HONDA INTEGRA 1994 4.G Workshop Manual

Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 1101 of 1413

A/C Compressor Belt

Replacement

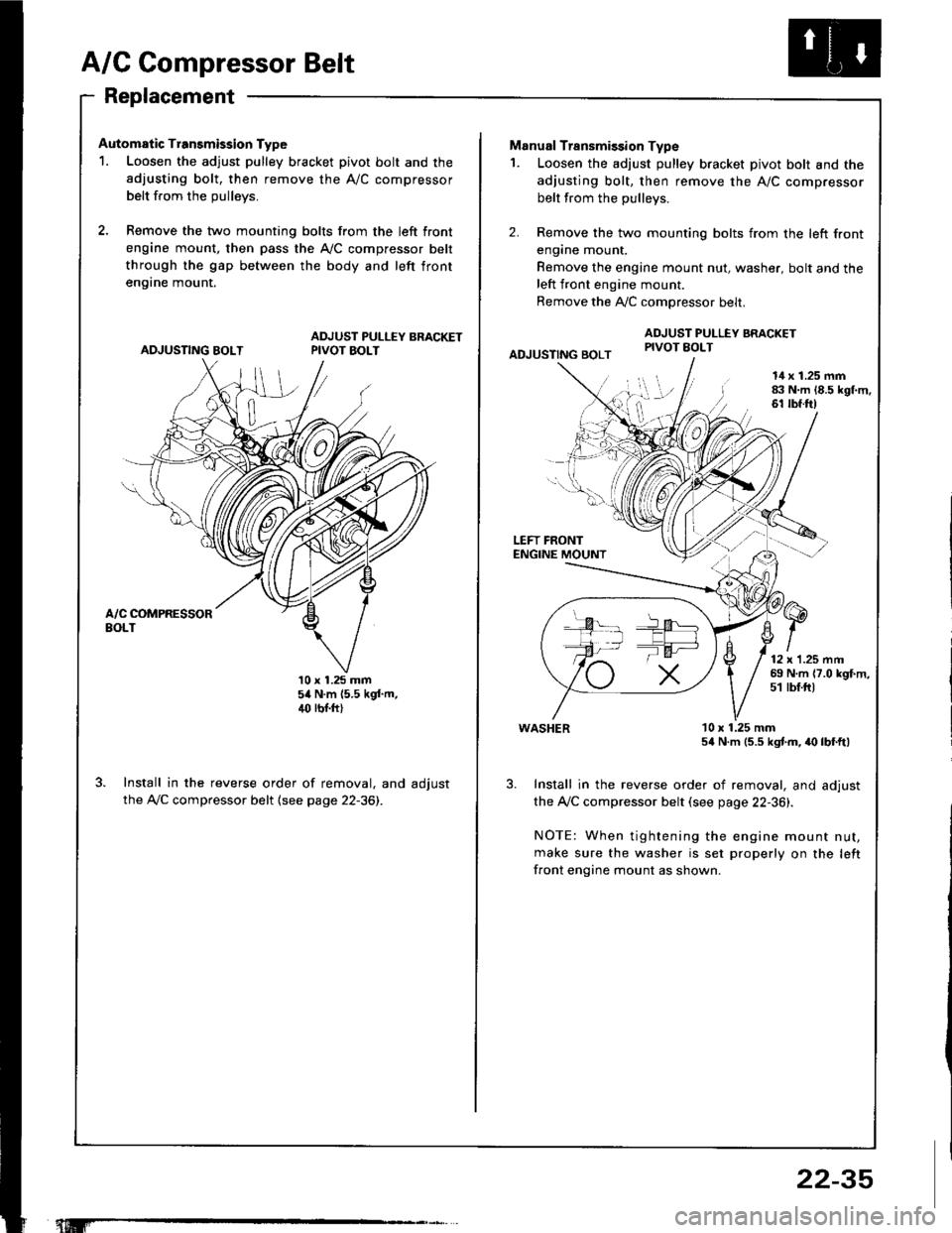

Automatic Transmission Type

1. Loosen the adjust pulley bracket pivot bolt and the

adjusting bolt, then remove the A/C compressor

belt from the oullevs.

2, Remove the two mounting bolts from the left front

engine mount, then pass the A,/C compressor belt

through the gap between the body and left front

en9rne mount.

ADJUSTING BOLTADJUST PULLEY BRACKETPIVOT BOLT

10 x 1.25 mm54 N.m (5.5 kgf.m,4(' rbr.ft)

Install in the reverse order of removal, and adjust

the A,/C compressor belt (see page 22-36).

"t.M'

22-35

-la ar-

Manual Transmission Type

1. Loosen the adjust pulley bracket pivot bolt and the

adjusting bolt, then remove the A/C compressor

belt from the pullevs.

2. Remove the two mounting bolts from the left front

engane mount.

Remove the engine mount nut, washer, bolt and theleft front engine mount.

Remove the A,./C comoressor belt.

ADJUSTING BOLT

ADJUST PULLEY BRACKETPIVOT EOLT

l!l',

I

14 x 1.25 mm83 N.m 18.5 kgl.m.61 tbf.ft)

LEFT FRONTENGINE MOUNT

12 x'1.25 mm69 N.m {7.0 kgf.m,51 tbf.ftt

WASHER

Install in the reverse order of removal, and adjust

the Ay'C compressor belt (see page 22-36).

NOTE: When tightening the engine mount nut,

make sure the washer is set properly on the left

front engine mount as shown.

10 x 1.25 mm54 N.m (5.5 kgtm, irc lbf.ft)

