Throttle HONDA CR-V 2000 RD1-RD3 / 1.G Service Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 397 of 1395

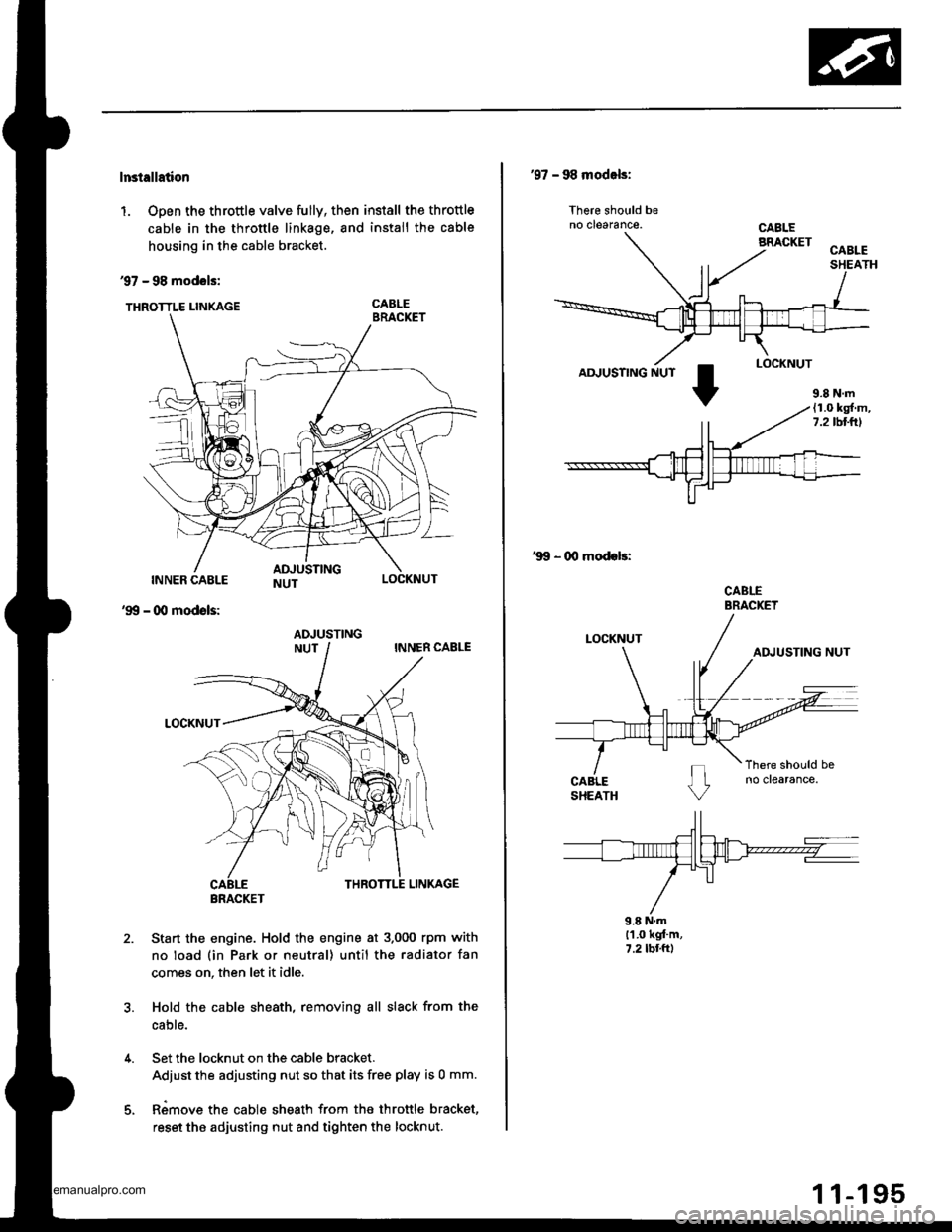

lnstellation

1. Open the throttle valve fully, then install the throttle

cable in the throttle linkage, and install the cable

housing in the cable bracket.

97 - 98 modols:

THRoTTLE LINKAGE CABLE

INNER CABLE

- (Xl modols:

LOCKNUT

'99

2.Sta.t the engine. Hold the engine at 3.000 rpm with

no load (in Park or neutral) until the radiator fan

comes on, then let it idle.

Hold the cable sheath, removing all slack from the

cable.

Set the locknut on the cable bracket.

Adiust the adjusting nut so that its free play is 0 mm.

Rimove the cable sheath from the throttle bracket,

reset the adjusting nut and tighten the locknut.

ADJUSTING

BRACKET

'97 - 98 modals:

lhere should beno clearance.

AD.'USTING NUT

'99 - 00 modeb:

