cv joint HONDA INTEGRA 1994 4.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 598 of 1413

Driveshafts

Disassembly (cont'd)

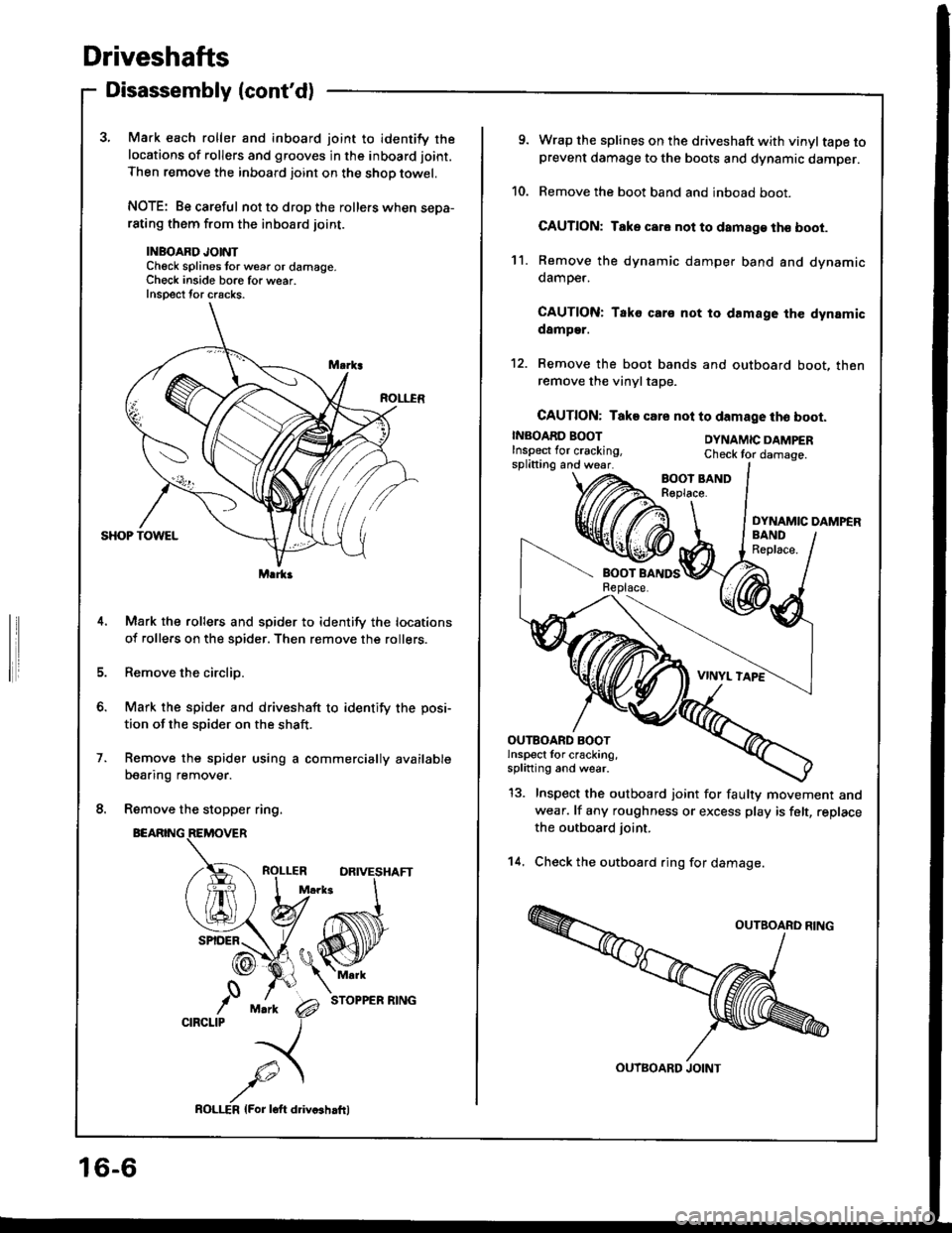

3, Mark each roller and inboard joint to identify the

locations of rollers and grooves in the inboard joint.

Then remove the inboard joint on the shop towel.

NOTE: Be careful not to drop the rollers when sepa-rating them from the inboard joint.

INBOARD JOINTCheck splines tor w6ar or damage.Ch€ck inside bore for wear.Inspect tor cracks.

Mark the rollers and spider to identify the locations

of rollers on the spider. Then remove the rollers.

Remove the circlip.

Mark the spider and driveshaft to identify the posi-

tion of the spider on the shaft.

Remove the spider using a commercially available

bearing remover.

Remove the stopper ring.

BEARING

STOPPER RING

Marka

o.

,'0CIRCLIP

16-6

ROLI-€R lFor loft ddvcshrfrl

9. Wrap the splines on the driveshaft with vinyltape toprevent damage to the boots and dynamic damper.

10. Remove the boot band and inboad boot.

CAUTION: Take car. not to damage th€ boot.

11. Remove the dynamic damper band and dynamicdamoer.

CAUTION: Tako cars not to damage the dynamicdamper.

12. Remove the boot bands and outboard boot, thenremove the vinyltape.

CAUTION: Take csre nol to damage tho boot.

INBOARD BOOTInspect lor cracking,splitting and wear.

DYNAMIC DAMPERCheck tor damage.

DYNAMIC DAMPER

13. Inspect the outboard joint for faulty movement andwear. lf any roughness or excess play is felt, replace

the outboard joint.

14. Check the outboard ring for damage.

OUTBOARD BOOTlnspect for cracking,splining and wear.

