section 23 HONDA INTEGRA 1994 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 1308 of 1413

Horn

SwitchTest(cont'd)

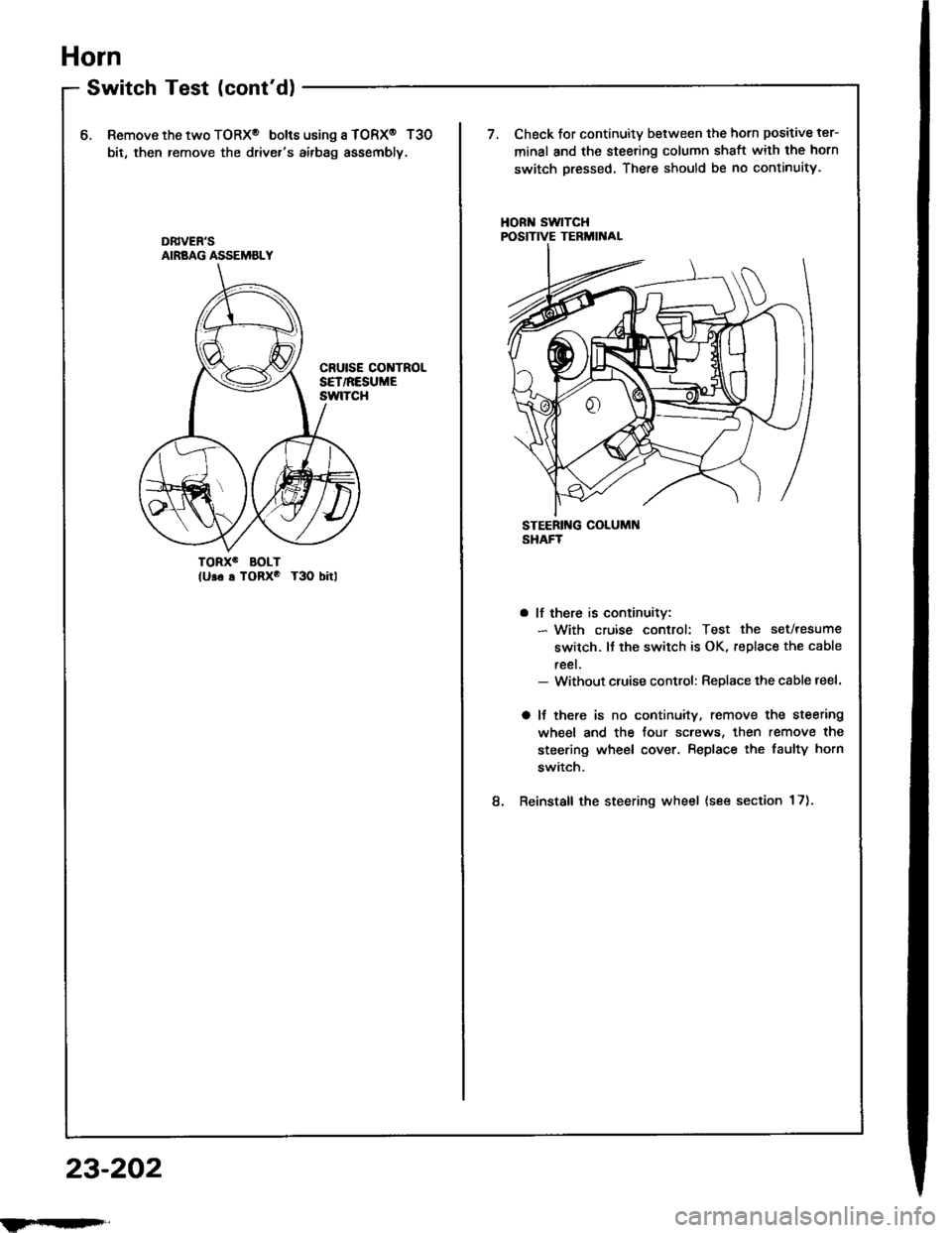

6.Remove the two TORX@ bolt6 using a TORX@ T30

bit, then remove the driver's airbag assembly.

Check for continuity between the horn positive ter-

minal and the steering column shaft with the horn

switch pressed, There should be no continuity.

HORN SwlTCHPOSITIVE TERMIITAL

TORXO BOLT(U!6 s TORxo T3O bitl

8.

a lf there is continuitv:- With cruise control: Test the set/resume

switch. lJ the switch is OK, replace the cable

reel.- Without cluise control: Replace the cable reel.

a lJ there is no continuity. remove the steering

wheel and the four screws, then remove the

steering wheel cover. Replace the faulty horn

switch.

Reinstall the steering wheel {see section 17).

DB|vEN'SAIRBAG ASSEMBLY

23-202

ilFrrI|qFrl"

Page 1316 of 1413

Rear Window Defogger

Function Test

CAUTION: Be carelul not to scratch 01 damago ths

defogger wires with th€ tsster probe.

1 . Check for voltage between the positive terminal and

body ground with the ignition switch and the delog-

ger switch ON. There should be battery voltage.

a lf there is no voltage, check for

- laulty detogger relay.- faulty defogger switch.- faulty integrated control unit.- an open in the BLK/GRN wire

a lJ there is baftery voltage, go to step 2.

NEGATIVE TERMIiIALPOSITIVE TERMINAL

Turn the rear window detogger switch OFF, Check

for continuity between the negative terminal and

body ground.

a It there is no continuity, check to. an open in the

defogger ground wire.

a ll there is continuity, go to step 3.

Touch the voltmeter positive lead to the halfway

point of each defogger wire, and the negative lead

to the negative terminal.

