HONDA INTEGRA 1994 4.G Workshop Manual

Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 141 of 1413

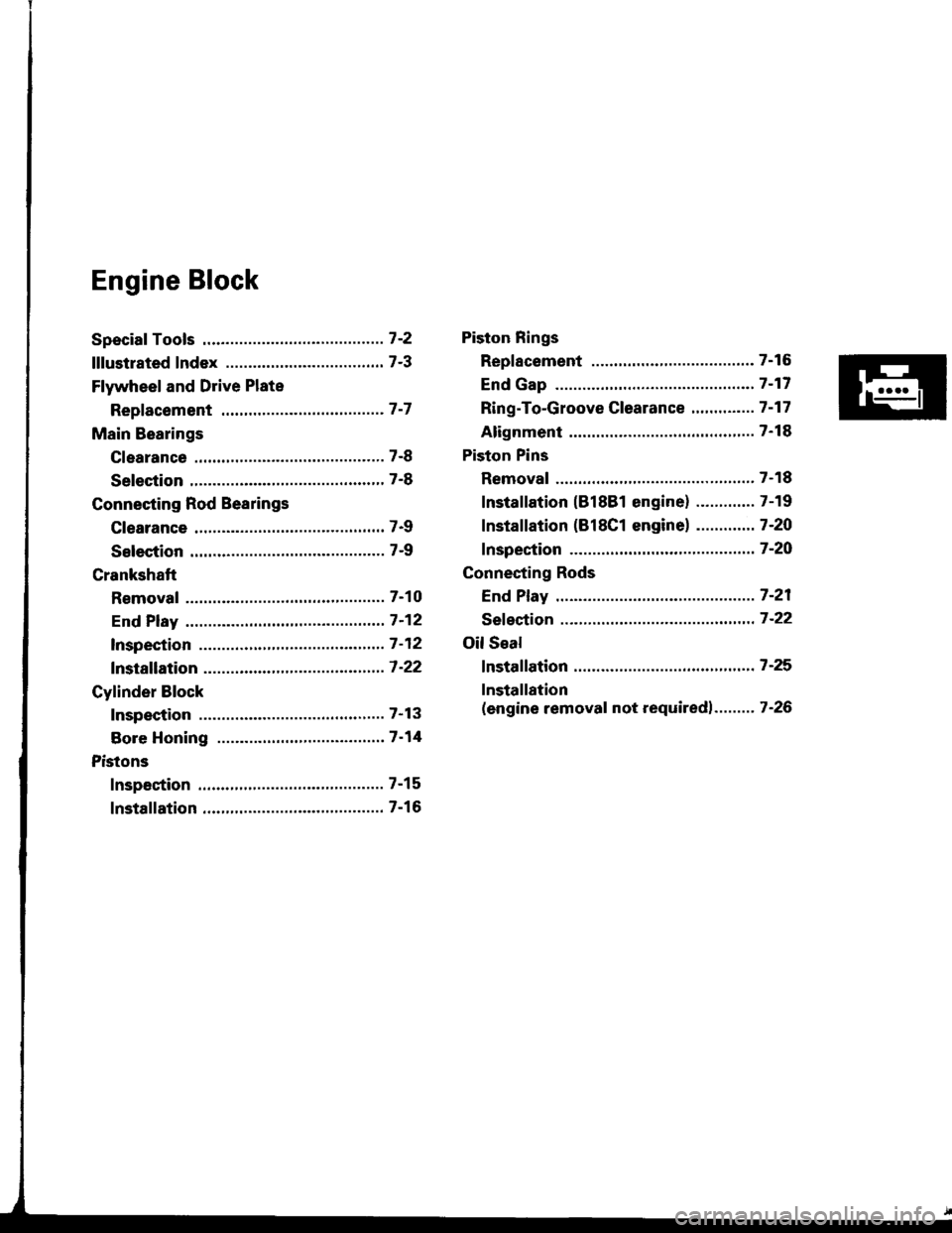

Engine Block

Speciaf Tools .............7'2

lllustrated Index ................................... 7-3

Flywheel and Drive Plate

Repfacement .........7-7

Main Bearings

Clearance ,.............. 7-8

Selection ................ 7-8

Connecting Rod Bearings

Clearance ............... 7-9

Selection ................ 7-9

Crankshaft

Removal .................7-10

End Play .................7-12

lnspection ........,,,.,,7-12

fnstallation .............7'22

Cylinder Block

Inspeetion ..............7-13

Bore Honing .....,.,,.7'14

Pistons

Inspaction ..............7-15

Installation .............7-16

Piston Rings

Replacement .........7-16

End Gap .................7-17

Ring-To-Groove C|earance,,,,.,,,...... 7 -17

Alignment ..............7-18

Piston Pins

Removal ........,........7-18

Installation (818B1 engine) ............. 7-19

fnstaffation (818C1 enginel ............. 7-20

fnspection ..............7-2O

Connecting Rods

