cv joint HONDA INTEGRA 1994 4.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 493 of 1413

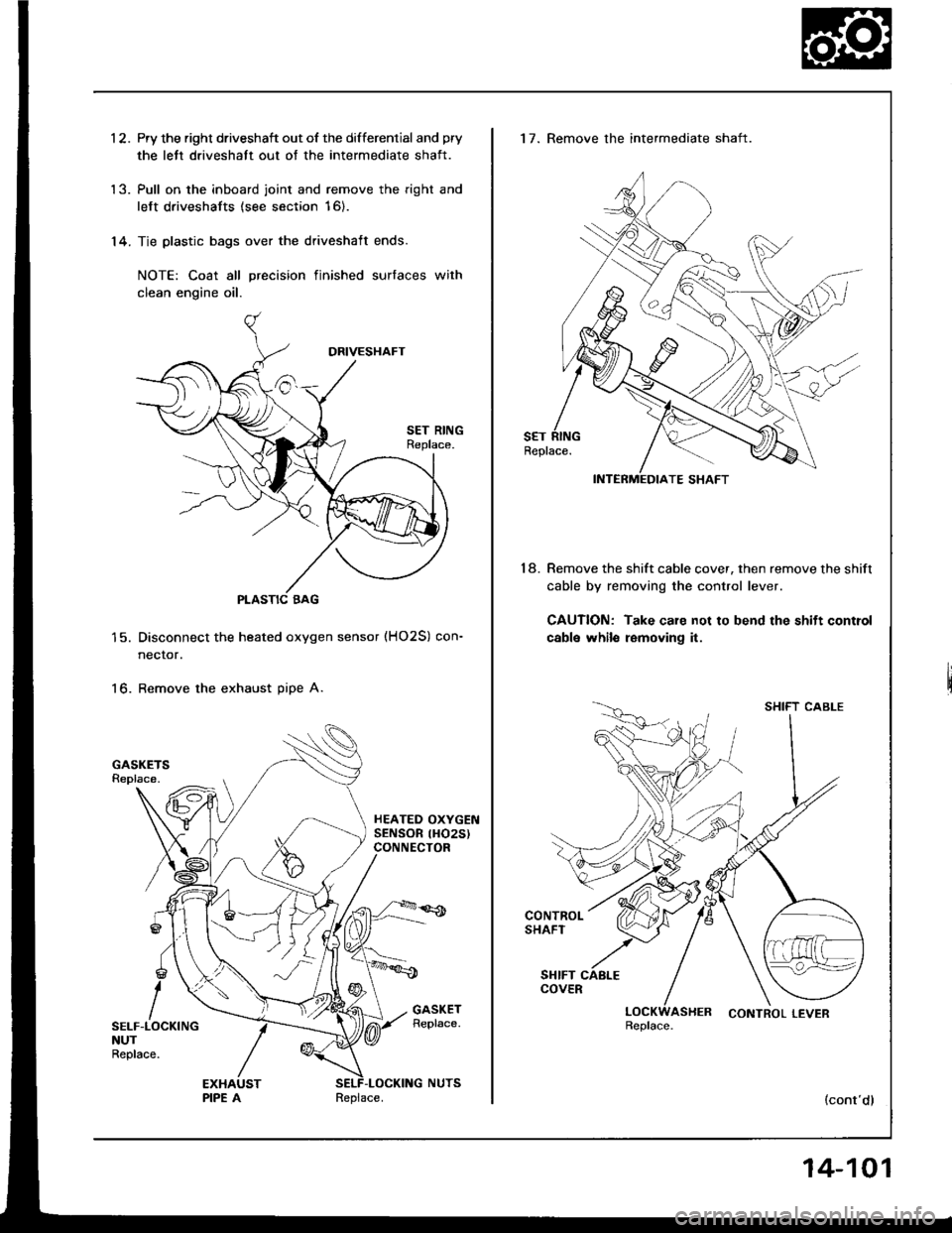

1 2. Pry the right driveshaft out of the differential and pry

the lett driveshatt out of the intermediate shaft.

'13. Pull on the inboard joint and remove the right and

left driveshafts (see section 16).

'14. Tie plastic bags over the driveshaft ends.

NOTE: Coat all precision finished surfaces with

clean engine oil.

PLASTIC BAG

Disconnect the heated oxygen sensor (HO2S) con-

necror.

Remove the exhaust pipe A.16.

SELF-LOCKINGNUTReplace.

Replace.

14-101

17. Remove the intermediate shaft.

Remove the shift cable cover, then remove the shift

cable by removing the control lever.

CAUTION: Take care not to bend the shift control

cabls whilo removing it.

18.

SHIFT CABLE

LOCKWASHER CONTROLLEVERReplace.

