Clearance HONDA CR-V 2000 RD1-RD3 / 1.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 505 of 1395

Mainshaft Thrust Clearance

Adjustment (cont'dl

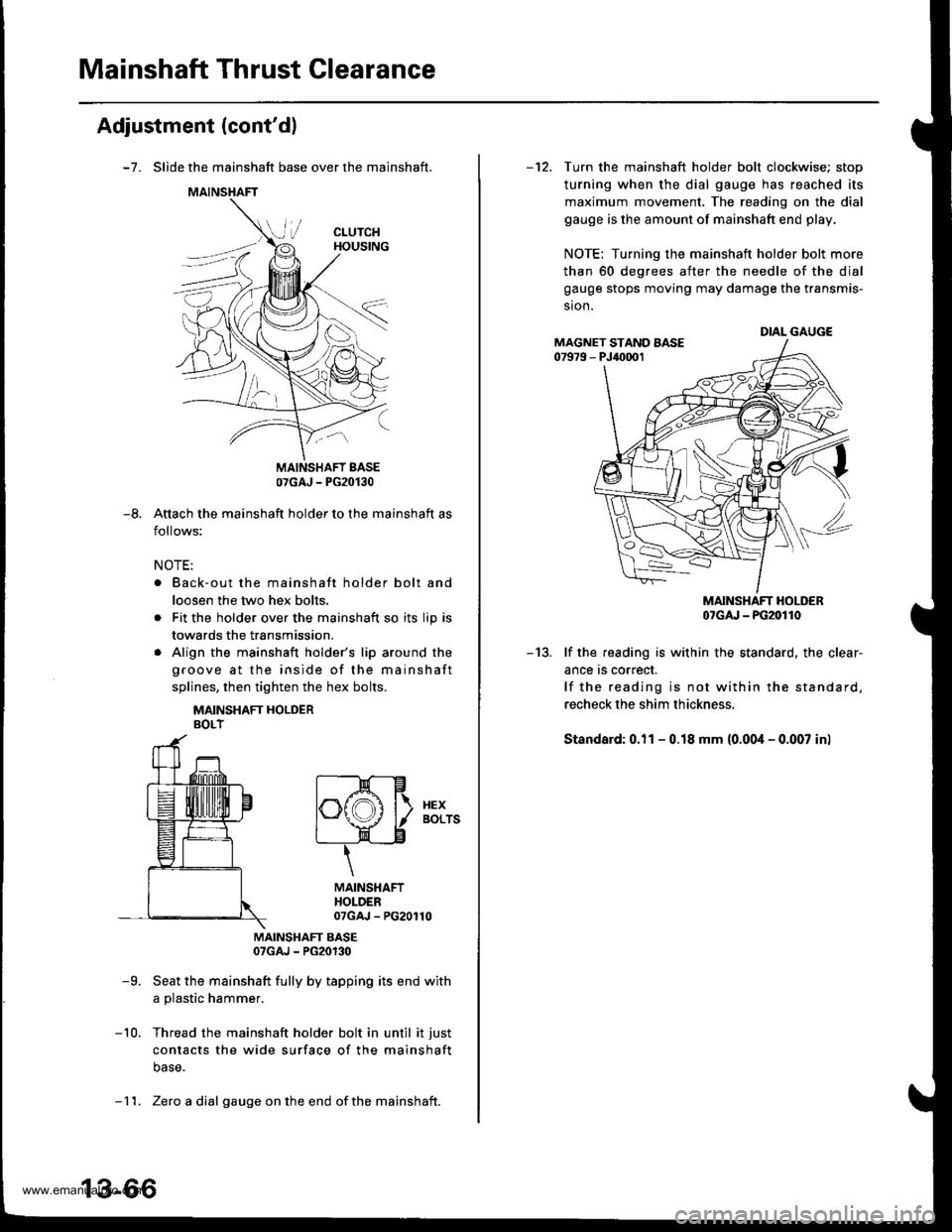

-7. Slide the mainshaft base over the mainshaft.

Attach the mainshaft holder to the mainshaft as

follows:

NOTE:

. Back-out the mainshaft holder bolt and

loosen the two hex bolts.

. Fit the holder over the mainshaft so its lip is

towards the transmission.

. Align the mainshaft holder's lip around the

groove at the inside of the mainshaft

splines, then tighten the hex bolts.

MAINSHAFT HOLDERBOLT

MAINSHAFT EASE07GAJ - PG20130

-9. Seat the mainshaft fully by tapping its end with

a plastic hammer.

-10. Thread the mainshaft holder bolt in until it just

contacts the wide surface of the mainshaft

base.

07GAJ - PG20130

-8.

t--E-Hlf\f,A l\. xex

l"\y I aors

t____=__)"n-____"8

\

MAINSHAFTHOLDER07GAJ - PG20110

- 11. Zero a dial gauge onthe end ofthe mainshait.

-12. Turn the mainshaft holder bolt clockwise; stop

turning when the dial gauge has reached its

maximum movement, The reading on the dial

gauge is the amount of mainshaft end play.

NOTE: Turning the mainshaft holder bolt more

than 60 degrees after the needle of the dial

gauge stops moving may damage the transmis-

sion.

MAINSHAFT HOLDER07cru - PG20110

-13. lf the reading is within the standard, the clear-

ance rs correct.

lf the reading is not within the standard,

recheck the shim thickness.

Standard: 0.11 - 0.18 mm (0.00i1- 0.007 inl

DIAL GAUGEMAGNET STAND AASE07979 - PJ40001

www.emanualpro.com

Page 517 of 1395

Automatic Transmission

Special Tools . 14'2OescriptionGeneral Operation . .... 14 3Power Flow . . .. '14_6

Electronic Control System .. .. . . .. .14_15Hydraulic Control .. 14 24Hydraulic Flow....-....... .. . .... .. .. . 14_29Lock'up Syslem .. .'t4'39Electrical SystemComponenl Locdlrons 14 45

PCM Circuil Dragram (A/T Control Svstem)'97 Model ....................... . . .. - . ... .14-46'98Model ................. . ... .. .. .1450'99 00Models.... . .... . . . 1452

PCM Terminal Voltage/Measuring ConditionsA"/T Control System-'97Model ...... ..14'48A,/T Control System -'98 00 Models . . .. . . 14 54

Troubleshooting Procedures .. ..... ... - 14_56Svmotom to comoonent CharlEiectr,cal Syslem -'97 Model . . 14 60Electrical System -'98 - OO Models . .. . . 14_62Electrical Troubleshooting ('97 Model)Troubleshooting Flowaharts .... ..... . .. . . 14_64