End Play .................7-21

Sefeetion ..........,,,,,,7-22

Oil Seal

fnstaffation .............7-25

Installation

(engine removal not requiredl.. .......7-26

Page 142 of 1413

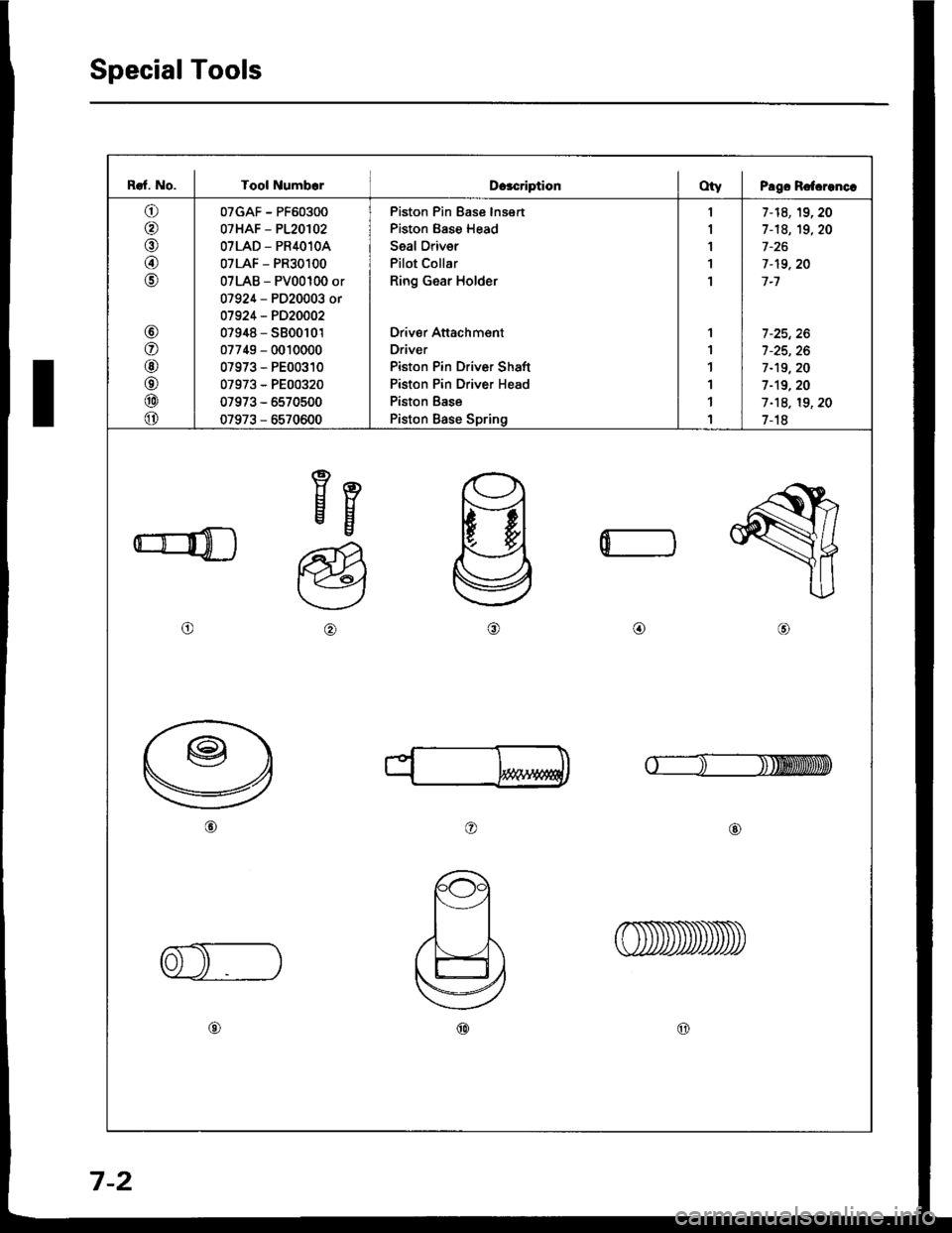

Special Tools

I

Raf. No. I Tool NumbcrDcacriptionOty I Pago Rotcrenc.

o

@

@

@

o

@

o

@

o

@

o

07GAF - PF60300

07HAF - P120102

OTLAD _ PR4O1OA

07LAF - PR30100

07LAB - PV00100 or

07924 - PD20003 or

01924 - PD20002

07948 - S800101

07749 - 0010000

07973 - PE00310

07973 - PE00320

07973 - 5570500

07973 - 6570600

Piston Pin Ease lnsert

Piston Base Head

Seal Oriver

Pilot Collar

Ring Gear Holder

Driver Attachment

Driver

Piston Pin Driver Shaft

Piston Pin Driver Head

Piston Base

Piston Base Spring

1

I

1'I

1

1

1

1

1

1

1

7-14,19,20

1-18, 19,20

7-19,20

7-1

7 -25, 26

7-19,20

1-19.20

1-18, 19, 20

1-18

Eg

o@,a\

o@

@@

0

7-2

Page 143 of 1413

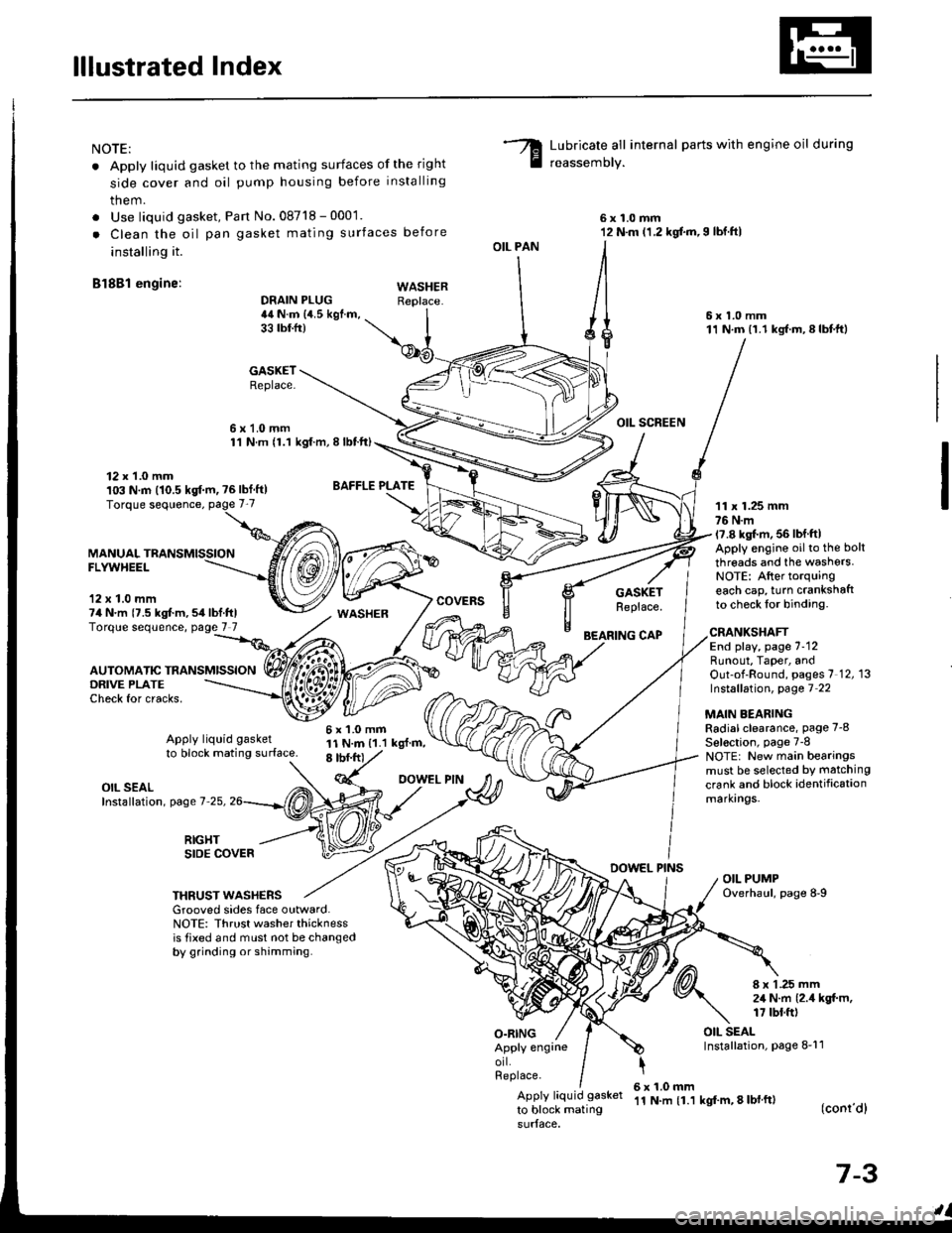

lllustrated Index

NOTE:

. Apply liquid gasket to the mating surfaces of the right

side cover and oil pump housing before installing

them.