There should be apptoximately 6 V with the ignition

switch and defogger switch ON.

a lf the voltage is as specified, the defogger wire

is OK.

a lf the voltage is not as specified. repai, the defog-

ger wire:

lf it is more than 6 V, look for the damage on

the negative half on the grid.

- lf it is less than 6 V. iook for the damage on

the positive half of the grid.

Defogger Wires Repair

NOTE: To make an eftective repair. the broken section

must be no longer than one inch.

1 . Lightly rub the area around the break with line steel

wool, then clean it with alcohol.

2. Carefullv mask above and below the broken portion

of the defogger wire with cellophane tape.

Using a small brush, apply a heavy coat of silver con-

ductive paint extending about 3 mm ( 1/8 inl on both

sides of the break. Allow 30 minutes to dry.

NOTE: Thoroughly mix the paint before use.

Check for continuity in the repaired wire.

Apply a second coat of paint in the same way.

it drv three hours betore removing the tape.

4.

OPEN

23-210

tLet

Page 1317 of 1413

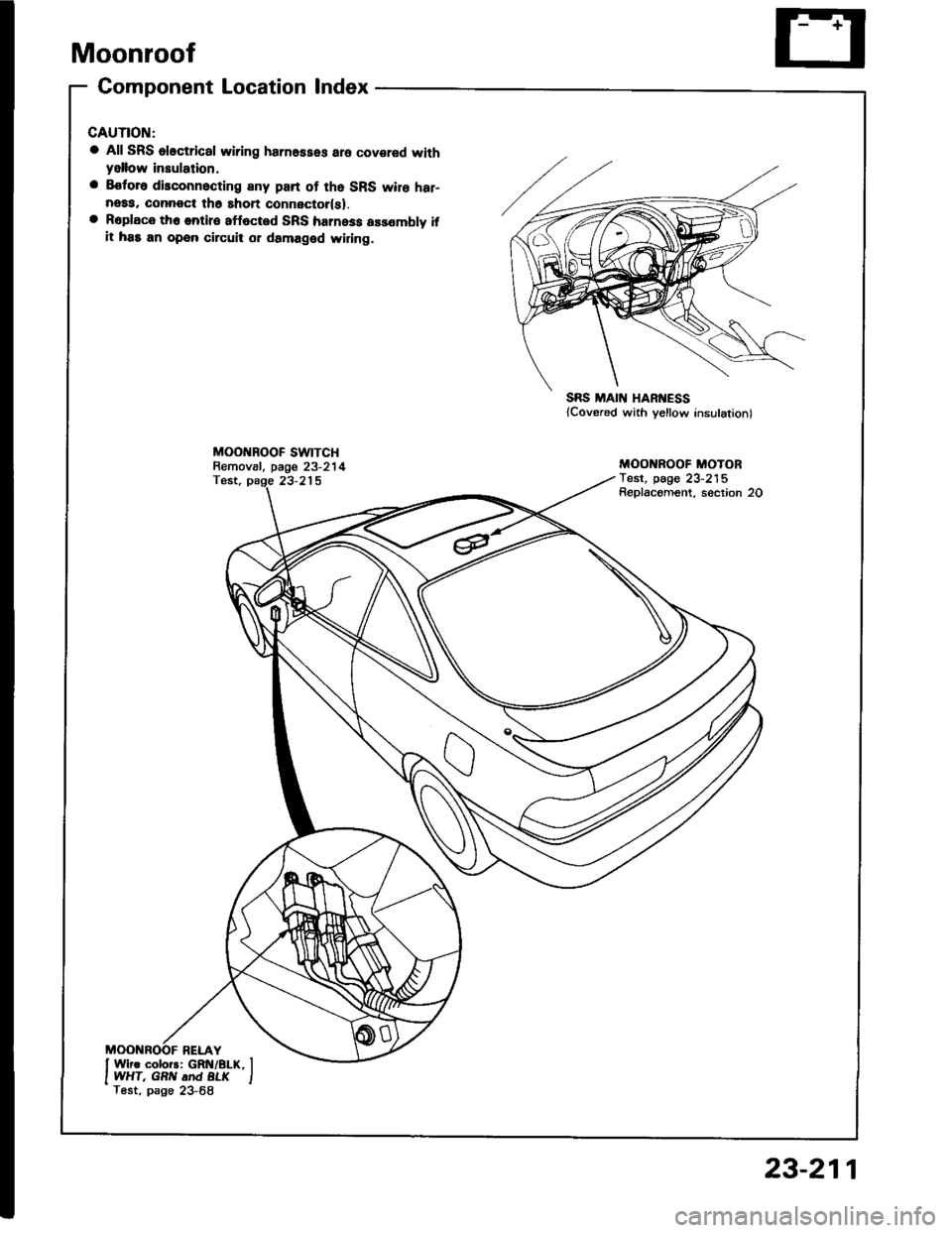

Moonroof

Gomponent Location lndex

a All SRS oloctrical wiring harnesses aro covared withyellow insulation,

a Eoforo disconnocting any part of tho SRS wire har-neaa, connoct th6 shon connector(sl.a Roplace th6 entire 8ff6cted SRS harness assombly ifit has an open circuit or damaged widng.

