section 23 HONDA INTEGRA 1994 4.G Manual PDF

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 619 of 1413

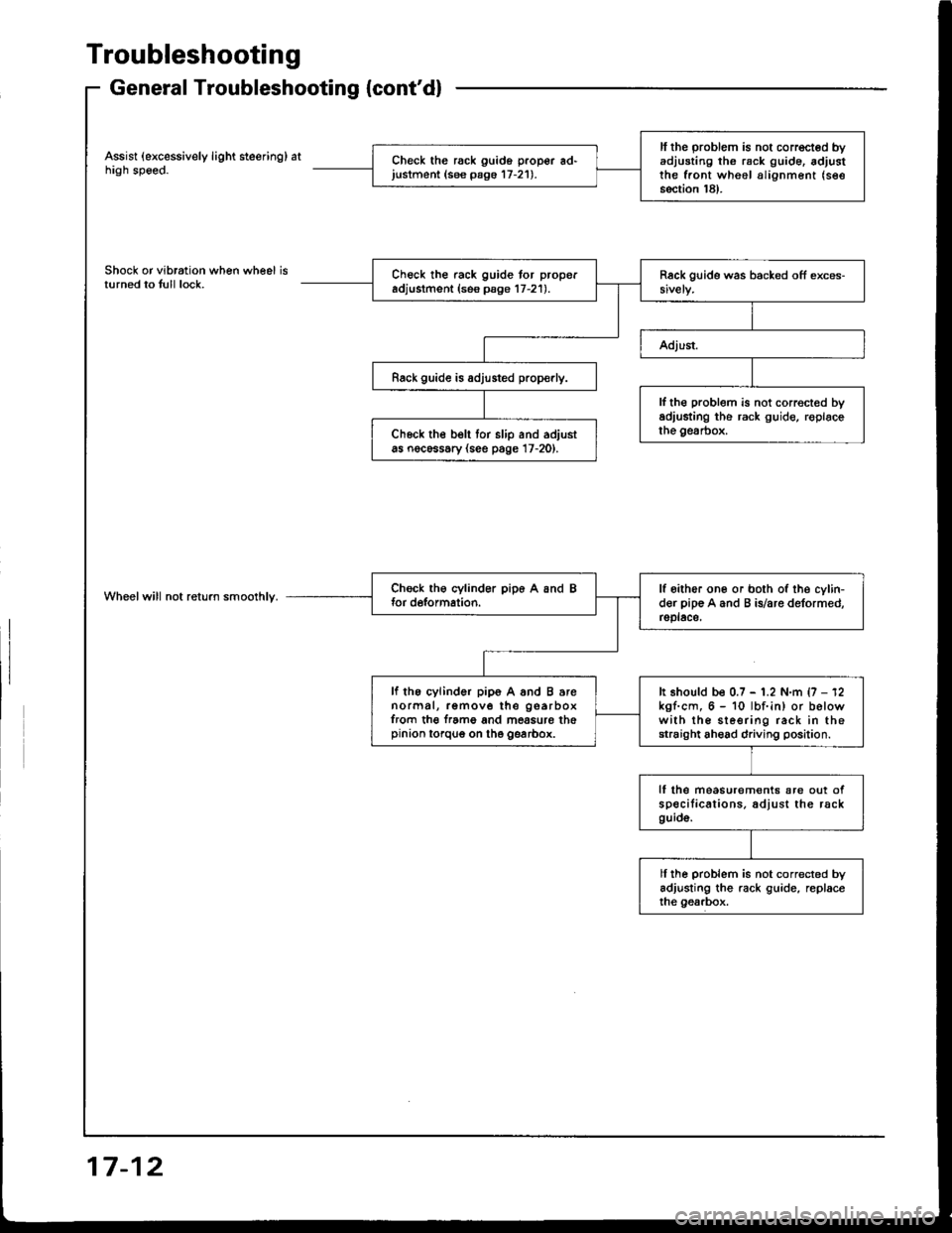

Troubleshooting

General Troubleshooting {cont'd}

Assist (excessively light steering) athigh speed.

Shock or vibration when wheel isturned to tull lock.

Wheelwill not return smoolhly.

ll the problem is not corrected byadjusting th6 rack g!ide. adjustthe front wheel alignment (see

section 18).

Check the rack guido proper ad'justment (see pago 17-21).

Check the rack guide tor properadjustment (ses psge 17-21).

Rack guide is adjusted prop€rly.

lf th€ problem is not correct€d byadiusting the rack guide, roplacethe gesrbox.Ch6ck the belt tor slip and adjustas nocessary (see page 17-20).

lf oither one or both of the cylin-der pip€ A and B is/are deformed,rsplace,

lf the cylinder pip6 A and B arenormal, remove the gearboxfrom th€ f.ame and mossure thepinion torqug on the gearbox.

It should be 0.7 - 1.2 N.m {7 - 12kgf.cm, 6 - 10 lbf.in) or belowwith the sleering rack in thestraight ahead driving position.

lf lhe measurem€nts are out ofspecilications. adjust the rackguid6.

ll ihe problem is not corrected byadjusting the rack guide, replaceihe gearbox.

