srs HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 13 of 1395

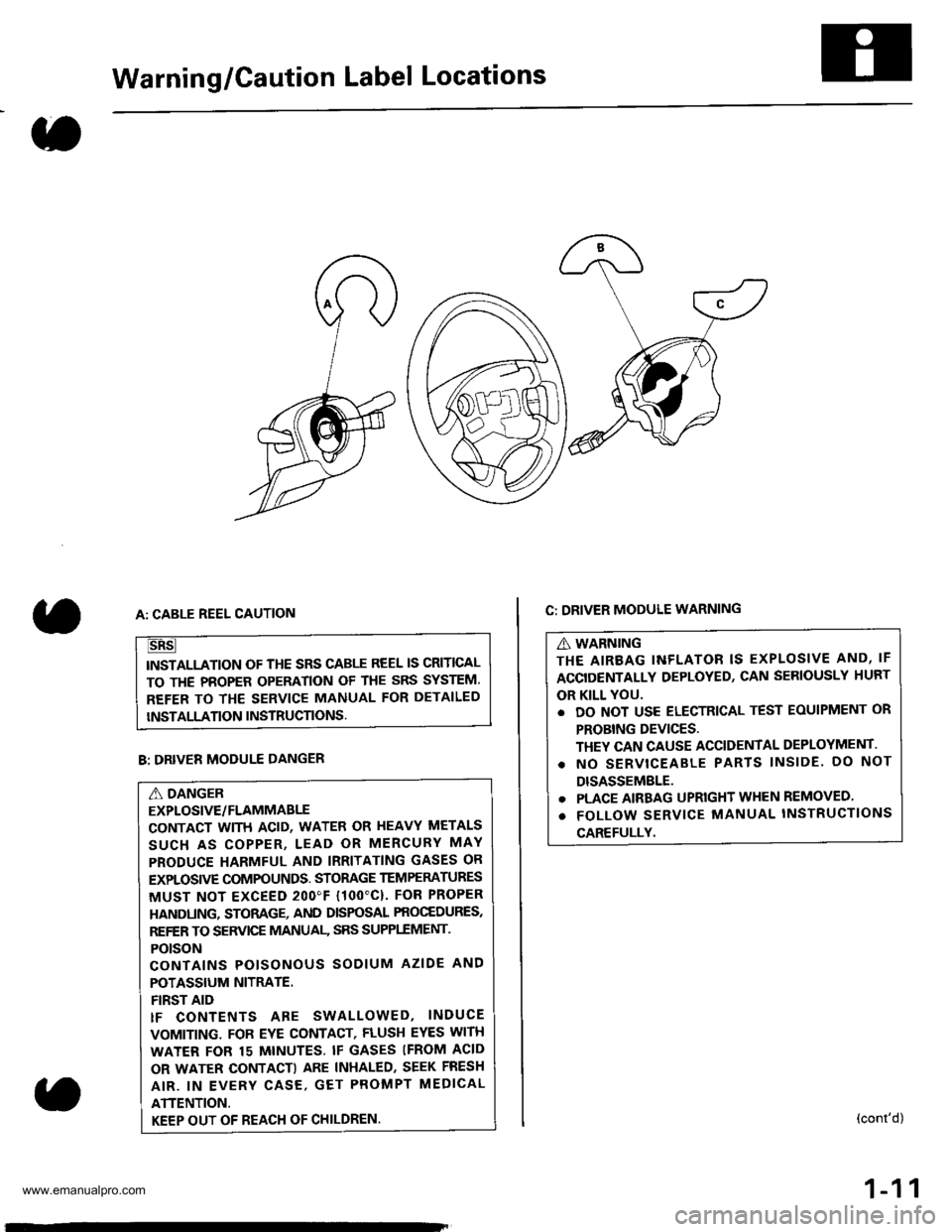

Warning/Caution Label Locations

C: DRIVER MODULE WARNING

A WARNING

THE AIREAG INFLATOR IS EXPLOSIVE AND, IF

ACCIDENTALLY DEPLOYED, CAN SERIOUSLY HURT

OR KILL YOU.

. DO NOT USE ELECTRICAL TEST EOUIPMENT OR

PROBING DEVICES.

THEY CAN CAUSE ACCIDENTAL DEPLOYMENT.

. NO SERVTCEABLE PARTS lNSlDE. DO NOT

DISASSEMBLE.

. PLACE AIRBAG UPRIGHT WHEN REMOVED

. FOLLOW SERVICE MANUAL INSTRUCTIONS

CAREFULLY.

A: CABLE REEL CAUTION

TNSTALLATION OF THE SRS CABLE REEL IS CRITICAL

TO THE PBOPER OPERATION OF THE SRS SYSTEM.

REFER TO THE SERVICE MANUAL FOR DETAILED

INSTALLATION INSTRUCTIONS.

(cont'd)

1-11

B: DRIVER MODULE DANGER

A DANGER

EXPLOSIVE/FLAMMABLE

CONTACT WITH ACID, WATER OR HEAVY METALS

SUCH AS COPPER, LEAD OR MERCURY MAY

PRODUCE HARMFUL AND IRRITATING GASES OR

EXPLOSIVE COMPOUNDS. STOMGE TEM PERATURES

MUST NOT EXCEED 2OO"F {1OO'C}. FOR PROPER

HANDUNG, STORAGE, AND DISPOSAL PROCEDURES.

REFER TO SERVICE MANUAI- SRS SUPPI.EMENT,

POTSON

CONTAINS POISONOUS SODIUM AZIDE AND

POTASSIUM NITRATE.

FIRST AID

tF CONTENTS ARE SWALLOWED, INDUCE

VOMITING. FOR EYE CONTACT, FLUSH EYES WITH

WATER FOR 15 MINUTES. IF GASES IFROM ACID

OR WATER CONTACTI ARE INHALED, SEEK FRESH

AIR. IN EVERY CASE, GET PROMPT MEDICAL

ATTENTION.