(cont'dl

Page 494 of 1413

Transmission

Removal (cont'dl

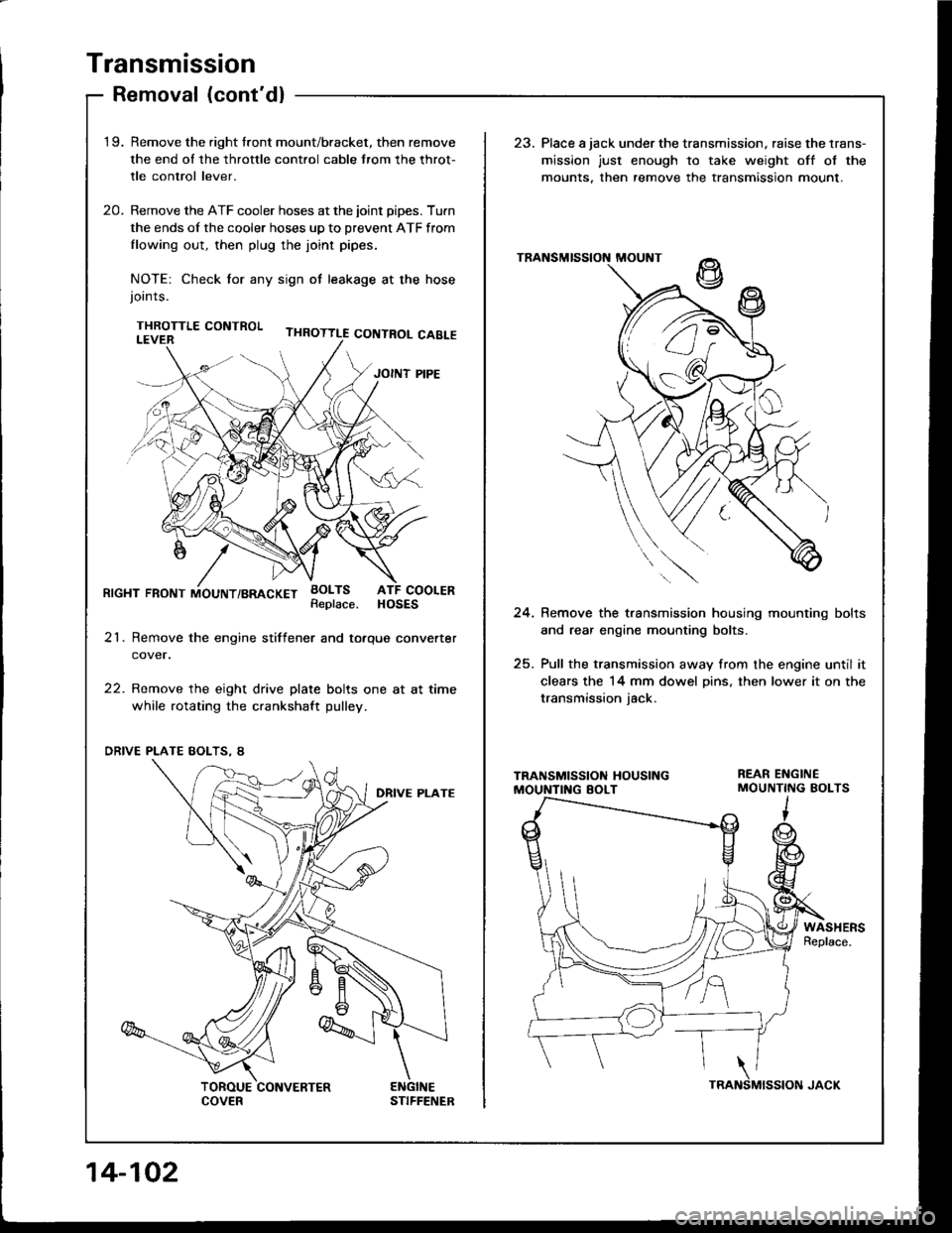

'1 9.Remove the right tront mount/bracket, then remove

the end ol the throttle cont.ol cable trom the throt-

tle control lever.

Remove the ATF cooler hoses at the joint pipes. Turn

the ends of the cooler hoses up to prevent ATF from

flowing out, then plug the joint pipes.

NOTE: Check tor any sign ot leakage at the hosejoints.

THROTTLE CONTROL

23. Place a jack under the transmission, raise the lrans-

mission just enough to take weight off ol the

mounts. then remove the transmission mount.

20.

RrcHT FRoNT iiouNT/BRAcKET BoLTsATF COOLERHOSESReplace.24. Remove the t.ansmission housing mounting bolts

and rear engine mounting bolts.

25. Pull the transmission away from the engine until it

clears the 14 mm dowel Dins, then lower it on the

transmission iack.

21. Remove the engine stiftener and totque converter

cover.

22. Remove the eight drive plate bolts one at at time

while rotating the crankshaft pulley.

WASHERSReplace.

'i z/'l e

" (-J t'

14-102

Page 496 of 1413

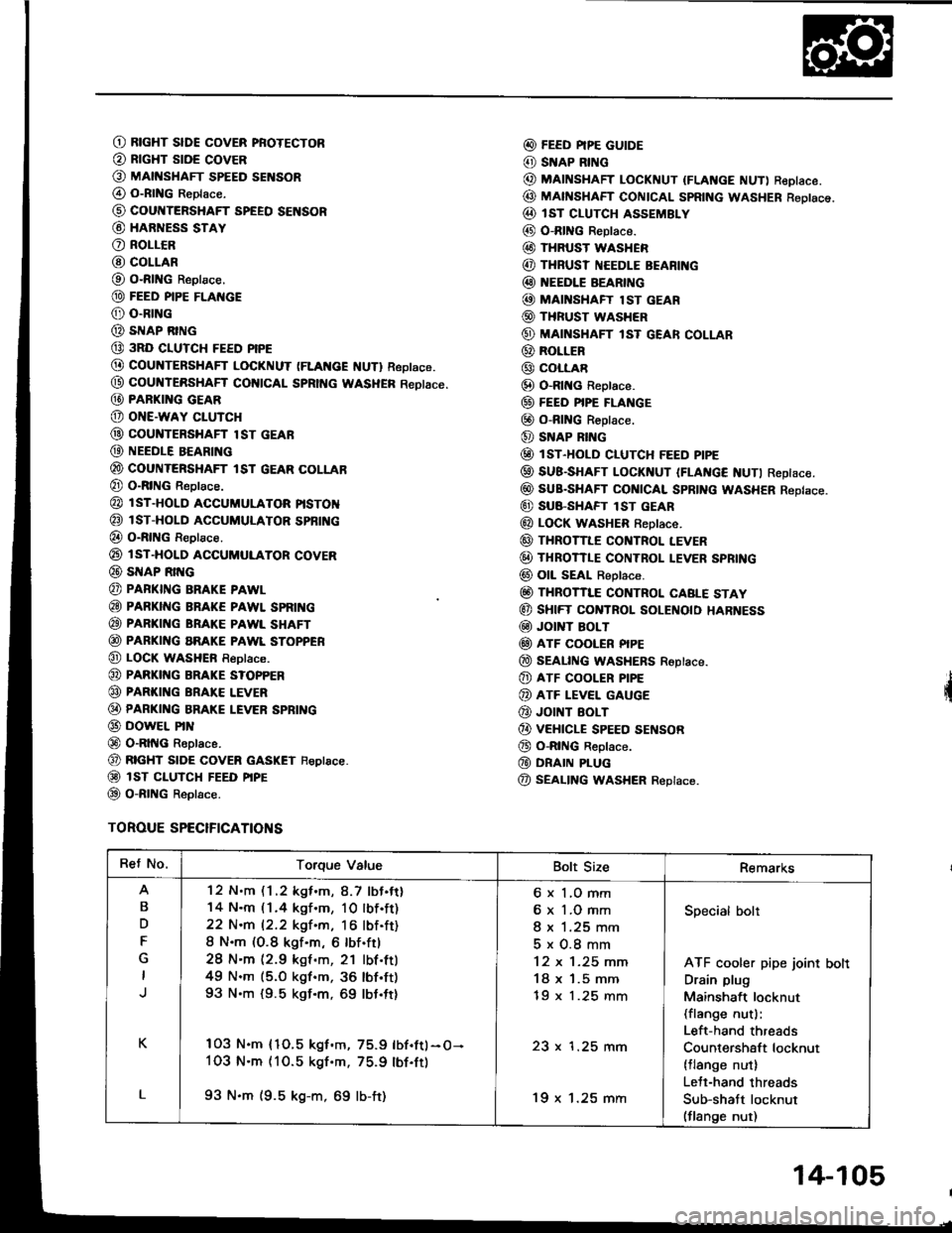

O RtcHT slDE covER pRoTEcToR

@ RrcHT stDE covER

O MAtt{sHAFr spEED sENsoR

@ o-RtNG Reptace.