Electrical Troubleshooting ('98 - 00 Models)Troubleshootinq Flowclt"n" .... . ....- . .14-93ElectricalTroublesliooting('99 00Models)Troubleshootino FlowchartO/D OFF Indicator Light Does Not Come On 14 131

O/D OFF Indicator Liaht On ConstantlY . . . .1!-132O/D OFF Indicator Light Does Not Come OnEven Though O/D Switch ls Pressed . .... - 14_133

Lock up Control Solenoid Valve A,/B AssemblyTest....................-......... . .14-135Replacement . .ll_135Shifr ControlSolenoid Valve Ay'B Assembl,Test .............................. . .. 14-136

Replacement..............- . .14'136Linear Solenoid AssemblYTest.............................................. .. .... . 14_137Replacement .. . 14138Marnshaftlcountershafl Speed SensorsReplacement ...-... 14_138A/T Gear Position SwitchTest ..........................-... . .. 14-139ReplacementA/T Gear Positionlndicator.................. 14-140

Valve Eodynepair ............................... ..... . . .. - . .. ... 14 192

Assembly .................... .. 1{_193

Valve CapsDesciiption....-........................ .. ...... 14194

tnspeition ................... .. 14' 195

N4ain Valve BodyDisassembly/lnspection/Reassemblv - ...... .. 14_196

Secondarv Valve BodYDisassemblv4nspectron/ReassemblY .. . 14 198

Reoulator Valve Bodvbisassembtv,lnspiction/Reassemblv . 14199

Servo EodvDisassembly/lnspection/Reassembly ... ....14'200

Lock'uo Valve BodYDis;ssembly/lnspection/Reassembly .... . 14_201

MainshaftDisassembly/lnspection/Reassembly .. .. .. ..14'202

Inspection ....-.............. ..11_203

Sealing RingsReilaceient ...... ..... . 14'204

CountershaftDisassembly/lnspection/Reassembly .. . . . . . 11-205

Disassembly/Reassemb|y . . ........ ...... . .. 14_206Inspedron ................ . .... . 14 207

One wav ClutchDisassembly/lnspection/ReassemblY ... 11_209

Sub-shaftDisassembly/lnspection/Reassembly ... . .. . 14-210

oisassembly/Re6ssembly . . ... .-...... . . ..14-211

Sub-shaft BearingsReplacement .......14'212

Clutchllfustrated Index .......... . . .14-213

Disassembly .... .. .....14-216Reassembfy .... . .. .. . 14'218

Differentialllfustrated Index " 14-222Backlash Inspection . .... . .14'223

Bearing Repiacement .. 11-223

Differe-ntial Carrier Replacement .. .. . . . .. ..11-2?4

OifSeal Replacement. . .. 14'225

Side Clearance lnspection . . - .. ... . - ...... . .. 11'226

Transmission Housing BearingsMainshaJVCountershaft EearingsRepfacement .......14221Sub'siralt Eearing Replacement . . . . . . . . . ..11'224

Toroue Converter Housing BearingsMainshattEearing/OilSe6lReplacement . .. l4229

Countershaft Bea;ing Replacement.. .... .. ..14-230

Input Test - '97 - 98 ModelsInput Test '99 - 00 Models

Symptom to-Component ChartHydraulic System ...............

Checking

Removal ...,lllustrated Index (4WD)

Interlock SystemInterlock ControlUnit lnputTest. -..... -.. .... . - 14 144* Key Interlock Solenoid Test .- .. . . . - . . . ..... 14_146* Shift Lock Solenoid Test ..............-.-. . .. . ... .... 14 147*Shift LockSolenoidReplacement...... .. . .. .. 14 148* park pin Switch Test ......... 14 119' Park Pin Switch Replacement- '97 - 98 Models ....... 14-150* Park Pin Swirch/Over Drive (O/Di SwitchReplacemenl '99-00Models . .. 14_151over-Drive (O/D) Switch {'99 00 [4odels]Test........_..................... .......14-152Hydr.ulic System

..............._............... t4 142.................................. 14-143

Control Lever AssemblyR6placement ......,.,Reverse ldler Gear

lllustrated lndex

.......... 14-230

14 231

11-231

1nsta1|ation ..................Park StopInspeclion/AdjustmenlTransfer AssemblY.......14.232

RoadTest.............-.... ........ .StallSpeedTest ....._........................ ....... 14-159Fluid Level......_................... 14'160

Disessembly .................... 14-235Transfer Drive Gear BearingReplacementTrans{er Driven Gesf Shaft BearingReplacementTransfer Housing Roller BearingReplacementTransfer Cov€r A Bearing Outer RaceReplacementTransfer Housing Bearing Outer RaceReplacement ......-..,,,,,.....ReassemblvTransmassaonBeassembly ... -.. .... .14 250

Torque Converier/Drive Plate . .-. .... .. . ... .....14_258

Transmissionlnstatlation .................. ....... 14'259

Cooler Flushing . . ......11-261ATF Cooler HosesConnection.................. ....... 14-266I Shift LeverRemoval/lnstallation . .. 14'261

Disassemblv/Reassemblv - '97 - 98 Models . . 14_264

Disassembli/Reassemblv -'99 - 00 Models . 14-269

Over'Orive (O/D) Switch WireClearanceAdjustment. - ... . . . .. .. . 14'270

Detent Spring Replscement . . -.. ... .14'271*Shift CableAdiustment ....... 14'272

Repfacement.............. . 11'273

14 15711-237

11-237

14-238

$-234

11-23914-240

Transmigrion

Inspeclron ....., ...........Transfer AssemblyRemova1,.,,,..............,lnstallalion ........... .. ...Transmission

14 164

14-16514,167

14-169

End Cover/Transmissio . 14'174Transmission Housing .... ... .. . . .... .. 14-176Torque Converter Housingly'alve Body.. - ... -. 14 178

lllustrated lndex (2WD)End Cover/Transmissio ....... 14 180Transmission Housing . . ... . .. .... ... 14'182Torque Convener Housing/r'alve Body ......- 14-184