CABLEBRACKET

9.8 N.ml'1.0 kgt'm,7.2 tbr.ft)

9.8 N.m(1.0 kg{.m,7.2lbllrl

www.emanualpro.com

Page 398 of 1395

Intake Air System

Throttle Body

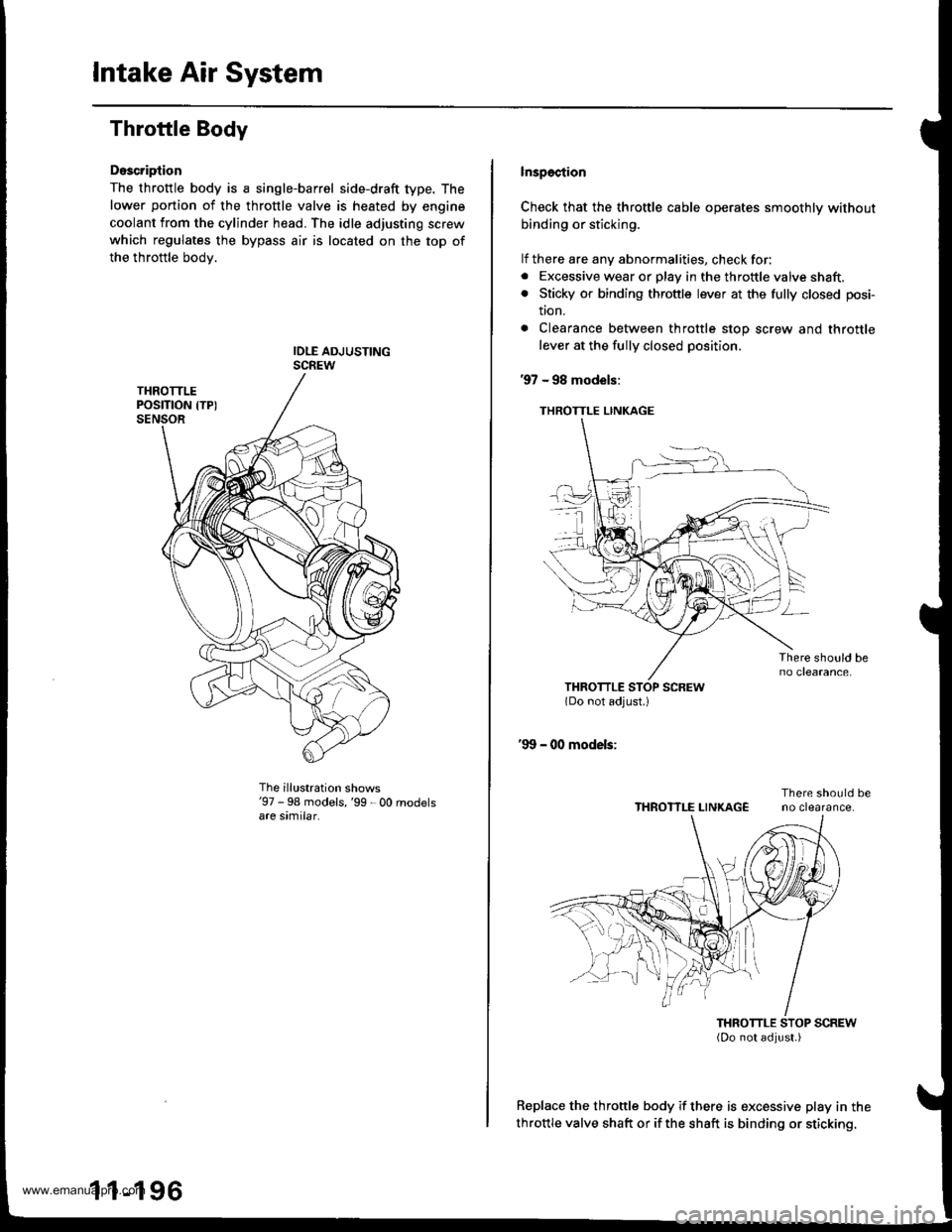

Doscription

The throttle body is a single-barrel side-draft type. The

lower portion of the throttle valve is heated by engine

coolant from the cylinder head. The idle adjusting screw

which regulates the bypass air is located on the top of

the throttle bodv.

The illustration shows'97 - 98 models,'99 - 00 rnodelsare similar.

1 1-196

lnspection

Check that the throttle cable operates smoothly without

binding or sticking.

lf there are any abnormalities, check for:. Excessive wear or play in the throftle valve shaft.. Sticky or binding throttle lever at the fully closed posi-

tton.

. Clearance between throttle stop screw and throttle

lever at the fully closed position.

97 - 98 models:

THROTTLE LINKAGE

Replace the throttle body if there is excessive play in the

throttle valve shaft or if the shaft is binding or sticking.

THROTTLE LINKAGE

www.emanualpro.com

Page 399 of 1395

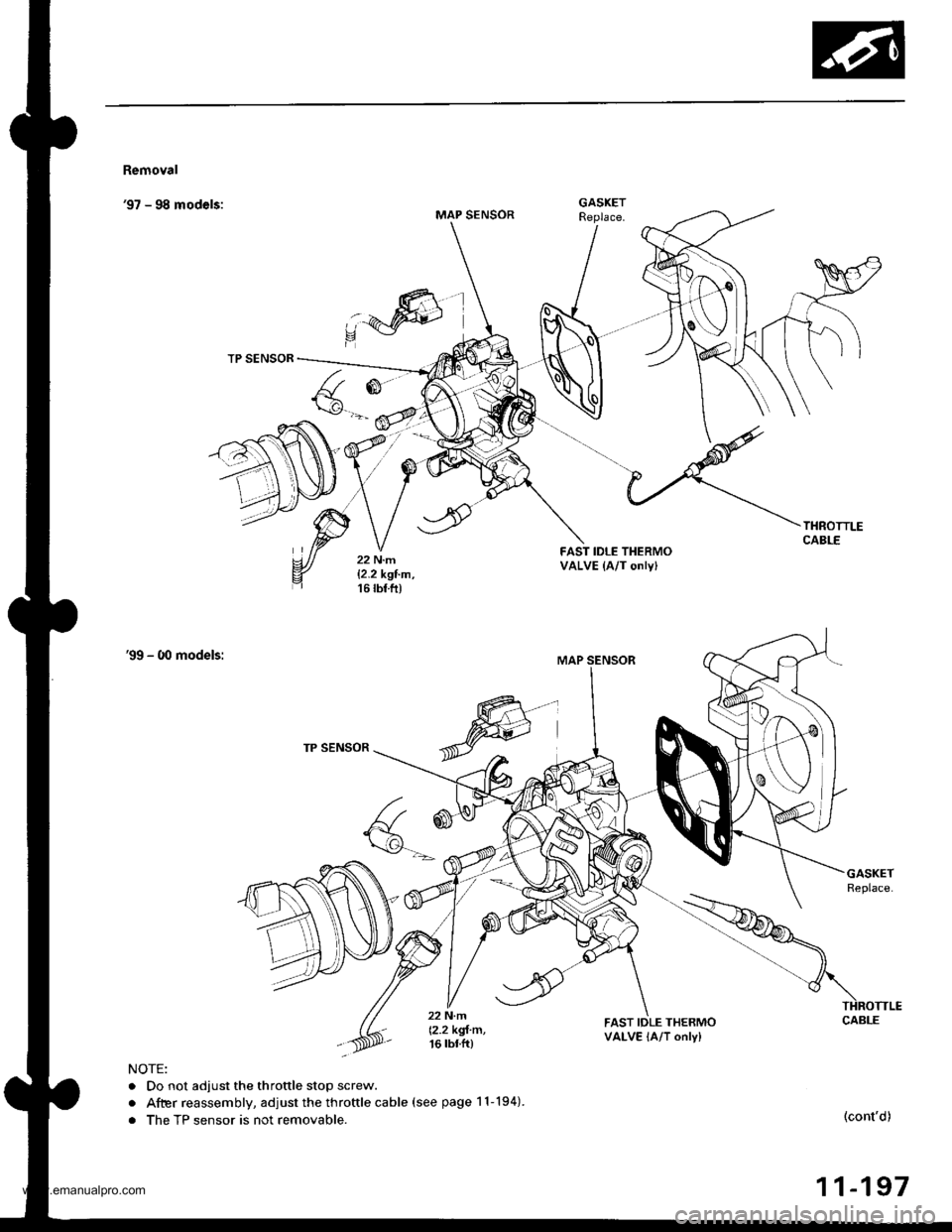

Removal

'97 - 98 models:MAP SENSOR

R

,:4W)