@ cour{TERSHAFT SPEEO SENSOR

@ HARNESS STAY

O RoLLCR

@ COLLAR

O O-RING Reptace.

@ FEED PIPE FLAI{GE

@ o-RrNG

@ sIrlAP RING

@ 3RD CIUTCH FEED PIPE

@ COUNTERSHAFT LOCKNUT (FLAt{cE f{UTl Reptace.

@ coultTERsHAFf col{tCAL SpRtt{c WASHER Reotace.

@ PARKI G GEAR

@ oNE-waY cLUTcH

@ couNTERsHAFr lsr GEAR

@ NEEDLE BEARING

@ couNTERsHAFr tsr GEAR coLLAB

@ O-RING Reptace.

@ l sT-HoLD accuMuLAToR ptsToN

@ isT-HoLD ACCUMULAToR spBfi{c

@ o-RtNG Reptace.

@ rsT-HoLD ACGUMULAToR covER

@ SNAP Rrr{G

@ PAFKING BRAKE PAWL

@ PARKING BRAKE PAWL SPRII{G

@ PARKING BRAKE PAWL SHAFT

@ PARKING aRAKE PAWL SToPPER

@ LOCK wasHEn Reptace.

@ PARKI G BRAKE s?oPPER

@ PARKING BRAI(E LEVER

@ PARKI G BRAKE LEVER SPBING

@ DowEL PrN

@ O-RltIG Reptace.

@ RTGHT stoE covER GASKET Feptace.

@ isT ct-uTcH FEED ptpE

@ o-RtNG Reptace.

TOROUE SPECIFICATIONS

@ FEED PIPE GUIDE

@ SNAP RING

@ MAINSHAFT LocKNUT {FLANGE NUT) ReDIace.

@ MAfISHAFT CONTCAL SpRtNG WASHER Reotsce.

@ IsT cLUTcH ASSEMBLY

@ O-RING Reptace.

@ THRUST WASHER

@ THRUSI NEEDLE BEARI G

@ EEDLE BEARING

@ MAI'{SHAFT lsT GEAR

@ THRUST WASHER

@ MAINSHAFT lsT GEAR coLLAR

@ RoLLER

@ coLLAR

@ O-Rlt{c Reptace.

@ FEEo PIPE FLANGE

@ o-RING R€ptace.

@ SNAP RING

@ lsr-HoLD cLUTcH FEED ptpE

@ SUB-SHAFT LoCKNUT IFLAt{c€ NUTI Reptace.

@ suB-sHAFr cot{tcAl spRtNG WASHER Reptace.

@ SU8-SHAFT lST GEAR

@ LOCK WASHER f,eptace.

@ THRoTILE cor{TRoL LEVER

@ THRoTTLE coNTRoL I.EVER SPRING

@ oll sEAt Reptace.

@ THRoTTI"E coNTRoL CABLE STAY

@ sHtFT CONTROL SOLEI{O|O HARNESS

@ Jor T BoLT

@ ATF COOLER PIPE

@ SEAL|NG WASHERS Roptace.

@ ATF cooLER P|PE

@ ATF LEVEL GAUGE

@ JOINT EOLT

@ vEHtcLE spEED sEf{soR

@ o-RtNG Reptace.

@ DRAIN PLUG

@ SEALING WASHER Replace.

Ret No.Torque ValueBolt SizeRemarks

B

D

F

K

L

'12 N.m (1 .2 kgf .m, 8.7 lbJ.tt)

14 N.m (1.4 kgf.m, 10lbf.ft)

22 N.m 12.2 kgf.m, 16 lbf.ft)

8 N.m (O.8 kgf.m, 6 lbf.ftl

28 N'm (2.9 kgf .m, 21 lbf.ttl

49 N.m (5.O kgf.m, 36 lbf'ft)

93 N.m {9.5 kgf.m, 69 lbt.ft}

103 N.m {1O.5 kgf.m, 75.9 lbf.ftl-O-

1O3 N.m (10.5 kgf'm. 75.9 lbf.ft)

93 N.m (9.5 kg-m, 69 lb-ft)

6 x 1,O mm

6 x 1.O mm

I x 1.25 mm

5x0.8mm

12 x 1-25 mm

18 x '1.5 mm

tY x t.z5 mm

23 x 1.25 mm

'19 x 1.25 mm

Specialbolt

ATF cooler pipe joint bolt

Drain plug

Mainshaft locknut(flange nut):

Left-hand threads

Countershaft locknut(tlange nut)

Lett-hand threads

Sub-shatt locknut(flange nut)

