head HONDA INTEGRA 1994 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 1178 of 1413

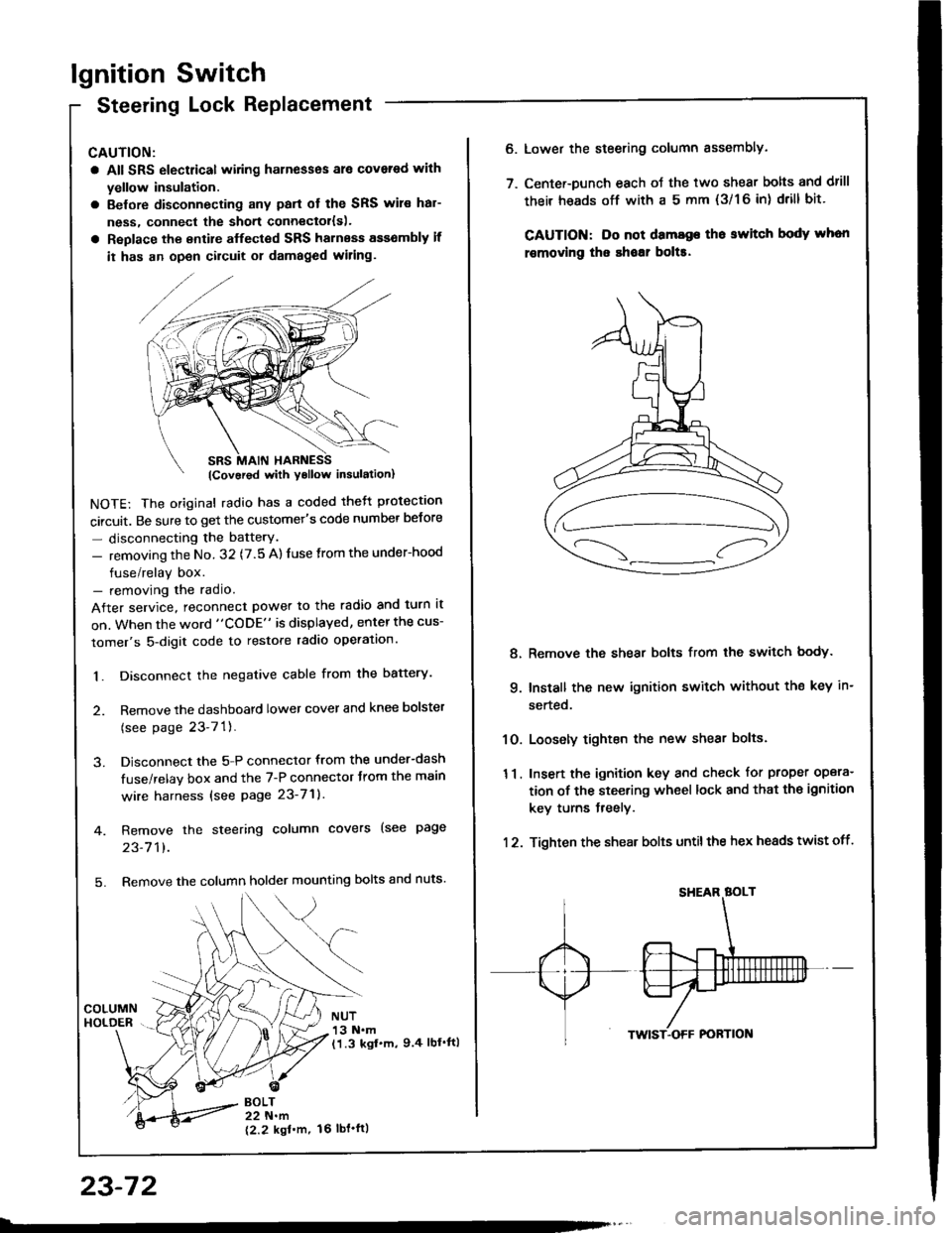

lgnition Switch

Steering Lock Replacement

CAUTION:

a All SRS electrical wiring harnesses ale covsred with

yellow insulation.

a Belore disconnecting any parl ot the SRS wir€ hal-

ness, connecl the short connector{s).

a Replace the entire alfected SRS harness a$6mbly il

it has an open circuit or damaged wiring.

NOTE: The original radio has a coded thett protection

circuit. Be sure to get the customer's code number betore

- disconnecting the batterY.

- removing the No. 32 (7.5 A) fuse from the under-hood

fuse/relay box.- removing the radio.

After service, reconnect power to the radio and turn it

on. When the word "CODE" is displayed, enter the cus-

tomer's 5-digit code to restore radio operation.

1. Disconnect the negative cable from the battery.

2. Remove the dashboald lower cover and knee bolster

(see page 23-7'l ).

3. Disconnect the 5-P connector from the under-dash

fuse/relay box and the 7-P connector trom the main

wire harness {see page 23-71).

4. Remove the steering column covers (see page

23-711.

5. Remove the column holder mounting bolts and nuts'

BOLT22 N.m

12.2 kgl'm.

NUT13 N.m(1.3 kgf.m, 9.4 lbl'ftl

23-72

16 tbt.ftl

6. Lower the steering column sssembly.

7. Center-Dunch each oJ the two shear bolts and drill

their heads off with a 5 mm {3/1 6 in) drill bit'

CAUTION: Do not dama96 tho switch body whon

r€movlng the shoar bol$.

Remove the shear bolts from the switch body.

Install the new ignition switch without the key in-

serted.

Loosely tighten the new shear bolts.

Insert the ignition key and check for proper opera-

tion of the steering wheel lock and that th€ ignition

key turns freely.

Tighten the shear bolts untilthe hex heads twist off.

8.

q

10.

11.

12.

