wire HONDA CR-V 2000 RD1-RD3 / 1.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 89 of 1395

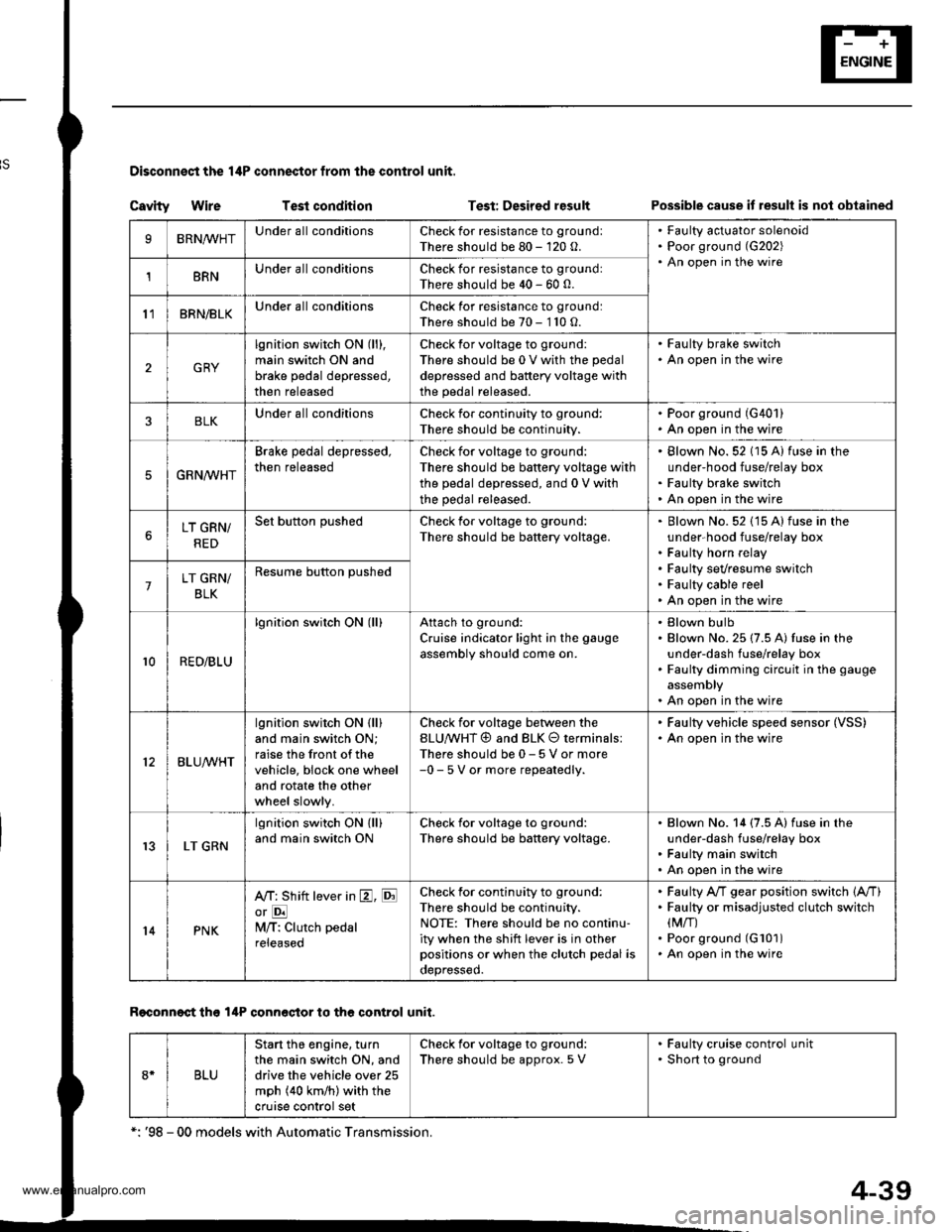

Disconnest the lilP connector from the control unit.

Csvity WireTest condition

R€conn€ct tho 14P connGctor to the control unit.

Test: Desired resultPossible cause it result is not obtained

BRNAr'VHTUnder all conditionsCheck for resistance to groundl

There should be 80 - 120 o.

Faulty actuator solenoid

Poor ground (G202)

An open in the wire1BRNUnder all conditionsCheck for resistance to groundl

There should be 40 - 60 0.

11BRN/BLKUnder all conditionsCheck for resistance to ground:

There should be 70 - 110 O.

2GRY

lgnition switch ON (ll),

main switch ON and

brake pedal depressed,

then released

Check for voltage to ground:

There should be 0 V with the pedal

depressed and battery voltage with

the pedal released.

. Faulty brake switch. An open in the wire

BLKUnder all conditionsCheck for continuity to ground:

There should be continuity.

. Poor ground (G401). An open in the wire

5GRNMHT

Brake pedal depressed,

then released

Check for voltage to ground:

There should be battery voltage with

the pedal depressed, and 0 V with

the pedal released.

Blown No.52 1'15 Alfuse in the

under-hood fuse/relay box

Faulty brake switch

An open in the wire

LT GRN/

RED

Set button pushedCheck for voltage to ground:

There should be battery voltage.Blown No. 52 {'15 A} fuse in the

under-hood fuse/relay box

Faulty horn relay

Faulty sevresume switch

Faulty cable reel

An open in the wire7LT GRN/

BLK

Resume button pushed

10RED/BLU

lgnition switch ON lll)Attach to ground:

Cruise indicator light in the gauge

assembly should come on.

Elown bulbBlown No. 25 (7.5 A) tuse in theunder-dash fuse/relay box

Faulty dimming circuit in the gauge

assembly

An open in the wire

ELU^r'r'HT

lgnitjon switch ON {ll}and main switch ON;

raise the front of the

vehicle, block one wheel

and rotate the other

wheel slowly.

Check for voltage between the

ELUA/VHT @ and BLK O terminalsl

There should be 0 - 5 V or more-0 - 5 V or more repeatedly.

Faulty vehicle speed sensor (VSS)

An open in the wire

r3LT GRN

lgnition switch ON {ll}and main switch ONCheck for voltage to ground:

There should be battery voltage.

Blown No. 14 (7.5 A) fuse in theunder-dash fuse/relay box

Faulty main switch

An open in the wire

l4PNK

A'/T: Shift lever in E, EotE

lvl/T: Clutch pedal

releaseo

Check for continuity to ground:

There should be continuity.NOTE: There should be no continu-

ity when the shift lever is in otherpositions or when the clutch pedal is

oepresseo.