KEEP OUT OF REACH OF CHILDREN

www.emanualpro.com

Page 14 of 1395

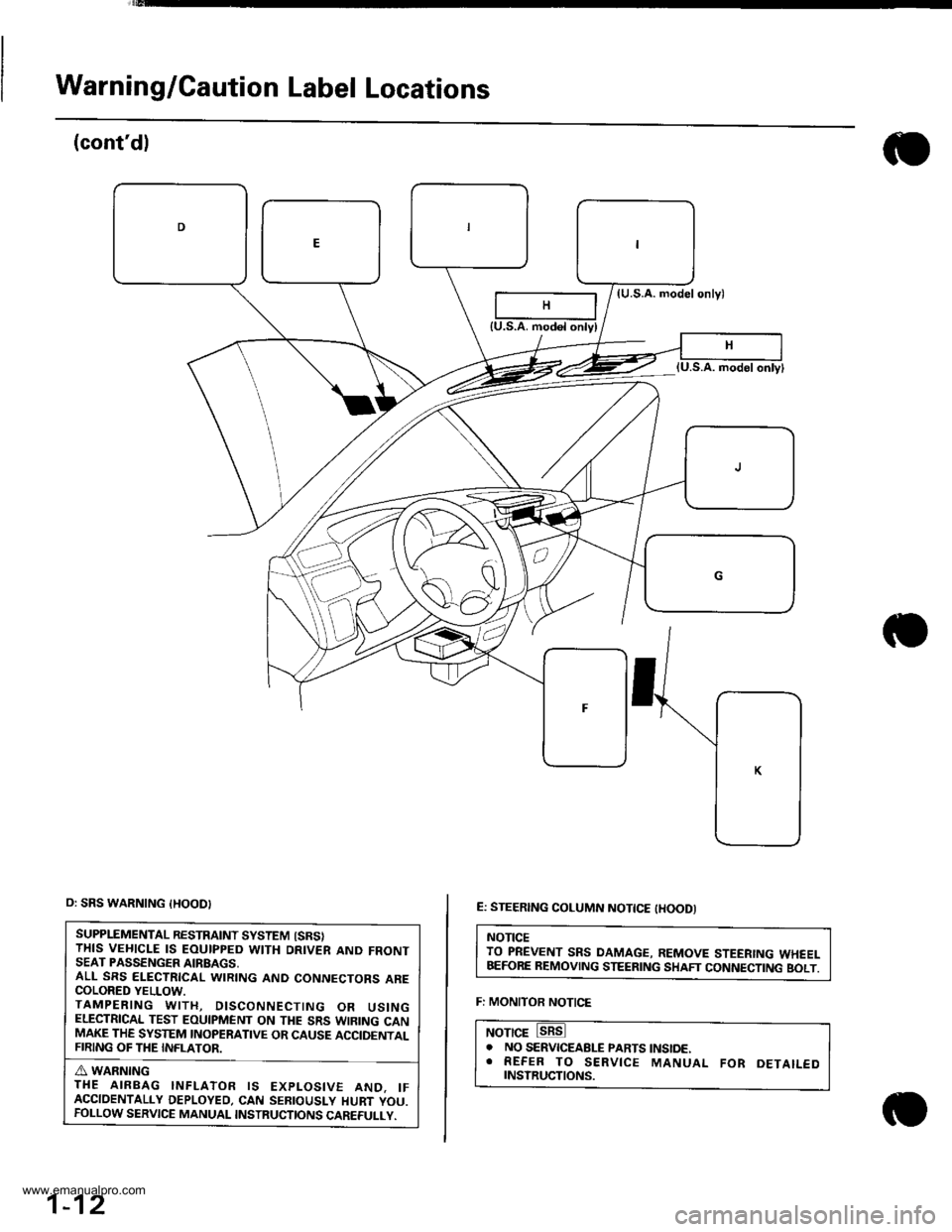

Warning/Caution Label Locations

(cont'dl

(U.S.A. modelonlyl

E: STEERING COLUMN NOTTCE tHOODI

NOTICETO PREVENT SRS DAMAGE, REMOVE STEERING WHEELBEFORE REMOVING STEERING SHAFT CONNECTING BOLT.

F: MONITOR NOTICE

NOTICE. NO SERVICEABLE PARTS tNStoE.. REFER TO SERVICE MANUAL FoR DETAILEDrNsrRucTtoNs.

{U.S.A. modol onlyl

o: SRS WARNING {HOOD}

SUPPLEMENTAL RESTRAINT SYSTEM {SRSITHIS VEHICLE IS EOUIPPED WITH DRIVER AND FRONTSEAT PASSENGER AIRBAGS,ALL SRS ELECTRICAL WIRING AND CONNECTORS ARECOLORED YELLOW.TAMPERING WITH, DISCONNECTING OR USINGELECTRICAL TEST EOUIPMENT ON THE SRS WIRING CANMAKE THE SYSTEM INOPERATIVE OR CAUSE ACCIDENTALFIRING OF THE INFLATOR.

A WARNINGTHE AIRBAG INFLATOR IS EXPLOSIVE AND. IFACCIDENTALLY DEPLOYED, CAN SEBIOUSLY HURT YOU.FOLLOW SERVICE MANUAL INSTRUCTIONS CAREFULLY.

