Section 23 HONDA CR-V 2000 RD1-RD3 / 1.G Manual Online

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 664 of 1395

Interlock System

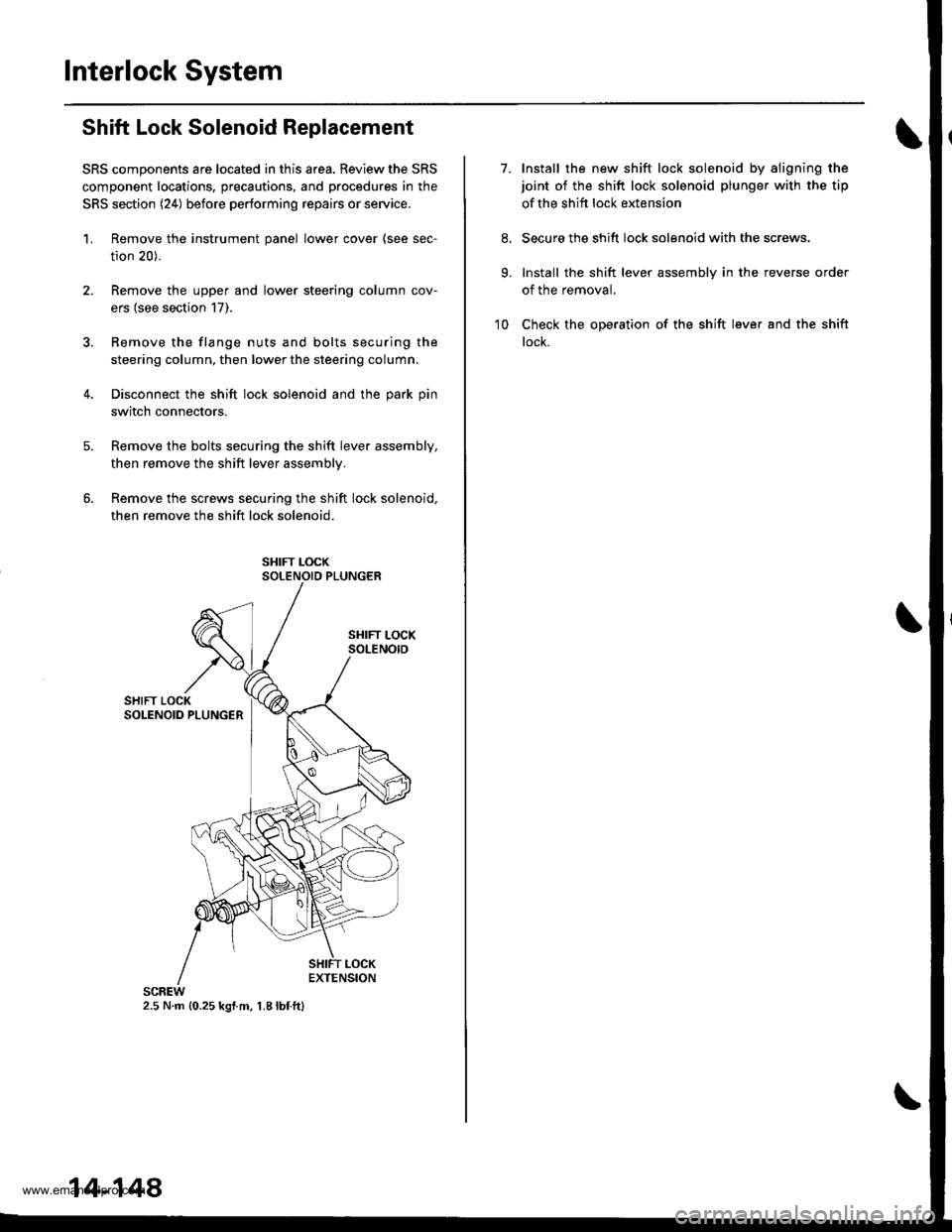

Shift Lock Solenoid Replacement

SRS components are located in this area. Review the SRS

component locations, precautions, and procedures in the

SRS section (24) before performing repairs or service.

'L Remove the instrument panel lower cover (see sec-

tion 20).

2. Remove the upper and lower steering column cov-

ers (see section 17).

3. Bemove the flange nuts and bolts securing the

steering column, then lower the steering column.

4. Disconnect the shift lock solenoid and the park pin

switch connectors.

Remove the bolts securing the shift lever assembly,

then remove the shift lever assemblv.

Remove the screws securing the shift lock solenoid,

then remove the shift lock solenoid.

2.5 N.m {0.25 kgl.m, 1.8lbf.ft}

14-148

7.Install the new shift lock solenoid by aligning the

joint of the shift lock solenoid plunger with the tip

of the shift lock extension

Secure the shift lock solenoid with the screws,

Install the shift lever assembly in the reverse order

of the removal.

Check the operation of the shift lever and the shift

lock.

9.