Page 1197 of 1413

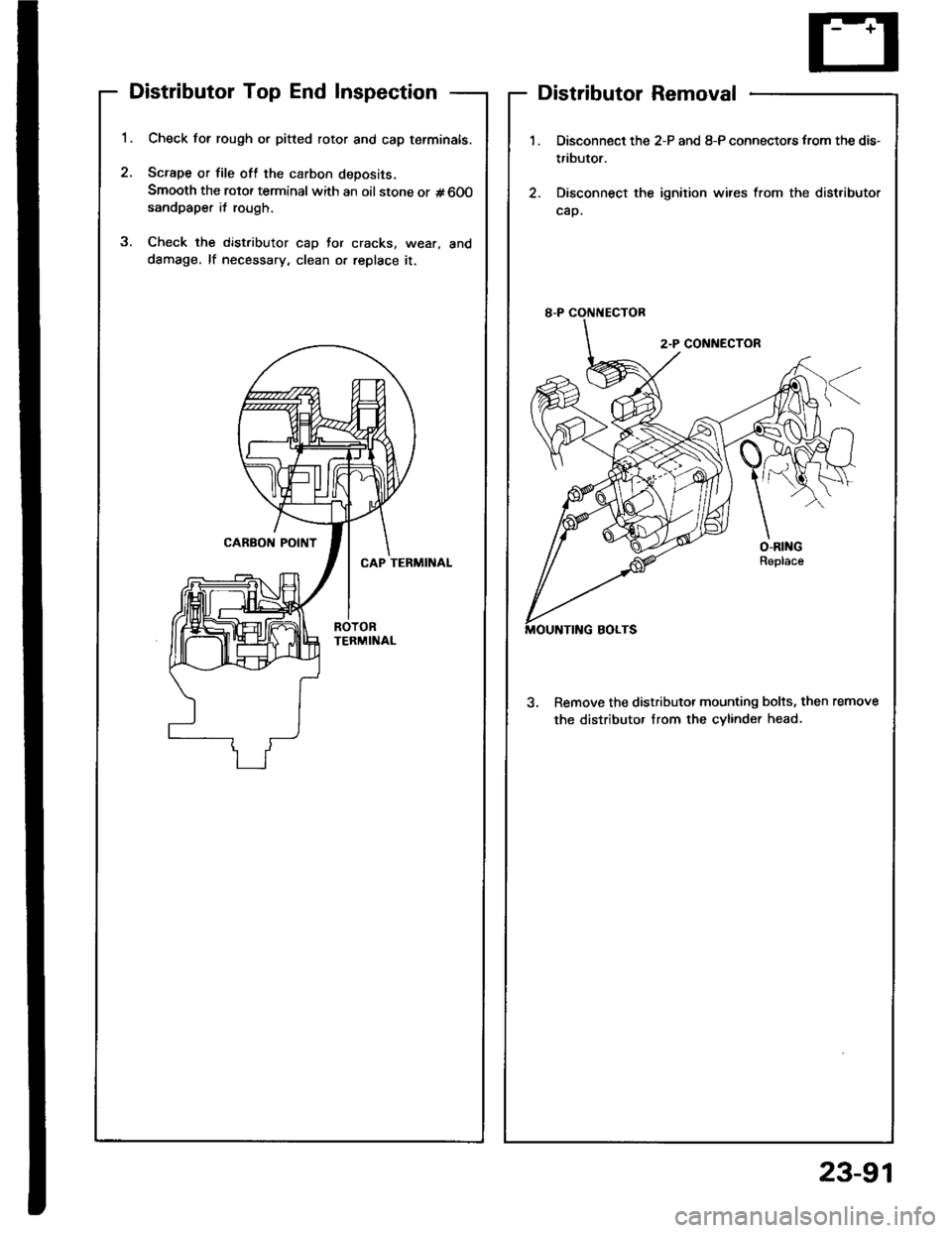

Distributor Top End Inspection

1.

2.

Check for rough or pitted rotor and cap tefminals.

Scrape or file oft the carbon deposits.

Smooth the rotor terminal with an oil stone or #600sandpaper i{ rough.

Check the distributor cap Jor cracks, wear, and

dSmage, lf necessary, clean or replace it.

2

Distributor Removal

1.

2.

Disconnect the 2-P and 8-P connectors from the dis-

tributor.

Disconnect the ignition wires from the distributor

cap.

3. Remove the distributor mounting bolts, then remove

the distributor Irom the cvlinder head.