Page 1102 of 1413

A/C Compressor Belt

Adjustment

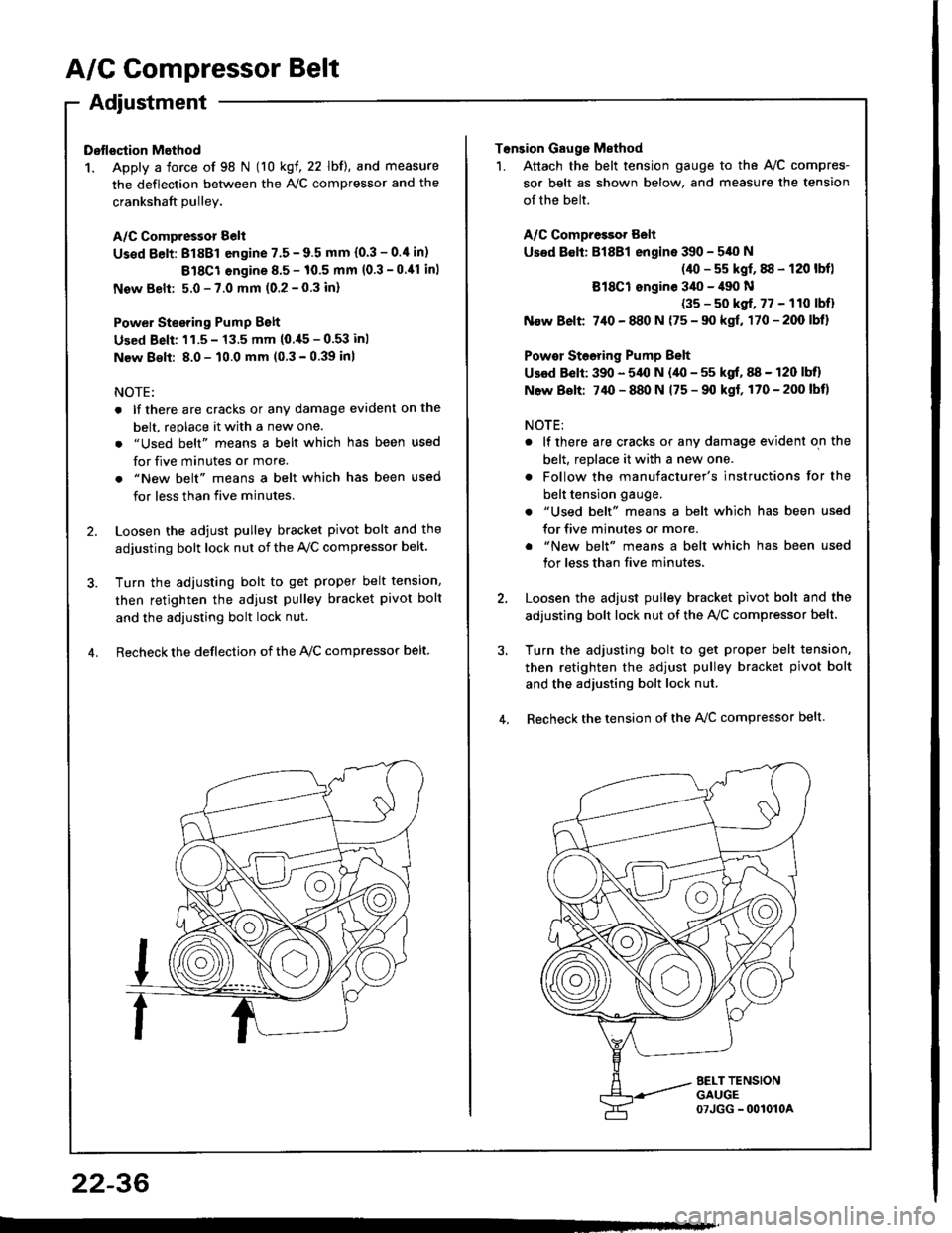

Dstlsqtion Method

1. Apply a force of 98 N (10 kgf, 22 lbf), and measure

the deflection between the A,/C compressor and the

crankshaft Dullev.

A/C Compressor Belt

Us€d Eelt: 81881 engine 7.5 - 9.5 mm (0.3 - 0.4 in)

Bl8Cl engine 8.5 - 10.5 mm (0.3 -0.11 inl

New Belt: 5.0 - 7.0 mm (0.2 - 0.3 inl

Power Stesring Pump Belt

Used Beli: 'l1.5 - 13.5 mm (0.,[5 - 0.53 inl

New 8€lt: 8.0 - 10.0 mm (0 3 - 0.39 inl

NOTE:

. lf there are cracks or any damage evident on the

belt, replace it with a new one.

. "Used belt" means a belt which has been used

for five minutes or more.

. "New belt" means a belt which has been used

for less than five minutes.

2. Loosen the adjust pulley bracket pivot bolt and the

adjusting bolt lock nut of the Ay'C compressor belt.

3. Turn the adiusting bolt to get proper belt tension,

then retighten the adjust pulley bracket pivot bolt

and the adjusting bolt lock nut.

4. Recheck the deflection of the lvc compressor belt

22-36

Tonsion Gauge Method

1. Attach the belt tension gauge to the Ay'C compres-

sor belt as shown below, and measure the tension

of the belt.

A/C Compressot Belt

Used 8€lt: Bl8Bl engine 390 - 540 N

(40 - s5 kgf, 88 - 120 lbfl

Bl8Cl ongine 3il0 - il90 N

(35 - s0 kgf, 77 - 110 lbfl

N€w Belt 7,10 - 880 N {75 - 90 kgf, 170-200lbl}

Powor Steoring Pump Belt

Used Belt: 390 - 5,{l N (40 - 55 kgf, 88 - 120 lbll

N6w Bolt: 74O - 880 N 175 - 90 kgf, 170-200lbt)

NOTE:

. lf there are cracks or any damage evident on the

belt, replace it with a new one.

. Follow the manufacturer's instructions for the

belt tension gauge.

. "Used belt" means a belt which has been used

for five minutes or more.

. "New belt" means a belt which has been used

tor less than five minutes,

2. Loosen the adjust pulley bracket pivot bolt and the

adjusting bolt lock nut of the AVC compressor belt.

3, Turn the adjusting bolt to get proper belt tension,

then retighten the adjust pulley bracket pivot bolt

and the adjusting bolt lock nut.

4. Recheck the tension of the A{/C compressor belt.

Page 1103 of 1413

Condenser

Replacement

RAOIATOR UPPENMOUNT BRACKETS

Recover the relrigerant with a Becovery/Recycling/

Charging System (see page 22-221.

Remove the coolant reservoir,

NOTE: Do not disconnect the reservoir hose from

the coolant reservoir and the radiator.

COOLANT RESERVOIR

Remo.ve the bolts and the radiator upper mount

brackets, and remove the bolt from thg suction hose

bracket.

9.8 N.m {1.0 kgf.m.7.2 lbtftl

'1Iffi

22-37

6x1.0mm9.8 N.m (1.0 kgl.m,7.2 lbt.ft)

......-.....

CONOENSER LINE

Remove the bolts. and disconnect the discharge line

and the condenser line from the condenser.

NOTE: Plug or cap the lines immediately after dis-

connecting to avoid moisture and dust contamina-

tion into the system.

DISCHARGE LINE

Remove the two mounting bolts, then lift out the

condenser as shown.

NOTE: Do not damage the radiator and condenser

fins when removing the condenser.

6x1.0mm9.8 N.m (1.0 kgf.m, 7.2 lbl.tt)

Install in the reverse order of removal. and:

. if you're installing a new condenser, add refriger-

ant oil (ND-OIL 8: P/N 38899 - PR7 - A01) (see

page 22-21t,.

. replace the O-rings with new ones at each fitting,

and apply a thin coat of refrigerant oil {ND-OIL 8:

P/N 38899 - PR7 - A01) before installing them.