MOO BOOF SWTTCHRemov8l, page 23-214Test, page 23-215

SRS MAIN HARI{ESS{Covered with yellow insulation)

MOO ROOF MOTORTest, pag€ 23-215Replacoment, section 20

23-211

Page 1321 of 1413

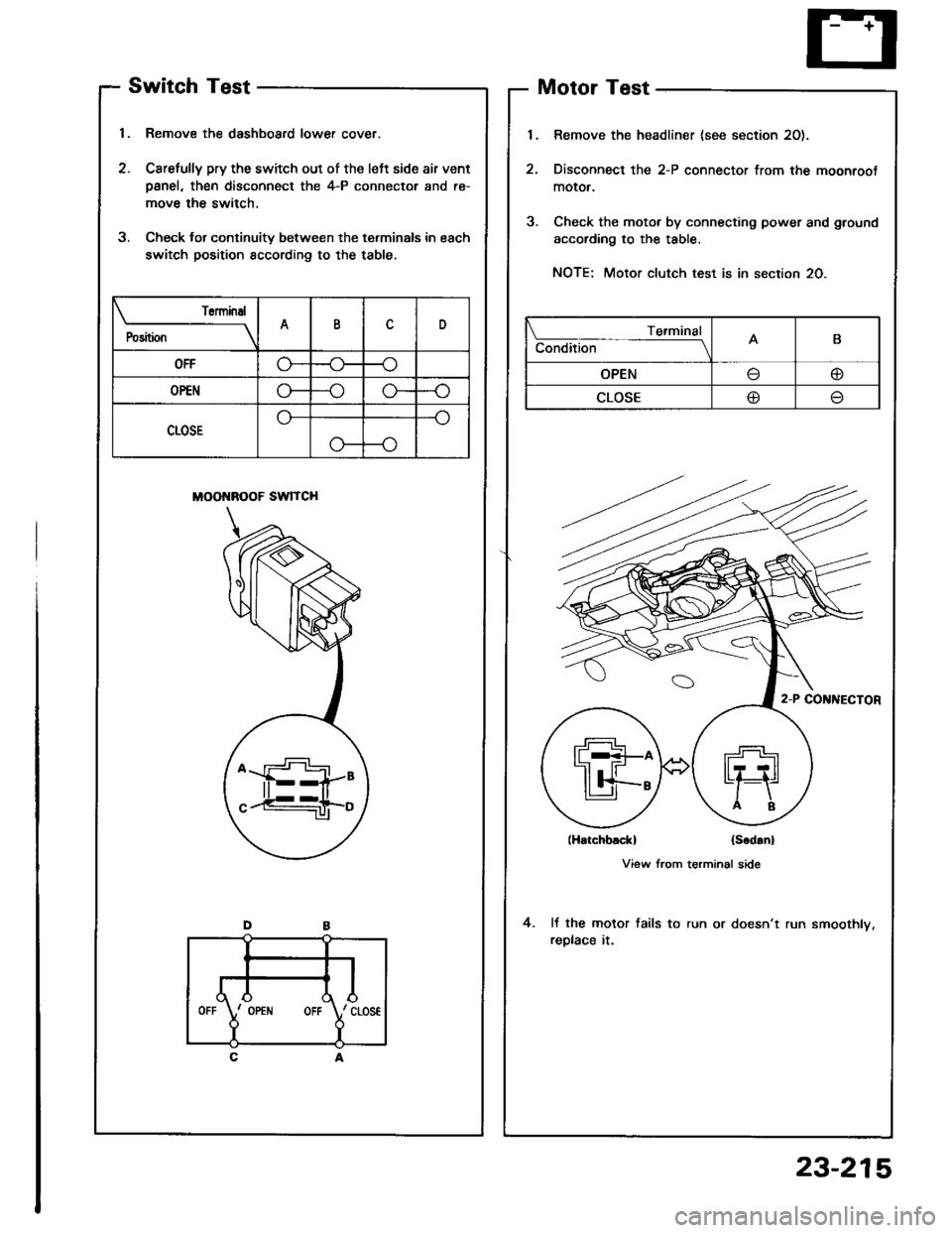

Switch Test

1, Remove the dashboard lower cover.

2. Carefully pry the switch out of the left side air vent

Danel, then disconnect the 4-P connector and re-

move the switch.

3. Check lor continuity between the terminals in each

switch position sccording to the table,

MOONROOF SWITCH

Motor Test

Remove the headliner (see section 20).

Disconnect the 2-P connector from the moonroot

moror.

Check the motor by connecting power and ground

according to the table.

NOTE: Motor clutch test is in section 20.

lHatchblckl (Scd!n)

View from terminal side

It the motor fails to run or doesn't run smoothly.

replace it.

4.