. Use liquid gasket, Pan No.08718 - 0001.

. Clean the oil pan gasket mating surfaces before

installing it.

Bl8Bl engine: wAsHEF

Lubricate all internal parts with engine oil during

reassemory.

6x1.0mm12 N.m (1.2 kgf.m,I lbf.ftl

6x1.0mm11 N.m (1.1 kgf.m,8lbtft)

OIL SCREEN

11 x 1.25 mm76 N.m17.8 kgl.m, 56 lbf ftlApply engine oilto the bolt

threads and the washers.NOTE: After torquingeach cap, turn crankshaftto check lor binding.

DRAIN PLUG44 N.m {4.5 kgf.m,33 tbtfr)

GASKETReplace.

6x1.0mm1'l N.m {1.1 kgt.m, I lbtft)

OIL PAN

O.RING

GASKETReplace.

BEARING CAP

12 x 1.0 mm103 N.m (10.5 kgf.m, ?6lbf ft)

MANUALFLYWHEEL

'12 x 1.0 mm74 N.m {7.5 kgt m,54lbf.ftlTorque sequence, page 7 7

DRIVE PLATECheck for cracks,

AUTOMATIC TRANSMISSION

WASHER

6x1.0mm11 N.m {1.1 kgl.m,8 tbf.frt

CRANKSHAFTEnd play, page 7-12Runout, Taper, andOut-of-Round, pages 7 12, 13Instsllation, page 7 22

MAIN BEARINGRadial clearance, page 7-8

Sel€ction, page 7-8NOTE: New main bearingsmust be selected by matching

crank and block identificationmarkrngs.

Apply liquid gasket

to block mating surface.

OIL SEALInstallation, page 7-25,

RIGHTSIDE COVERDOWEL PINSOIL PUMPOverhaul, page 8-9THRUST WASHERSGrooved sides face outward.NOTE: Thrust washer thicknessis tixed and must not be changedby grinding or shamming.

8 x 1 .25 mm2,1 N.m {2.4 kgt m,17 tbt.ft)

OIL SEALInstallation, page 8-11Apply engrneorl.Replace.

Apply liquid gasket

to block mating

6x1.0mm'11 N.m {1.1 kgf'm, 8 lbl ft)(conr'dl

7-3

Page 144 of 1413

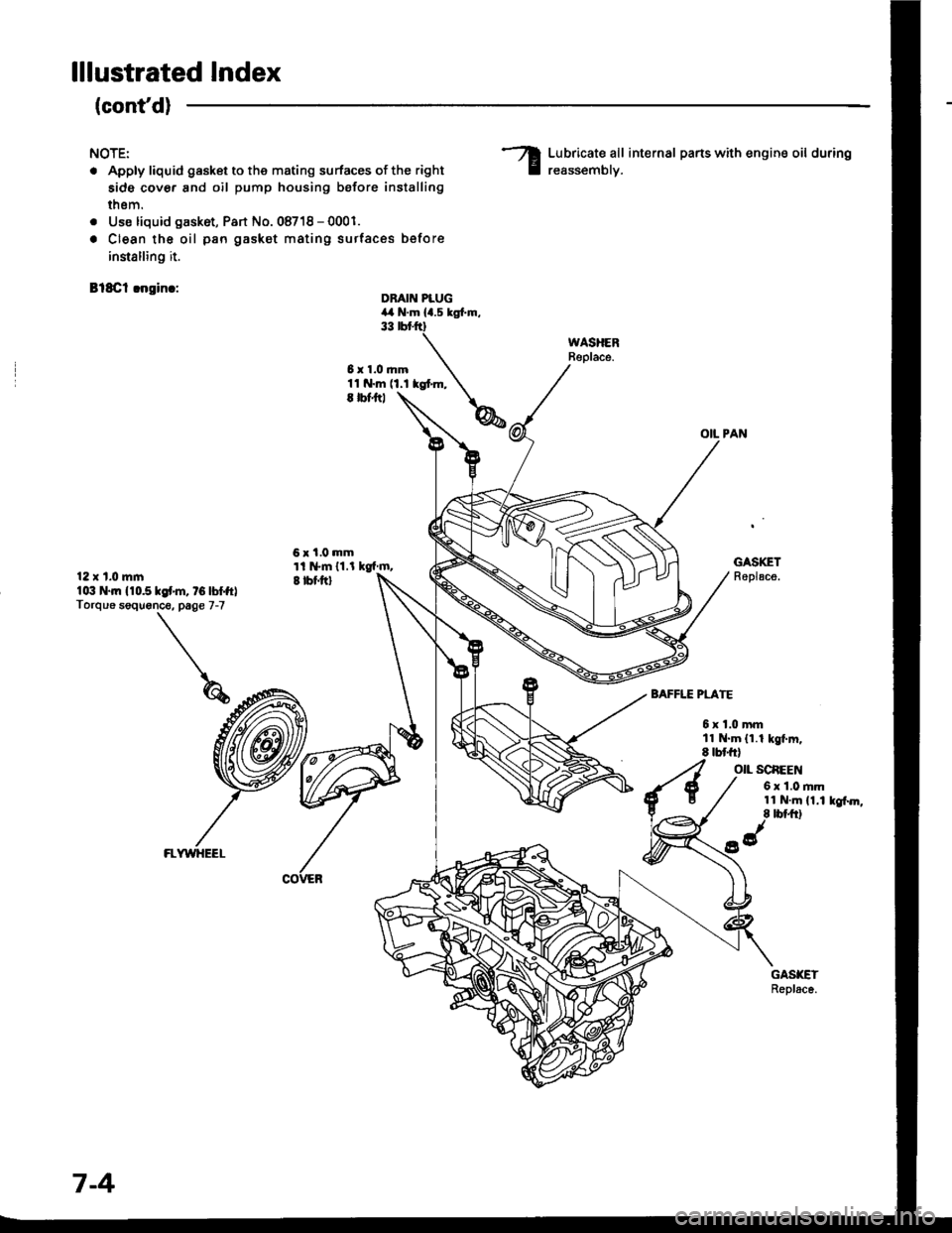

lllustrated Index

(cont'd)

NOTE:

. Apply liquid gasket to the mating surfaces of the right

side cover and oil pump housing before installing

thsm.

. Use liquid gask6t, Part No. 08718 - 0001.

. Clean the oil pan gasket mating surtac€s before

innalling it.

Bl8Cl !ngin.:

Lubricate all internal parts with engine oil during

reassemblv.