NOTE: Be sure to use the right O-rings for HFC-

134a (R-134a) to avoid leakage.

a do not damage the radiator and condenser fins

when installing the condenser,

. be sure to install the condenser mount cushions

securely into the holes.

. charge the system (see page 22-39) and test its

performance (see page 22 24!�.

Page 1104 of 1413

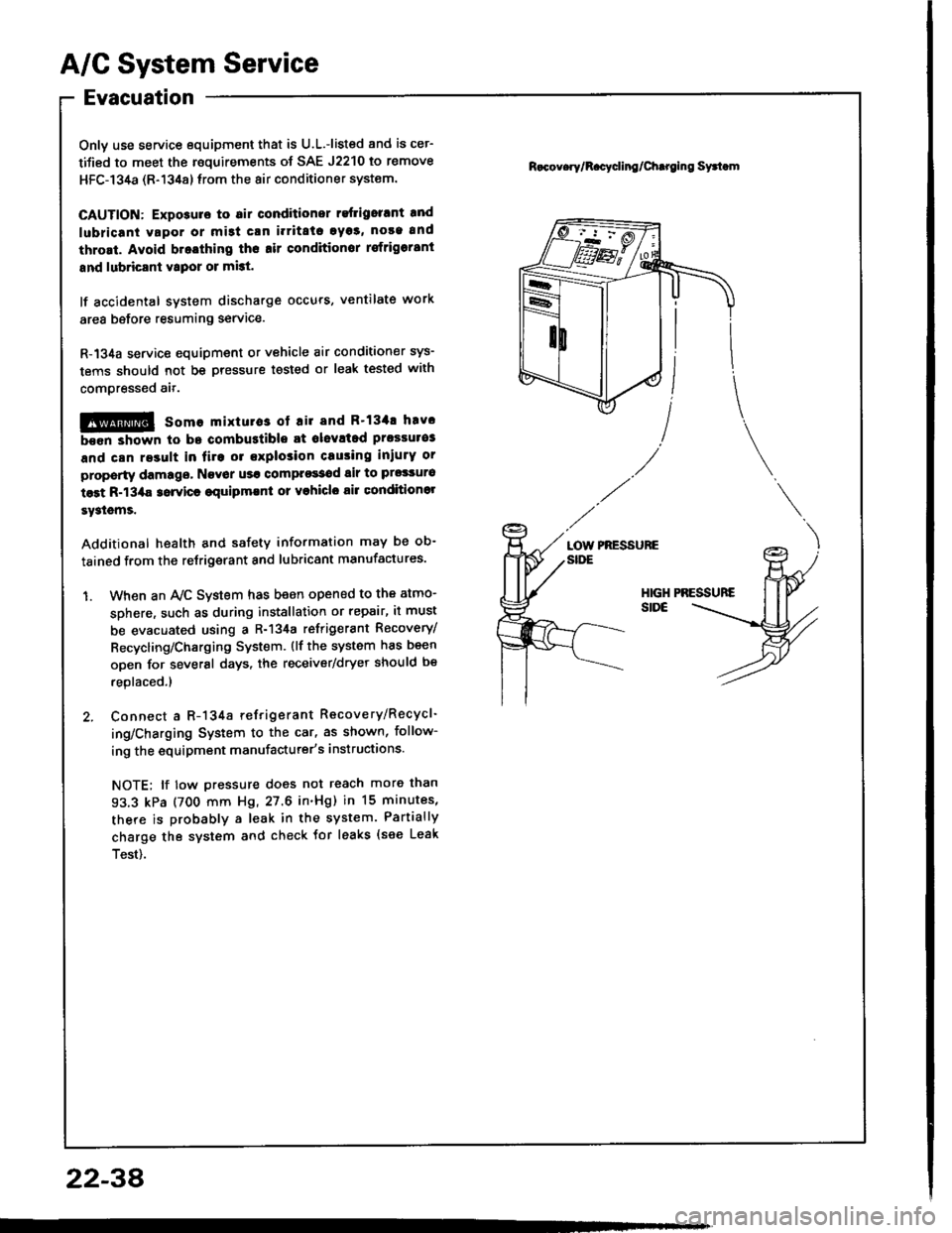

A/G System Service

Evacuation

Only use service equipment that is U.L.-listed and is cer-

tified to meet the roquirements of SAE J2210 to remove

HFC-134a (R-134a) lrom the 8ir conditioner system.

CAUTION: Exposulo to 6ir conditioner refligorrnt and

lubricani vapor or mi3t crn i.ritato 9y33, noaa and

thrort. Avoid bratthing ths .ir conditionor rsfrigorrnt

snd lubricsnt vtpor or mist.

lf accidental system discharge occurs, ventilate work

area before resuming service.

R-134a service equipment or vehicle 8ir conditioner sys-

tems should not be pressure tested or leak tested with

compressed ait.

!@ somo mixtuto3 ot ril and R'134! hav.

been shown to bo combustible at olevltad prossulo3

and can re3ult in fire or explosion crusing inlurY or

property damago, Navor us! comprossod air to prgsauro

test R-13/aa 3orvicr €quipmlnl or vohiclo air conditionol

sy3lems.

Additional health and safety information may be ob-

tained from the retrigerant and lubricant manufactures.

1. When an Ay'C System has been opened to the atmo-

sDhere, such as during installation or repair, it must

be evacuated using a R-134a refrigerant Recovery/

Recycling/Charging System. {lf the system has been

open for several days, the receiver/dryer should be

replaced.l

2. Connect a R-134a refrigerant Recovery/Recycl-

ing/Charging System to the car, as shown, follow-

ing the equipment manufacturer's instructions.

NOTE; lf tow pressure does not reach more than

93.3 kPa (700 mm Hg, 27.6 in'Hg) in 15 minutes,

there is probably a leak in the system. Partially

charge the system and check tor leaks {see Leak

Test).

