Water HONDA CR-V 2000 RD1-RD3 / 1.G Service Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 1069 of 1395

Spare Tire Gover

Emblem Installation

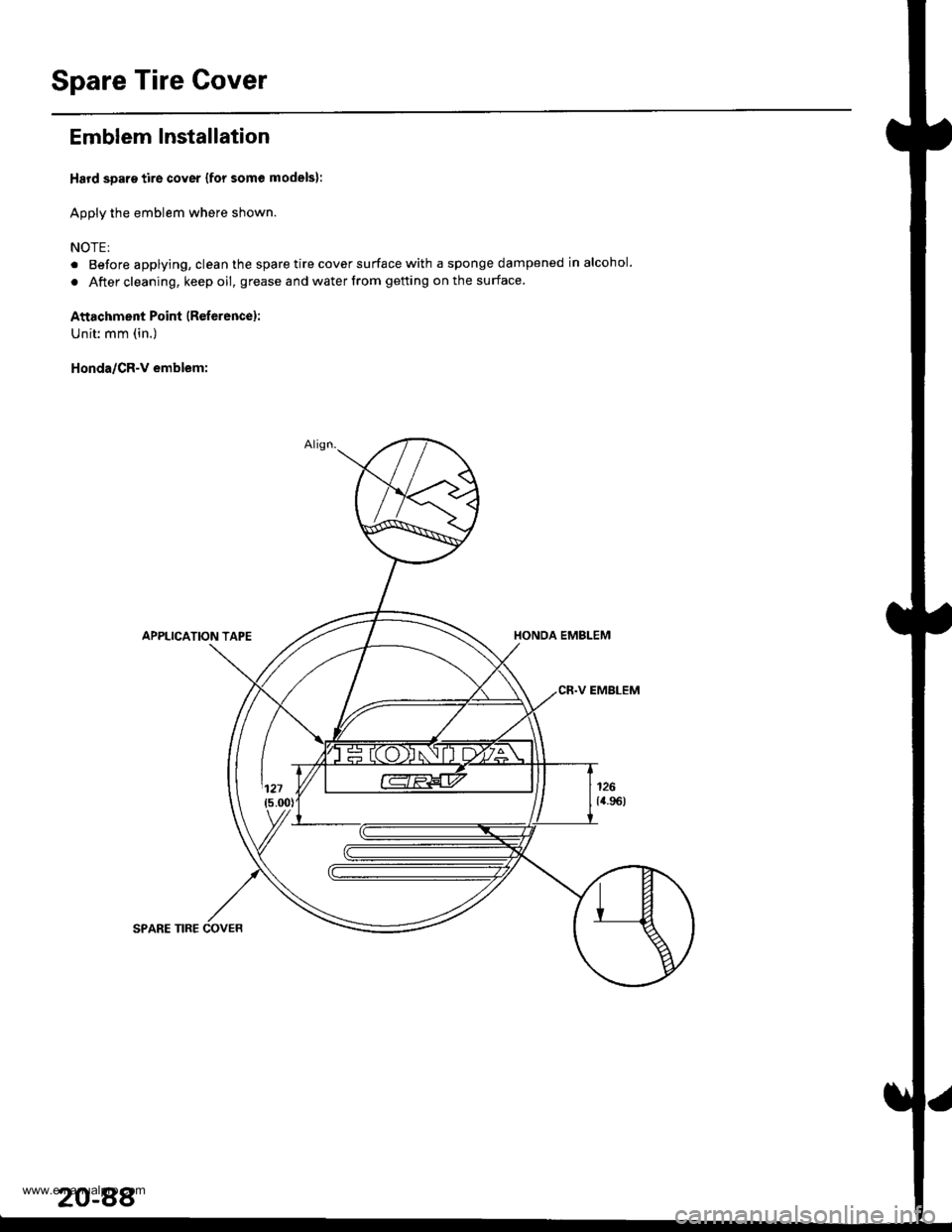

Hard spare tire cover {for some models}:

Apply the emblem where shown.

NOTE:

. Before applying, clean the spare tire cover surface with a sponge dampened in alcohol.

. After cleaning, keep oil, grease and water from getting on the surface

Attachment Point lR€ferencel:

Unit: mm (in.)

Honda/CR-v emblem:

APPLICATION TAPEHONDA EMBLEM

CR.V EMBLEM

SPARE TIRE COVEB

20-88

www.emanualpro.com

Page 1134 of 1395

Evaporator Temperature

SensorPower Transistor

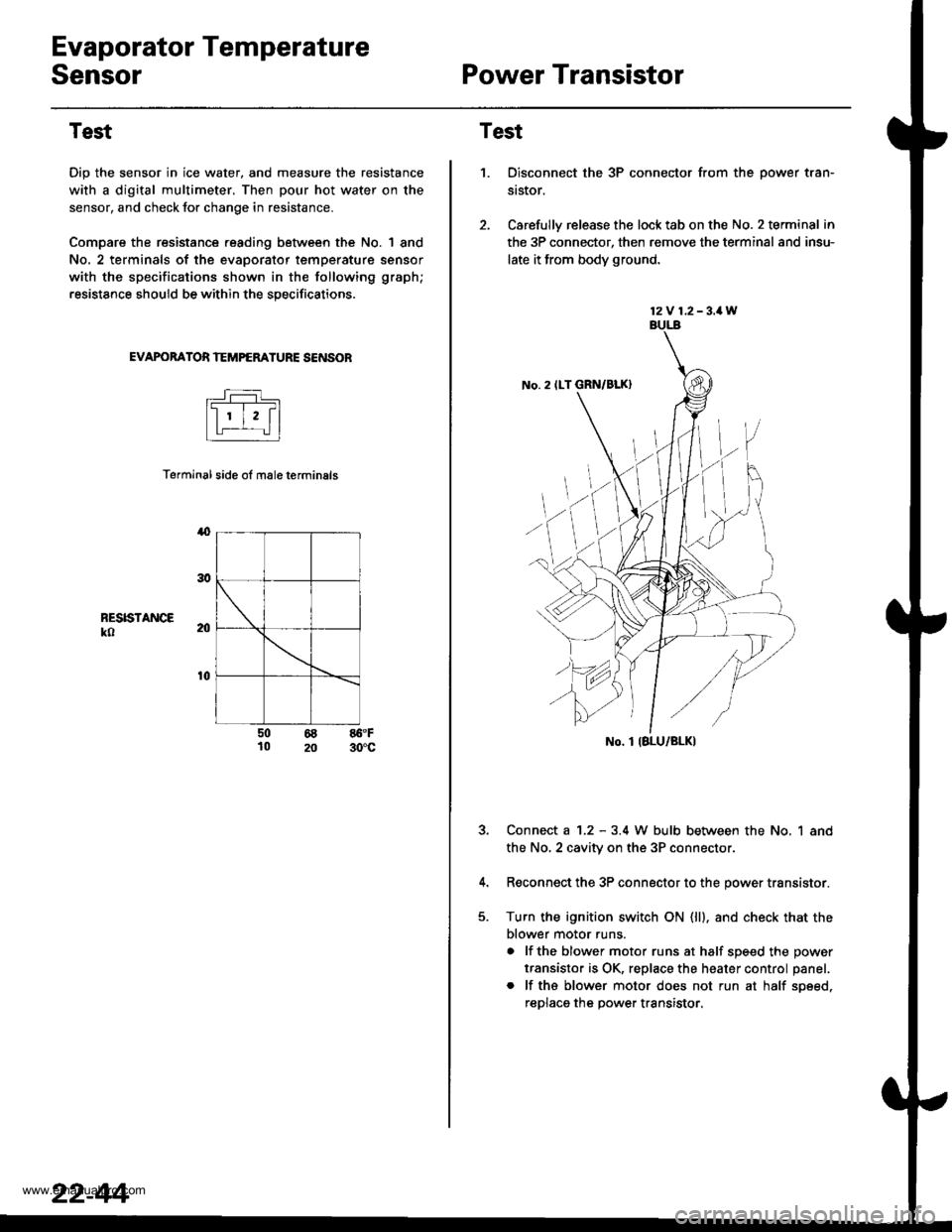

Test

Dip the sensor in ice water, and measure the resistance

with a digital multimeter. Then pour hot water on the

sensor, and check lor change in resistance.

Compare the resistance reading between the No. | 8nd

No. 2 terminals of the evaporator temperature sensor

with the specifications shown in the following graph;

resistance should be within the specifications.

EVAPOBATOR TEMPERATURE SENSOB

Terminal side ol male terminals

4

RESISTANCEko

t0

50 68 86.F10 20 30'c

22-44

12V 1.2-3.1W

No. 2 ILT GRN/BLK)

No. I IBLU/BLK)

Test

1.Disconnect the 3P connector from the oower tran-

st$or.

Carefully release the lock tab on the No. 2 terminal in

the 3P connector, then remove the terminal and insu-

late it from body ground.

Connect a 1.2 - 3.4 W bulb between the No, 1 and

the No,2 cavity on the 3P connectol

Reconnect the 3P connector to the power transistor.

Turn the ignition switch ON (ll). and check that the

blower motor runs.

a lf the blower motor runs at half soeed the oower

transistor is OK, replace the heater control panel.

. lf ths blower motor does not run at half soeed,

reDlaca the Dower transistor.

www.emanualpro.com

Page 1148 of 1395

A/C System Service

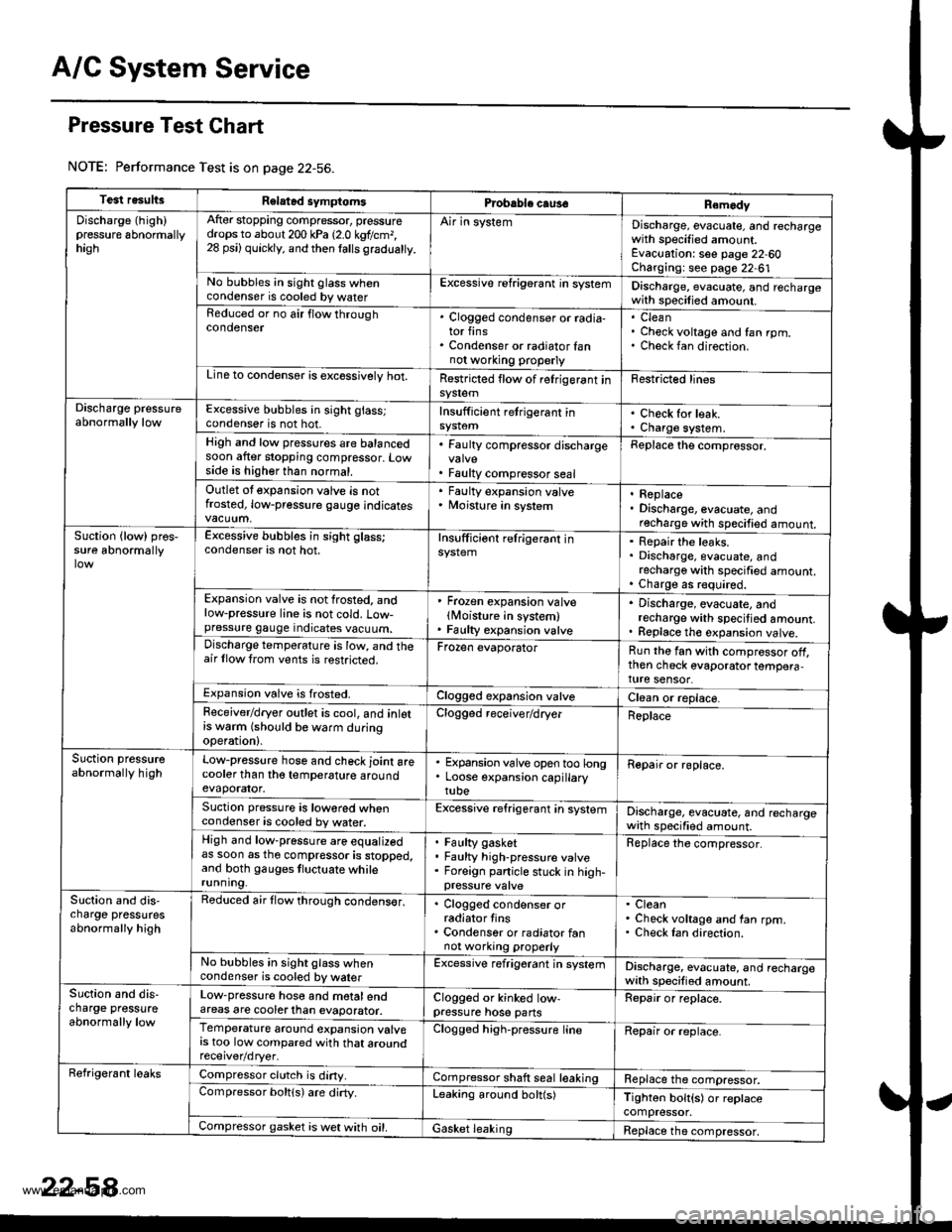

Pressure Test Chart

NOTE: Performance Test is on page 22-56.