OIL PAN

DBAIN PLUG4,a N.m la.s tgl.m.33 rbr.ftt

6x1.0mm11 N.m (1.1 kgt m,E |bfitl

6x1.0mmti l*m 11.l kgf m,I tbf.ftl

GASKETReplace.12 x t.0 mlnlo:t N.|n 110.510f'm, tG lbffrlTorque soquonce. page 7-7

BAFFLE PLATE

6xl.0mmll N.m (1.1 kgt m.8 tbt frl

O|L SCAEEN

6 x 1.0 rim11 N.m (1.1 kgf.m,8 tbt ft)

FLWYHEEL

7-4

Page 145 of 1413

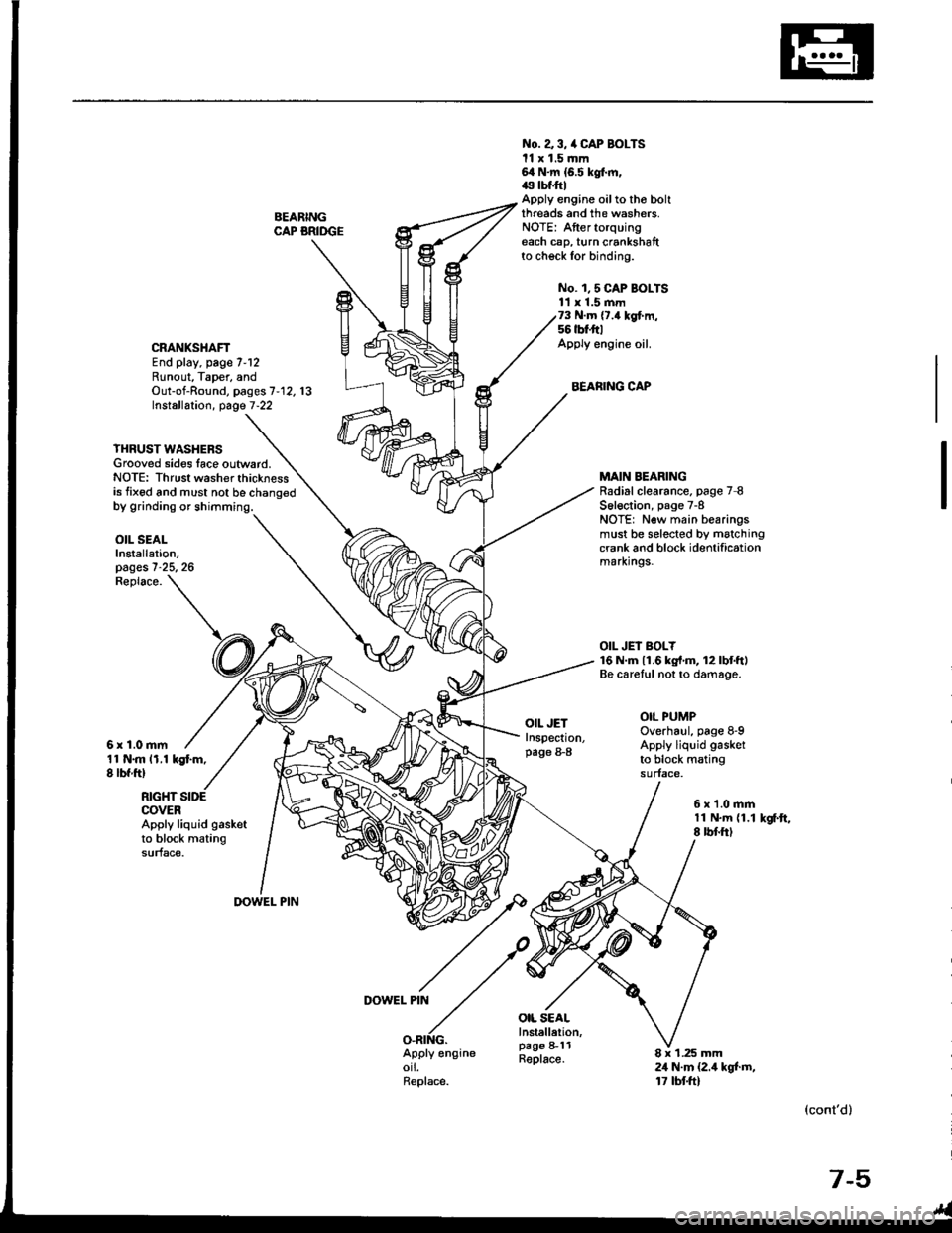

BEARINGCAP BRIDGE

No. a 3, /a CAP BOLTSll x 1.5 mm64 N.m {6.5 kgt m,49 tbf.ftlApply engine oilto tho boltthreads and the washers.NOTE: Aftertorquingeach cap, turn crankshaftto check for binding.

No. 1,5 CAP BOI-TS11 x 1.5 mm73 N.m {7.4 kgf.m,56 tbt'ft|Apply engine oil.

BEARING CAP

CRANKSHAFTEnd play, page 7-12Runout, Taper, andOut-of-Round, pages 7'12. 13Installation, page 7-22

YHRUST WASHERSGrooved sides lace outward.NOTE: Thrust washer thicknessis fixed and must not be chano€d

MAIN BEARINGRadial clearance. page 7 8S6l€ction, page 7-8NOTE: New main bearingsmust be selected by matchingcrank and block identificationmarxrngs.

OIL JEI BOLY16 N.m 11.6 kg{'m, 12lbtftlBe caretul not to damage.

OIL PUMPOverhaul, page 8-9Apply liquid gasket

to block matingsurface.

OIL SEALInstallation,pages 7-25, 26

11 N.m 11.1 kgt m,8 lbf ftl

Replace.

6r1.0mm

OIL JETInspection,page 8-8

OIL SEALInstellelion,page 8-11Replace.

RIGHT SIDECOVERApply liquid gasketto block matingsurface.

6x1.0mm11 N.m {1.18 rbf.ftlkSf.ft,

DOWEL PIN

DOWEL PIN

O.RING.Apply engineorl.Replace.