End CovefRemovat ...................... ....... 14'186Transmission HousingRemoval ...................... .. 14_188Torque Convener HousingA/alve BodYRemovat ................-..... .-..... 14-190

www.emanualpro.com

Page 667 of 1395

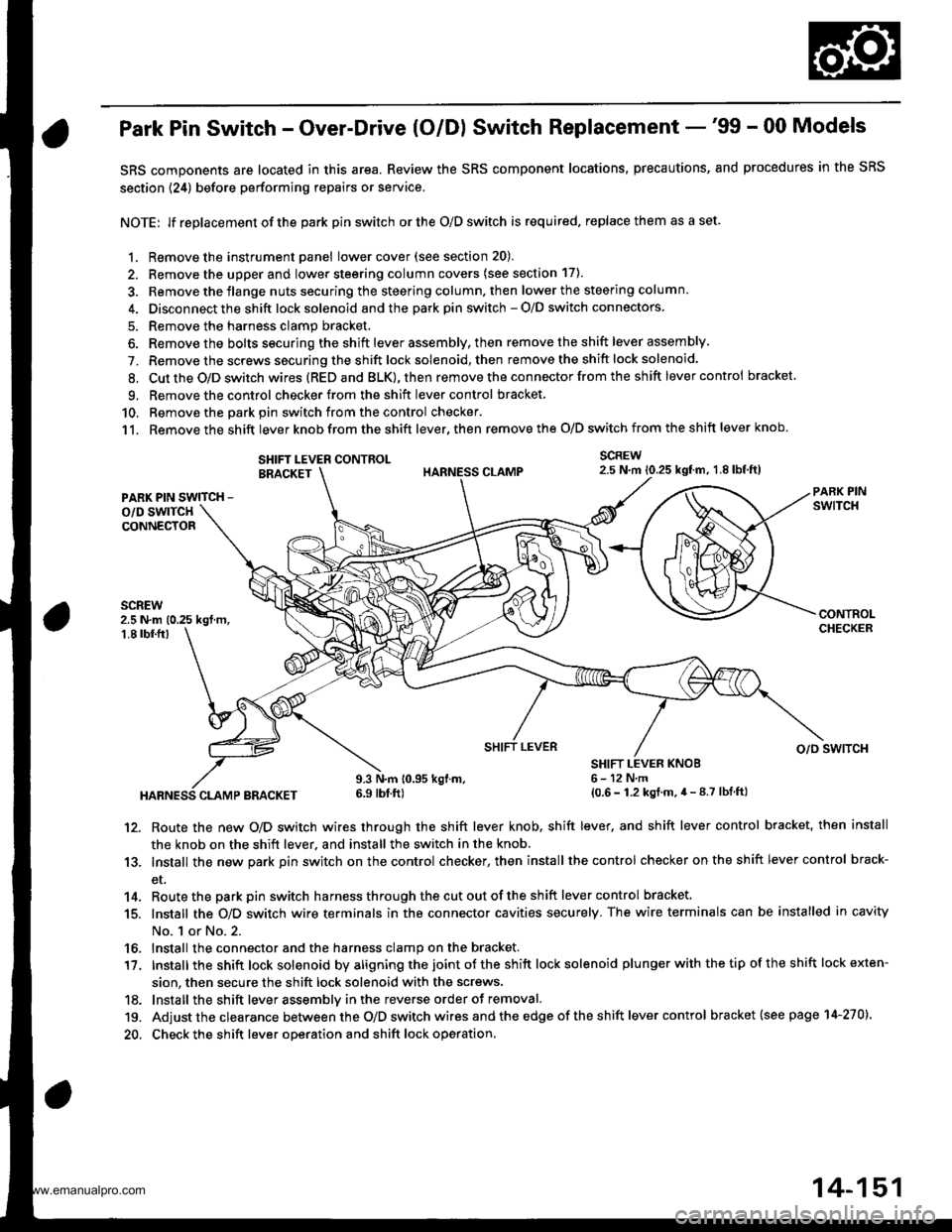

Park Pin Switch - Over-Drive (O/Dl Switch Replacement -'99 - 00 Models

SRS components are located in this area. Review the SRS component locations, precautions, and procedures in the SRS

section {24) before performing repairs or service.

NOTE: lf replacement of the park pin switch or the O/D switch is required. replace them as a set.

1. Remove the instrument panel lowercover(see section 20).

2. Remove the upper and lower steering column covers (see section 17).

3. Remove the flange nuts securing the steering column. then lower the steering column.

4. Disconnect the shift lock solenoid and the park pin switch - O/D switch connectors

5. Remove the harness clamp bracket.

6. Remove the bolts securing the shift lever assembly, then remove the shift lever assembly.

7. Remove the screws securing the shift lock solenoid, then remove the shift lock solenoid.

8. Cut the O/D switch wires (REDand BLK),then remove the con nector from the shift lever control bracket

9. Remove the control checker from theshift lever control bracket

10. Remove the oark oin switch from the control checker.

11. Remove the shift lever knob from the shift lever, then remove the O/D switch from the shift lever knob.

SCREW2.5 N.m 10.25 kgtm, 1.8lbf,ft)SHIFT LEVER CONTROLBRACKET

PARK PIN SWITCH -

o/D swlTcHCONNECTOR

2.5 N.m (0.25 kgt m,1.8 tbf.fr)

HABNESS CLAMP BRACKET

9.3 N.m 10.95 kgl.m.6.9 tbf ft)

SHIFT LEVER KNOB6-12N,m{0.6 - 1.2 kgt.m.4 - 8.7 lbf ftl

SHIFT LEVERo/o swlTcH

12. Route the new O/D switch wires through the shift lever knob, shift lever, and shift lever control bracket, then install

the knob on the shift lever, and install the switch in the knob.

13. Install the new park pin switch on the control checker, then install the control checker on the shift lever control brack-

et.

14. Routethe parkpin switch harnessthroughthecutoutoftheshift lever control bracket.

15. Install the O/D switch wire terminals in the connector cavities securely. The wire terminals can be installed in cavity

No. 1 or No.2.

16, Install the connector and the harness clamp on the bracket.

17. tnstall the shift lock solenoid by aligning the joint ot the shift lock solenoid plu nger with the tip of the shift lock exten-

sion, then secure the shift lock solenoid with the screws,

18. lnstall the shift lever assemblv inthe reverse order of removal.

19. Adjust the clearance between the O/D switch wires and the edge of the sh ift lever control bracket (see page 14-270).