1-12

www.emanualpro.com

Page 15 of 1395

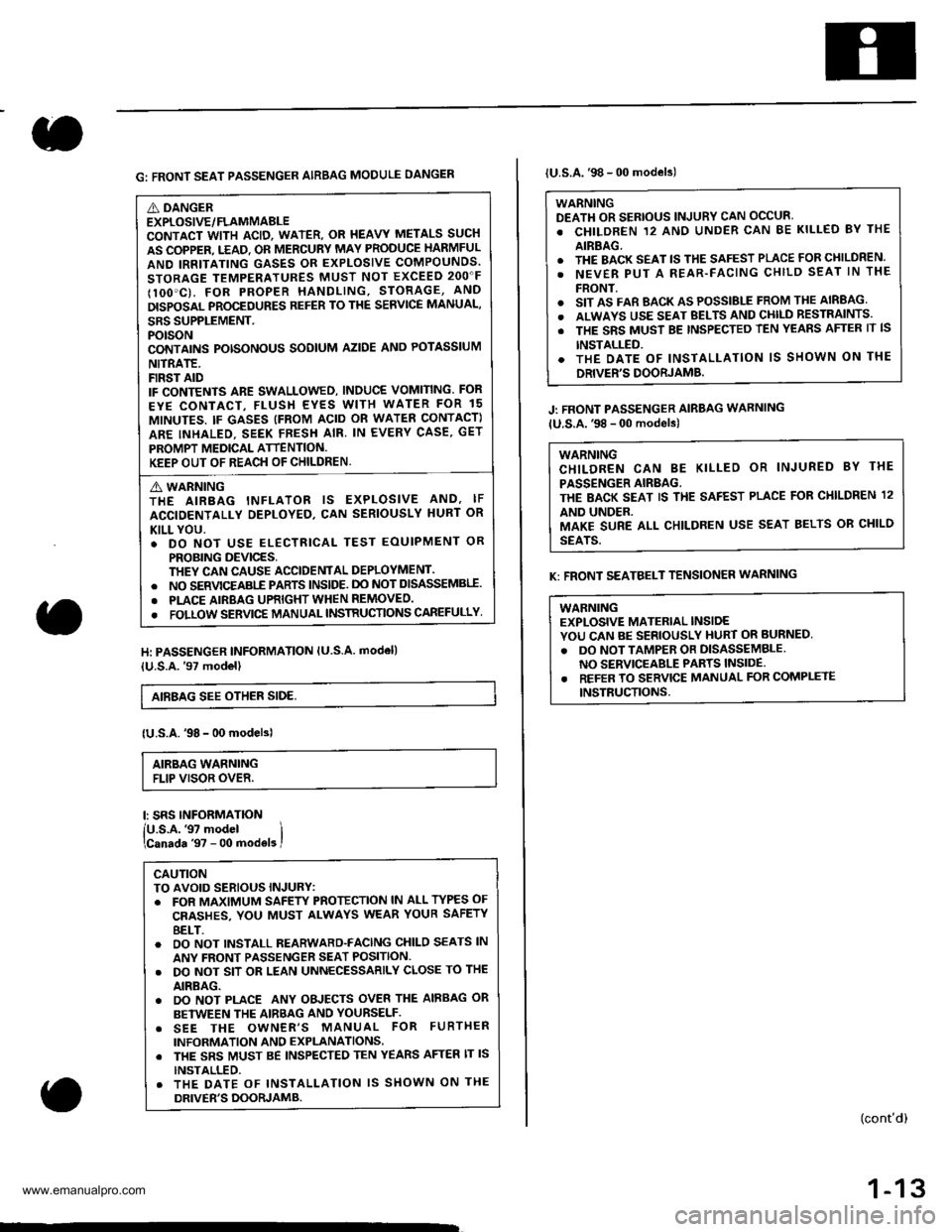

G: FRONT SEAT PASSENGER AIRBAG MODULE DANGEN

A DANGEREXPLOSIVE/FLAMMABLECONTACT WITH ACID, WATER. OR I{EAVY METALS SUCH

AS COPPER. T.EAD. OR MERCURY MAY PRODUCE HARMFUL

AND IRRITATING GASES OR EXPLOSIVE COMPOUNDS.

STORAGE TEMPERATURES MUST NOT EXCEED 2OO"F

IlOO'C). FOR PROPER HANDLING, STORAGE, AND

DISPOSAL PROCEDURES REFER TO THE SERVICE MANUAL,

SRS SUPPLEMENT.POTSONCONTAINS POTSONOUS SODIUM AZIDE ANO POTASSIUM

NITRATE.FIRST AIDIF CONTENTS ARE SWALLOWED, INDUCE VOMITING. FOR

EYE CONTACT, FLUSH EYES WITH WATER FOR 15

MINUTES. IF GASES (FROM ACID OR WATEN CONTACT)

ARE INHALEO. SEEK FRESH AIR. IN EVERY CASE, GET

PROMPT MEDICAL ATTENTION.KEEP OUT OF REACH OF CHILDREN.

A WARNINGTHE AIRBAG INFLATOR IS EXPLOSIVE AND, IF

ACCIDENTALLY DEPLOYED, CAN SERIOUSLY HURT OR

KILL YOU.. DO NOT USE ELECTRICAL TEST EOUIPMENT OR

PROBING DEVICES,THEY CAN CAUSE ACCIDENTAL DEPLOYMENT.. NO SERVICEABI-E PARTS lNSlDE. DO NOT DISASSEMBII.

. PLACE AIRBAG UPRIGHT WHEN REMOVEO.

. FOLLOW SERVIC€ MANUAL INSTRUCTIONS CAREFULLY

H: PASSENGER INFORMATION lU S.A. modell

{U.S.A.'97 model}

AIEBAG SEE OTHER SIDE,

{U.S.A.'98 - 00 modelsl

AIRBAG WARNINGFLIP VISOR OVER.

l: SRS INFORMATION

lU.s.A.'97 model ilcanada '97 - 00 mod€ls I

CAUTIONTO AVOID SERIOUS INJURY:. FOR MAXIMUM SAFEW PROTECTION lN ALL TYPES OF

CRASHES, YOU MUST ALWAYS WEAR YOUR SAFETY

8ELT.o OO NOT INSTALL REARWARD-FACING CHILO SEATS lN

ANY FRONT PASSENGER SEAT POSITION.. DO NOT SIT OR LEAN UNNECESSARILY CLOSE TO THE

AIRBAG.. DO NOT PLACE ANY OBJECTS OVER THE AIRBAG OR

BETWEEN THE AIRBAG AND YOURSELF.. SEE THE OWNER'S MANUAL FOR FURTHER

INFORMATION AND EXPLANATIONS. THE SRS MUST BE INSPECTED TEN YEARS AFTER lT lS

INSTALLED.. THE DATE OF INSTALLATION lS SHOWN ON THE

DRIVER'S DOORJAMB.

lU.S.A.'98 - 00 models)

WARNINGDEATH OR SERIOUS INJURY CAN OCCUR'

. CHILDREN 12 ANO UNDER CAN BE KILLED BY THE

AIRBAG.. THE BACK SEAT lS THE SAFEST PLACE FOR CHILDREN.

. NEVER PUT A REAR-FACING CHILD SEAT lN THE

FRONT.o SIT AS FAR BACK AS POSSIBLE FROM THE AIRBAG

. ALWAYS USE SEAT BELTS AND CHll-D RESTRAINTS.

. THE SRS MUST BE TNSPECTED TEN YEAnS AFTER lT lS

INSTALLED.. THE OATE OF INSTALLATION lS SHOWN ON THE

DRIVER'S DOORJAMB.

J: FRONT PASSENGER AIRBAG WARNING

lU.S.A.'98 - 00 models)

WARNINGCHILDREN CAN BE KILLED OR INJURED 8Y THE

PASSENGER AIRBAG.THE BACK SEAT IS THE SAFEST PLACE FOR CI{ILDREN 12

AND UNDER.MAKE SURE ALL CHILDREN USE SEAT BELTS OR CHILD

SEATS.

K: FRONT SEATBELT TENSIONER WARNING

WABNINGEXPLOSIVE MATERIAL INSIDEYOU CAN BE SERIOUSLY HURT OR BURNED,

. DO NOT TAMPER OR DISASSEMBLENO SERVICEABLE PARTS INSIDE.. REFER TO SERVICE MANUAL FOR COMPLETE

INSTRUCTIONS.

(cont'd)