TP SENSOR

FAST IDLE THERMOVALVE (A/T onlyl

'99 - O0 models:

TP SENSOR

a

F(\g-.-'

22 N.m

12.2 kgl m,16 tbtft)

FAST IDLE THERMOVALVE lA/T only)

NOTE:

. Do not adjust the throttle stop screw.

. After reassembly, adjust the throftle cable (see page 11-194).

. The TP sensor is not removable.(cont'd)

11-197

GASKET

www.emanualpro.com

Page 400 of 1395

Intake Air System

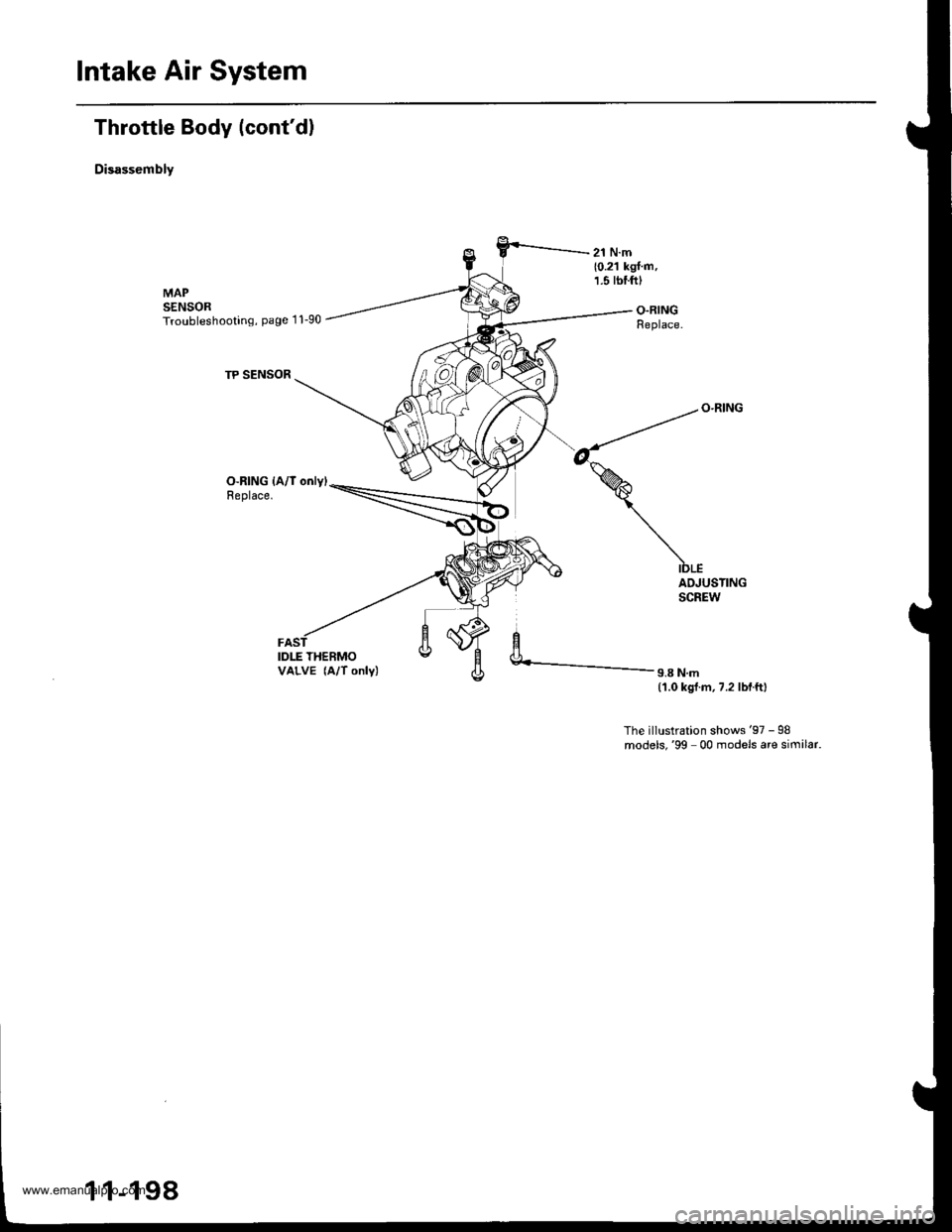

Throttle Body (cont'd)

Disassembly

O-RING {A/l only)Replace.

IDLE THERMOVALVE (A/T only)

ADJUSTINGSCREW

9.8 N.m(1.0 kgl.m,7.2 lbf.ftl

The illustration shows'97 - 98models,'99 00 models are similar.