20. Check the shift lever operation and shift lock operation.

14-151

www.emanualpro.com

Page 670 of 1395

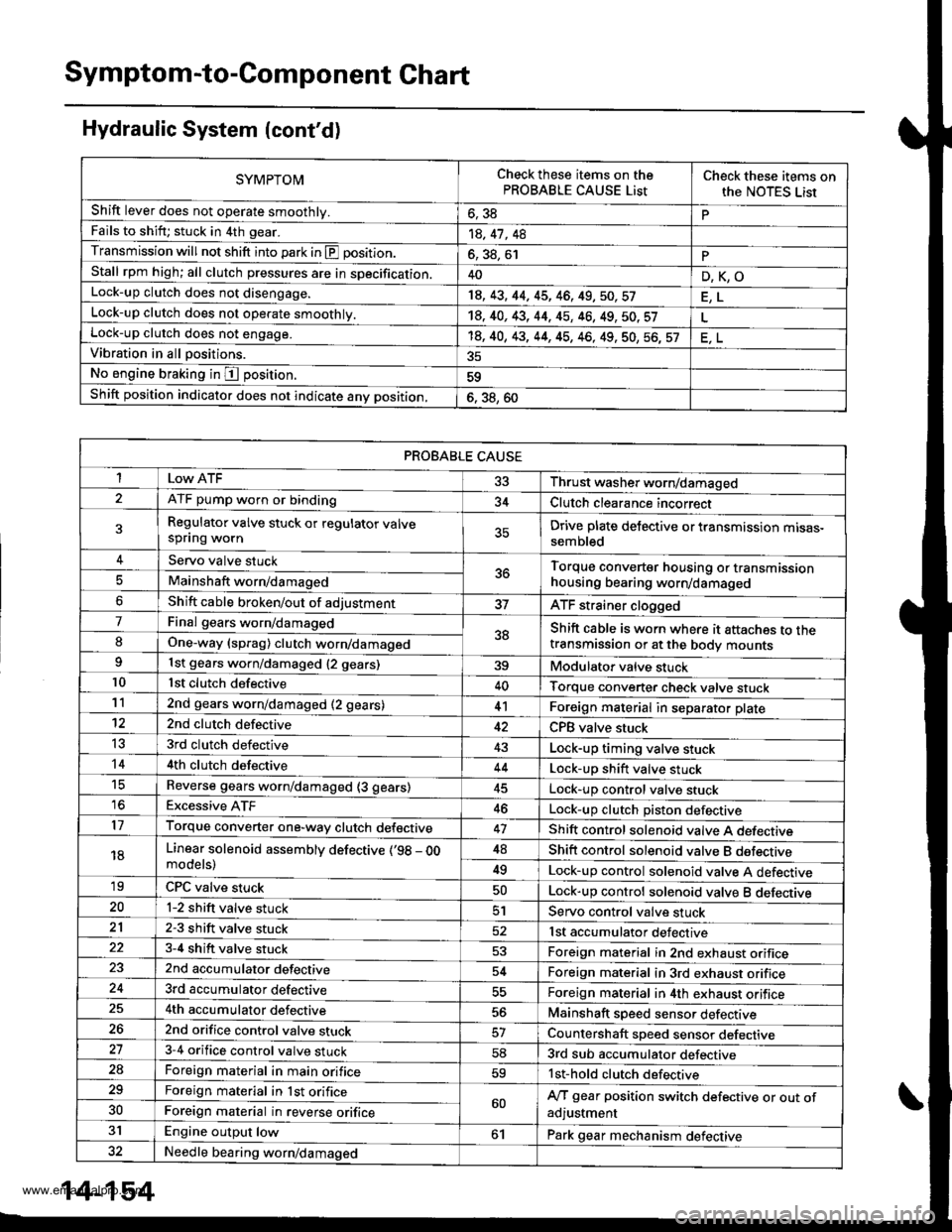

Symptom-to-Component Chart

Hydraulic System (cont'd)

SYMPTOMCheck these items on thePROBABLE CAUSE ListCheck these items onthe NOTES Lisr

Shift lever does not operate smoothly.o, JdPFails to shift; stuck in 4th gear.14, 41 , 48

Transmission will not shift into park in E position.6, 38, 61PStall rpm high; all clutch pressures are in specification.40D,K,OLock-up clutch does not disengage.18, 43, 44, 45, 46, 49,50,57

Lock-up clutch does not operate smoothly.14, 40, 43, 44, 45, 46, 49, 50. 57Lock-up clutch does not engage.'t8, 40, 43, 44, 45, 46, 49, 50, 56, 57Vibration in all positions.

No engine braking in I position.59

Shift position indicator does not indicate anv position,6. 38, 60

PROBABLE CAUSE

I 33 Thrust washer worn/damaged

ATF pump worn or binding34Clutch clearance incorrect

Regulator valve stuck or regulator valvespflng wornDrive plate delective or transmission mtsas-sembled

Servo valve stuck5ttTorque converter housing or transmissionhousing bearing worn/damagedMainshaft worn/damaged

Shift cable broken/out of adjustmentATF strainer clogged

7Final gears worn/damaged38Shift cable is worn where it attaches to thetransmission or at the body mountsIOne-way (sprag) clutch worn/damaged

1st gears worn/damaged {2 gears)39Modulator valve stuck10lst clutch defective40Torque converter check valve stuck112nd gears worn/damaged (2 gears)41Foreign material in separator plate't22nd clutch defectiveCPB valve stuck

t53rd clutch defective43Lock-up timing valve stuck144th clutch defective44Lock-up shift valve stucktcReverse gears worn/damaged (3 gears)Lock-up control valve stuck16Excessive ATF46Lock-up clutch Diston defective17Torque converter one-way clutch defective47Shift control solenoid valve A defecttve

18Linear solenoid assemblv defective (,98 - OOmodels)48Shift control solenoid valve B dsfectrve

49Lock-up control solenoid valve A defective'19CPC valve stuckLock-up control solenoid valve B deleqtve20l-2 shift valve stuck51Servo control valve stuck212-3 shift valve stuck52lst accumulator defective3-4 shift valve stuck53Foreign material in 2nd exhaust orifice2nd accumulator defective54Foreign material in 3rd exhaust orifice3rd accumulator defectiveForeign material in 4th exhaust orifice4th accumulator defective56Mainshaft speed sensor defective262nd orifice control valve stuckCountershaft speed sensor defective273-4 orifice control valve stuck583rd sub accumulator defective2aForeign material in main orifice59lst-hold clutch defective29Foreign material in lst orifice60A/T gear position switch defective or out ofadjustment30Foreign material in reverse orifice

31Engine output low61Park gear mechanism defective32Needle bearing worn/damaged

14-154

www.emanualpro.com

Page 671 of 1395

The following symptom can be caused

by improper repair or assemblYCheck these items

. lmproper clutch clearance

. lmproper gear clearance

One-way (sprag) clutch installed upside down

Park lever installed upside down

Shift fork bolt not installed

Vehicle creeps in N position.

Vehicle does not move in E, [D.lj, or E

position.

Transmission locks up in E position.

Excessive drag in transmission.ATF pump binding and seizure

Use proper tools when replacing the ATF pump gears, and be careful

to damage the ATF pump when torque down the main valve body.