8 x 1.25 mm24 N.m {2.4 kgt m,17 tbtft)

(cont'd)

7-5

Page 146 of 1413

lllustrated IndexF

(cont'd)

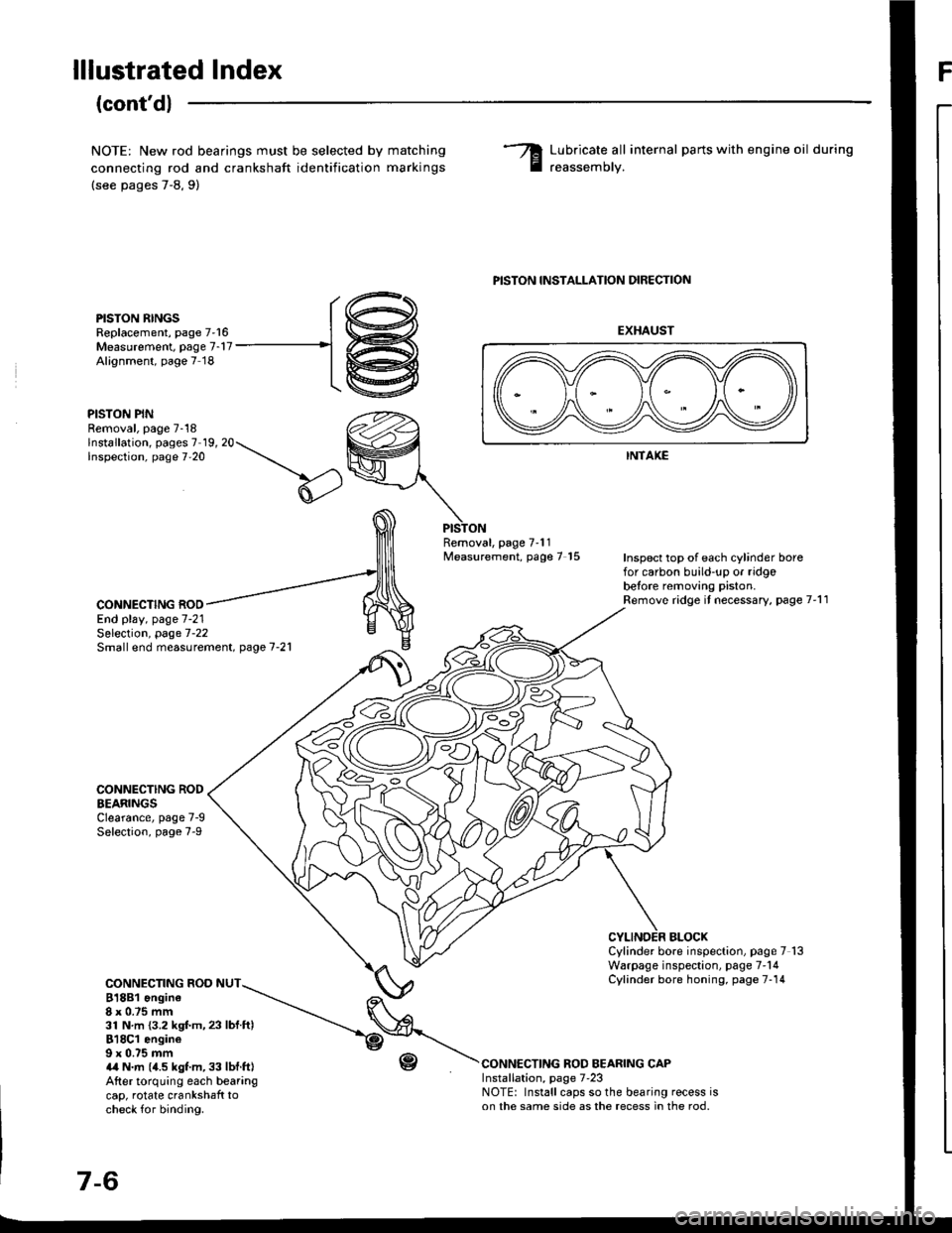

NOTE: New rod bearings must be selected by

connecting rod and crankshaft identification

(see pages 7-8,9)

matching

marKrngs

Lubricate all internal parts with engine oil during

reassemorv.

PISTON RINGSReplacement, page 7'16Measurement. page 7-17Alignment, page 7 18

PISTON PINRemoval, page 7-18lnstallation, pages 7 19, 20Inspection, page 7'20

PISTON INSTALLATION DIRECTION

EXHAUST

INTAKE

Removal, page 7'11Measurement, page 7 15Inspect top of each cylinder borefor carbon build-up or ridgobetore removing piston.Remove ridge it necessary, page 7'11CONNECTING ROOEnd play, page 7-21

CONNECTING RODEEARINGSClearance, page 7-9Selection, page 7-9

CONNECTING ROD NUT818B1 ongine8x 0.75 mm31 N.m {3.2 kgf.m,23 lbf ftl818C1 engine9 x 0.75 mma,a N.m (4.5 kgt m, 33 lbf.ft|After torquing each bearangcap, rotate crankshaft tocheck for binding.

r-(,

Selection, page 7-22Small end measurement. page 7-21

BLOCXCylinder bore inspection, page 7 13Warpage inspection, page 7'14Cylinder bore honing, page 7-14

CONNECTING ROD BEARING CAPInstallation, page 7'23NOTE: Install caps so the bearing recess ison the same side as the recess in the rod.