23-91

Page 1203 of 1413

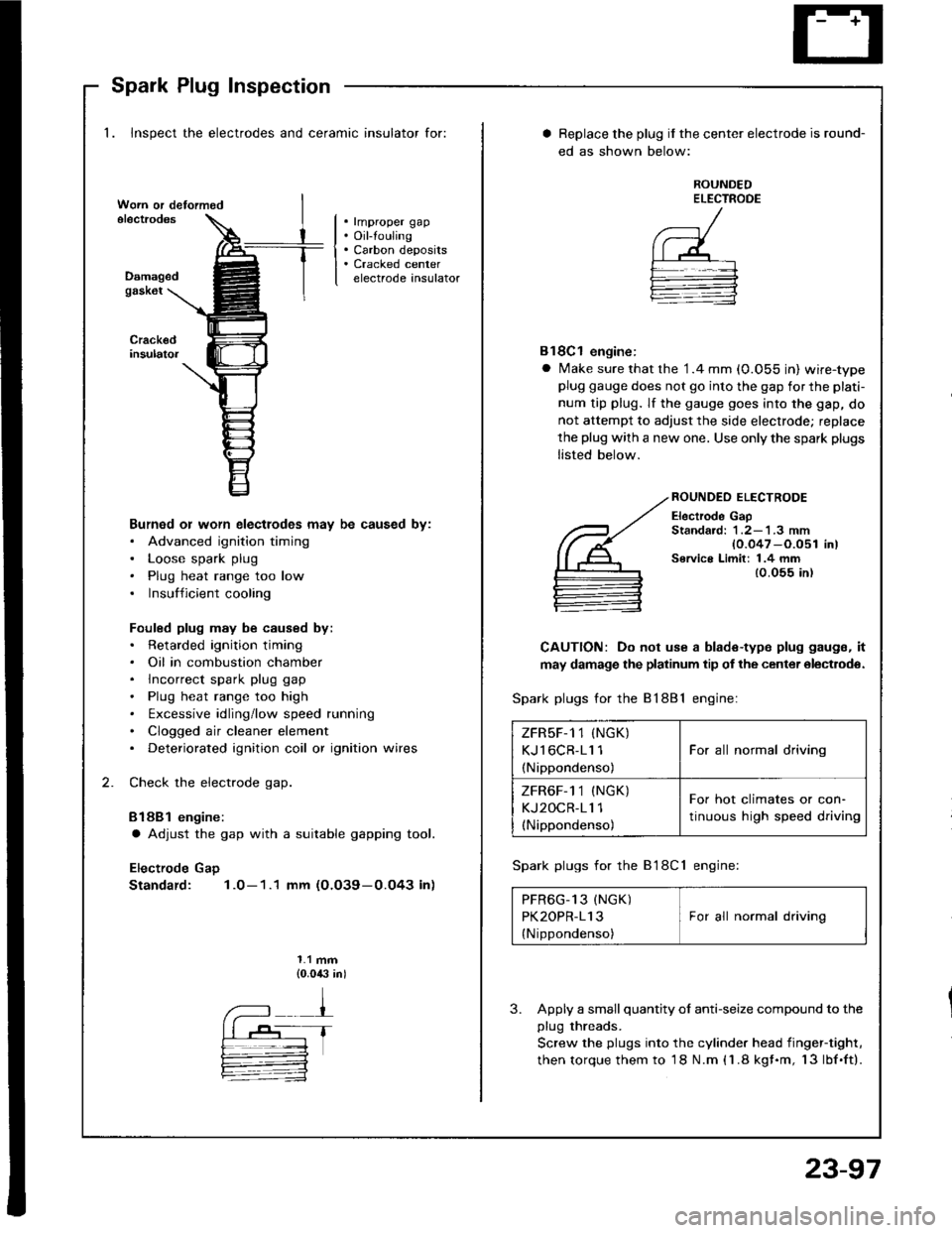

Spark Plug Inspection

1. Inspect the electrodes and ceramic insulator for:

. rmproper gap. Oil-touling. Carbon deposits. Cracked centerelectrode insulatorDamagedgask6t

Burned or worn electlodes may be caused by:. Advanced ignition timing. Loose spark plug. Plug heat range too low. Insufficient cooling

Fouled plug may be caused by:. Retarded ignition timing. Oil in combustion chamber. lncorrect spark plug gap. Plug heat range too high. txcessive idling/low speed running. Clogged air cleaner element. Deteriorated ignition coil or ignition wires

Check the electrode gap.

Bl88l engine:

a Adjust the gap with a suitable gapping tool.

Electrode Gap

Standard: 1.0-1.1 mm (O.O39-0.O43 in)

1.1 mm{0.0,$ in)

Replace the plug if the center electrode is round-

ed as shown below:

ROUNDEDELECTROOE

Bl8Cl engine:

a Make sure that the '1.4 mm (0.055 in) wire-typeplug gauge does not go into the gap for the plati-

num tip plug. lf the gauge goes into the gap, do

not attempt to adjust the side electrode; replace

the plug with a new one. Use only the spark plugs

listed below.

ROUNDEO ELECTRODE

Electrode GapStandard: 1 .2-'l .3 mm{0.047 -O.051 in)Service Limit: 1.4 mm{0.055 in)

CAUTION: Do not use a blade-type plug gaugs, it

may damage the platinum tip of the center olectrodo.

Spark plugs for the 81881 engine:

Spark plugs for the B'l8Cl engine:

PFR6G_13 (NGK) IPK2OPR-113 I For all normal driving

{Nippondenso)

3. Apply a small quantity ol anti-seize compound to the

plug threads.

Screw the plugs into the cylinder head iingef-tight,

then torque them to 18 N.m (1.8 kgf.m, 13lbf.ft).

ZFRsF-1 1 (NGK)

KJl6CR-11 1

(Nippondenso)

For all normal driving

ZFR6F-1 1 (NGK)

KJ2OCR-11 1(Nippondenso)

For hot climates or con-

tinuous high speed driving

23-97

Page 1260 of 1413

![HONDA INTEGRA 1994 4.G Workshop Manual Lighting System

Circuit Diagram (USAI

UNOER - HOOD RJSE/NELAY 8OX

-r lo| ,-. otFDIMMER II

No.2l|l0A]iil;

)

ttNo.lo 1 No,22 t No.gtloAr (0oA) (floAr

IT

HEADLIGHTRIGHTHEAOUGHT

HIGH EEAMINOICATORLIGH HONDA INTEGRA 1994 4.G Workshop Manual Lighting System

Circuit Diagram (USAI

UNOER - HOOD RJSE/NELAY 8OX

-r lo| ,-. otFDIMMER II

No.2l|l0A]iil;

)

ttNo.lo 1 No,22 t No.gtloAr (0oA) (floAr

IT

HEADLIGHTRIGHTHEAOUGHT

HIGH EEAMINOICATORLIGH](/img/13/6067/w960_6067-1259.png)