10

www.emanualpro.com

Page 665 of 1395

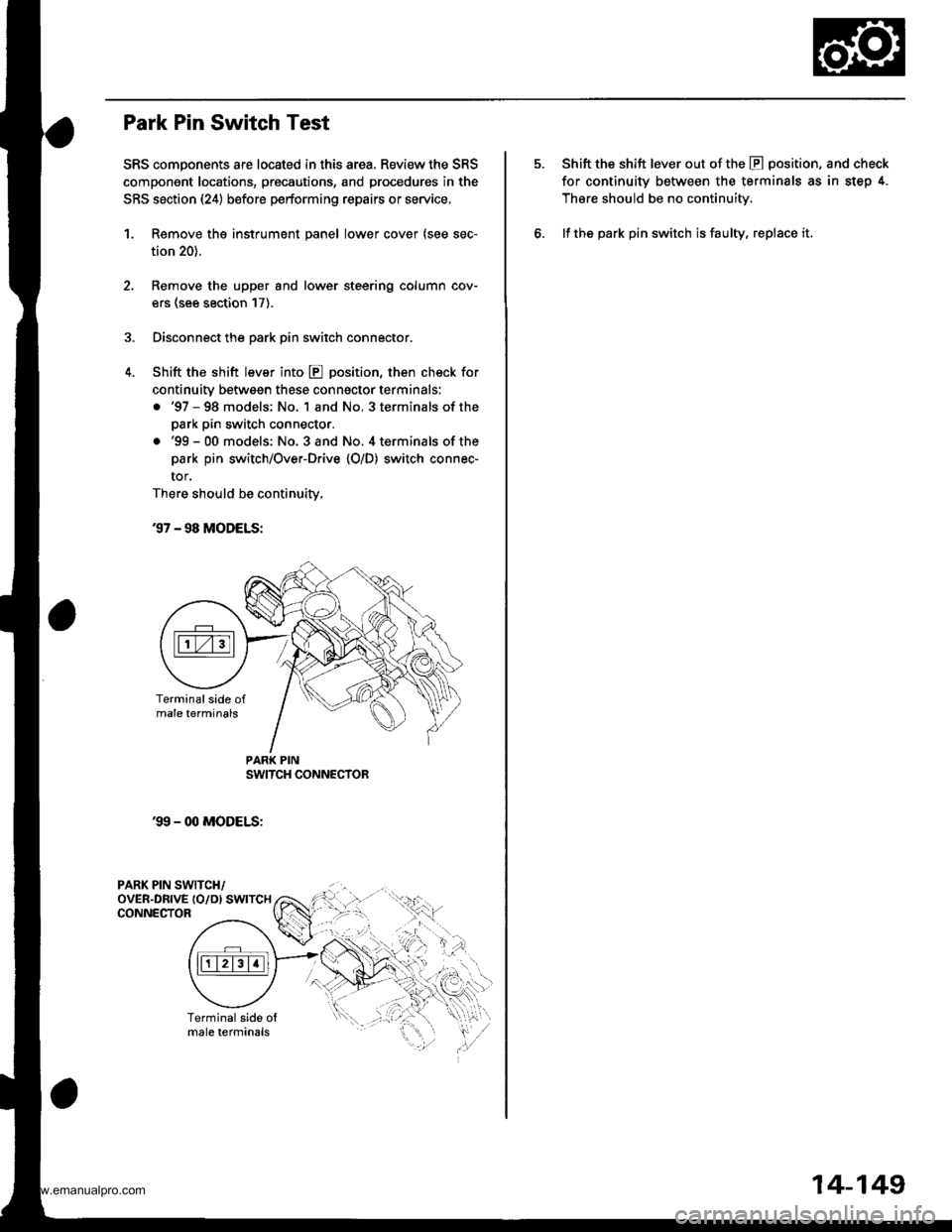

Park Pin Switch Test

SRS components are located in this area. Review the SRS

compongnt locations, precautions, and procedures in the

SRS section (24) before performing repairs or service,

1. Remove tho instrument panel lower cover (see sec-

tion 20).

Remove the upper and lower steering column cov-

ers (see section 17).

Disconnect the park pin switch connector.

Shift the shift lever into E position, then check for

continuity betwsgn these conngctor terminals:

. '97 - 98 models; No. 1 and No, 3 terminals of the

park pin switch connector.

.'99-00 models: No. 3and No. 4terminalsof the

park pin switch/Over-Drive {O/D) switch connec-

tor.

There should be continuity,

37 - 98 MODELS:

'99 - 00 MODELS:

PARK PIN SWITCH/oVER-DRTVE {O/D) SWTTCHCONNECTOR

PAR( PIN

.qI

Shift the shift lever out of the E position, and check

for continuity between the terminals as in step 4.

Thsre should be no continuity.

lf the park pin switch is faulty, replace it.

14-149

www.emanualpro.com

Page 666 of 1395

Interlock System

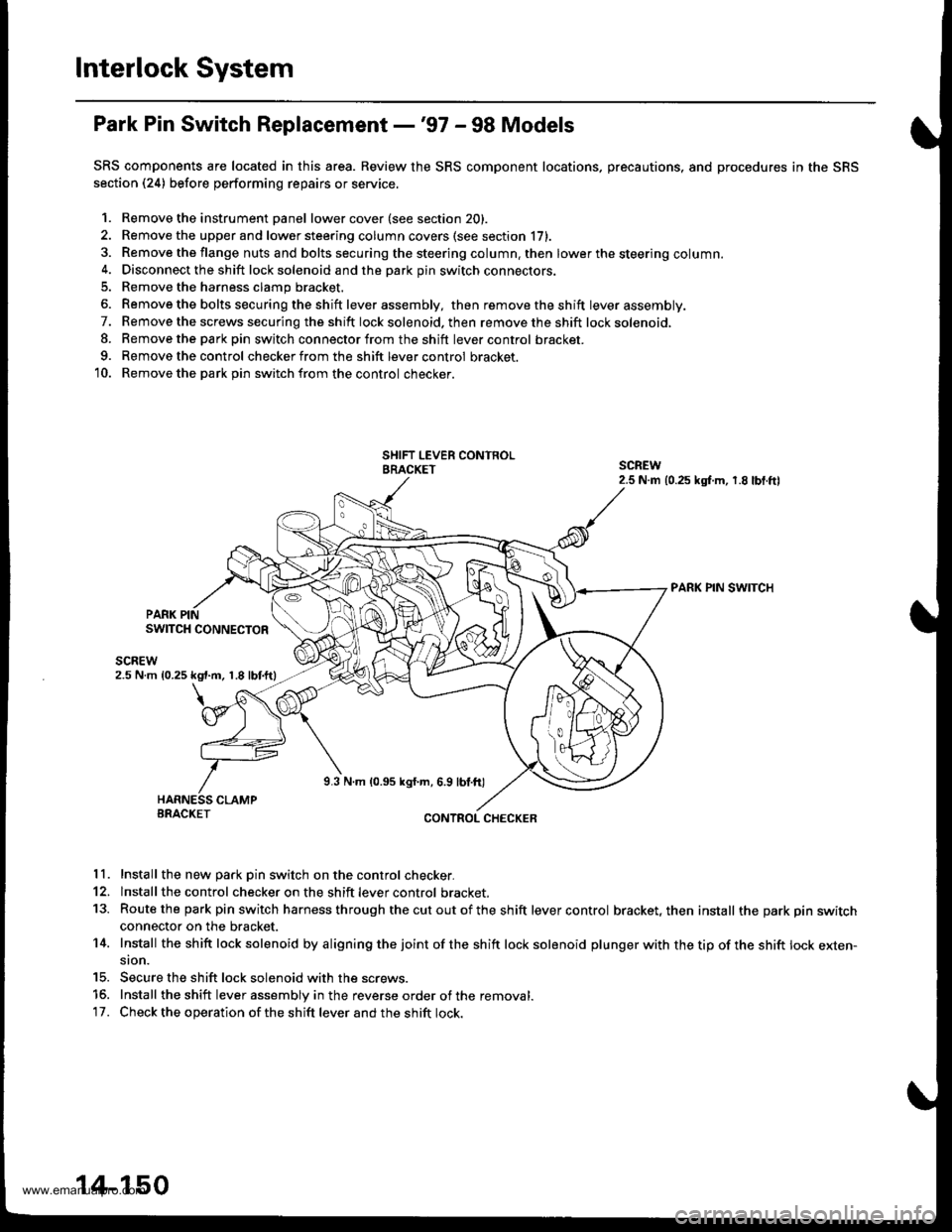

Park Pin Switch Replacement -'97 - 98 Models

SRS components are located in this area. Review the SRS component locations, precautions, and procedures in the SRS

section (24) before performing repairs or service.

