Oil pan HONDA CR-V 2000 RD1-RD3 / 1.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 677 of 1395

Pressure Testing

Changing

NOTE: Keep all foreign particles out of the transmis-

sion.

1. Bring the transmission up to operating temperature

(the radiator fan comes on) by driving the vehicle.

Park the vehicle on level ground. turn the engane

off. then remove the drain Plug.

NOTE: lf a cooler flusher is to be used, see page

14-264 and 14-265.

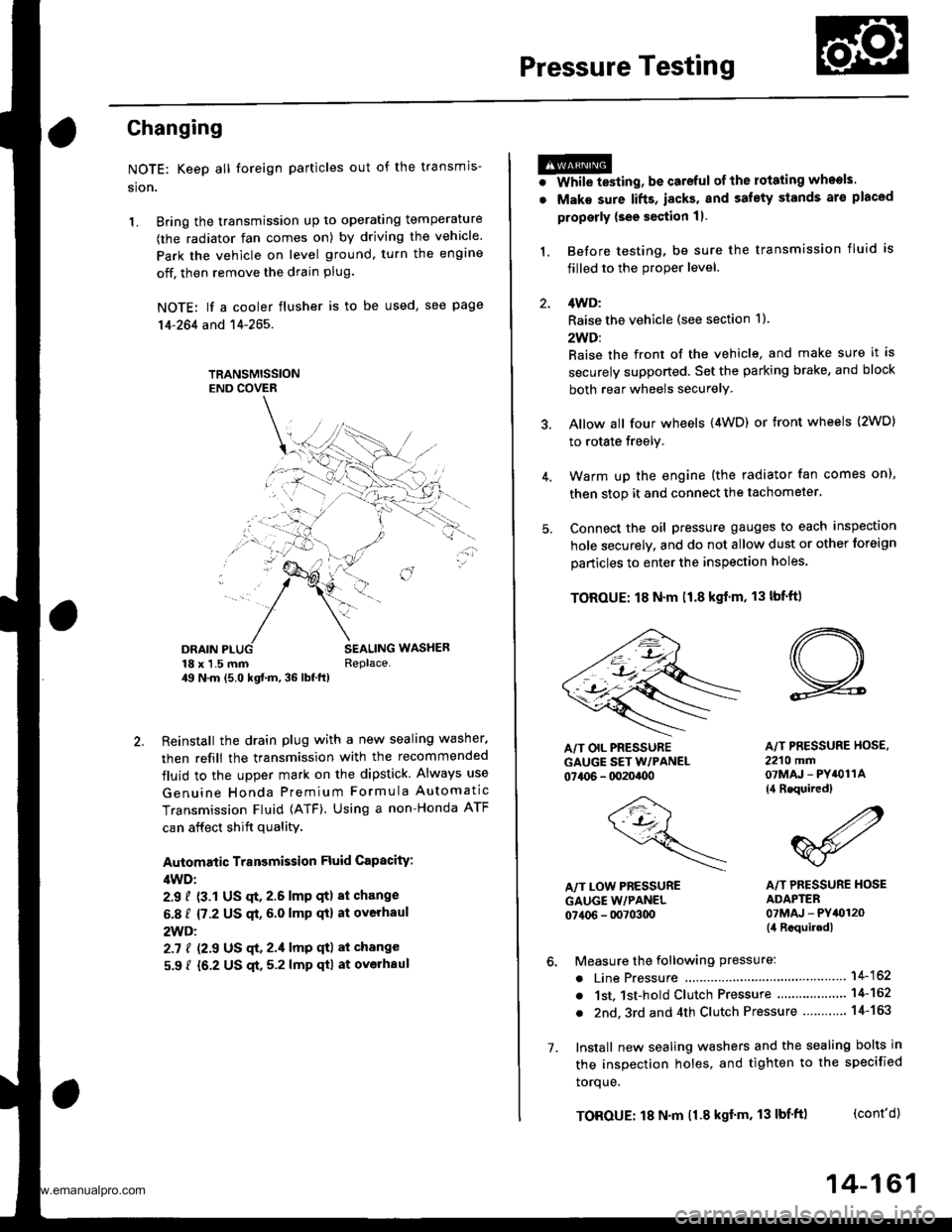

TRANSMISSIONEND COVER

DRAIN18 x 1.5 mmSEALING WASHEBReplace.49 N.m {5.0 kgt.m, 36 lbf.tl)

Reinstall the drain plug with a new sealing washer,

then refill the transmission with the recommended

fluid to the uDper mark on the dipstick. Always use

Genuine Honda Premium Formula Automatic

Transmission Fluid (ATF) Using a non-Honda ATF

can affect shift quality.

Automatic Transmission Fluid Capacity:

4WD;

2.9 { (3.1 US qt. 2.6 lmp qt) 8t change

5.8 ? {7.2 US $, 6.0 lmp qt} at ovethaul

2WD:

2.7 | l2.S US qt,2.1lmp qtl ai change

5.9 ? {6.2 US $, 5.2 lmp qtl at ovolhaul

2.

a

a

1.

Wlrile testing, be careful of the rotaling wheols.

Mako sure lifts, iacks, and safety stands ar€ placed

properly (see scction 11.

Before testing, be sure the transmission fluid is

filled to the proPer level.

4WD:

Raise the vehicle (see section 11.

2WD:

Raise the front of the vehicle, and make sure it is

securely supported. Set the parking brake, and block

both rear wheels securely.

Allow all four wheels {4WD) or front wheels (2wD}

to rotate freely.

Warm up the engine (the radiator fan comes on),

then stop it and connect the tachometer.

Connect the oil pressure gauges to each inspection

hole securely, and do not allow dust or other foreign

particles to enter the inspection holes.

TOROUE: 18 N'm ll.8 kgf'm, 13 lbf'ft)

5.

A/T PRESSURE HOS€,2210 mm07MAJ - PYiOllA

{4 Requircd}

,4'/"' ,a

W'

A/T PRESSURE HOSEADAPTER07MAJ - PYt0120(il Rcquiledl

6. Measure the following Pressure:. Line Pressure ..........,14-162

. 1st. 1st-hold Clutch Pressure .............'. 14-162

. 2nd,3rd and 4th Clutch Pressure .......... 14-163

7. Install new sealing washers and the sealing bolts in

the inspection holes, and tighten to the specified

toroue.

(cont'd)

A/T OIL PRESSUREGAUGE SET W/PANEL07{06 - 0020400

/4\\-J-- (

+..\.-.\-'-\

A/T LOW PBESSUREGAUGE w/PANEL07406 - 0070300

TOROUE: 18 N'm 11.8 kgf'm, 13 lbf'ft)

14-161

www.emanualpro.com

Page 680 of 1395

Transfer

4.

Inspection

@E Mako suro lifts, jacks, and safety standsare placod properly lsoe section t).