14-105

Page 501 of 1413

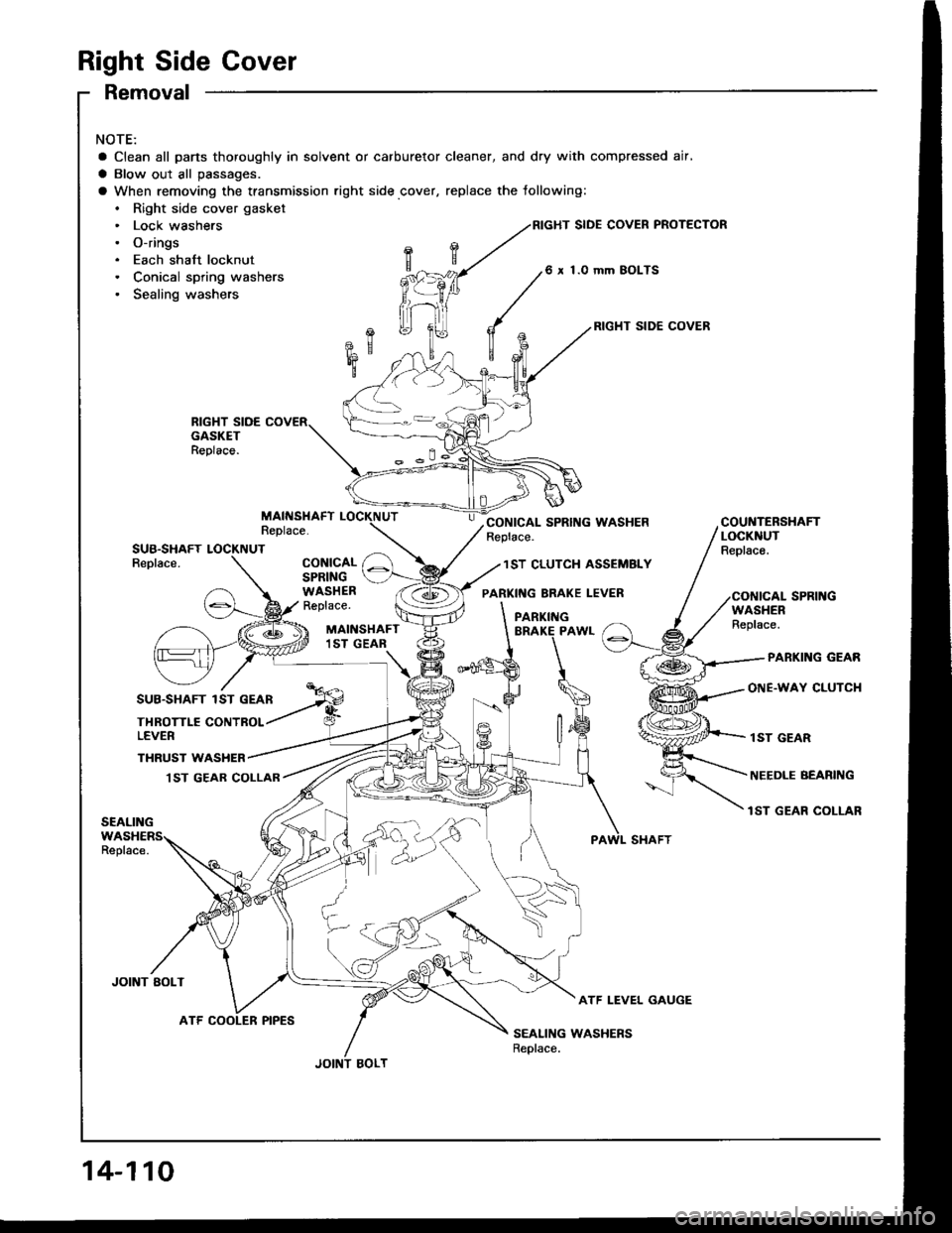

Right Side Cover

Removal

NOTE:

a Clean all pans thoroughly in solvent or carburetor cleaner, and dry with compressed air,

a Blow out all passages.

a When removing the transmission right side cover, replace the following:. Right side cover gasket. Lock washers. O-rings. Each shaft locknut. Conical spring washers. Sealing washers

RIGHT SIDE COVER

SIDE COVER PROTECTOR

1.O mm BOLTS

SUB.SHAFTReplace.

THROTTLE CONTBOLLEVER

MAINSHAFT1ST GEAR

CONICALSPRINGWASHERReplace.WASHERReplace.

PARKING GEAR

ONE.WAY CLUTCHSUB.SHAFT 1ST GEAN

JOINT AOLT

THRUST WASHER,I ST GEAB COLLAR

1ST GEAR

NEEDLE BEABING

lST GEAR COLLAR

ATF LEVEL GAUGE

SEALING WASHERSReplace.

14-110

ATF COOLER PIPES

Page 555 of 1413

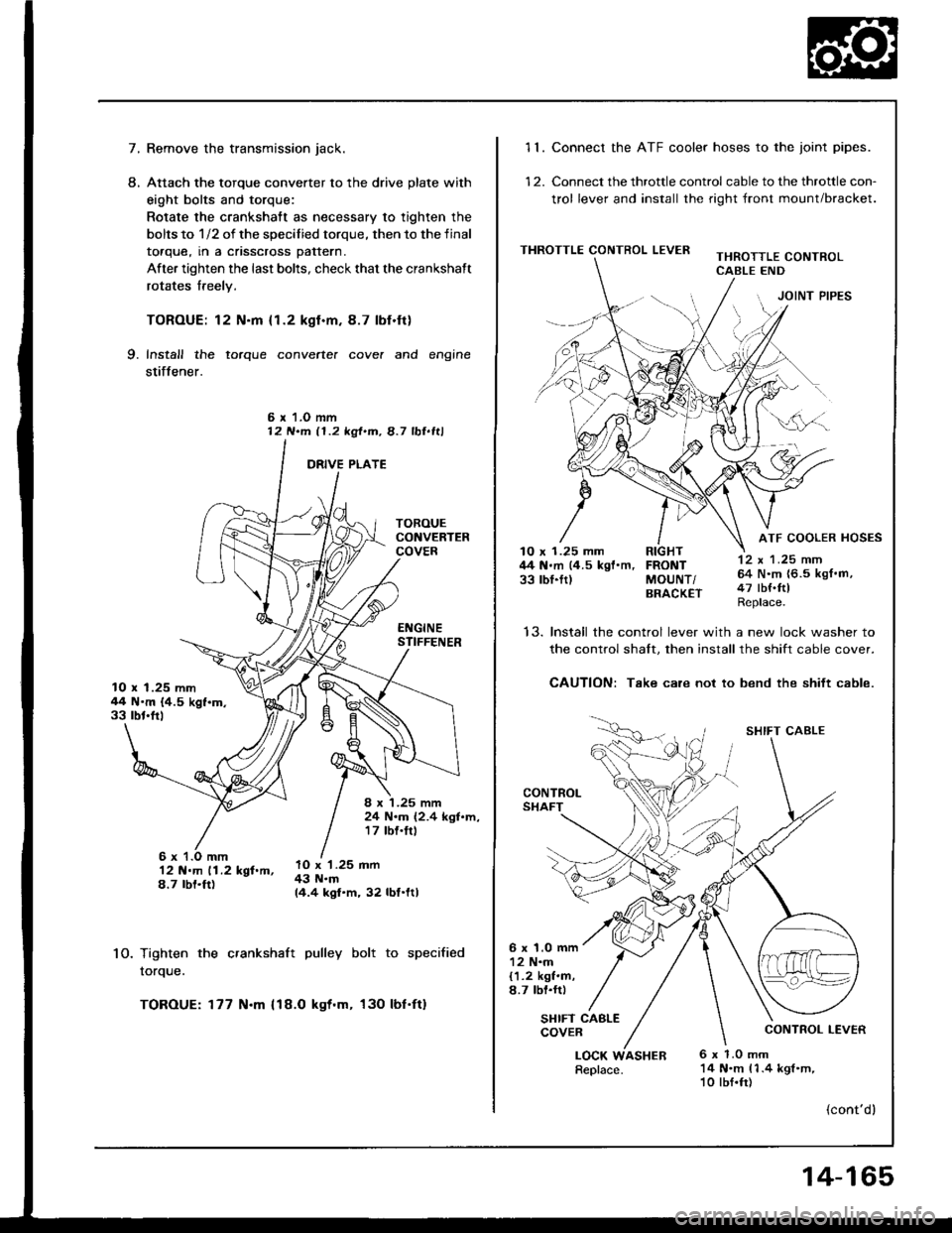

7.Remove the transmission jack.