1. Remove the instrument Danel lower cover (see section 20).

2. Remove the upper and lower steering column covers (see section li,.

3. Remove the flange nuts and bolts securing the steering column. then lower the steering column.4. Disconnect the shift lock solenoid and the park pin switch connectors.

5. Remove the harness clamp bracket.

6. Remove the bolts secu ring the shift lever assembly, then removetheshift lever assembly.

7. Remove the screws securing the shift lock solenoid. then remove the shift lock solenoid,

8. Remove the parkpin switch connector from the shift lever control bracket.

9. Remove the control checker from the shift lever control bracket.

10. Remove the park Din switch from the control checker.

PARK PIN SWITCH

PARK PINSWITCH CONNECTOR

scnEw2.5 N m 10.25 kgt.m, 1.8 lbtftl

9.3 N.m 10.95 kgf.m, 6.9 lbl.ft)

BRACKETCONTROL CHECKER

11. Install the new Dark Din switch on the control checker.

12. lnstall the control checker on the shift lever control bracket.

13. Routethe park pin switch harness through thecutoutofthe shift lever control bracket, then install the park pin switchconnector on the bracket.

14. Install the sh ift lock solenoid by a ligning the joint of the sh ift lock solenoid plu nger with the tip of the shift lock exten-sion.

15. Secure the shift lock solenoid with the screws.

15. Install the shift lever assembly in the reverse order of the removal.'17. Check the operation of the shift lever and the shift lock.

14-150

www.emanualpro.com

Page 667 of 1395

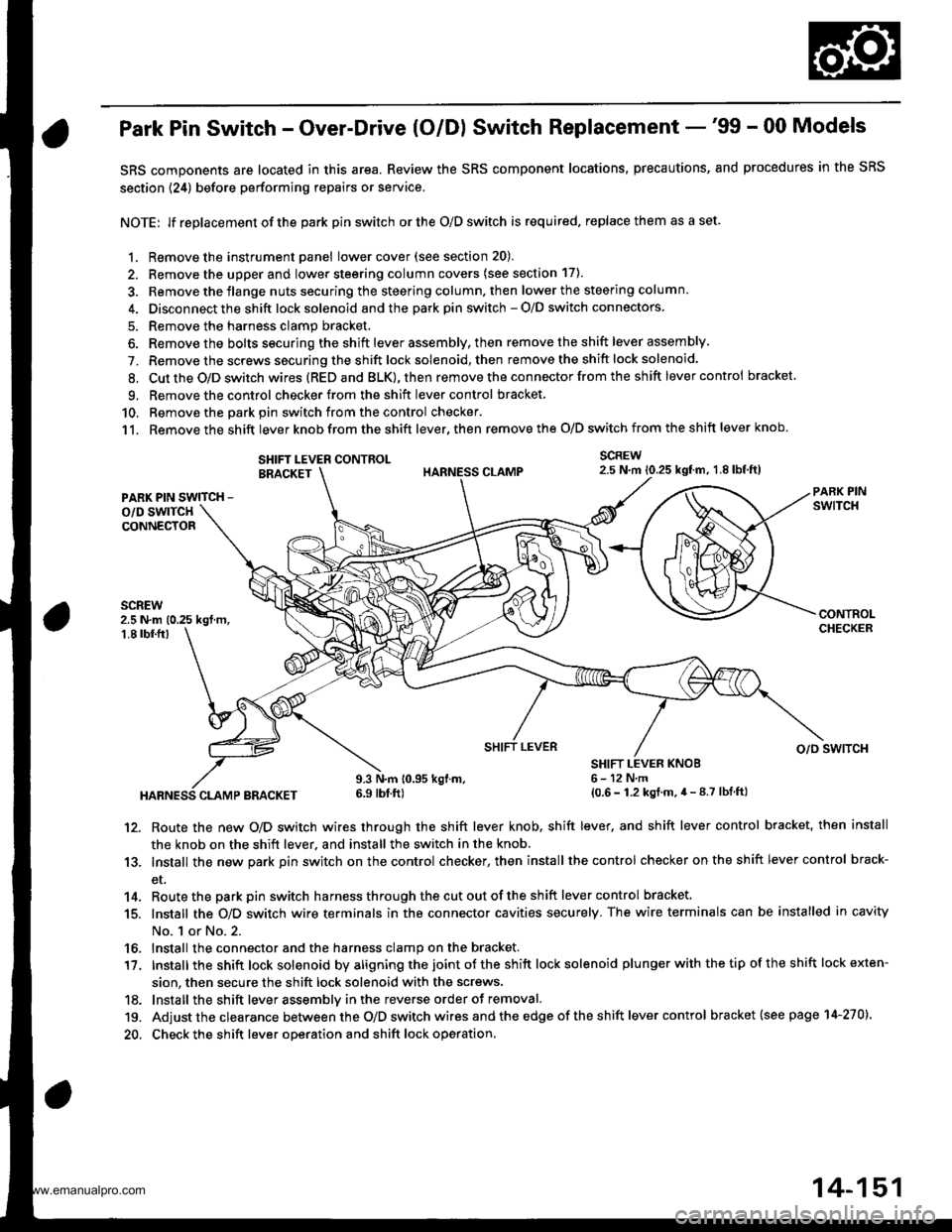

Park Pin Switch - Over-Drive (O/Dl Switch Replacement -'99 - 00 Models

SRS components are located in this area. Review the SRS component locations, precautions, and procedures in the SRS

section {24) before performing repairs or service.

