door connector HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 299 of 1395

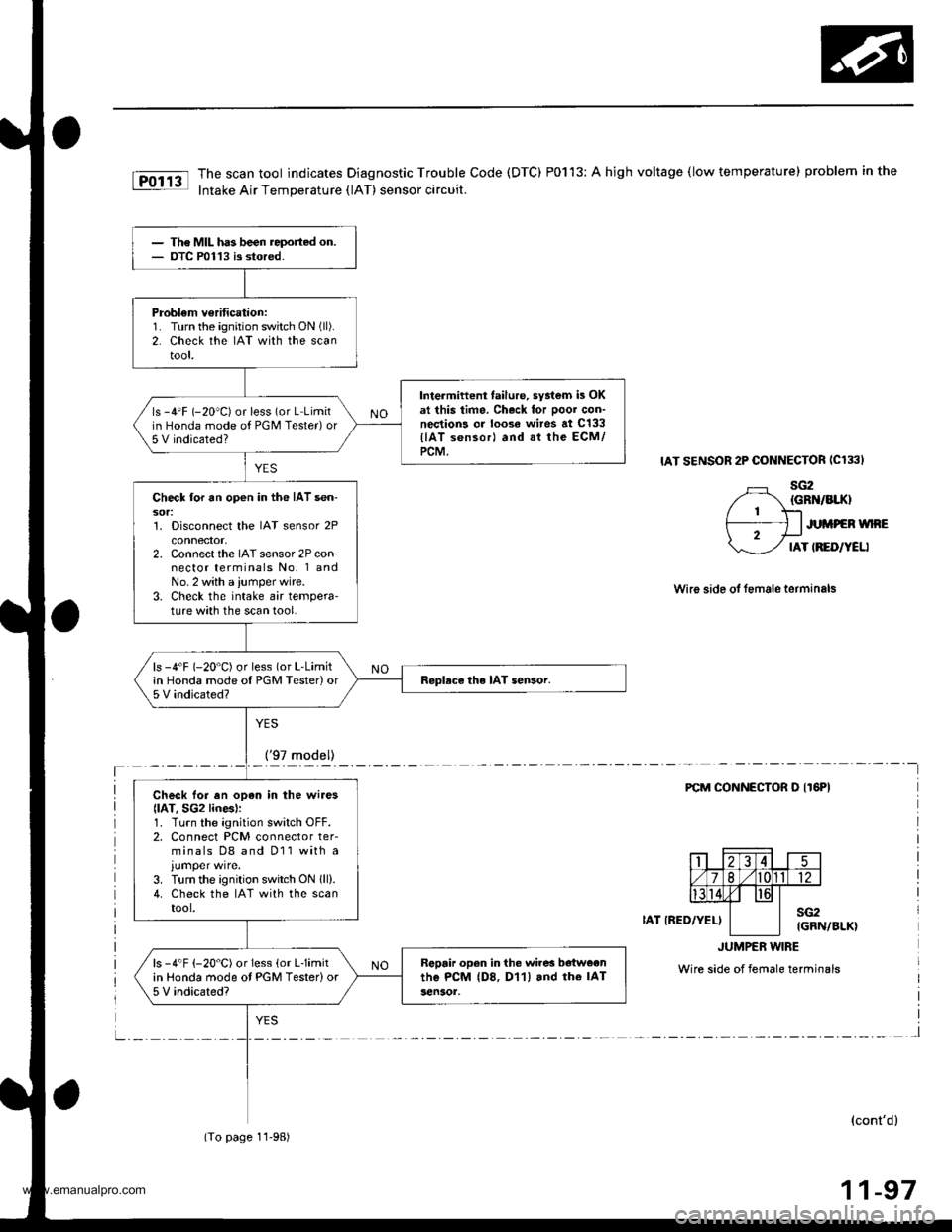

The scan tool indicates Diagnostic Trouble Code (DTC) P0113: A high voltage (low temperature) problem in the

Intake Air Temperature (lAT) sensor circuit.

IAT SENSOR 2P CONNECTOR ICl33I

sG2{GRN/BIIO

JUMPEN WNE

IAT IRED/YELI

Wire side ol female terminals

YES

_!!7rqd9ll_____-

FCM CONNECTOR O IT6PI

IAT IRED/YEL)sG2IGRN/BLK}

JUMPER w|BE

Wire side of female terminals

l

(cont'd)

11-97

The MIL has been reported on.OTC P0113 is stored.

Problem v€rification:1. Turn the ignition switch ON (ll).

2. Check the IAT with the scantool,

Intermiftent failure, syatem is OKat this time. Ch.ck for Door con-nections or loose wires at c133

llAT s6nsorl and at the ECM/PCM.

ls -4'F (-20"C) or less (or L Limitin Honda mode of PGM Tester)or5 V indicated?

Check lor an open in the IAT sen-sor:1. Disconnect the IAT sensor 2Pconnector,2. Connect the IAT sensor 2P connector terminals No. 1 andNo. 2 with a ,umper wire.3. Check the intake air tempera'ture with the scan tool.

ls -4'F (-20"C) or less (or L-Limitin Honda mode oI PGM Tester)or5 V indicated?Replace the IAT sensor.

Check lor en opan in the wires

llAT, SG2 lines):1. Turn the ignition switch OFF.2. Connect PCM connector ter-minals D8 and D11 with a

3. Turn the ignition switch ON lll).4. Check the IAT with the scantool.

Rgpair open in the wires b€tweenthe PcM (D8. D11) and rhe IAT3en30r,

ls -4"F {-20"C) or Iess (or Llimitin Honda mode ot PGM Tester)or5 V indicated?