OUTBOARD JOINT

Page 599 of 1413

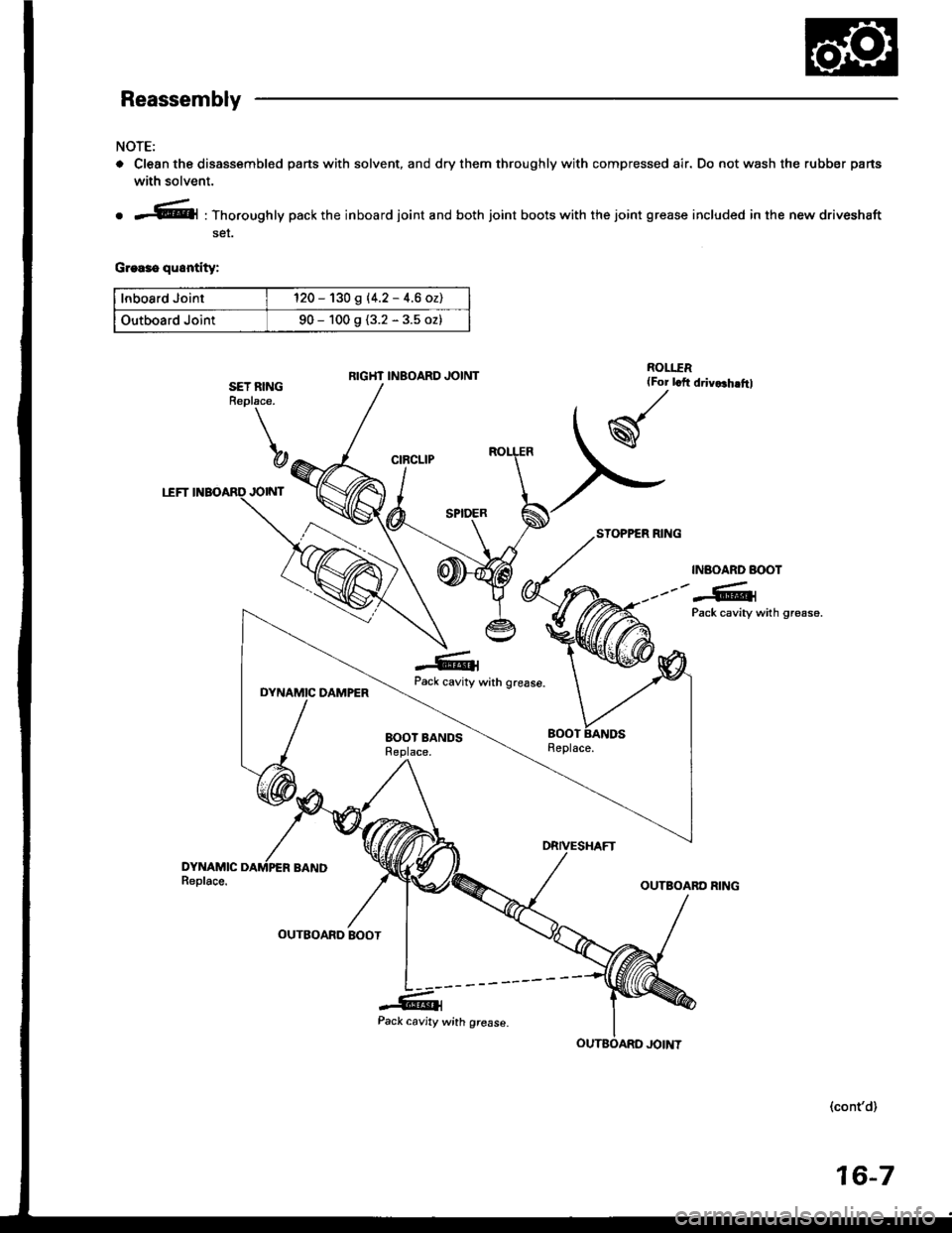

Reassembly

NOTE:

o Clean the disassembled pans with solvent, and dry them throughly with compressed air. Do not wash the rubber parts

with solvent.

ROLI.TR{For lcft

w

o *.'.l|@l : Thoroughly pack the inboard joint and both joint boots with the joint grease included in the new driveshaft

ser.

G.ea3o quontity:

lnboard Joint120 - 130 g |'4.2 - 4.6 ozl

Outboard Joint90 - 100 g {3.2 - 3.5 oz}

INAOARD BOOT

---"-G1Pack cavity with gr€ase.

DYNAMIC DAMPERwrth grease.

SET RINGReplace.

b

,RD JOINT

-GlPack cavity

EOOT BANDSReplace.

(cont'd)