NOTE: lf replacement of the park pin switch or the O/D switch is required. replace them as a set.

1. Remove the instrument panel lowercover(see section 20).

2. Remove the upper and lower steering column covers (see section 17).

3. Remove the flange nuts securing the steering column. then lower the steering column.

4. Disconnect the shift lock solenoid and the park pin switch - O/D switch connectors

5. Remove the harness clamp bracket.

6. Remove the bolts securing the shift lever assembly, then remove the shift lever assembly.

7. Remove the screws securing the shift lock solenoid, then remove the shift lock solenoid.

8. Cut the O/D switch wires (REDand BLK),then remove the con nector from the shift lever control bracket

9. Remove the control checker from theshift lever control bracket

10. Remove the oark oin switch from the control checker.

11. Remove the shift lever knob from the shift lever, then remove the O/D switch from the shift lever knob.

SCREW2.5 N.m 10.25 kgtm, 1.8lbf,ft)SHIFT LEVER CONTROLBRACKET

PARK PIN SWITCH -

o/D swlTcHCONNECTOR

2.5 N.m (0.25 kgt m,1.8 tbf.fr)

HABNESS CLAMP BRACKET

9.3 N.m 10.95 kgl.m.6.9 tbf ft)

SHIFT LEVER KNOB6-12N,m{0.6 - 1.2 kgt.m.4 - 8.7 lbf ftl

SHIFT LEVERo/o swlTcH

12. Route the new O/D switch wires through the shift lever knob, shift lever, and shift lever control bracket, then install

the knob on the shift lever, and install the switch in the knob.

13. Install the new park pin switch on the control checker, then install the control checker on the shift lever control brack-

et.

14. Routethe parkpin switch harnessthroughthecutoutoftheshift lever control bracket.

15. Install the O/D switch wire terminals in the connector cavities securely. The wire terminals can be installed in cavity

No. 1 or No.2.

16, Install the connector and the harness clamp on the bracket.

17. tnstall the shift lock solenoid by aligning the joint ot the shift lock solenoid plu nger with the tip of the shift lock exten-

sion, then secure the shift lock solenoid with the screws,

18. lnstall the shift lever assemblv inthe reverse order of removal.

19. Adjust the clearance between the O/D switch wires and the edge of the sh ift lever control bracket (see page 14-270).

20. Check the shift lever operation and shift lock operation.

14-151

www.emanualpro.com

Page 668 of 1395

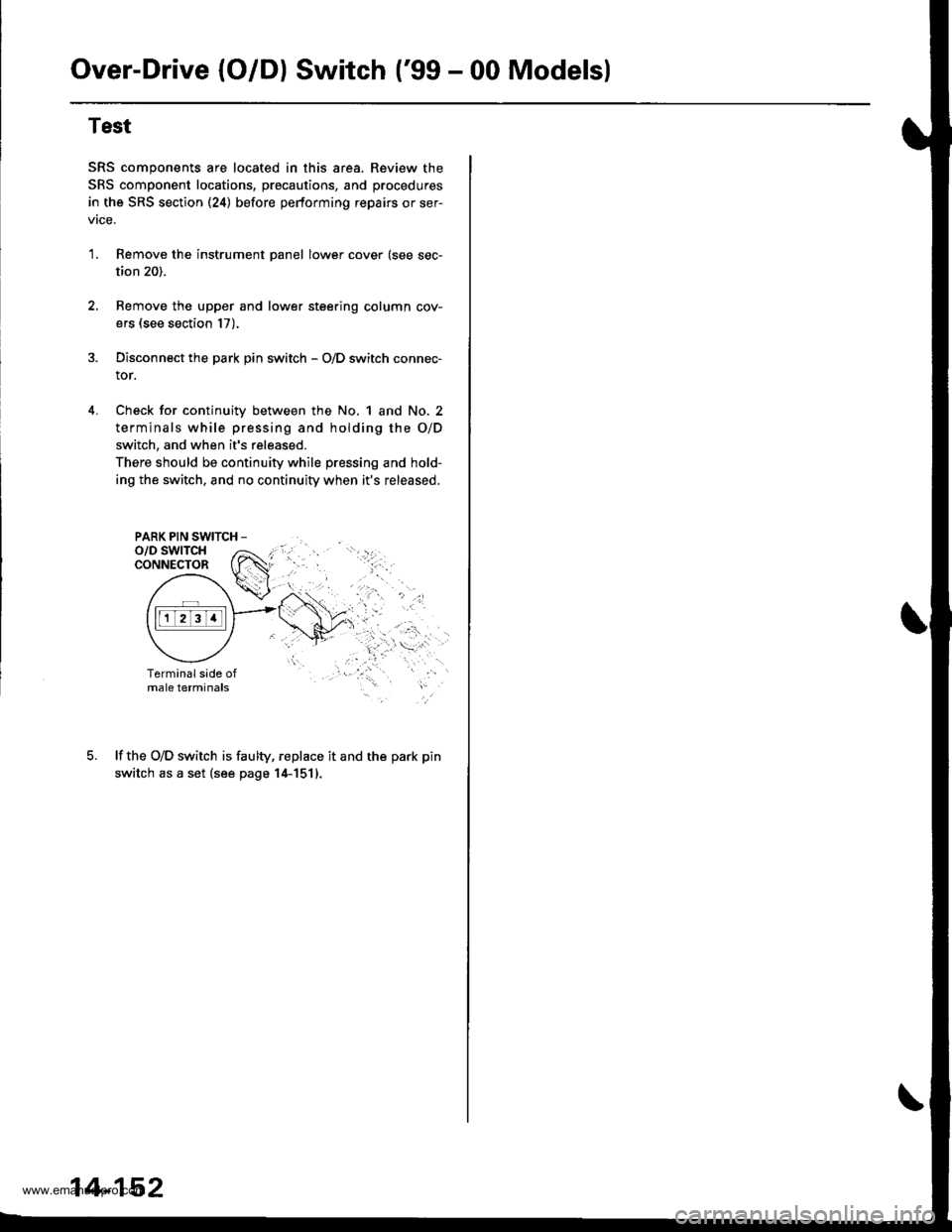

Over-Drive (O/Dl Switch ('99 - 00 Modelsl

4.

Test

SRS components are located in this area. Review the

SRS component locations, precautions, and procedures

in the SRS section (24) before pertorming repairs or ser-

vtce.

1.Remove the instrument panel lower cover (see sec-

tion 20).