(To page 11-98)

www.emanualpro.com

Page 407 of 1395

'97 model:

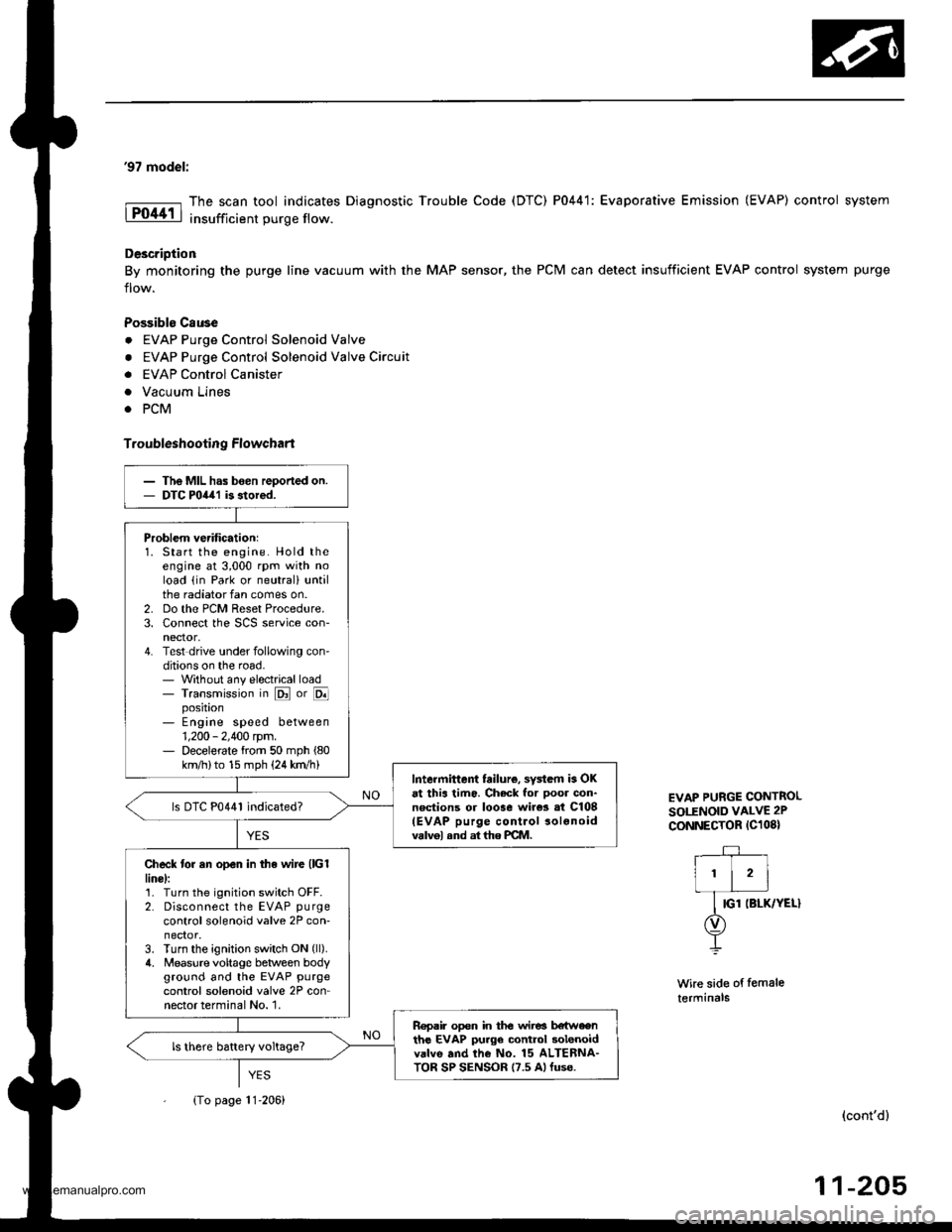

The scan tool indicates Diagnostic Trouble Code (DTC) P0441: Evaporative Emission (EVAP) control system

insufficient purge flow.

Description

By monitoring the purge line vacuum with the MAP sensor, the PCM can detect insufficient EVAP control system purge

flow.

Possiblo Cause

. EVAP Purge Control Solenoid Valve

. EVAP Purge Control Solenoid Valve Circuit

. EVAP Control Canister

. Vacuum Lines

. PCM

Troubleshooting Flowchart

EVAP PURGE CONTROL

SO1TNOID VALVE 2P

CoNNECTOR (C108)

(v)

YL

Wire side of female

termrnals

(cont'd)

11-205

Th€ MIL has b€en reooited on.DTC P0441 is .tored.

Problem verificationl1. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neut.al) untilthe radiator fan comes on.2. Do the PCM Reset Procedure.3. Connect the SCS service con-nector,4. Test drive under following con'ditions on the road.- without any electrical load- Transmission in @ or @position- Engine speed between1 ,2OO - 2,4OO rpfi.- Decelerate from 50 mph (80

km/h)to 15 mph (24 km/h)Intermittent trilure, sydern is OKat this time. Check for Door con-nections or loose wir€3 at C108

IEVAP purge control solonoidvalvol .nd at the PCM.

ls DTC P0441 indicated?

Check tor an open in the wire (lcl

linel:1. Turn the ignition switch OFF.2. Disconnect the EVAP purge

control solenoid valve 2P con-nector.3. Turn the ignition switch ON (ll).

4. Measure voltage between bodyground and the EVAP purge

control solenoid valve 2P con-nector terminal No. '1,

R€pafu open in thc wir6 b€tw€enthG EVAP purge control solenoidvalve and the No. 15 ALTEBNA-TOR SP SENSOR (7.5 A)fuse.

ls there batlery voltage?

(To page 11'206)