Attach the torque converter to the drive plate with

eight bolts and torque:

Rotate the crankshatt as necessary to tighten the

bolts to 1/2 of the specilied torque, then to the final

toaque, rn a cnsscross pattern.

After tighten the last bolts, check that the crankshaft

rotates freely.

TOROUE: 12 N.m {1.2 kgl.m.8.7 lbf.ft}

Install the torque converte. cove. and engine

stiffener.

L

9.

6 r 1.O mm12 N.m 11.2 kgt.m, 8.7 lbl.ltl

10.

12 N.m 11.2 kgf.m,8.7 rbt.ft)

Tighten the crankshaft pulley bolt to specified

rorque.

TOROUE: 177 N.m {18.O kgt.m, 130 lbf'ft}

10 x 1.25 mm44 N'm {4.5 kgf.m.33 rbt'frl

8 x '1.25 mm24 N.m (2.4 kgl.m,17 tbf.trl

lO x '1.25 mm43 N.m14.4 kgf.m, 32 lbf.ltl

11. Connect the ATF cooler hoses to the joint pipes.

12. Connect the throttle control cable to the throttle con-

trol lever and install the right front mount/bracket.

THROTTLE CONTROL LEVERTHROTTLE CONTROLCABLE END

JOINT PIPES

12 x 1 .25 mm64 N.m {6.5 kgf.m,47 tbf.ftlReplace.

ATF COOLER HOSES10 x 1.25 mm RIGHT44 N.m (4.5 kgf'm, FRONT33 rbl.ftl MoUNT/BRACK€T

t5.Install the control lever with a new lock washer to

the control shalt. then install the shift cable cover.

CAUTION: Take care not to bend the shift cable.

CONTROLSHAFT

SHIFT CABLE

CONTROL LEVER

6 x 1.0 mm12 N.m{1.2 kgf.m,8.7 lbl.rr)

SHIFT CABLECOVER

LOCK6 x 1.0 mm14 N.m 11.4 kgl.m,10 lbf.fr)

(cont'dl

Replace.ASHER

14-165

Page 556 of 1413

Transmission

Installation {cont'd)

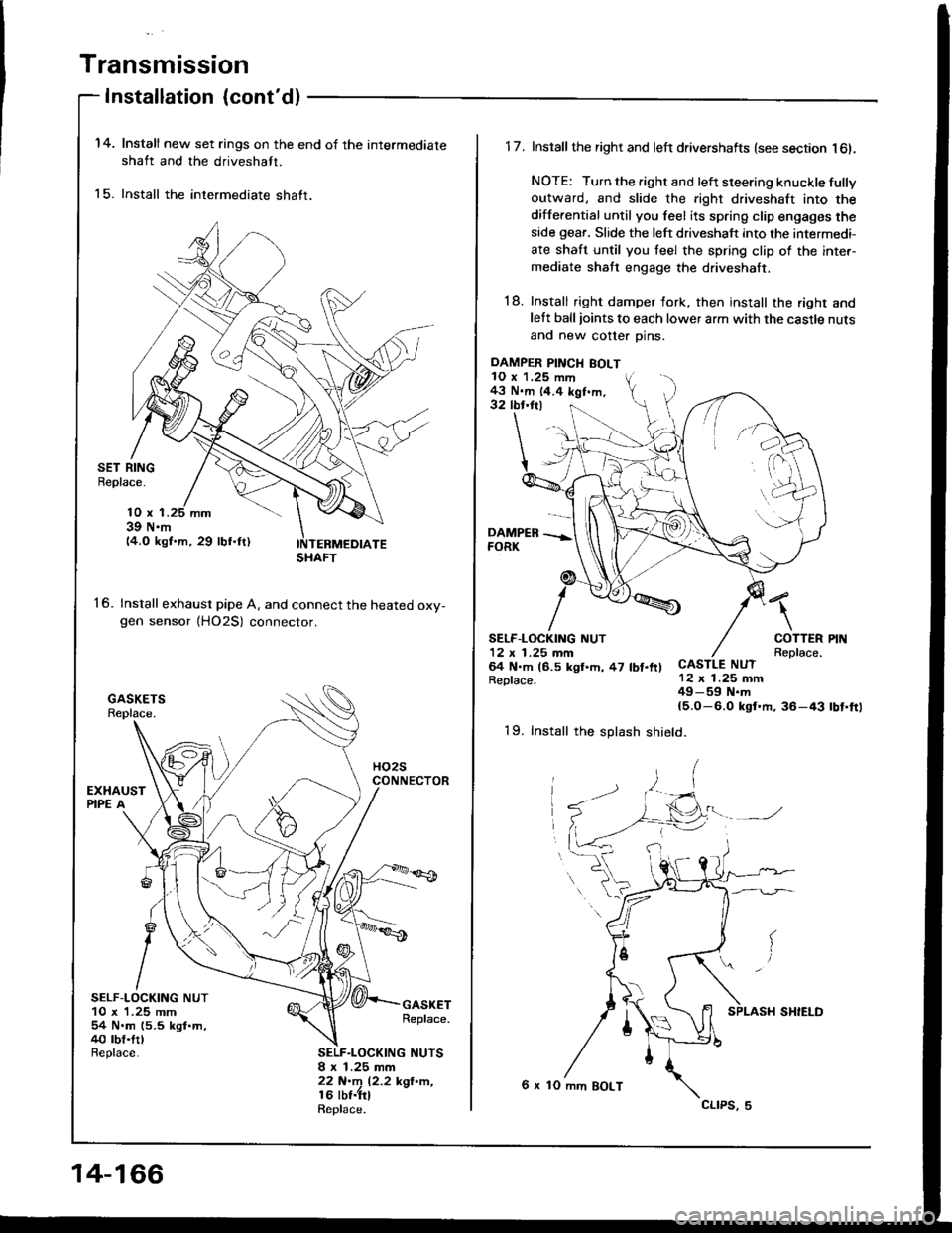

14.

15.

Install new set rings on the end of the intermediate

shaft and the driveshaft.

Install the intermediate shaft.

SET RINGBeplace.

16.

10 x 139 N.m14.O kgf.m, 29 lbf.ftl

Install exhaust pipe A. and connect the heated oxv-gen sensor {HO2S) connector.

SELF-LOCKING NUT10 x 1.25 mm54 N.m (5.5 kgl.m,40 rbt.trlReplace.

GASKETReplace.

SELF.LOCKING NUTSI x 1.25 mm22 N.m 12.2 kgl'n,16 lbt.trlRepl6ce.

SHAFT

14-166

DAMPER PINCH BOLT10 x 1.25 mm43 N.m 14.4 kgf.m,32 tbr.ftl

1 7. Install the right and left drivershafts (see section l6l.

