ECU HONDA ELEMENT 2010 1.G Owner's Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2010, Model line: ELEMENT, Model: HONDA ELEMENT 2010 1.GPages: 342, PDF Size: 5.76 MB

Page 274 of 342

Put a new washer on the filler bolt,

then reinstall the filler bolt and

tighten it securely.

If Honda MTF is not available, you

may use an SAE 10W-30 or 10W-40

viscosity motor oil with the API

Certification Seal that says‘‘FOR

GASOLINE ENGINES ’’as a

temporary replacement. However,

motor oil does not contain the proper

additives, and continued use can

cause stiffer shifting. Replace as soon

as it is convenient.

The transmission should be drained

and refilled with new fluid according

to the maintenance minder (see page243).

If you are not sure how to check and

add fluid, contact your dealer. Rear Differential Fluid

4WD models only

The rear differential should be

drained and refilled with new fluid

according to the time and distance

recommendations shown on the

maintenance minder display. Have

your dealer replace the rear

differential fluid.

Use Honda Dual Pump Fluid II only.

Do not use automatic transmission

fluid (ATF).

Brake and Clutch Fluid

Check the fluid level in the

reservoirs monthly.

There are up to two reservoirs,

depending on the model. They are:

● Brake fluid reservoir (all models)

● Clutch fluid reservoir (manual

transmission only)

Replace the brake fluid according to

the time recommendation in the

maintenance minder schedule.

Always use Honda Heavy Duty

Brake Fluid DOT 3. If it is not

available, you should use only DOT 3

or DOT 4 fluid, from a sealed

container, as a temporaryreplacement.

Transmission Fluid, Rear Differential Fluid, Brake and Clutch Fluid

258

Table of Contents

Page 278 of 342

2. Remove the electrical connectorfrom the bulb by pulling the

connector straight back.

3. Remove the rubber weather seal by pulling on the tab.

4. Unclip the end of the hold-down wire from its slot. Pivot the wire

out of the way, then remove thebulb. 5. Install the new bulb into the hole,

making sure the tabs are in their

slots. Pivot the hold-down wire

back in place, and clip the end into

the slot.

6. Install the rubber seal over the back of the headlight assembly.

Make sure one of the three arrows

on the rubber seal is facing up; it ismarked ‘‘

’’.

7. Push the electrical connector onto the new bulb. Make sure it is

connected securely. Turn on the

headlights to test the new bulb.

8. (Driver's side) Install the front end of the air

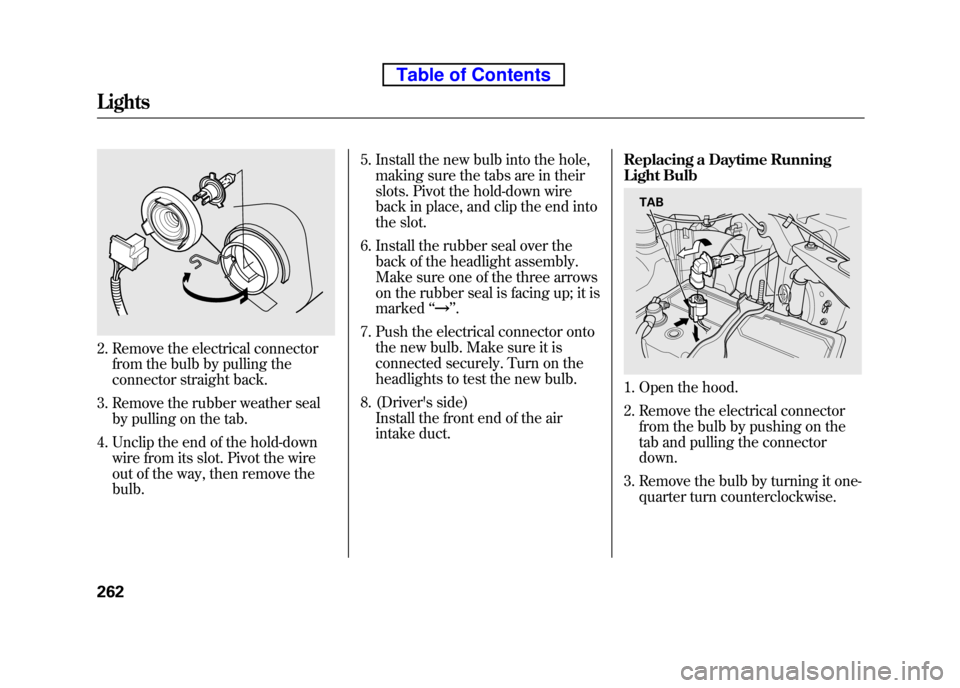

intake duct. Replacing a Daytime Running

Light Bulb

1. Open the hood.

2. Remove the electrical connector

from the bulb by pushing on the

tab and pulling the connectordown.