Remove the upper and lower steering column cov-

ers (see section 17).

Disconnect the park pin switch - O/D switch connec-

tor.

Check for continuity between the No, 1 and No. 2

terminals while pressing and holding the O/D

switch, and when it's released.

There should be continuity while pressing and hold-

ing the switch, and no continuity when it's released.

PARK PIN SWITCH -

lf the O/D switch is faulty, replace it and the park pin

switch as a set (see page 14-1511.

14-152

www.emanualpro.com

Page 672 of 1395

Symptom-to-Com ponent Chart

Hydraulic System (cont'd)

NOTES

See flushing procedure, page l4-264 and 265,

BSet idle rpm in gear to specified idle speed. lf still no good, adjust motor mounts as outlined in enginesection of this manual.

clf the large clutch piston O-ring is broken, inspect the piston groove for rough machining.

Dlf the clutch pack is seized or is excessively worn. inspect the other clutches fot wear, and check the orificecontrol valves, CPC valve, and linear solenoid for free movement.

lf the linear solenoid is stuck, inspect the clutches for wear.

lf the 1-2 shift valve is stuck closed. the transmission will not upshift. lf stuck open, the transmission hasno lst gear.

Hlf the 2nd orifice control valve is stuck, inspect the 2nd and 3rd clutch Dacks for wear.

lf the 3-4 orifice control valve is stuck, inspect the 3rd and 4th clutch packs for wear.

Jlf the clutch pressure control valve is stuck closed. the transmission will not shift out of lst gear.

Klmproper alignment of main valve body and torque converter housing may cause ATF pump seizure. Thesymptoms are mostly an rpm-related ticking noise or a high-pitched squeak.

Llf the ATF strainer is clogged with particles of steel or aluminum, inspect the ATF pump and differentialpinion shaft. lf both are OK and no cause for the contamination is found, replace the torque converter.

Mlf the lst clutch feed pipe guide in the end cover is scored by the mainshaft. inspect the ball bearing forexcessive movement in the transmission housing. lf oK, replace the end cover as it is dented. The o-rinounder the guide is probably worn.

N' Replace the mainshaft if the bushing for the 4th feed pipe is loose or damaged, lf the 4th feed pipe is darrFaged or out of round. replace the end cover.' Replace the mainshaft if the bushing for the l st feed pipe is loose or damaged. lf the 1st feed pipe is dam-aged or out of round, replace it.

oA worn or damaged sprag clutch is mostly a result of shifting the transmission in E!. E, or E positionwhile the wheels rotate in reverse. such as rocking the vehicle in snow.

PInspect the frame for collision damage.

lnspect for damage and wear:

l. Reverse selector gear teeth chamfers.

2. Engagement teeth chamfers of countershaft 4th and reverse gear.

3. Shift fork for scuff marks in center.

4. Differential pinion shaft for wear under pinion gears.

5. Bottom of 3rd clutch for swirl marks.

Replace items 1, 2, 3. and 4 if worn or damaged. lf transmission makes a clicking, grinding, or whirring noise,also replace mainshaft 4th gear, reverse idler gear, and countershaft 4th gear in addition to 1,2, 3, or 4.lf differential pinion shaft is worn, overhaul differential assembly, replace ATF strainer, and thoroughly cjeantransmission, flush torque converter. cooler, and lines,lf bottom of 3rd clutch is swirled and transmission makes gear noise. replace the countershaft and final drivenoear,

Be very careful not to damage the torque converter housing when replacing the main ball bearing. you

may also damage the ATF pump when you torque down the main valve body. This will result in ATF pumpseizure if not detected. Use the Drooer tools.

SInstall the main seal flush with the torque converter housing. lf you push it into the torque converterhousing until it bottoms out, it will block the fluid return passage and result in damage.

