Trunk HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 21 of 1395

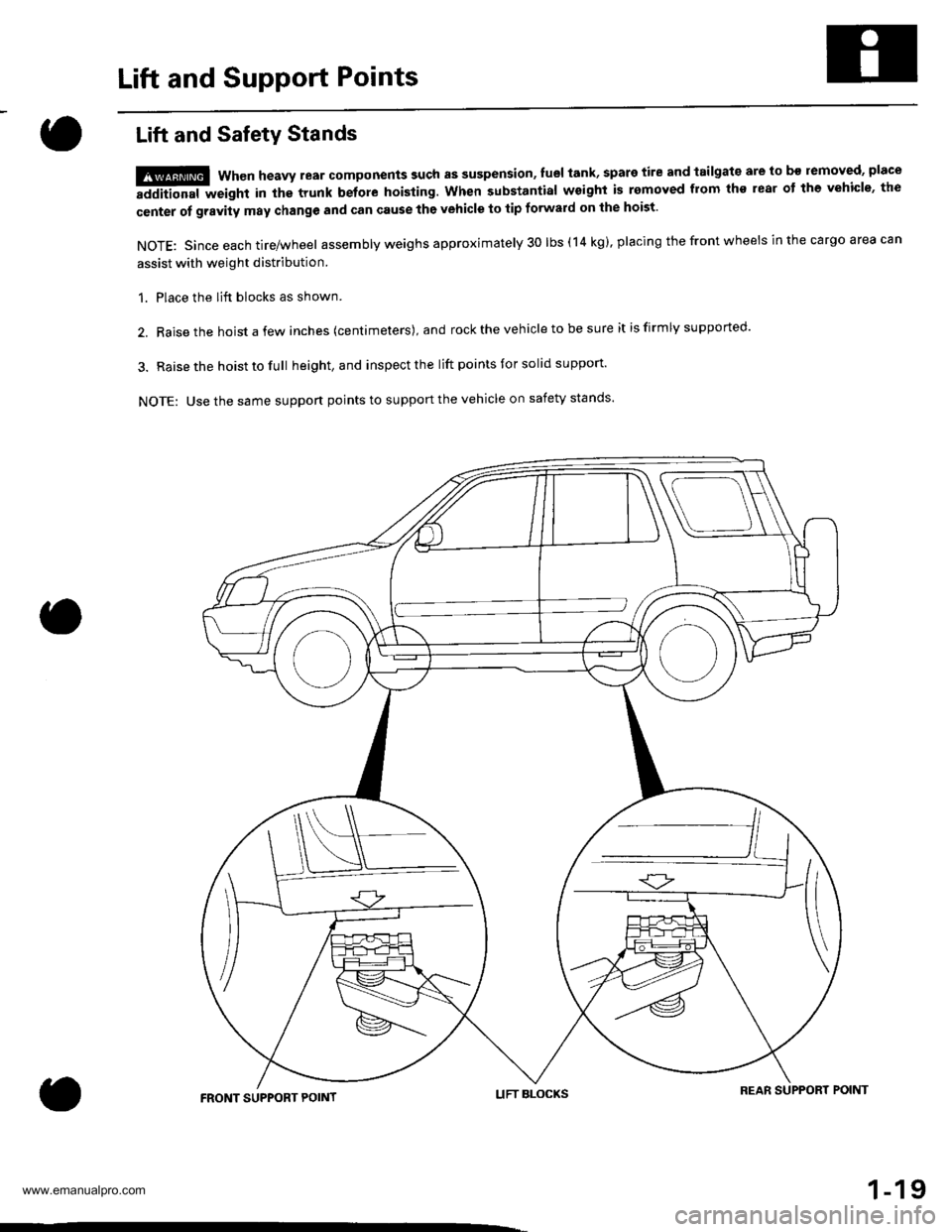

Lift and Support Points

Lift and Safety Stands

ffi When heaw rear components such as suspension, Iuel tank, spare tire and tailgate are to b€ lemoved, place

!iiii-'rn"t r""igtrt in the trunk before hoisting. When substantial weight is removed flom the lear ot the vehicle, the

center of gravity may change and can cause the vehicle to tip fotward on the hoist'

NOTE: Since each tire/wheel assembly weighs approximately 30 lbs (14 kg), placing the front wheels in the cargo area can

assist with weight distribution.