RIGHT INBOARD JOINT

16-7

Page 600 of 1413

Driveshafts

Reassembly (cont'dl

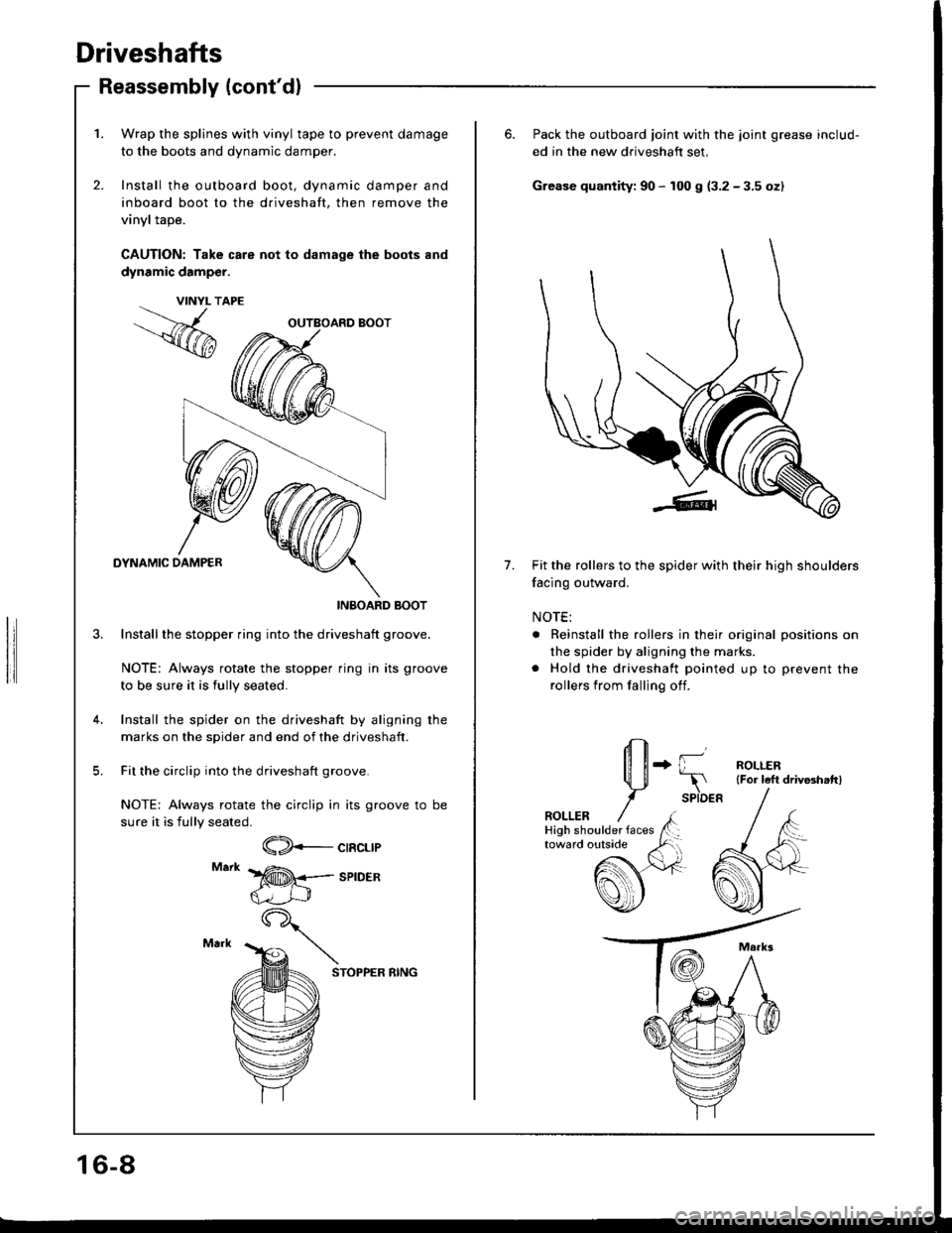

1. Wrap the splines with vinyl tape to prevent damage

to the boots and dynamic damper.

2. Install the outboard boot, dynamic damper and

inboard boot to the driveshaft, then remove the

vinyl tape.

CAUTION: Take care not to damage the boots and

dynamic damp€r.

DYNAMIC DAMPER

INBOARD BOOT

Installthe stopper ring into the driveshaft groove.

NOTE: Always rotate the stopper ring in its groove

to be sure it is fully seated.

Install the spider on the driveshaft by aligning rhe

marks on the spider and end of the driveshaft.

Fit the circlip into the driveshaft groove.

NOTE: Always rotate the circlip in its groove to be

sure it is fully seated.

VINYL T

,.%

CIRCLIP

SPIDER

STOPPER RING

OUTBOARD BOOT

16-8

6. Pack the outboard joint with the joint grease includ-

ed in the new driveshaft set,

Grease quantity: 90 - 100 g (3.2 - 3.5 oz)

7.Fit the rollers to the spider with their high shoulders

facing outward.

NOTE:

. Reinstall the rollers in their original positions on

the spider by aligning the marks.

. Hold the driveshaft pointed up to prevent the

rollers from falling off.

+ {l--r

SPIDER

ROLLER{For left driv8hattl

ROLLER

Page 601 of 1413

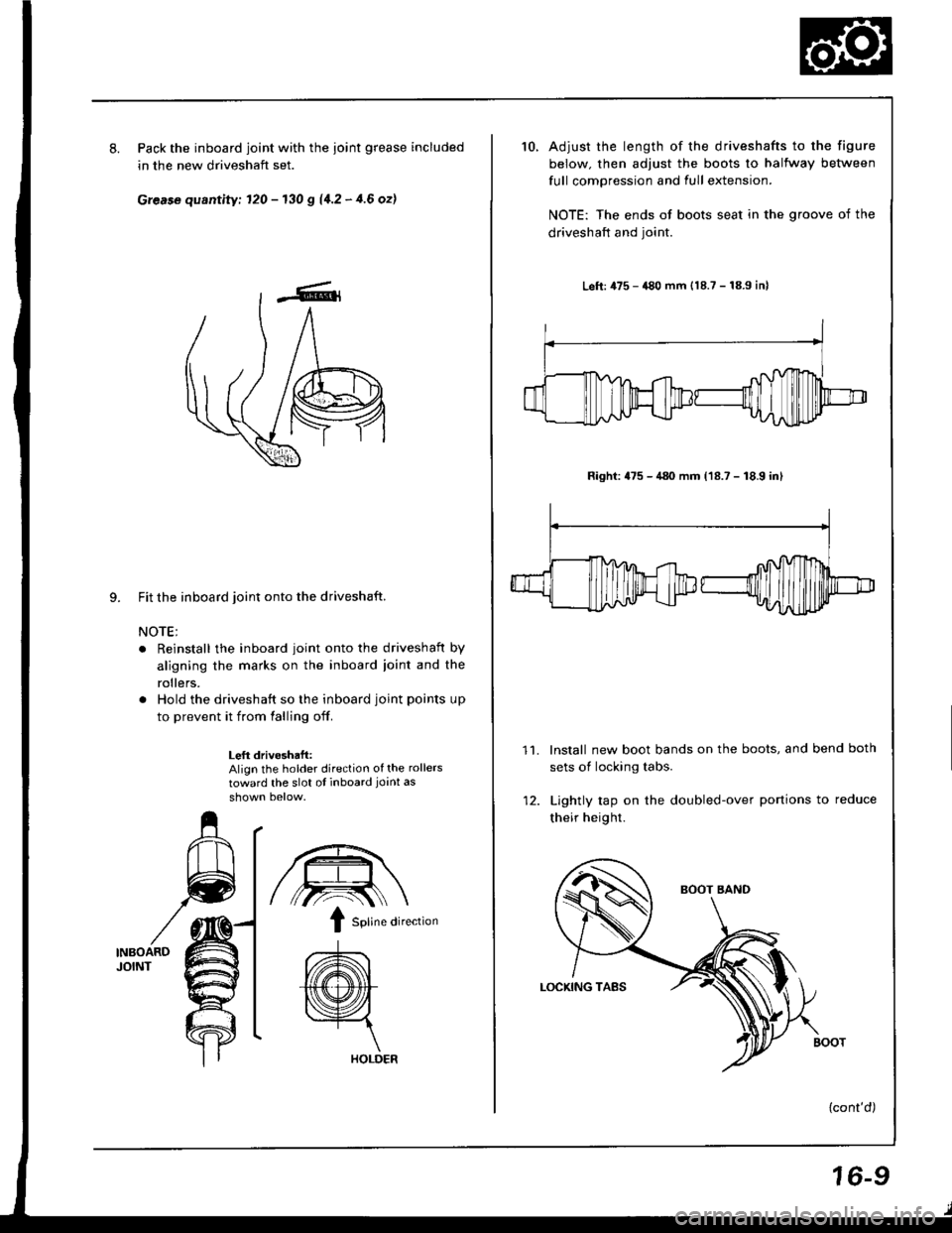

8.Pack the inboard joint with the ioint grease included

in the new driveshaft set.