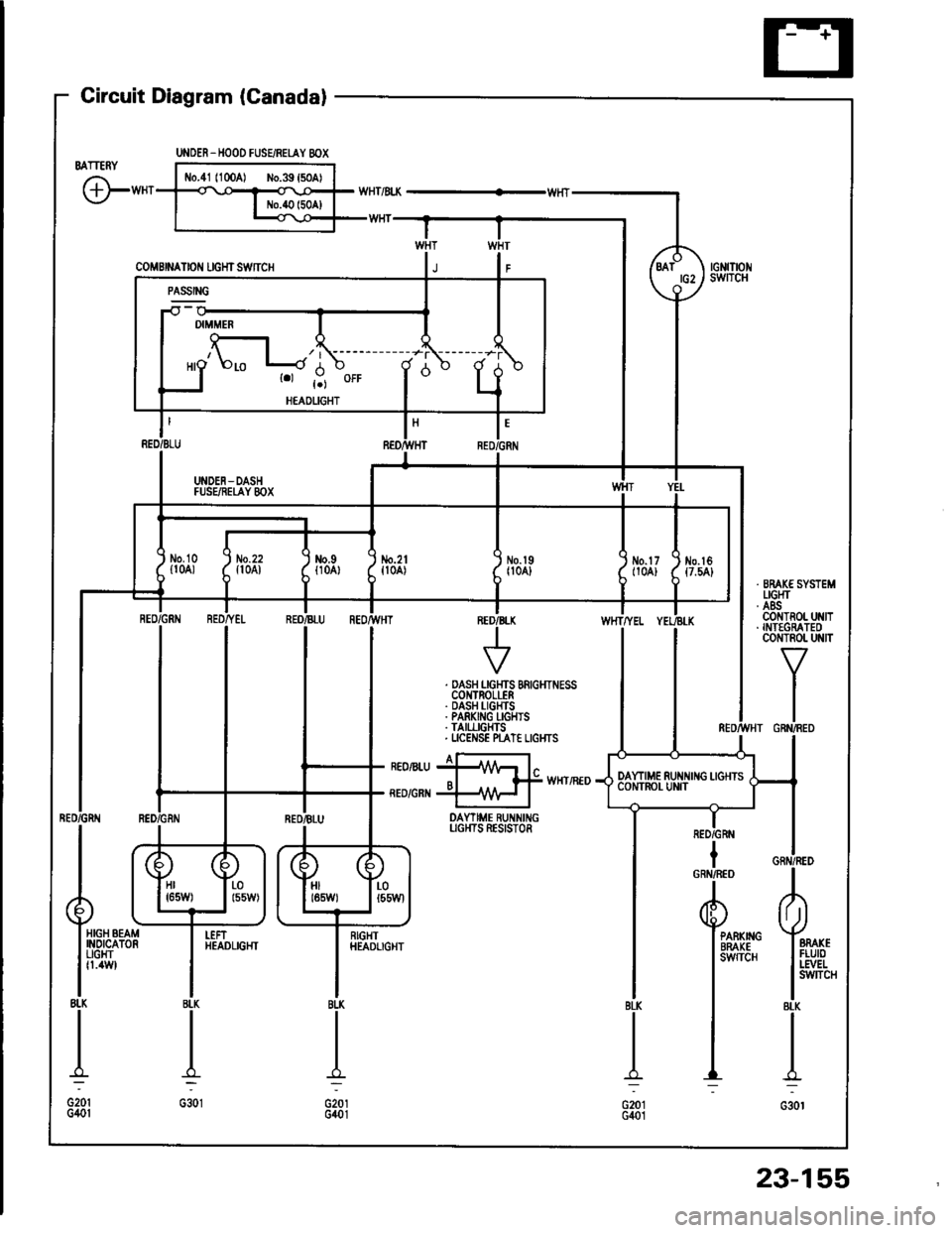

Lighting System

Circuit Diagram (USAI

UNOER - HOOD RJSE/NELAY 8OX

-r lo| ,-. otFDIMMER I'I

No.2l|l0A]iil;

)

ttNo.lo '1 No,22 ''t No.gtloAr (0oA) (floAr

IT

HEADLIGHTRIGHTHEAOUGHT

HIGH EEAMINOICATORLIGHTfi.4W)@il,", @f,*,6il* 6p*

. PAR(II{G UGHI. TAILUGI{TS. UCENSE PI.ATE

UtrloER - D SHRJSE/RELAYsox

REO/GNN

8LK

I

G20lG401

DASH UGI{TS88rGr{T ESSCONTrcUTRDASH UGHTSPAR(II{C UGHTSTAItUGt{TSUCENSE PI.ATEUGHTS

8tK

G301G20'�|G40l

23-154

Page 1261 of 1413

Gircuit Diagram (Canadal

BATTERY

G"*

UNOER_HOOD FUSEiRETAY 8OX

coMBrNAtor{ rcHrswnc

-il w

| '.=r" I

ll'L I I

I I *o\." l-'li' ;- ;j

I LI

"- r.r-,9 "orr

I

d "