Test resultsRelatad symptomsPrcbable caus€Remody

Discharge (high)pressure 6bnormallyhagh

After stopping compressor, pressuredrops to about 200 kPa 12.0 kgtlcm,,28 psi) quickly, and then lalls gradualty.

Air in systemDischarge, evacuate, and rechargewith specified amount.Evacuation: see page 22-60Charging: see page 22-61No bubbles in sight glass whencondenser is cooled by waterExcessive refrigerant in systemDischarge, evacuate, and rechargewith specilied amount.Reduced or no air flow throughcondenser. Clogged condenser or radia-tor fins. Condenser or radiator fannot wo.king properly

CleanCheck voltage and fan rpm.Check fan direction.

Line to condensor is excossivelv hot.Restricted flow of relrigerant insy$emFestricted lines

Discharge pressureabnormally lowExcessive bubbles in sight glass;condenser is not hot.Insufficient retrigerant inCheck for leak.Charge system.High and low pressures are balancedsoon after stopping compressor. Lowside is higher than normal.

. Faulty compressor discharge

. Faulty compressor seal

Replace the comprossor.

Outlet ot expansion valve is notfrosted, low-pressure gauge indicates

' Faulty expansion valve. Moisture in system. Replace. Discharge, evacuate, andrecharge with specified amount.Suction {low) pros,sure abnormallyExcessive bubbles in sight glass;condenser is not hot.Insufficiont relrigerant inRepair the leaks.Discharge, evacuate, andrecharge with specified amount.Charge as r€quired.Expansion valve is not frosted, andlow-pressure line is not cold. Low-pressure gauge indicates vacuum.

' Frozen expansion valvelMoisture in system). Faulty expansion valve

. Discharge, evacuate, andrecharge with specitied amount.. Replace th€ expansion valve.Discharge temperature is low, and theair llow trom vents is restricted.Frozen evaporatorRun the fan with compressor off,then check evaporator tempera,ture sensor.Expansion valve is frosted.Clogged expansion valveClean or replace.Feceiver/dryer outlet is cool, and inlotrs w6rm (should be warm duringoperation).

Clogged receiver/dryerReplace

Suction pressureabnormally highLow-pressure hose and check joint arecooler than tho temperature aroundevaporator.

. Expansion valve open too long. Loose expansion capillarytube

Repair or roplace.

Suction pressure is lowored whencondenser is cooled by water.Excessive refrigerant in systemDischarge, evacuate, and rechargewath specified amount.High and low-pressure are equalizedas soon as tho compressor is stopped,and both gauges tluctuate whilerunning.

Faulty gasketFaulty high-pressure valveForeign panicle stuck in high-

Replace the compressor.

Slction and dis,charge pressutesabnormally high

Reduced air flow through condens€r,. Clogged condenser orradiator tins. Condenser or radiator fannot working properly

CleanCheck voltage and fan rpm.Check Ian direction.

No bubbles in sight glass whencondenser is cooled by walerExcessive refrigerant jn systemDischarge, evacuate, and rechargewith specified amount.Suction and dis-charge pressureabnormally low

Low-pressure hose and motalendareas are cooterlhan evaporator.Clogged or kinked low-pressure hose pansRepair or replace.

Temperature around expansion valvers too low compared with that aroundClogged high-pressure lineRepair or replace.

Refrigerant leaksCompressor clutch is diny.Compressor shaft seal leakingReplace the compressor.Compressor boltls) are dirty.Leaking around bolt(s)Tighton bolt{s) or replacecompressor.Compressor gasket is wet with oil.Gasket leakingReplace the compressor,