www.emanualpro.com

Page 411 of 1395

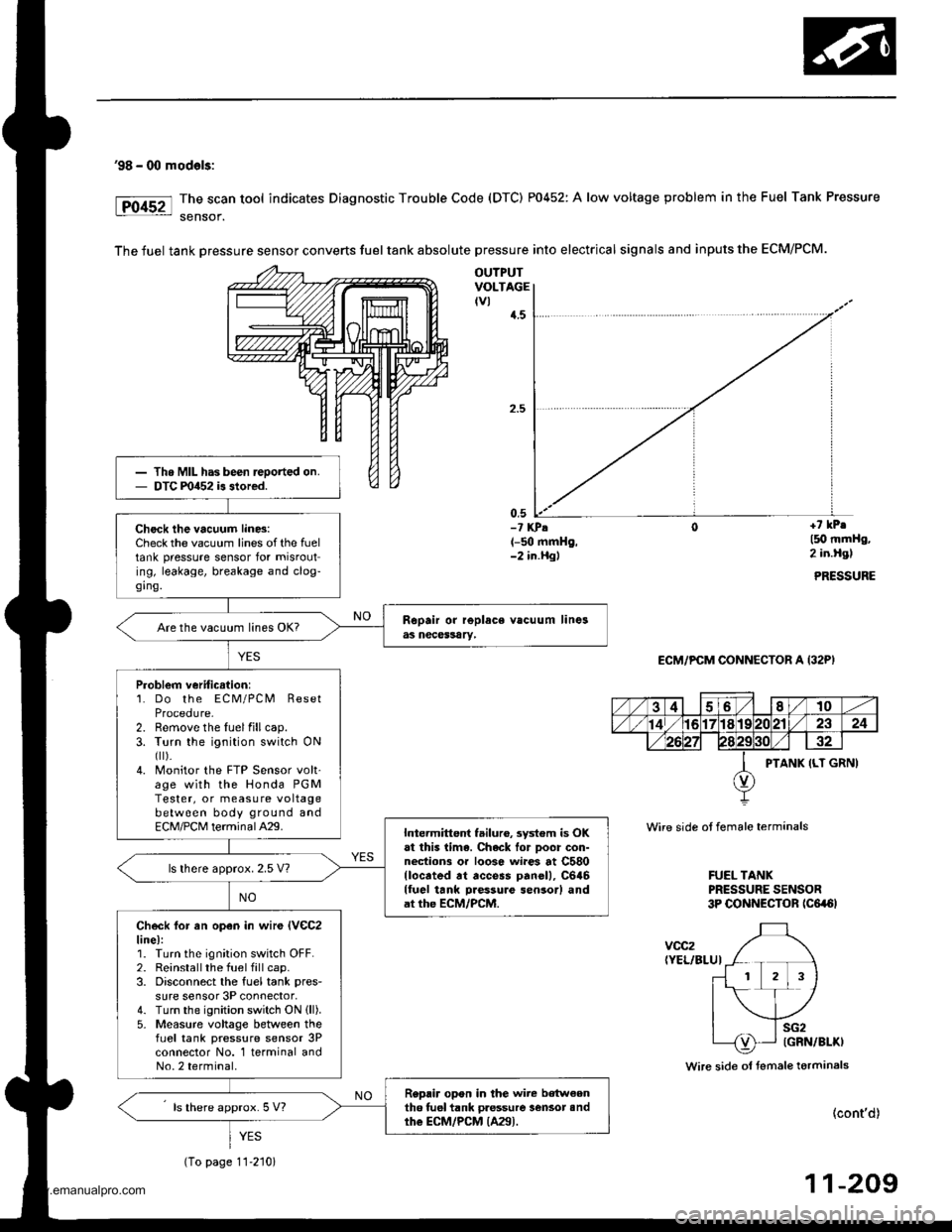

'98 - 00 mod€ls:

The scan tool indicates Diagnostic Trouble Code (DTC) P0452: A low voltage problem in the Fuel Tank Pressure

sensof.

The fuel tank Dressure sensor converts fuel tank absolute pressure into electrical signals and inputs the ECM/PCM.

OUTPUTVOLTAGEtvl{.5

0,5-? KPA(-50 mmHg,-2 in.Hgl

+7 kPr

l5O mmHg,2 in.Hgl

PRESSURE

ECM/PCM CONNECTOR A (32P)

Wire side ot female terminals

FUEL TANKPRESSURE SENSOR3P CONNECTOR tc6a6l

voc2(YEL/BLUI

Wire side ol fsmale terminals

(cont'd)

11-209

Th. MIL has been reoorted on.DTC m452 is stored.

Check the vacuum lin6:Check the vacuum lines of the fueltank pressure sensor for misrouting, leakage, breakage and clog-ging.

Are the vacuum lines OK?

Problem veriticstion:1. Do the ECM/PCM ResetProcedure-2. Remove the luelfillcap.3. Turn the ignition switch ONfl r).4. Monitor the FTP Sensor volt'age with the Honda PGMTester, or measure voltagebetween body ground andECM/PCM terminalA29.Intermittent failuro, system is OKat this lima. Chack lor Door con-nections or loose wi.es at C580llocrted rt access panell, C646lluel tank Daessure sensor) andat the ECM/PCM.

ls lhere approx. 2.5 V?

Check lor an open in wir€ lVeC2line):1. Turn the ignition switch OFF.2. Reinstallthe fuel fill cap.3. Disconnect the fuel tank pres-

sure sensor 3P connector,4. Turn the ignition switch ON (ll).

5- Measure voltage between thefLrel tank pressure sensor 3Pconnector No. 1 terminal andNo.2 terminal.

Replir opon in the wire b€tw€enth6 tuel tank pressure lensot andthe ECM/PCM {A29).ls there approx. 5 V?

YES

(To page 11-210)