3. Remove the bulb by turning it one- quarter turn counterclockwise.

TAB

Lights

262

Table of Contents

Page 281 of 342

9. Put the inner fender cover in place.Install the holding clip.

Lock the clip in place by pushing

on the center.

Install the wheel arch protector

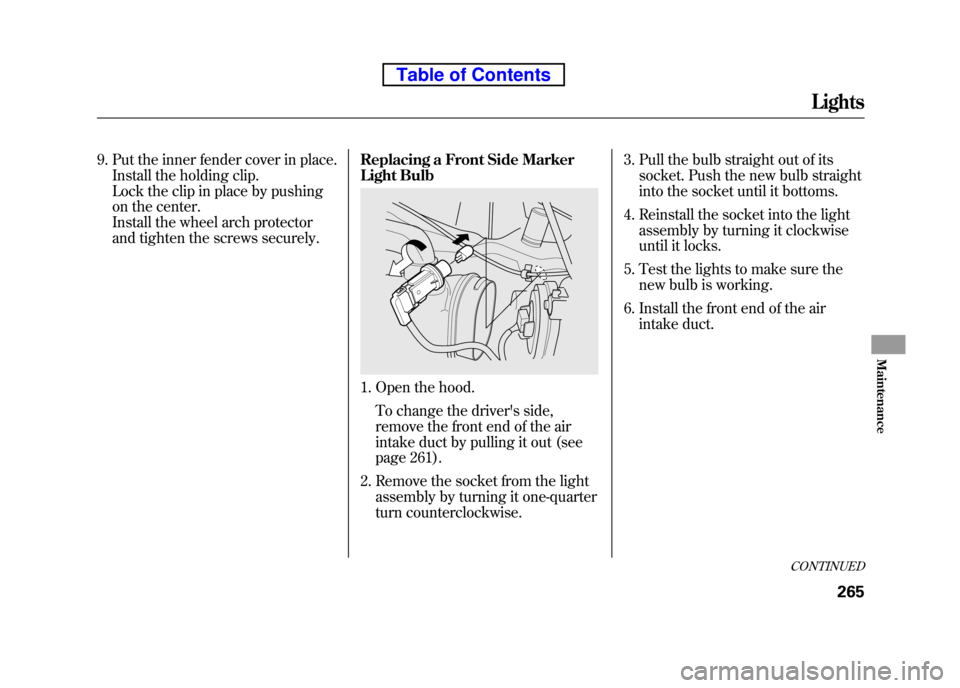

and tighten the screws securely. Replacing a Front Side Marker

Light Bulb

1. Open the hood.

To change the driver's side,

remove the front end of the air

intake duct by pulling it out (see

page 261).

2. Remove the socket from the light assembly by turning it one-quarter

turn counterclockwise. 3. Pull the bulb straight out of its

socket. Push the new bulb straight

into the socket until it bottoms.

4. Reinstall the socket into the light assembly by turning it clockwise

until it locks.

5. Test the lights to make sure the new bulb is working.

6. Install the front end of the air intake duct.

CONTINUED

Lights

265

Maintenance

Table of Contents

Page 292 of 342

Tire Chains

Mount tire chains on your tires when

required by driving conditions or

local laws. Install them only on the

front tires.

On all models except SC

Because your vehicle has limited tire

clearance, use only SAE Class‘‘S ’’

cable-type traction devices, with

rubber chain tensioners, on the front

tires. Use traction devices only when

required by driving conditions or

local laws. Make sure they are the

correct size for your tires. Metal link-type ‘‘chains ’’should not be used.

Traction devices that are the wrong size

or improperly installed can damage

your vehicle's brake lines, suspension,

body, and wheels. Stop driving if they

are hitting any part of the vehicle.

On SC model

Because your vehicle has limited tire

clearance, Honda strongly

recommends using the chains listed

below, made by Security Chain

Company (SCC).

Cable-type: SCC Super Z6 SZ 139 When installing cables, follow the

manufacturer's instructions, and

mount them as tight as you can.

Make sure they are not contacting

the brake lines or suspension. Drive

slowly with them installed. If you

hear them coming into contact with

the body or chassis, stop and

investigate. Remove them as soon as

you begin driving on cleared roads.

Using the wrong chains, or not

properly installing chains, can

damage the brake lines and

cause a crash in which you can

be seriously injured or killed.

Follow all instructions in this

owner's manual regarding the

selection and use of tire chains.