R.cov.ry/R.cycling/Chtroing Syttom

PRESSUREaotnSIDE

2234

Page 1105 of 1413

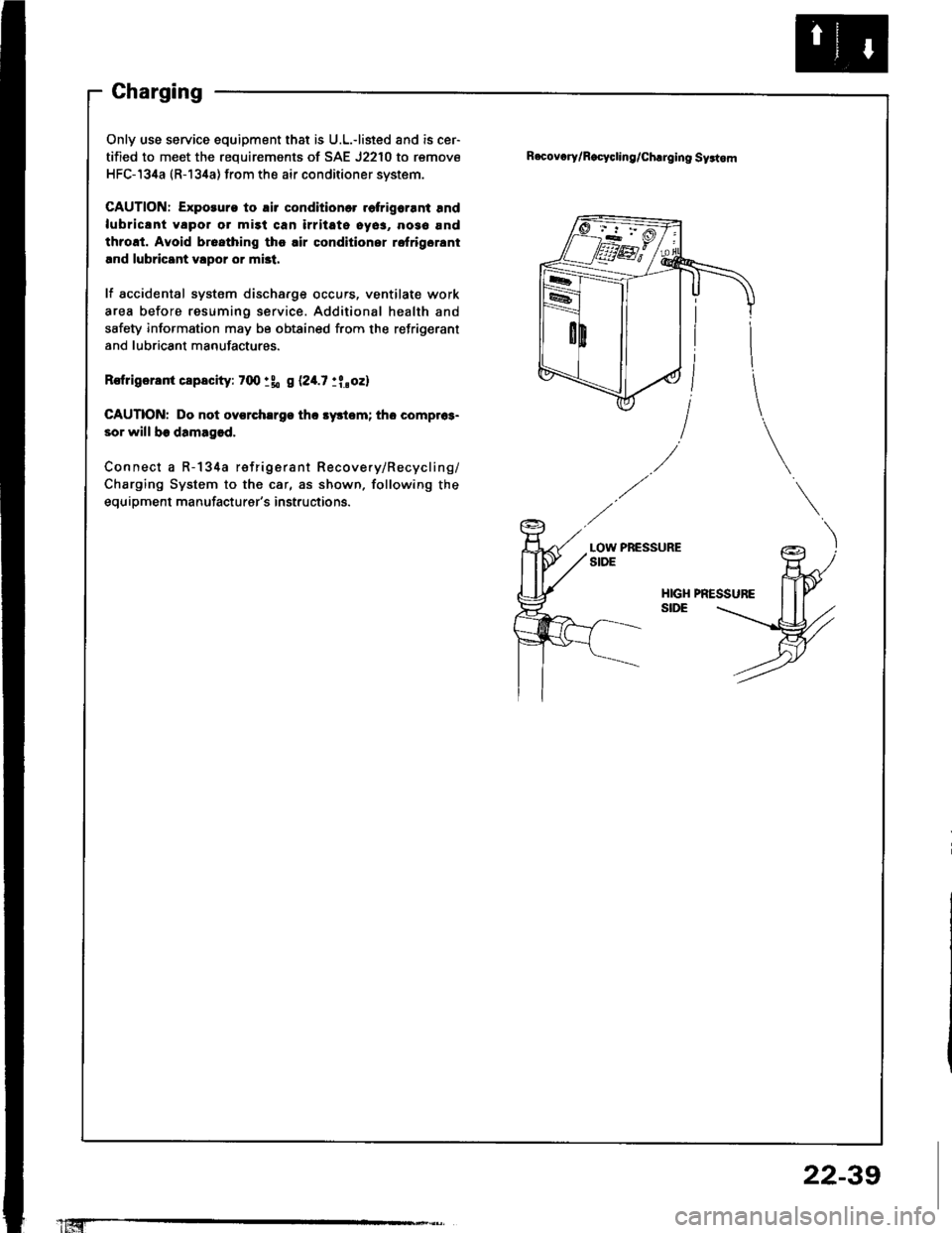

Charging

Only use service equipment that is U.L.-listed and is cer-

tified to meet the requirements of SAE J2210 to remove

HFC-134a (R-134a) from the air conditioner svstsm.

CAUTION: Exporuro to rir conditionor .etrigorant and

lubric8nt yapor or misl can irritats cyos, no36 and

throlt. Avoid broathing tho lir conditionor rofrig6rant

lnd lubricant vlpor or mbt,

It accidental system discha.ge occurs, ventilate work

area before resuming service. Additional health and

safety information may be obtained from the refrigerant

and lubricant manufactures.

Rofrigerant capacity: f00:3n g (24.7:l,oz)

CAUTION: Do not ovorchlrgo thc syrtem; tho compr6s-

sor will be damagad.

Connect a R-134a refrigerant Recove.y/Recycling/

Charging System to the car, as shown, following the

equipment manufacturer's instructions.