Faulty A/f gear position switch 1A,/TlFaulty or misadjusted clutch switch

fi{/r)Poor ground (G101)

An open in the wire

BLU

Start tho engine. turnthe main switch ON, anddrive the vehicle over 25

mph (40 km/h)with the

crurse control set

Check for voltage to ground:

There should be approx.5 V

. Faulty cruise control unit. Shod to ground

*: '98 - 00 models with Automatic Transmission.

4-39

www.emanualpro.com

Page 90 of 1395

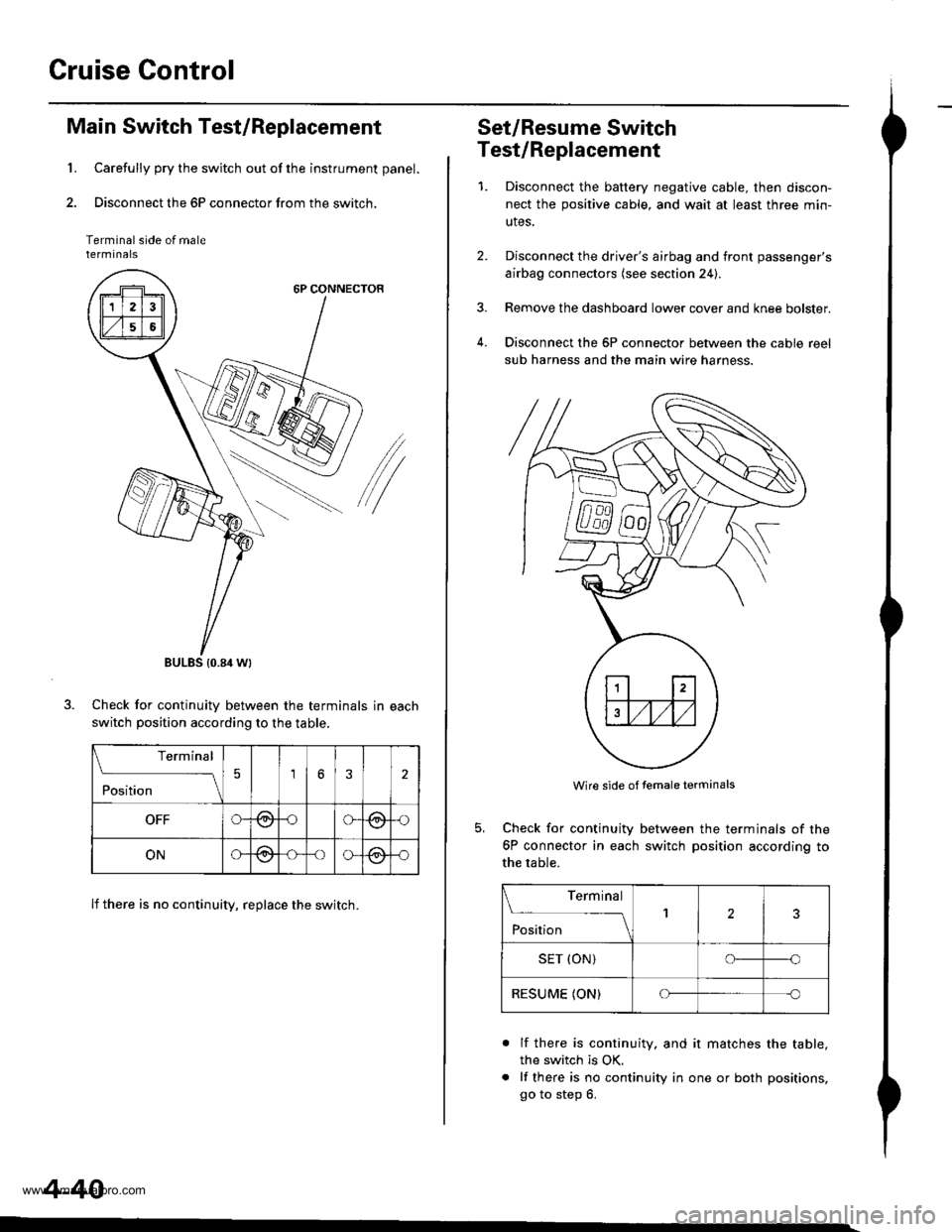

Cruise Control

1.

Main Switch Test/Replacement

Carefully pry the switch out of the instrument panel.

Disconnect the 6P connector from the switch,

Terminal side of malerermtnats

6P CONNECTOR

/

Check for continuitv between the terminals in each

switch position according to the table.

lf there is no continuity, replace the switch.

BULES {0.84 Wt

Terminal

;;;

-_\56

OFFG-@oG(9,{)

ONG@-oo-@-o

4-40

Set/Resume Switch

Test/Replacement

1.Disconnect the baftery negative cable, then discon-

nect the positive cable, and wait at least three min-

utes.

Disconnect the driver's airbag and front passenger's

airbag connectors (see section 24).

Remove the dashboard lower cover and knee bolster.

Disconnect the 6P connector between the cable reel

sub harness and the main wire harness.

4.

Wire side of temale terminals

Check for continuity

6P connector in each

the table.

between the terminals of the

switch position according to

Terminal

;;;

--_l2

SET (ON)o--o

RESUME (ON)Cf-c

a

lf there is continuity. and it matches the table,

the switch is OK.

lf there is no continuity in one or both positions,

go to step 6.