www.emanualpro.com

Page 1163 of 1395

Troubleshooting

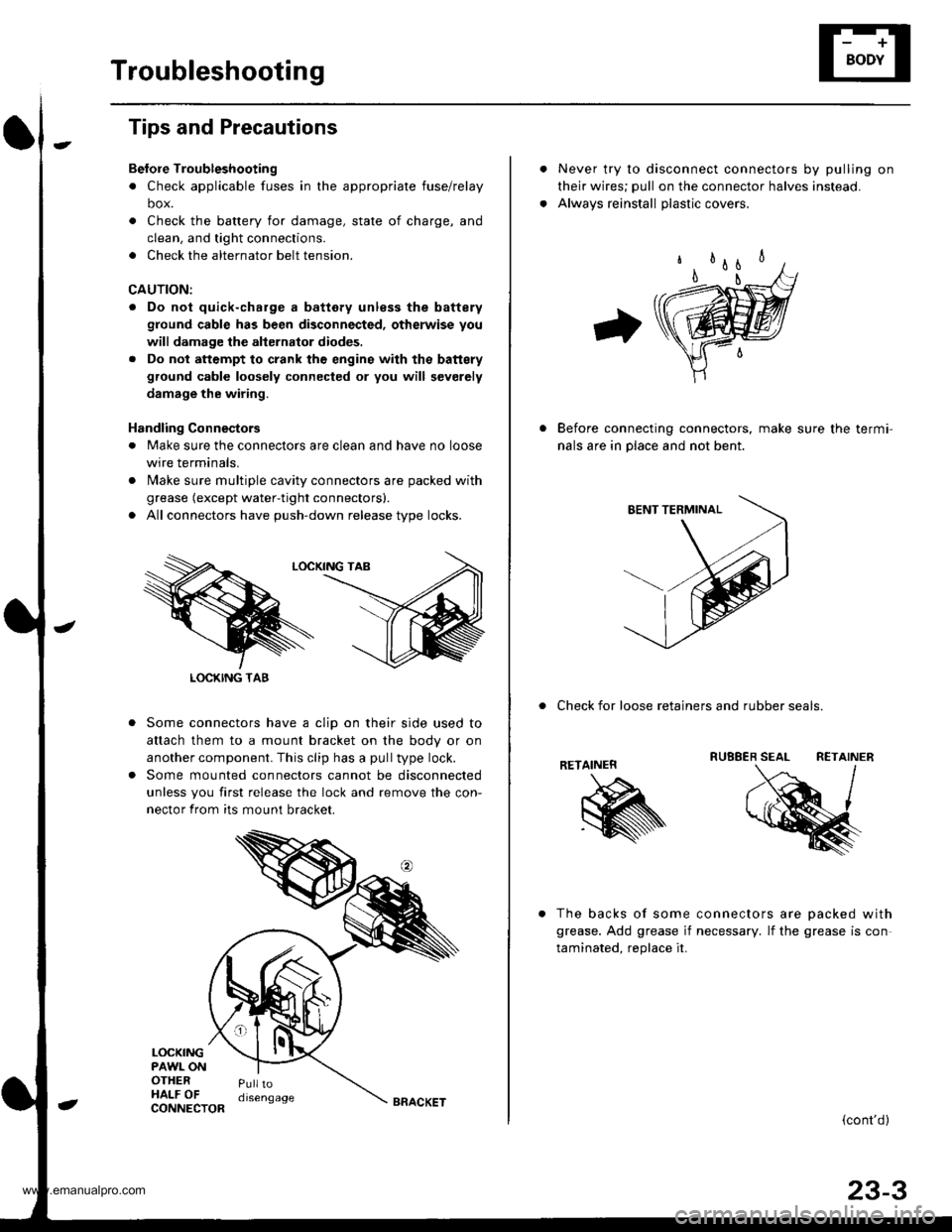

Tips and Precautions

Bef ore Troubleshootin g

. Check applicable fuses in the appropriate fuse/relay

box.

. Check the battery for damage, state of charge, and

clean. and tight connections.

. Check the alternator belt tension.

CAUTION:

. Do not quick-charge a battery unless the battery

ground cable has been disconnected, otherwise you

will damage the alternator diodes.

. Do not attempt to crank thc engins wilh the battery

ground cable loosely connected or you will severely

damage the wiring.

Handling Connestors

. Make sure the connectors are clean and have no loose

wire terminals,

. N4ake sure multiple cavity connectors are packed with

grease (except water-tight connectors).

. All connectors have push-down release type locks.

Some connectors have a clip on their side used to

attach them to a mount bracket on the body or on

another component. This clip has a pull type lock.

Some mounted connectors cannot be disconnected

unless you first release the lock and remove the con-

nector from its mount bracket.

LOCKINGPAWL ONOTHERHALF OFPulltodisengage

LOCKING TAB

CONNECTORBRACKET

Never try to disconnect connectors by pulling on

their wires; pull on the connector halves instead.

Alwavs reinstall olastic covers.

Before connecting connectors, make sure the termi-

nals are in place and not bent.

. Check for loose retainers and rubber seals.

RETAINER

The backs of some connectors are oacked with

grease. Add grease if necessary. lf the grease is con

taminated. reolace it.

{cont'd}

23-3

www.emanualpro.com

Page 1164 of 1395

Troubleshooting

Tips and Precautions (cont'dl

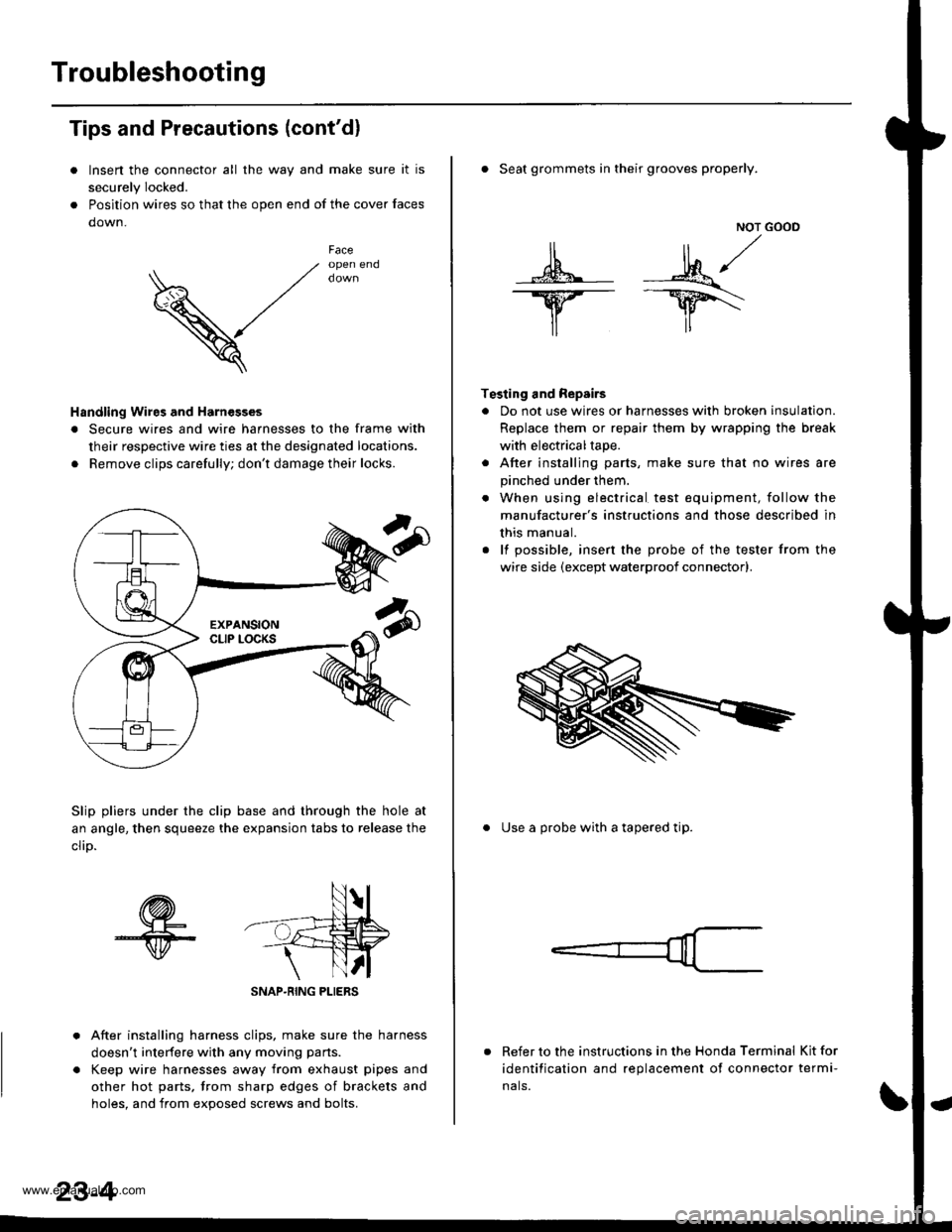

Insen the connector all the way and make sure it is

securely Iocked.