Grease quantity; 120 - 130 g 11.2 - 4.6 ozl

9. Fit the inboard joint onto the driveshaft.

NOTE;

. Reinstall the inboard joint onto the driveshaft by

aligning the marks on the inboard ioint and the

rollers.

. Hold the driveshaft so the inboard joint points up

to prevent it from falling off.

Left drivoshaft:Align the holder direction of the rollers

toward the slot ot inboard joint as

INBOARDJOINT

/,.-:--\ \

I sotine di,ection

A\

{(@}

HOLDER

10.Adjust the length of the driveshafts to the figure

below. then adjust the boots to halfway between

full compression and full extension.

NOTE: The ends of boots seat in the groove of the

driveshaft and joint.

Left: 475 - 480 mm {18.7 - 18.9 inl

Right: 475 - 480 mm (18.7 - 18.9 inl

lnstall new boot bands on the boots, and bend both

sets of locking tabs.

Lightly rap on the doubled-over portions to reduce

their height.

{cont'd)

11.

16-9

Page 602 of 1413

Driveshafts

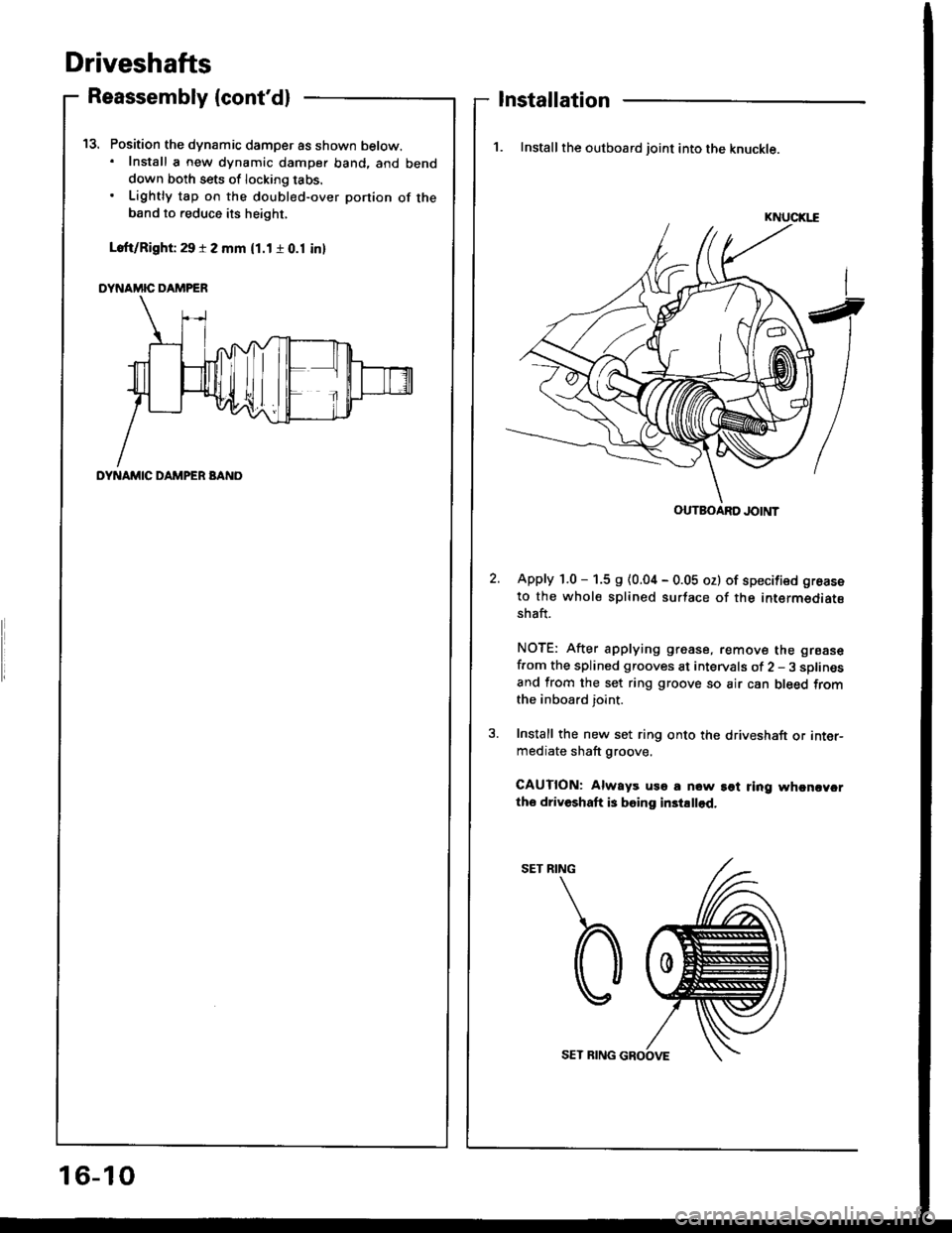

Position the dynamic damper as shown below.. Install a new dynamic damper band. and benddown both sets of locking tabs.

Lightly tap on the doubl€d-over ponion of theband to reduce its height,

Loft/Right 29 r 2 mm (1.1 r 0.1 inl

DYNAMIC DAMPER

t5.