1. Place the lift blocks as shown.

2. Raise the hoist a few inches (centimeters), and rock the vehicle to be sure it is firmly supported.

3. Raise the hoist to full height, and inspect the lift points for solid support'

NOTE: Use the same suppon points to support the vehicle on safety stands'

LIFT BLOCKSREAR SUPPORT POIMTFRONT SUPPORT POINT

1-19

www.emanualpro.com

Page 917 of 1395

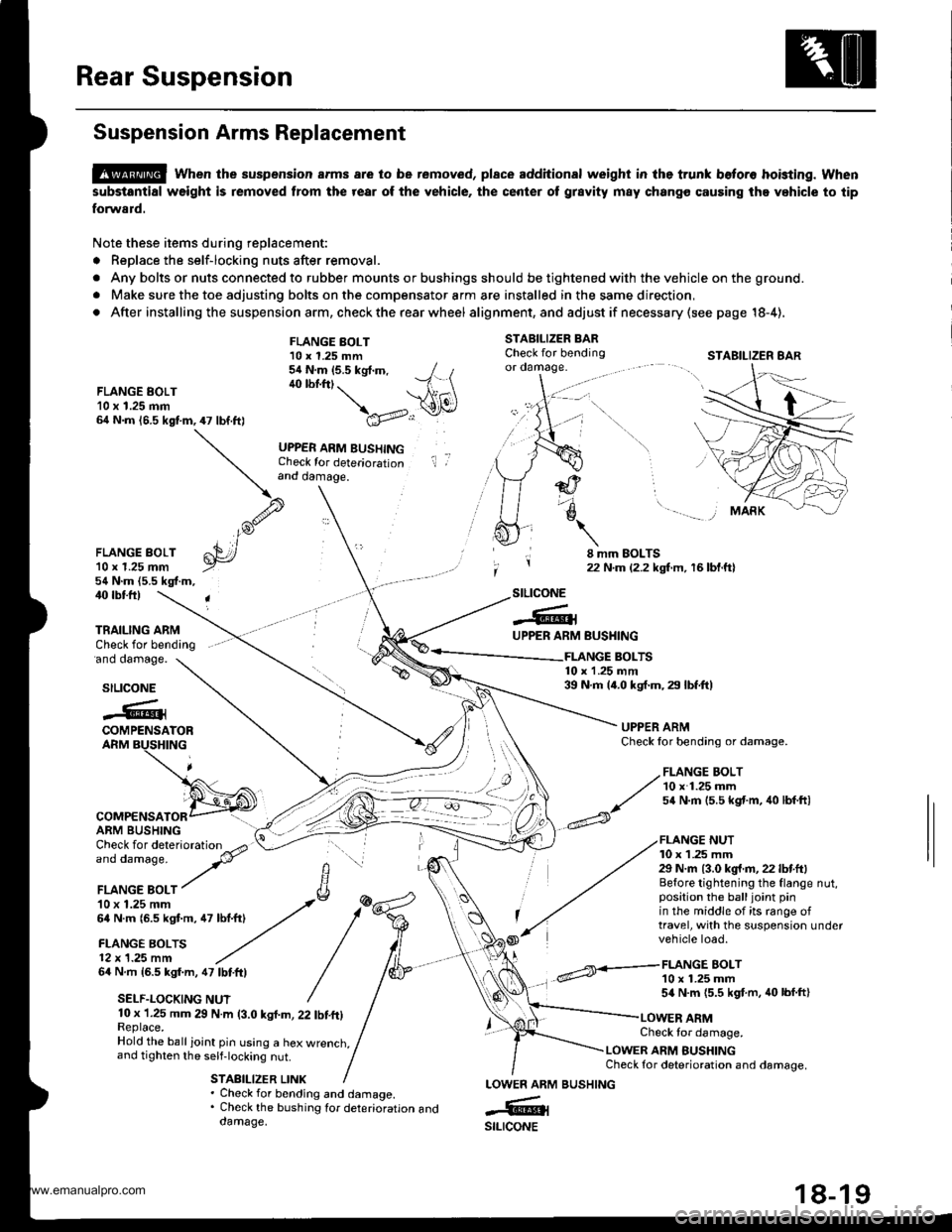

Rear Suspension

Suspension Arms Replacement

@ when the suspension arms are to be removed, plsce additional weight in lhe trunk beto.o hoisting. when

substantial weight is removed from the rear of the vehicle, the center ot grsvity m8y chango causing the vehicle to tip

forward.

Note these items during replacement:

. Replace the self-locking nuts after removal.

. Any bolts or nuts connected to rubber mounts or bushings should be tightened with the vehicle on the ground.

. Make sure the toe adjusting bolts on the compensator arm are installed in the same direction,

. After installing the suspension arm, check the rear wheel alig nment, and adjust if necessa ry (see page 18-4),

STABILIZER BARCheck for bendingor oamage.