www.emanualpro.com

Page 99 of 1395

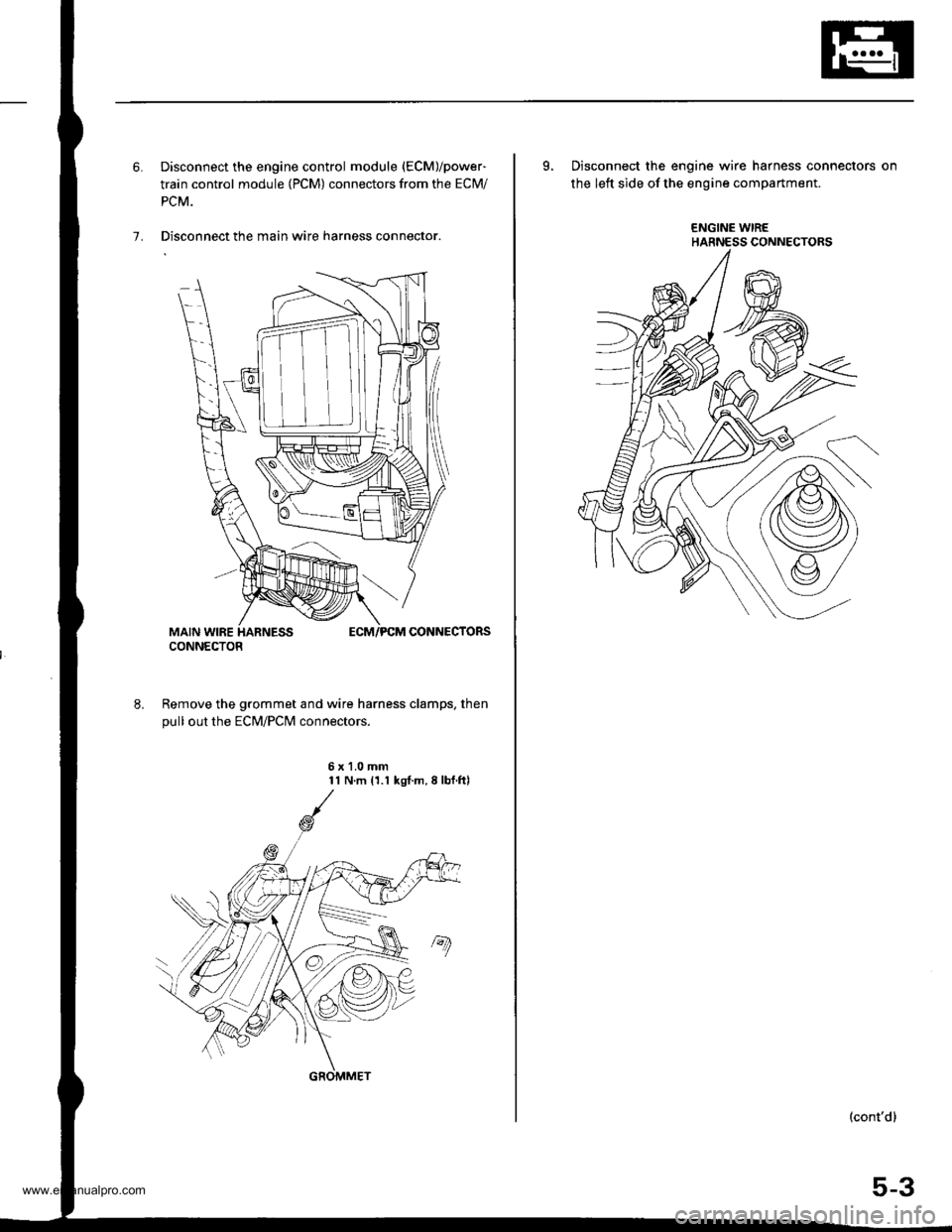

6. Disconnect the engine control module (ECM)/power-

train control module (PCM) connectors from the ECM/

PCM.

7. Disconnect the main wire harness connector.

Remove the grommet and wire harness clamps, then

pull out the EcM/Pclvl connectors.

6x1.0mm11 N.m 11.1 kgl.m,8lbf.ftl

CONNECTOR

GROMMET

L Disconnect the engine wire harness connectors on

the left side of the engine compartment.

ENGINE WIREHARNESS CONNECTORS

(cont'd)

5-3

www.emanualpro.com

Page 102 of 1395

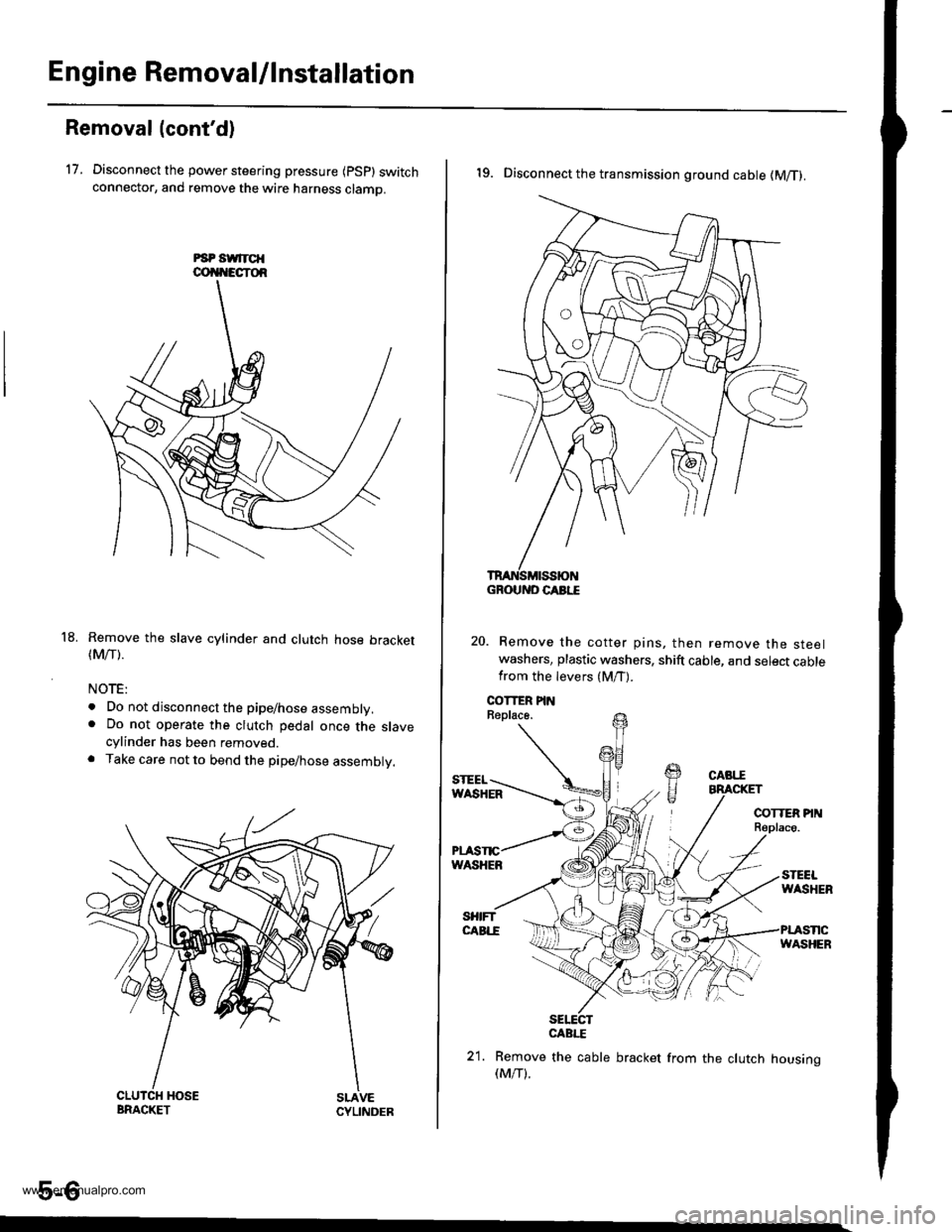

Engine Removal/lnstallation

Removal (cont'd)