1. Raise the front of the vehicle, and make sure it issupported securely.

2. Set the parking brake, and block both rear wheelssecurely.

Shift to E position.

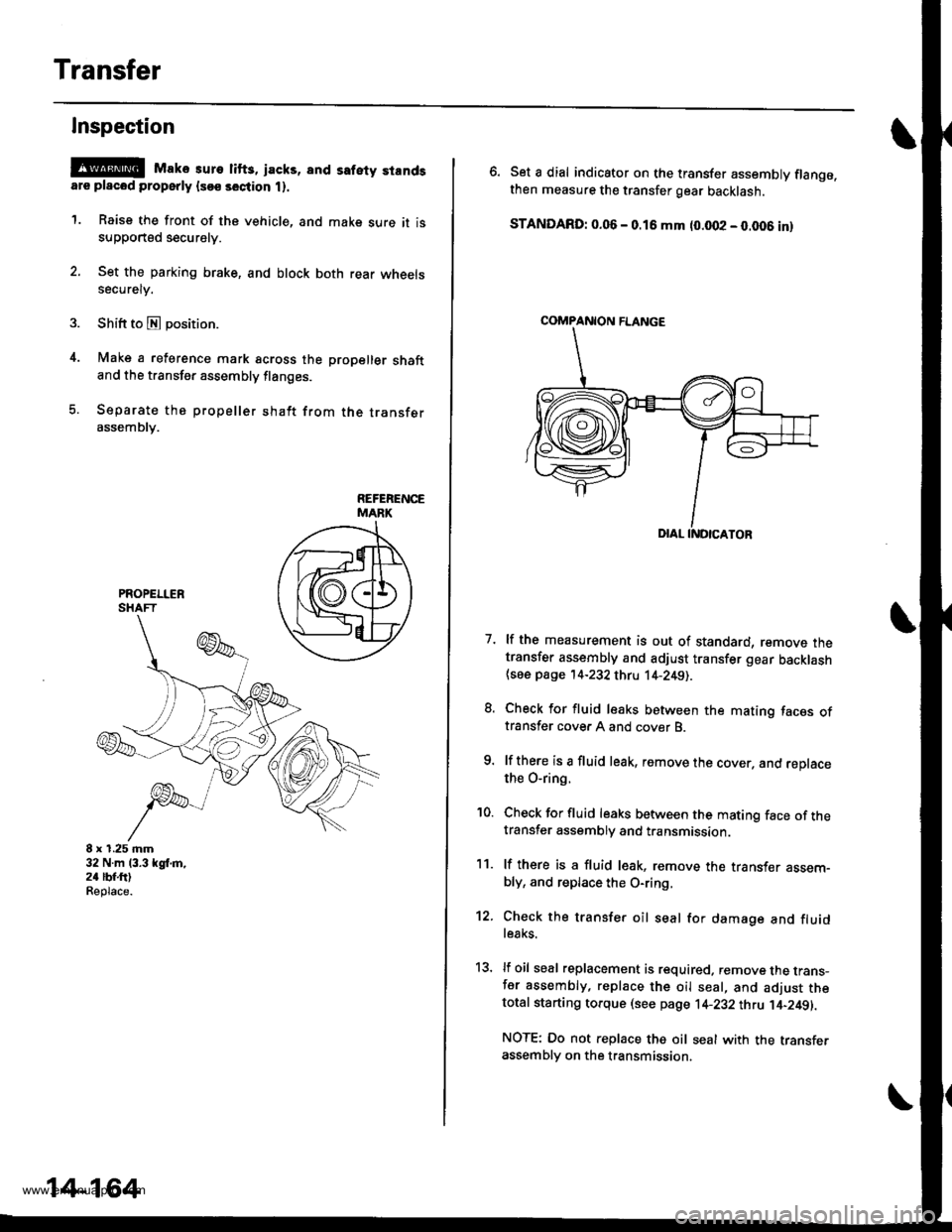

Make a reference mark across the propeller shaftand the transfer assembly flanges.

Separate the propeller shaft from the transferassembly.

8 x 1.25 mm32 N.m 13.3 kgl,m,24 lbf.ftlReplace.

14-164

\

6. Set a dial indicator on the transfer assembly flange.then measure the transfer gear backlash.

STANDARD: 0.06 - 0.16 mm (0.002 - 0.006 inl

7. lf the measurement is out of standard, remove thetransfer assembly and adjust transfer gear backlash{see page '14-232 thru 14-2491.

8. Check for fluid leaks between the mating faces oftransfer cover A and cover B.

9. lf there is a fluid leak, remove the cover, and reDlacethe O-ring.

'10. Check for fluid leaks between the mating face of thetransfer assembly and transmission.

11. lf there is a fluid l€ak, remove the transf€r assem-bly, and replace the O-ring,

12. Check the transfer oil seal for damage and fluidle8ks.

13, lf oil seal replacement is required. remove the trans-fer assembly, replace the oil seal, and adjust thetotal starting torque (see page 1+232 thtu ]'4-249||.

NOTE: Do not replace the oil seal with the transferassembly on the transmission.

COMPANION FLANGE

www.emanualpro.com

Page 699 of 1395

oatl,6

@!.,

ao6l

@o@@@@@o@@@)@@@@@@@@@@)