R.cov.rylRccacling/Ch.rging Syrtom

22-39

Page 1106 of 1413

A/C System Service

Leak Test

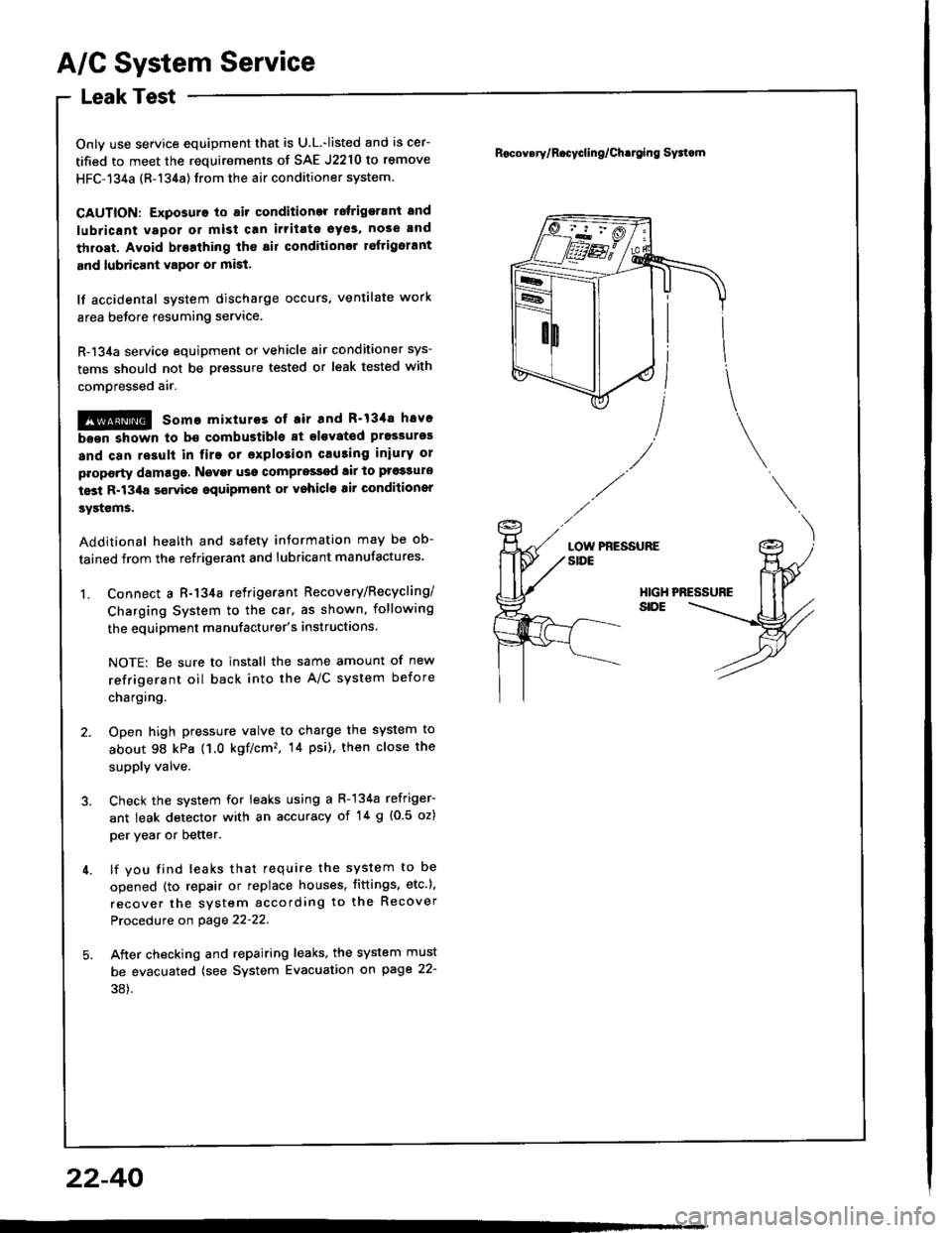

Only use service equipment that is U.L.-listed and is cer-

tified to meet the requirements of SAE J2210 to remove

HFC-134a (R-134a) from the air conditioner system.

CAUTION: Exposura to air condition ratrigerant and

lubaicant vapor or mist can irritato oyes. nose and

throat. Avoid br€athing tho sir conditionsr reftigolant

and lubricant vapor or mist.

lf accidental svstem discharge occurs, ventilate work

area before resuming service.

R-134a service equipment or vehicle air conditioner sys-

tems should not be pressure tested or leak tested with

comoressed air.

@ some mixturos ot air and R'13'la have

b.6n shown to b€ combustible at glsvated pressur€s

and can result in firo or sxplo3ion causing iniury or

proporty damage. Ngvar uso compress€d tir to pro33ure

tost R-134a $rvics oquipmont or vohicl€ air Gonditionsr

systcms.

Additional health and satetY information may be ob-

tained from the refrigerant and lubricant manufactures'

1. Connect a R-134a retrigerant Recovery/Recycling/

Charging System to the car. as shown, following

the equipment manufacturer's instructions.

NOTE: Be sure to install the same amount of new

refrigerant oil back into the A/C system before

chargtng.

2. Open high pressure valve to charge the system to

about 98 kPa (1.0 kgf/cm'�, 14 psi), then close the

supply valve.

3. Check the system for leaks using a R-134a refriger-

ant leak detector with an accuracy of '!4 g {0.5 oz)

per year or better.

4. lf you find leaks that require the system to be

opened (to repair or replace houses, fittings, etc.),

recover the system according to the Recover

Procedure on page 22-22.

5. Aiter checking and repairing leaks, the system must

be evacuated (see System Evacuation gn page 22-

38).

Rocov.ry/R.cycling/Ch.tging Sy3tcm

LOW PRESSURESIDE

HIGHSIDE

22-40

Page 1107 of 1413

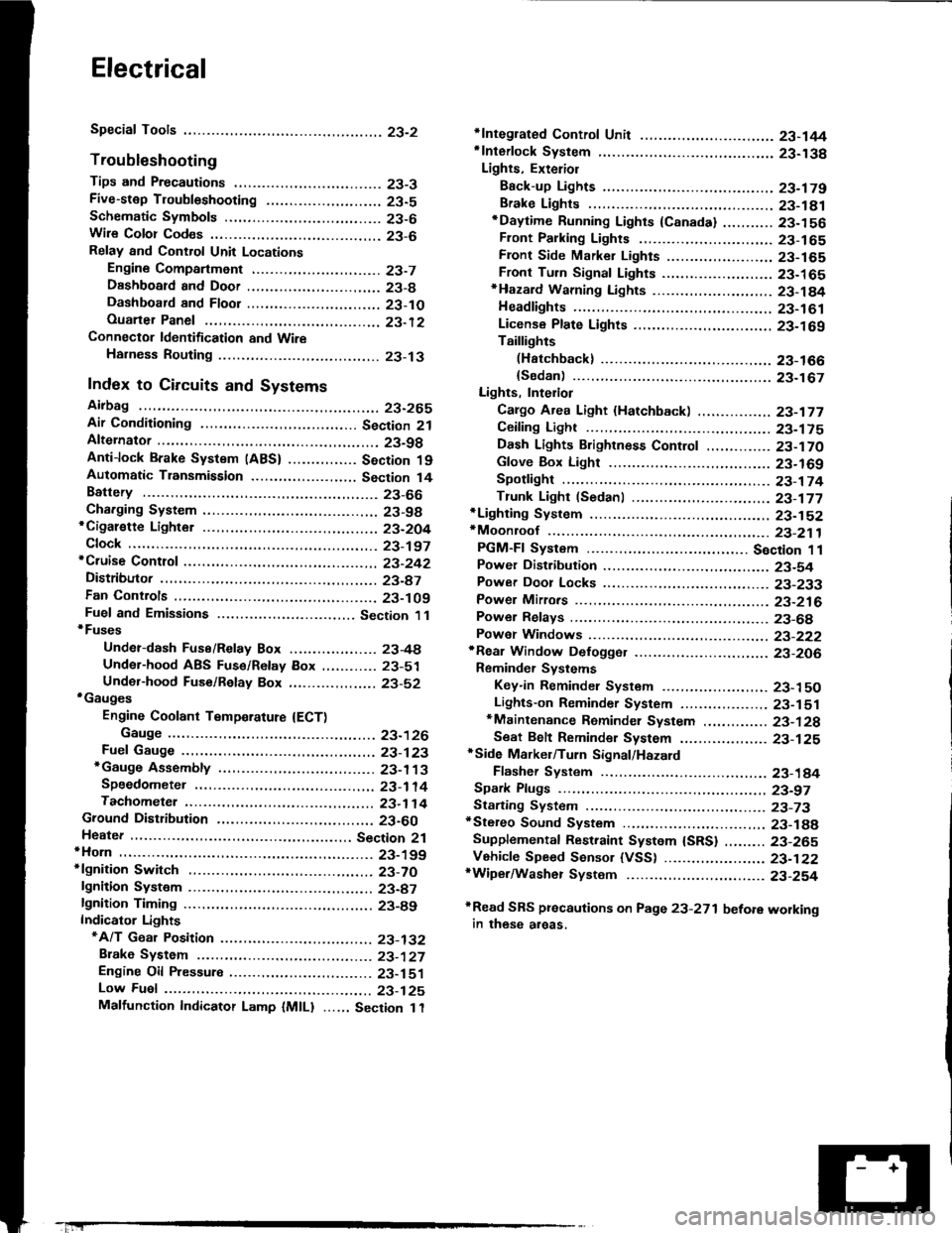

Electrical

Special Tools

Troubleshooting

Tips and Precautions ................................ 23-3Five-stop Tloubleshooting ..............,...-..-... Z3-sSchematic Symbols ................................_. 23-6wire Color Cod€s ..................................... 23-6Relay and Control Unit Locations