1 1-198

www.emanualpro.com

Page 520 of 1395

Description

General Operation (cont'dl

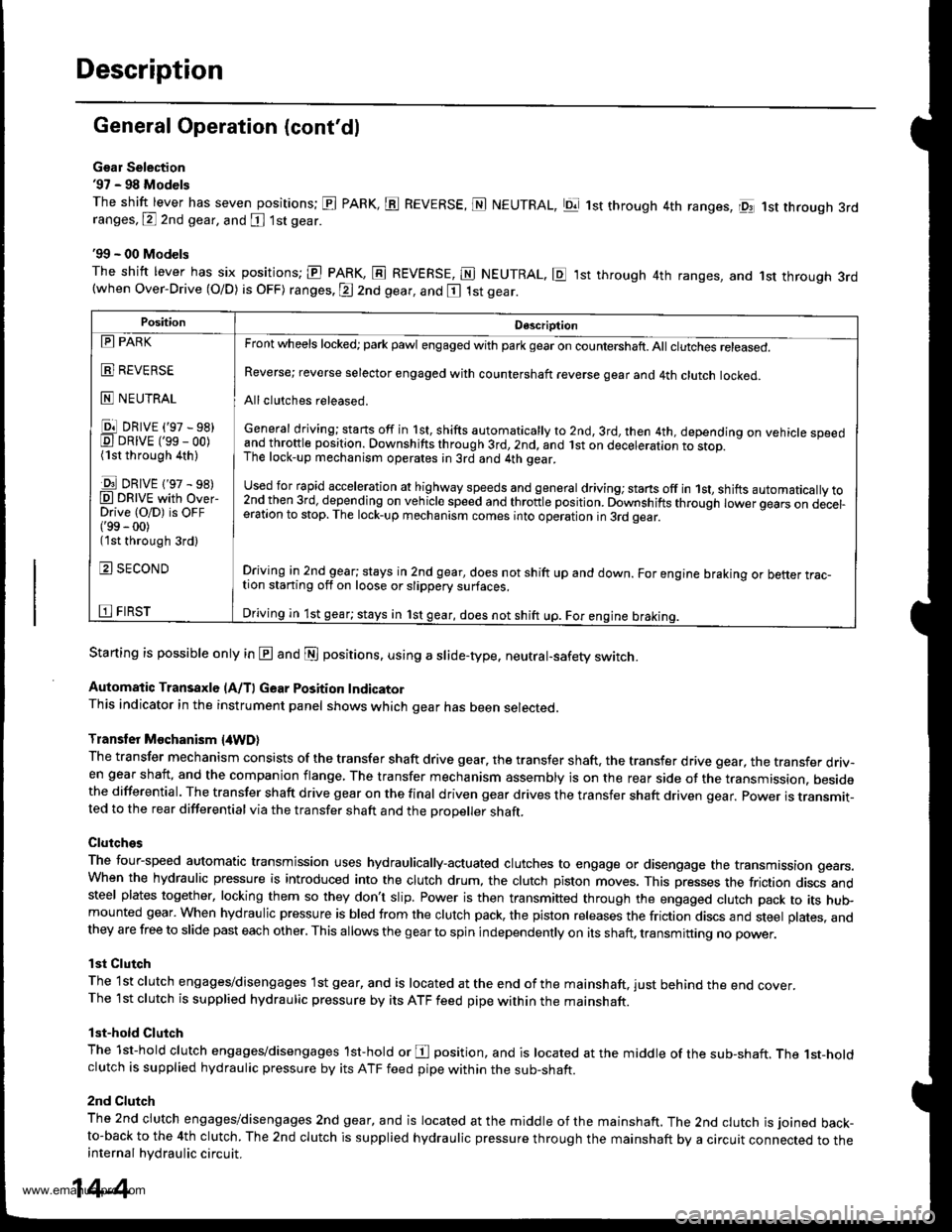

Gsar Selection'97 - 98 Models

The shift lever has seven positions; El PARK, ts REVERSE, N NEUTRAL, Ell 1st through 4th ranges, lpq 1st th.ough 3rdranges, P 2nd gear, and [ 1st gear

'99 - 00 Models

The shitt lever has six positions; El PARK, E REVERSE, E NEUTRAL. E ,lst through 4th ranges, and 1st through 3rd(when Over-Drive (O/D) is OFF) ranges. @ 2nd gear, and E 1st gear.

Starting is possible only in @ and @ positions. using a slide-type. neutral-safety switch.

Automatic Transaxle (A/T) Gear Position IndicatorThis indicator in the instrument panel shows which gear has been selected.

Transler Mochanism {4WD}

The transfer mechanism consists of the transfer shaft drive gear. the transfer shaft. the transfer drive gear, the transfer driv-en gear shaft, and the companion flange, The transfer mechanism assembly is on the rear side ot the transmission. besidethe differential. The transfer shaft drive gear on the final driven gear drives the transfer shaft driven qear. power is transmit-ted to the rear differential via the transfer shaft and the Drooeller shaft.

Clutches

The four-speed automatic transmission uses hydraulically-actuated clutches to engage or disengage the transmission gears.When the hydraulic pressure is introduced into the clutch drum, the clutch piston moves. This presses the friction discs andsteel plates together, locking them so they don't slip. Power is then transmifted through the engaged clutch pack to its hu$mounted gear. When hydraulic pressure is bled from the clutch pack, the piston releases the friction discs and steel plates, andthey are free to slide past each other. This allows the gearto spin independently on its shaft, transmitting no power.

lst Clutch

The 1st clutch engages/disengages lst gear, and is located at the end ofthe mainshaft, just behind the end cover.The 1st clutch is supplied hydraulic pressure by its ATF feed pipe within the mainshaft.

lst-hold Clutch

The 1st-hold clutch engages/disengages 1st-hold or E position, and is located at the middle of the sub-shaft. The 1st-holdclutch is supplied hydraulic pressure by its ATF feed pipe within the sub-shaft.

2nd Clutch

The znd ciutch engages/disengages 2nd gear, and is located at the middle of the mainshaft. The 2nd clutch is joined back-to-back to the 4th clutch. The 2nd clutch is supplied hydraulic pressure through the mainshaft by a circuit connected to theinternal hydraulic circuit.

PositionDescription

Reverse; reverse selector engaged with countershaft reverse gear and 4th clutch locked.

Allclutches released.

General driving; starts off in 1st, shifts automatically to 2nd, 3rd, then 4th, depending on vehicle speedand throftle position. Downshifts through 3rd,2nd, and lst on deceleration to stop.The lock-up mechanism operates;n 3rd and 4th gear.

used for rapid €cceleration at highway speeds and general driving; stans off in 1st, shifts automatically to2nd_then 3rd, dejending on vehicle speed and throttle position. Downshifts through lower gears on decel-eration to stop. The lock-up mechanism comes into operation in 3rd gear.

Driving in 2nd_gear; stays in 2nd gear, does not shift up and down. For engine braking or better trac_tion starting off on loose or slippery surfaces.