@@@@)@@@@@@@

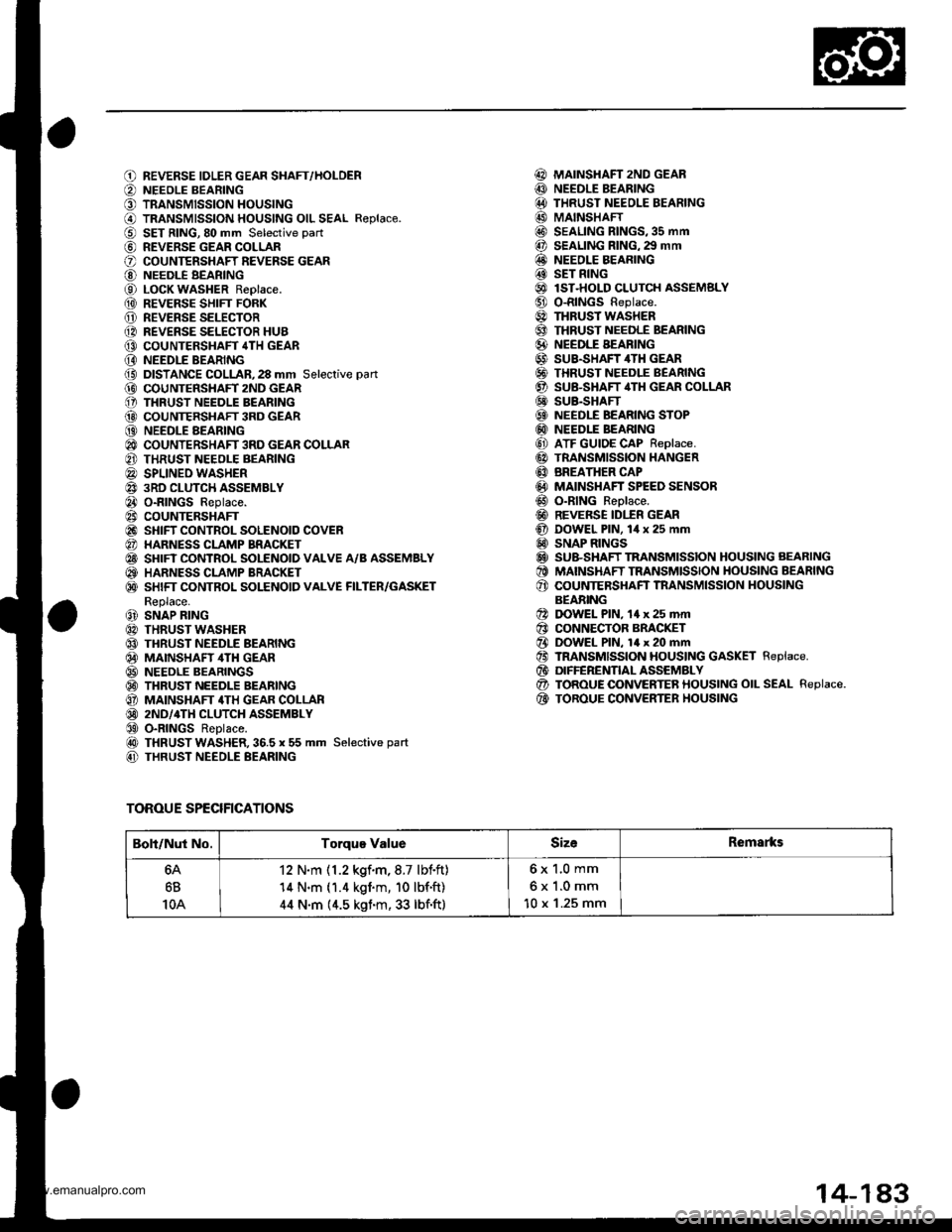

REVERSE IDLER GEAR SHAFT,/HOLDERNEEOLE BEARINGTRANSMISSION HOUSINGTRANSMISSION HOUSING OIL SEAL R€place.SET RING,80 mm Selective part

REVERSE GEAR COLLARCOUNTERSHAFT REVERSE GEARNEEDLE BEARINGLOCK WASHER Replace.REVERSE SHIFT FORKREVERSE SELECTORREVERSE SELECTOR HUBCOUNTERSHAFT 4TH GEARNEEDLE BEARINGDISTANCE COLLAR,28 mm Selective pan

COUNTERSIIAFT 2ND GEARTHRUST NEEDLE BEARINGCOUNTERSHAFT 3RD GEARNEEDLE AEARINGCOUNTERSHAFT 3RD GEAR COLLARTHRUST NEEOLE BEARINGSPLINEO WASHER3RD CLUTCH ASSEMBLYO-RINGS Replace.COUNTERSHAFTSHIFT CONTROL SOLENOID COVERHARNESS CLAMP BRACKETSHIFT CONTROL SOLENOID VALVE A/B ASSEMBLYHARNESS CLAMP BRACKETSHIFT CONTROL SOLENOID VALVE FILTER/GASKETReplace.SNAP RINGTHRUST WASHERTHRUST NEEDLE BEARINGMAINSHAF ,ITH GEARNEEDLE BEARINGSTHRUST NEEDLE BEARINGMAINSHAFT 4TH GEAR COLLAR2ND/4TH CLUTCH ASSEMBLYO-RINGS ReDlace.THRUST WASHER,36.5 x 55 mm Selective part

THRUST NEEDLE BEARING

MAINSHAFT 2ND GEARNEEDLE BEARINGTHRUST NEEOLE BEARINGMAINSHAFTSEALING RINGS,35 mmSEALING RING. 29 mmNEEDLE BEARINGSET RINGlST-HOLD CLUTCH ASSEMSLYO-RINGS Replace.THRUST WASHERTHRUST NEEDLE BEARINGNEEDLE BEARINGSUB.SHAFT 4TH GEARTHRUST NEEDLE BEARINGSU&SHAFT,ITH GEAR COLLARSUB.SHAFTNEEDLE BEARING STOPNEEDLE BEARINGATF GUIDE CAP Replace.TRANSMISSION HANGERBREATHER CAPMAINSHAFT SPEED SENSORO-RING Reolace.REVERSE IDI.fR GEARDOWEL PlN, lil x 25 mmSNAP RINGSSU&SHAFT TRANSMISSION HOUSING AEARINGMAINSHAFT TRANSMISSION HOUSING BEARINGCOUNTERSHAFT TNANSMISSION HOUSINGBEABINGDOWEL PlN, 14 x 25 mrnCONNECTOR BRACKETDOWEL PlN, 14 x 20 mmTRANSMISSION HOUSING GASKET Replace.DIFFERENTIAL ASSEMBLYTOROUE OONVERTER HOUSING OIL SEAL Replace.TOROUE CONVERTER HOUSING

@@@@@@@@@@@@@@@@@@@@@@@)@@@@@@@

@@@@@@@

TOROUE SPECIFICATIONS

Boli/Nut No.Torque ValueSizeRemarks

6B

10A

12 N.m (1.2 kgf.m,8.7 lbf.ft)'14 N.m (1.4 kgim, 10 lbf'ft)

44 N.m (4.5 kgim, 33 lbf.ft)

6x 1.0 mm

6x1.0mm

10 x '1.25 mm

14-1A3

www.emanualpro.com

Page 752 of 1395

Transfer Assembly

Disassembly (cont'd)

7.