Check that the shift fork bolt is installed on the shift fork shaft

not

Excessive vibration, rpm related.Torque converter not fully seated in ATF pump

Reverse selector hub installed upside downNoise only with wheels moving.

Mainshaft oil seal po9s out.Mainshaft oil seal improperly installed

lnstallthe mainshaft oil seal tlush with the torque converter housing lf

the mainshaft oil seal is installed into the torque converter housing until

it bottoms. it will block the fluid return passage and result in damage

Various shifting problems.. Springs improperly installed

. Valves improperly installed

Harsh upshift.Check valve balls not installed

(cont'd)

4-155

www.emanualpro.com

Page 711 of 1395

ATF Pump

Inspection

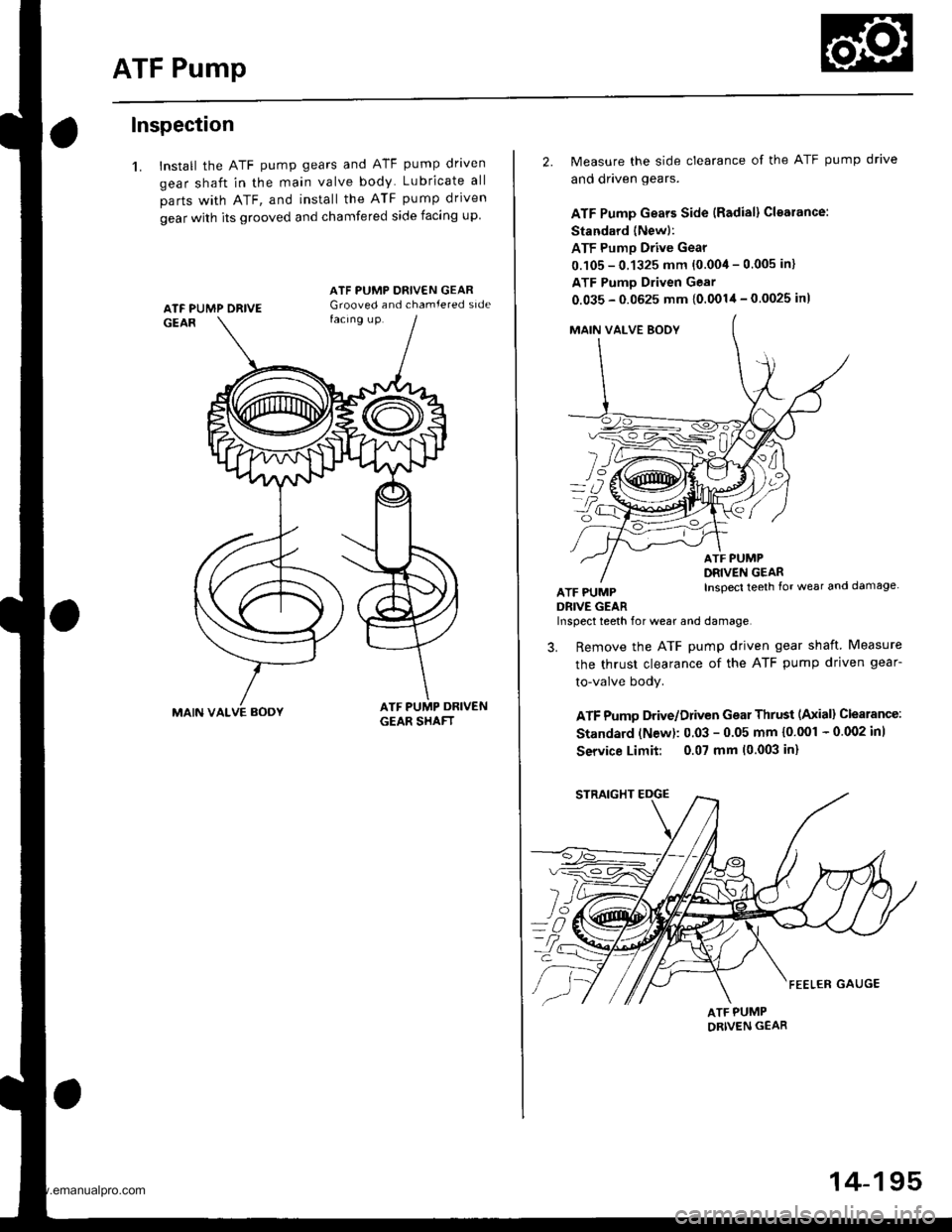

1. Install the ATF pump gears and ATF pump driven

gear shaft in the main valve body Lubricate all

parts with ATF, and install the ATF pump driven

gear with its grooved and chamfered side facing up

MAIN VALVE AOOY

ATF PUMP ORIVE

2. Measure the side clearance of the ATF pump drive

and driven gears.

ATF Pump Gears Side {Radial} Cloarance:

Standard (Newl:

ATF Pump Drive Gear

0.105 - 0.1325 mm {0.004 - 0.005 in}

ATF Pumo Driven Gear

0.035 - 0.0625 mm {0.0014 - 0.0025 in)

MAIN VAI-VE BOOY

fl

L/

ATF PUMPDRIVE GEAR

ATF PUMPDRIVEN GEARInspecl teeth {or wear and damage

Inspect teeth for wear and damage,

3. Remove the ATF pump driven gear shaft Measure

the thrust clearance of the ATF pump driven gear-

to-valve body.

ATF Pumo Drive/Driven Gear Thrust (Axiall Clearance:

Standard (N€w): 0.03 - 0.05 mm {0'001 - 0 002 inl

Service Limit: 0.07 mm 10.003 in)