17. Disconnect the power steering pressure {psp} switchconnector, and remove the wire harness clamo.

Remove the slave cylinder and clutch hose bracket(Mrr).

NOTE:

. Do not disconnect the pipe/hose assembly.. Do not operate the clutch pedal once the slavecylinder has been removed.. Take care not to bend the pipe/hose assembly.

5-6

18.

19. Disconnect the transmission ground cable (M/T).

Remove the cotter pins, then remove the steelwashers, plastic washers, shift cable, and select cablefrom the levers (M/T).

sElEcrCABI."E

21. Remove the cable bracket from the clutch housing(M/T).

GROUND CABI."E

www.emanualpro.com

Page 107 of 1395

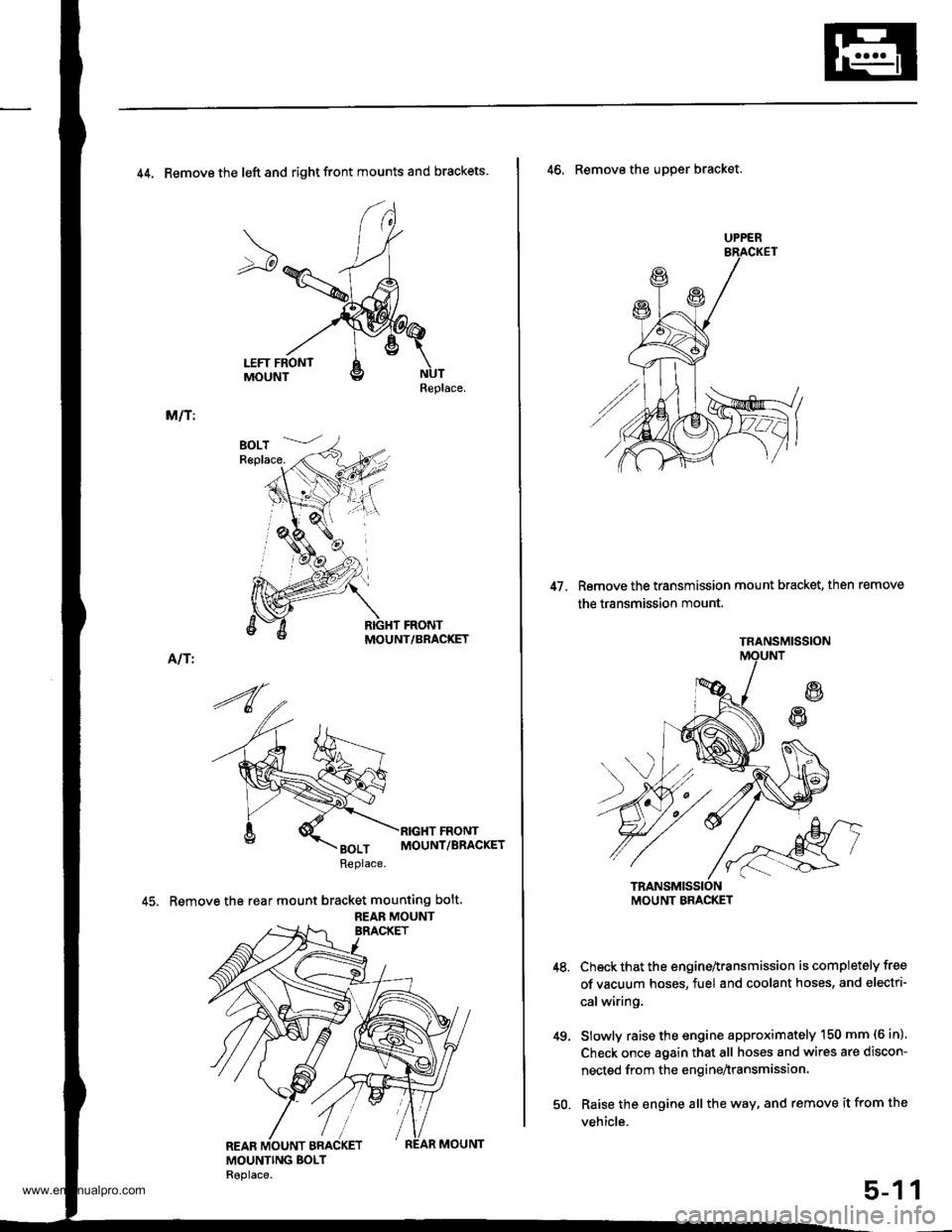

44. Remove the left and right front mounts and brackets

Replace.

M/T:

MOUNT/BRACKET

Alf I

45. Remove the rear mount bracket mounting bolt.

REAB MOUNT

UPPER

47. Remove the transmission mount bracket, then remove

the transmission mount.

46. Remove the uDper bracket.

Check that the engine^ransmission is completely free

of vacuum hoses, fuel and coolant hoses, and electri-

calwiring.

Slowly raise the engine approximately 150 mm (6 in)'

Check once again that all hoses and wires are discon-

nected from the enginenransmission.

Raise the engine all the way, and remove it from the

vehicle.

49.

1

TRANSMISSION

MOUNT BMCKET

50.