r@

-1@

Page 147 of 1413

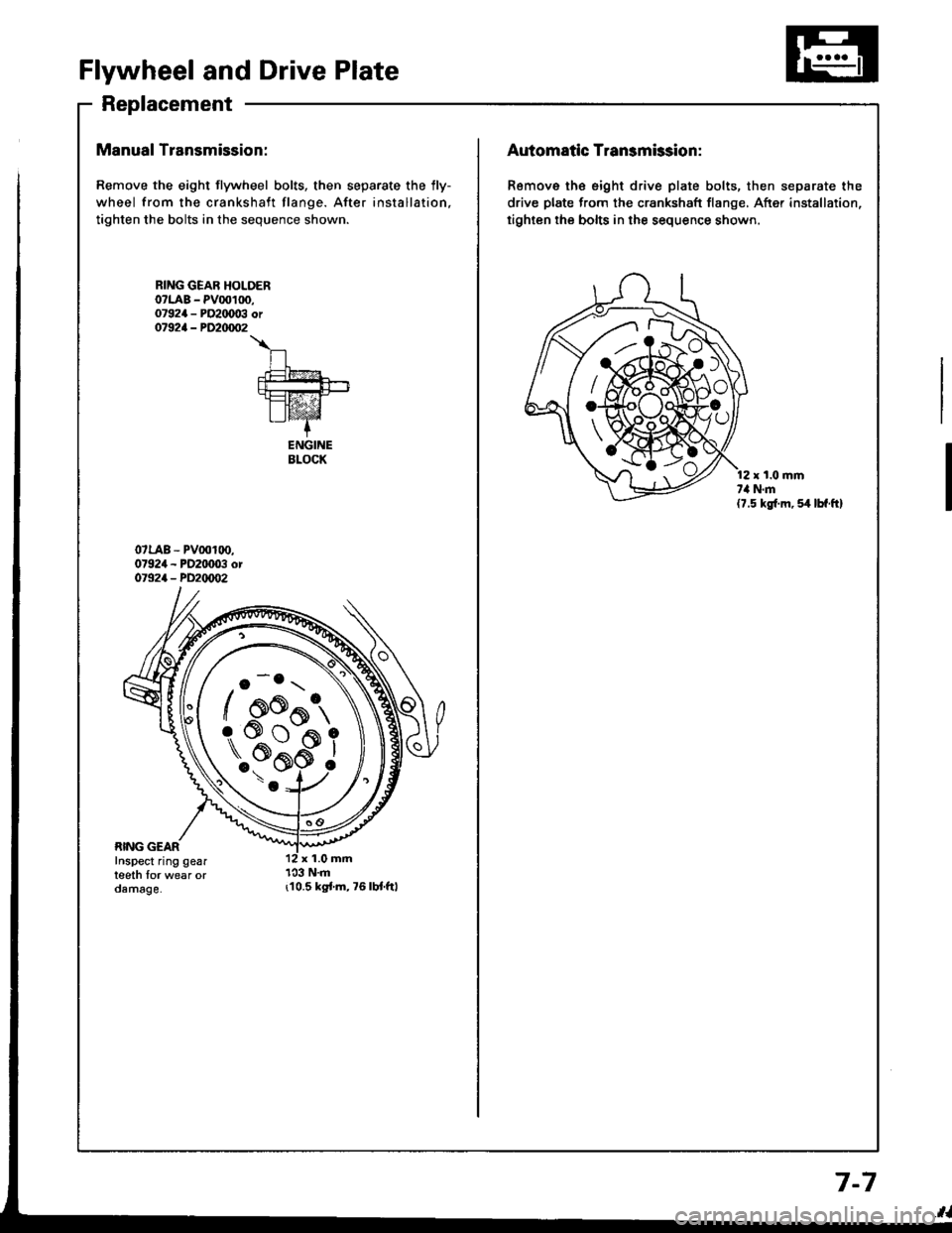

Flywheel and Drive Plate

Replacement

Manual Transmission:

Remove the eight flywheel bolts, then separate the lly-

wheel from the crankshaft flange. After installation,

tighten the bolts in the sequence shown.

r10.5 kgi.m,76lbt.ftl

RING GEAR HOLOERo?LAB - PV00100,07924 - PO2IX)03 or07924 - PD20/m�2

\

n.t=?4

fut!!-+-rt=tz-21I lvaz'Z-+

ENGINEBLOCK

o -o.r \

/ oo^t,

\..?bi

/ AK{:{AAo

rs#*ffi_9

Automatic Transmission:

Remove th€ eight drive plate bolts, then separate the

drive plate from the crankshaft flange, After installation,

tighten the bolts in the sequence shown.

r t.0 mmt,l N.m(7.5 kg{.m, 54 lbf.ft}

7-7

Page 148 of 1413

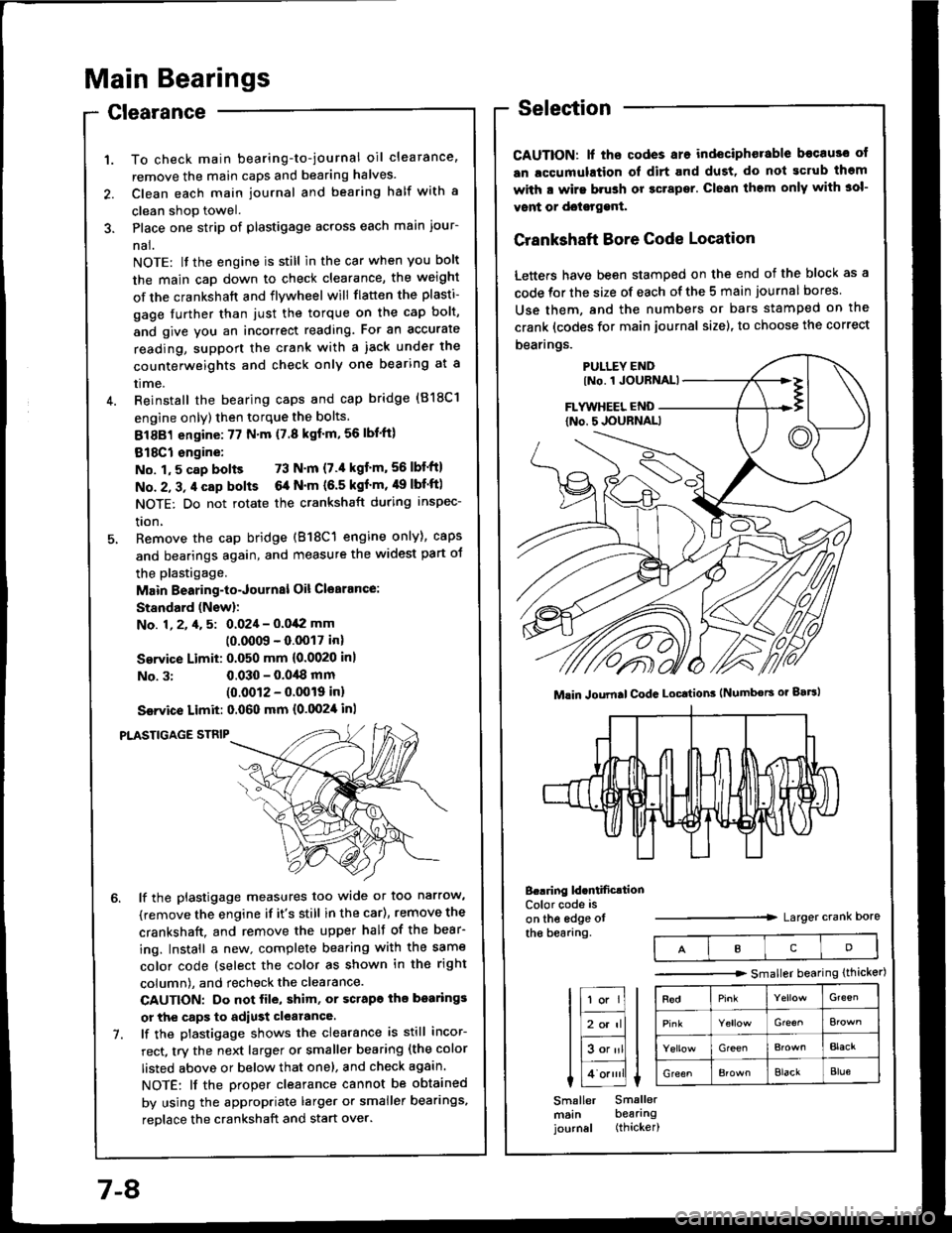

Main Bearings

Clearance

To check main bearing-to-journal oil clearance,

remove the main caps and bearing halves.

Clean each main journal and bearing half with a

clean shop towel.

Place one strip of plastigage across each main iour-

nal.