ATF PUMPORIVEN GEAR

14-195

www.emanualpro.com

Page 719 of 1395

Inspection

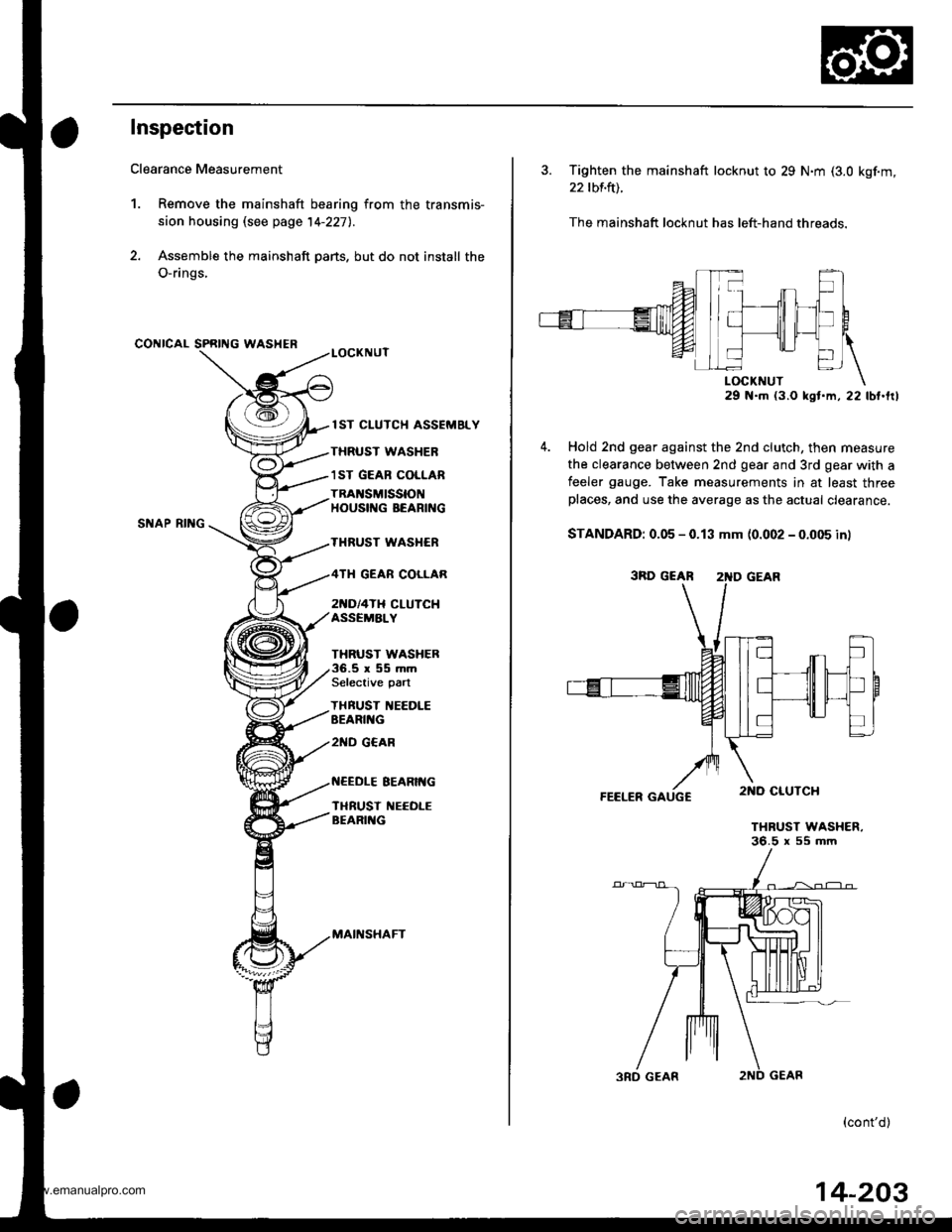

Clearance Measurement

1. Remove the mainshaft bearing from the transmis-

sion housing lsee page 14-227l..

2. Assemble the mainshaft parts, but do not install the

O-rings,

CONICAL SPRING WASHER

SNAP RII{G

lST CLUTCH ASSEMELY

THRUST WASHER

1ST GEAB COLLAR

TRAI{SMISSIONHOUSIf{G BEARING

THRUST WASI{ER

2[{D/4TH CLUTCHASSEMALY

GEAR COLLAR

THRUST WASHER.5r55mmSelective part

THBUST IIEEDLEEEARII{G

2ND G€AR

EEARIt{G

TI{RUST NEEOLEBEARII{G

MAII{SHAFT

3. Tighten the mainshaft locknut to 29 N.m (3.0 kgf.m,

22 tbf.ft).

The mainshaft locknut has left-hand threads.

29 N.m (3.O kst.m, 22 lbt.frl

Hold 2nd gear against the 2nd clutch, then measure

the clearance between 2nd gear and 3rd gear with a

feeler gauge. Take measurements in at least threeplaces, and use the average as the actual clearance.

STANDARD: 0.05 - 0.13 mm (0.002 - 0.005 in)

FEELER GAUGC

THRUST WASHER.36.5 x 55 mm

(cont'd)