FLANGE EOLT10 x 1.25 mm64 N.m 16.5 kgf.m,47 lbf.ft)

FLANGE BOLT10 x 1.25 mm54 N.m (5.5 kgt.m, / t40 lbf.ftt. --1 \ \A1(\

\a'v..:r

UPPER ARM BUSHINGCheck for deteriorationand damage.

il ,

FLANGE BOLT'l0 r 1.25 mm54 N.m (5.5 kgf.m,

8 mm EOLTS22 N.m {2.2 kgf.m, 16 bl.ftl

40 rbtft)

'ano oamage.

TRAILING ARMCheck for bending

stLtcoNE

-6lUPPER ARM

COMPENSATORARM BUSHING

64 N.m 16.5 kgf.m, 47 lbtftl

SELF.LOCKING NUT

BUSHING

FLANGE BOLT10 x 1.25 mm54 N.m {5.5 kgf.m, 40 lbf.ft}

FLANGE BOLTS10 x 1.25 mm39 N.m 14.0 kgf.m, 29 lbf.ft)stLtcoNE

.@iCOMPENSATORARM BUSHING

UPPER ARMCheck lor bending or damage.

FLANGE NUT10 x 1 .25 mm29 N.m {3.0 kg{.fl,22 lbf.ft}Before tightening the flange nut,position the balljoint pinin the middle of its range oftravel, with the suspension undervehicle load.

10 x 1.25 mm 29 N.m (3.0 kgl.m, 22 tbf.ft)Replace.Hold the ball ioint pin using a hex wrenct,,and tighten the self-locking nut.

STABILIZER LINK

Check tor damage.

LOWER ARM BUSHINGCheck for deterioration and damage.

. Check for bending and damage.. Check the bushing tor deterioration anddamage.