17-12

Page 620 of 1413

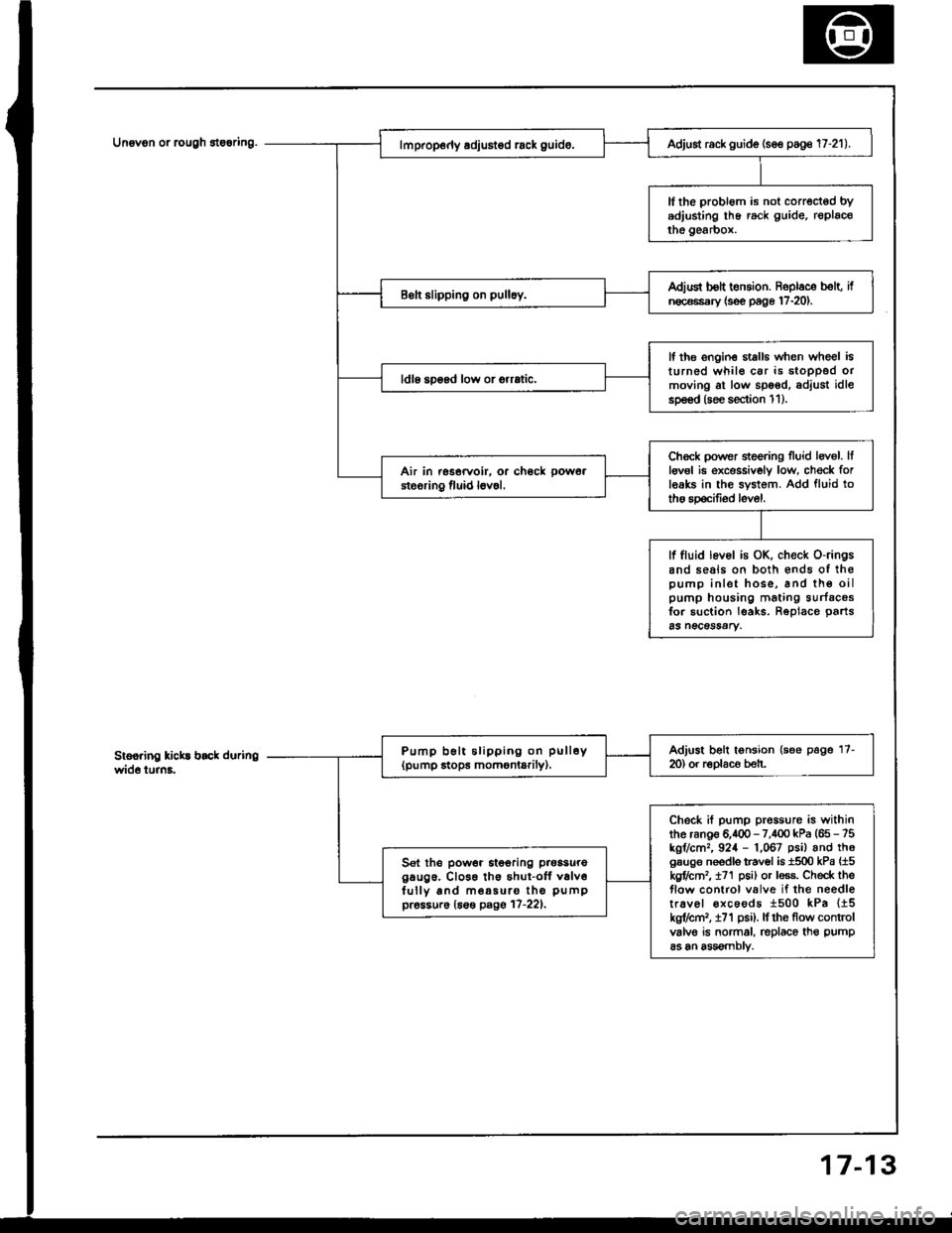

Unovon or rcugh 8te6ring.

3

Adjust rack guide (se€ poge 17-21).

ll the probl6m is not corrected bYadjusting lhe rack guide. replacothe gearbox.

Adiud bolt t€nsion. Roplace b€lt, ifn€c€ssary {s€e page 17-20).

lf the ongin€ stalls when wheel isturned whil€ car is stoDPed ormoving at low spoed, adjust idlesp€€d (soe section 1 1 ).

ldl6 soosd low or orrrtic.

Chock power sieering Iluid levol. Itlgv6l ie excessivoly low, ch€ck forleaks in the system. Add fluid totho spocifiod level.

Air in rssorvoir. or ch€ck pow6a

steoring fluid l6v6l.

lf fluid lev6l is OK, check o-ringsand seals on both €nds of ihopump inlet hose, and th€ oilpump housing mating surfacosfor suction leaks. Reolace oarts65 n€CeSSAry.

Adjust belt tonsion (see page 17-m) or r€Dlaco beh.Pump b6lt slipping on pull6y(pump stops momontarily).

Check if pump prossure is withinthe ranoe 6.400 - 7,100 kPa (65 - 75kgr/cm,, 924 - 1,067 psil and th6gsuge needls travol is 1500 kPa {15kgflctn2, t71 p6i) or less. Check theflow control valve if the needletr.vel €xcoods 1500 kPa {15kg?cm,, i71 psi). lf rhe flow controlvalvo is normal, replace th€ pump

as an assomblv.

Sel the power itooring p.oasuregaug6. Cl066 th€ shut-off v6lv6fully and m€a5uro tho pumppr6ssur6 (6s€ pagg 17-221,