Tires

276

Table of Contents

Page 303 of 342

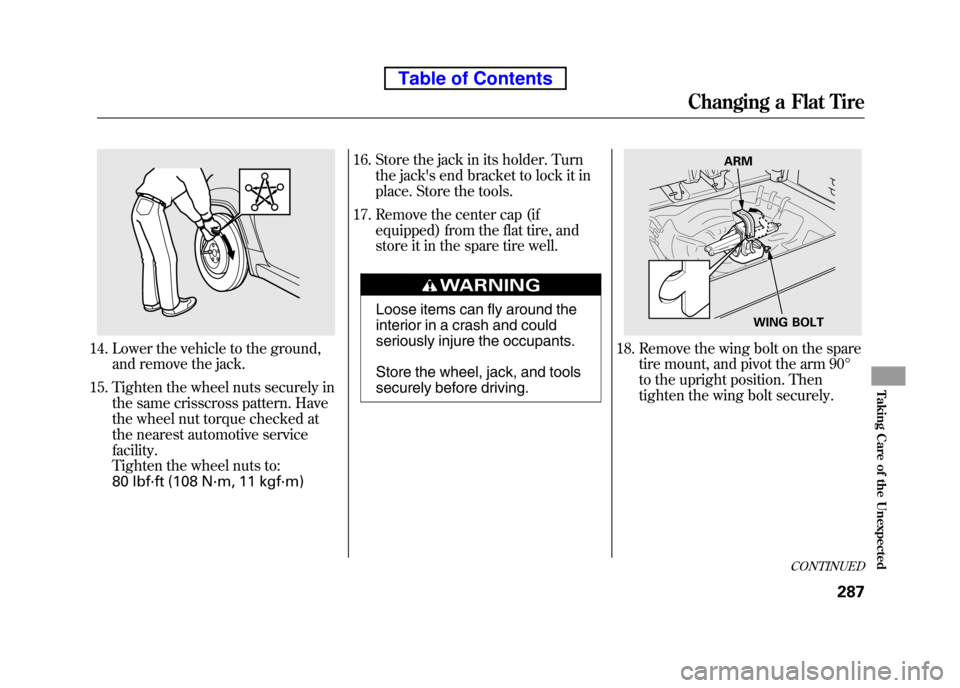

14. Lower the vehicle to the ground,and remove the jack.

15. Tighten the wheel nuts securely in the same crisscross pattern. Have

the wheel nut torque checked at

the nearest automotive servicefacility.

Tighten the wheel nuts to:

80 lbf·ft (108 N·m, 11 kgf·m) 16. Store the jack in its holder. Turn

the jack's end bracket to lock it in

place. Store the tools.

17. Remove the center cap (if equipped) from the flat tire, and

store it in the spare tire well.

Loose items can fly around the

interior in a crash and could

seriously injure the occupants.

Store the wheel, jack, and tools

securely before driving.

18. Remove the wing bolt on the spare tire mount, and pivot the arm 90°

to the upright position. Then

tighten the wing bolt securely.