LOWEN ARM

-6ilstLrcoNE

STABILIZER 8AR

,/ FLANGE BOLT

// 10 x 1.25 mm

^/ s4 N.m 15.5 kst'm, 40 lbf ftl

BUSHING

www.emanualpro.com

Page 1021 of 1395

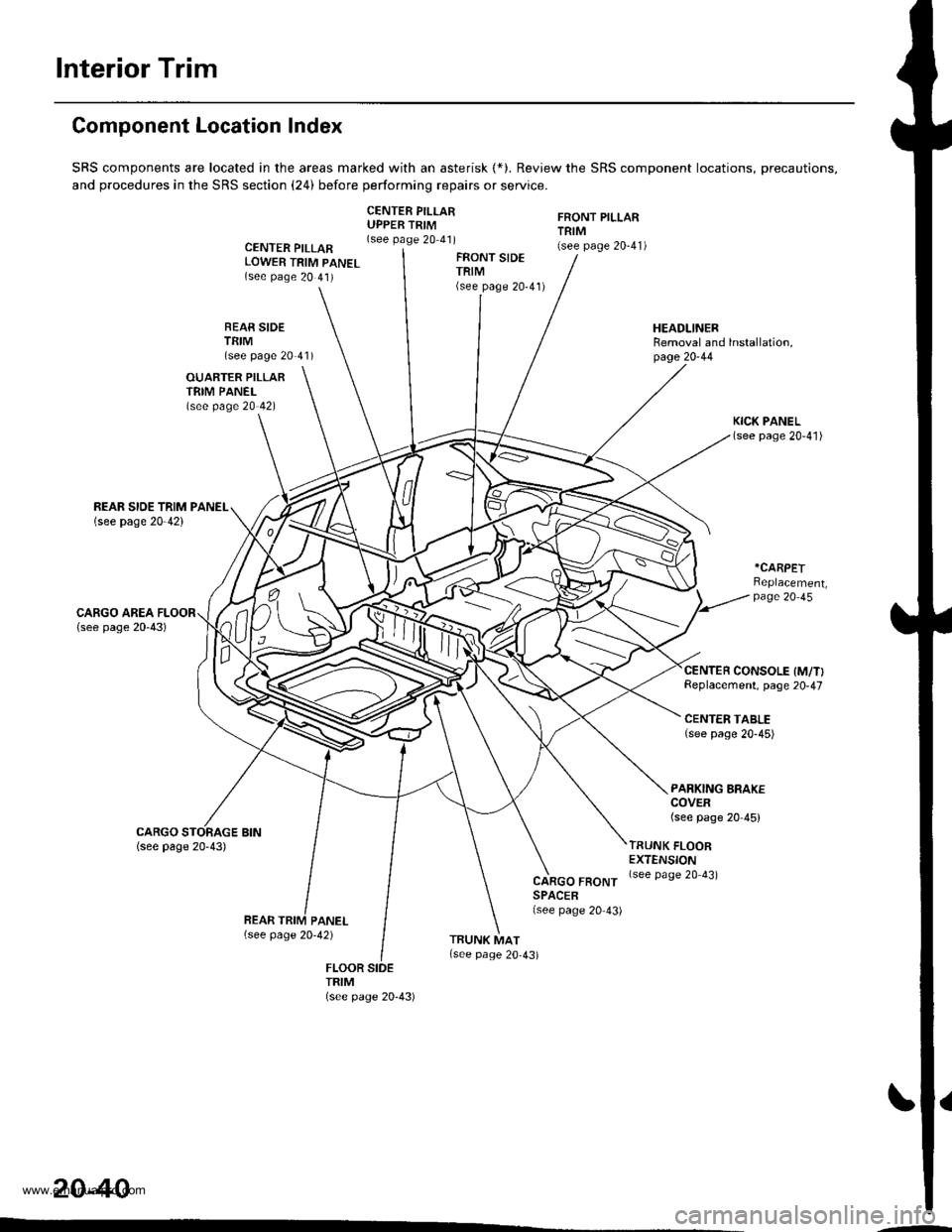

lnterior Trim

20-40

CARGO FRONTSPACER(see page 20 43)

FRONT PILLARTRIM(see page 20-41)

TRUNK FLOOREXTENSION(see page 20 43)

HEADLINERRemoval and lnstallation,page 20-44

Component Location Index

SRS components are located in the areas marked with an asterisk (*). Review the SRS component locations, precautions,

and procedures in the SRS section (24) before performing repairs or service.

CENTER PILLARUPPER TRIM(see page 20 41)CENTER PILLARLOWER TRIM PANEL(see page 20 41)

FRONT SIDETRIM(see page 20-41)

BEAR SIDETEIM(see page 20'41)

OUARTER PILLARTRIM PANEL(see page 20 42)

*CARPET

Replacement,page 20 45

CENTER CONSOLE IM/T}Replacement, page 20-47

CENTEN TABLE(see page 20-45)

PARKING BRAKECOVER(see page 20-45)