7-1

Page 632 of 1413

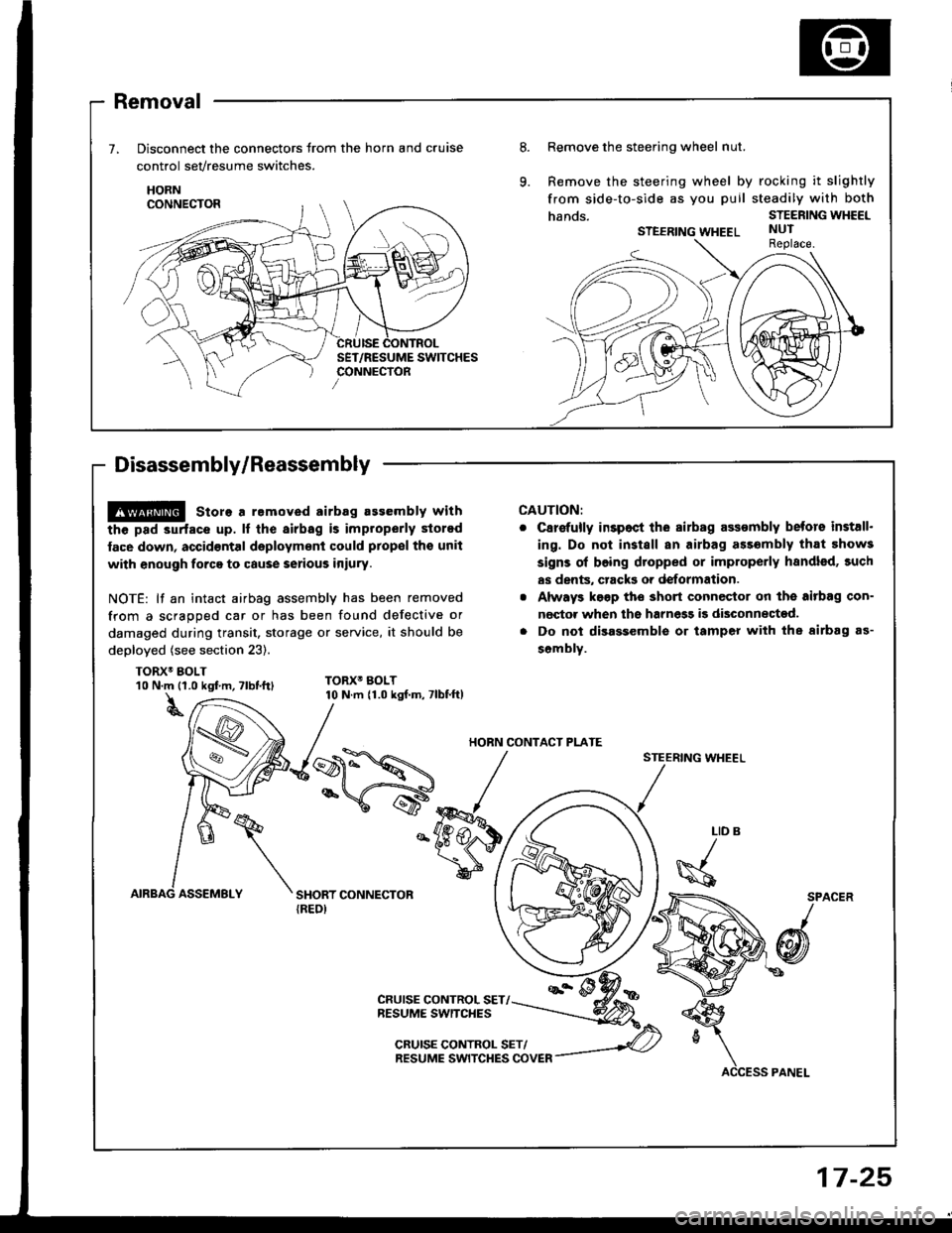

Removal

Disconnect the connectors trom the horn and cruise

control sevresume switches.

HORN

Disassembly/Reassembly

8.Remove the steering wheel nut.

Remove the steering wheel by rocking it slightly

from side-to-side as you puil steadily with both

hands.STEERING WHEEL

STEERING WHEELNUTReplace.

@ store a removed airbag assembly with

the pad 3urfacs up. lf the airbag is improperly stored

face down, accid€ntal daployment could prop€l tho unit

with enough forca to cause serious iniury.

NOTE: lf an intact airbag assembly has been removed

from a scragoed car or has been found defective or

damaged during transit. storage or service, it should be

deployed (see section 23).

TORX6 BOLT

CAUTION:

C8r€{ully inspoct ihe sirbag assombly betors install.

ing. Do not install an airbag ass6mbly that 5how3

signs ol boing dtopped or improperly handled, such

as dents, crack3 or deformation.

Always k€gp tho short connector on the aitbag con-

nector when ths harnegg i9 disconnected.

Do not disassemble or tamper with the airbag as-

sombly.

STEERING WHEEL

10 N.m {1.0 kgf m, Tlbt.ttl

t

TORX6 BOLT10 N.m {1.0 kgf.m, 7lbf.ft)

LID

\s

SPACER

/

@

CRUISE CONTROL SET/NESUME SWITCHES

CRUISE CONTROL SET/RESUME SWITCHES COVER

HORN CONTACT PI-ATE

17-25

Page 652 of 1413

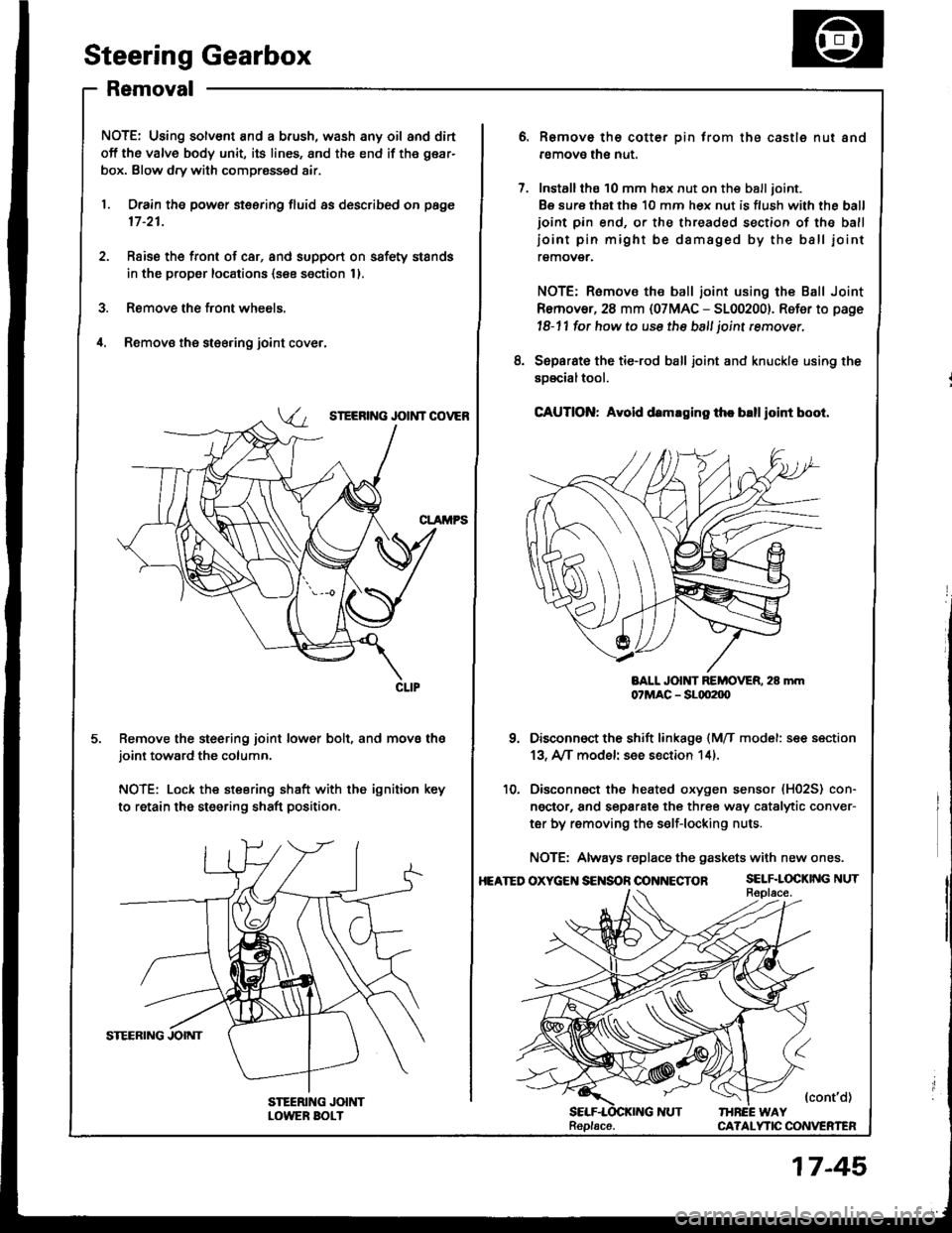

Steering Gearbox

Removal

NOTE: Using solvent and a brush, wash any oil and dirt

off the valve body unit, its lines, and the end if the gear-

box. Blow dry with compressed air.