www.emanualpro.com

Page 677 of 1395

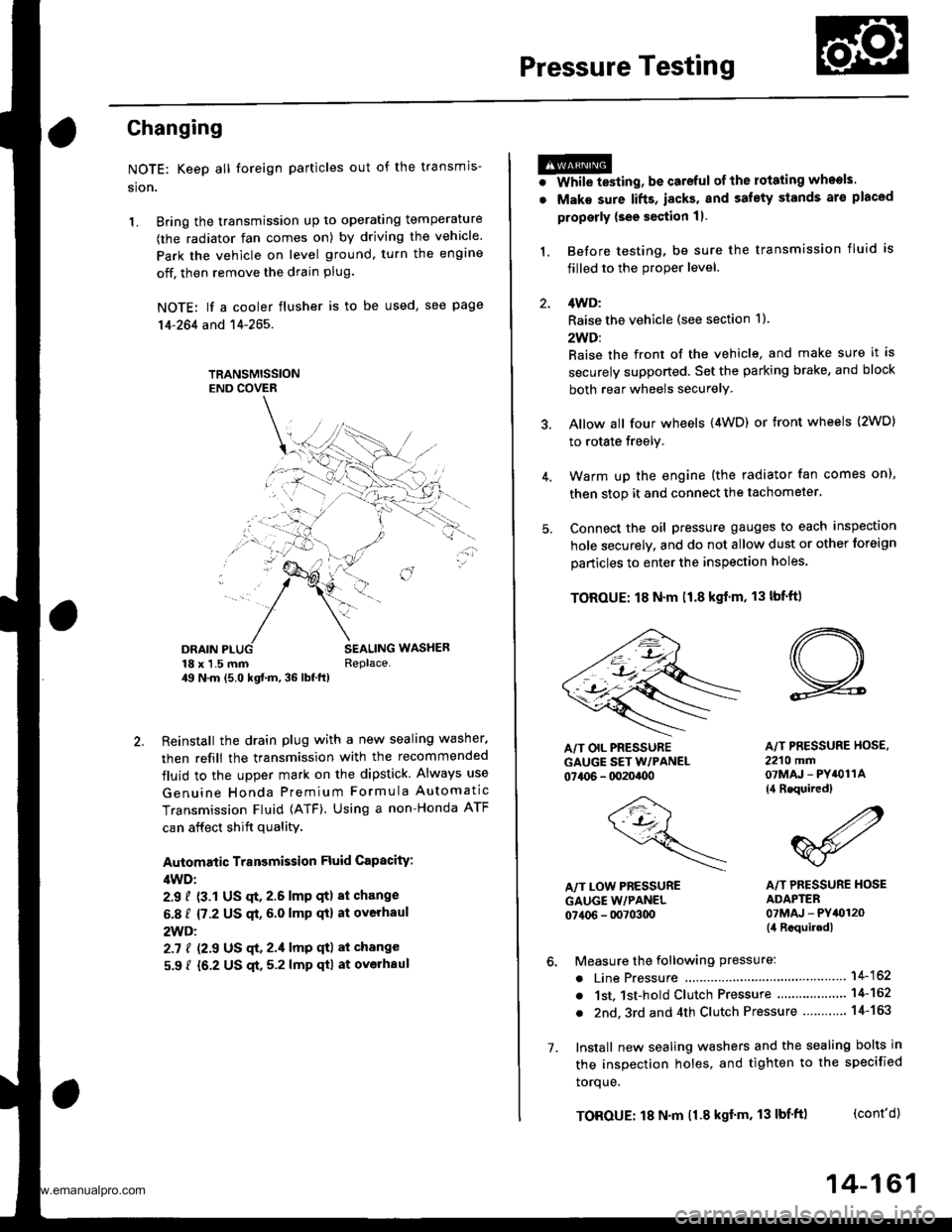

Pressure Testing

Changing

NOTE: Keep all foreign particles out of the transmis-

sion.

1. Bring the transmission up to operating temperature

(the radiator fan comes on) by driving the vehicle.

Park the vehicle on level ground. turn the engane

off. then remove the drain Plug.

NOTE: lf a cooler flusher is to be used, see page

14-264 and 14-265.

TRANSMISSIONEND COVER

DRAIN18 x 1.5 mmSEALING WASHEBReplace.49 N.m {5.0 kgt.m, 36 lbf.tl)

Reinstall the drain plug with a new sealing washer,

then refill the transmission with the recommended

fluid to the uDper mark on the dipstick. Always use

Genuine Honda Premium Formula Automatic

Transmission Fluid (ATF) Using a non-Honda ATF

can affect shift quality.

Automatic Transmission Fluid Capacity:

4WD;

2.9 { (3.1 US qt. 2.6 lmp qt) 8t change

5.8 ? {7.2 US $, 6.0 lmp qt} at ovethaul

2WD:

2.7 | l2.S US qt,2.1lmp qtl ai change

5.9 ? {6.2 US $, 5.2 lmp qtl at ovolhaul

2.

a

a

1.

Wlrile testing, be careful of the rotaling wheols.

Mako sure lifts, iacks, and safety stands ar€ placed

properly (see scction 11.

Before testing, be sure the transmission fluid is

filled to the proPer level.

4WD:

Raise the vehicle (see section 11.

2WD:

Raise the front of the vehicle, and make sure it is

securely supported. Set the parking brake, and block

both rear wheels securely.

Allow all four wheels {4WD) or front wheels (2wD}

to rotate freely.

Warm up the engine (the radiator fan comes on),

then stop it and connect the tachometer.

Connect the oil pressure gauges to each inspection

hole securely, and do not allow dust or other foreign

particles to enter the inspection holes.

TOROUE: 18 N'm ll.8 kgf'm, 13 lbf'ft)

5.

A/T PRESSURE HOS€,2210 mm07MAJ - PYiOllA

{4 Requircd}

,4'/"' ,a

W'

A/T PRESSURE HOSEADAPTER07MAJ - PYt0120(il Rcquiledl

6. Measure the following Pressure:. Line Pressure ..........,14-162

. 1st. 1st-hold Clutch Pressure .............'. 14-162

. 2nd,3rd and 4th Clutch Pressure .......... 14-163

7. Install new sealing washers and the sealing bolts in

the inspection holes, and tighten to the specified

toroue.

(cont'd)

A/T OIL PRESSUREGAUGE SET W/PANEL07{06 - 0020400

/4\\-J-- (

+..\.-.\-'-\

A/T LOW PBESSUREGAUGE w/PANEL07406 - 0070300

TOROUE: 18 N'm 11.8 kgf'm, 13 lbf'ft)