NOTE: lf the engine is still in the car when you bolt

the main caD down to check clearance, the weight

of the crankshaft and flywheel will flatten the plasti-

gage further than just the torque on the cap bolt,

and give you an incorrect reading. Fot an accurate

reading, support the crank with a iack under the

counterweights and check only one bearing at a

trme.

Reinstall the bearing caps and cap bridge (818C1

engine only) then torque the bolts.

81881 engine:77 N'm (7.8 kgf'm,56lbl'ft)

818C1 engine:

No. 1,5 cap bolts 73 N'm (7.'l kgt'm,56lbf'ftl

No. 2, 3, 4 cap bolts 6a N'm (6.5 kgf'm, 49 lbf'ftl

NOTE: Do not rotate the crankshaft during inspec-

tron,

Remove the cap bridge (818C1 engine only), caps

and bearings again, and measure the widest part oJ

the plastigage.

Main Bearing-to-Journal Oil Cl€arance:

Standard (Newl:

No. 1, 2, 4, 5: 0.024 - 0.042 mm

10.0009 - 0.0017 inl

Service Limit: 0.050 mm {0.0020 inl

No. 3:0.030 - 0.0,18 mm(0.0012 - 0.0019 inl

Ssrvice Limit: 0.060 mm {0.0024 inl

PLASTIGAGE STNIP

lf the plastigage measures too wide or too narrow,

(remove the engine if it's still in the car), remove the

crankshaft. and remove the upper half of the bear-

ing. Install a new. complete bearing with the same

color code (select the color as shown in the right

column), and recheck the clearance.

CAUTION: Do not file, shim, or scrapo ihe bo.rings

or the caps to adiust clearance.

lf the plastigage shows the clearance is still incor-

rect, try the next larger or smaller bearing (the color

listed above or below that one), and check again.

NOTE: lf the Droper clearance cannot be obtained

by using the appropriate larger or smaller bearings,

reolace the crankshaft and start over.

Selection

CAUTION: lf ths codes are indeciphorable becau3o ot

an lccumulation ol dirt and dust, do not gcrub thgm

with a wirs brush or gcrapsr. Clean them only with 3ol-

vont or doisrggnt.

Crankshaft Bore Code Location

Letters have been stamped on the end of the block as a

code for the size of each of the 5 main journal bores

Use them, and the numbers or bars stamped on the

crank (codes for main journal size), to choose the correct

bearings.

B..ring ld.ntificrtionColor code is

on the edge otthe bearang.Larger crank Dore

Mlin Joumal CodG Locttion3 (Numbors or gaBl

IcD

tr;;lIl

Itr-tl

lE;tl I tlHlt

I Lo.""li L

Smaller Smallermsin bearingjournal (thicker)

-------.r> smaller bearing (thicker)

G'een

Gre€^

GreenBlacr

GreenElackBlue

7-8

Page 149 of 1413

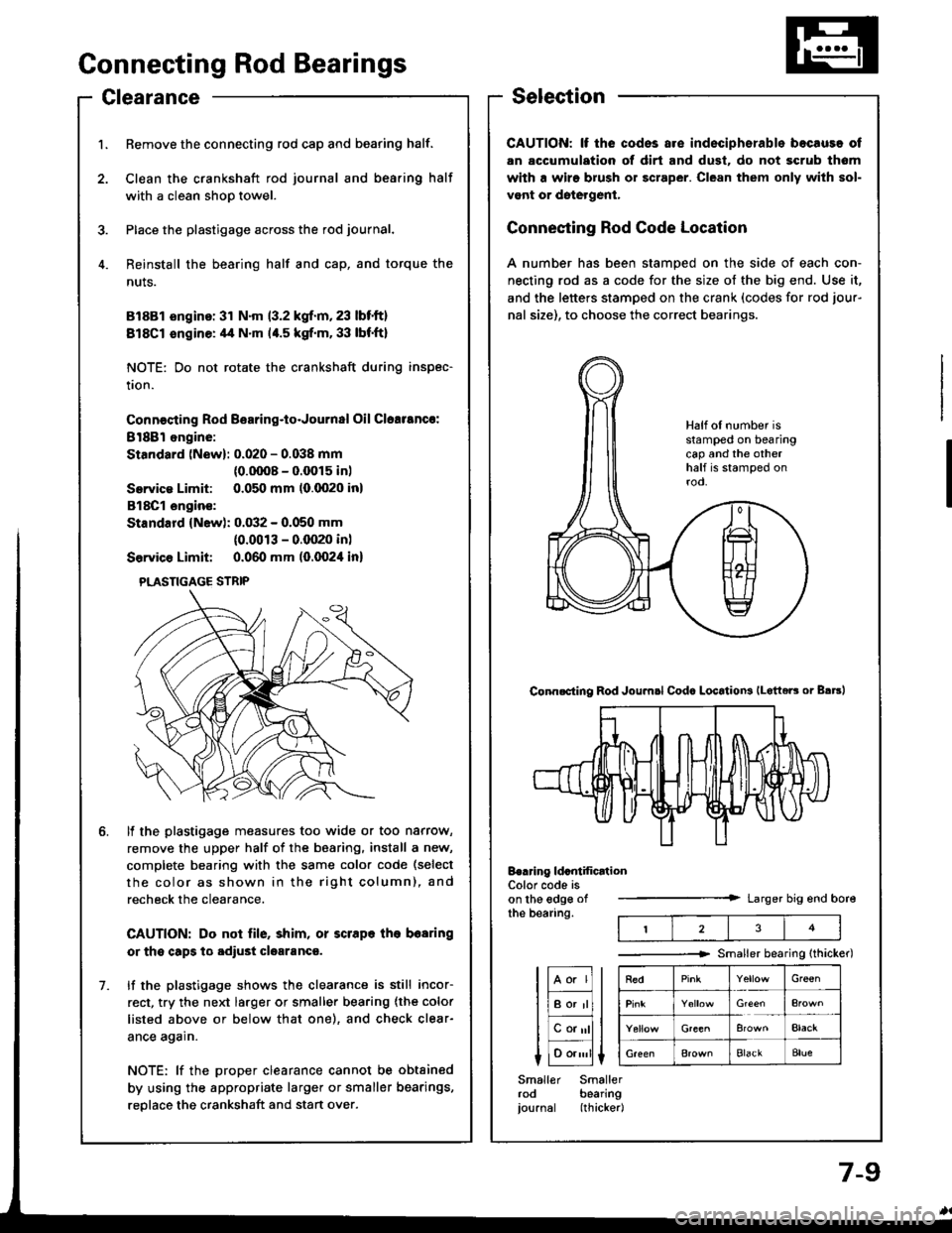

ConnectingRod Bearings

ClearanceSelection

CAUTION: lf the codss are indeciphsrable bocause of

an accumulation of dirt and dust. do not scrub tham

with a wiro brush or scraper. Clean them only with sol-

vont or dotetgenl.