Reassembly (cont'dl

DYNAMIC DAMPER BANO

Installation

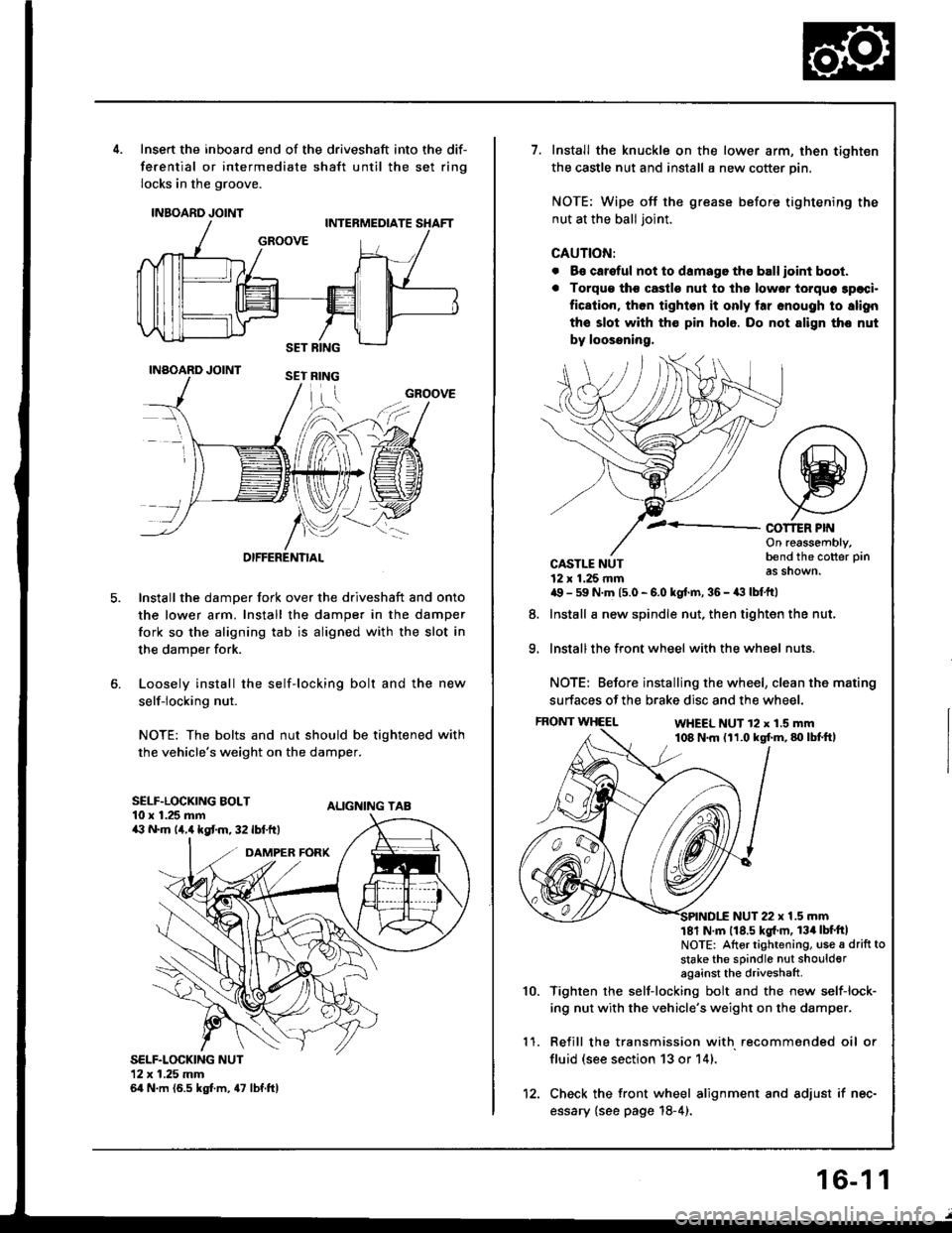

1. Install the outboard joint into the knuckle.

KNUCIGE

Apply 1.0 - 1.5 s (0.04 - 0.05 oz) of specified groase

to the whole splined surtace of the intermediatsshaft.

NOTE: After applying grease, remove the grsase

f.om the splined grooves at intervals of 2 - 3 sDlinesand from the set ring groove so air can bleed fromthe inboard joint.

Install the new set ring onto the driveshaft or inter-mediate shaft groove.

CAUTION: Always uso a now sot ring whcncycrtho driveshaft is boing in3tallod.

RING

b

OUTBOARD JOINT

16-10

SET RING GROOVE

Page 603 of 1413

5.

Insert the inboard end of the driveshaft into the dif-

ferential or intermediate shaft until the set ring

locks in the groove.

INBOARD JOINT

INAOARD JOINT

OIFFERENTIAL

Install the damper fork over the driveshaft and onto

the lower arm. Install the damper in the damper

fork so the aligning tab is aligned with the slot in

the damper fork.

Loosely install the self-locking bolt and the new

self-locking nut.

NOTE: The bolts and nut should be tightened with

the vehicle's weight on the damper.

ALIGNING TAB

SELF.LOCKING NUT12x 1.25 mm64 N.m (6.5 kgt m, 47 lbf.ftl

GROOVE

SELF.LOCKING BOLT10 x 1.25 mma:' N.m lir,4 kgt m, 32 lbf.ftt

1.Install the knuckle on the lower arm, then tighten

the castle nut and install a new cotter pin.

NOTE: Wipe off the grease before tightening the

nut at the ball joint.

CAUTION:

. B€ careful not to damago tho ball ioint boot.

. Torqu€ tho castle nut to ths lower torquo 3paci.

fication, then tighlon it only tar snough to slign

the slot with th€ pin hole. Do not align tho nut

by loossning,

COT1ER PIf{On reassembly,bend the cotter pin

as shown.

9.

CASTLE NUT12 x 1.25 rnma9 - 59 N.m 15.0 - 6.0 kgt.m, 36 - a:t lbtftl

Install a new spindle nut, then tighten the nut,

Install the front wheel with the wheel nuts.

NOTE: Before installing the wheel, clean the mating

surfaces of the brake disc and the wheel.

FRONT WHEELWHEEL NUT 12 x 1.5 mm108 N.m (11.0 kgf.m,80lbtft,

8.

1 '�I.

10.

NUT 22 x 1.5 mm181 N m 118.5 kgl'm, 134lbt'ftlNOTE: Altor tightening, use a drift to

stake the sPindle nut shoulderagainst the driveshaft

Tighten rhe self-locking bolt and the new self-lock-

ing nut with the vehicle's weight on the damper.