TRIM

www.emanualpro.com

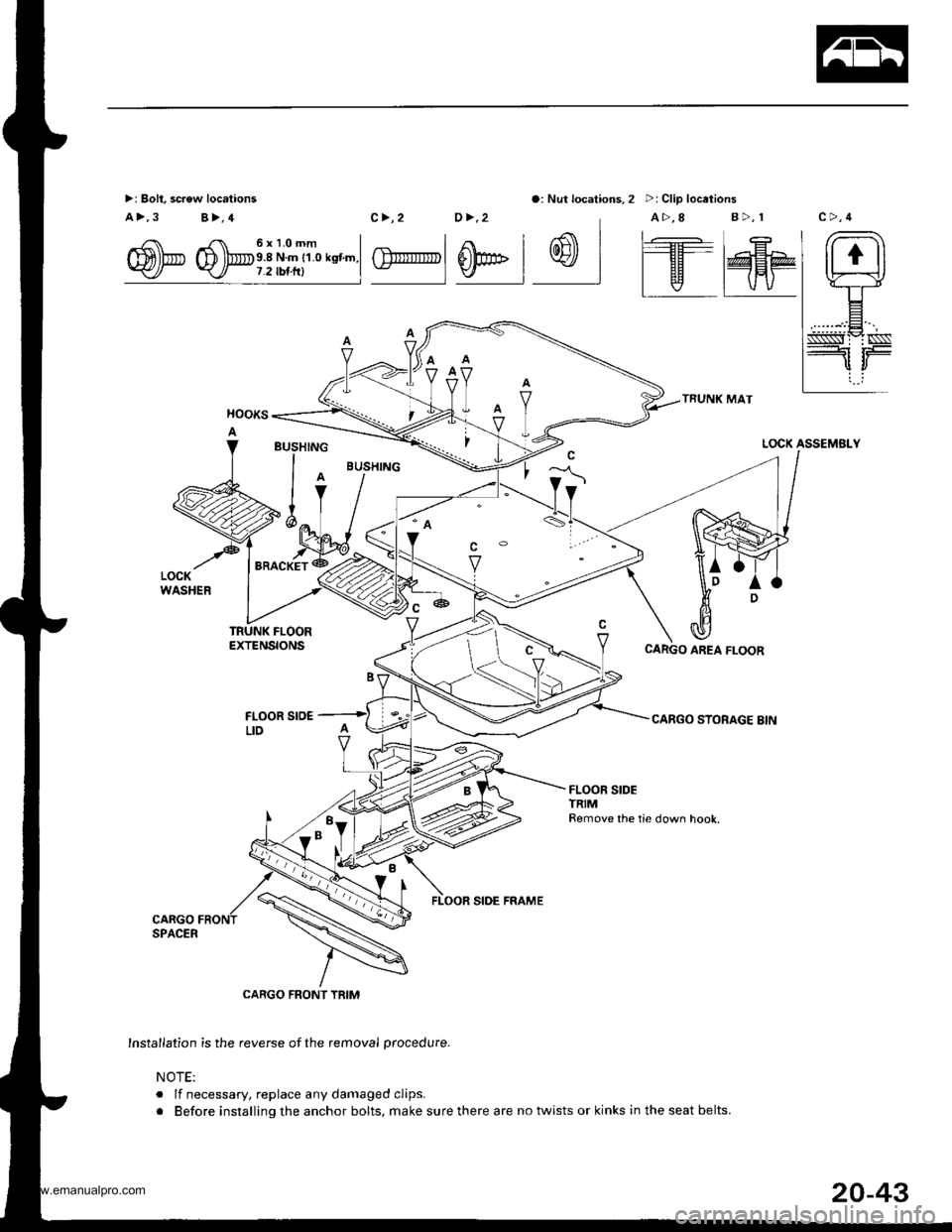

Page 1024 of 1395

>: Bolt, screw locations

a>,3 B>,4

o: Nut locations, 2 >: Clip locations

TRUNK MAT

CARGO STORAGE BIN

/ rr. 6xl.Omm I

m)b D lbe.8 Nm r1.o ksnm.l-

c>,2 0>,2 A>,8 B>,r

| .€ | r- -I At I tl1|r' t I l���'---llH- | E

GlrrIIITTpl 0pE l w I l--Tr@HPv | | v I vv

LOCK ASSEMBLY

TRUNK FLOOREXTENSIONS

FLOOR SrO€LID

FLOOR SIDE FRAME

CARGO FRONT TRIM

Insta,lation is the reverse of the removal procedure.

NOTE:

. lf necessary, replace any damaged clips.

r Before installing the anchor bolts, make sure there are no twists or kinks in the seat belts.