www.emanualpro.com

Page 988 of 1395

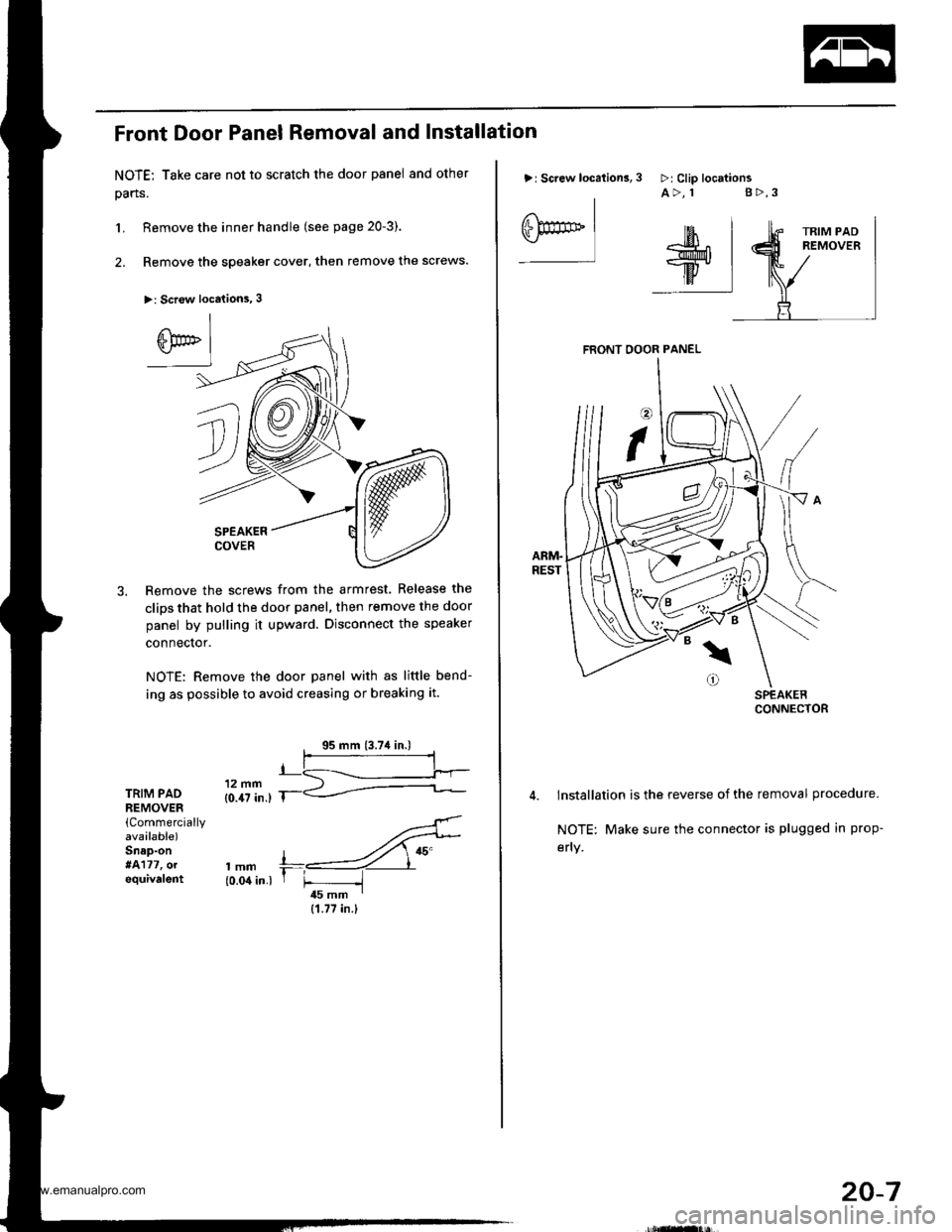

Front Door Panel Removal and Installation

NOTE: Take care not to scratch the door panel and other

pans.

L Remove the inner handle (see page 20-3).

2. Remove the speaker cover, then remove the screws.

>: Scr€w locations, 3

SPEAKERCOVER

Remove the screws from the armrest. Release the

clips that hold the door panel, then remove the door

panel by pulling it upward. Disconnect the speaker

connector.

NOTE: Remove the door panel with as little bend-

ing as possible to avoid creasing or breaking it.

TRIM PADREMOVER(Commercially

avaalable)Snap-on*4177, olequivalent

'..4'

,mm +,----ZY"{0.04 in.) r F -i45 mm I

{1.77 in.}

>: Screw location3,

I

eF** Iffil$;^r*l-w.

ttv IilF:I

3 >:Clip locttionsA>, 1 g>,3

FRONT OOOR PANEL

lnstallation is the reverse of the removal procedure.

NOTE: Make sure the connector is plugged in prop-

efly.

20-7

www.emanualpro.com

Page 990 of 1395

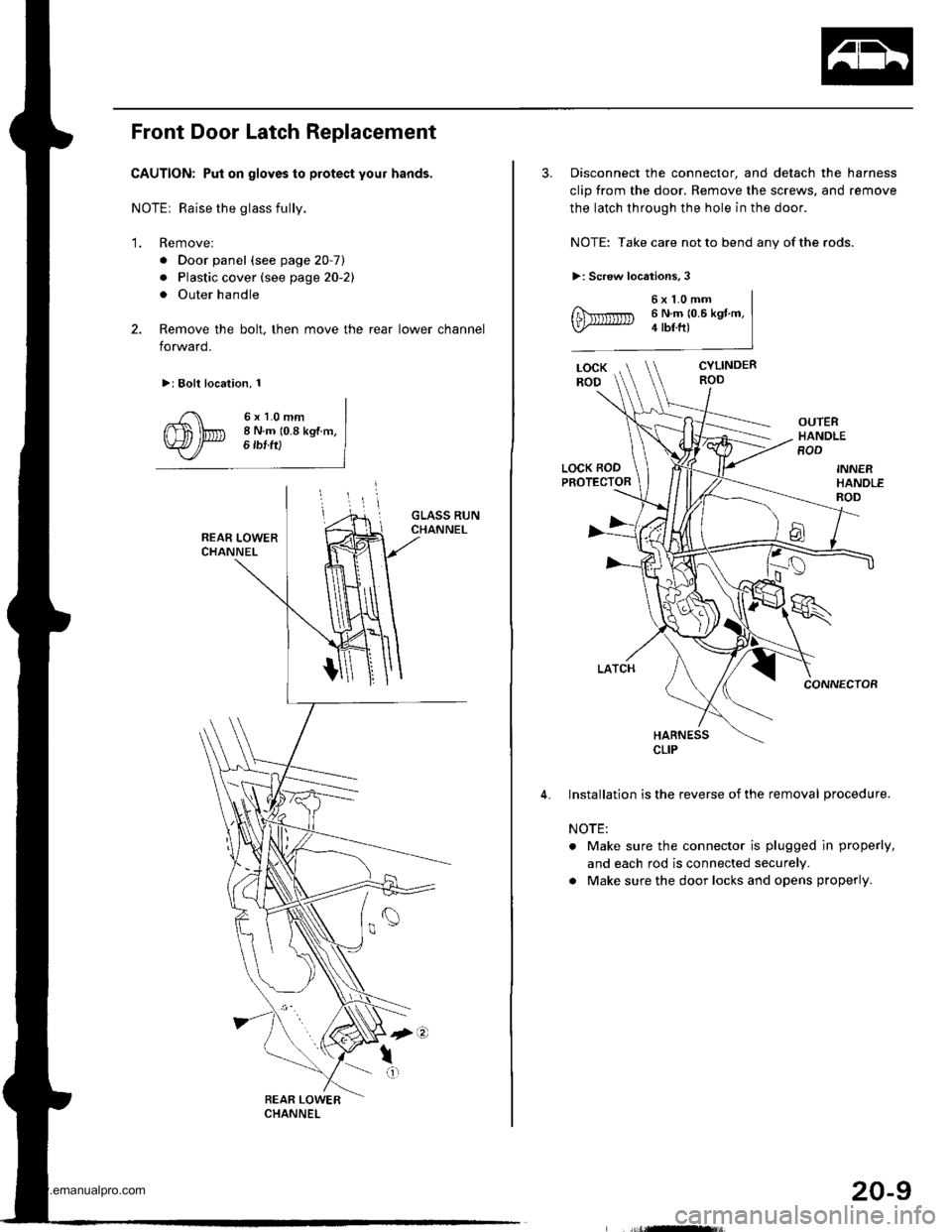

Front Door Latch Replacement

CAUTION: Put on gloves to protect your hands,

NOTEr Raise the glass fully.