1-13

www.emanualpro.com

Page 18 of 1395

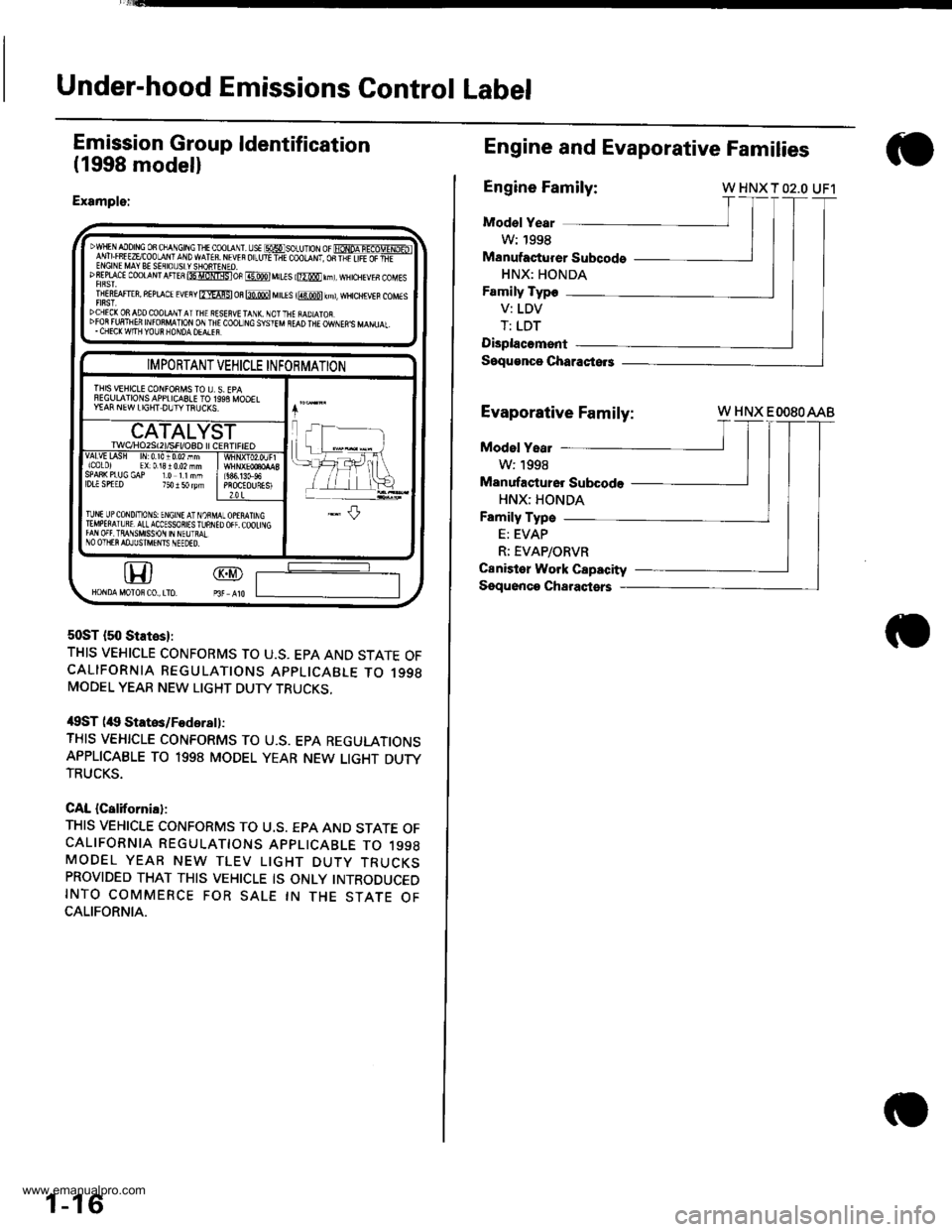

Under-hood Emissions Control Label

Emission Group ldentification

(1998 modell

Example:

50ST {50 States}:

THIS VEHICLE CONFORMS TO U.S. EPA AND STATE OFCALIFORNIA REGULATIONS APPLICABLE TO 1998MODEL YEAR NEW LIGHT DUTY TRUCKS,

/$ST (itg Statos/Fodsrsll:

THIS VEHICLE CONFORMS TO U.S. EPA REGULATIONSAPPLICABLE TO 1998 MODEL YEAR NEW LIGHT DUTYTRUCKS.

CAL {California}:

THIS VEHICLE CONFORMS TO U.S. EPA AND STATE OFCALIFORNIA REGULATTONS APPLICABLE TO 1998MODEL YEAR NEW TLEV LIGHT DUTY TRUCKSPROVIDED THAT THIS VEHICLE IS ONLY INTRODUCEDINTO COMMERCE FOR SALE IN THE STATE OFCALIFORNIA.

DwlF AIo|NG oB cha\Gtftc I + coot r

-s€ msoru1or or FoNoA-IEaoTTxD-ibl1'v! Lrff EzEcoo-aN' a\D wATfB. M w r or_ut-ir coolqNt, oR-l;ir,FEaFEf-ENGINE MAY BE SEflIOUSLYSIONTENEO.DSEPLACI CoOTANT AnEs 85 itNlgsloF @ MILIS l@0 rnl, wHrcHEvEs coMEs

TNEREAFT€R, REPLACE EvEny fmAFSl m m M[Es i@ kml, wHcHrvEB coMEs

DCHEC(ONADOCOOLqNTATTHE RSSEFVETANX. NOTTHE iAD]ATOR.DFOR FUFTNEfr INFO8MATION ON IN€ COOT]NC SYSIEM NEAD THE OWNEN'S MANUAL,. CHECK W|TH YOUR NONDA OEALEF.

@GD

IMPORTANT VEHICLE INFORMATION

THIS VEHICLE CONFOEMS TO I], S. EPAFEGIJLAIIONSAPPLICASLE TO 1993 MOOELY€AF NEW LIGHT DUIYTNUCXS.

CATALYSTrwqHozst2l/sFt/osD l cERI|FtEOvAlvttAsH lrr0.l010.02nmicolo) EX:01310.02mmSPAS( PIUG GAP I.O IINMlDLl SPTED 750 I 50 rym686,13G96PROCEOURESI2.0 L

TlNt UPCoND/ToNS: ENGINE AT NOiMIEMPETAIURT,ALLACCESSORIESTUNNIfAN OFf. TRAI1SMISSON IN NEUTMINO OIIIER AOJUSTI\TFIIS IIEEOED.

1-16

Engine and Evaporative Families

Engine Family:W HNX T O2.O UF1

Mod€l Year

W: 1998

Manufacturer Subcods

HNX: HONDA

Family Typo

V: LDV

T: LDT

Displacomsnt

Soqu€nco Characiors

Evaporative Fami

Family:

Model Yeat

W:1998

Manufastu16r Subcode

HNX: HONDA

Family Type

E: EVAP

R; EVAP/ORVR

Canister Work Capacity

Sgquonco Charaqtsrs

W HNX EOOSOAAB

www.emanualpro.com

Page 88 of 1395

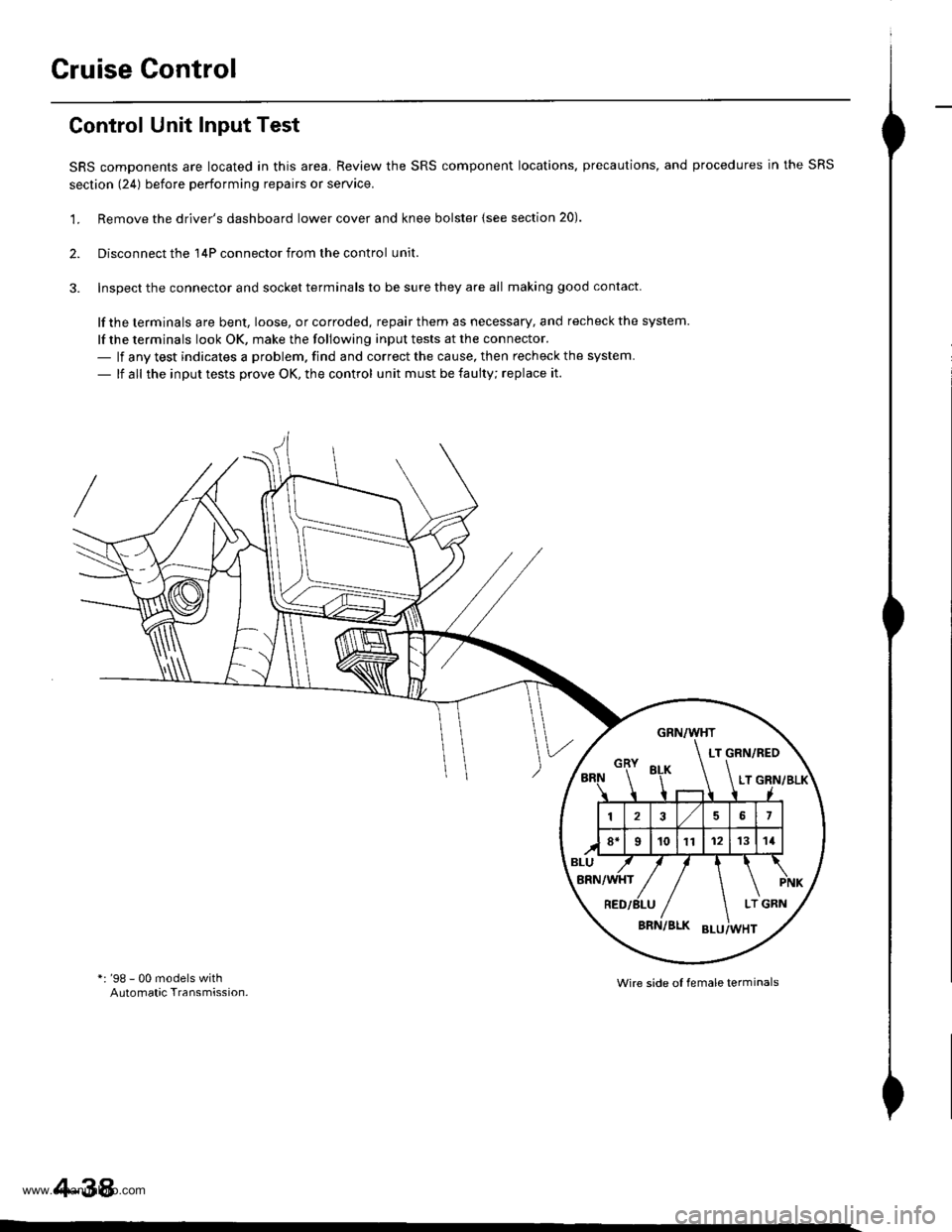

Cruise Control

Control Unit Input Test

SRS components are located in this area. Review the SRS component locations. precautions, and procedures in the SRS

section (241 before performing repairs or seryice.

'1. Remove the driver's dashboard lower cover and knee bolster {see section 20).

2. Disconnect the 'l4P connector from the control unit.

3. Inspect the connector and socket terminals to be sure they are all making good contact

lf the terminals are bent, loose, or corroded, repair them as necessary, and recheck the system.

lf the terminals look OK, make the following input tests at the connector.- lf any test indicates a problem. find and correct the cause, then recheck the system.

- lf all the input tests prove OK, the control unit must be faulty; replace it.

*: '98 - 00 models withAutomatic Transmission.Wire side ol female terminals

4-38

www.emanualpro.com

Page 91 of 1395

n-

n-

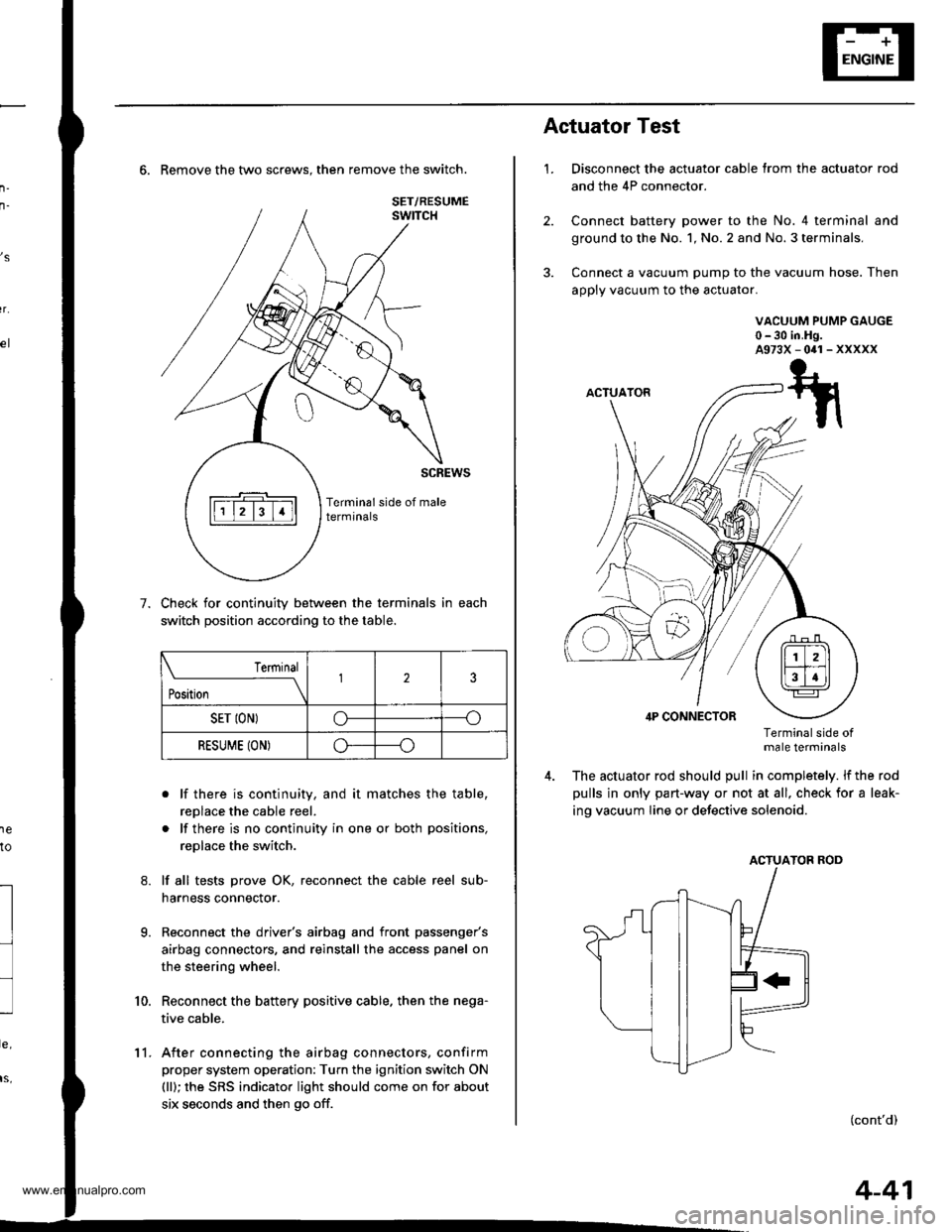

6. Remove the two screws. then remove the switch.

Check for continuity between the terminals in each

switch position according to the table.