Engine Compartment .........,............ ... --. 23-7Dsshboard and Door ..,,......................... 23-gDashboard and Floor ............................. 23-t OOuaner Panel .....-.....23-12Connector ldentification and WireHarness Routing ........ 23-i 3

Index to Circuits and Systems

Airbag ............... ...-..-... 2g-26sAir Conditioning ....,.. Section 2lAltelnator ......_.............. 23-99Anti-lock Brake Systsm (ABS) Section 19Automatic Transmission Section 14Battery .............. .......... 23-66Chafging System ........... 23-98rCigalstte Lighter .....................-...-......-..-.. Z3-2O4Cfock ................. ..........23-197rcruise Controf .......--..-... 23-242Distributor .................... 23-87Fan Controls ................. 23-1ogFuel and Emissions ... Section 1i*Fuses

Under-dash Fuse/Relay Box ................... 23-48Undor-hood ABS Fuse/Retay Box ............ 23-51Under-hood Fuse/Relay Box,.................. 23-52rGauges

Engine Coolant Temperature {ECT)Gauge ................ ..23-126Fuef cauge ............... 2g-123'Gauge Assembly ....--.23-113Speedometer .....-...,,. 23-114Tachometer .....,.....-.. 23-114Ground Distribution ........ 23-60Heater ,,,........,.... ..... Section 2lrHorn ................. ........... 23-199*fgnition Switch ............. 23-70fgnition Syst6m .......-..-.. 23-A7lgnition Timing .............. 23-89Indicator Lights"A/T Gear Position .............. ................... 23-1 32B1ak6 System ...,..,..-.23-127Engine Oil Pressura .............................. _ 23-1 51Low Fuel ............ ......23-125Malfunction Indicator Lamp {MlL} ...,,. Section I l

tfnteglated Control Unit ...29-144*lnterlock System ...................................... 23-1 3gLights, Exteriol

Back-up Lights ........... 23-179Brake Lights .............. 23-t8ltDaytime Running Lights {Csnada} ........... 23-156Front Palking Lights ............................. 23-1 65Flont Side Marker Lights ....................... 23-165Front Turn Signal Lights ........................ 23-1 65*Hazard Warning Lights .........................- 2g-1A4Headlights ................. 23-t6tLicense Plate Lights .............................. 23-1 69Taillights(Harchback) .......... 23-166

{Sedan) .............. .. 23-167Lights. Inteliol

Cargo Area Light {Hatchback) ...... -.. -.. -... 23-177Ceifing Light ........-..-.23-175

Dash Lights Blightness Controt .............. 23-t70Glove Box Lighr ................................... 23-1 69Spotfighr ............ ....-.23-174Trunk Light (Sedanl ............... .............. - 23.-177*Lighting Sysrem .......-.-... 23-152:Moonroof ,,.,.......,..,,,,,.-.23-211PGM-FI Systom ........ S€crion 11Power Distribution .,.-..--..23-54Power Door Locks .............,,..................... 23-233Power Mirors ..,..,....-...- 23-216Power Relays ...........,..... 23-68Power Windows ............ 29-222*Rear Window Defogger ........,... ..........,..... - 23-20,6Reminder Systems

Key-in Remindel System ....,.............,.... 23-1 50Lights-on Reminder System ................... 23-l 5f*Maintenance Reminder system ..,,.... -.. - -. 23-.1 2gSeat Belt Reminder System ..................- 23-125*Side Markel/Turn Signal/Hazard

Ffasher System .,..,..-.23.-1A4Spark Pfugs .........-...-..... 23-97Starting System ....,,.....-. 23-73*Stereo Sound System ...,.......................,,.. 23-l gg

Supplemental Restraint System {SRS} ......... 23-265Vehicfe Speed Sensor {VSS) .............--..-.... 23-122*Wiper/Washer Systom ...............--.........-..- Zg-254

rRead SRS pi€cautions on Page 23-271 betore workingin these areas.