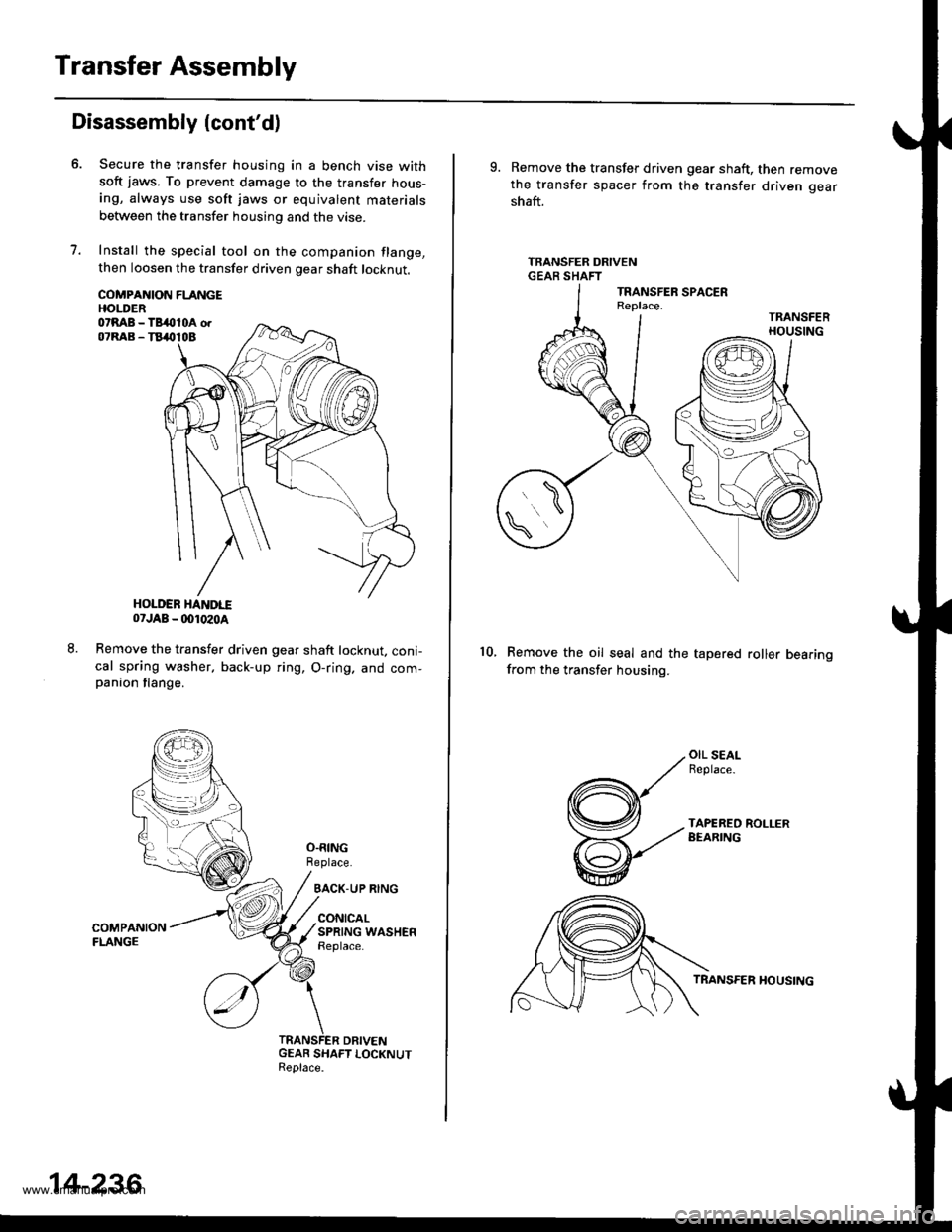

Secure the transfer housing in a bench vise withsoft iaws. To prevent damage to the transfer hous-ing, always use soft jaws or equivalent materials

between the transfer housing and the vise.

Install the special tool on the companion flange,then loosen the transfer driven gear shaft locknut.

COMPANION FLANGEHOI.DER07RAB - TB4lll0A orOTRAB - TB&TOB

HOLDER HAITDI..E07JAB _ (x)1020a

Remove the transfer driven gear shaft locknut, coni-cal spring washer, back-up ring, O-ring. and com-panion flange.

O.RINGReplace.

BACK-UP RING

CONICALSPRING WASHENReplace.

GEAR SHAFT LOCKNUTReplace.

14-236

9. Remove the transfer driven gear shaft, then removethe transfer spacer from the transfer driven gear

shaft.

TRANSFER DRIVENGEAR SHAFT

Remove the oil seal and the tapered roller bearingfrom the transfer housing.

10.

OIL SEALFeplace-

TAPEREO ROLLERBEARING

TRANSFER HOUSING

www.emanualpro.com

Page 757 of 1395

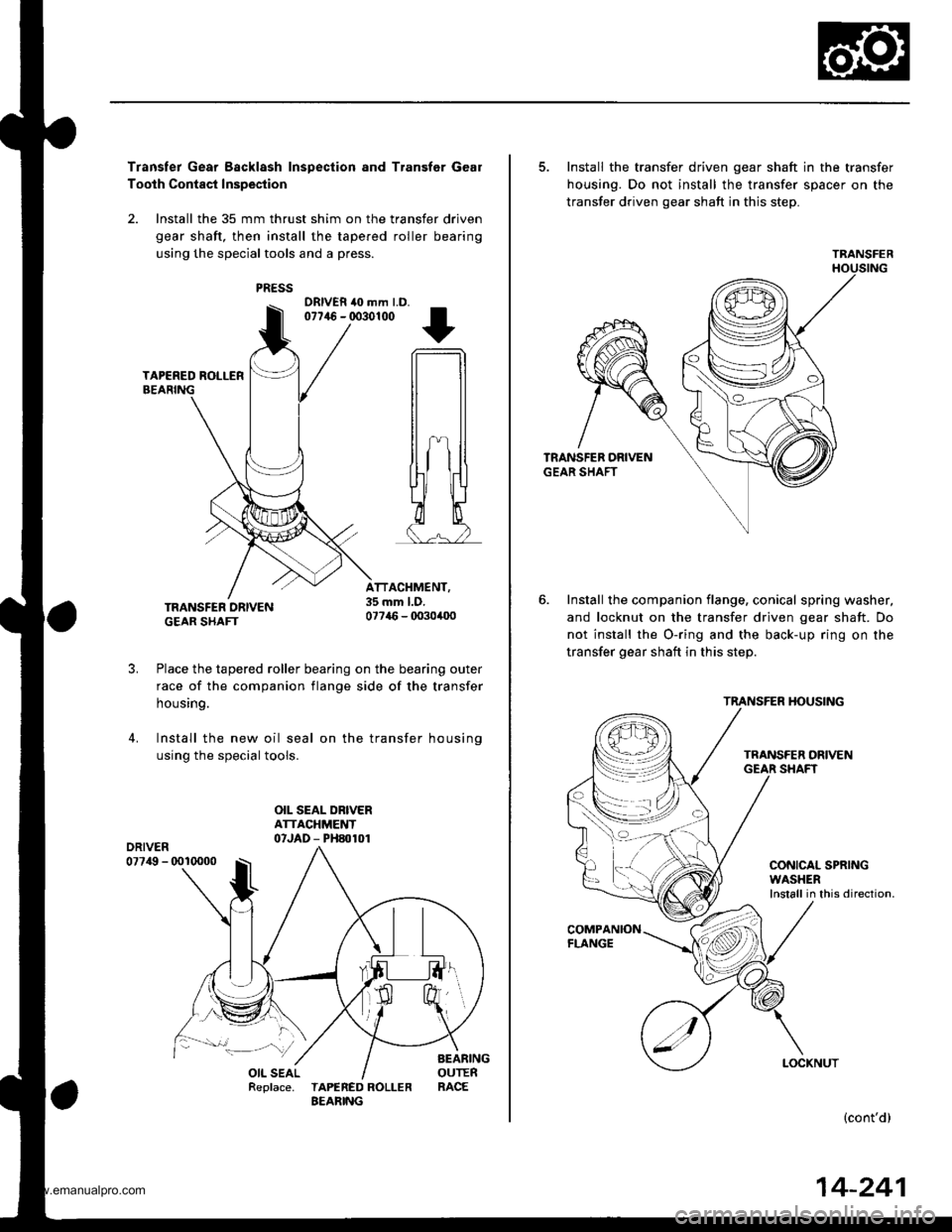

Transfer Gear Bscklash Inspection and Transfer Gear

Tooth Contact Inspection

2. Install the 35 mm thrust shim on the transfer driven

gear shaft, then install the tapered roller bearing

using the special tools and a press.