'1. Remove:

. Door panel (see page 20-7)

. Plastic cover (see page 20-21

. Outer handle

2. Remove the bolt, then move the rear lower channel

forward.

>: Bolt location, 1

6xl.0mm8 N.m (0.8 kgf m,6 tbf ft)

3. Disconnect the connector, and detach the harness

clip from the door. Remove the screws, and remove

the latch through the hole in the door.

NOTE: Take care not to bend any of the rods.

>: Screw locations,3

6x1.0mm6 N.m 10.6 kgt m,4 tbf.ft)

CYLINDERROD

OUTERHANDLEROD

LOCK RODPROTECTOR

CONNECTOR

HARNESS

Installation is the reverse of the removal procedure.

NOTE:

. Make sure the connector is plugged in properly,

and each rod is connected securely.

a Make sure the door locks and opens properly.

CLIP

20-9

www.emanualpro.com

Page 991 of 1395

Doors

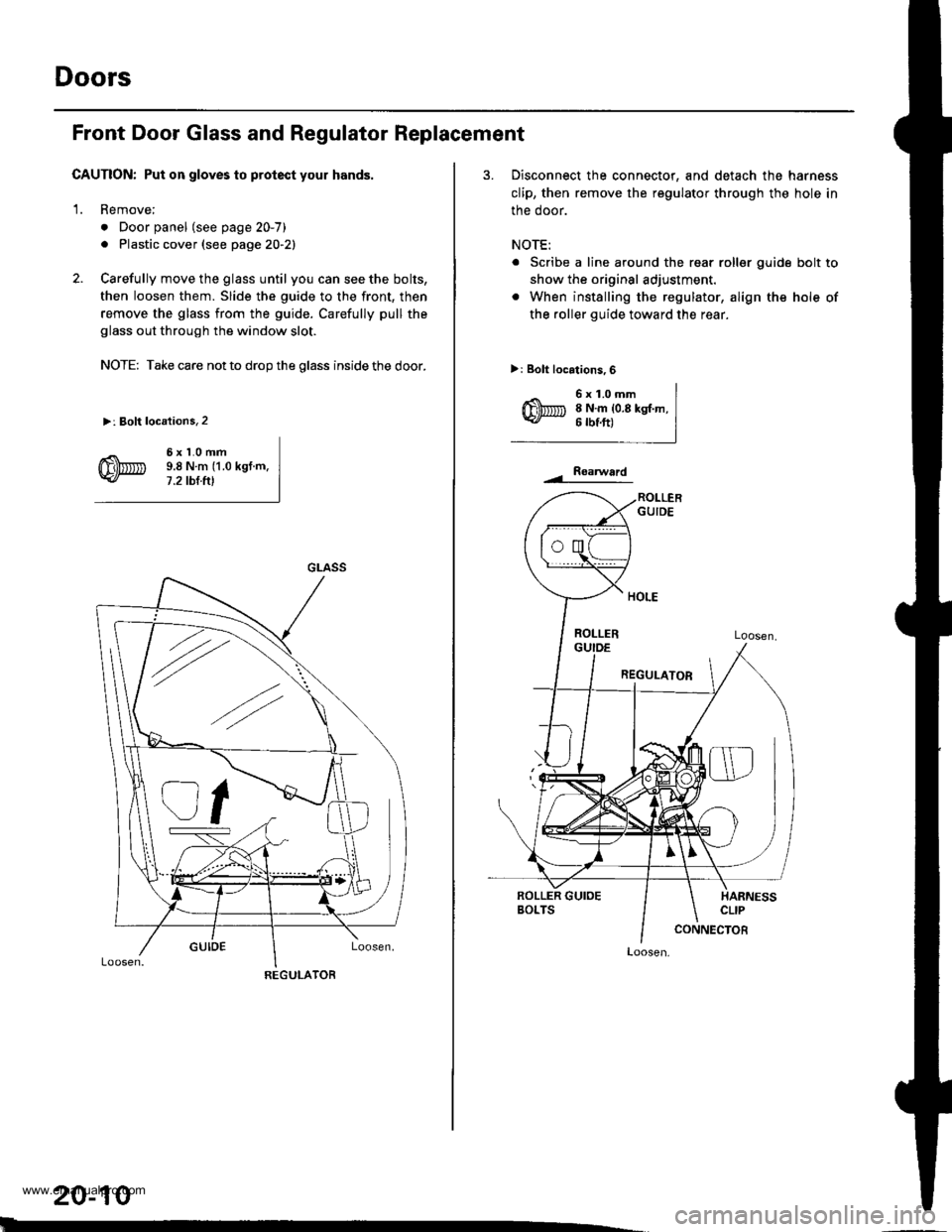

Front Door Glass and Regulator Replacement

CAUTION: Put on gloves to protect your hands,

1. Remove;

. Door panel (see page 20-7)

. Plastic cover (see page 20-21

2. Carefully move the glass until you can see the bolts,

then loosen them. Slide the guide to the front, then

remove the glass from the guide. Carefully pull the

glass out through the window slot.

NOTE: Take care not to drop the glass inside the door.

>: Bolt locations,2

6xl.0mm9.8Nm(1.0kgt.m.7.2 tbt.ftl

GLASS

REGULATOR

20-10

3. Disconnect the connector, and detach the harness

clip, then remove the regulator through the hole in

the door.

NOTE:

. Scribe a line around the rear roller guide bolt to

show the original adjustment.

. When installing the regulator, align the hole of

the roller guide toward th€ rear.