. lf there is continuity, and it matches the table,

replace the cable reel.

. lf there is no continuity in one or both positions,

replace the switch.

lf all tests prove OK, reconnect the cable reel sub-

harness connector.

Reconnect the driver's airbag and front passenger's

airbag connectors, and reinstall the access panel on

the steering wheel.

Reconnect the battery positive cable. then the nega-

tive cable.

After connecting the airbag connectors, confirm

proper system operation: Turn the ignition switch ON

(ll); the SRS indicator light should come on for about

six seconds and then go off.

,s

r.

1e

to

7.

l

9.

10.

SET/RESUME

Terminal

t*,r*

-__\l23

SET ION)o----o

RESUME (ON)o----o

11.

4-41

1.

Actuator Test

Disconnect the actuator cable trom the actuator rod

and the 4P connector.

Connect battery power to the No. 4 terminal and

ground to the No. 1, No. 2 and No. 3 terminals,

Connect a vacuum pump to the vacuum hose. Then

apply vacuum to the actuator.

VACUUM PUMP GAUGE0-30 in.Hg.A973X-041-XXXXX

Terminalside otmale terminals

The actuator rod should pull in completely. lf the rod

pulls in only part-way or not at all, check for a leak-

ing vacuum Iine or defective solenoid.

ACTUATOB ROD

(cont'd)

www.emanualpro.com

Page 275 of 1395

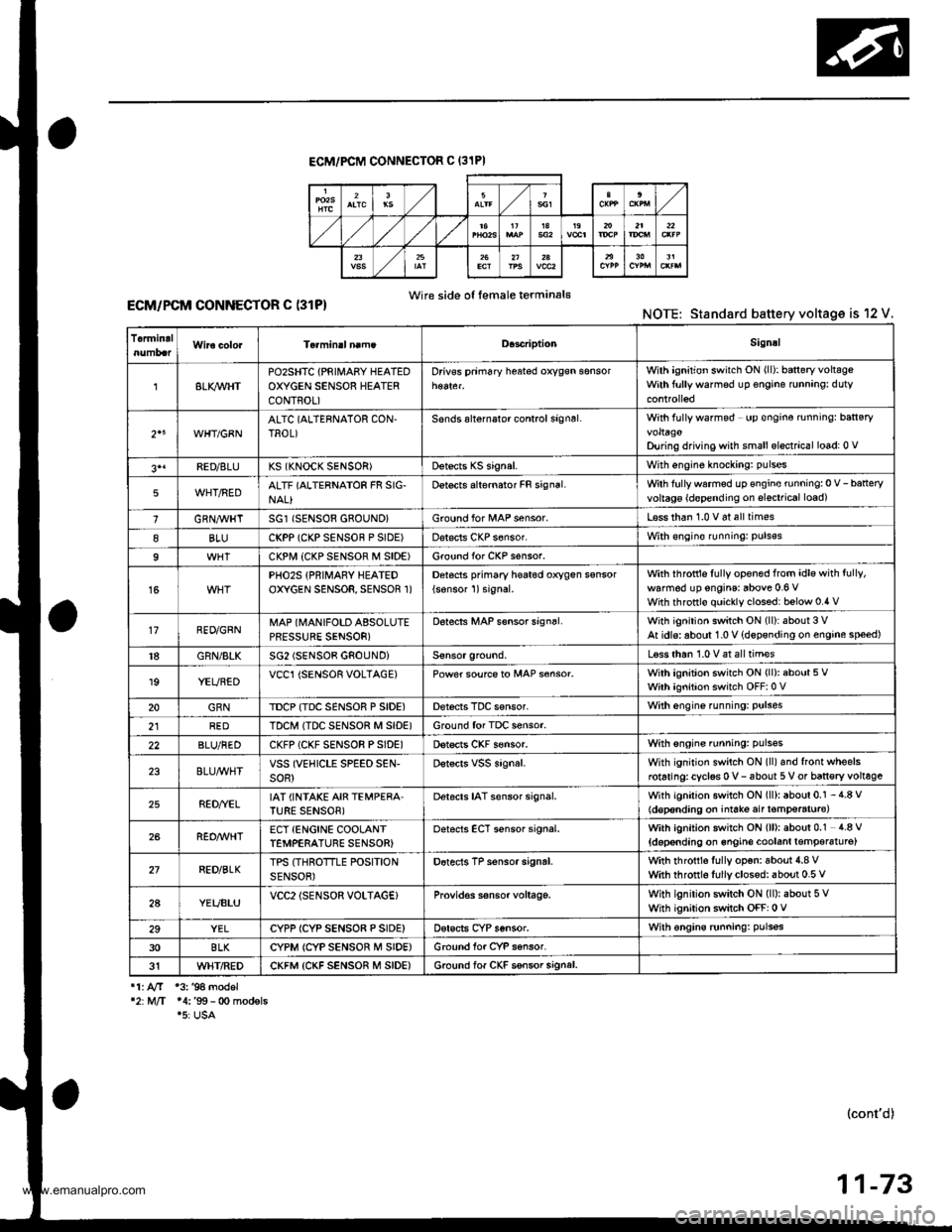

ECM/PCM CONNECTOF C (31PI

Wire side o{ female terminal€ECM/PCM CONNECTOR C (31P)NOTE: Standard battery voltage is 12 V.

TermidalD.3criptionSignal

8LI(WHTPOzSHTC {PRIII4ABY HEATEDOXYGEN SENSOR HEATERCONTROL)

Drivss prim6ry h$ted oxygsn sensorWilh ignition switch ON (ll): baneryvoltsgeWith ftrllywarmsd up €ngine runnang: duty

2"WHT/GBNALTC (ALTERNATOR CON,TROL)Sonds alternalor control signsl.With fully wafmod up €ngine rnningr ban€ryvoltagoDu ng driving with small elsctrical lo6d: 0 v

3'1FED/8LUKS (KNOCK SENSOR)Dstects KS signal.With engine knockang: pulses

5WHT/REDALTF (ALTERNATOR FR SIG-NAL}Detects alternator FR signal.Wth fullywarmed up €ngine running:0 V-batteryvoltag€ {d€pending on slsctrical load)

1GRN,4trHTSG1 (SENSOR 680UND}Ground for l/tAP sensor.L€ss than 1.0 v 6t all times

8BLUCKPP (CKP SENSOF P SIDE)Dat€cls CKP s6nsor.With €ngin€ runningr puls€s

9CKPI.,I| {CKP SENSOF M SIDE)Ground for CKP s€nsor.