Position wires so that the open end of the cover faces

down.

V

Faceopen end

Handling Wires and Harnesges

. Secure wires and wire harnesses to the frame with

their respective wire ties at the designated locations.

. Remove clips carefully; don't damage their locks.

Slip pliers under the clip base and through the hole at

an angle, then squeeze the expansion tabs to release the

clrD.

After installing harness clips, make sure the harness

doesn't interfere with any moving pans.

Keep wire harnesses away from exhaust pipes and

other hot parts, trom sharp edges of brackets and

holes. and from exoos€d screws and bolts.

NOT GOOD

A -M/

lr lr*

T€sting and Repairs

. Do not use wires or harnesses with broken insulation.

Replace them or repair them by wrapping the break

with electricaltape.

. After installing parts, make sure that no wires are

pinched under them.

. When using electrical test equipment, follow the

manufacturer's instructions and those described in

this manual.

. lf possible, insert the probe of the tester from the

wire side (except waterproof connector).

. Seat grommets in their grooves properly.

. Use a probe with a tapered tip.

Refer to the instructions in the Honda Terminal Kit for

identification and replacement of connector termi-

nals.

www.emanualpro.com

Page 1210 of 1395

Battery

Test

@M. Battery fluid (eleqtrolyte) contains sulturic acid. lt may couse sevore burns if it gets on your skin or in your eyes. Wearprotective clothing and a fac6 shield.- lf elestrolyte gets on your skin o. clothos, rinse it otf with wator imm€diately.- lf €leqtrolyte gets in your eyes. tlush it out by splashing water in your syes for at least 15 minutes; call a physicianimmediately.

. A battery gives off hydrogon gas. lf ignited, the hydrogen will €xplode and could crack the battery case and splatt€racid on you. Kgop sparks. flamss, and cigarettes away from the batt€ry,. Overcharging will raise the tomperatute of the electrolyte. This may torcs electrolyto to spray out of the battEry vents,Follow the charger manutacturer's instructions, and charge the battery at a proper ral€,

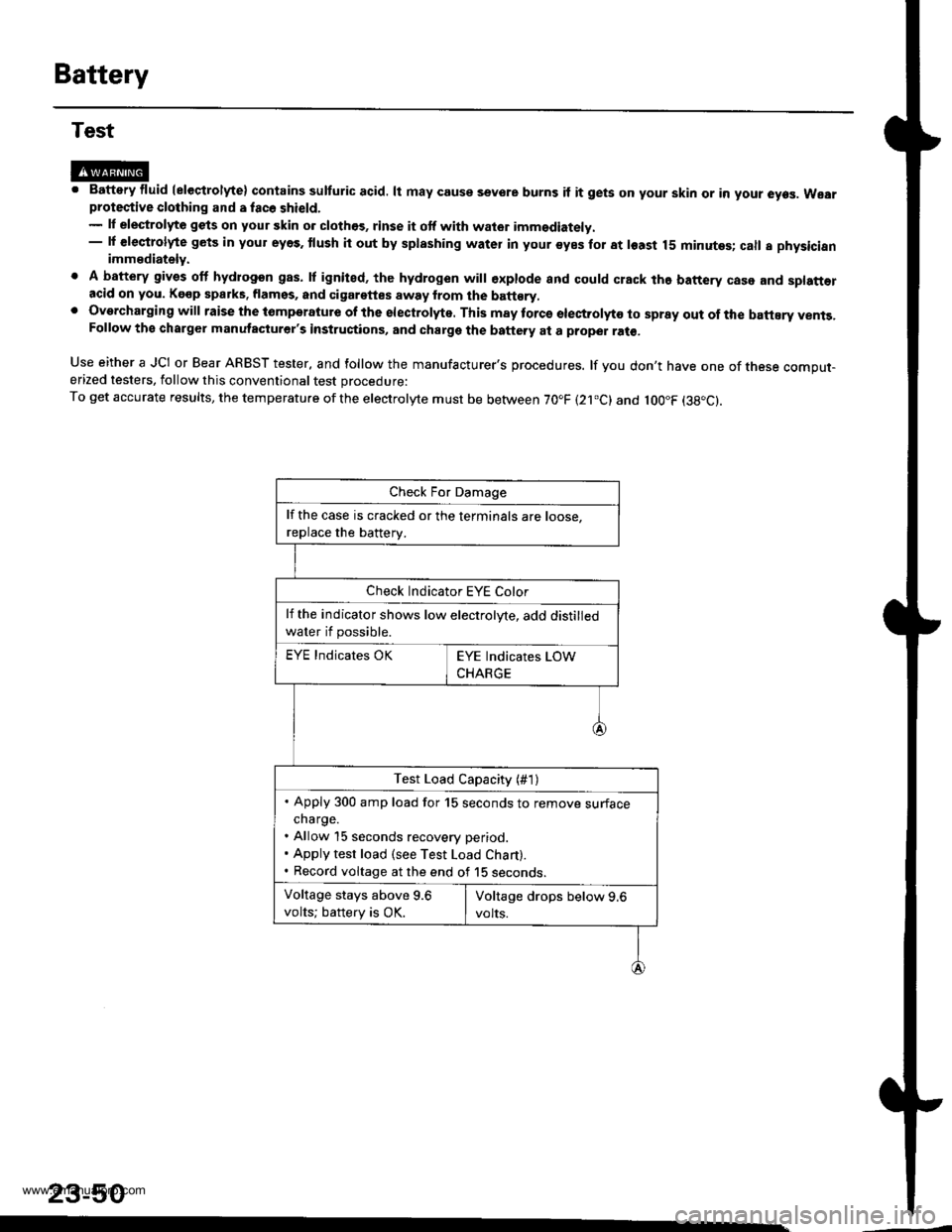

Use either a JCI or Bear ARBST tester, and follow the manufacturer's procedures. lf you don't have one of tnese comput-erized testers, follow this conventional test procedure:

To get accurate results, the temperature ofthe electrolyte must be between 70.F (21.c) and loo"F (38"c).