Driving in 1st gear; stays in 1st gear, does not shift up. For engine braking.

tll PARK

t!!l l|EvEn>E

E NEUTRAL

Ell DRrvE ('97 - sB)E DRrvE ('ss - oo)(1st through 4th )

E DRrvE {'97 - s8)O DRTVE with over-Drive (O/D) is OFF('99 - 00)(1st through 3rd)

E SECOND

E FIRST

14-4

www.emanualpro.com

Page 526 of 1395

Description

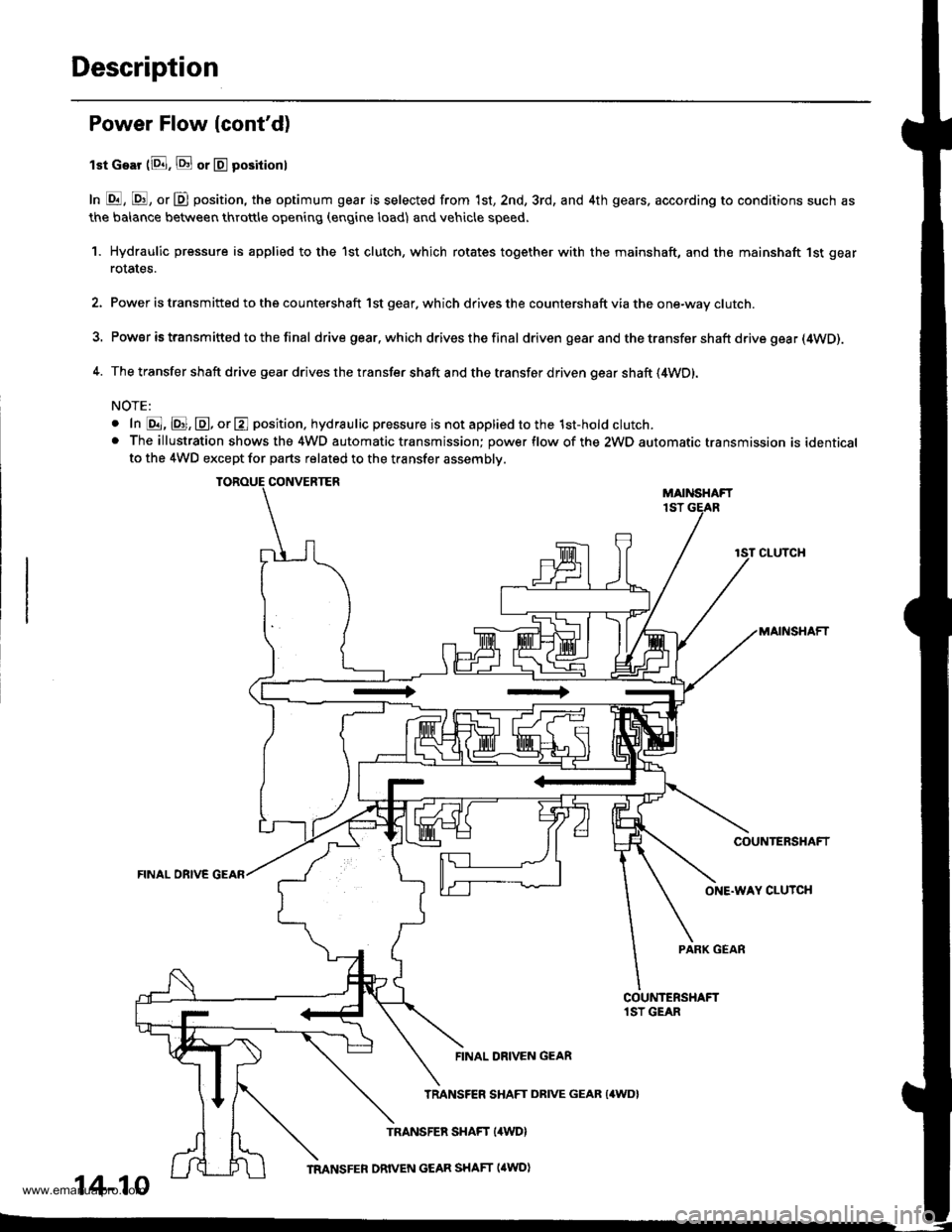

Power Flow lcont'd)

lst Gear (8. E or E positionl

In E, E, or D position, the optimum gear is selected from 1st, 2nd, 3rd, and 4th gears, according to conditions such as

the balance between throttle opening (engine load) and vehicle speed.

1. Hydraulic pressure is applied to the 1st clutch, which rotates together with the mainshaft, and the mainshaft 1st gear

rotates.

2. Power is transmitted to the countershaft 1st gear. which drives the countershaft via the one-way clutch.

3. Power is transm itted to the final drive gear.which drives the final driven gear and the transfer shaft drive gea r (4WD).

4. The transfer shaft drive gear drives the transfer shaft and the transfer driven gear shaft (4WD).

NOTE:

o In @, @, @, or E position. hydraulic pressure is not applied to the 1st-hold clutch.. The illustration shows the 4WD automatic transmission; power flow of the 2WD automatic transmission is identicalto the 4WD except for parts related to the transfer assembly.