BUSHING

l^IV

>ilv '%L

"ro"*i*

CARGO AREA FLOOR

l*,hl

20-43

www.emanualpro.com

Page 1025 of 1395

lnterior Trim

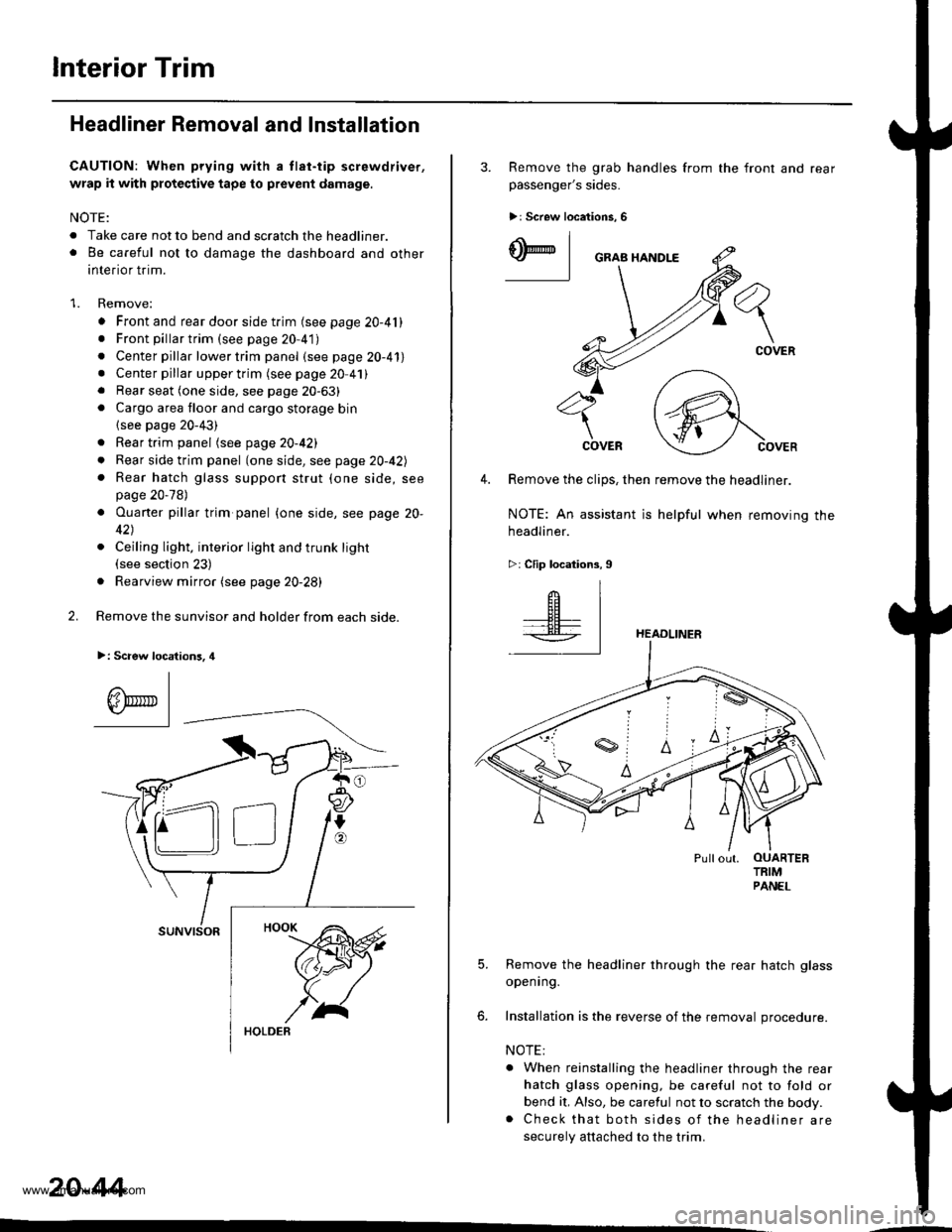

Headliner Removal and Installation

CAUTION: When prying with a tlat-tip screwdriver,

wrap it with protective tape to prevent damage.

NOTE:

. Take care not to bend and scratch the headliner.o Be careful not to damage the dashboard and other

interior trim.

1. Remove:

. Front and rear door side trim (see page 20-41). Front pillartrim (see page 20-41)

. Center pillar lower trim panel (see page 20-41). Center pillar upper trim (see page 20 41). Rear seat (one side, see page 20-63). Cargo area floor and cargo storage bin

{see page 20-43)

. Rear trim panel (see page 20-421

. Rear side trim panel (oneside, see page 20-42l,

. Rear hatch glass support strut (one side, seepage 20-78)

. Ouaner pillar trim panel {one side, see page 20-

42)

. Ceiling light, interior light and trunk light(see section 23)

. Rearview mirror (see page 20-28)

2. Remove the sunvisor and holder from each side.

>: Scaew location3, 4

I

A\"r- |Yr* || -

suNvtsoR

20-44

3. Remove the grab handles from

passenger's sides.

>r Screw locations, 6

the front and rear

ry_l

COVER

4. Remove the clips, then remove the headliner.

NOTE: An assistant is helpful when removing the

headliner.

>: Clip locations,9

HEADLINER

Pullout. OUARTERTRIMPANEL

5. Remove the headliner through the rear hatch glass

openrng.

6. Installation is the reverse of the removal procedure.

NOTE:

. When reinstalling the headliner through the rear

hatch glass opening, be careful not to fold or

bend it, Also, be careful not to scratch the body.. Check that both sides of the headliner are

securely attached to the trim.