5-1

www.emanualpro.com

Page 132 of 1395

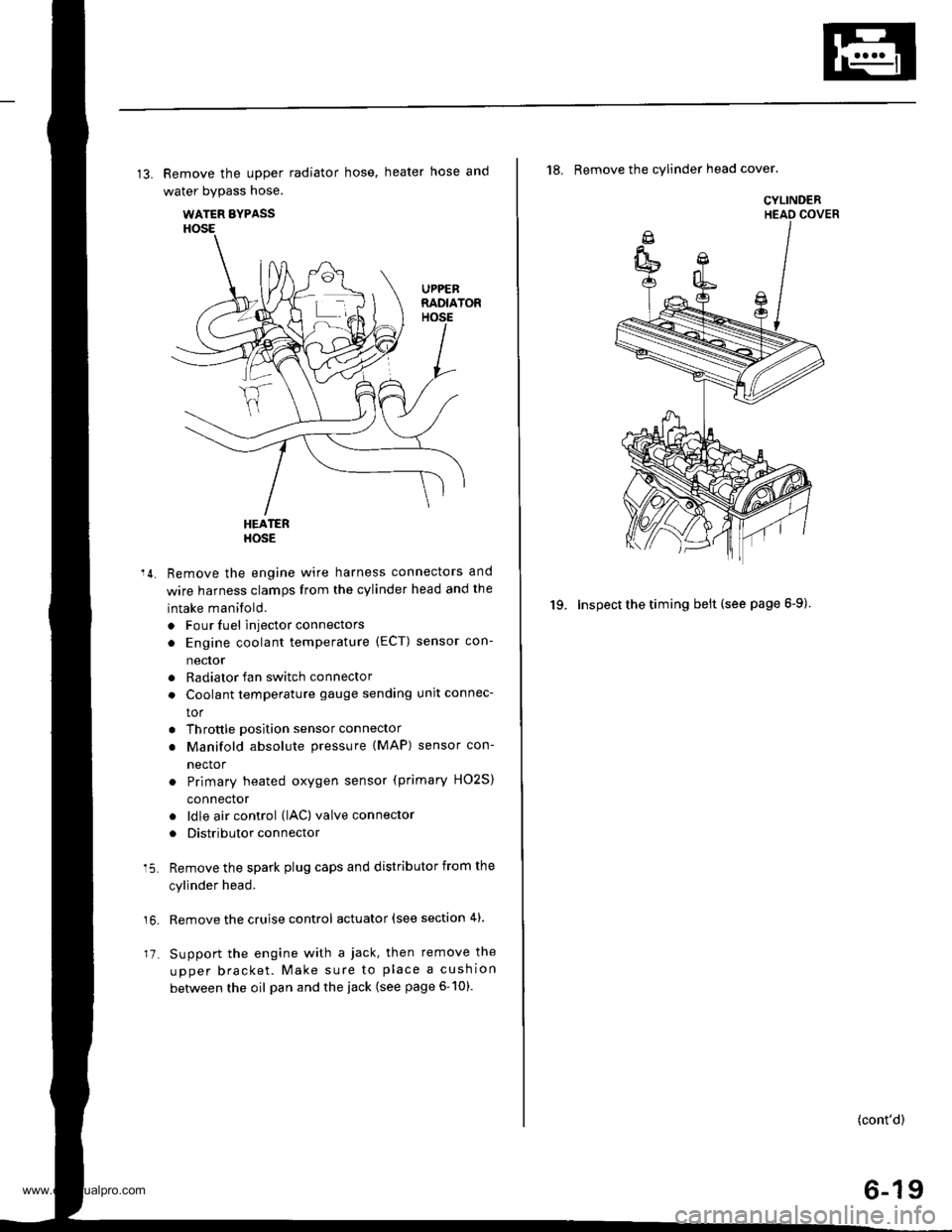

13. Remove the upper radiator hose, heater hose and

water bypass hose.

WATER BYPASS

UPPEBRADIATORHOSE

17

HEATERHOSE

Remove the engine wire harness connectors and

wire harness clamps from the cylinder head and the

intake manifold.

o Four fuel injector connectors

. Engine coolant temperature (ECT) sensor con-

neclor

. Radiator fan switch connector

. Coolant temperature gauge sendlng unlt connec-

tor

. Throttle position sensor connector

. Manifold absolute pressure {MAP) sensor con-

nector

Primary heated oxygen sensor (primary HO2S)

connector

ldle air control (lAC) valve connector

Distributor connector

Remove the spark plug caps and distributor from the

cylinder head.

Remove the cruise control actuator (see section 4).

Support the engine with a jack, then remove the

upper bracket. Make sure to place a cushion

between the oil pan and the iack (see page 6-10).

a

18. Remove the cylinder head cover.

19. Inspect the timing belt (see page 6-9).

CYLINDER

(cont'd)