3RD GEAR 2'{D GEAR

14-203

www.emanualpro.com

Page 720 of 1395

MainshaftSealing Rings

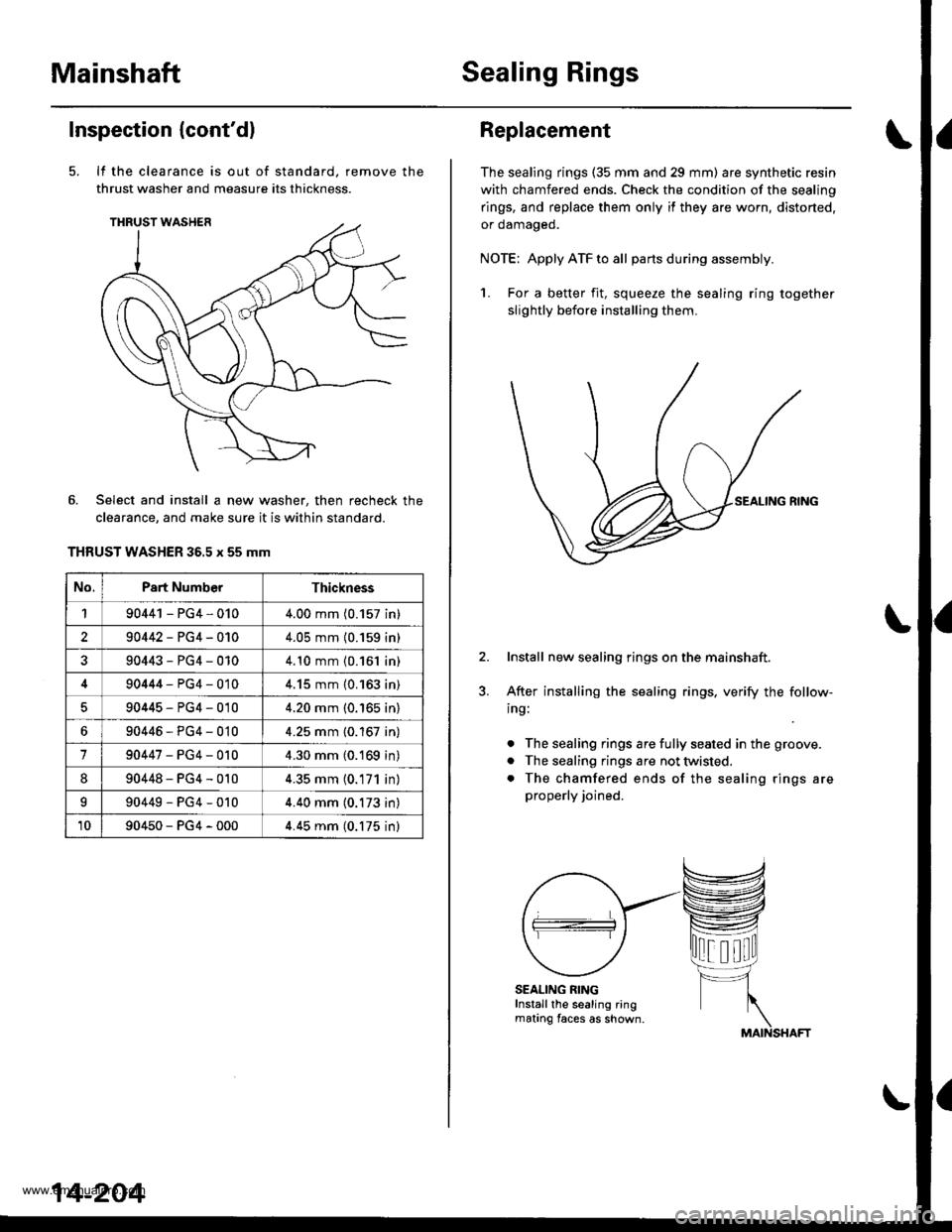

Inspection (cont'dl

It the clearance is out of standard, remove the

thrust washer and measure its thickness.

Select and install a new washer, then recheck the

clearance, and make sure it is within standard.

THRUST WASHER 36.5 x 55 mm

No.Part NumberThickness

190441 - PG4,0104.00 mm (0.157 in)

290442-PG4-0104.05 mm (0.159 in)

90443-PG4-0104.10 mm {0.161 in)

90444-PG4-0104.15 mm {0.163 in)

90445-PG4-0104.20 mm (0.'165 in)

690446-PG4-0104.25 mm {0.167 in)

190447-PG4-0104.30 mm (0.169 in)

890448-PG4-0104.35 mm (0.171 in)

I90449-PG4-0104.40 mm (0.173 in)

1090450-PG4-0004.45 mm (0.175 inl

14-204

Replacement

The sealing rings (35 mm and 29 mm) are synthetic resin

with chamfered ends. Check the condition of the sealing

rings, and replace them only if they are worn, distorted,

or oamageo.

NOTE: Apply ATF to all partsduring assembly.

1. For a better fit, squeeze the sealing ring together

slightly before installing them.

Install new sealing rings on the mainshaft.

After installing the sealing rings, verify the follow-

ing:

. The sealing rings are fully seated in the groove.

. The sealing rings are not twisted.

. The chamfered ends of the sealing rings are

properly joined.

SEALING RINGInstall the sealing ringmating faces as shown.

www.emanualpro.com

Page 723 of 1395

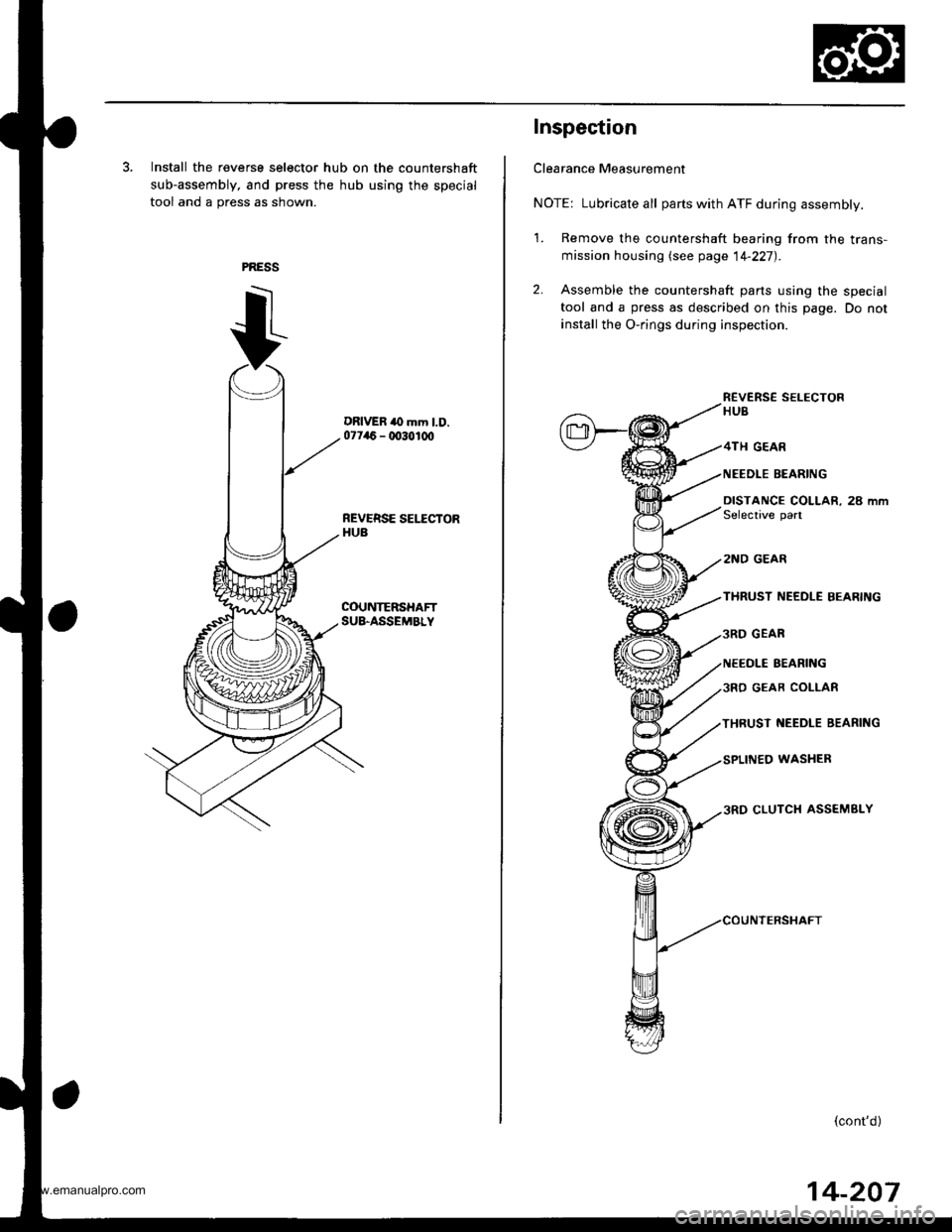

3. Install the reverse selector hub on the countershaft

sub-assembly, and press the hub using the special

tool and a press as shown.