1. Drain the power steering fluid as described on page

17 -21.

2. Rsise the front of car, and support on safety stands

in the propsr locations (see section 1).

3. Remove the front wheels.

il. Removs the st€ering joint cove.,

SIEERING JOIi{T COVEB

Remove the steering joint lower bolt, and move thejoint toward the column.

NOTE: Lock the steering shaft with the ignition key

to retain the steering shaft position.

Remove the cotter pin trom the castle nut and

removo the nut.

Installthe 10 mm hex nut on the balljoint.

Be sure that ths 10 mm hex nut is flush with the ball

ioint pin end, or the threaded section of the ball

ioint pin might be damaged by the ball iointremover.

NOTE: Remove the ball joint using the Ball Joint

Remover, 28 mm {07MAC - 5100200}. Refer to page

l8-11 fot how to use the ball joint rcmover,

Separat€ the tie-rod ball joint and knuckle using the

soscialtool.

CAUTION: Avold d.maging th. blllloint boot.

BALL JOlt{T REMOVER. 28 mm07MAC - SLqt2|X)

Disconnect the shift linkage {MfI model: see section

13, A/[ model see section 14).

Disconnect the heated oxygen sensor (H02S) con-

ngctor, and separate the three way catalytic conver-

ter by removing the s€lf-locking nuts.

NOTE: Always replace the gaskets with new ones.

OXycEt{S€NSOnOONNECTOR SELF.LOCKINGNUT

{cont'd)IHREE WAYCA?ALYTIC CONVERTEN

8.

10.

HEATED

Replacs.

17-45

Page 668 of 1413

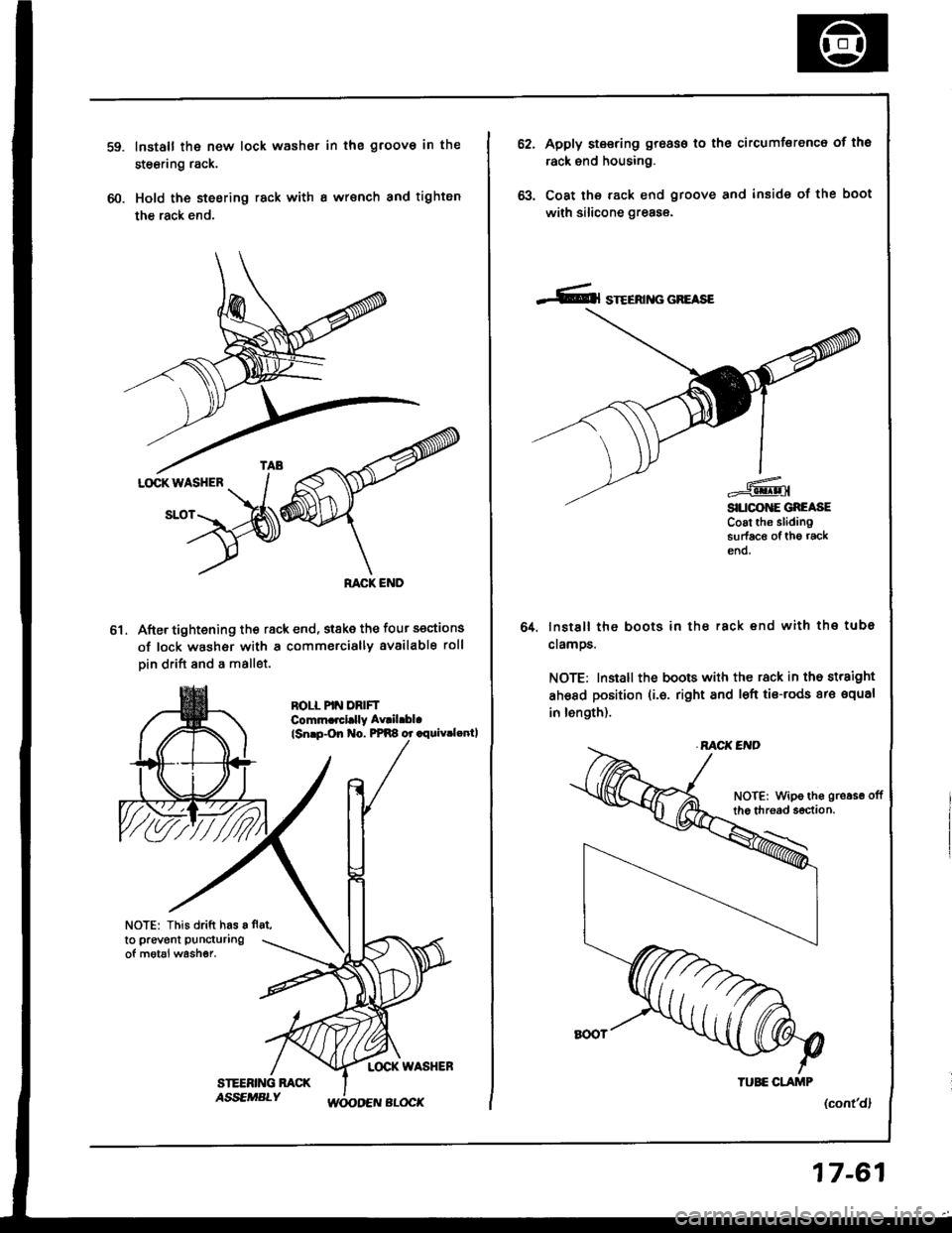

60.

Install the new lock washor in the groov€ in the

steering rack.

Hold the steering rack with I wrsnch and tighten

the rack end.

After tightening th€ rack end, stske the four sections

of lock washer with a commercially available roll

Din drift and a mallet.

ROLL PIN DRIFTComm.rcl.lly Av|il.bl.

lsnrp-On No. PPR8 or .rquiv.lenll

NOTE: This drift has a fl8t,

to prevent puncturing

of motal washer.

ol

62.Apply steering groass to the circumferenc6 of tho

rack end housing.