23-50

lf the case is cracked or the terminals are roose.

replace the batterv.

Check Indicator EYE Color

lf the indicator shows low electrolyte, add distilled

water if possible.

EYE Indicates OK

Test Load Capacity (#1)

. Apply 300 amp load for 15 seconds to remove surfacecharge.. Allow 15 seconds recovery period.. Apply test load (see Test Load Chart).. Record voltage at the end of 15 seconos.

Voltage stays above 9.6

volts; battery is OK.

www.emanualpro.com

Page 1242 of 1395

Rear Side Marker Lights/

License Plate LightTaillights

Replacement

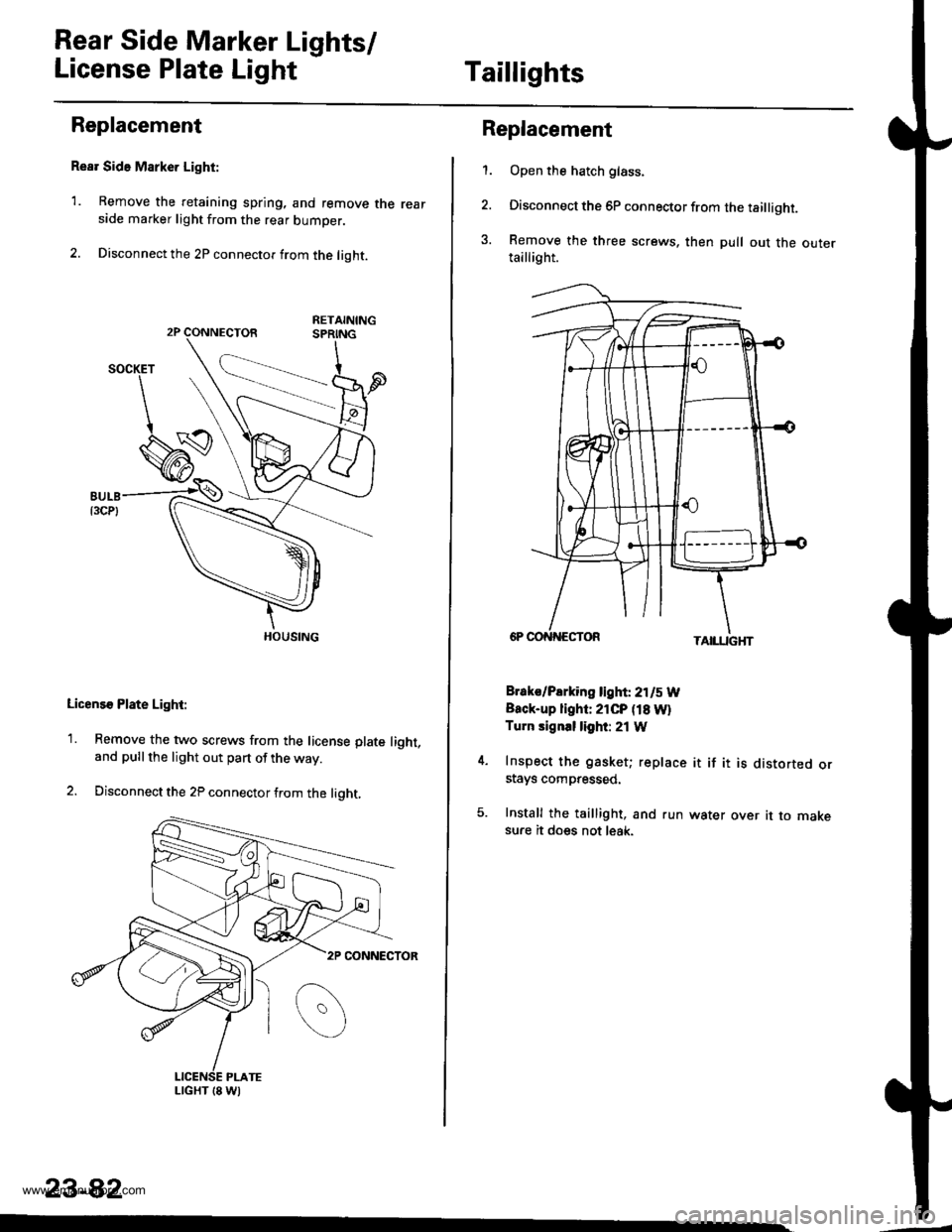

Rear Side Marke. Light:

1. Remove the retaining spring, and remove the rearside marker light from the rear bumper.

2. Disconnect the 2P connector from the light.

RETAINING

HOUSING

Licens€ Plate Light:

1. Remove the two screws from the license plate light,and pull the light out part of the way.

2. Disconnect the 2P connector from the light,

23-A2

LIGHT (8 WI

Replacement

1. Open the hatch glass.

2. Disconnect the 6P connector from the taillight.

3. Remove the three screws, then pull out the outertaillight.

Brak€/Plrking light 2115 W

Back-up light: 21CP (18 W)

Turn signll light 21 W

Inspect the gasket; replace it if it is distorted or$ays compressed.

Install the taillight, and run water over it to makesure it does not leak.

www.emanualpro.com

Page 1316 of 1395

Precautions/Procedures

)General Precautions

Carefully inspect any SRS part before you install it.

Do not install any part that shows signs of being drop-

ped or improperly handled, such as dents, cracks or

deformation:

- Airbags- Cable reel- SRS unit- Seat belt tensioners

N

)-

Use only a digital multimeter to check the system, lf

it's not a Honda multimeter, make sure its output is

10 mA (0,01 A) or less when switched to the smallest

value in the ohmmeter range. A tester with a higher

output could damage the airbag circuit or cause acci-

dental deployment and possible injury.

Do not install used SRS Dans from another vehicle,

When making SRS repairs, use only new pans.

Except when performing electrical inspections,

always disconnect both the negative cable and posi-

tive cable from the batterv. and wait at least three

minutes before beginning work.