Torminal

P"ri i-

---__\AID

OFFG---o

OP€No---oG-

CLOSE

o---o

Te.minal

Condition -- ---------lAB

OPENo

CLOSE@

,l

rd\./ cLos€

Y

IOPEiIIOFF

23-215

Page 1324 of 1413

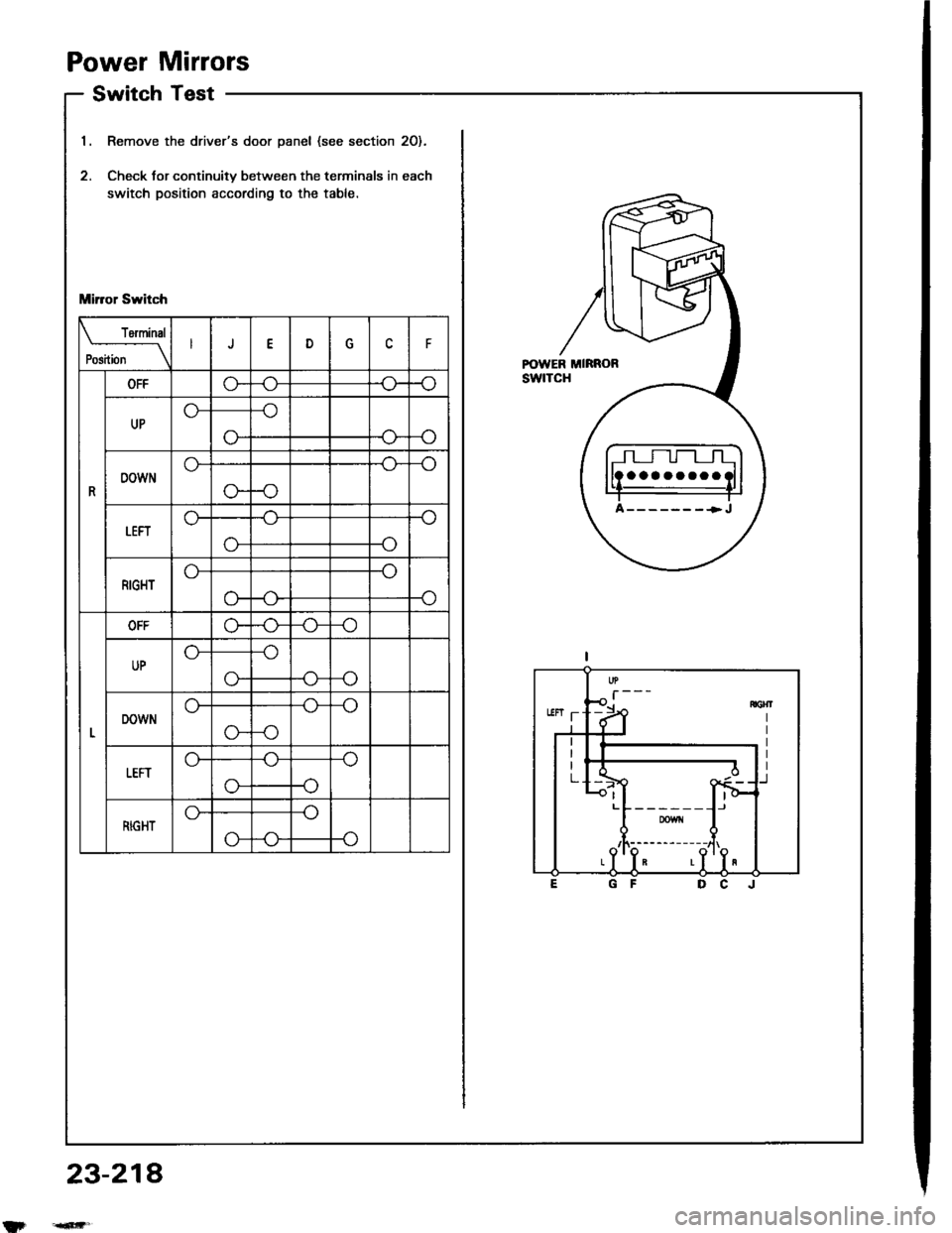

Power Mirrors

Switch Test

Remove the driver's door panel (see section 2O).

Check tor continuitv between the terminals in each

switch position according to the table.

Mirror Switch

rermrnal

Position \J

R

OFFG"