14-161

www.emanualpro.com

Page 680 of 1395

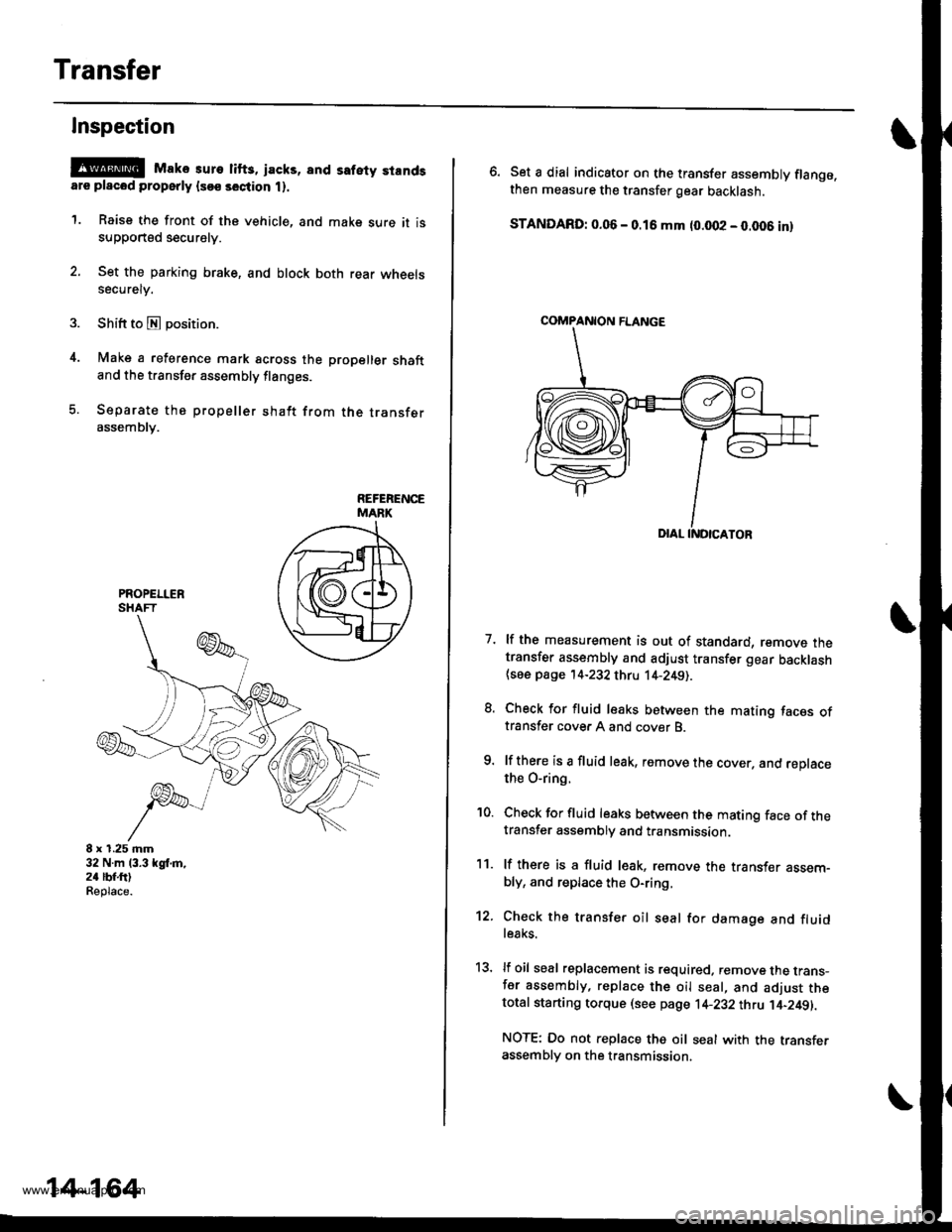

Transfer

4.

Inspection

@E Mako suro lifts, jacks, and safety standsare placod properly lsoe section t).

1. Raise the front of the vehicle, and make sure it issupported securely.

2. Set the parking brake, and block both rear wheelssecurely.

Shift to E position.

Make a reference mark across the propeller shaftand the transfer assembly flanges.

Separate the propeller shaft from the transferassembly.

8 x 1.25 mm32 N.m 13.3 kgl,m,24 lbf.ftlReplace.

14-164

\

6. Set a dial indicator on the transfer assembly flange.then measure the transfer gear backlash.

STANDARD: 0.06 - 0.16 mm (0.002 - 0.006 inl

7. lf the measurement is out of standard, remove thetransfer assembly and adjust transfer gear backlash{see page '14-232 thru 14-2491.

8. Check for fluid leaks between the mating faces oftransfer cover A and cover B.

9. lf there is a fluid leak, remove the cover, and reDlacethe O-ring.

'10. Check for fluid leaks between the mating face of thetransfer assembly and transmission.

11. lf there is a fluid l€ak, remove the transf€r assem-bly, and replace the O-ring,

12. Check the transfer oil seal for damage and fluidle8ks.

13, lf oil seal replacement is required. remove the trans-fer assembly, replace the oil seal, and adjust thetotal starting torque (see page 1+232 thtu ]'4-249||.

NOTE: Do not replace the oil seal with the transferassembly on the transmission.

COMPANION FLANGE

www.emanualpro.com

Page 681 of 1395

Transfer Assembly

Removal

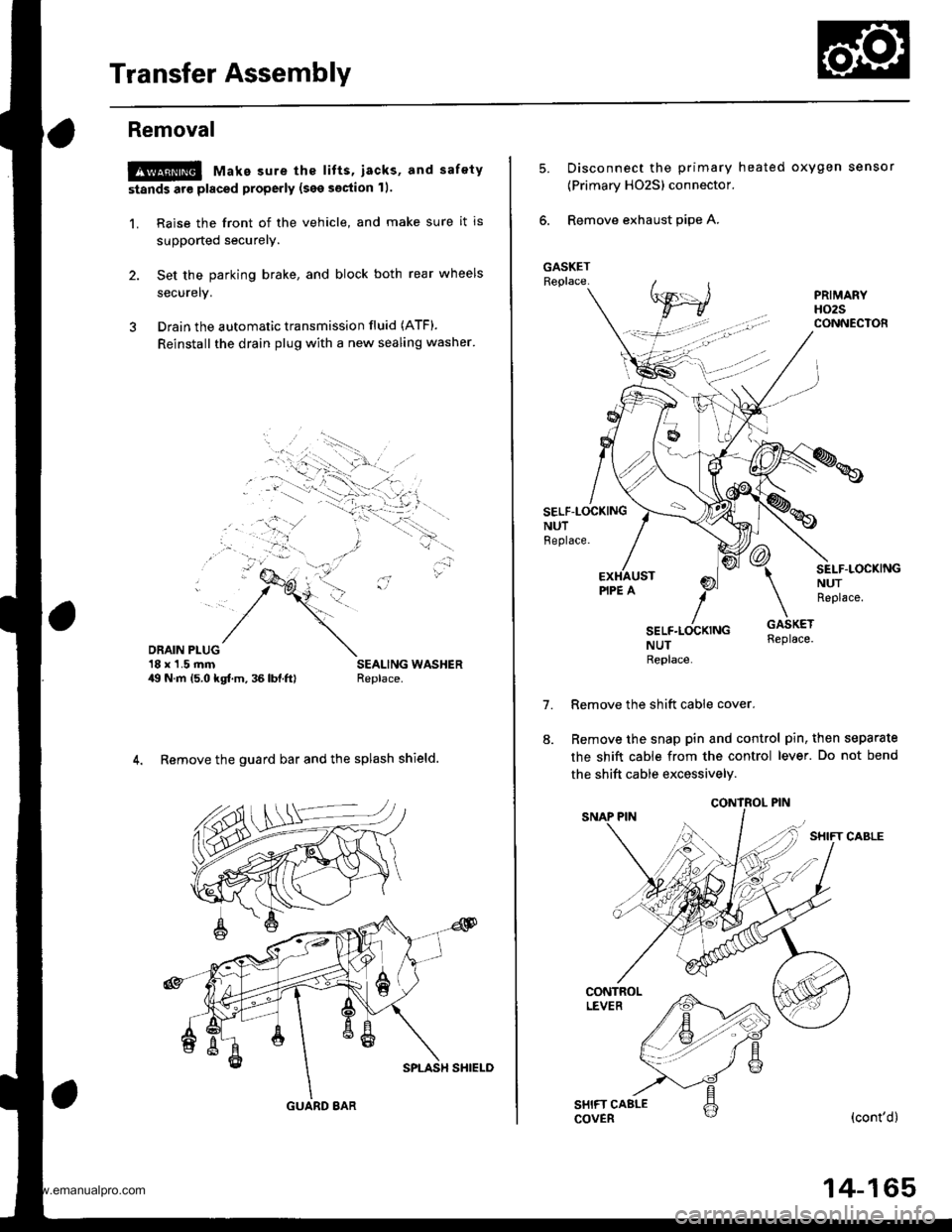

@ Make sure the lifts, iacks, and safety

stands are placed properly (see section 11.