>: Bolt locations,6

6x1.0mm8 N.m {0.8 kgt.m,6 rbtft)

Roaru/ard

Loosen,

www.emanualpro.com

Page 994 of 1395

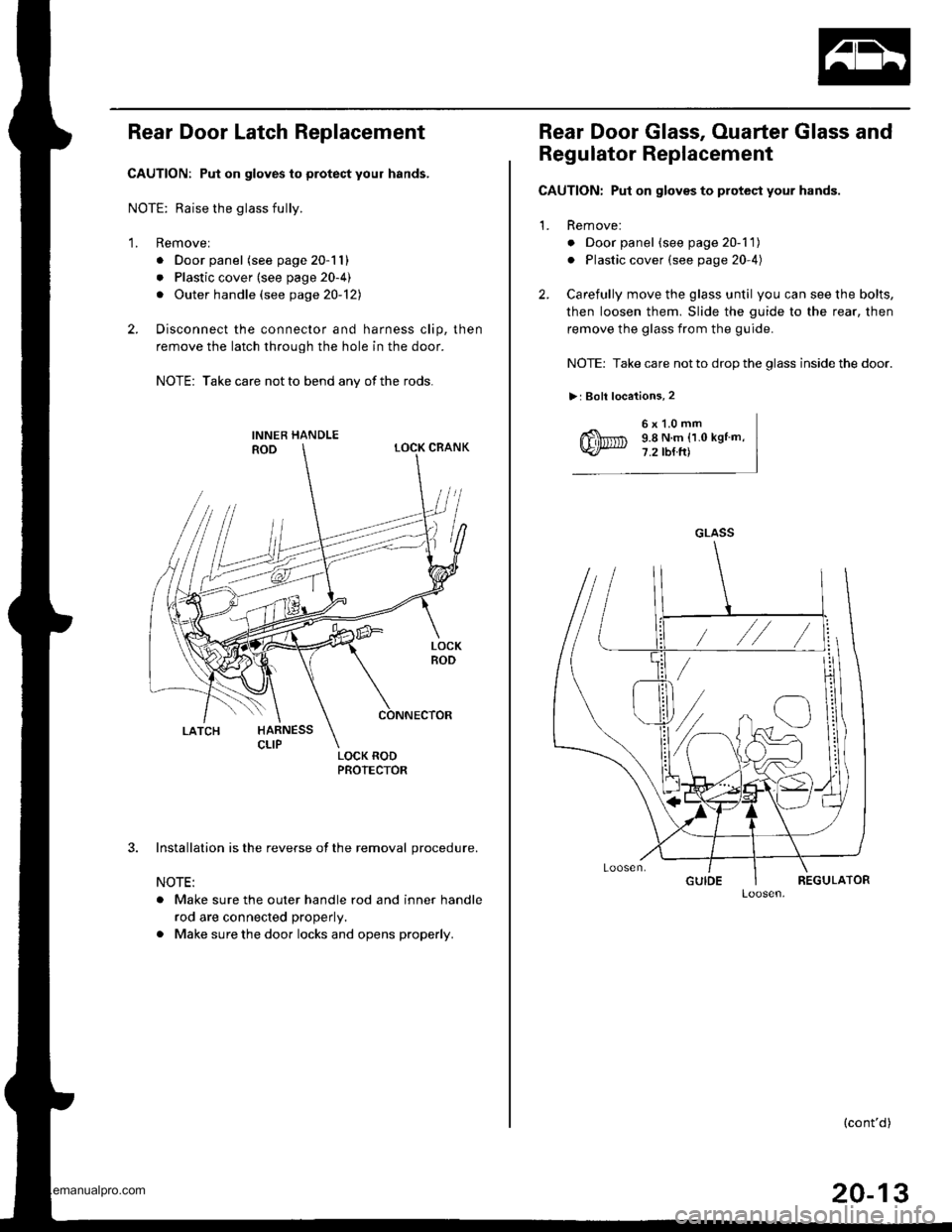

Rear Door Latch Replacement

CAUTION: Put on gloves to protect your hands,

NOTE: Raise the glass fully.

1. Removel

. Door panel (see page 20-11)

. Plastic cover (see page 20-4)

. Outer handle (see page 20-121

2. Disconnect the connector and harness clip, then

remove the latch through the hole in the door.

NOTE: Take care not to bend any of the rods.

3. Installation is the reverse of the removal procedure.

NOTE:

. Make sure the outer handle rod and inner handle

rod are connected properly.

. Make sure the door locks and opens properly.

Rear Door Glass, Ouarter Glass and

Regulator Replacement

CAUTION: Put on gloves to protect your hands.

1. Remove:

o Door panel (see page 20-1 1)

. Plastic cover (see page 20-4)

2. Carefully move the glass until you can see the bolts,

then loosen them. Slide the guide to the rear, then

remove the glass from the guide.

NOTE: Take care not to drop the glass inside the door.

>: Boll locations, 2

6x1.0mm9.8 N.m (1.0 kgtm,7.2 tb{ft)

GLASS

(cont'd)