6-19

www.emanualpro.com

Page 154 of 1395

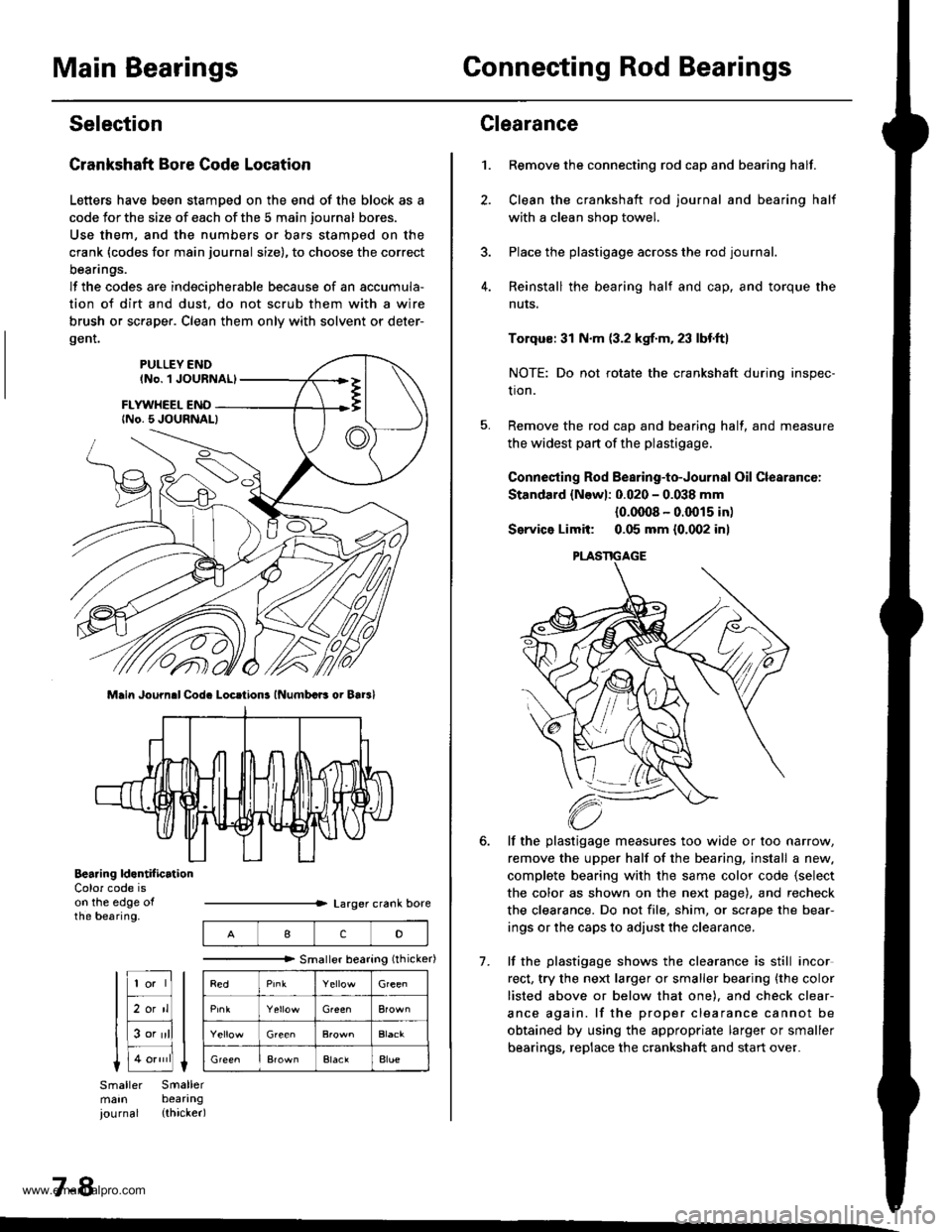

Main BearingsConnecting Rod Bearings

Selection

Crankshaft Bore Code Location

Letters have been stamDed on the end of the block as a

code Jor the size of each of the 5 main journal bores.

Use them, and the numbers or bars stamped on the

crank (codes for main journal size), to choose the correct

beanngs.

lf the codes are indecipherable because of an accumula-

tion of dirt and dust. do not scrub them with a wire

brush or sc.aper. Clean them only with solvent or deter-

gent.

Main Journ.l Cod. Locrtions lNumbcB oi Bar3l

Bearing ld.ntif icrtionColor code ison the edge ofthe bearing.

7-8

IcD

"""""""" Smallerbearing(rhicker)

Green

Green

ElaclAlue

Clearance

Remove the connecting rod cap and bearing half.

Clean the crankshaft rod journal and bearing half

with a clean shop towel.

Place the plastigage across the rod journal.

Reinstall the bearing half and cap, and torque the

nuts.

1.

7.

Torqus: 31 N.m (3.2 kgf.m. 23 lbf.ft)

NOTE: Do not rotate the crankshaft during inspec-

tion.

Remove the rod cap and bearing half, and measure

the widest part of the plastigage.

Connesting Rod Bearing-to-Journal Oil Clearancc:

Standard {Newl: 0.020 - 0.038 mm

{0.0008 - 0.0015 in)

Service Limit: 0.05 mm {0.002 inl

lf the plastigage measures too wide or too narrow,

remove the upper half of the bearing, install a new.

complete bearing with the same color code {select

the color as shown on the next page), and recheck

the clearance. Do not file, shim, or sc.ape the bear-

ings or the caps to adjust the clearance.

lf the plastigage shows the clearance is still incor

rect, try the next larger or smaller bearing {the color

listed above or below that one). and check clear-

ance again. lf the proper clearance cannot be

obtained by using the appropriate larger or smaller

bearings. replace the crankshaft and start over.