-+

Page 1108 of 1413

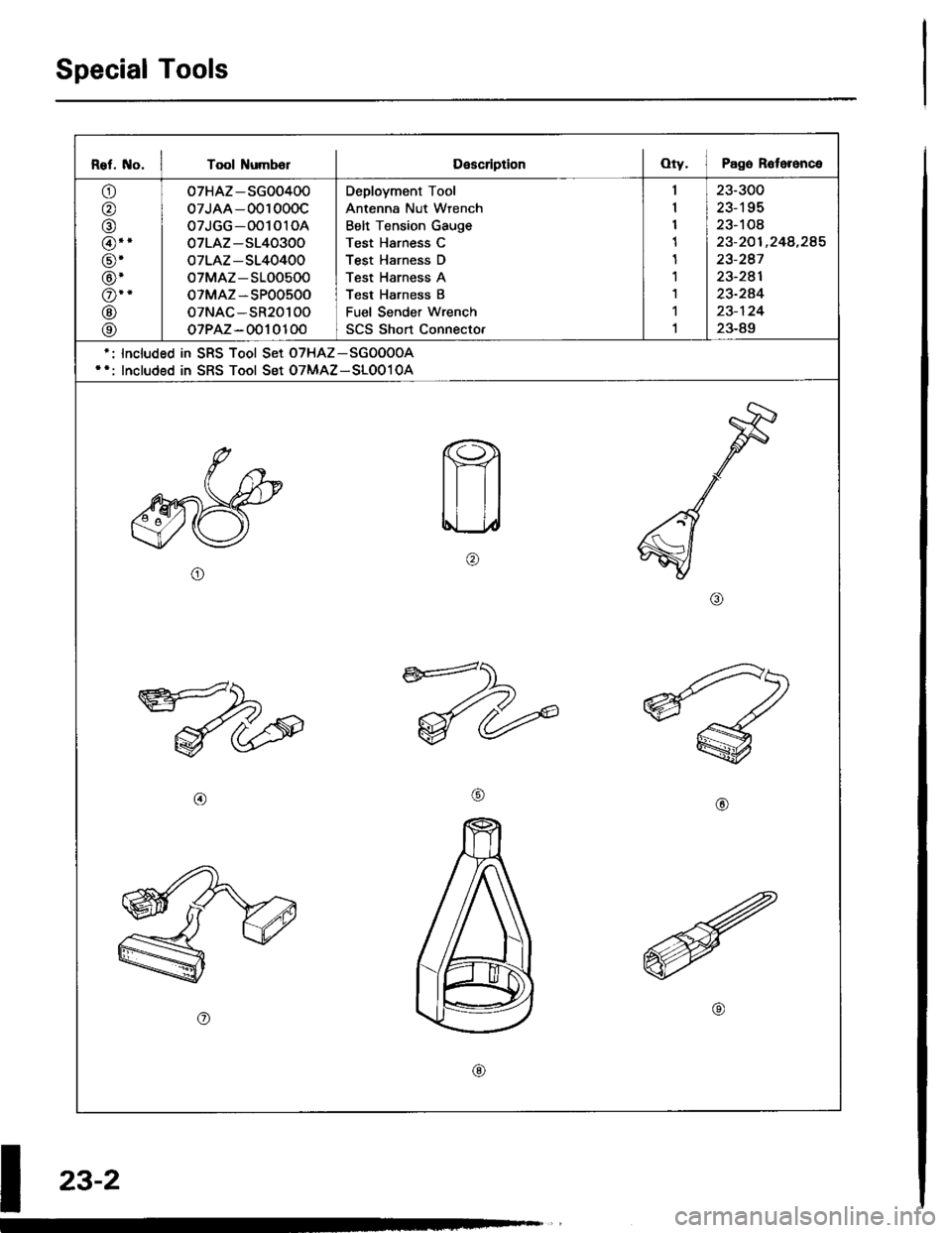

Special Tools

Rel. No. I Tool NumbolDescriptionOty. I Pago R6toronce

o

o

@

@.'

@'

@'

o--

@

@

07HAZ-SG00400

07JAA-001000c

07JGG-001010A

07LAZ-S140300

oTLAZ-S140400

oTMAZ-S100500

oTMAZ-SP00500

oTNAC-SR20100

oTPAZ-0010100

Deployment Tool

Antenna Nut Wrench

Belt Tension Gauge

Test Harness C

Test Harness D

Test Harness A

Test Harness B

Fuel Sender wrench

SCS Short Connecto.

23-300

23-195

23-108

23-201 ,248,285

23-247

23-241

23-244

23-124

23-89

lncluded in SRS Tool Set oTHAz-SGoOooA

Included in SRS Tool Set OTMAZ-SLOo10A

o

@@

o

@

I

z3-2

Page 1109 of 1413

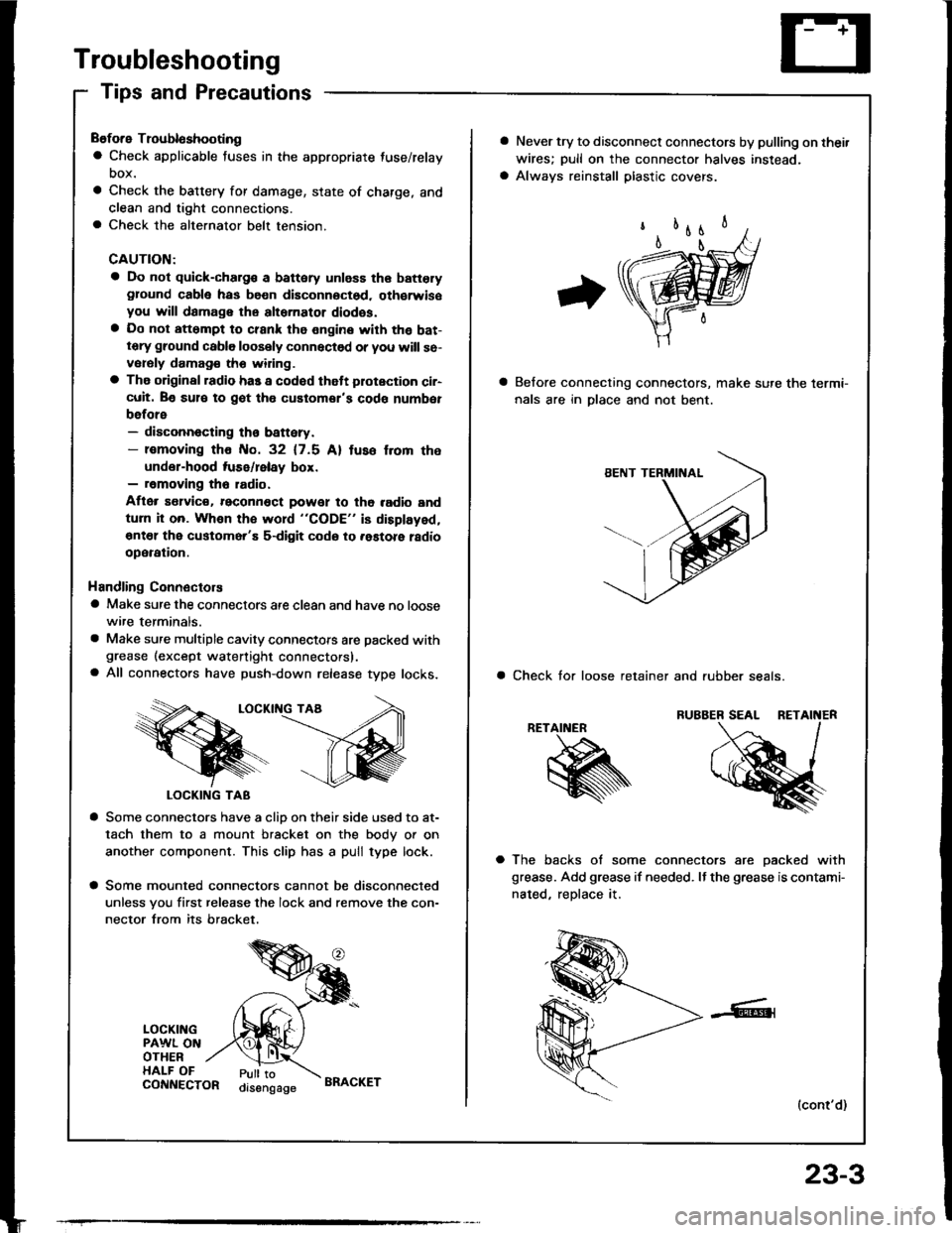

Troubleshooting

Tips and Precautions

Before Troubloshooting

a Check applicable fuses in the appropriate fuse/relay

DOX.

a Check the battery for damage, state of charge, and

clean and tight connections.a Check the alternator belt tension.

CAUTION:

a Do not quick-charg€ a battery unless the batteryground cabla has be€n disconnoctsd. oth€rwisoyou will damage the alternator diodss.a Do not att6mpt to crank the engine with the bat-tery ground cable loosely connectsd or you will se-vorsly damag€ tho widng.

a The original radio has a codod thatt plotection ci.-cuit. Be sul€ to got tho customor's code numbet

before- disconnecting th€ battery.- lomoving tho No. 32 (7.5 Al tuso f.om the

under-hood tuse/lelay box.- removing tho radio.