20-13

www.emanualpro.com

Page 995 of 1395

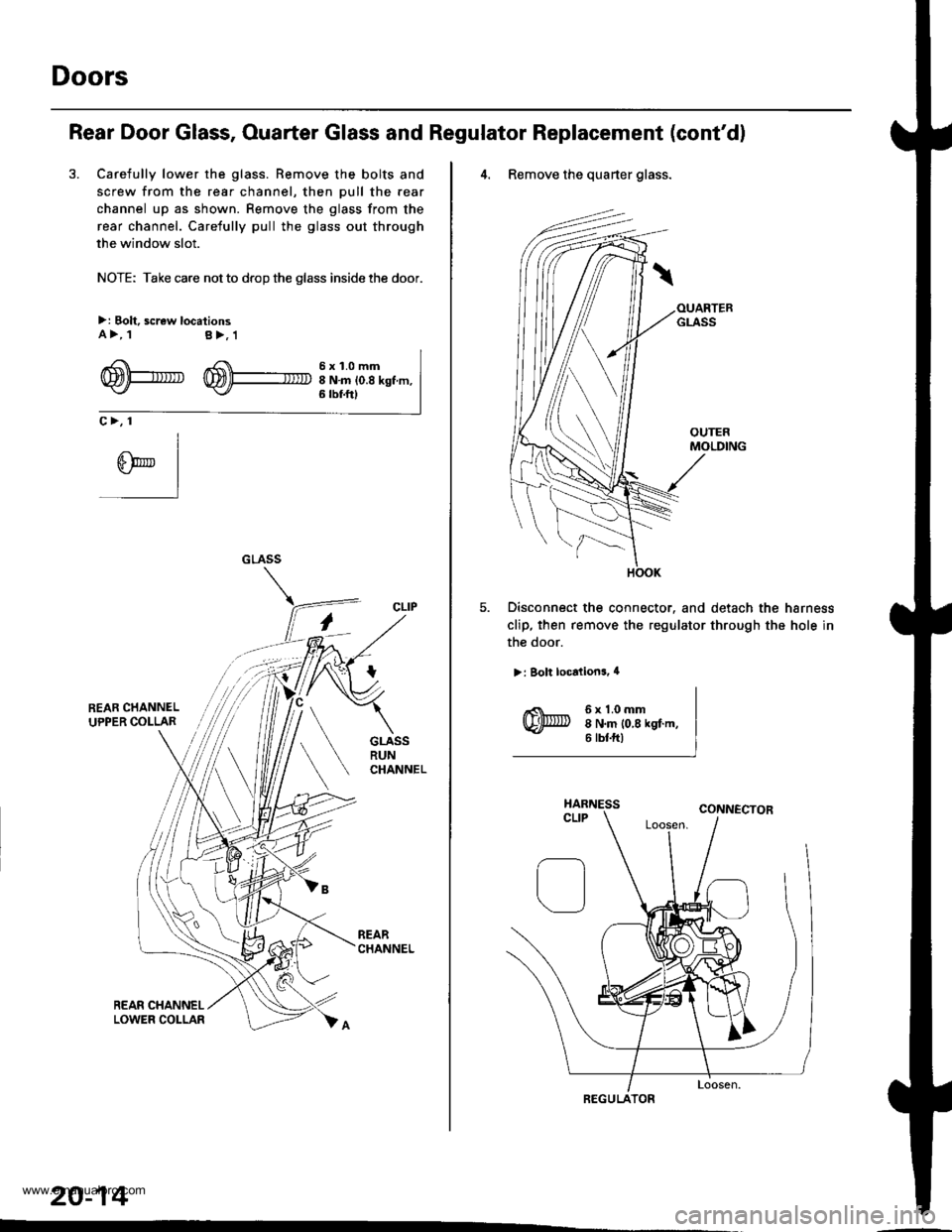

Doors

Rear Door Glass, Ouarter Glass and Regulator Replacement (cont'd)

3. Carefully lower the glass. Remove the bolts and

screw from the rear channel, then pull the rear

channel up as shown. Remove the glass from the

rear channel. Carefully pull the glass out through

the window slot.

NOTE: Take care not to drop the glass inside the door.

>: Bolt, screw locationsA>, tB>,1

-4 f 6 x 1.0 mmrTmtl-larR '^S\\\-.- -

WPU W)+ INmio.8ksf m,6 tbf.ftt

c>, 1

CLIP

20-14

''

4. Remove the quarter glass.

Disconnect the connector. and detach the harness

clip, then remove the regulator through the hole in

the door.

>: Bolt localions, 4

6x1.0mm8 N.m 10,8 kgf.m,6 tbtftl

REGULATOR

www.emanualpro.com

Page 999 of 1395

Doors

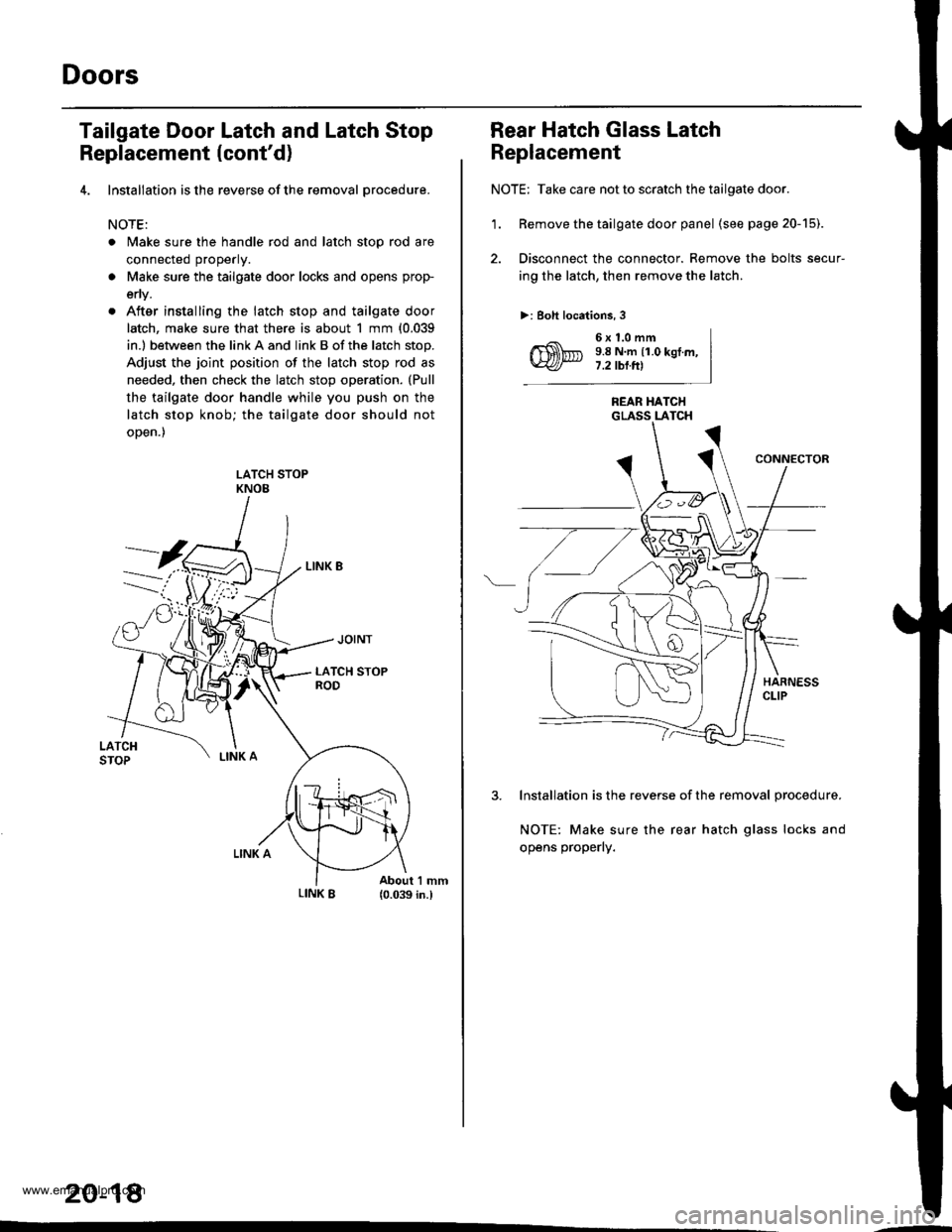

Tailgate Door Latch and Latch Stop

Replacement (cont'd)

4. lnstallation is the reverse of the removal orocedure.