www.emanualpro.com

Page 1241 of 1395

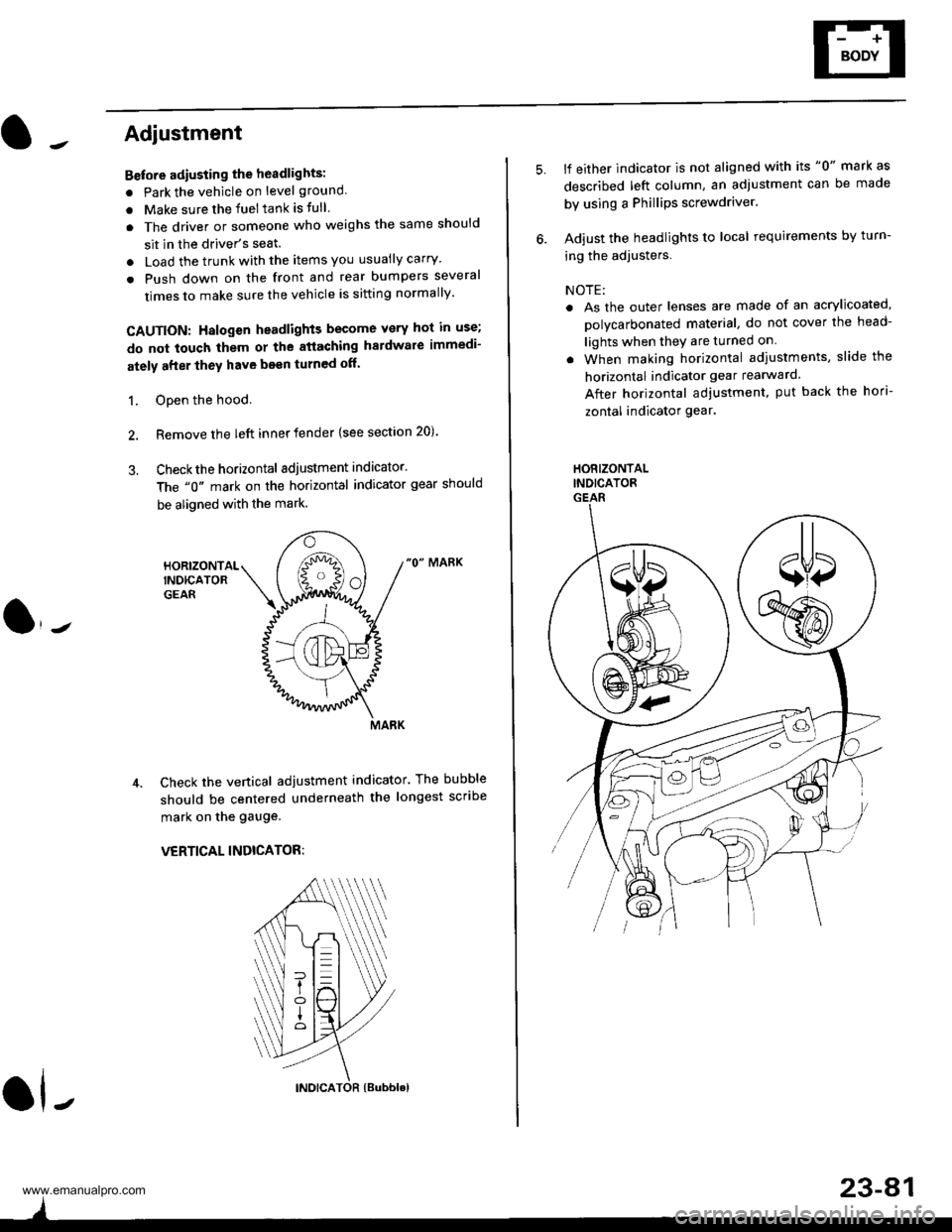

Adjustment

Bstore adiusting the headlights:

. Park the vehicle on level ground

. Make sure the fuel tank is tull

. The driver or someone who weighs the same should

sit in the driver's seat.

. Load the trunk with the items you usually carry'

. Push down on the front and rear bumpers several

times to make sure the vehicle is sitting normally'

CAUTION: Halogen headlights become very hot in use;

do not touch them or the atiaching hardware immedi-

ately after they have been turned off.

1. ODen the hood.

2. Remove the left inner fender {see section 20).

3. Checkthe horizontal adjustment indicator.

The "0" mark on the horizontal indicator gear should

be aligned with the mark.

"0" MARK

Check the vertical adjustment indicator. The bubble

should be centered underneath the longest scribe

mark on the gauge.

VERTICAL INDICATOR:

ol-

)

5.lf either indicator is not aligned with its "0" mark as

described left column, an adjustment can be made

by using a Phillips screwdriver.

Adjust the headlights to local requirements by turn-

ing the adjusters.

NOTE:

. As the outer lenses are made of an acrylicoated,

polycarbonated material, do not cover the head-

lights when they are turned on

. When making horizontal adiustments, slide the

horizontal indicator gear rearward.

After horizontal adjustment, put back the hori-

zontal indicator gear.

