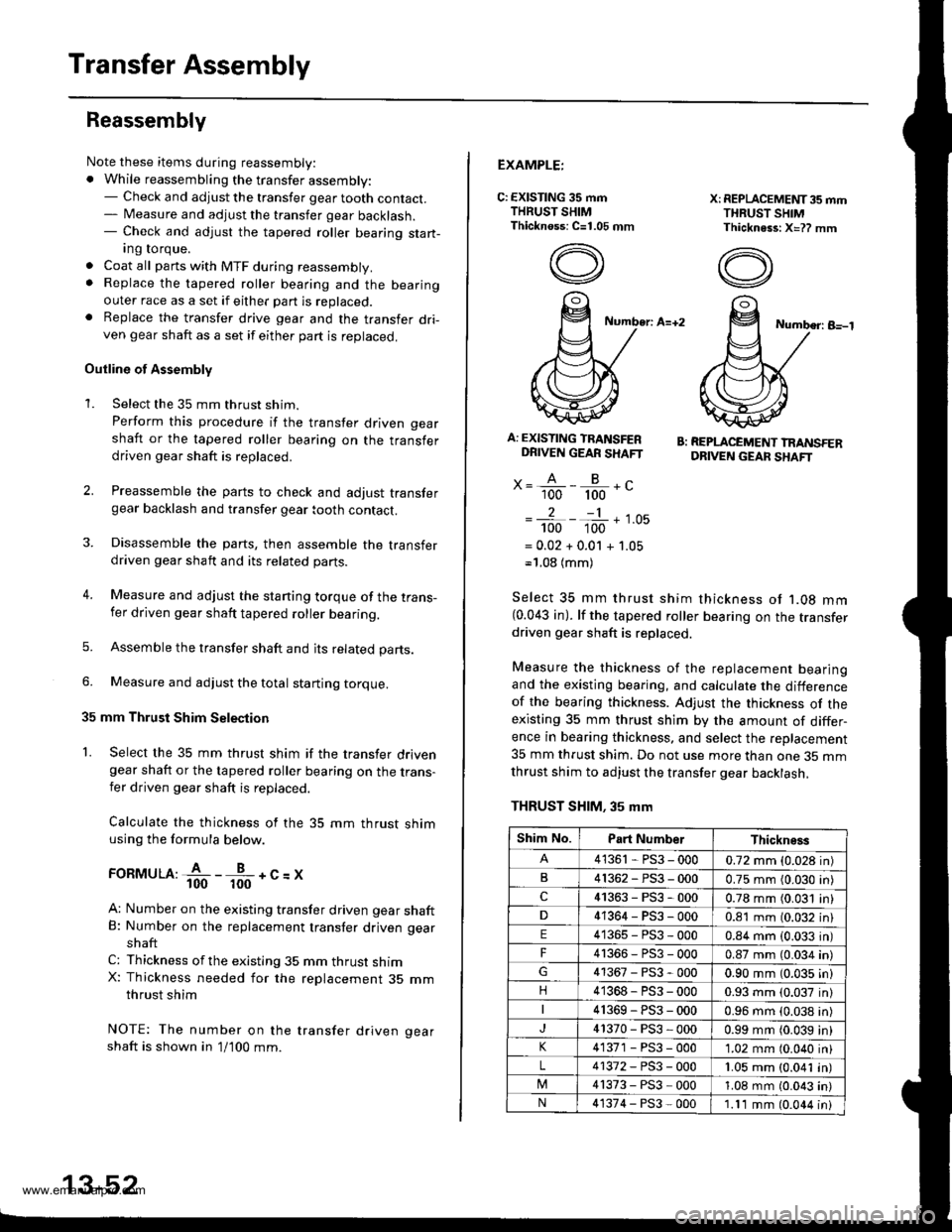

35 mm Thrust Shim Seleqtion

1. Select the 35 mm thrust shim if the transfer drivengear shaft or the tapered roller bearing on the trans-fer driven gear shaft is replaced.

Calculate the thickness of the 35 mm thrust shimusing the formula below.

ronrvruu:fi--fr-+c=x

A: Number on the existing transfer driven gear shaftB: Number on the replacement transfer driven gear

shaft

C: Thickness ofthe existing 35 mm thrust shimX: Thickness needed for the replacement 35 mmthrust shim

NOTE: The number on the transfer driven gear

shaft is shown in 1/100 mm.

2.

3.

13-52

EXAMPLE:

C: EXISTING 35 mmTHRUST SHIMThicknoss: C=1.05 mm

X: REPLACEMET{T35 mmTHRUST SHIMThickness: X=?? mm

Number: A=+2Number: B-l

A: EXISTING TRANSFERDRIVEN GEAR SHAFT

x= A - B -.'- 100 100 -

2-1

100 100 '-

= 0.02 + 0.01 + 1.05-'1.08 (mm)

B: REPLACEMENT TRANSFERDRIVEN GEAF SHAFT

Select 35 mm thrust shim thickness ot '1.08 mm(0.043 in). lf the tapered roller bearing on the transferdriven gear shaft is replaced.