CONVERTERMAIiISHAFT1ST

CLUTCH

MAINSHAFT

COUNTERSHAFT

FINAL OBIVE GEAR

ONE.WAY CLUTCH

PARK GEAR

FINAL DRIVEN GEAR

14-10

TRANSFER SHAFT DRIVE GEAR {4WD}

www.emanualpro.com

Page 532 of 1395

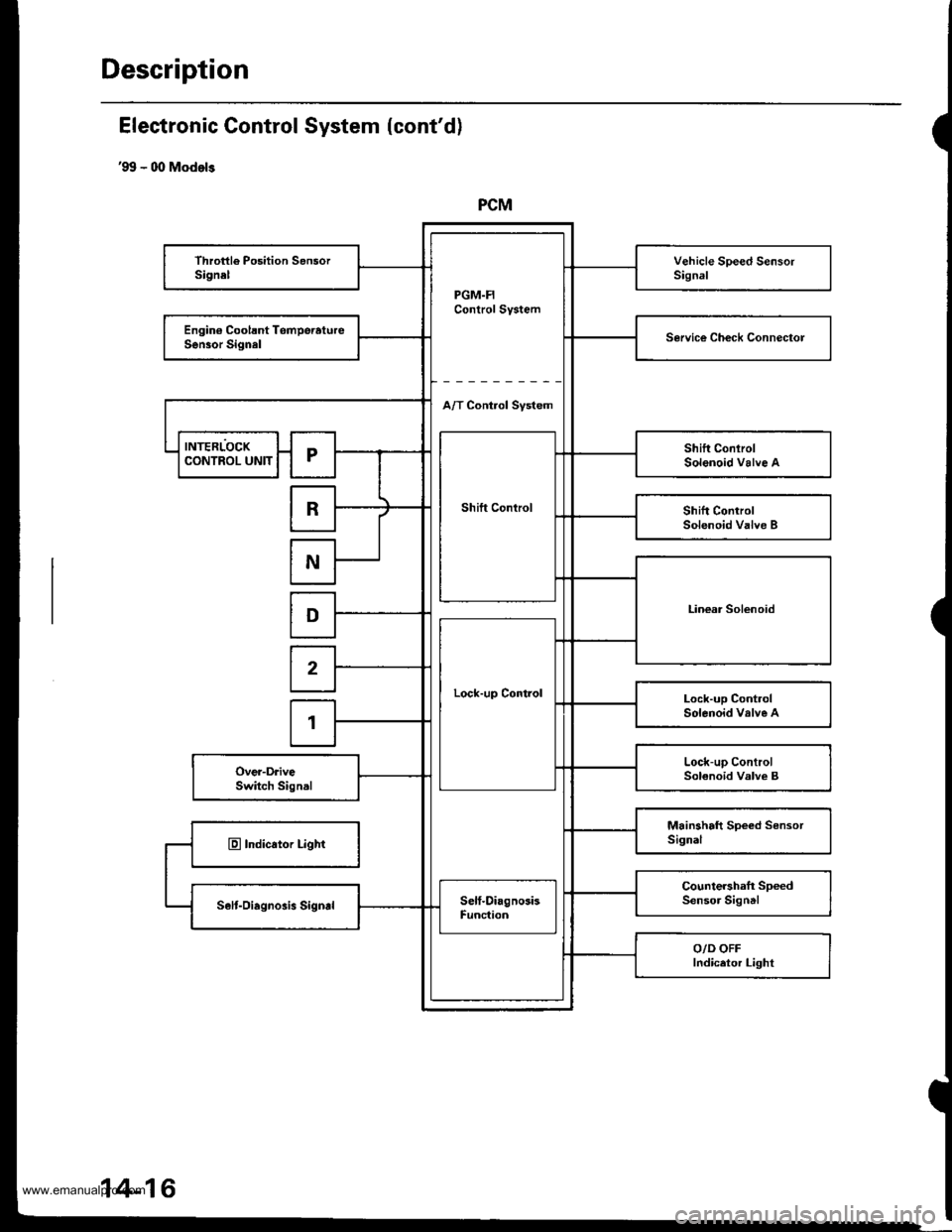

Description

PCM

PGM.FIControl System

Throttle Position SensorSignelVehicle Speed SensorSignal

Engin€ Coolsnt TomperatureSen30r SignalService Ch€ck Connectol

A/T Control Svstem

INTERLOCK

Shift Control

Shift ConlrolSolenoid Valve ACONTROL UNITr

RShift ControlSolenoid Valve B

N

Linear SolenoidD

Lock-up Control

2

Lock-up ControlSolenoid valve A1

Lock-up ControlSolenoid Valve BOver-DriveSwitch Signal

Mainshaft Speed SensorSignalE Indicator Light

Countershaft SpeedSensor SigntlSelt-Oiagnosis SigndSelf-DiagnosisFunc{ion

O/D OFFIndicetor Light

Electronic Gontrol System (cont'd)