NOTE:

. Make sure the handle rod and latch stop rod are

connected properly.

a Make sure the tailgate door locks and opens prop-

env.

. After installing the latch stop and tailgate door

latch, make sure that there is about 1 mm {0.039

in.l between the link A and link B of the latch stop.

Adjust the joint position of the latch stop rod as

needed, then check the latch stop operation. (Pull

the tailgate door handle while you push on the

latch stop knob; the tailgate door should not

oDen.)

LATCH STOPKNOE

20-18

Rear Hatch Glass Latch

Replacement

NOTE: Take care not to scratch the tailgate door.

'1. Remove the tailgate door panel (seepage20-15).

2. Disconnect the connector. Remove the bolts secur-

ing the latch, then remove the latch.

>: Boh locations, 3

6x1.0mm9.8 N.m {1.0 kgI.m,7.2 tbl.Itl

REAR HATCHGLASS LATCH

3. Installation is the reverse of the removal procedure.

NOTE: Make sure the rear hatch glass locks and

opens properly.

www.emanualpro.com

Page 1000 of 1395

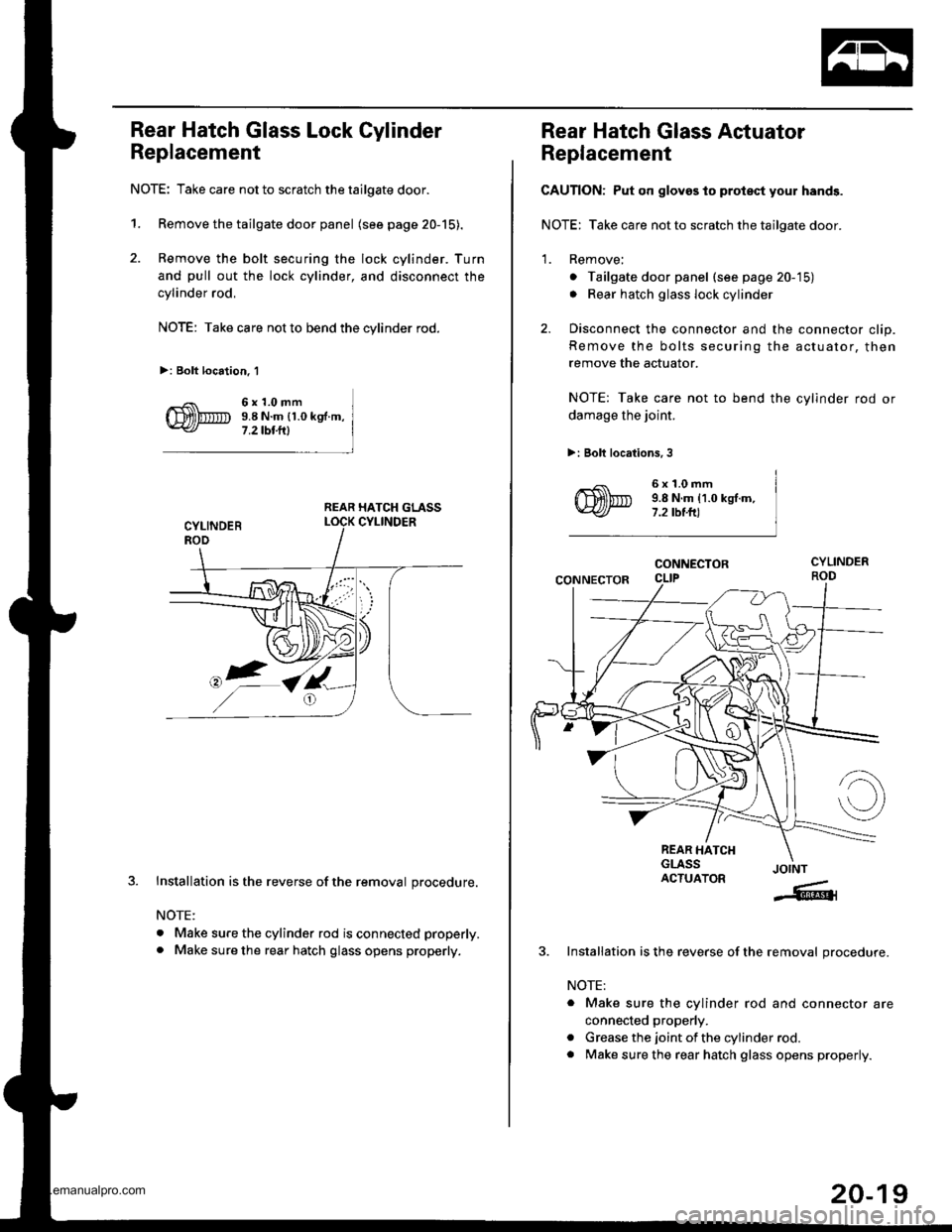

Rear Hatch Glass Lock Cylinder

Replacement

NOTE: Take care not to scratch the tailgate door.

1. Remove the tailgate door panel (see page 20-15).

2. Remove the bolt securing the lock cylinder. Turn

and pull out the lock cylinder, and disconnect the

cylinder rod,

NOTE: Take care not to bend the cylinder rod.

>: Bolt location. 1

6x1.0mm9.8 N.m {1.0 kg .m,

7 .2 tbt.lll

REAR HATCH GLASS

J.Installation is the reverse of the removal procedure.

NOTE:

. Make sure the cylinder rod is connected properly.

. Make sure the rear hatch glass opens properly.

Rear Hatch Glass Actuator

Replacement

CAUTION: Put on gloves to protsct your hands.

NOTE: Take care not to scratch the tailgate door.

1. Remove;

o Tailgate door panel (see page 20-'15)

. Rear hatch glass lock cylinder

2. Disconnect the connector and the connector clip.

Remove the bolts securing the actuator, then

remove the actuator.

NOTE: Take care not to bend the cylinder rod or

damage the joint.

>: Bolt locations, 3

6x1.0mm9.8 N.m 11.0 kgt.m,7.2 tbt.ft)

CONNECTOR

CONNECTOR

REAR HATCHGLASSACTUATORJOINT

-6{

Installation is the reverse of the removal procedure.

NOTE:

. Make sure the cylinder rod and connector are

connected properly.

. Grease the joint of the cylinder rod.

. Make sure the rear hatch glass opens properly.

20-19

www.emanualpro.com