HORIZONTALINDICATORGEAR

23-A1

www.emanualpro.com

Page 1305 of 1395

)J

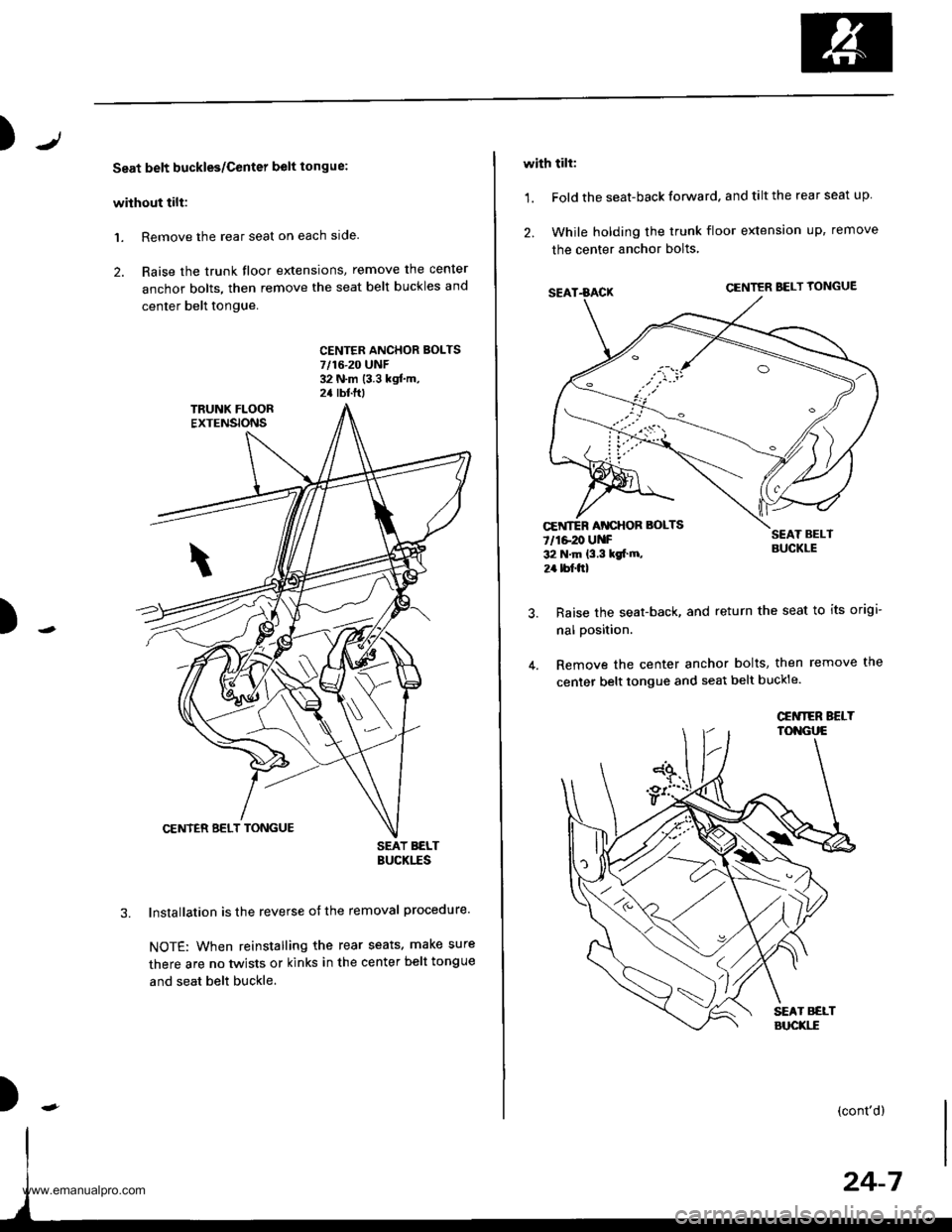

Seat belt buckles/Center belt tongue:

without tilt:

1. Remove the rear seat on each slde.

2. Raise the trunk floor extensions, remove the cenler

anchor bolts, then remove the seat belt buckles and

center belt tongue.

CENTFR ANCHOR BOLTS7/16-20 UNF32 N.m (3.3 kgf.m,2a rbtftt

)

SEAT BELTBUCKITS

lnstallation is the reverse of the removal procedure.

NOTE: When reinstalling the rear seats. make sure

there are no twists or kinks in the center belt tongue

and seat belt buckle.

)

with tilt:

1. Fold the seat-back forward. and tilt the rear seat up

2. While holding the trunk floor extension up, remove

the center anchor bolts

SEAT.BACKCENTER BELT YONGUE

SEAT BELTBUCKLE

Raise the seat-back, and return the seat to its origi-

nal position.

Remove the center anchor bolts, then remove the

center belt tongue and seat belt buckle.

CEiITER AT{CHOR BOLTS

7/1e20 UNF32 N.m {3.3 kgt m,

2r bf.frl

\\

(cont'd)

www.emanualpro.com