Aflor s€lvic€. reconn€ct powet to tho radio and

turn it on. Whon the word "CODE" is displayed,

€nt€l the customer'E s-digit codo to .astore ladio

operation.

Handling Connectors

a Make sure the connectors are clean and have no loose

wire terminals.

a Make sure multiple cavity connectots are packed withgrease (except watertight connectors).a All connectors have push-down release type locks.

LOCKII{G TAA

LOCKING TAB

a Some connectors have a clio on their side used to at-

tach them to a mount bracket on the body or on

another component. This clip has a pull type lock.

a Some mounted connectors cannot be disconnected

unless you first release the lock and remove the con-

nector from its bracket.

LOCKINGPAWL ONOTHERHALF OFPull toorsengageCONNECTORBRACKET

23-3

a Never try to disconnect connectors by pulling on thei.

wires; pull on the connector halves instead.

a Always reinstall plastic covers.

Belore connecting connectors, make sure the lermi-

nals are in Dlace and not bent.

a Check tor loose retainer and rubber seals.

RETAINER

a The backs of some connectors are oacked with

grease. Add grease if needed. It the grease is contami-

nated, reDlace it.

(cont'd)

Page 1110 of 1413

Troubleshooting

Tips and Precautions (cont'dl

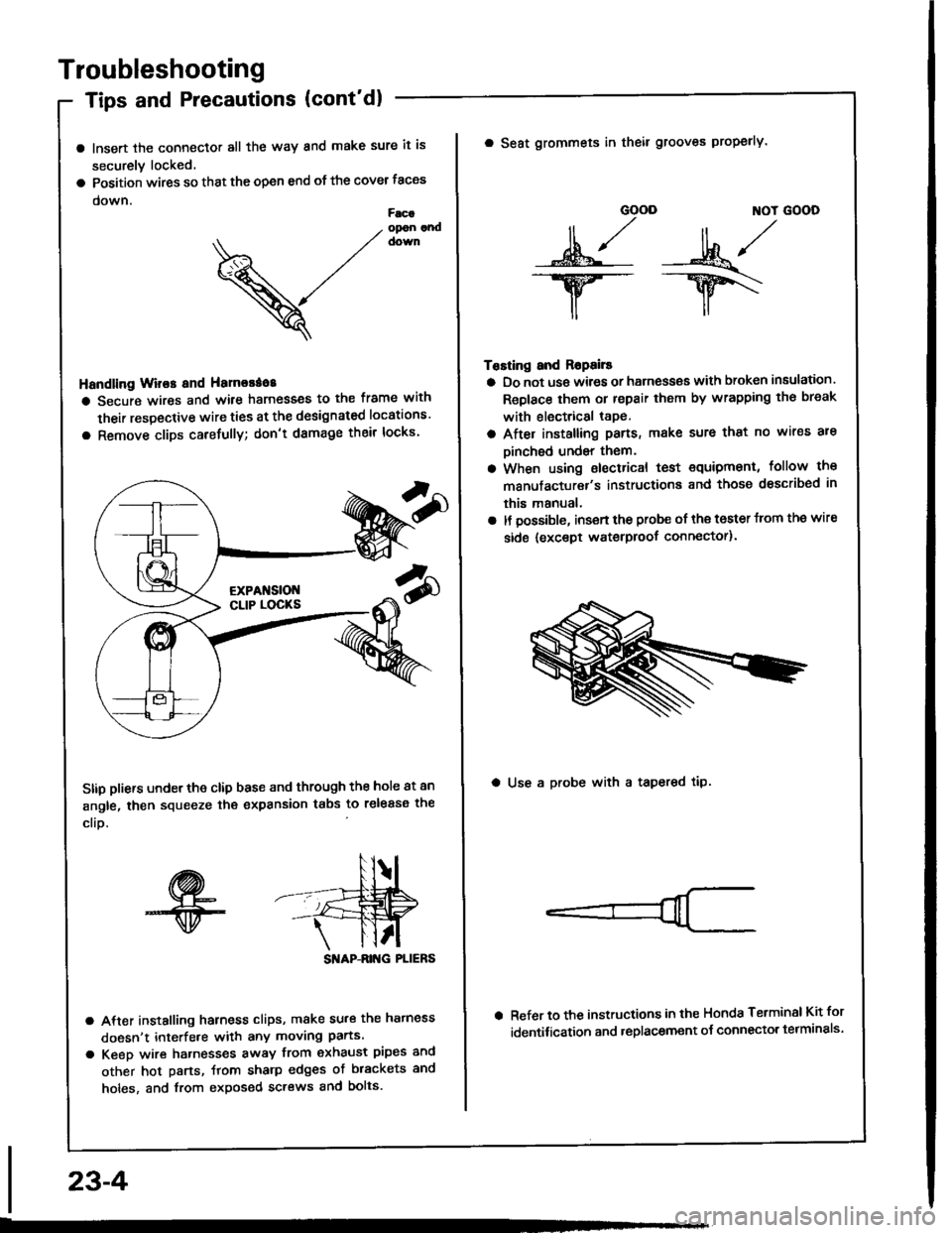

a lnsert the connector all the way and make sure it is

securely locked.

a Position wires so that the open end of the cover taces

down.Facaopon andcown

V

Handling Wir€s and Hamorao8

a Secure wires and wile harnesses to the frame with

their respective wire ties at the designated locations'

a Remove clips carefully; don't damage their locks'

Stip pliers under the clip base and through the hole at an

angle, then squeeze the expansion tabs to release the

clio.

SI'IAP-ANG PLIERS

a After installing harness clips, make su.€ the hatness

doesn't interfe.e with any moving parts.

a Keeo wire hatnesses away from exhaust pipes and

other hot parts, ftom sharp edges of brackets and

holes, and from exposed screws and bolts.

23-4

GOOD ]TOT GOOD

n,/r/ll ,,' ll ,,

s*j -:ut*/-.w-- --ry\

il,,

Tosting and Ropails

a Do not us€ wires or harness€s with broken insulation.

Replace them or repair them by wrapping th€ break

with electrical tape.

a After installing pans, make sure that no wir€s are

Dinched undsr them.

a When using electrical test €quipment, follow the

manufacturer's instructiona and those dsscribed in

this manual,

a It possible, insert the probe of the toster from the wire

side {except waterproof connector).

a Seat grommets in theil grooves properly.

a Use a probe with a tapered tip.

Refer to the instructions in the Honda Terminsl Kit for

identification and .eplacement o{ connector telminals'