UP

-o

o--<>-

DOWN

-o

o--o

LEFTo-

-o

RIGHT

-o

o-

OFFo--o

UP

o--(J_

DOWN

-o

G--o

tEFT

-o

-o

RIGHTG-

P-o

23-214

aaaaaaaa

A-------+J

Page 1327 of 1413

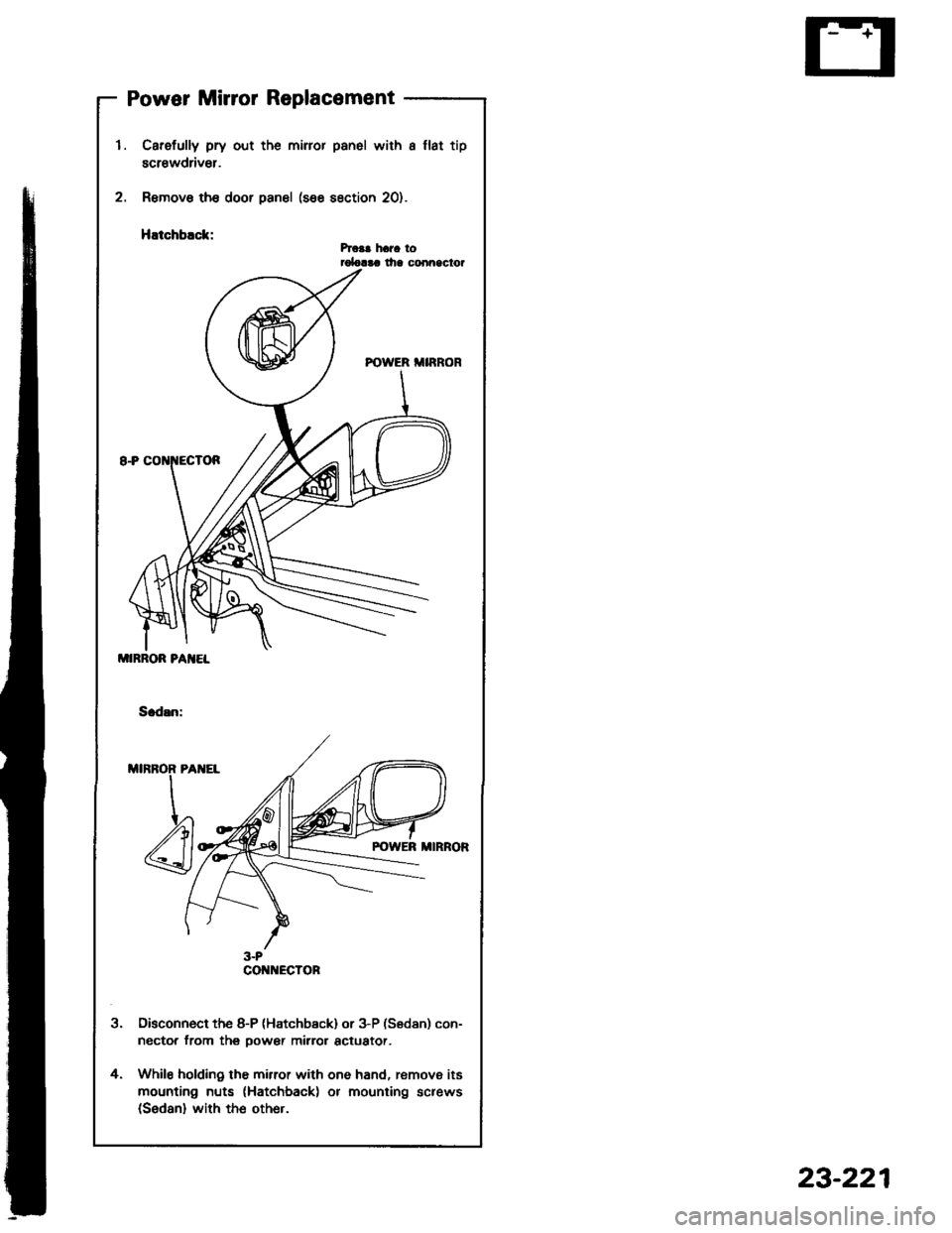

Power Mirror Replacement

2.

l.

t

Carefully pry out the miror panel with a llat tip

screwdriv€r.

Remove th€ door panel (see section 20).

HEtchblck:hca! hara torolalaa lha conn9clor

Disconnect the 8-P (Hatchb€ck) or 3-P (Sedan) con-

nector from thg oower mirror actuator.

While holding the mirror with one hand, remove its

mounting nuts (Hatchback) or mounting screws(Sedan) with the other.

4.

MIRROR PA]IEL

CO ECTOR

23-221

Page 1335 of 1413

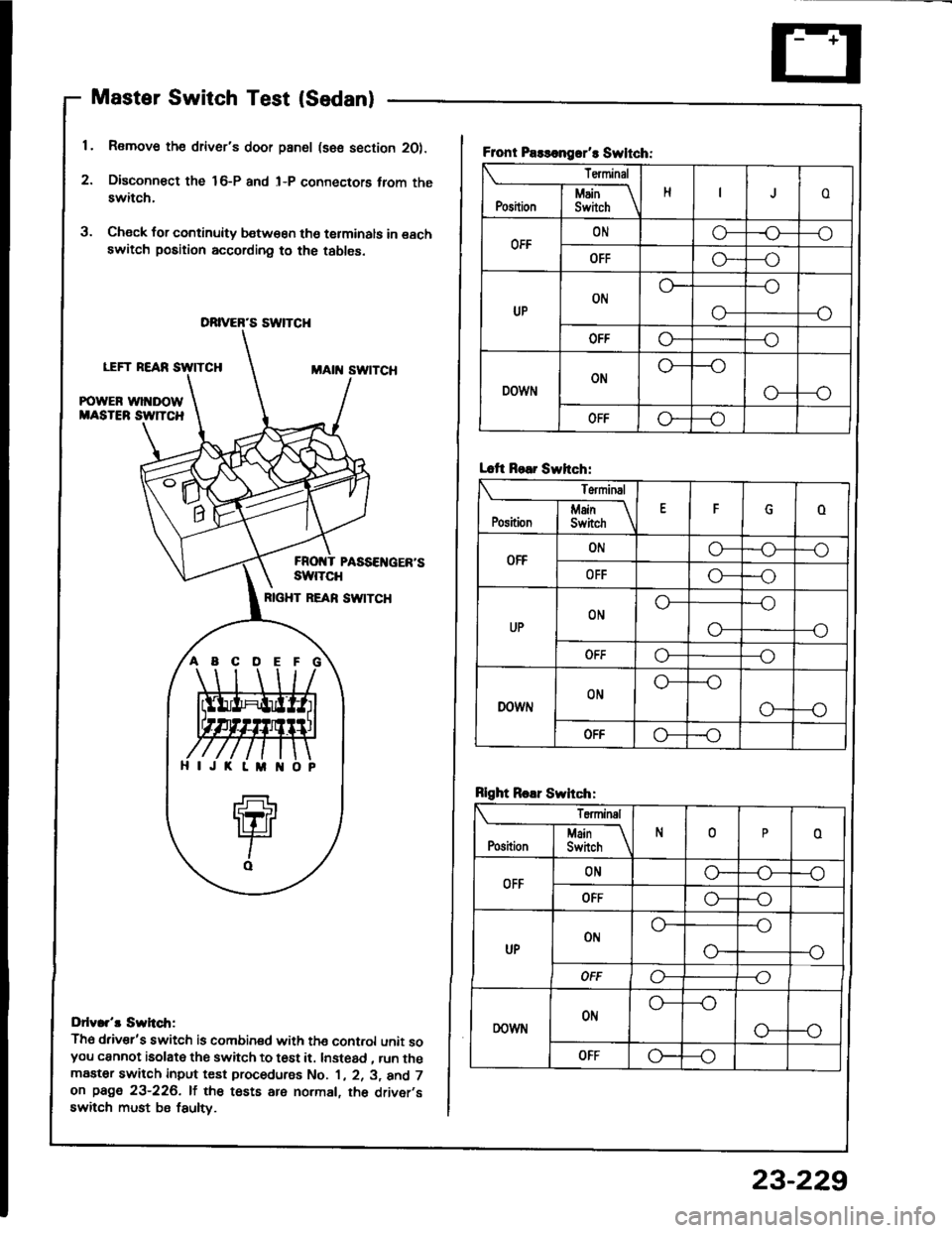

Master Switch Test (Sedan)

1. Remove the driver's door pan6l (sse section 2O).

2. Disconn€ct the 16-P and l-P connectors trom theswitch.

3. Check for continuity b€tw€€n tho terminals in eachswitch position according to the tables.

LEFT REARMAtit swtTcH

POWER wl DOWMASTEB SW]TCH

PASSEI{GER'SswtTcH

RIGHT REAN SW|TCH

Ddv.r't Swh.tr;

Th6 driv€r's switch is combined with the cont.ol unit soyou cannot isolate the switch to t6st it. Instead , run themaater switch input test procedurss No. 1 , 2. 3, and 7on page 23-226. lf the tests are normal, th6 driver,sswitch must be fsulty.