L

RED/BLU REO/}VHT RED,ll

I UNDEN-DASH II FUSEiIEI,AY 8OX I

tl

L-J

t'GRN

/d\BATtG2\9-l

rGNrTrot{swITcH

No.2lfl0A)\I

No.l9|l04]Jm.tr (

t10A) ttt

I

No.l6{7.54}

tl

i,"#

llrrff li'rrt,

RED/GRtIIBLU REOr'TVHTINED/B

V

WHTTYEL

. DASH LGHTS BRIGHTNESSCOI{TROLLER. DASH I-IGHTS. PARKING I-GHIS. TAII,LIGHTS. UCENSE N"AT€ LIGI{TS

I a-rneonru jllA/Vr l"o I f# wxrintoRED/GRI{ +\{H I

DAYTIME RUNNINGUGI{TS RESISTOR

IRED/GRN

Hr I r-01651,1/) | l55W)HIt85W)LOt55Wl

HIGH BEAMINOICATORUGHTfl.4W

I

RIGHTHEADLIGHTPARKIIIGBRAKEsw{TcH

23-155

Page 1263 of 1413

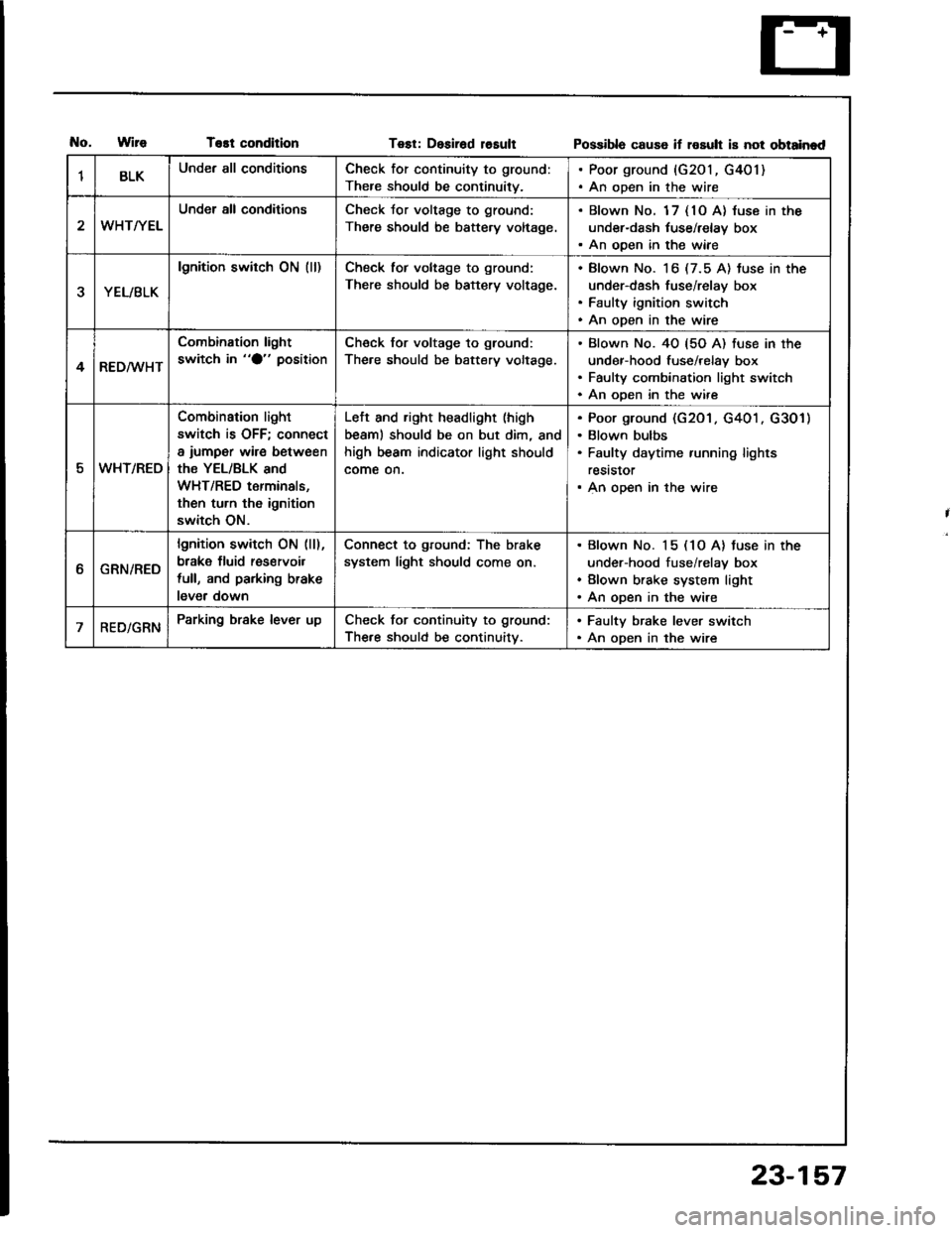

T€st conditionTest: Desirad losultPossibla cause if rosult is not obtainad

1BLKUnder all conditionsCheck for continuity to ground:

There should be continuity.

. Poor ground {G201, G401). An open in the wire

WHT/YEL

Under all conditionsCheck Jor voltage to ground:

There should be battery voltage.

. Blown No. 1 7 { 10 A} luse in the

under-dash tuse/relay box. An ooen in the wiae

YEL/BLK

lgnition switch ON (ll)Check tor voltage to ground:

There should be battery voltage.

Blown No. 16 (7.5 A) tuse in the

under-dash fuse/relay box

Faulty ignition switch

An open in the wire

4RED/WHT

Combination light

switch in "O" positionCheck for voltage to ground:

The.e should be battery voltage.

Blown No. 40 {5O A) fuse in the

under-hood fuse/relay box

Faulty combination light switch

An ooen in the wire

5WHT/REO

Combination light

switch is OFF; connect

a iumper wire between

the YEL/BLK and

WHT/RED terminals,

then turn th6 ignition

switch ON.

Left and right headlight (high

beaml should be on but dim, and

high beam indicator light should

come on.

Poor ground (G201 . G401 . G301)

Blown bulbs

Faulty daytime running lights

reststor

An open in the wire

ttGRN/RED

lgnition switch ON (ll),

brake fluid res€rvoil

full, and parking brake

lever down

Connect to ground: The brake

system light should come on.

Blown No. 15 (1O A) tuse in the

under-hood fuse/relay box

Blown brake system light

An open in the wire

RED/GRNParking brake lever upCheck for continuity to ground:

The.e should be continuitv.