NOTE: Turn the right and left steering knuckle fullyoutward, and slide the right driveshaft into the

differential until you feel its spring clip engages theside geaf. Slide the left driveshaft into the intermedi-

ate shaft until you teel the spring clip of the inter-mediate shaft engage the driveshaft.

18. Install right damper fork, then install the right andlett balljoints to each lower arm with the castle nuts

and new cotter Dins.

\

COTTERReplace.CASTLE NUT12 x 1.25 mm49-59 N.m{5.O-6.0 ksf.m, 36-43

SELF.LOCKING NUT12 x 1 .25 mm64 N.m (6.5 kgl.h, 47 lbt.ftlReplace.

rbt'ft1

19. Install the splash shield.

6 x 10 mm BOLT

cltPs, 5

Page 594 of 1413

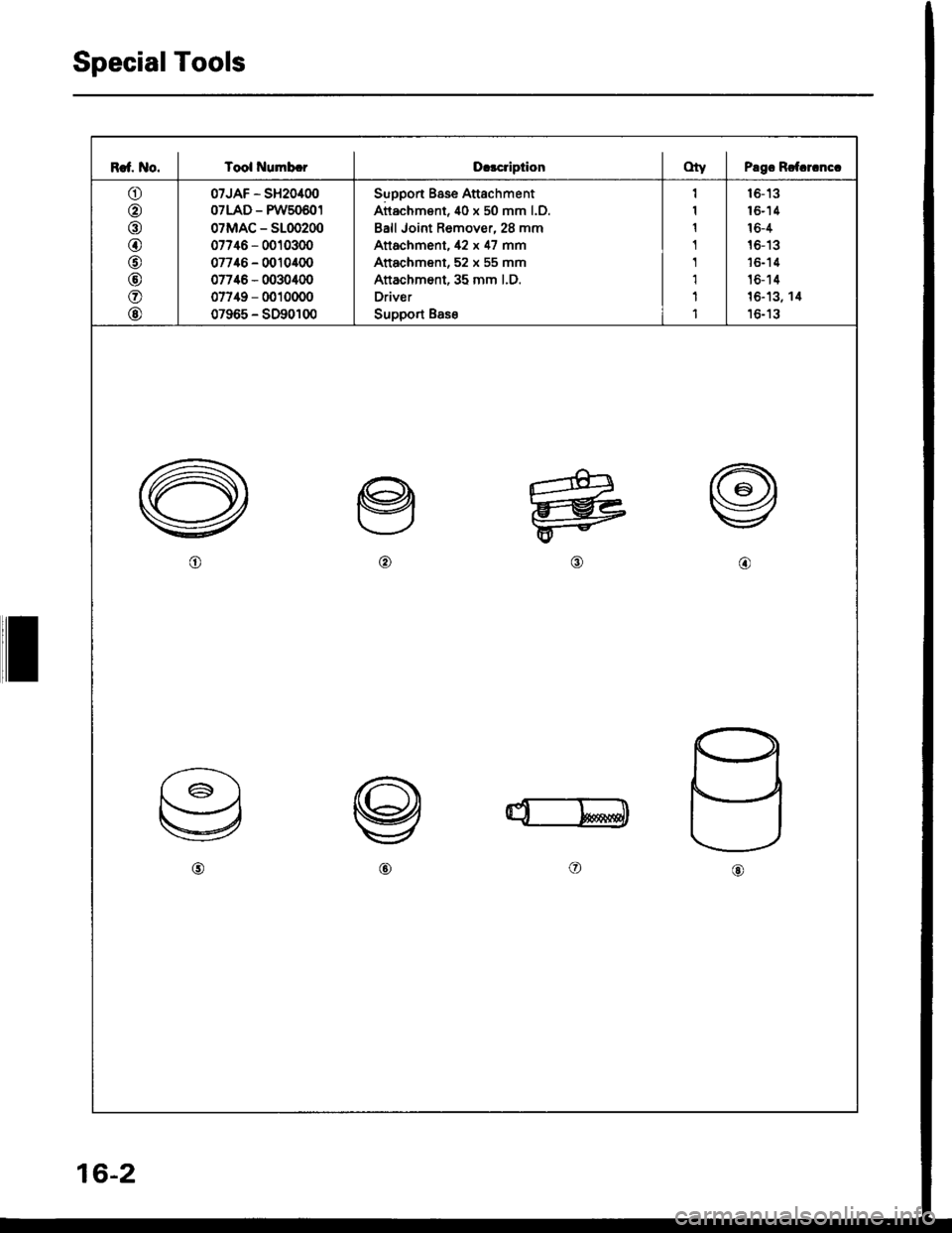

SpecialTools

R!t. No. I Tool NumbcrD.lcriptionOty I Psgo Rctcr.nct

o

@

o

@

@

@

o

@

07JAF - SH20400

07LAD - PW50601

07MAC - 5100200

07746 - 0010300

07746 - 0010400

07746 - 0030400

07749 - 0010000

07965 - SD90100

Suppon Bsse Attachment

Attachment, 40 x 50 mm l.O.

Ball Joint Remover, 28 mm

Anachment, 42 x 47 mm

Attachment, 52 x 55 mm

Attachment, 35 mm l.D.