Connecting Rod Code Location

A number has been stamped on the side of each con-

necting rod as a code for the size of the big end. Use it,

and the letters stamped on the crank (codes for rod jour-

nal size), to choose the correct bearings.

tF;l I tl-lf

liBor'rll I

lEalll t

I 1o.,,,'ll L

Smaller Smallerrod bearingjournal (thicker|

Half of number isstamped on bearingcap and the otherhalf is stamped onrod.

Conn.cting Rod Joumsl Codc LocatioN lLotteE or B.trl

Berring ldcntification

t23

Color code ison the edge ofthe bearing.Larger big end bore

Smaller bearing {thicker)

RedGr€€n

Elack

Bla€kBlue

1. Remove the connecting rod cap and bearing half.

2. Clean the crankshaft rod journal and bea.ing half

with a clean shoo towel.

3. Place the plastigage across the rod journal.

4. Reinstall the bearing half and cap, and torque the

nuts.

81881 sngino: 31 N'm 13.2 kgf.m,23 lbt'ft)

818C1 sngine: 4,1 N.m 14.5 kgf.m. 33 lbf'ft}

NOTE: Do not rotate the crankshaft during inspec-

tion.

Connecting Rod B€aring-to-Journal Oil Clcalancr:

8l88l ongine:

Standard (New): 0.020 - 0.038 mm

{0.0008 - 0.0015 in)

Servica Limit: 0.050 mm (0.0020 inl

818C1 engin€:

Standard (New): 0.032 - 0.050 mm

(0.0013 - 0.(XP0 inl

Service Limit: 0.060 mm (0.0024 in)

ll the plastigage measures too wide or too narrow,

remove the upper half of the bearing. install a new,

complete bearing with the same color code (select

the color as shown in the right column), and

recheck the clearance.

CAUTION: Do not file, shim, or scrape lhe bearing

or the capg tq adiust clgaranca.

lf the plastigage shows the clearance is still incor-

rect, try the next la.ger or smaller bearing {the color

listed above or below that one), and check clear-

ance again.

NOTE: lf the proper clearance cannot be obtained

by using the appropriate larger or smaller bearings,

reolace the crankshaft and stan over.

1.

PLASTIGAGE STRIP

Page 150 of 1413

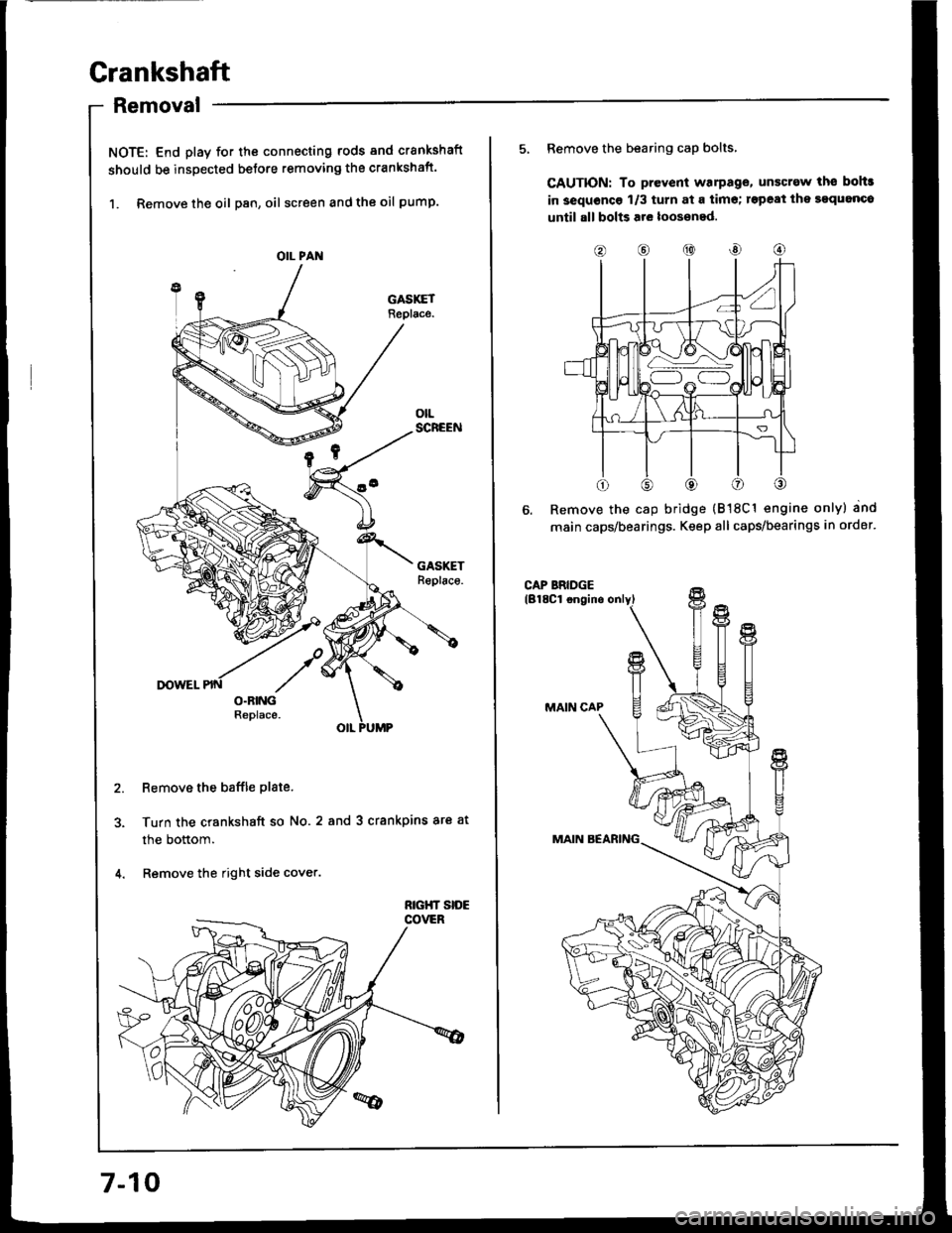

Crankshaft

Removal

NOTE: End play for th€ connecting rods and crankshaft

should be inspected betore removing the crankshaft.

1. Remove the oil Dan, oil screen and the oil pump.

Remove the baffle plate.

Turn the crankshaft so No.2 and 3 crankpins ar€ at

the bottom.

Remove the right side cover.

OIL PAN

7-10

o@@

5, Remove the bearing cap bolts,

CAUTION: To prevent warPag€, unscrew ths bohr

in 3equoncg 1/3 turn at a tim€; rspeat ihe sgquanco

until all bolts are loos€ned.

Remove the cap bridge {818C1 engine only} and

main caps/bearings. Keep all caps/bearings in order.