DRIVER {0 mm LD.077146 - 0030100

TRANSFER DRTVEN ;;.GEAR SHAFT u, 745 - 0O304O0

Place the tapered roller bearing on the bearing outer

race of the companion flange side of the transfer

housrng.

Install the new oil seal on the transfer housing

using the special tools.

OIL SEAL DRIVERATTACHMENT07JAD - PH80101

5. Install the transfer driven gear shaft in the transfer

housing. Do not install the transfer spacer on the

transfer driven gear shaft in this step.

Install the companion flange, conical spring washer,

and locknut on the transfer driven gear shaft. Do

not install the O-ring and the back-up ring on the

transfer gear shaft in this step.

6.

COMPANIONFLANGE

{cont'd)

TRANSFER

TRANSFER HOUSING

14-241

www.emanualpro.com

Page 794 of 1395

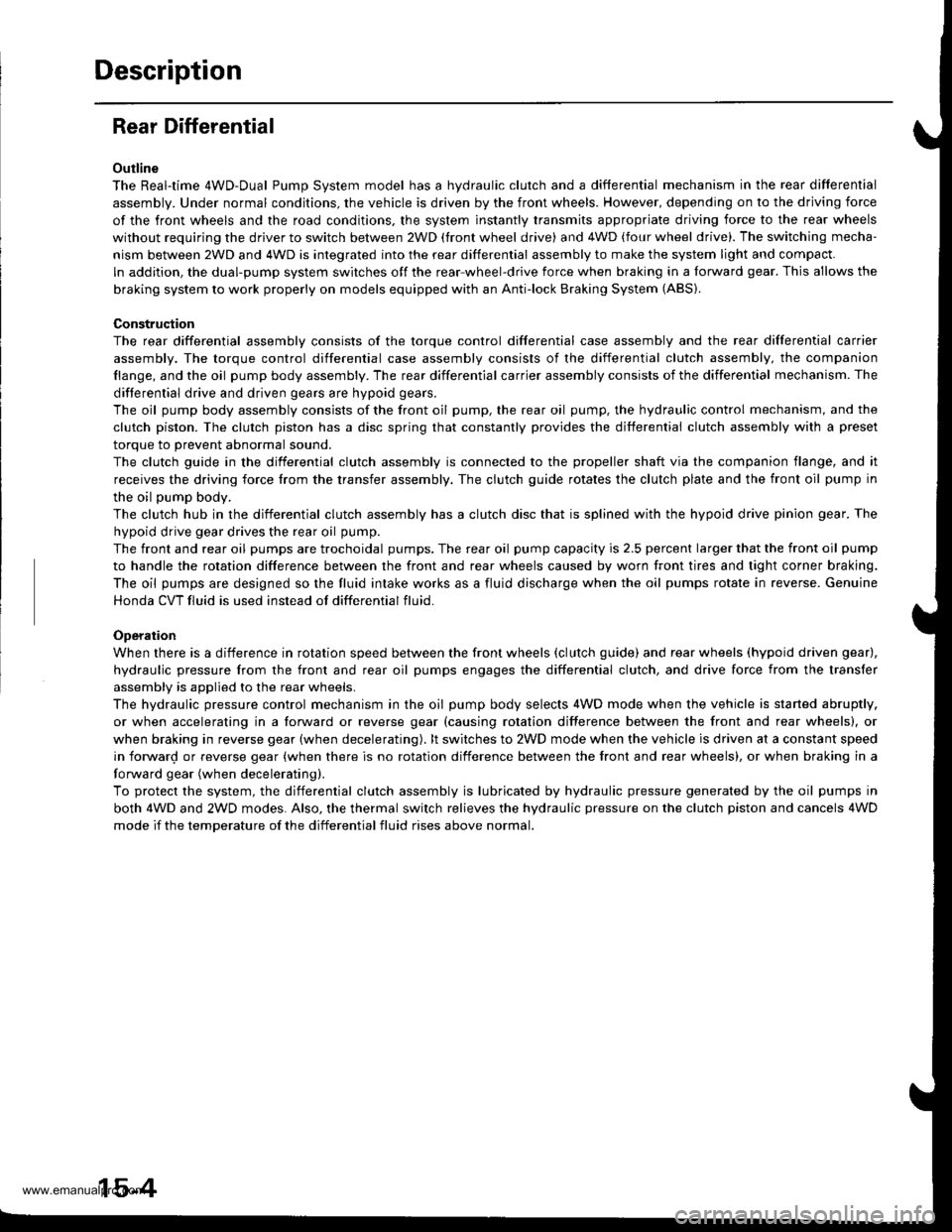

Description

Rear Differential

Outline

The Real-time 4WD-Dual Pump System model has a hydraulic clutch and a differential mechanism in the rear differential

assembly. Under normal conditions, the vehicle is driven by the front wheels. However, depending on to the driving force

of the front wheels and the road conditions. the system instantly transmits appropriate driving force to the rear wheels

without requiring the driver to switch between 2WD (tront wheel drive) and 4WD (four wheel drive). The switching mecha-

nism between 2WD and 4WD is integrated into the rear differential assembly to make the system light and compact.

ln addition, the dual-pump system switches off the rear-wheel-drive force when braking in a forward gear. This allows the

braking system to work properly on models equipped with an Anti-lock Braking System (ABS).

Construction

The rear differential assembly consists of the torque control differential case assembly and the rear differential carrier

assembly. The torque control differential case assembly consists of the differential clutch assembly, the companion

flange, and the oil pump body assembly. The rear differential carrier assembly consists of the differential mechanism. The

differential drive and driven gears are hypoid gears.

The oil pump body assembly consists of the front oil pump, the rear oil pump, the hydraulic control mechanism, and the

clutch piston. The clutch piston has a disc spring that constantly provides the differential clutch assembly with a preset

torque to Drevent abnormal sound.