Driver

Support Bas€

1

1

1

1

1

1

1

1

16- 13

16-14

16-4

16-13

16-14

16-'r 4

16-13, 14

16-13

(4,

o

16-2

Page 595 of 1413

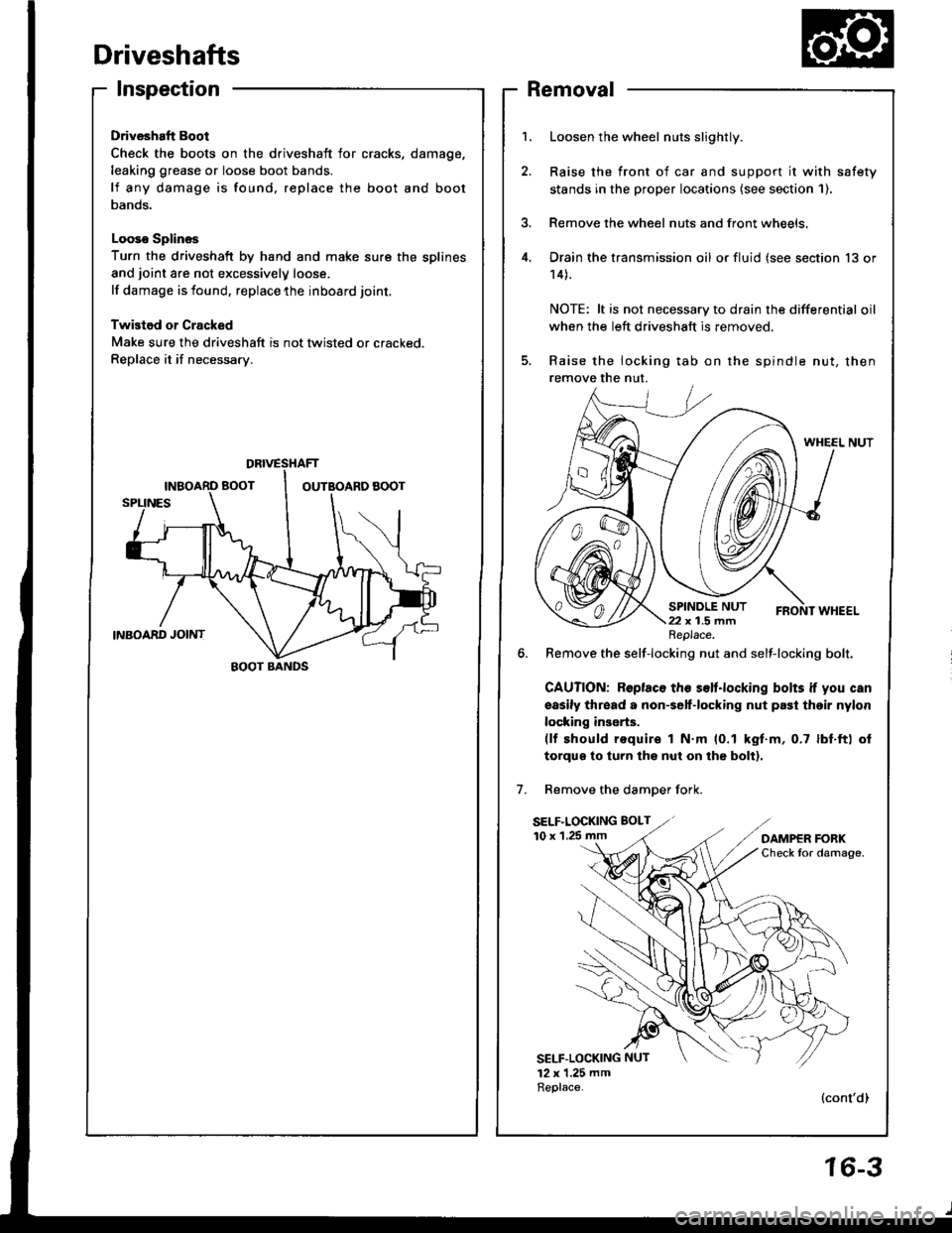

Driveshafts

Inspection

Driveshaft Boot

Check the boots on the driveshaft for cracks,

leaking grease or loose boot bands.

lf any damage is found, replace the boot

Danos.

Looso Splines

Turn the driveshaft by hand and make sure the splines

and joint are not excessivelV loose.

lf damage is found, replace the inboard joint,

Twistod or Cracked

Make sure the driveshaft is not twisted or cracked.

Replace it if necessarv.

damage,

and boot

Removal

Loosen the wheel nuts slightly.

Raise the front of car and support it with safety

stands in the proper locataons (see section 1),

Remove the wheel nuts and front wheels,

Drain the transmission oil or fluid (see section 13 or

14).

NOTE: lt is not necessary to drain the differential oil

when the left driveshaft is removed.

Raise the locking tab on the spindle nut, then

remove the nut.

WHEEL NUT

6. Remove the self-locking nut and self-locking bolt.

GAUTION: Roplaco th€ s€lt.locking bolts if you can

sasily thread a non€elf-locking nut prst thoir nylon

locking inserts.(lf should require I N.m (0.1 kgt.m, 0.7 lbf.ft) ol

torqus to turn lhs nut on the bolt).

Remove the damDer fork.

SELF.LOCKING BOLT

10 x 1.25 mm

SELF-LOCKING NUT

12 x 1.25 mmReplace.(cont'dl

DBIVESTIAFT

EOOT BANDS

Replace.