. Faulty brake lever switch. An open in the wire

23-157

Page 1267 of 1413

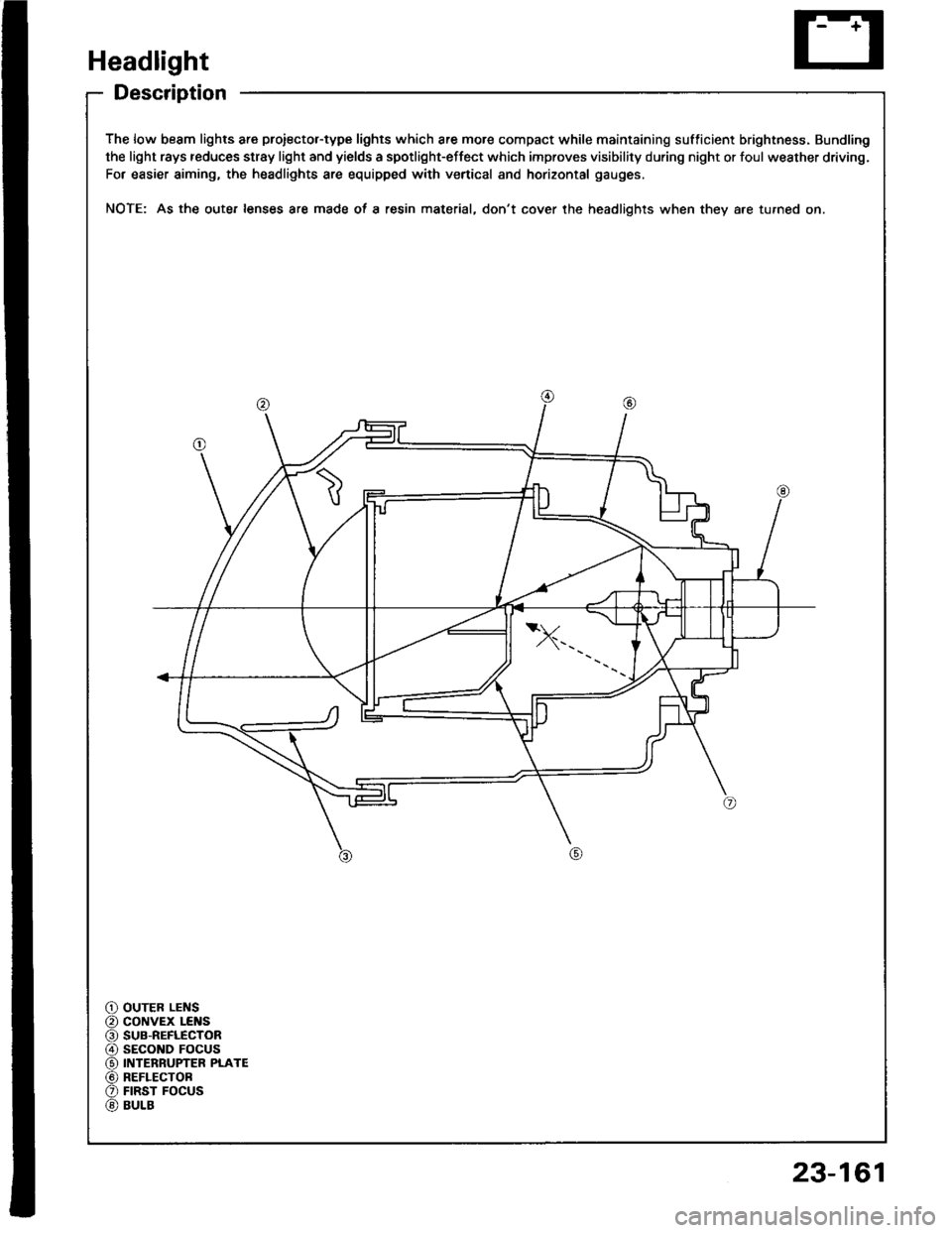

Headlight

Description

The low beam lights are proiector-type lights which are more compact while maintaining sufficient brightness. Bundling

the light rays reduces stray light and yields a spotlight-effect which improves visibility during night or foul weather driving.

For easier aiming, the headlights are equipped with vertical and horizontal gauges.

NOTE: As the oute. lenses are made oI a resin material, don't cover the headlights when they a.e turned on.