Coat the rack end groove and inside of the boot

with silicone greas€.

lnstsll the boots in ths rack end with the tube

clamos.

NOTE: Install the boots with the rack in the straight

ahsad position (i.6. right and l€ft tis-rods ar€ squal

in length).

(cont'dl

64.

NOTE: Wipe ths gro.se offthe thread s€ction.

TUEE CLAJTIP

17-61

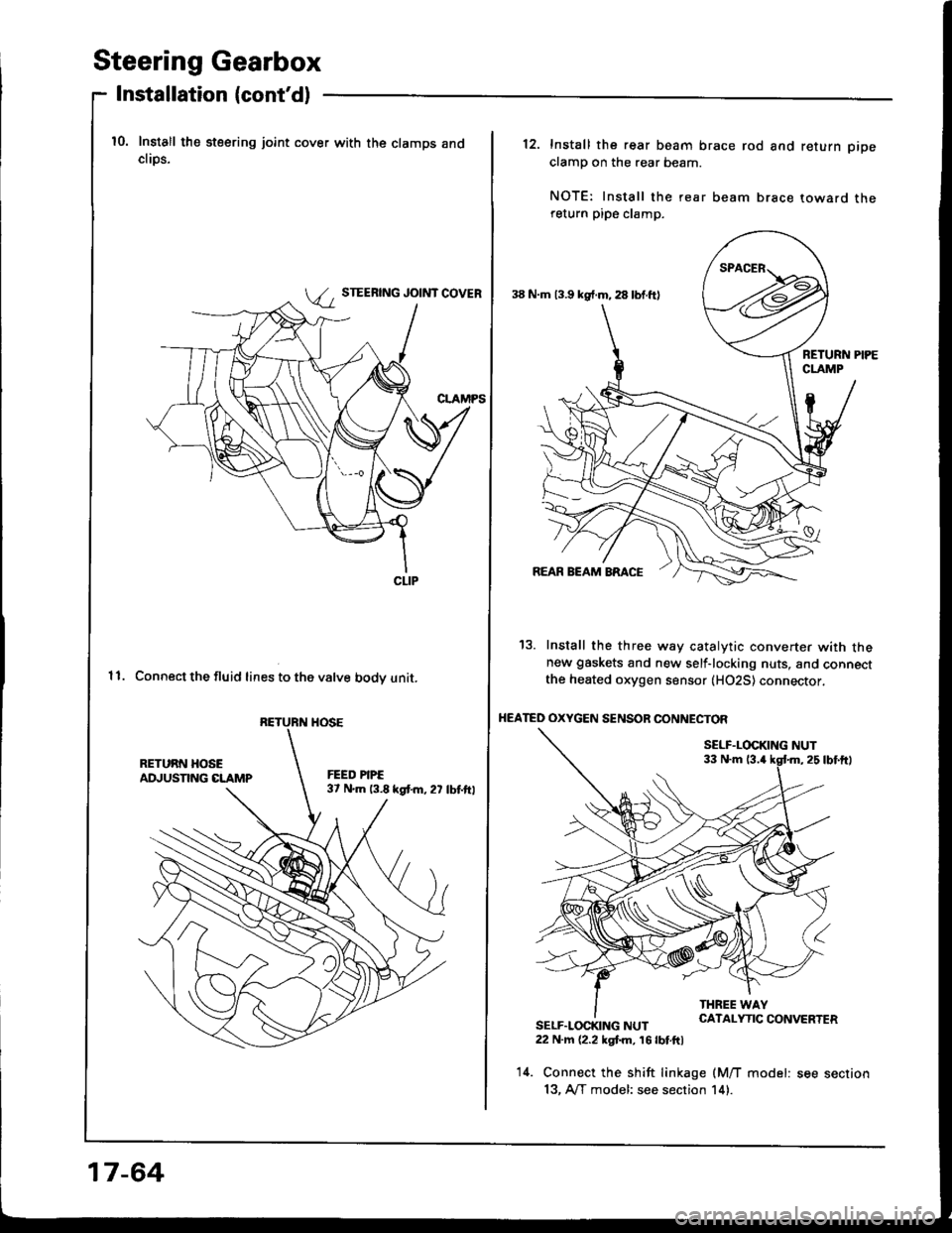

Page 671 of 1413

Steering Gearbox

Installation (cont'd)

10. Install the steering joint cover with the clamps andcliDs.

STEERING JOINT COVER

11. Connect the fluid lines to the valve bodv unit.

CLIP

RETURN HOSE

17-64

38 N.m 13.9 kg{.m, 28 lbf.ft)

12. Install the rear beam brace rod and return pipe

clamp on the rear beam.

NOTE: Install the rear beam brace toward thereturn pipe clamp.

13. Install the three way catalytic converter with thenew gaskets and new self-locking nuts, and connectthe heated oxygen sensor (H02S) connector,

HEATED OXYGEN SENSOR CONNECTOF

SELF.LOCKING NUT33 N.m 13.4

SELF.LOCKING NUT22 N.m (2.2 kgt m, 16 lbt.ftl

14. Connect the shift linkage (M/T model: see section

13, A/T model: see section 14).