The clutch guide in the differential clutch assembly is connected to the propeller shaft via the companion flange, and it

receives the driving force lrom the transfer assembly. The clutch guide rotates the clutch plate and the front oil pump in

the oil pump body.

The clutch hub in the differential clutch assembly has a clutch disc that is splined with the hypoid drive pinion gear. The

hypoid drive gear drives the rear oil pump.

The front and rear oil pumps are trochoidal pumps. The rear oil pump capacity is 2.5 percent larger that the front oil pump

to handle the rotation difference between the front and rear wheels caused by worn front tires and tight corner braking.

The oil pumps are designed so the fluid intake works as a fluid discharge when the oil pumps rotate in reverse. Genuine

Honda CVT fluid is used instead of differential fluid.

Operation

When there is a difference in rotation speed between the front wheels (clutch guide) and rear wheels (hypoid driven gear),

hydraulic pressure from the front and rear oil pumps engages the differential clutch, and drive force from the transler

assembly is applied to the rear wheels.

The hydraulic pressure control mechanism in the oil pump body selects 4WD mode when the vehicle is started abruptly,

or when accelerating in a forward or reverse gear (causing rotation difference between the front and rear wheels). or

when braking in reverse gear {when decelerating). lt switches to 2WD mode when the vehicle is driven at a constant speed

in forwar! or reverse gear (when there is no rotation difference between the front and rear wheels), or when braking in a

fo rwa rd gear (when decelerating).

To protect the system, the differential clutch assembly is lubricated by hydraulic pressure generated by the oil pumps in

both 4WD and 2WD modes. Also, the thermal switch relieves the hydraulic pressure on the clutch piston and cancels 4WD

mode if the temDerature of the differential fluid rises above normal.