15PHO2S {PRIMARY HEATEDOXYGEN SENSOR, SENSOR 1)Detocts pfimary he6t6d oxygen ssnsor

{sonsor 1)signal.with ihfottls fully opened from idle with fully,

walm6d up engins: above 0.6 VWith throttlo quickly clossd: below 0.4 v

17RED/GRNMAP (MANIFOLD ABSOLUTEPRESSURE SENSOR)

D6tects MAP s€nsor sign6l.With ignition switch ON (ll):about 3 VAt idls: aboul 1.0 V {dspsnding on engine speed)

18GRN/BLKSG2 (SENSOB GNOUNDiLsss than 1.0 V at all tim€s

19YEUBEDVCCl {SENSOR VOLTAGE)Power soufce to MAP s€nsor.With ignition switch ON (ll): about 5 VWith ignition switch OFF:0 V

20GRNTDCP {TDC SENSOR P SIDE)Derecis TDC sensor.With engine funning: Pulses

2lREDTDCM ITDC SENSOR M SID€)Ground for TDC sensor.

22BLU/REDCKFP (CKF SENSOR PSIDE)Dstscts CKF s€nsor.With sngins running: pulsss

23BLU/WHTVSS (VEHICLE SPEED SEN-soR)Dstscrs vss signal.With ignition switch ON (ll)and front wheelsrotaringrcyclss 0 v- 6bout 5 V or ban€ry voltage

25RED//ELIAT (INTAKE AIR TEMPERA'TURE SENSOB)Detacts IAT sensor signal.With igniiion switch ON (ll): about 0.1 - 4.8 V(d€p€nding on iniate air t€mp€raturc)

26REO/WHTECT {ENCINE COOLANTTEMPERATURE SENSOR)oetscts ECT sensor signal.With ignition switch ON (ll): about 0.1 4.8 V

{doponding on 6ngin€ coolanl lemper6tu16)

27RED/BLKTPS (THROTTLE POSITIONSENSOR)Dotects TP sensor signrl.with rhrottls fully op€n: aboui 4.8 vwith throtrl6 fullyclosed: about 0.5 v

2AYEUBLUVCC2lSENSOR VOLTAG€}Provid€s s€nsor voltage.With ignilion switch ON (ll): about 5 VWhh ignition switch OFF: 0 V

29YELCYPP ICYP SENSO8 P SIDE)Dsrscts CYP sensor.With €ngins runningr pulsss

30BLKCYPM (CYP SENSOR M SIDE)Ground for CYP sansor.

31WHT/REDCKFM {CKF SENSOR M SIDE)6.ound lof CKF ssnsor signal.

11. AfT 13. '94 model'2:M/T 14:'99- 0o modsls.5: USA

(cont'd)

11-73

www.emanualpro.com

Page 628 of 1395

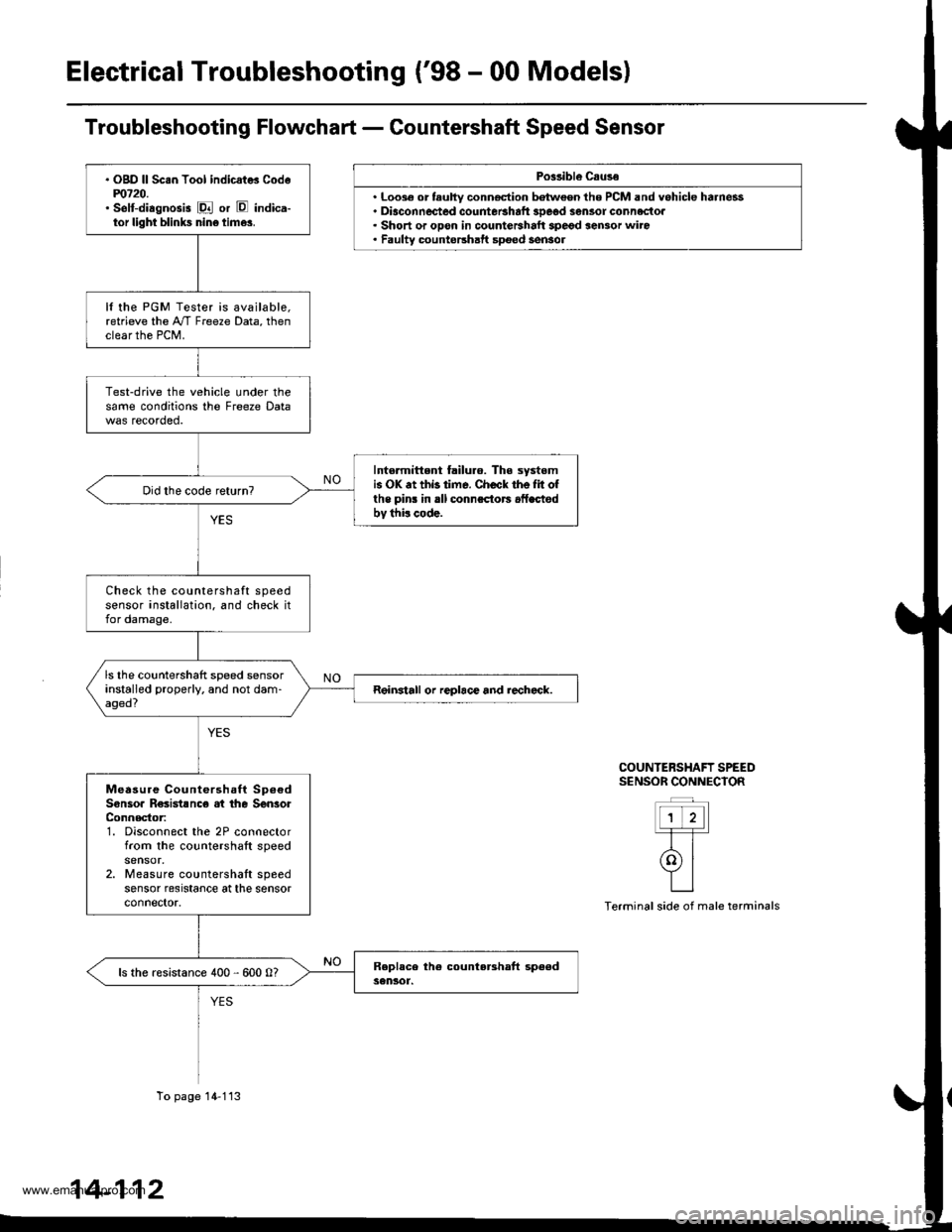

Electrical Troubleshooting ('98 - 00 Models)

Po$ibl€ Csuse

. Loo3€ or tauhy conn€ction batween the PCM and vehicle harness. Diaconnected countetshaft 3Deod sensor connectoa. Short or opon in countershalt spegd sensor wiro. Faulty countershatt spoed sensol

COUNTERSHAFT SPEEDS€NSOR CONNECIOR

ttt'l-T-T-

rolYILI

Terminal side of male terminals

. OgD ll Sc.n Tool indicat* Codem720.' selt-diagnosis E or E indica-tor light blinks nin6 time3.

It the PGM Tester is available,retrieve the A"/T Freeze Data, thenclear the PCM.

Test-drive the vehicle under thesame conditions the Freeze Data

Intormittent failuro. The systomis OK .t thb time. Check the Iit ofthe pins in rll connsctors .fLctodbv thi! code.

Check the countershaft speedsensor installation. and check itfor damage.

ls the countershaft speed sensorinstalled properly. and not dam-aged?Reinstall or replace and rechcck.