Page 672 of 1413

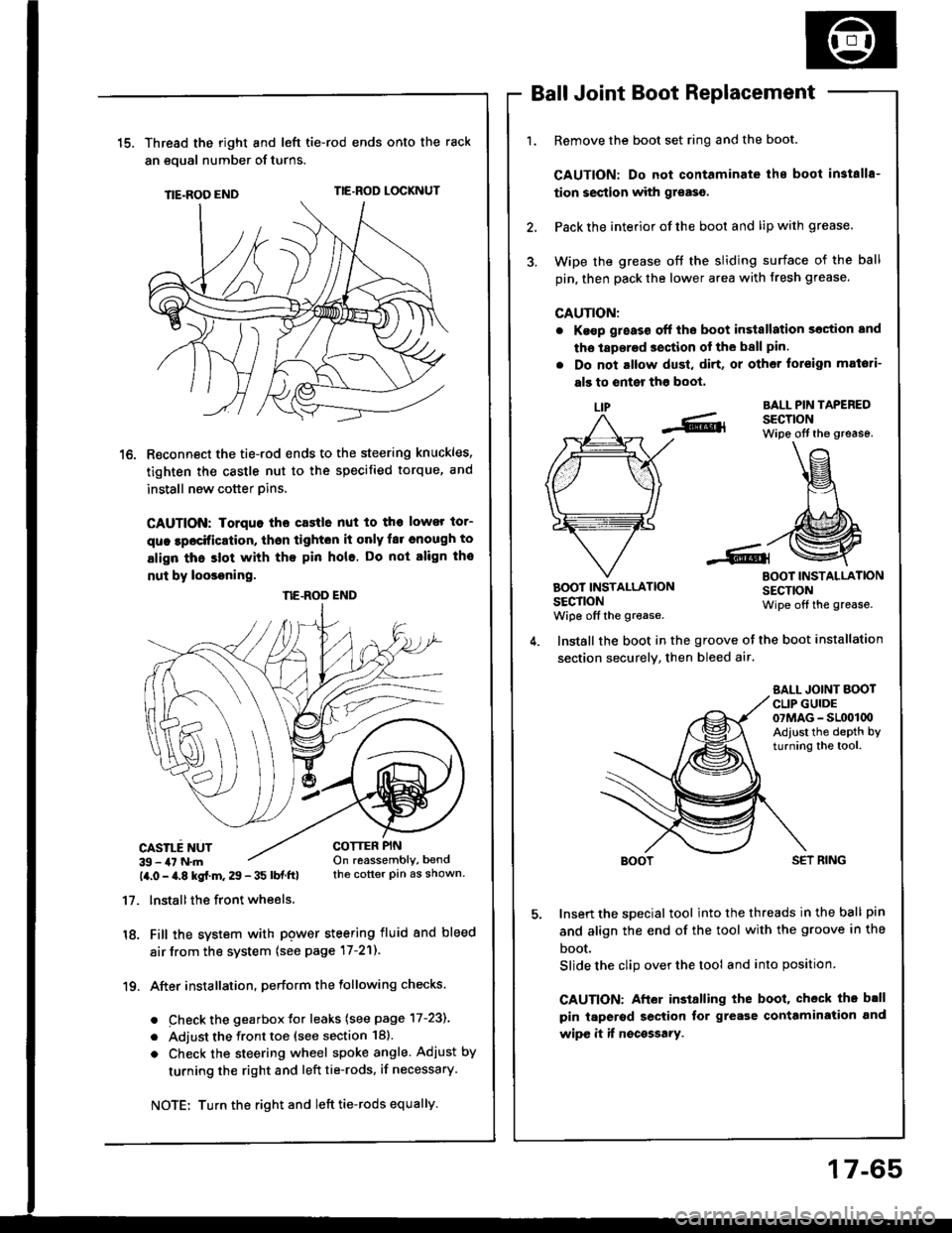

15.Thread the right and lefi tie-rod ends onto the rack

an eoual number of turns.

TIE-ROO ENDTIE.ROD LOCKNUT

R€connect the tie-rod ends to the steering knuckles,

tighten the castle nut to the specified torque, and

install new cotter pins.

CAUTION: Iorquo tho castle nut to tho lower tor-

que lpocification, thsn tighton it only far cnough to

align thc slot with tho pin hole. Do not align tho

nut by loosoning.

CASILE NUT39 - 47 N.m14.0 - a.8 kgf.m. 29 - 35 lbf ftl

17. lnstallthe front wheels.

18. Fill the system with pgwer steering fluid and bleed

air from the system (see page 17-21).

19. After installation. perform the following checks.

. Check the gearbox Jor leaks (see page 17-231

. Adjust the front toe (see section 18).

o Check the steering wheel spoke angle. Adjust by

turning the right and left tie-rods, if necessary.

Ball Joint Boot Replacement

Remove the boot set ring and the boot.

CAUTION: Do not contaminate ihe boot in3talls-

tion section with gr€aso.

Pack the interior of the boot and lip with grease.

Wipe the grease off the sliding surface of the ball

pin, then pack the lower area with fresh grease.

CAUTION:

. Ke€p g;eass off the boot in3tallation section and

tho laperad section of the ball pin.

. Do not altow dust, di.t, or other toreign mat6ti-

als to enter tho boot,

LIPBALL PIN TAPEREDSECTIONWipe off the grease.

BOOT INSTALLATIONSECTIONwiDe off the grease.

BOOT INSTALLATIONSECTIONWipe off the grease.

COTTER PINOn reassembly, bendthe cotter pin as shown.

Install the boot in the groove ot the boot installation

section securely, then bleed air.

SALL JOINT BOOTCLIP GUIDE07MAG - SL(x)l00Adiust the depth byturning the tool.

SET RING

Insert the special tool into the threads in the ball pin

and align the end of the tool with the groove in the

boot.

Slide the clip over the tool and into position

CAUTION: After installing the boot, check th. b.ll

pin taperod section tor grease contamiration and

wipe it if nocossary.

NE.ROD END

Turn the right and left tie-rods equally.