OUTER LENScoNvEx LEI{SSUB-REFLECTORsEcoND FOCUSINTERRUPTER PLATEREFLECTOBFIRST FOCUSBULB

23-161

Page 1268 of 1413

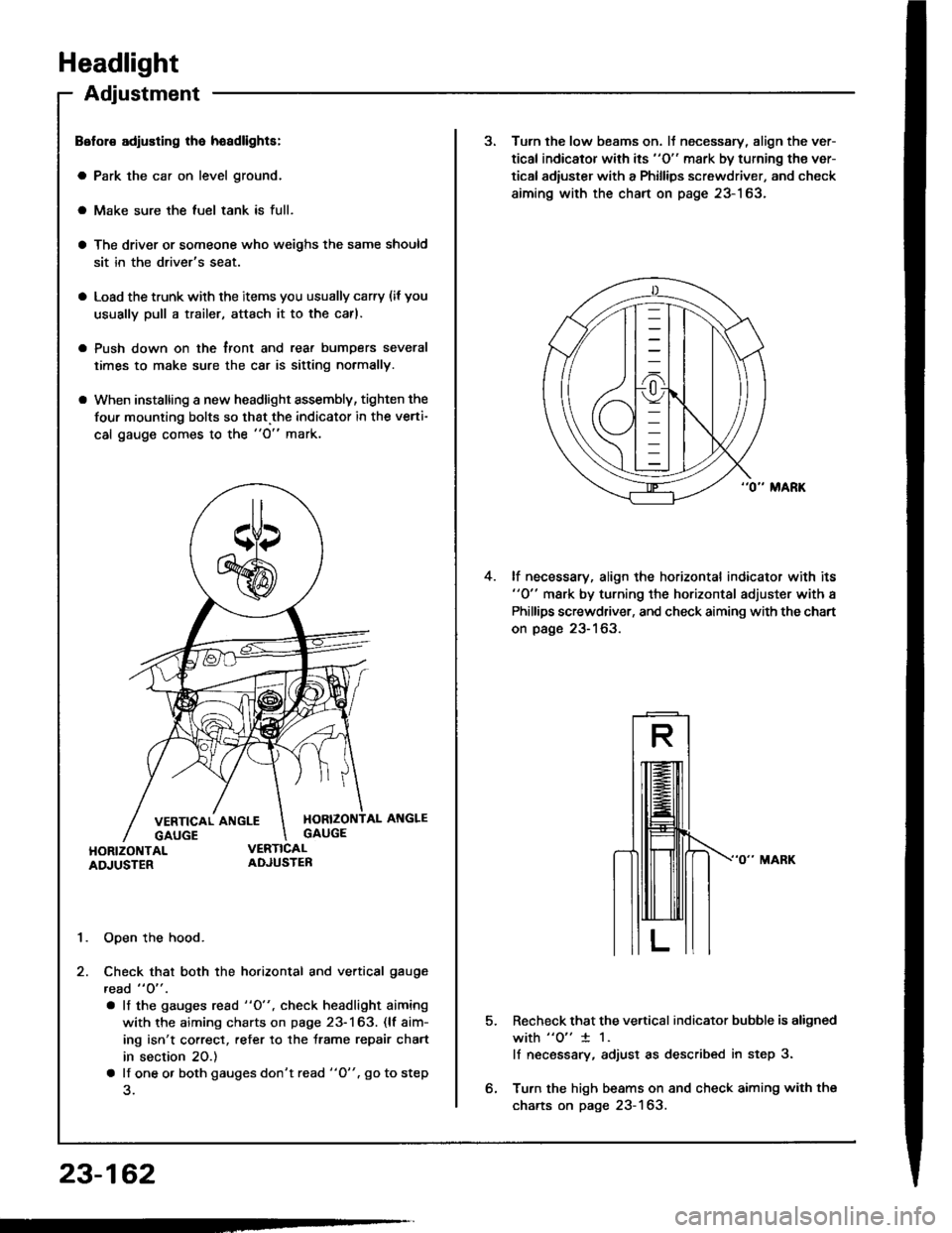

Headlight

Adjustment

Belol€ adiusting lha hoadlights:

a Park the car on level ground.

a Make sure the luel tank is full.

a The driver or someone who weighs the same should

sit in the driver's seat.

a Load the trunk with the items you usually carry (if you

usually pull a trailer, attach it to the carl.

a Push down on the tront and rear bumDers several

times to make sure the car is sitting normally.

a When installing a new headlight assembly, tighten the

four mounting bolts so that.the indicator in the verti-

cal gauge comes to the "O" mark.

1. Open the hood.

2. Check that both the horizontal and vertical gauge

read " O" .

. lf the gauges rcad "O", check headlight aiming

with the aiming charts on page 23-163. (lf aim-

ing isn't correct, refer to the trame repair chart

in section 20.)

a lf one o. both gauges don't read "O". go to step

23-162

3. Turn the low beams on. lJ necessary, align the ver-

tical indicator with its "O" mark by turning the ver-

tical adiuster with a Phillips screwdriver, and check

aiming with the chart on page 23-163.

lf necessary, align the horizontal indicator with its"0" mark by turning the horizontal adjuster with a

Phillips screwdriver, and check aiming with the chart

on page 23-163.

4.

5.Recheck that the vertical indicator bubble is aligned

with "o" 1 1.

lf necsssary, adjust as described in step 3.

Turn the high beams on and check aiming with the

charts on page 23-163.

Page 1269 of 1413

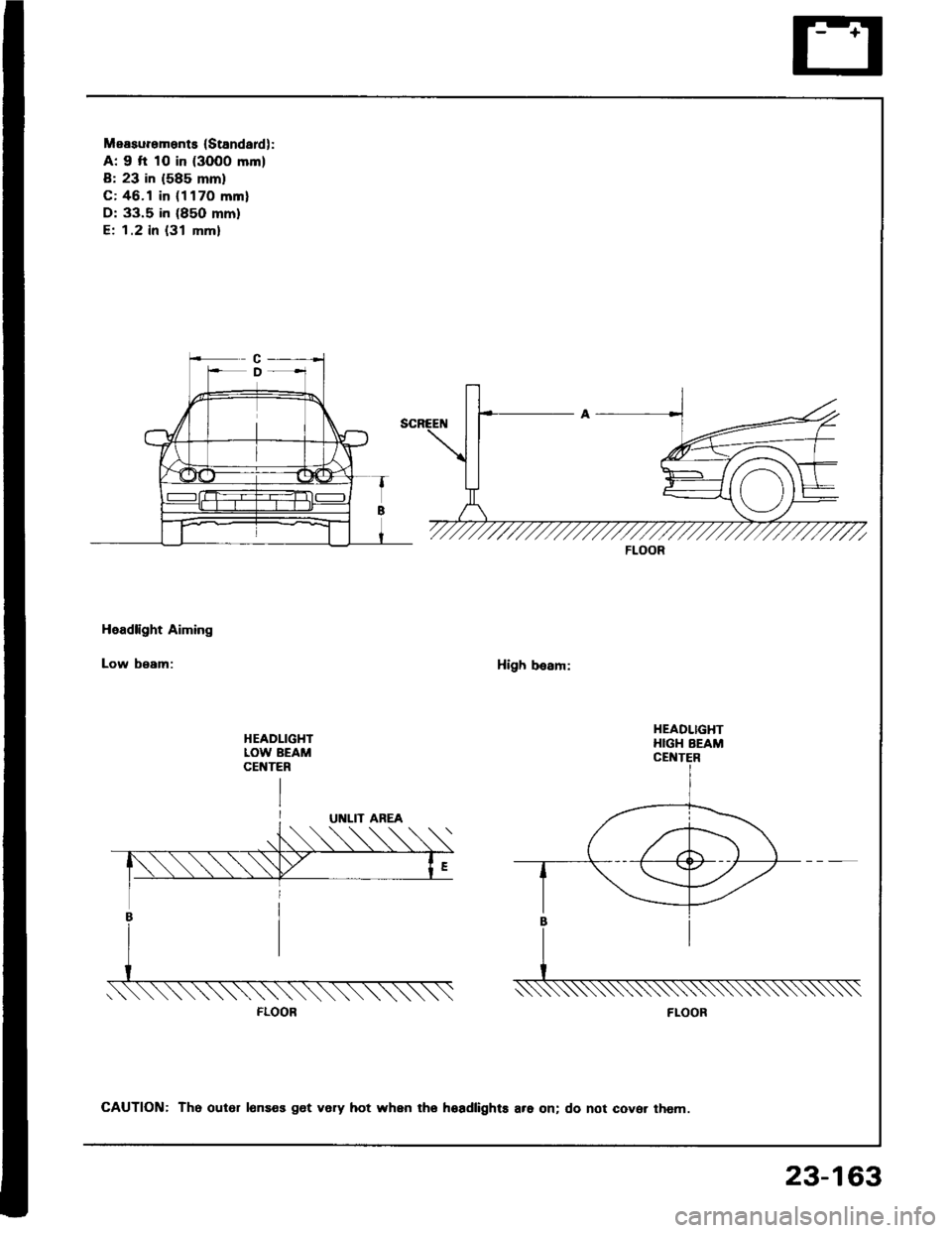

Measurements (Standardl:

A: 9 fi 10 in (3000 mm)

B: 23 in (585 mm)

C: 46.1 in (1170 mml

D: 33.5 in (85O mm)

E; 1.2 in {31 mm}

Headlight Aiming

Low beam:High besm:

HEADLIGHTLOW BEAMCEt{TER

FLOOR

HEADLIGHTHIGH BEAM

FLOOR

CAUTION: Th6 out6r lonses get very hot when tho hoadlights are on; do not cover them.

23-163

Page 1270 of 1413

Headlight

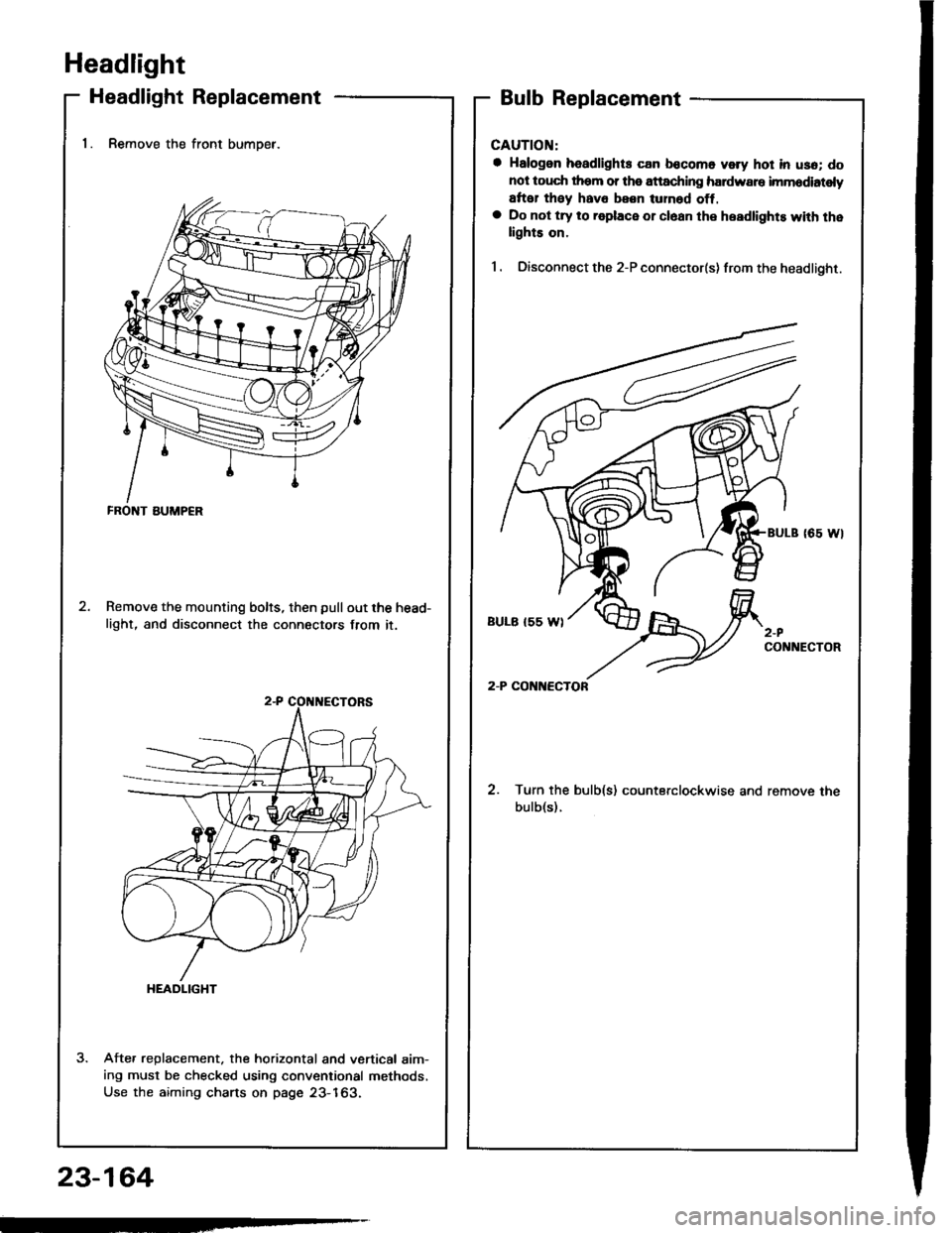

Headlight Replacement

1. Remove the front bumoer.

Remove the mounting bolts, then pullout the head-

light, and disconnect the connectors from it.

Afte. replacement. the horizontal and vertical aim-ing must be checked using conventional methods,

Use the aiming charts on page 23-163.

Bulb Replacement

CAUTION:

a Halogon headlights can bocomo voly hot in usa; do

not touc$ them or tho attaching hardware imm6diatoly

arter they hava been lurnod off,a Do not try to roplace or cl6an the headlights with thelights on.

I . Oisconnect the 2-P connector(s) from the headlight.

coNlrtEcToR

2. Turn the bulb(s) counterclockwise and remove the

bulb(s).

FRONT BUMP€R

HEADLIGHT

23-164