'99 - 00 Models

14-16

www.emanualpro.com

Page 534 of 1395

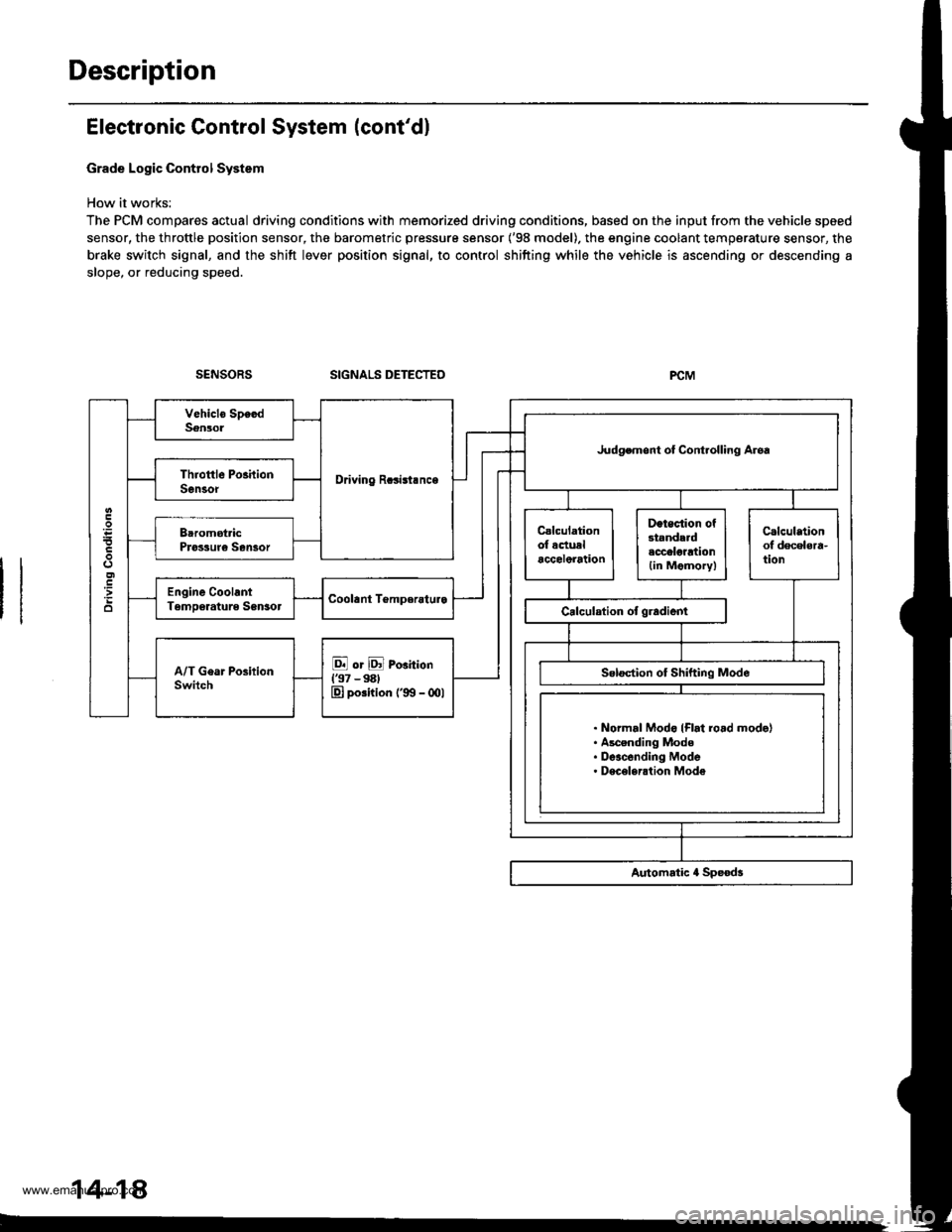

Description

Electronic Control System (cont'dl

Grade Logic Control System

How it works:

The PCM compares actual driving conditions with memorized driving conditions, based on the input from the vehicle speed

sensor, the throttle position sensor, the barometric pressure sensor ('98 model). the engine coolant temperature sensor, the

brake switch signal, and the shift lever position signal, to control shifting while the vehicle is ascending or descending a

slope, or reducing speed.

SIGNALS DETECTED

Driving Rcsisl.nce

Judgemont ot Controlling Aroa

. Normal Modo {Flrt ro.d mode}. Ascending Mode. Deacending Mode. Deceleration Mode

14-14

www.emanualpro.com

Page 536 of 1395

Description

Electronic Control System (cont'd)

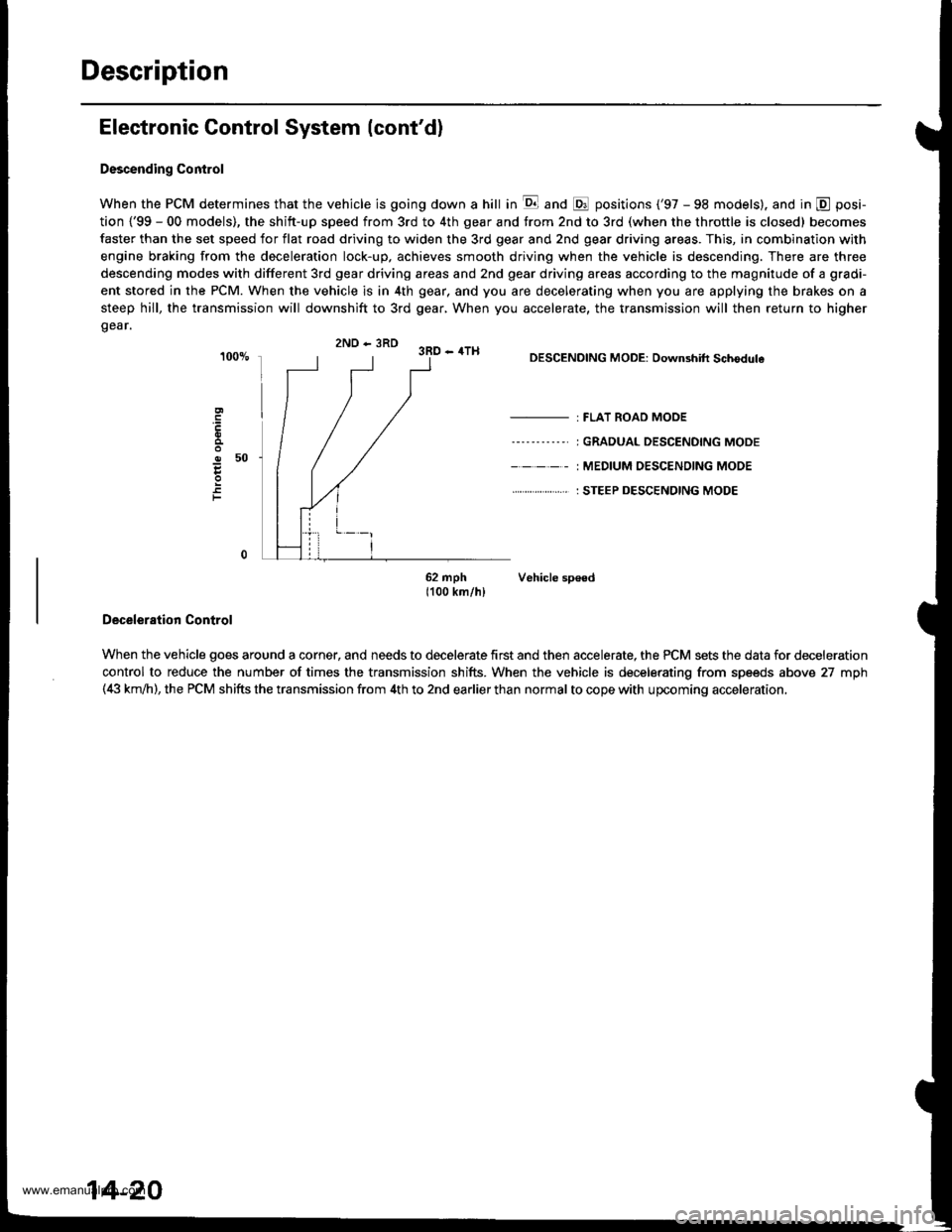

Descending Control

When the PCM determines that the vehicle is going down a hill in E and @ positions ('97 - 98 models). and in @ posi-

tion {'99 - 00 models), the shitt-up speed from 3rd to 4th gear and from 2nd to 3rd (when the throttle is closed) becomes

faster than the set speed for flat road driving to widen the 3rd gear and 2nd gear driving areas. This, in combination with

engine braking from the deceleration lock-up, achieves smooth driving when the vehicle is descending. There are three

descending modes with different 3rd gear driving areas and 2nd gear driving areas according to the magnitude of a gradi-

ent stored in the PCM. When the vehicle is in 4th gear, and you are decelerating when you are applying the brakes on a

steep hill, the transmission will downshift to 3rd gear, When you accelerate, the transmission will then return to higher

gear.