16-3

Page 596 of 1413

Driveshafts

Removal (cont'dl

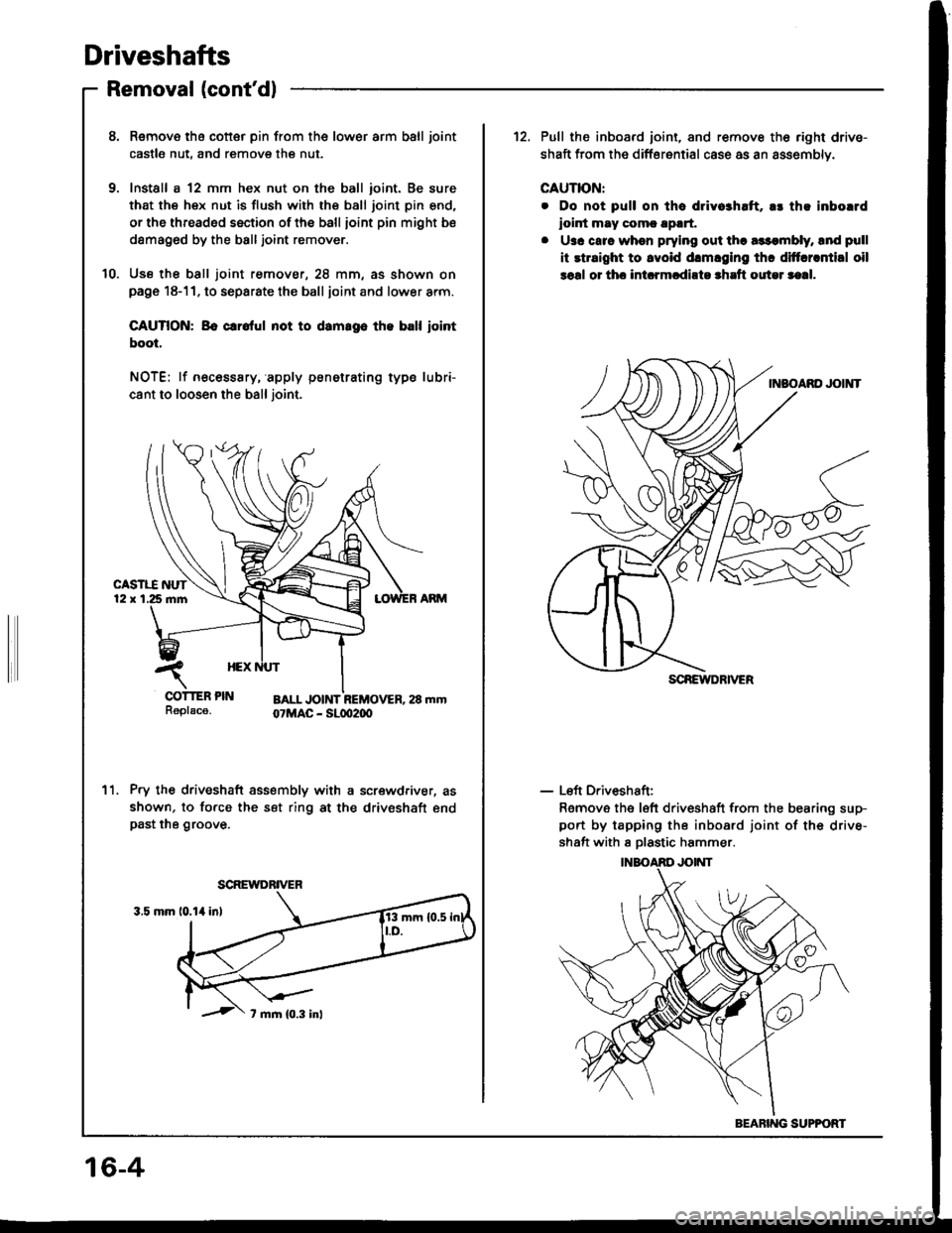

8. Remove tha cotter pin from the lower arm ball joint

castle nut, and remove the nut.

9. Install a 12 mm hex nut on the ball ioint. Be sure

that the hex nut is flush with the ball joint pin end,

or the threaded section of the ball ioint pin might be

damag6d by the balljoint remover.

10. Use th€ ball joint remover, 28 mm, as shown onpage 18-11. to separate the ball joint and lower arm.

CAUTION: Bo crrolul not to damrgo th. ball iointboot.

NOTE: lf necesssry, apply penetrating type lubri-

cant to loosen the ball joint.

Pry the driveshaft assembly with a screwdriver, as

shown, to force the set ring at the driveshaft endpast the groove.

11.

SCREWDRIVER

12. Pull the inboard joint, and remove th6 right drive-

shaft from the differential case as an assemblv.

CAUTION:

. Do not pull on tha dlivo3haft, a! th! inborrd

ioint may comc !p!rt,

. U3c carc when prying out tha a$qnbly, lnd pull

it rtraight to lvoid drmlging thc diftcrrntial oil

soal or thc int.rmcdirto shrft outel saal.

- Left Driveshaft:

Remove the left driveshaft from the bearing sup-

port by tapping the inboard joint of the drive-

shaft with I Dlastic hammer.

SCREIYDRIVER

BEARING SUPPOFT

16-4

Page 597 of 1413

KNUCKLE

DRIVESHAFT

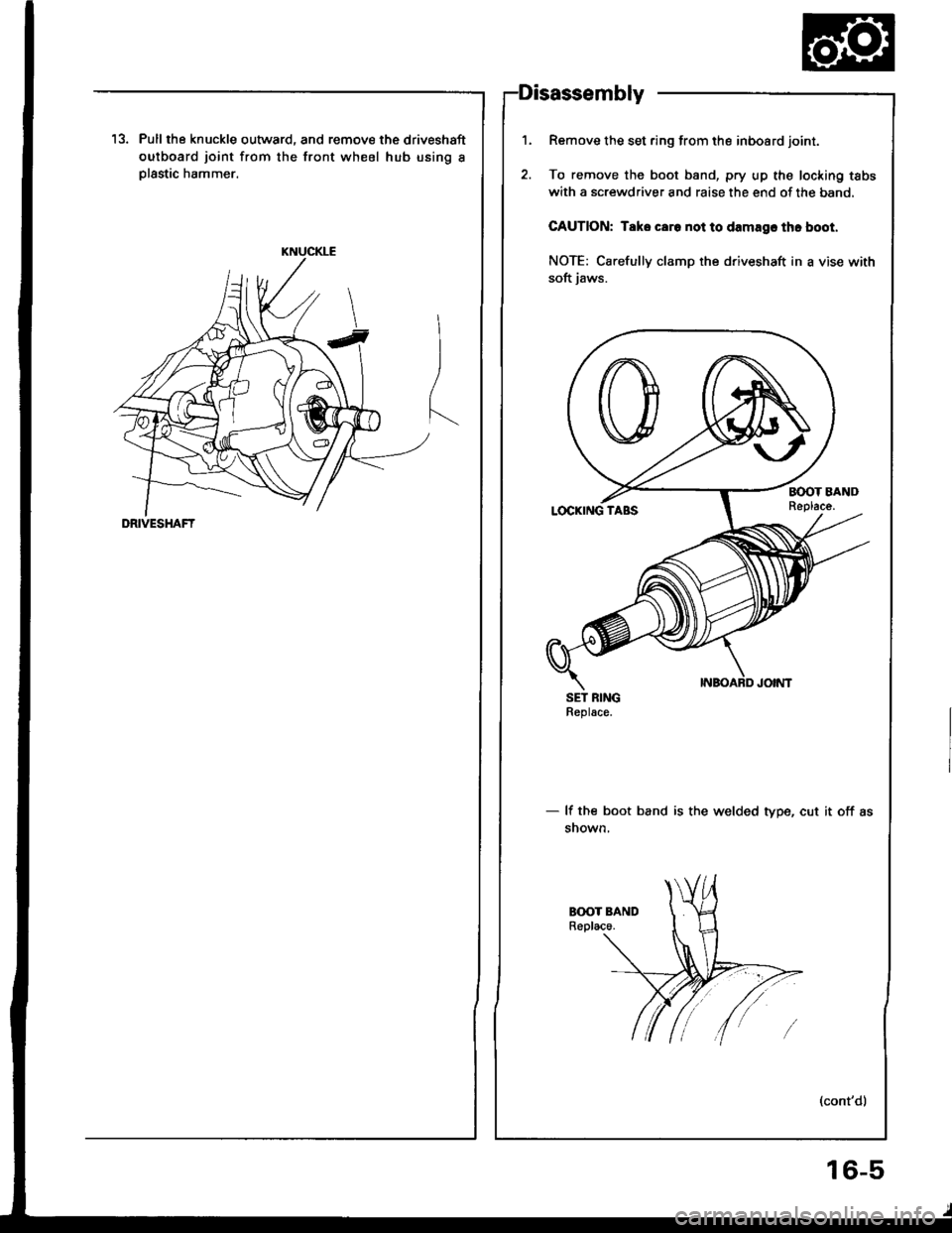

13. Pull the knuckle outward, and remove the driveshaft

outboard joint from the front wheel hub using I

Dlastic hammer.

Remove the set ring from the inboard joint.

To remove the boot band, pry up the locking tabs

with a screwdriver and raise the end of the band,

CAUTION: Taks caro not to damagc thc boot.

NOTE: Carefully clamp the driveshaft in a vise with

soft iaws.

SET RINGReplace.

- lf the boot band is the welded type, cut it off as

snown,

1.

16-5