Refill the transmission with recommended oil or

fluid (see section 13 or 14).

Check the front wheel alignment and adjust if nec-

essary {see page 18-4).

12.

16-1 1

Page 608 of 1413

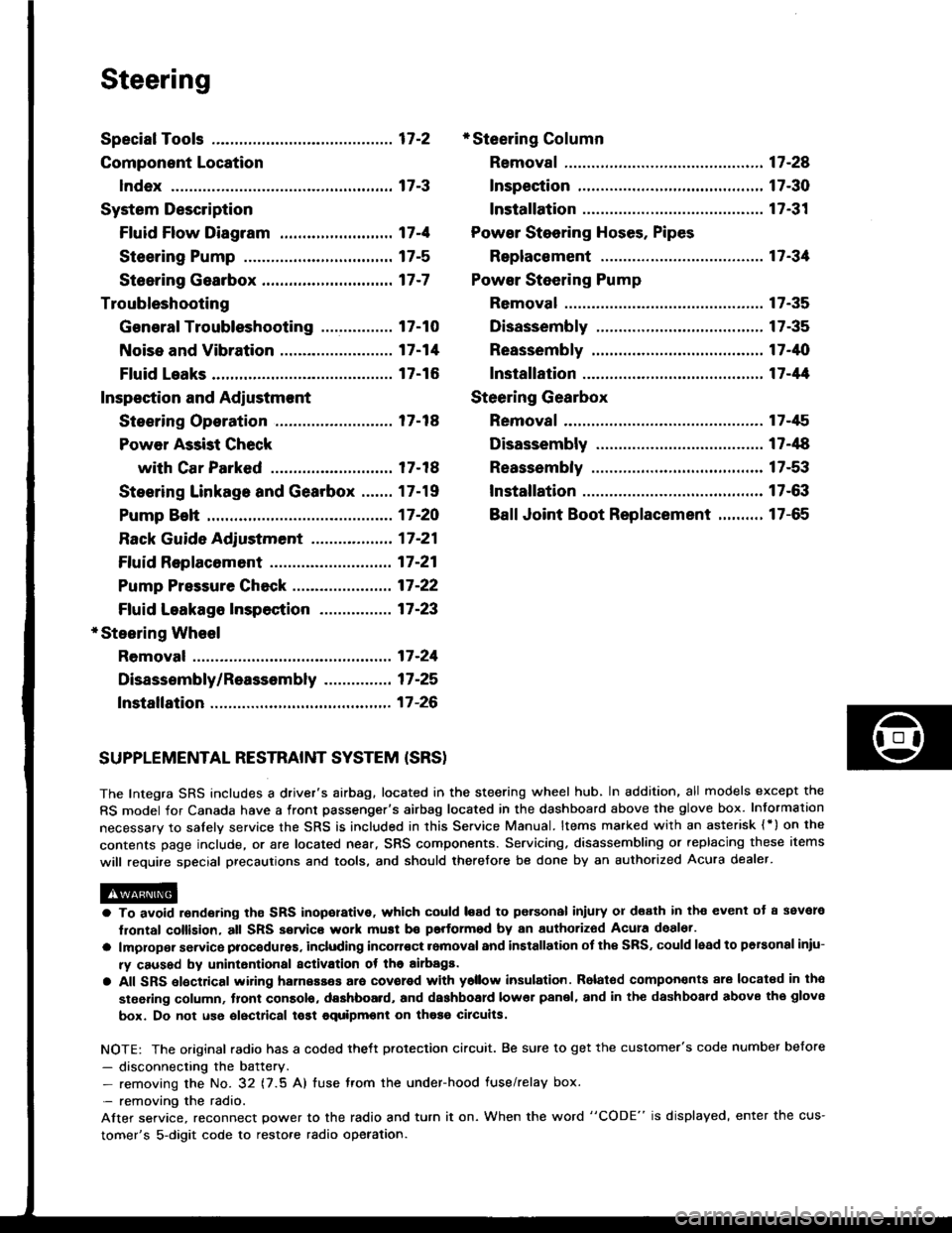

Steering

Special Tools ............. 17-2

Component Location

lndex ................ ...... 17-3

System Description

Ff uid Flow Diagram ......................... 17 -1

Steering Pump ................................. 17-5

Steering Gearbox ............................. 17-7

Troubleshooting

General Troubleshooting ................ 17-10

Noise and Vibration ......................... 17-14

Fluid Leaks ............. 17-16

Inspection and Adiustment

Steoring Operation .......................... 17 -14

Power Assist Check

with Car Parked ........................... 17-18

Steering Linkage and Gearbox ....... 17-19

Pump Beh .............. 17-20

Rack Guide Adjustment ............. ..... 17-21

Ff uid Replacement ...................... ..... 17 -21

Pump Pressure Check .................. .... 17 -22

Ffuid Leakage lnspection ................ 17-23

+ Steering Wheel

Removal ..,,,,,,,........ 17-24

Disassembly/Reassembly ............... 17 -25

fnstallation ,......,,,,,. 17-26

* Steering Column

Removaf .................17-28

Inspection .............. 17-30

Installation ............. 17-31

Power Steering Hoses. Pipes

Replacemont ......... 17-3tl

Power Steering Pump

Removal ................. 17-35

Disassembly .......... 17-35

Reassembly ........... 17-'10

lnstallation ........,..., l7-tltl

Steering Gearbox

Removaf .,.,............. 17-45

Disassembly .......... 17-/E

Reassembly ........... 17-53

lnstallation ............. 17-63

Ball Joint Boot Replacement .......... 17-65

SUPPLEMENTAL RESTRAINT SYSTEM {SRSI

The Integra SRS includes a driver's airbag. located in the steering wheel hub, In addition, all models except the

RS model for Canada have a front passenger's airbag located in the dashboard above the glove box. Information

necessarv to safely service the SRS is included in this Service Manual. ltems marked with an asterisk {') on the

contents page include, or are located near, SRS components. Servicing. disassembling or replacing these items

will require special precautions and tools, and should therefore be done by an authorized Acura dealer.

a To avoid rsndering ths SRS inoporative, which could load to po.sonal iniury 01 d€ath in th€ event ot a ssvare

lrontal collision, all SRS service work muat be performod by an authorizod Acura deal6t.

a lmploper service procodules. including incorloct romoval and installation of the SRS, could lead to personal iniu-

ry caused by unintontional activation ot the airbags.

a All SRS elsctdcal wiring harnesses ara covorod with ysllow insulation. Rolalod compon€nts 8re locatsd in tho

stse ng column, tront console, dashboard, and dashboard lower panel, and in the dashboard above the glove

box. Do not use oloctrical tost equipmoni on thosa cilcuits.