17-65

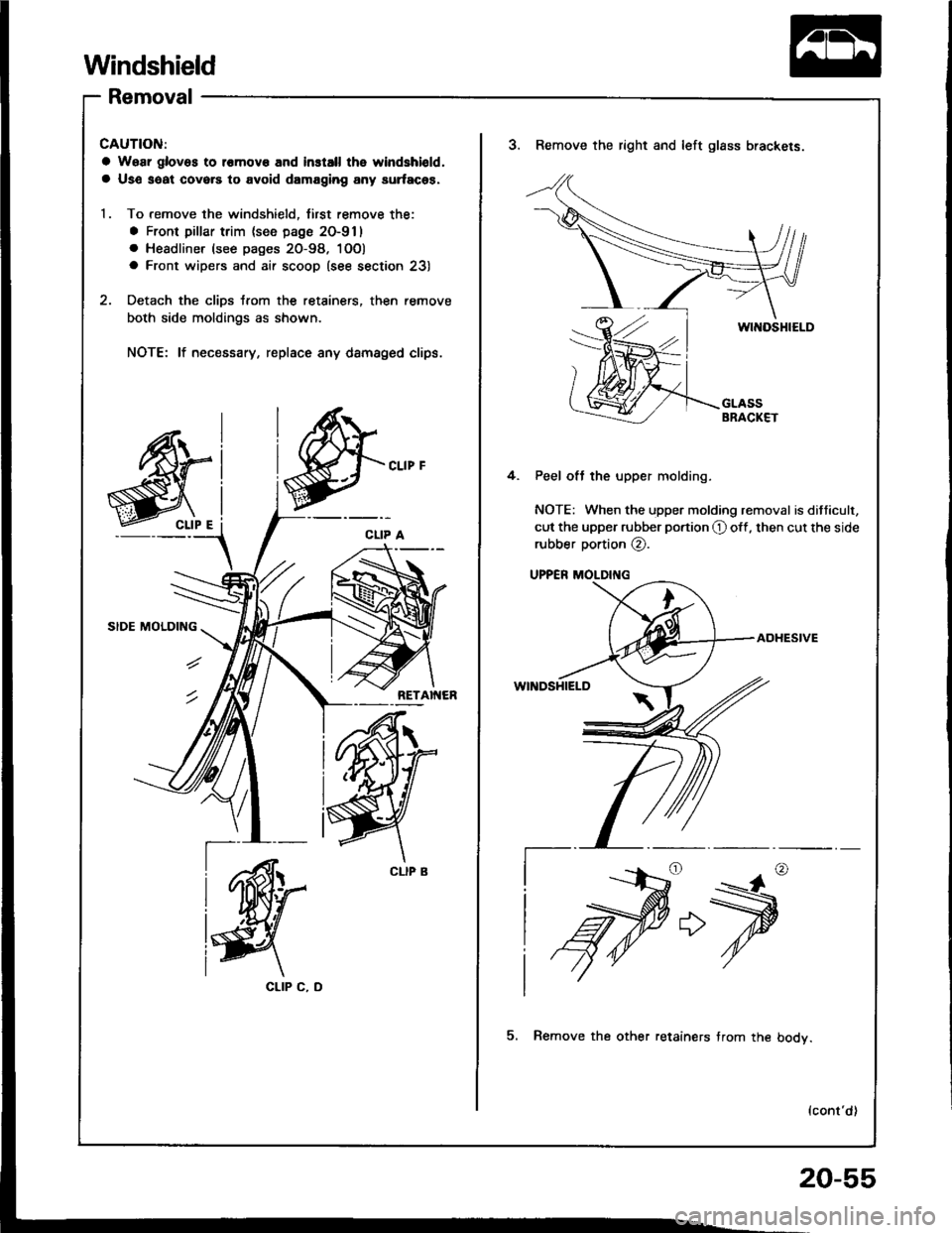

Page 924 of 1413

Windshield

Removal

CAUTION:

a Woar glovos to l€mov€ and install the windshiold,

a Us€ saat covers to avoid damaging any surfaces.

1. To remove the windshield, first remove the:

a Front pillar trim (see page 20-911

. Headliner (see pages 20-98. 1OO)

a Front wipers and air scoop (see section 23)

2. Detach the clips trom the retainers, then remove

both side moldings as shown.

NOTE: lf necessary, replace any dsmaged clips.

CLIP C, D

3. Remove the right and left glass brackels.

4. Peel oft the upper molding.

NOTE: When the upper molding removal is ditticult,

cut the upper rubber portion O off, then cut the side

rubber portion @.

UPPER MOLDII{G

ADHESIVE

WINDSHIELD

f--

5. Remove the other retainers trom the bodv.

lcont'd)

>

20-55

Page 930 of 1413

Rear Window

Removal

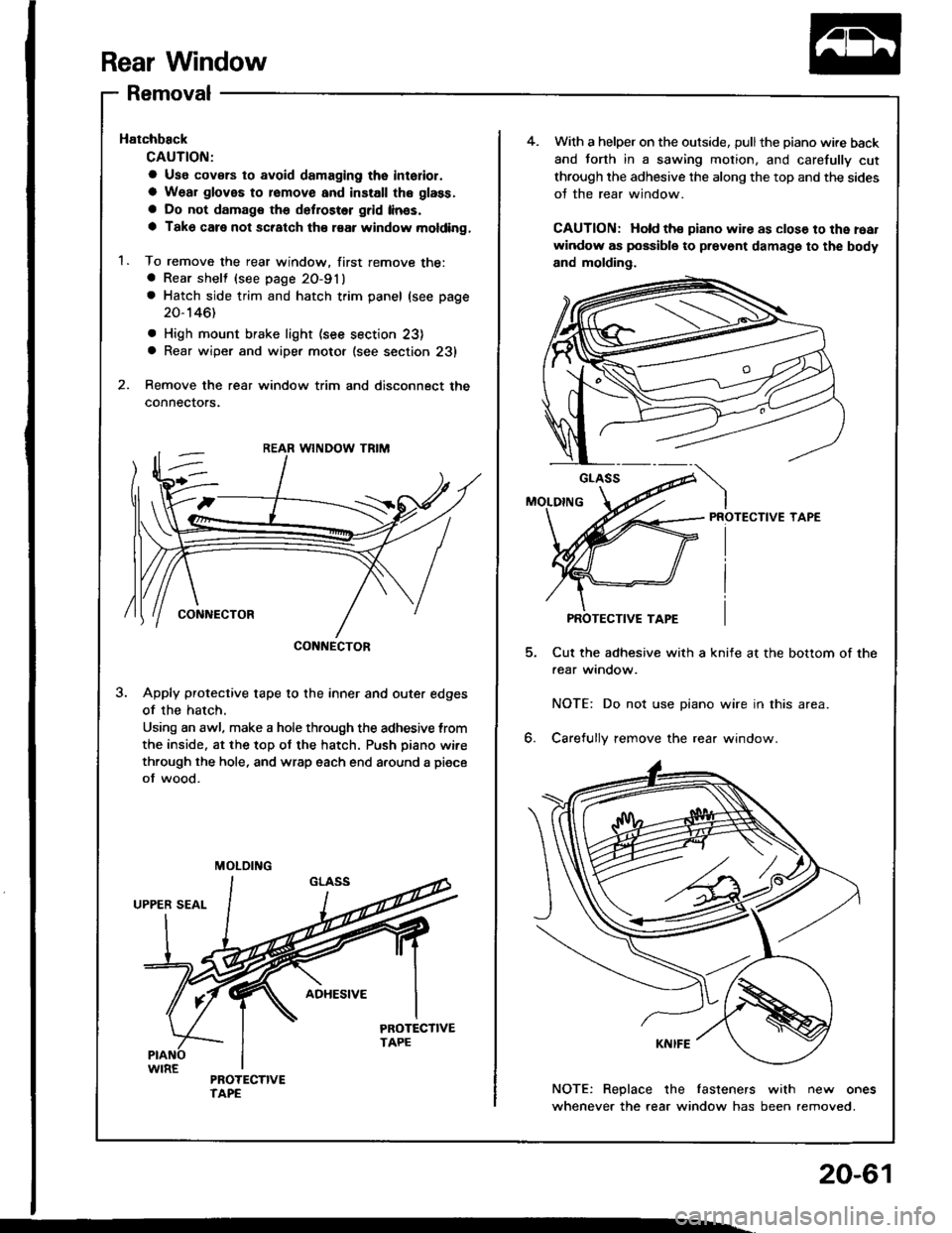

Hatchback

CAUTION;

a Use covsrs to avoid damaging tho interior.

a Wear gloves to romove and install the glass.

a Do not damags the defroster grid linss.

a Tako care not scratch th€ raar window molding,

1. To remove the rear window. first remove the:a Rear shelt (see page 20-91)

a Hatch side trim and hatch trim panel (see page

20-146)

. High mount brake light (see section 23)a Rear wiper and wiper motor (see section 231

2. Remove the rear window trim and disconnect the

connectors.