Measure the thickness of the replacement bearingand the existing bearing, and calculate the differenceof the bearing thickness. Adjust the thickness of theexisting 35 mm thrust shim by the amount of differ-ence in bearing thickness. and select the replacement

35 mm thrust shim. Do not use more than one 35 mmthrust shim to adjust the transfer gear backlash,

THRUST SHIM. 35 mm

Shim No.Part NumberThickness

41361 - PS3 - 0000.72 mm (0.028 in)

B41362-PS3-0000.75 mm (0.030 in)

c41363-PS3-0000.78 mm (0.031 in)

41364-PS3-0000.81 mm (0.032 in)

E41365-PS3-0000.84 mm (0.033 in)

F4r366-PS3-0000.87 mm (0.034 in)

41367-PS3-0000.90 mm (0.035 in)

n41368-PS3-0000.93 mm (0.037 in)

41369-PS3-0000.96 mm {0.038 in)

41370-PS3-0000.99 mm (0.039 in)

41371 - PS3 - 0001.02 mm (0.040 in)

L41372-PS3-0001.05 mm (0.041 in)

41373-PS3-0001.08 mm (0.043 in)

N41374-PS3-0001.11 mm (0.044 in)

www.emanualpro.com

Page 492 of 1395

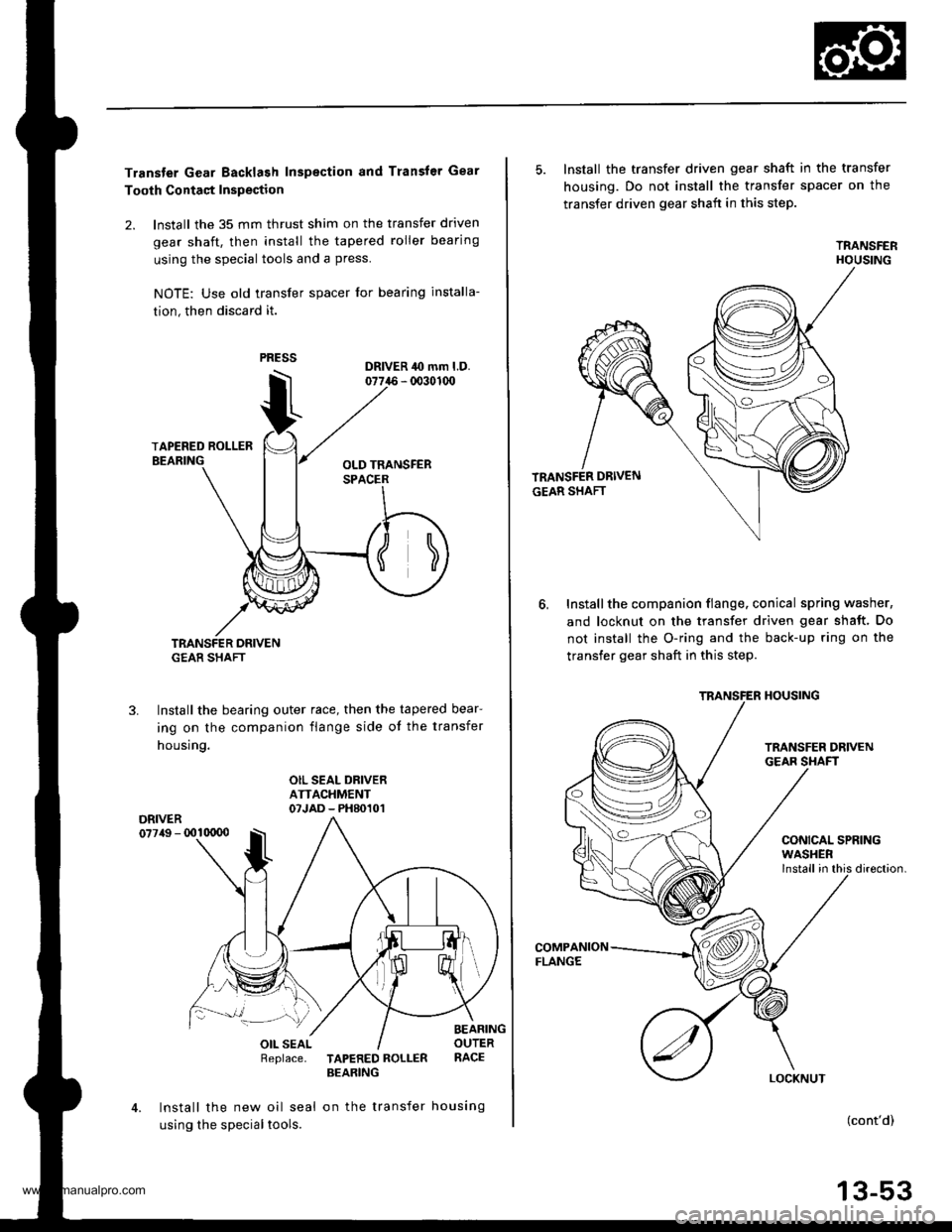

Transter Gear Backlash Inspection and Transfer Gear

Tooth Contaqt Inspection

2. lnstall the 35 mm thrust shim on the transfer driven

gear shaft, then install the tapered roller bearing

using the special tools and a press.

NOTE: Use old lransfer spacer for bearing installa-

tion, then discard it.

TRANSFER DRIVENG€AR SHAFT

Install the bearing outer race, then the tapered bear-

ing on the companion flange side ot the transfer

housing.

3.

OIL SEAL DRIVERATTACHMENT07JAD - PH80101DRIVER077/tg - 001qt00

Replace.TAPERED ROLLERBEARING

Install the new oil seal on the transfer housing

using the special tools.

5. Install the transfer driven gear shaft in the transfer

housing. Do not install the transfer spacer on the

transfer driven gear shaft in this step.

TRANSFERHOUSING

Installthe companion flange. conical spring washer,

and locknut on the transfer driven gear shaft. Do

not install the O-ring and the back-up ring on the

transfer gear shaft in this step.

6,

COMPANIONFLANGE

CONICAL SPRING

direction.

(cont'd)

13-53

TRANSFER HOUSING

WASHER

www.emanualpro.com