NOTE: The original radio has a coded thett protection circuit. Be sure to get the customer's code number before

- disconnecting the battery.- removing the No. 32 (7.5 A) tuse from the under-hood fuse/relay box.

- removing the radio.

Alter service, reconnect power to the radio and turn it on. When the word "CODE" is displayed' enter the cus-

tomer's 5-digit code to restore radio operation.

Page 609 of 1413

I

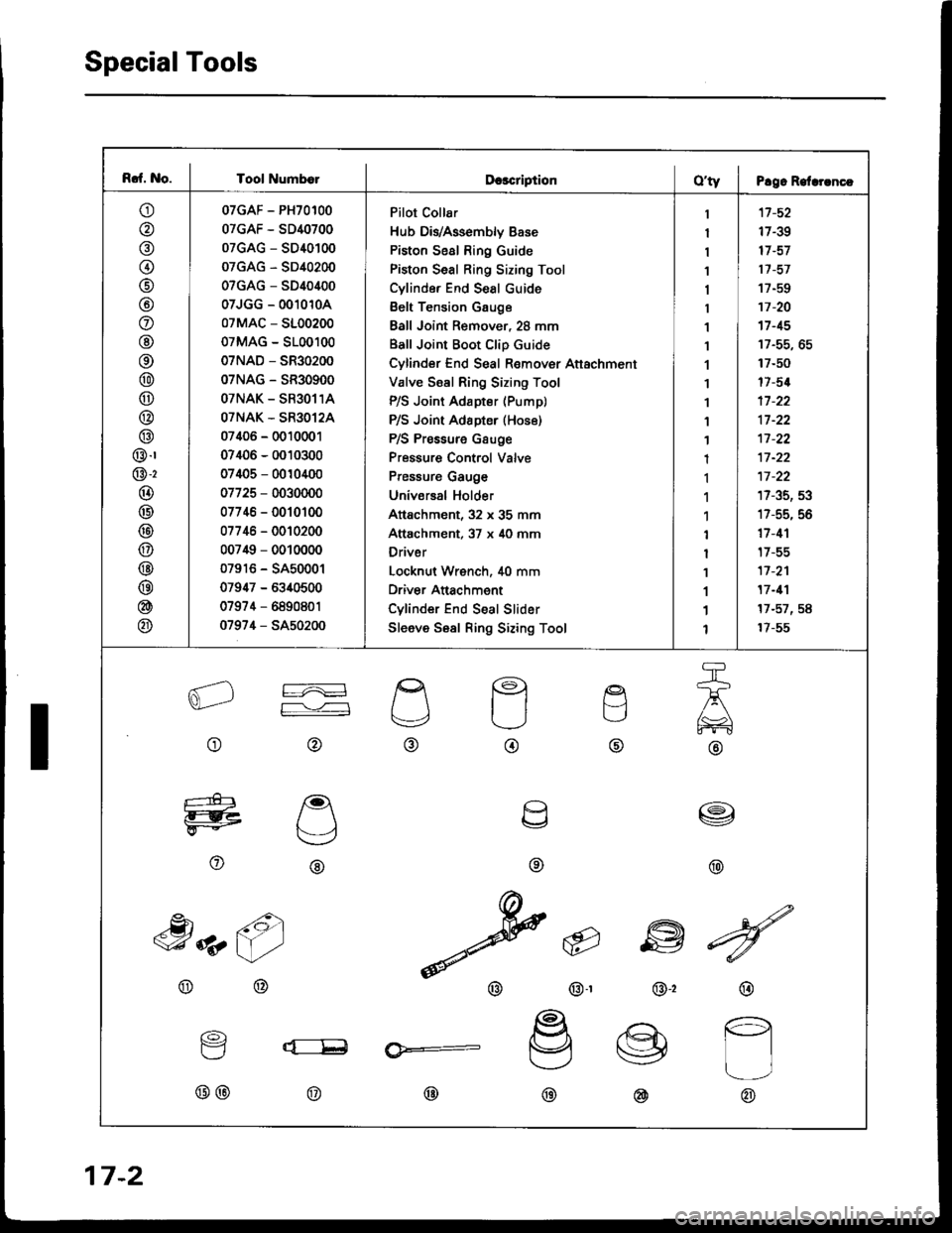

Rcf. No. I Tool Numb€lDcscriptionO'ty I P!9. Relrrrncc

o

@

@(t

@

@

o

@

@

@

@

@

@

@.r

@-2

@

@

@

@

@

@

@

@

07GAF - PH70100

07GAF - SD40700

07GAG - SD40100

07GAG - SD40200

07GAG - SD40400

07JGG - 0010104

07MAC - 5100200

07MAG - 5100100

07NAD - SR30200

07NAG - SR30900

OTNAK - SR3O11A

OTNAK - SR3O12A

07406 - 0010001

07406 - 0010300

07405 - 0010400

07725 - 0030000

07746 - 0010100

07746 - 0010200

007i$ - 0010000

07916 - SA50001

07947 - 6340500

07974 - 6890801

0797,1 - SA50200

Pilot Collar

Hub DivAssembly Base

Piston Seal Ring Guide

Piston Seal Ring Sizing Tool

Cylinde. End Seal cuide

Belt Tension Gauge

Ball Joint Remover, 28 mm

Ball Joint Boot Clip Guide

Cylinder End Seal Remover Attachment

Valve Ssal Ring Sizing Tool

P/S Joint Adapter (Pump)

P/S Joint Adapter (Hos6)