Measure Countershaft Sp6€dSonsoa R€sistsnc€ at the SenlorConnector:1. Disconnect the 2P connectorfrom the countershaft speed

2. Measure countershaft speedsensor resrstance at the sensorconnector.

ls the resistance 400 - 600 0?

To page 14-113

14-112

www.emanualpro.com

Page 630 of 1395

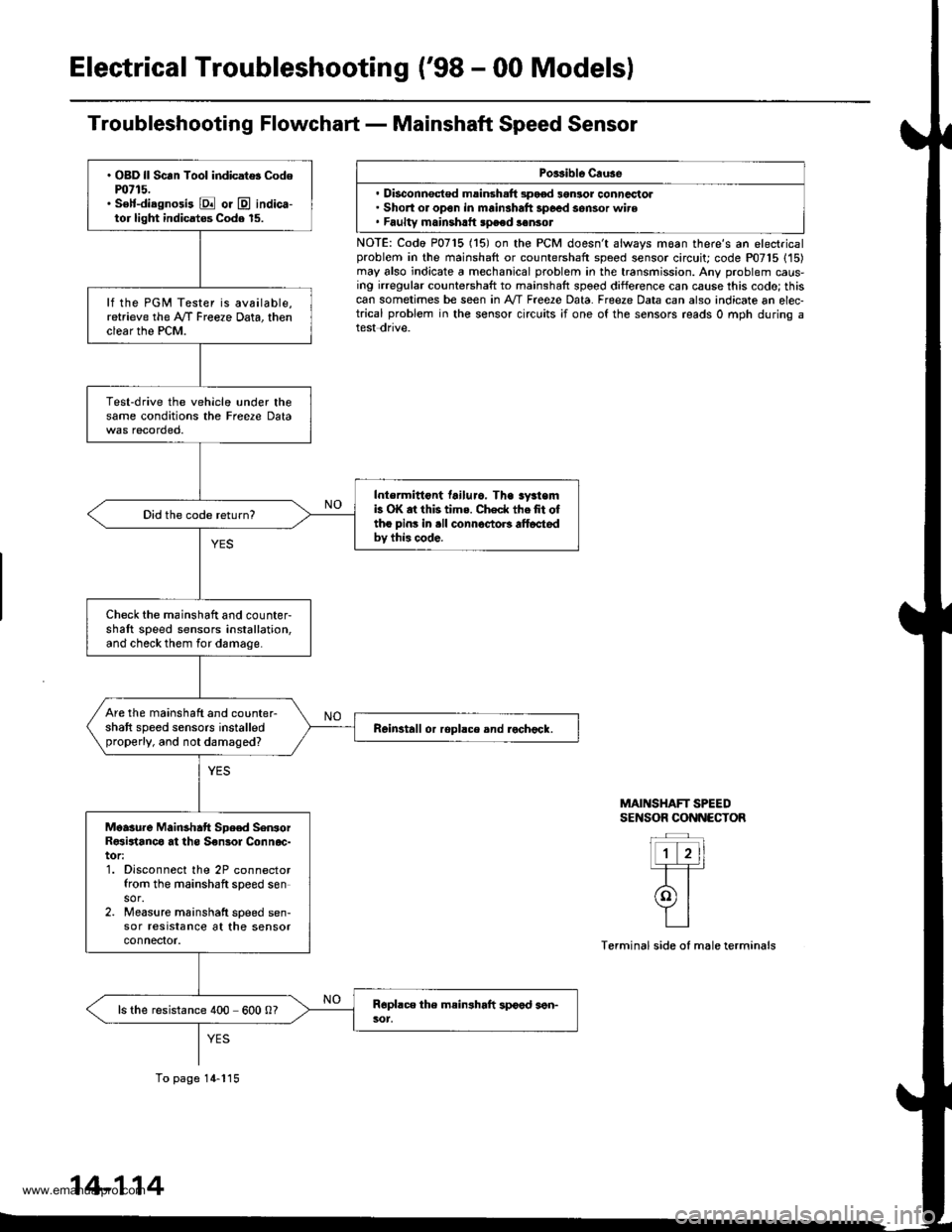

Electrical Troubleshooting ('98 - 00 Modelsl

Troubleshooting Flowchart - Mainshaft Speed Sensor

Porsible Cruse

. Disconnsct€d msinsh.ft 3pood 3gnlor conncctol. Short or open in mainshaft 3poed sensor wire. Faultv mainshrtt speed sonsot

NOTE: Codo P0715 (15) on the PCM doesn't always moan there's an electricalproblem in the mainshaft or countershaft speed sensor circuit; code P07'15 (15)may also indicate a mechanical problem in the transmission. Any problem caus-ing irregular countershaft to mainshaft spoed difference can cause this codo; thiscan sometimes be seen in A'/T Free2e Data. Freeze Data can also indicate an elec-trical problem in the sensor circuits ;f one of the sensors reads 0 mph during atest dnve.

MAINSHAFT SPEEDSENSOR CONNECTOR

Terminal side of male terminals

. OBD ll Scan Tool indicat$ Codem715.. S€lf-diagnosi3 E or @ indica-tor light indicatos Code 15.

lf the PGM Tester is available,retrieve the A/f Freeze Data, thenclear the PCM.

Test-drive the vehicle under thesame conditions the Freere Data

Intermittont tailuro. Tha sy3temb OK at this tims. Check thefit oftho pins in .ll connoctoB alt6ctedbv this code.

Did the code return?

Check the mainshaft and counter-shaft speed sensors installation,and check them for damage.

Are the mainshaft and counter-shaft speed sensors installedproperly, and not damaged?Reinstall or ropllce and rochock.

Moasure Mainshatt Spe€d SenrorR€sirtanco at ths S€nsol Connoc-tor:1. Disconnect the 2P connectorfrom the mainshaft speed sensor.2. Measure mainshatt speed sen-sor resrstance at the sensorconnefior.

ls the resistance 400 600 0?

To page 14-115

14-114

www.emanualpro.com

Page 660 of 1395

Interlock System

Interlock Control Unit Input Test

SRS components are located in this area. Review the SRS component locations, precautions, and procedures in the SRS

section (24) before performing repairs or service.

'1. Remove the instrument panel lower cover (see section 20).

2. Disconnect the 8P connector from the interlock control unit.

3. Inspect the connector and connector terminals to be sure they are all making good contact.

. lf the terminals are bent, loose, or corroded, repair them as necessary, and recheck the system

. lf the terminals look OK, make the following input tests at the connector.

- lf a test indicates a problem, find and correct the cause, then recheck the system

- lf all the input tests prove OK, substitute a known-good control unit, and recheck the system. lf the check is OK,

the control unit must be faulty; replace it.

NOTE: lf the shift lock solenoid clicks when the ign ition switch is tu rned ON (ll) while pressing the brake pedal withthe

shift lever in E position, the shift lock system is OK. lf the shift lever cannot be shifted from E position. test the A/T

gear position switch.

14-144

www.emanualpro.com