DRIVER'S SWTCH

ABCDE

Front Paslongrr't Swltch:

Terminal

HoI Main \Position I Swirch \

OFFONo-r)--o

OFFG----o

UPON

--o

O-

OFFo---o

DOWNON

o---o

OFFo--_o

Lcft Rear Swhch:

Terminal

EFoj Main IPosition I Switch \

OFFONo-o--o

OFFo---o

UPONo---o

--oo-

ut'fo---o

DOWNONo---o

G---o

OFF-o

Rlght Roar Swhch:

Teminal

N0oI Main If

Position I Switch \

OFFONG_o--o

OFFo---o

UPot'lo---o

--o

OFFo----o

DOWNONo---o

o--o

OFFG---o

23-229

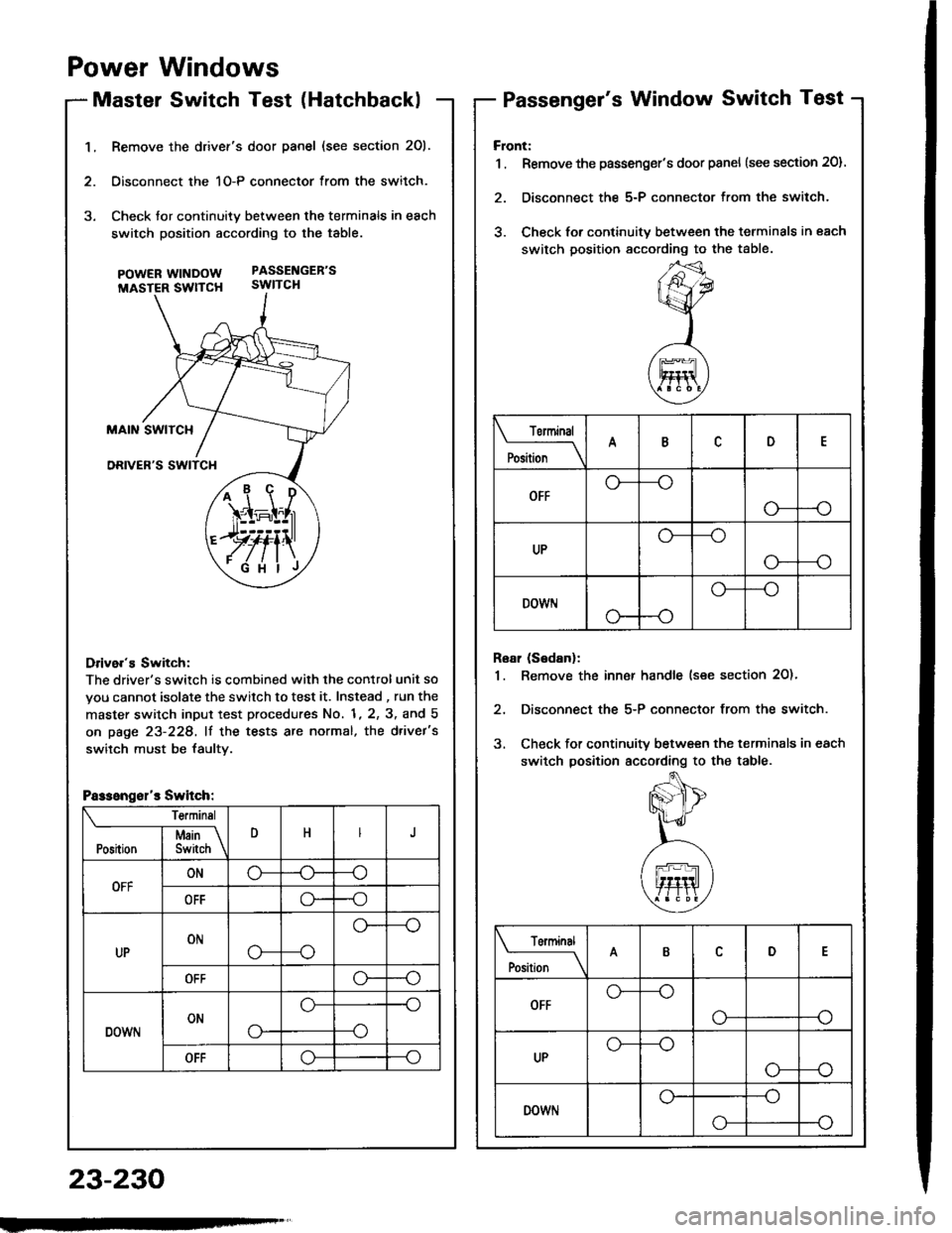

Page 1336 of 1413

1.Remove the drivef's door panel (see section 201.

Oisconnect the 1O-P connector from the switch.