Replacement of the combination light and wiper/

washer switches and cruise control switch can be

done without removing the steering wheel:

- Combination light and wiper/washer switch replace-

ment {see section 231.- Cruise control sevresume switch replacement (see

section 41.

Whenever the ignition switch is ON {ll}, or has been

turned OFF for less than three minutes, be careful not

to bump the SRS unit; the airbags could accidentally

deploy and cause damage or injuries.

Whenever the airbag has been activated, replace the

SRS unit.

The original radio has a coded theft protection circuit.

Be sure to get the customer's code number before dis-

connecting the battery cables.

)

Airbag/Seat Belt Tensioner

Handling and Storage

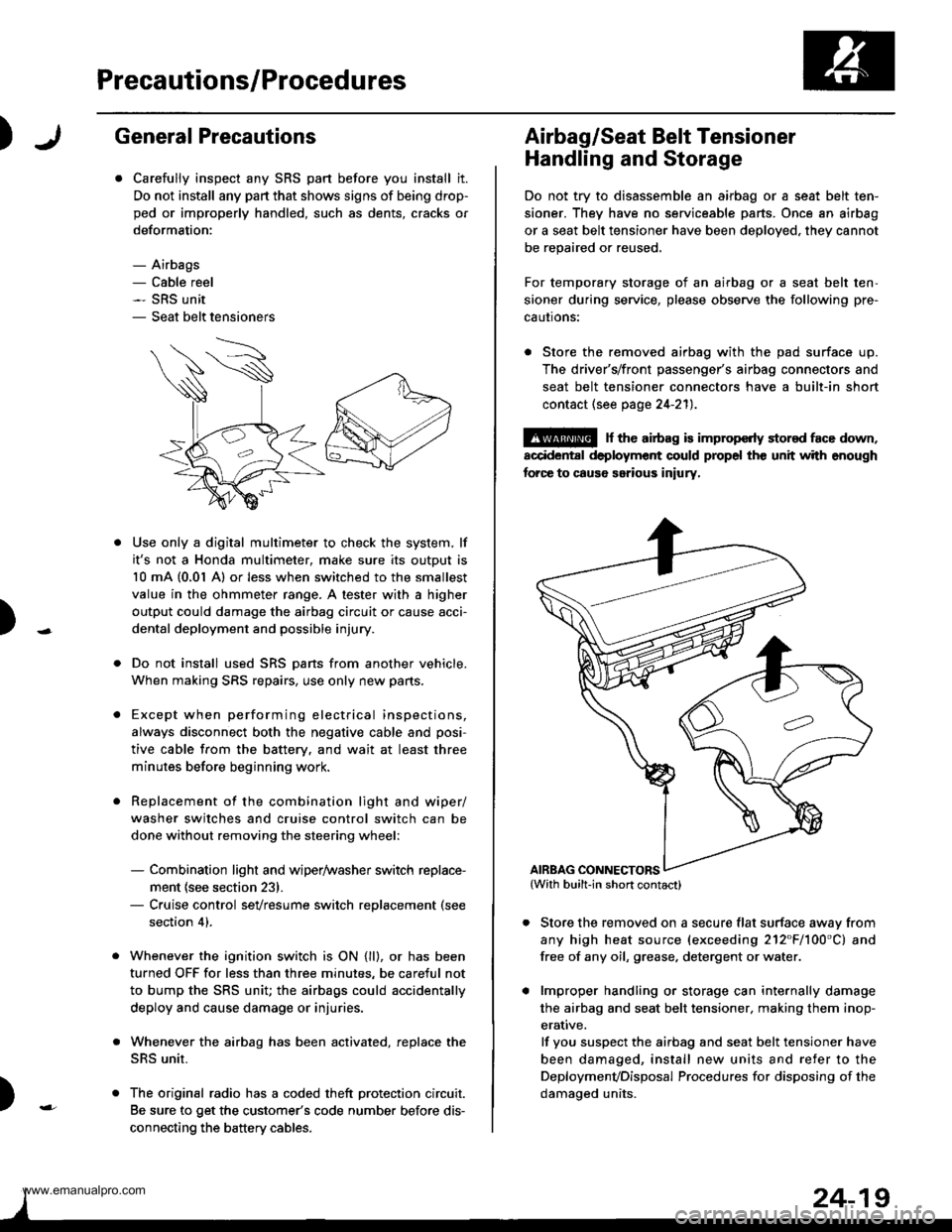

Do not try to disassemble an airbag or a seat belt ten-

sioner. They have no serviceable parts. Once an airbag

or a seat belt tensioner have been deployed. they cannot

be repaired or reused.

For temporary storage of an airbag or a seat belt ten-

sioner during service, please observe the following pre-

cautons:

. Store the removed airbag with the pad surface up.

The driver's/front passenger's airbag connectors and

seat belt tensioner connectors have a built-in short

contact (see page 24-211.

@ r th€ airb.g is impropcrty stor€d face down,

accidental deployment could propel the unit with enough

forc€ to caus6 serious iniury,

Store the removed on a secure flat surface awav from

any high heat source (exceeding 212"F/100'C) and

free of any oil, grease. detergent or water.

lmproper handling or storage can internally damage

the airbag and seat belt tensioner. making them inop-

erative.

lf you suspect the airbag and seat belt tensioner have

been damaged, install new units and refer to the

Deploymenvoisposal Procedures for disposing of the

damaoed units.

AIRBAG CONNECTORS

www.emanualpro.com

Page 1317 of 1395

Precautions/Procedures

SRS Unit Precautions

Take extra care when painting or doing body work in

the area below the dashboard. Avoid direct exposure

of the SRS unit or wiring to heat guns, welding, or

spraying equipment.

Disconnect the driver's/front passenger's airbag con-

nectors and seat belt tensioner connectors before

working below the dashboard near the SRS unit.

After any degree of frontal body damage, or after a

collision without airbag deployment, inspect the SRS

unit for physical damage. lf it is dented, cracked, or

detormed, reolace it,

Be sure the SRS unit is installed securelv.

Do not disassemble the SRS unit.

Store the SRS unit in a cool {less than about

104"F/40"C) and dry {less than 80o/o humidity. no

moisture) place. Do not spill water or oil on the SRS

unit, and keep it awav from dust.

During installation or replacement, be careful not to

bump (impact wrench, hammer, etc.) the area a[ound

the SRS unit, The airbags could accidentally deploy

and cause damage or injury.