ARM

WING BOLT

CONTINUED

Changing a Flat Tire

287

Taking Care of the Unexpected

Table of Contents

Page 304 of 342

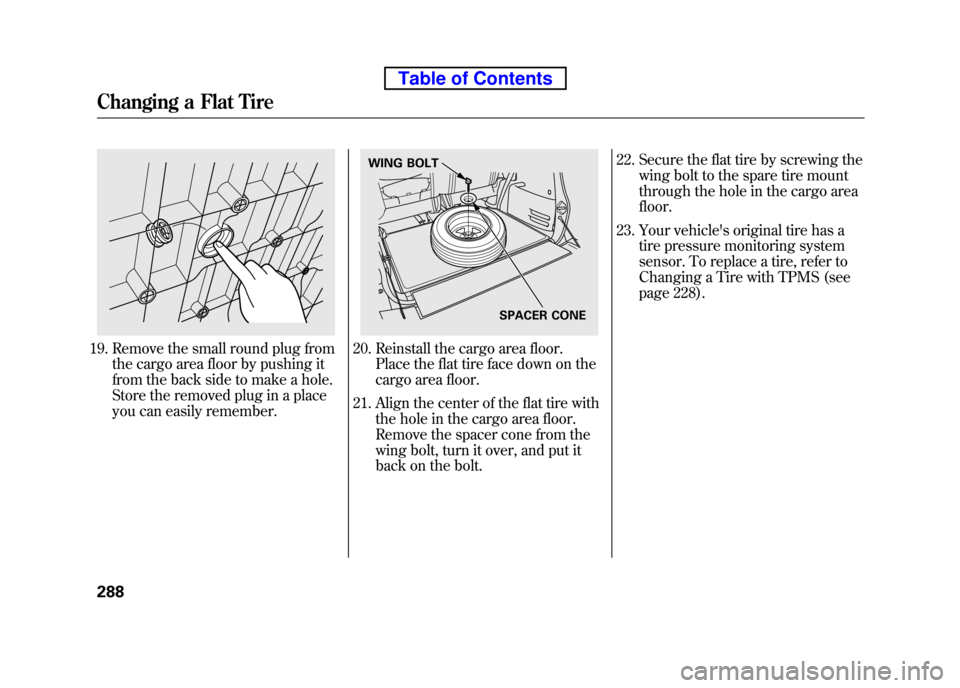

19. Remove the small round plug fromthe cargo area floor by pushing it

from the back side to make a hole.

Store the removed plug in a place

you can easily remember.20. Reinstall the cargo area floor. Place the flat tire face down on the

cargo area floor.

21. Align the center of the flat tire with the hole in the cargo area floor.

Remove the spacer cone from the

wing bolt, turn it over, and put it

back on the bolt. 22. Secure the flat tire by screwing the

wing bolt to the spare tire mount

through the hole in the cargo areafloor.

23. Your vehicle's original tire has a tire pressure monitoring system

sensor. To replace a tire, refer to

Changing a Tire with TPMS (see

page 228).

SPACER CONE

WING BOLT

Changing a Flat Tire

288

Table of Contents

Page 318 of 342

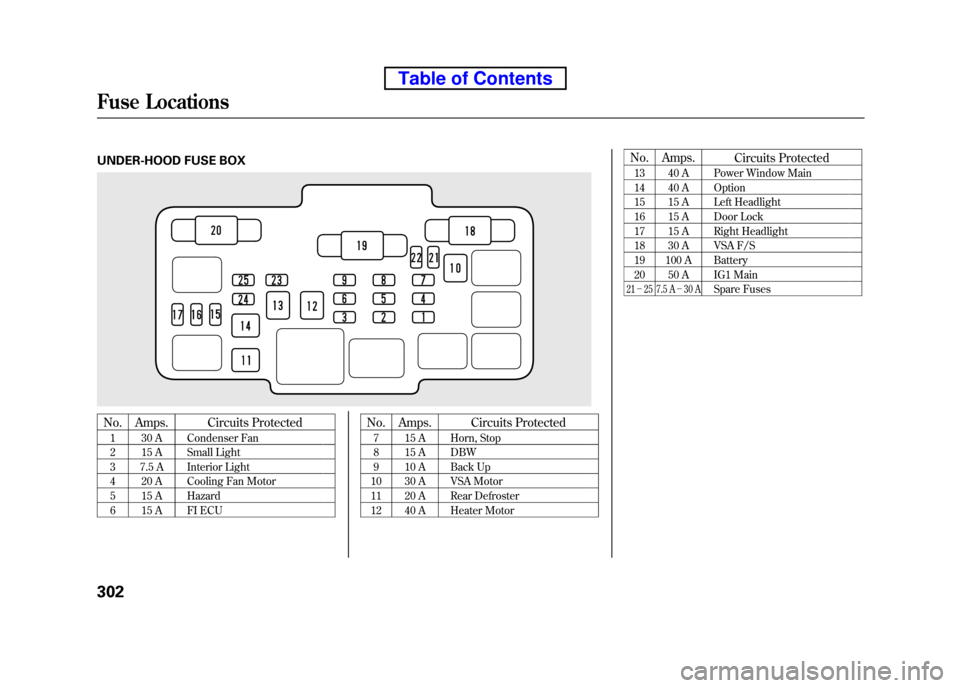

UNDER-HOOD FUSE BOX

No. Amps.Circuits Protected

1 30 A Condenser Fan

2 15 A Small Light

3 7.5 A Interior Light

4 20 A Cooling Fan Motor

5 15 A Hazard

6 15 A FI ECU No. Amps.

Circuits Protected

7 15 A Horn, Stop

8 15 A DBW

9 10 A Back Up

10 30 A VSA Motor

11 20 A Rear Defroster

12 40 A Heater Motor No. Amps.

Circuits Protected

13 40 A Power Window Main

14 40 A Option

15 15 A Left Headlight

16 15 A Door Lock

17 15 A Right Headlight

18 30 A VSA F/S

19 100 A Battery

20 50 A IG1 Main

21 - 25 7.5 A -30 ASpare Fuses

Fuse Locations

302

Table of Contents