Check tor continuity between the terminals in each

switch position according to the table.

pOWERWTNDOW PASSENGEB'S

MASTER SWTTCH SWITCH

Drive.'s Switch:

The driver's switch is combined with the control unit so

you cannot isolate the switch to test it. Instead , run the

master switch input test procedures No. 1, 2, 3, and 5

on page 23-228, lf the tests are normal, the d.ivet's

switch must be faultv.

i1\i

\4r-I^l,r

)rvti\

.Fi'ilj

Passengsl'r Switch:

Te.minsl

DHJI Msin \Position I Switch \

OFFONo-(J--o

OFFo--o

UPONo---o

o--

OFFo--o

DOWNONo-

o--o

--o

OFFo--o

Power Windows

Master Switch Test (HatchbacklPassenger's Window Switch Test

23-230

Front:

1 . Remove the passenger's door panel {see section 20).

2. Disconnect the 5-P connector from the switch.

3. Check for continuity between the terminals in each

switch position sccording to the table.

Rear (Sedanl:

1. Remove the inn€r handle (see section 2O)'

2, Disconnect the 5-P connector from the switch.

3. Check for continuity between the terminals in each

switch position according to the table.

Torminal

il;_\

ARD

OFFo-

--o

UPo---o

G_--o

DOWr.lo---o

Terminal

;;__\ID

OFFG_--o

o---o

UPG_--o

o---o

DOWNo---o

o-

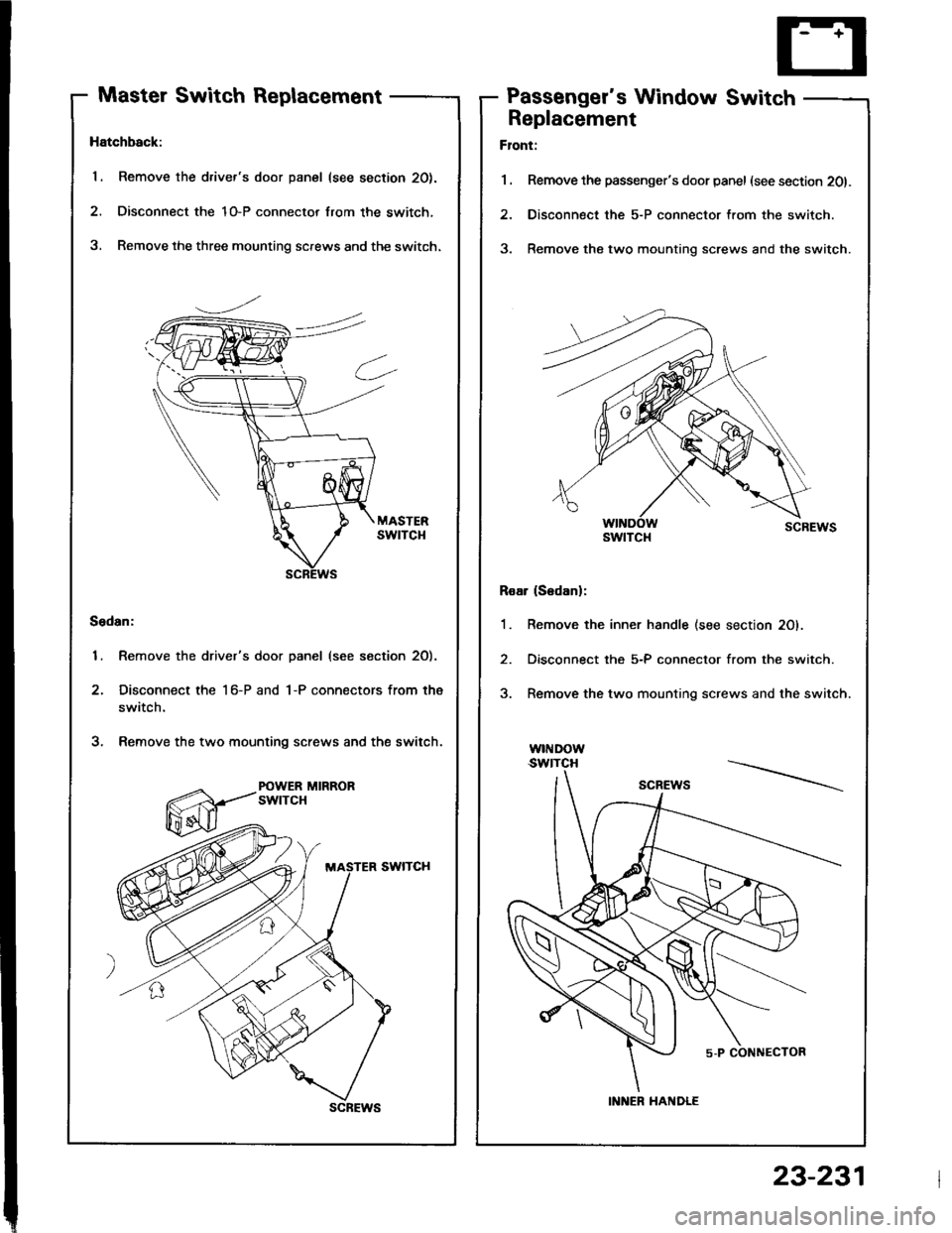

Page 1337 of 1413

Master Switch ReplacementPassenger's Window Switch

Hatchback:

1. Remove the driver's door panel (see section 20).

2. Disconnect the 1O-P connector lrom the switch,

3, Remove the three mounting screws and the switch.

Sedan:

1. Remove the driver's door panel (see section 2O).

2. Disconnect the 1 6-P and 1-P connectors from the

switch.

3. Remove the two mounting screws and the switch.

POWER MIRRORswtTcH

scREws

Replacement

Flont:

1 . Remove the passenger's door panel (see section 201.