24-20

,..4

Inspection After Deployment

After a collision in which the airbags were deployed.

replace the SRS unit, and inspect the following:

1. Inspect all the SRS wire harnesses. Replace, don't

repair, any damaged harnesses

2. Inspect the cable reel for heat damage, lf there is any

damage. replace the cable reel.

3. After the vehicle is completely repaired, turn the

ignition switch on. lf the SRS indicator light comes

on for about six seconds and then goes off, the SRS

system is OK. lf the indicator light does not function

properly, go to SRS Troubleshooting.

rD

www.emanualpro.com

Page 1392 of 1395

SRS Unit

).0Replacement

CAUTION:

. Before disconnecting any part of the SRS wire har-

nesg, disconnect the airbag connoctors (and soat beh

tensioner connectorsl.

. During installation or replacament, do not bump(impact wrench, hammer etc.) the area near the SRS

unit.

Do not damage the SFS unit terminalg or connsc-

lors.

Do not disassemble the SRS unit it has no saryice-

able parts,

Store the SRS unit in a clean, dry area.

Do not use any SRS unit which has been subiected

to water damage or shows signs ot being dropped orimproperly handlgd, such as dents, cracks or defor-

mation.

Disconnect the battery negative cable, then discon-

nect the positive cable from the battery, andwaitat

least three minutes.

Disconnect the airbag connectors (and seat belt ten-

sioner connectors). (When disconnected, the airbag

and seat belt tensioner connectors are automatical-

ly shorted.)

Driver's Side:

. Remove the access panel from the steering

wheel, then disconnect the 2P connector

between the driver's airbag and cable reel (see

page 24-231.

Front Passenger's Side:. Disconnect the 2P connector between the frontpassenger's airbag and SRS main harness (see

page 24-231.

Soat Beh Tensionor ('98 - 00 modelsr:. Remove the left and right center pillar lower trimpanels (see section 20).

. Disconnect the seat belt tensioner 2P connectors

from the left side wire harness (driver's side) and

the right wire harness (front passenger's side)(see page 24'231.

2.

a

a

'1.

)

)o

24-95

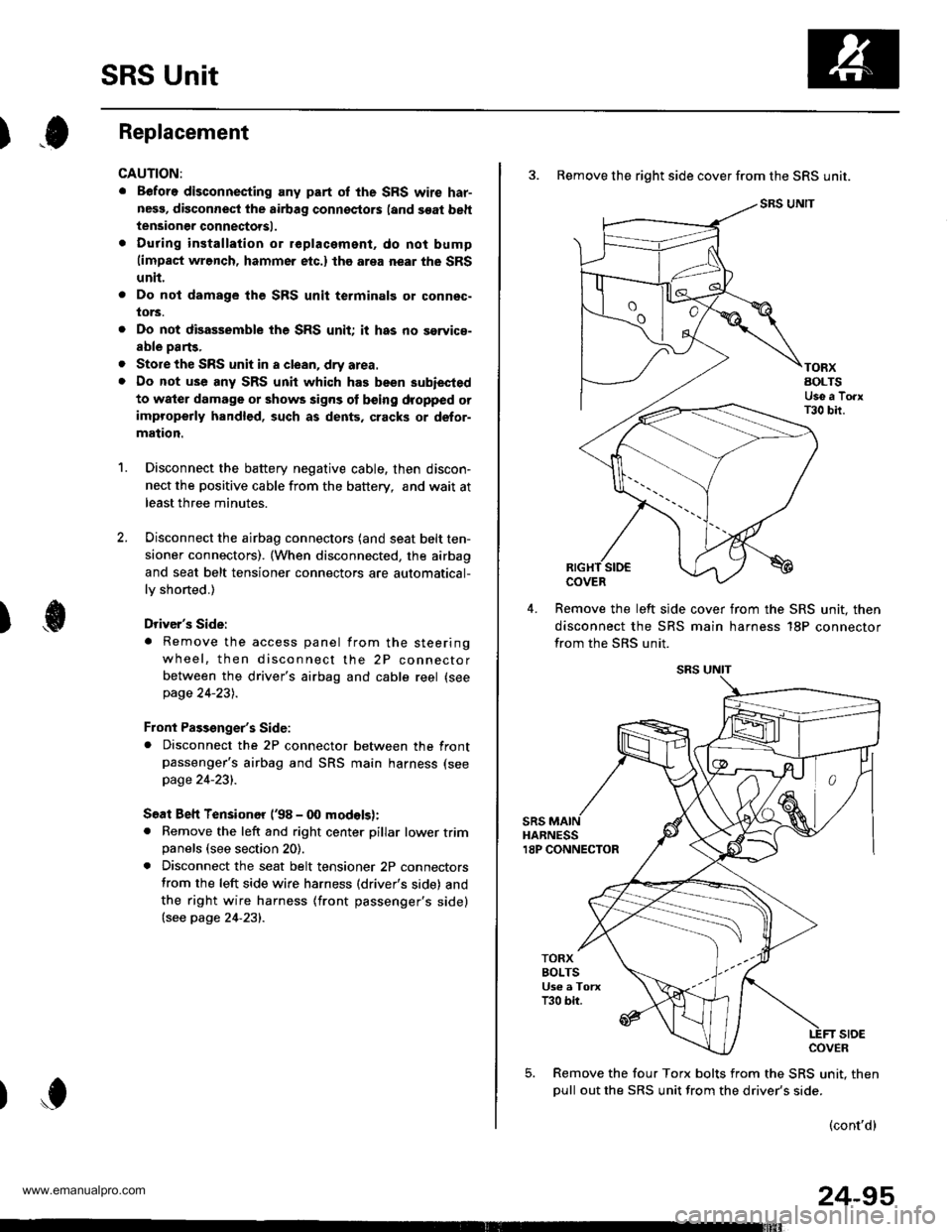

3. Remove the right side cover from the SRS unit.

SRS UNIT

TORXAOLTSUse a TorxT30 bir.

COVER

Remove the left slde cover from the SRS unit. then

disconnect the SRS main harness 18P connector

from the SRS unit.

sRsHARNESS18P CONNECTOR

TORXBOLTSUs€ a TorxT30 bir.

stoECOVER

Remove the four Torx bolts from the SRS unit. then

oull out the SRS unit from the driver's side.

(cont'd)

www.emanualpro.com