2ND - 3RD 3RD - 4TH

o50

F

DESCENDING MODE: Downshift Schodule

- : FLAT ROAD MODE

----'-----' I GRADUAL DESCENDING MODE

- - - - - : MEDIUM OESC€NOING MODE

. . ... : STEEP DESCENDING MODE

62 mph Vehicle sp€ed1100 km/hl

Deceleration Control

When the vehicle goes around a corner, and needs to decelerate first and then accelerate, the PCM sets the data for deceleration

control to reduce the number of times the transmission shifts. When the vehicle is decelerating from speeds above 27 mph(4i| km,ih), the PCM shifts the transmission from 4th to 2nd earlier than normal to cope with upcoming acceleration,

14-20

www.emanualpro.com

Page 643 of 1395

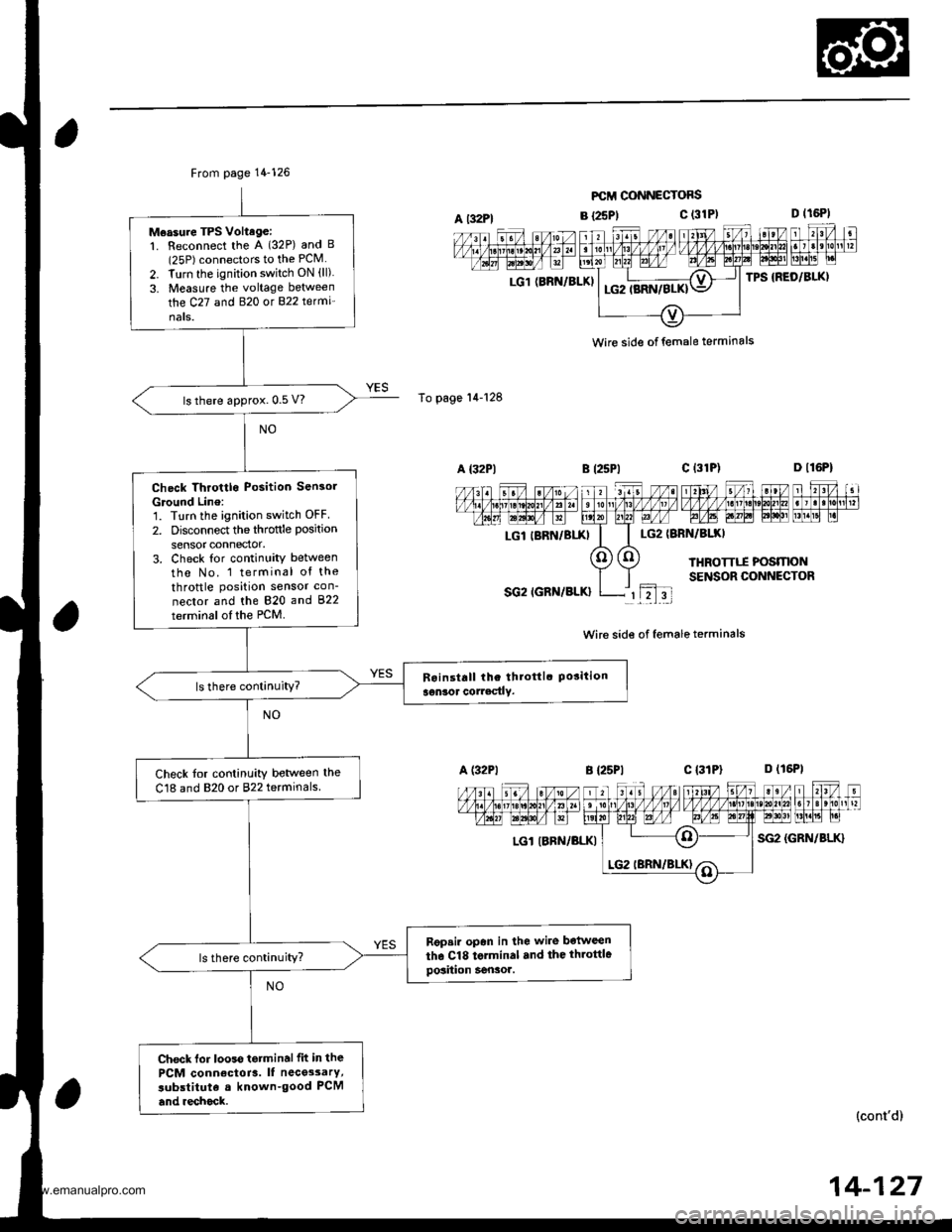

From page 14-126

Measure TPS Voltage:1. Reconnect the A (32P) and B(25P) connectors to the PCM

2. Turn the ignition switch ON (ll)

3. Measure the voltage between

the C27 and B�20 ot 822 te(mi'

nats.

ls there approx. 0.5 V?

Check Throttlo Position Sensol

Ground Line:'1. Turn the ignition switch OFF

2. Disconnect the throftle position

sensor connector.3. Check tor continuity between

tho No. 1 terminal of the

throttle position sensor con-

nector and the 820 and 822

terminsl of the PCM.

ls there continuity?

Check tor continuity betlveen the

C18 and 820 or 822 terminals

Rgpsir opan in lhe wire botween

the Cl8 torminal .nd the throttlegosiiion Sensor.ls there continuity?

Check lor looss tetminalfit in the

PCM conn€ctoia. It nece3sarY,

subslituta a known-good PCM

and .echock.

A t32Pl

To page'14-128

LG1 (BRN/BLKI

FCII CONNECTOFS

B {25P1c (31P)

LG2IBRN/BIXI

THROTTTI POSMONSENSOR CONNECTOR

SG2 IGRN/BLK}rL2l3t

Wire side of female terminals

B {25P1c l3lPl D (16P1

LGl IBRN/BLKISG2 {GRN/BLK}

n l,I-il nFFFTI,T';T;IEFML"| -

(cont'd)

wire side of female terminals

LGl IBRN/BIXI

14-127

www.emanualpro.com