www.emanualpro.com

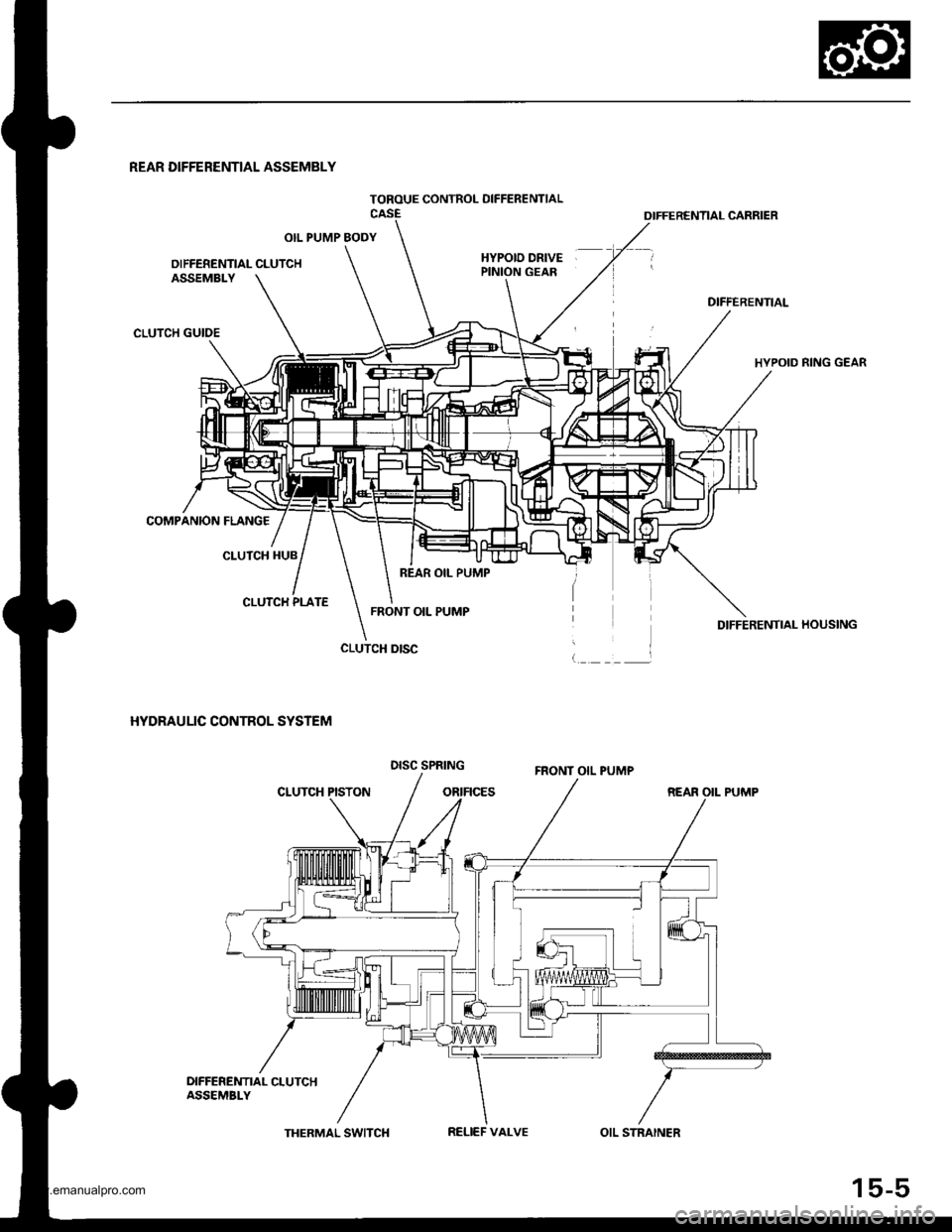

Page 795 of 1395

TOROUE CONTROL OIFFERENTIAL

REAR DIFFERENTIAL ASSEMBLY

OIL PUMP BODY

OIFFERENTIAL CLUTCHHYPOID DRIVEPINION GEAR

OIFFERENTIAL CARRIER

DIFFERENTIAL

HYPOID RING GEAR

DIFFERENTIAI- HOUSING

REAR OII- PUMP

ASSEMBLY

CLUTCH GUIDE

COMPANION FLANG€

CLUTCH HUB

CLUTCH PLATE

HYDRAULIC CONTROL SYSTEM

CLUTCH PISTON

CLUTCH DISC

REAR OIL PUMP

FRONT OIL PUMP

DISC SPRINGFRONT OIL PUMP

DIFFEREMT|AL CLUTCHASSEMBI-Y

THERMAL SWITCHRELIEF VALVEOIL STRAINER

15-5

www.emanualpro.com

Page 805 of 1395

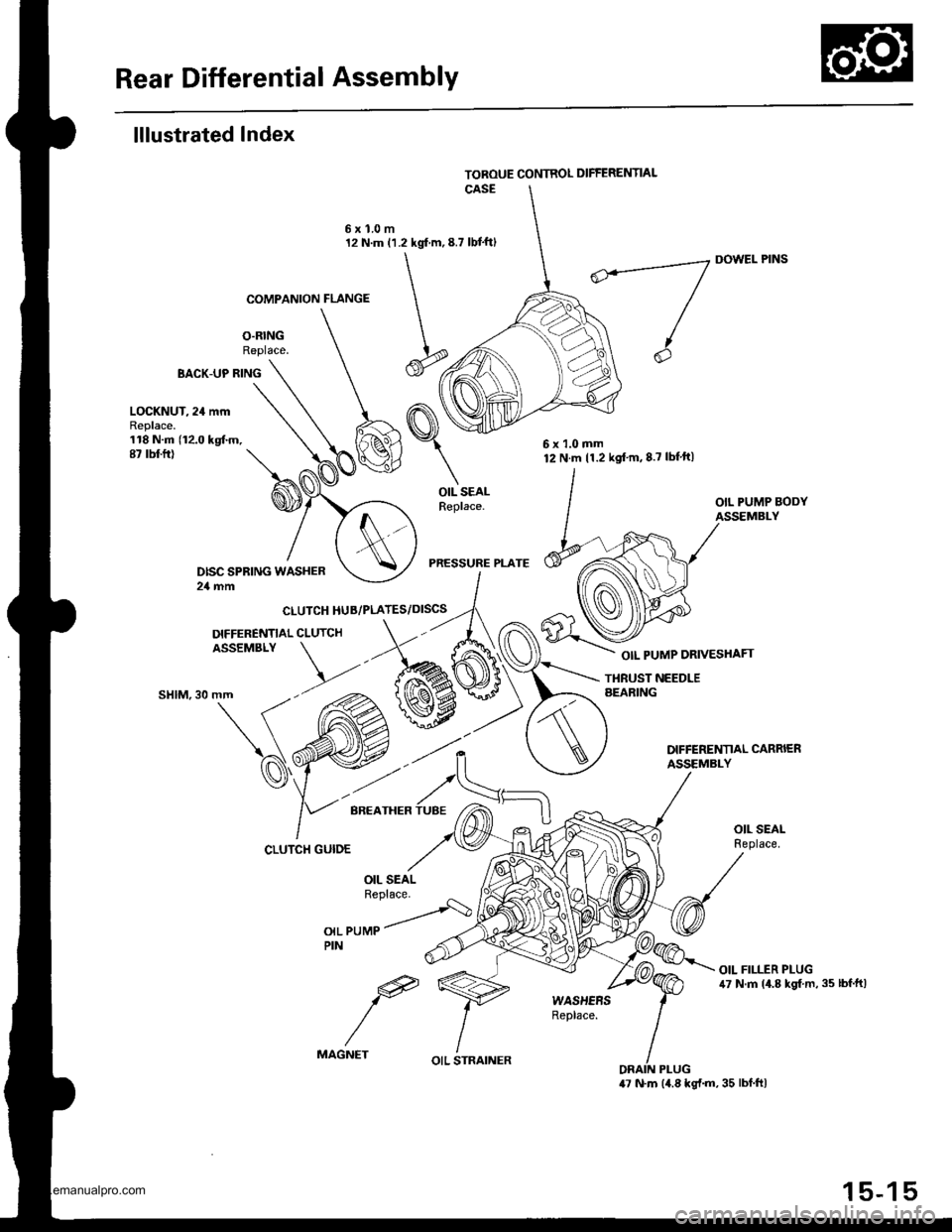

Rear Differential Assembly

lllustrated Index

O.RINGReplace.

6xl.0m12 N.m (1.2 kgf m,8.7 lbt'ftl

BACK-UP RING

COMPANION FLANGE

CLUTCH HUB/PLATES/DISCS

DIFFERENNAL CLUTCHASSEMBLY

DOWEL PINS

OIL PUMP DRIVESHAFT

LOCKNUT, 24 mmReplace.118 N.m (12.0 kgtm.87 rbt ft)

OIL SEALReplace.

PRESSURE PLATE

THBUST NEEDLEAEARING""t",at\(

'd'