2. Disconnect the 5-P connector from the switch.

3. Remove the two mounting screws and the switch.

Roar (S6danl:

1. Remove the inner handle (see section 20).

2. Disconnect the 5-P connector from the switch.

3. Remove the two mounting screws and the switch.

w|I{Dow.swtTcH

swtTcl{

INNER HANDLE

23-231

Page 1338 of 1413

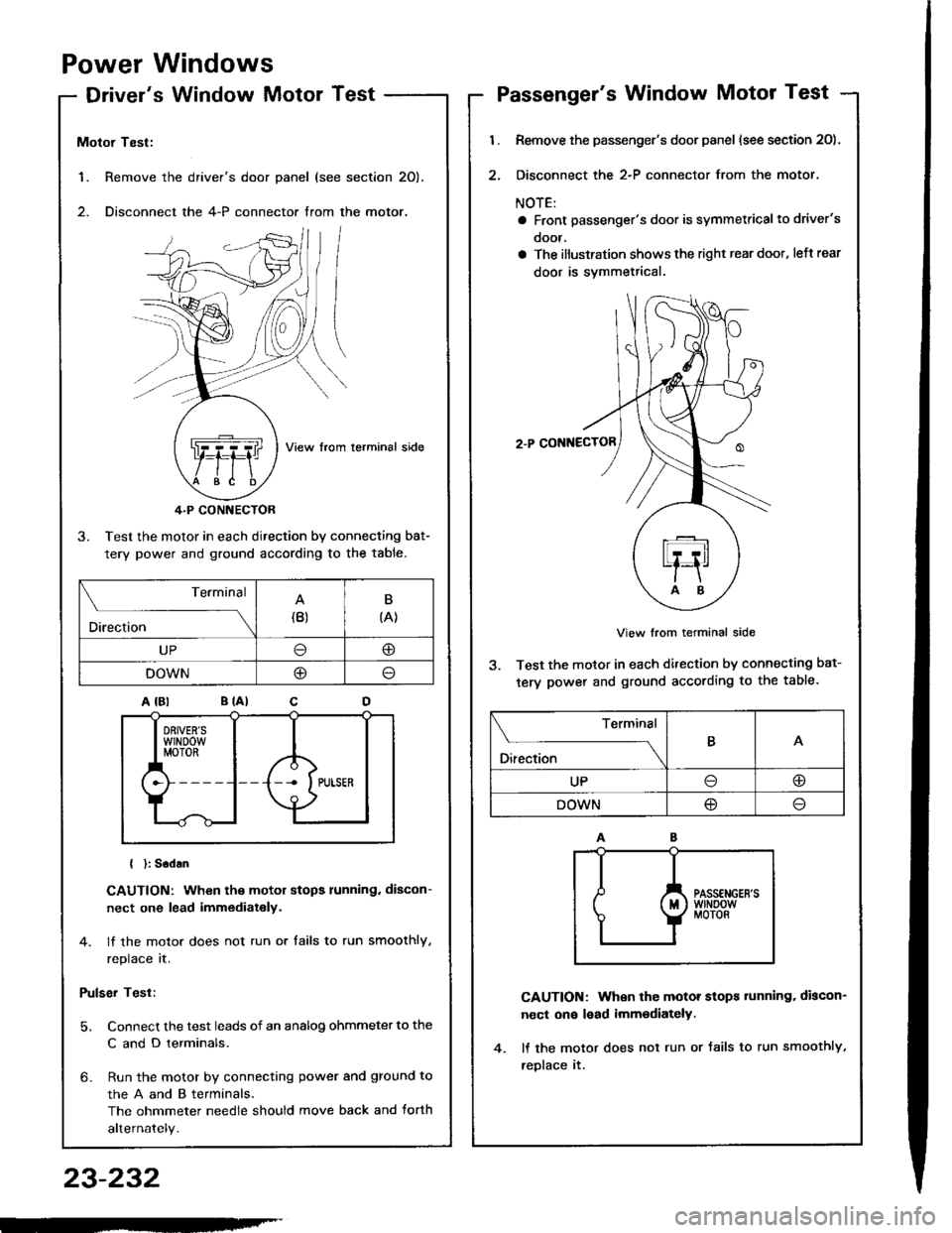

Power Windows

Driver's Window MotorTest

1. Remove the

2. Disconnect

Motor Test:

View from lerminal side

4.P CONNECTOR

3. Test the motor in each direction by connecting bat-

tery power and ground according to the table.

{ }: Sodan

CAUTION: When the motor stops running. discon-

nect one lead immediately.

4. lf the motor does not run or tails to run smoothly,

replace it.

Pulser Test:

5. Connect the test leads of an analog ohmmeter to the

C and D terminals.

6- Run the motor by connecting power and ground to

theAandBterminals,

The ohmmeter needle should move back and torth

alternately.

driver's door panel (see section 20).

the 4-P connector trom the motor.

. ,-,.f,/l l/

NZJI I

..Q]qql ,fiftl I

$e /tE \

Terminal

Direction(B)B

{A}

UP@

DOWNO

Passenger's Window Motor Test

l.

2.

Remove the passenger's door panel (see section 20).

Disconnect the 2-P connector from the motor.

NOTE:

a Front passenger's door is symmetricalto driver's

ooor.

a The illustration shows the right rear doot, left rear

door is svmmetrical.

2.P CONNECTOR

View from terminal side

3. Test the motor in each direction by connecting bat-

tery power and ground according to the table.

CAUTION: When the motor stops tunning. discon-

nect on€ lead imm€diately.

lf the motor does not run or Jails to run smoothly,

reDlace it.

Terminal

O*** \

BA

UPoo

DOWN@

23-232

-'