PLASTIGAGE

www.emanualpro.com

Page 155 of 1395

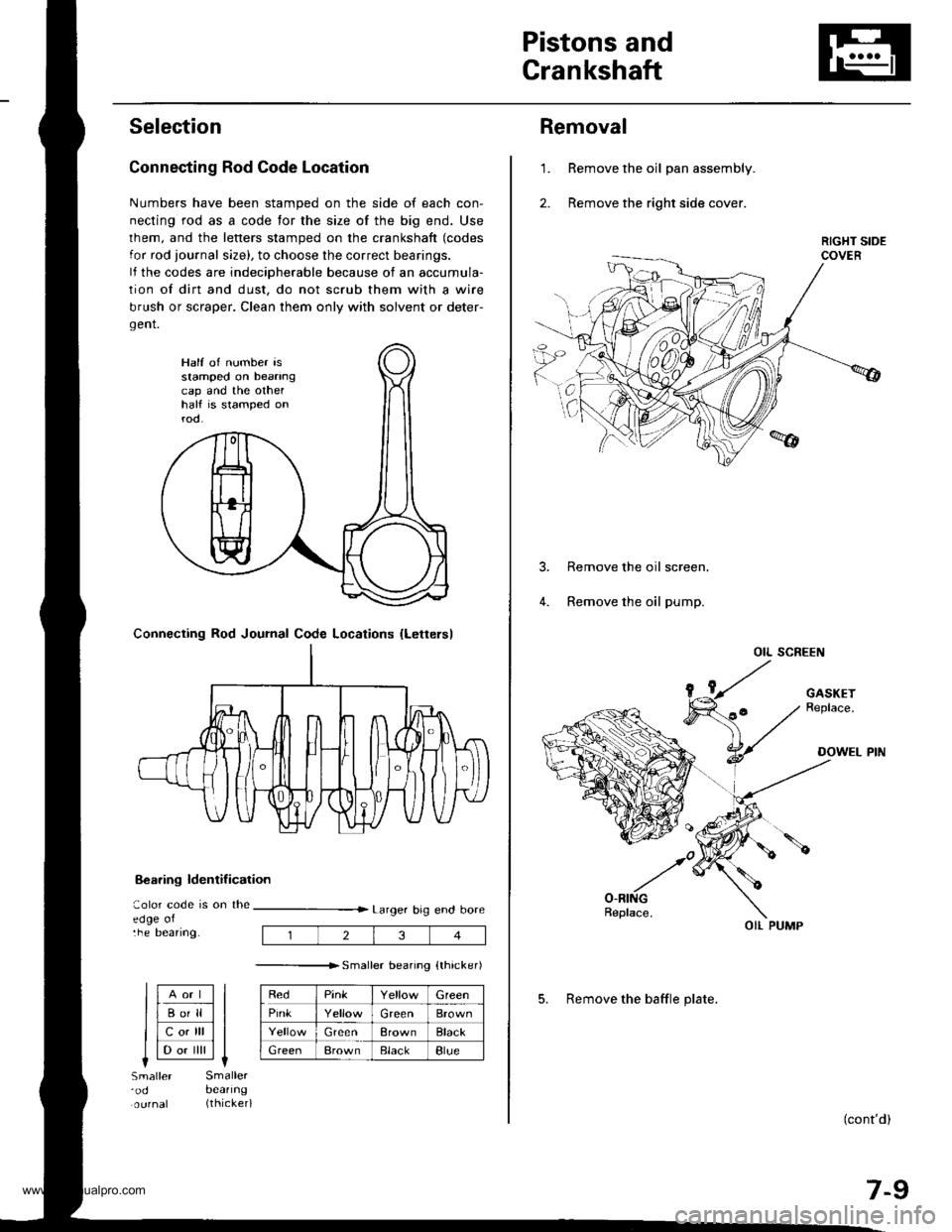

Pistons and

Crankshaft

Selection

Connecting Rod Code Location

Numbers have been stamped on the side of each con-

necting rod as a code for the size of the big end. Use

lhem, and the letters stamped on the crankshaft (codes

for rod journal size), to choose the correct bearings.

lf the codes are indeciDherable because of an accumula-

tion of dirt and dust, do not scrub them with a wire

brush or scraper. Clean them only with solvent or deter-

gent.

8€aring ldentif ication

aolor code is on theedge oltne Deanng.

Larger big end bore

---------------r. sma er bearino {thicker)

RedPinkGreen

PinkGreenBrown

GreenBrownBlack

GreenBrownElackBlue

Half of number isstamped on beanngcap and the othelhalf is stamped onrod.

Connecting Rod Journal Code Locations {Lettersl

llAort ll

llBo'll ll

llcotrll ll

I l-.. ilril It-lSmaller'odSmallerbeanng(thicker)

234

Removal

Remove the oil pan assembly.

Remove the right side cover.

1.

Remove the oil screen.

Remove the oil pump.

OIL SCREEN

(cont'd)

7-9

OIL PUMP

5. Remove the baffle plate.

www.emanualpro.com

Page 164 of 1395

Piston Rings

2.

Replacement

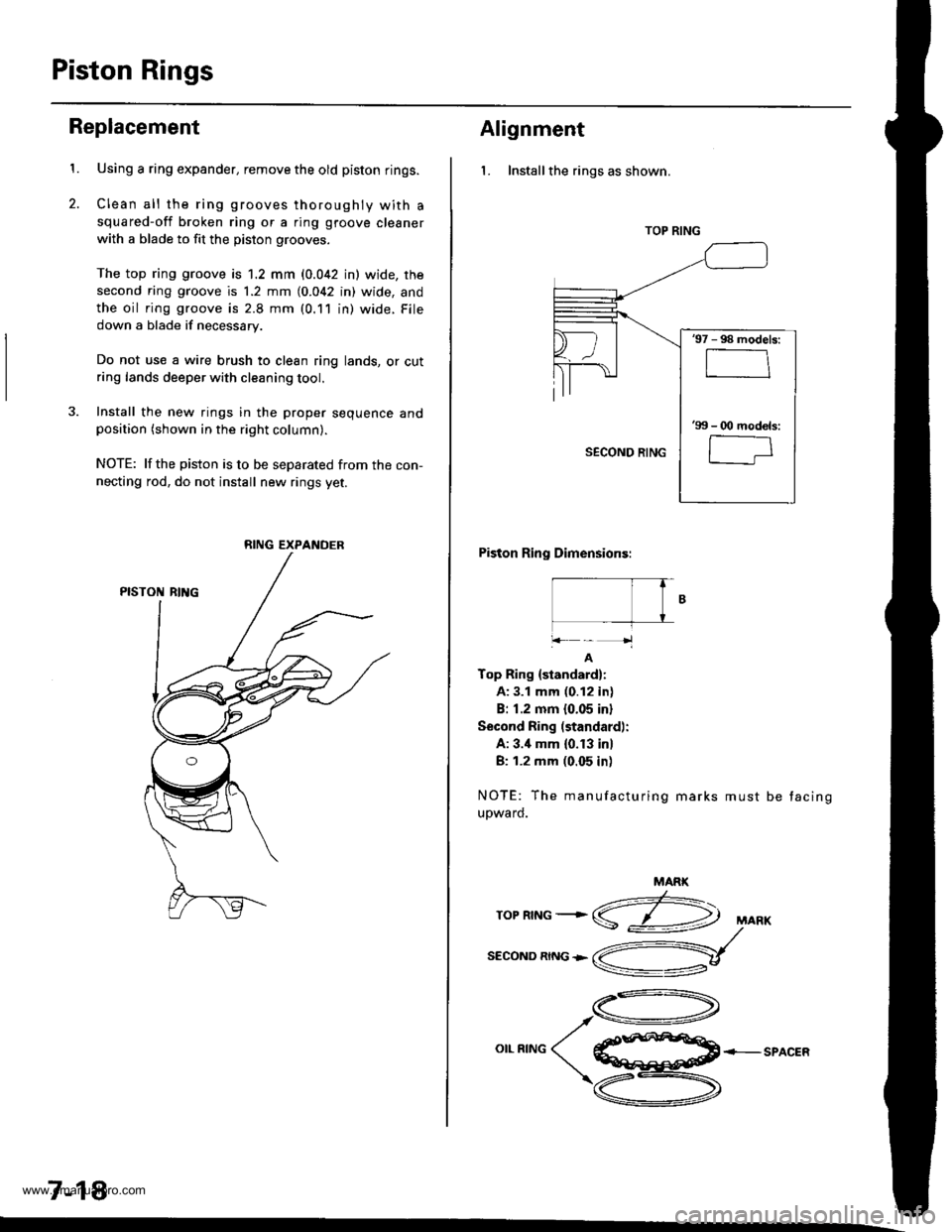

1.Using a ring expander, remove the old piston rings.

Clean all the ring grooves thoroughly with a

squared-off broken ring or a ring gtoove cleaner

with a blade to fit the piston grooves.