DRIVER to mm l.D.07746 - 0030100

REVERSE SEI.ICTORHUB

COUNTERSHAFTSU&ASSEMBLY

Inspection

Clearance Measurement

NOTE: Lubricate all parts with ATF during assembly.

1. Remove the countershaft bearing from the trans-

mission housing lsee page 14-227).

2. Assemble the countershaft parts using the special

tool and a press as described on this page. Do not

install the O-rings during inspection.

R€VERS€ SELECTORHUB

GEAR

NEEDLE BEARING

DISTANCE COLLAR, 28 mmSelective part

2NO GEAR

THRUST NEEDLE BEARING

GEAR

NEEOLE BEARING

GEAR COLIAR

THRUST NEEDLE BEARING

WASHER

CLUTCH ASSEMBLY

(cont'd)

14-207

www.emanualpro.com

Page 724 of 1395

Countershaft

Inspection (cont'd)

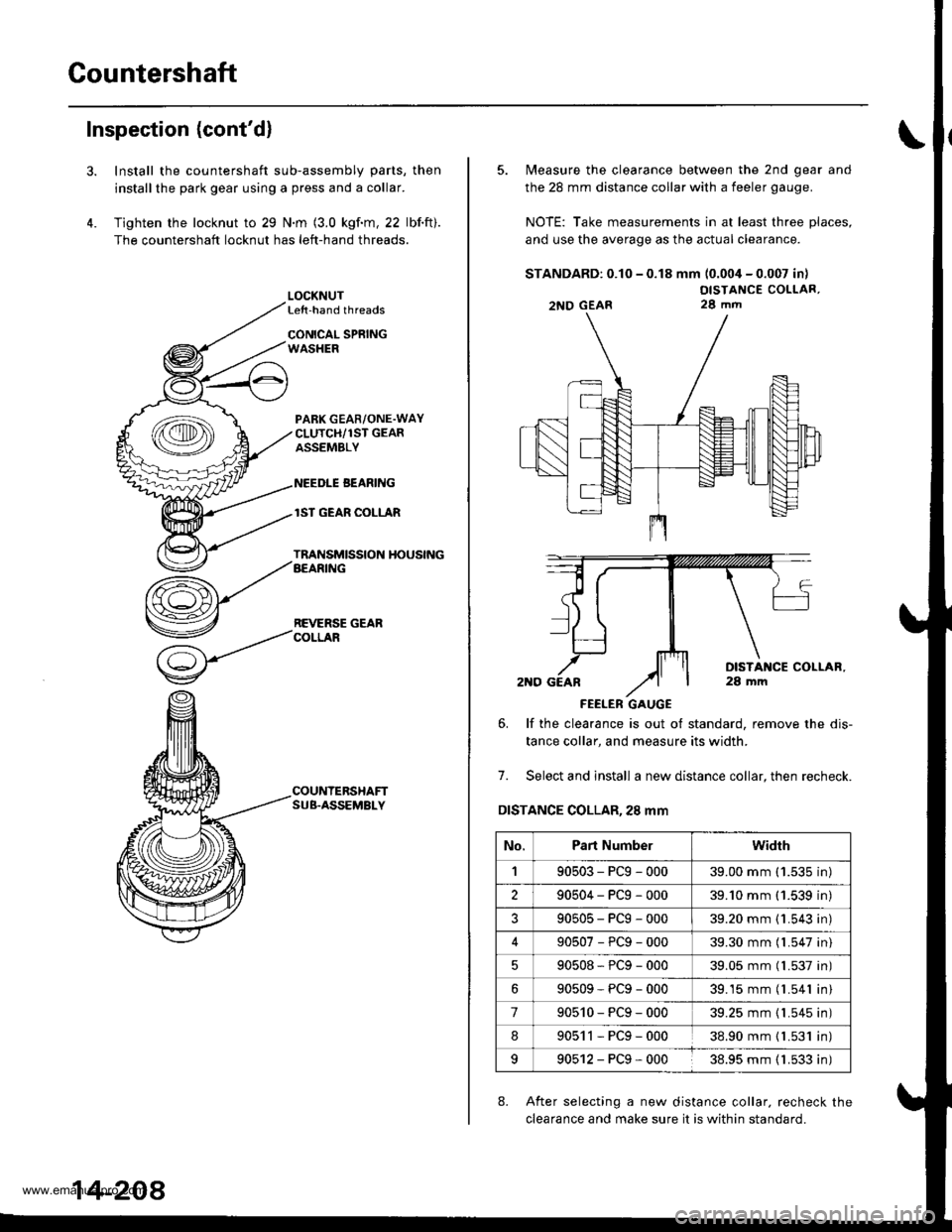

3.

4.

Install the countershaft sub-assembly parts, then

installthe park gear using a press and a collar.

Tighten the locknut to 29 N.m (3.0 kgf.m, 22 lbf.ft).

The countershaft locknut has left-hand threads.

LOCKNUTLe{t-hand threads

CONICAL SPRINGWASHER

PABK GEAR/ONE.WAYCLUTCH/1ST GEARASSEMBLY

NEEDLE BEANING

lST GEAR COLLAR

TRANSMISSION HOUSINGAEARING

REVERSE GEARCOLLAR

COUNTERSHAFTSUB.ASSEMBLY

14-208

5. Measure the clearance between the 2nd gear and

the 28 mm distance collar with a feeler gauge.

NOTE: Take measurements in at least three places,

and use the average as the actual clearance.

STANDARD: 0.10 - 0.18 mm (0.004 - 0.007 in)

OISTANCE COLLAR,28 mm

FEELER GAUGE

6. lf the clearance is out ot standard, remove the dis-

tance collar, and measure its width.

7. Select and install a new distance collar, then recheck.

DISTANCE COLLAR,28 mm

8. After selecting a new distance collar. recheck the

clearance and make sure it is within standard.

2NO GEAR

No.Part Numberwidrh

190503-PCg-00039.00 mm ('1.535 in)

290504-PCg-00039.'10 mm (1.539 in)

?90505-PCg-00039.20 mm {1.543 in)

90507-PCg-00039.30 mm (l.547 in)

90508*PCg-00039.05 mm (l.537 in)

90509-PCg-00039.15 mm (l.541 in)

790510-PCg-00039.25 mm {1.545 in)

890511-PCg-00038.90 mm { L531 in)

990512-PCg-00038.95 mm ( 1.533 in)

www.emanualpro.com