1. Raise the front of the vehicle, and make sure it is

supported securely.

2. Set the parking brake, and block both rear wheels

securelv.

3 Drain the automatic transmission fluid (ATF).

Reinstall the drain plug with a new sealing washer'

DRAIN PLUG'18 x'1.5 rnm49 N.m 15.0 kgf.m, 36 lbl.ftl

4. Remove the guard bar and the splash shield.

GUARD 8AR

14-165

5.Disconnect the primary heated oxygen sensor

{Primary HO2S) connector.

Remove exhaust pipe A.

SELF-LOCKINGNUTBeplace.

7.

SEI-F.LOCKINGNUTReplace.

NUTReplace

Remove the shift cable cover.

Remove the snap pin and control pin, then separate

the shift cable from the control lever. Do not bend

the shift cable excessively.

(cont'd)

www.emanualpro.com

Page 685 of 1395

Transmission

Removal

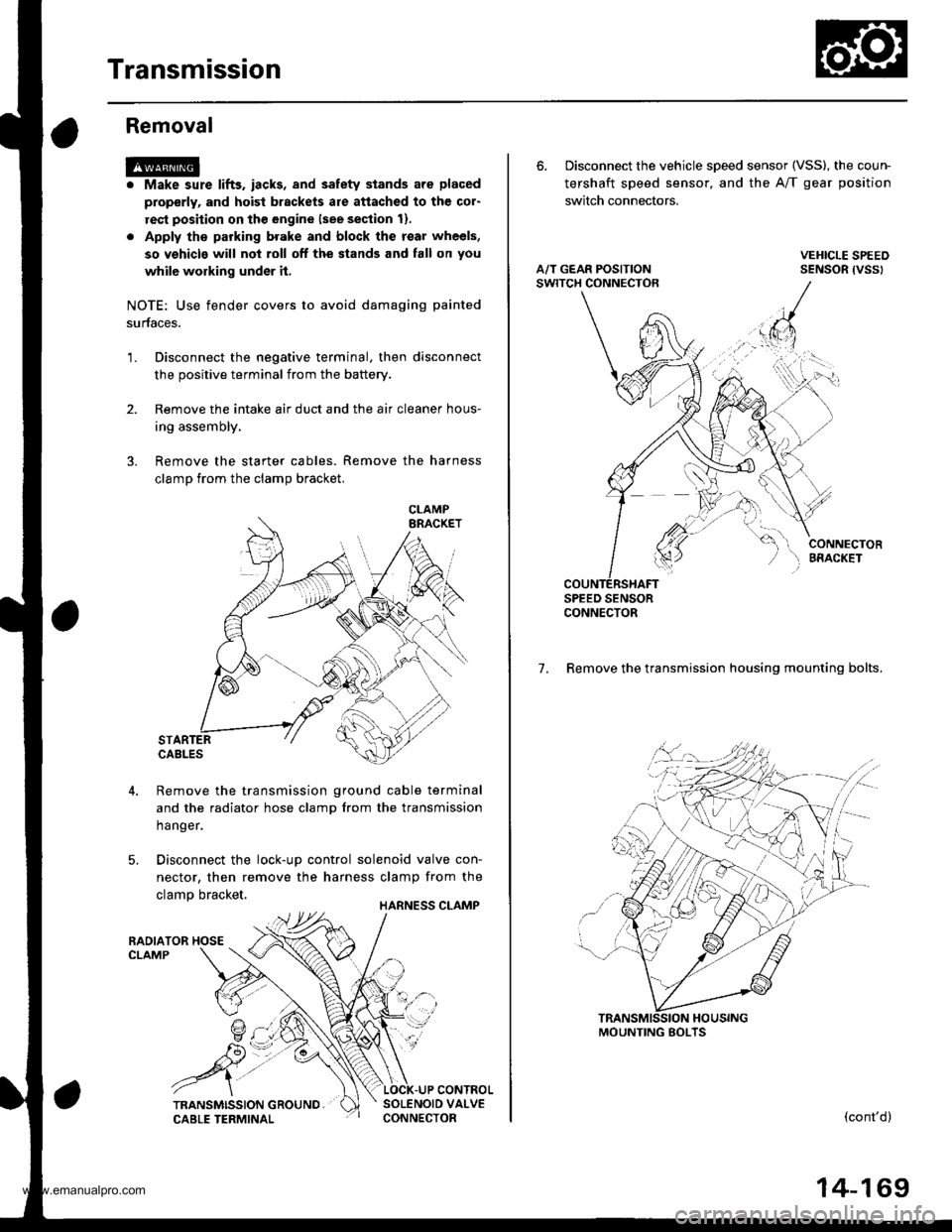

@

2.

'1.

Make sure lifts. iacks, and safety stands aro placed

properly, and hoist brackets are attached to the col-

rest position on the engine lsee section 11.

Apply th€ parking brake and block the r€ar wheels,

so vehicls will noi roll off the stands and fall on you

while working under it.

NOTE: Use fender covers to avoid damaging painted

surfaces.

Disconnect the negative terminal, then disconnect

the positive terminal from the battery.

Remove the intake air duct and the air cleaner hous-

ing assembly,

Remove the starter cables. Remove the harness

clamp from the clamp bracket.

5.

STARTERCABLES

Remove the transmission ground cable terminal

and the radiator hose clamp lrom the transmission

hanger.

Disconnect the lock-up control solenoid valve con-

nector, then remove the harness clamp from the

clamp bracket.HARNESS CLAMP

RADIATOR HOSECLAMP

CONTROLSOLENOID VALVECONNECTOR

CLAMP

6. Disconnect the vehicle speed sensor (VSS), the coun-

tershaft speed sensor, and the A/T gear position

switch connectors.

A/T GEAR POSITIONSWITCH CONNECTOR

VEHICLE SPEEDSENSOR |VSS'

CONNECTORBfiACKET

SPEED SENSORCONNECTOR

7. Remove the transmission housing mounting bolts.

MOUNTING BOLTS

(cont'd)

14-169

www.emanualpro.com