3. Apply protective tape to the inner and outer edges

of the hatch.

Using an awl. make a hole th.ough the adhesive trom

the inside. at the top ot the hatch. Push piano wire

through the hole, and wrap each end a.ound a piece

of wood.

CONNECTOR

MOLOING

4.With a helper on the outside, pullthe piano wire back

and forth in a sawing motion, and carefully cut

through the adhesive the along the top and the sides

oJ the rear window.

CAUTION: Hold ths piano wire as clos€ to the roat

window as possible to prevont damage to the body

and molding.

PROTECTIVE TAPE

Cut the adhesive with a knife at the bottom of the

aear window.

NOTE: Do not use piano wire in this area.

6. Carefully remove the rear window.

NOTE: Replace the fasteners with new ones

whenever the rear window has been removed.

PROTECTIVE TAPE

20-61

Page 964 of 1413

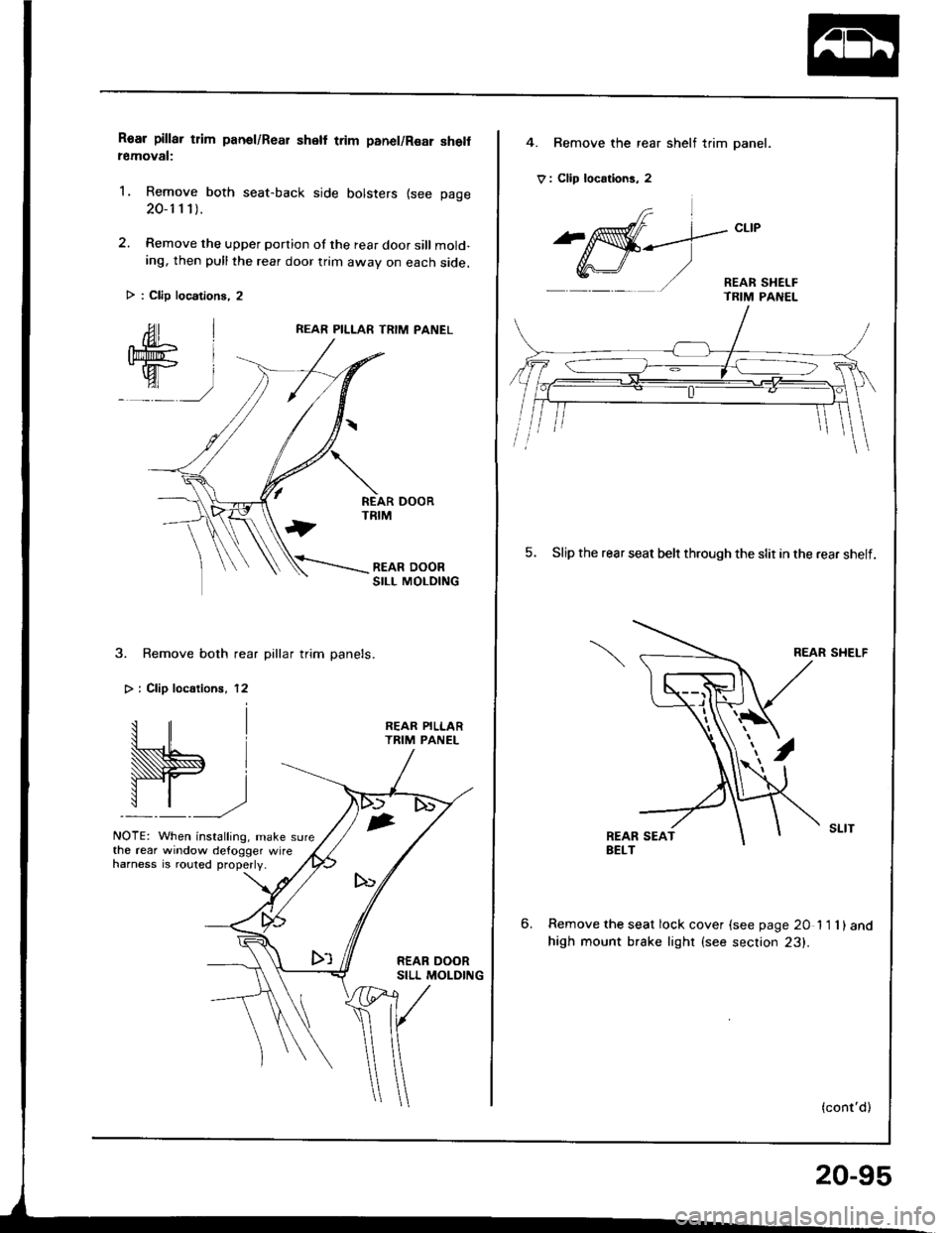

Roar pillar tlim panel/Rear shell trim panel/Rsar she removal:

1. Remove both seat-back side bolsters {see page

20-1 1 1).

2. Remove the upper portion of the rear door sill mold-ing, then pull the rear door trim awav on each side.

REAR PILLAR TRIM PANEL

3. Remove both rear pillar trim panels.

> i Clip localionr, 12

W.,

NOTE: When installing, make sure

REAR PILLARTRIM PANEL

the rear window defogger wireharness is .outed properly.

> : Clip locations, 2

4. Bemove the rear shelf trim panel.

V : Clip locrtions, 2

frl

^affi-_--.]-"t't

Y,r\-J/ '/ - REAR sHEr-F- TRIM PANEL

5. Slip the rear seat belr through the slit in the rear shelf.

REAR SHELF

6.Remove the seat lock cover {see page 20 11 1)and

high mount brake lighr (see section 23).

(cont'd)

20-95