CLUTCH GUIDE

OIL PUMPPIN

e

MAGNET

6x1.0mm12 N.m 11.2 kgt'm,8.7 lbf'ft|

OIL STRAINER

15-15

www.emanualpro.com

Page 807 of 1395

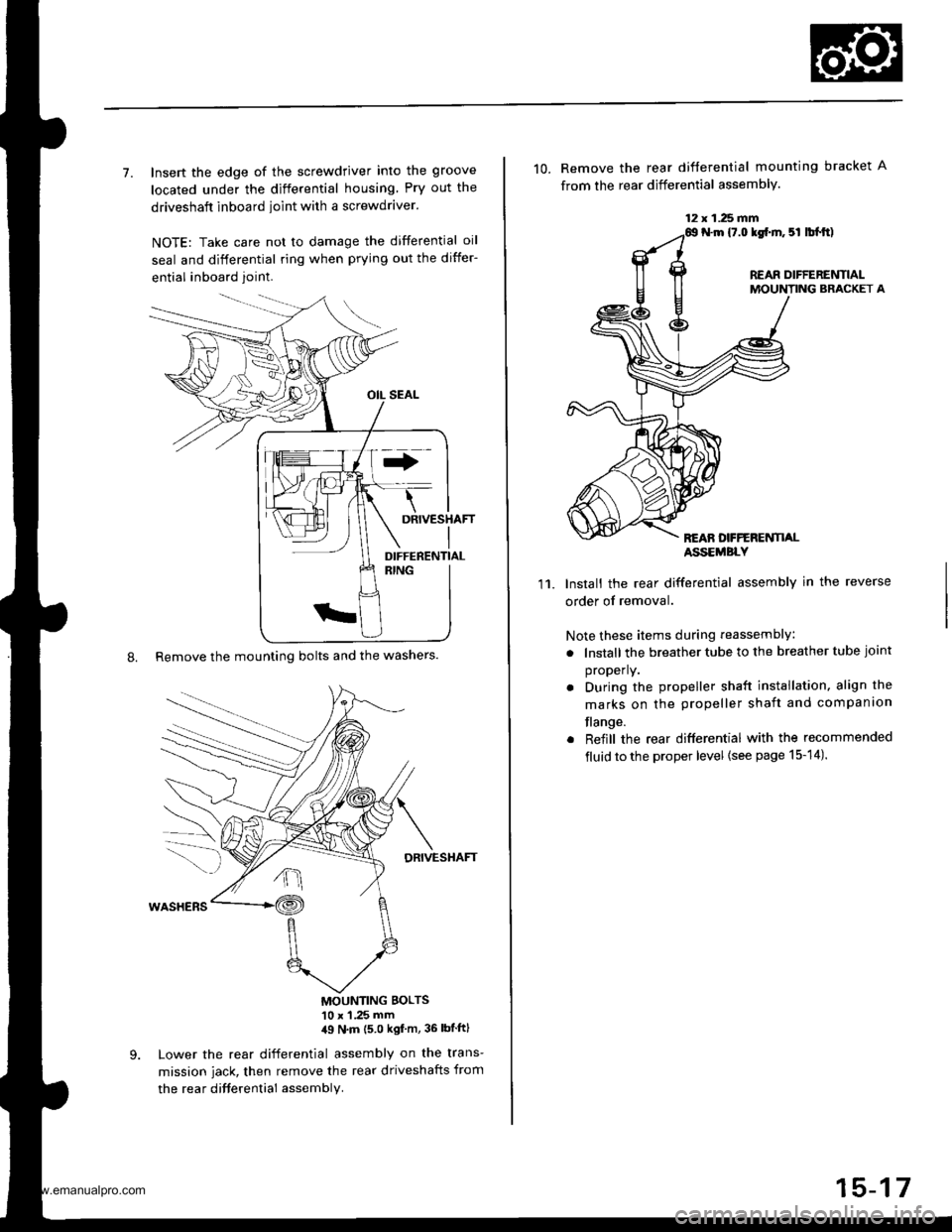

7. Insert the edge of the screwdriver into the groove

located under the differential housing Pry out the

driveshaft inboard ioint with a screwdraver.

NOTE: Take care not to damage the differential oil

seal and differential ring when prying out the differ-

ential inboard joint.

8. Remove the mounting bolts and the washers.

DRIVESHAFT

MOUNTING BOLTS'10 x 1 .25 mm,19 N'm (5 0 kgf m, 36 lbtftl

Lower the rear differential assembly on the trans-

mission jack, then remove the rear driveshafts from

the rea r difterential assembly.

DIFFERENTIAL

12 x 1.25 fifi

10. Remove the rear difterential mounting bracket A

from the rear differential assembly.

N.m {7.0 lgf.m. 5l lbl.tt)

REAR DIFFERENTIALMOUNTING BRACKET A

REAN DFFERENTI,ALASSEMBLY

11.Install the rear differential assembly in the reverse

order of removal.

Note these items during reassembly

. lnstall the breather tube to the breather tube joint

properly.

. During the propeller shaft installation, align the

marks on the propeller shaft and companion

flange.

. Reiill the rear differential with the recommended

fluid to the proper level {see page 15-14).

15-17

www.emanualpro.com

Page 815 of 1395

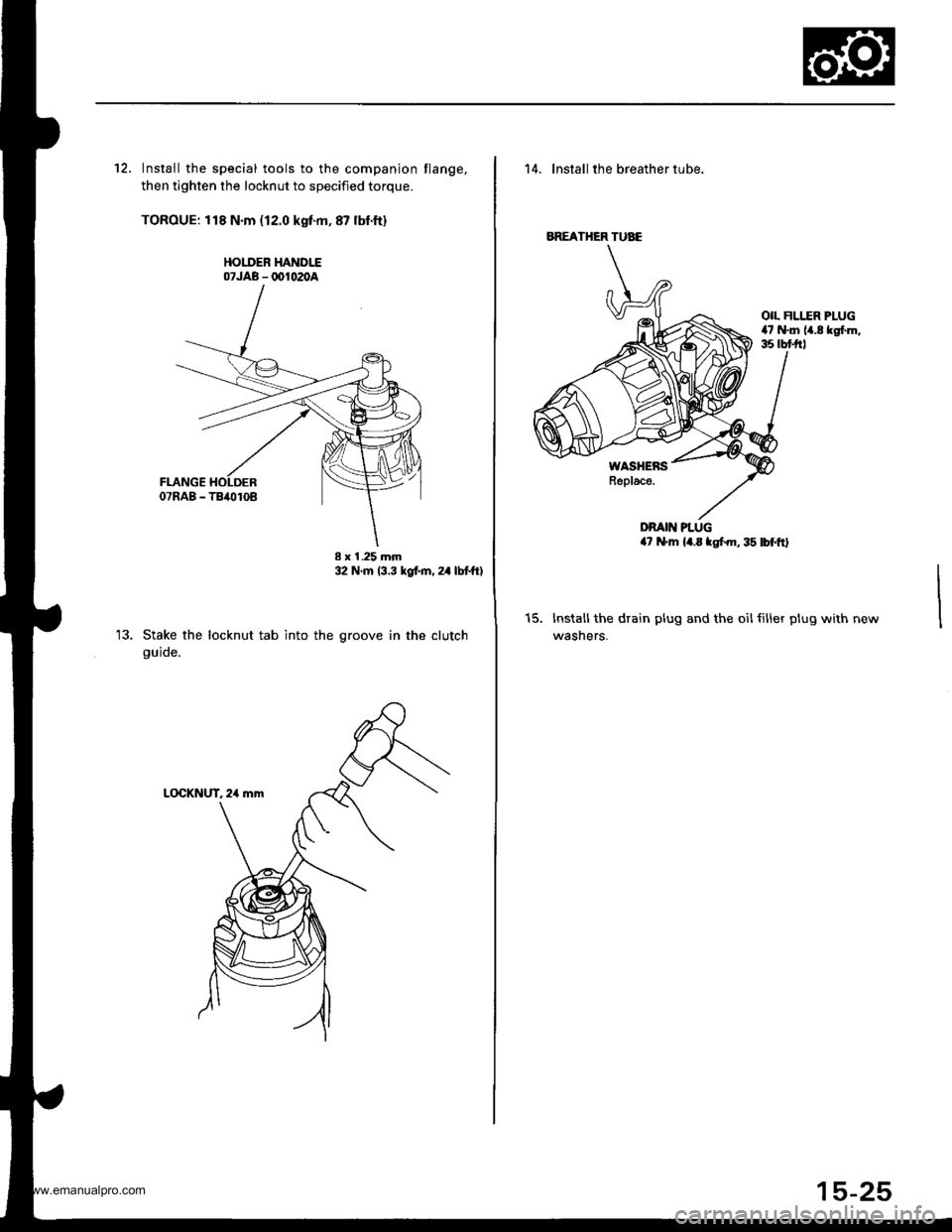

12. Install the special tools to the companion flange,

then tighten the locknut to specified torque.

TOROUE: 118 N.m (12.0 kgf-m,87 lbf'ft)

HOLDEB HANDLE07JAB - @1020A

Stake the locknut tab into the

guide.

I x I .25 mm32 N'm (3.3 kgt m, 24 lbtftl

groove in the clutch

14. lnstall the breather tube.

OIL FILI..ER PLUG47 N.m 14.8 kgf.m,35 tbt frl

WASHENSReplace.

DRAIN PLUG4? N'm l4.E tgf.m, 35 lbf'ftl

t5.Installthe drain plug and the oilfiller plug with

wasners.

BREATHER TUAE

www.emanualpro.com