The top ring groove is 1.2 mm (0.042 in) wide, rhe

second ring groove is 1.2 mm (0.042 in) wide, and

the oil ring groove is 2.8 mm (0.11 in) wide. File

down a blade if necessary.

Do not use a wire brush to clean ring lands, or cutring lands deeper with cleaning tool.

3. Install the new rings in the proper sequence andposition (shown in the right column).

NOTE: lfthe piston is to be separated from the con-

necting rod, do not install new rings yet.

7-18

RING EXPANDER

Alignment

l. Installthe rings as shown.

Piston Ring Dimensions:

|- T� fB

+k-'1

A

Top Ring {standard}:

A: 3.1 mm (0.12 in)

B: 1.2 mm 10.05 inl

Second Ring (standard):

A: 3.'1 mm (0. f 3 in)

B: 1.2 mm (0.05 in)

NOTE: The manufacturing marks must

upward.

be tacing

MARK

z:-\ropnrNG+S

SECOND RING +

,A-\

o**^o( €ffi+-sPAcER

\zu-\

v

TOP RING

'97 - 98 models:

'99 - O0 mod€ls:

l-;

www.emanualpro.com

Page 177 of 1395

Oil Pressure SwitchOil Pressure

Testing

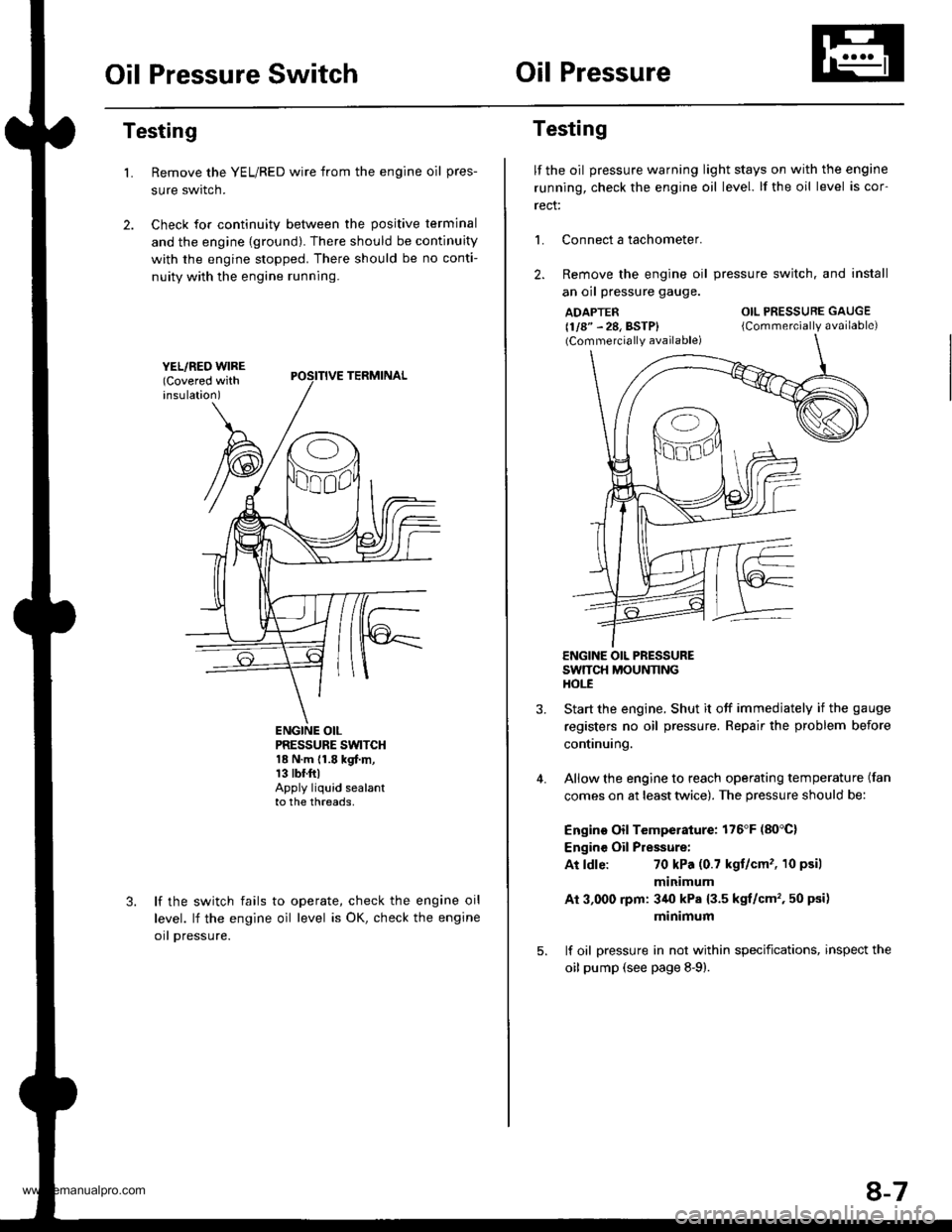

Remove the YEL/RED wire from the engine oil pres-

sure swrtcn.

Check for continuity between the positive terminal

and the engine {ground). There should be continuity

with the engine stopped. There should be no conti-

nuity with the engine running.

L

PRESSURE SWTCH18 N.m {1.8 kgf.m,13 tbr.ftlApply liquid sealantto the threads,

lf the switch fails

level. lf the engine

orl pressure.

to operate, check the engine oil

oil level is OK, check the engine

Testing

lf the oil pressure warning light stays on with the engine

running, check the engine oil level. lf the oil level is cor-

rect:

L Connect a tachometer.

2. Remove the engine oil

an oil pressure gauge.

ADAPTER(1/8" - 28, BSTP)(Commercially available)

pressure switch. and install

OIL PRESSURE GAUGE

{Commercially available)

4.

ENGINE OIL PRESSURESWTTCH MOUNNNGHOt-E

Start the engine. Shut it off immedjately if the gauge

registers no oil pressure. Repair the problem before

continuing.

Allow the engine to reach operating temperature (fan

comes on at least twice). The pressure should be:

Engino Oil Temperature: 176'F (80'C)

Engine Oil Pressure:

At ldle:70 kPa (0.7 kgt/cm'�, 10 psil

minimum

Ai 3,000 rpm: 3/r0 kPa {3.5 kgt/cm', 50 psi)

minimum

lf oil pressure in not within specifications, inspect the

oil pump (see page 8-9).

8-7

www.emanualpro.com