P/S Pressure Gsuge

Pressure Control Valve

Pressure Gauge

Universal Holder

Attachment, 32 x 35 mm

Attachment, 37 x 40 mm

Driver

Locknut Wrench, i[0 mm

Driver Anachment

Cylinder End Seal Slider

Sleeve Sesl Ring Sizing Tool

1

I

1

1

1

1

1

1

1'I

1

1

1

1

1

1'l

1

I

1

1

1

1

'17 -52

17-39

17 -57

17 -57

17-EO

17 -20't7 -15

17-50

17-5{

17 -22

17 -22't1-22

17 -22

17-35, 53

17-55, 56

17 -1'l

t7-55

17 -2'l

17 -11

17-57,58

17-55

aL2

o

re

F--,'---l

@

g

t.-,

@

q

o

etl

TJ

@

a\,

@

e

U

\v

o

I

@

,h z6)

@

@-r

6

w

@,2

^dN

v

@

@

16)

Y

@@

lx:__E

@

@:

@@

17-2

Page 610 of 1413

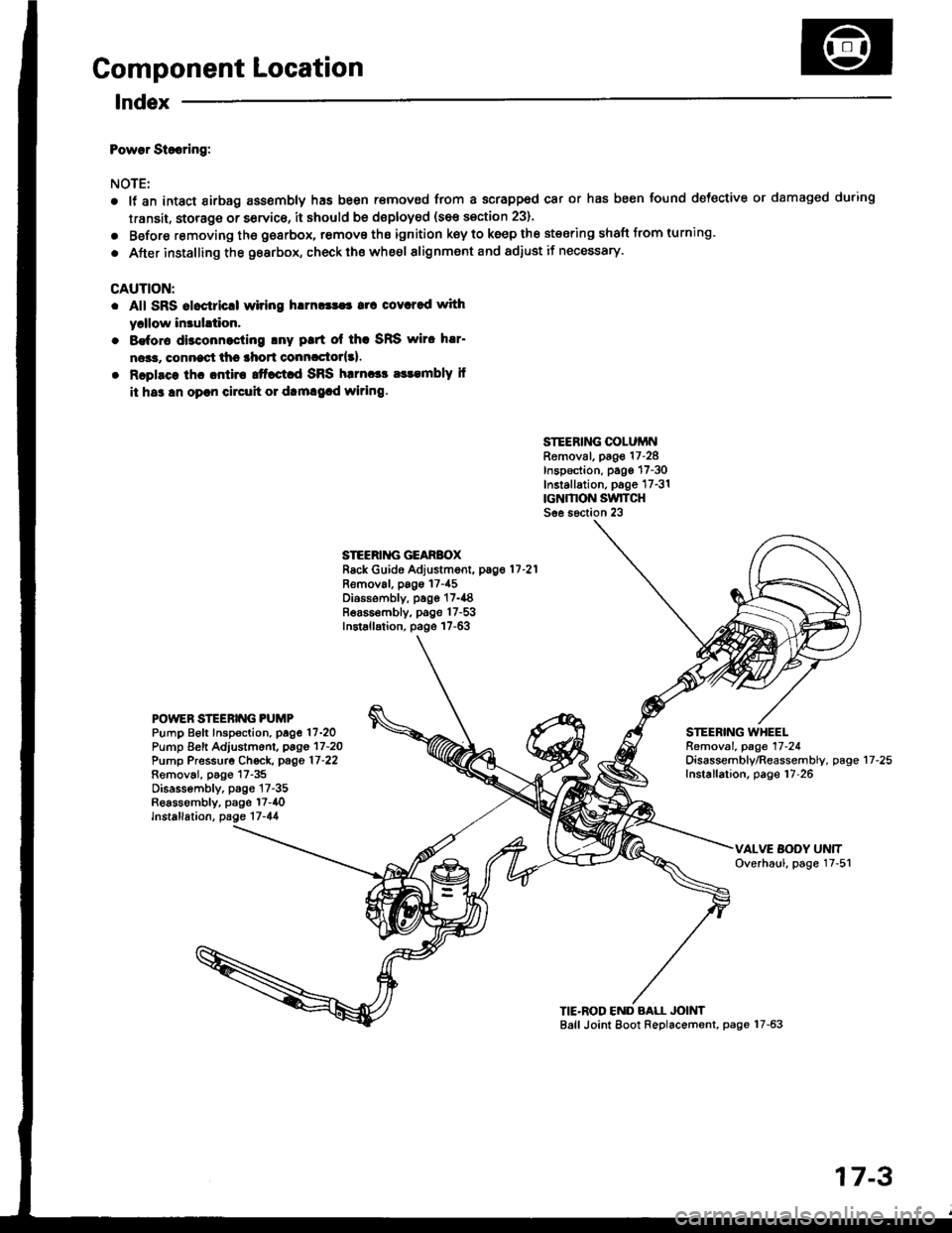

Component Location

lndex

Powar Siooring:

NOTE:

a

a

It an intact airbag ass€mbly has been r€moved from a scrapped car or has been found defective or damaged during

transit. storage or service, it should be doploy€d (see section 23).

Before removing tho gearbox, remove ths ignition key to keep the steering shaft Jrom turning.

After installing the gearbox, check ths whe€l alignment and adiust if necessary.

CAUTION:

. All SRS aloctricll wiring h!m!|$a rrc covcred with

yrllow in3uhtion.

. 8€for€ disconnocling lny ptrt ol thc SRS wiro h!r'

ne*r, connect thc lhort conncctor{3l.

. Rcplsce lhc ontira ttfact d SRS harnccc a$embly il

it hs3 !n oprn circuh 01 dtm!9.d wiring.

SIEERING COLUiINRemoval, page 17-28Inspection, pago 17-30Installation, p6ge 17-31rcNMON SwlTCHSee s6ction 23

STEERII{G GEARBOXRack Guide Adjustment, pag.11-21

Removal, pags 17-45Diossombly, page 17-{8Bea65€mbly, page 17-53Installation, page 17-63

POWEN STEERING PUMPPump Beft Inspoction. page 17-2OPump Eeft Adjustm6nl, pago 17-2OPump Pressurg Ch€ck, page 17-22Removai, p6go 17-35Disassembly, p3gs 17-35Reassombly, psge l7-40lnstallation, page 17-44

STEERING WHEELRemoval. page 17-24Oisassembly/Reassembly, pageInstallation, page 17-2617-25

TIE'ROD END BALL JOINTBall Joint Eoot Replacement, page 17-63

17-3

Page 618 of 1413

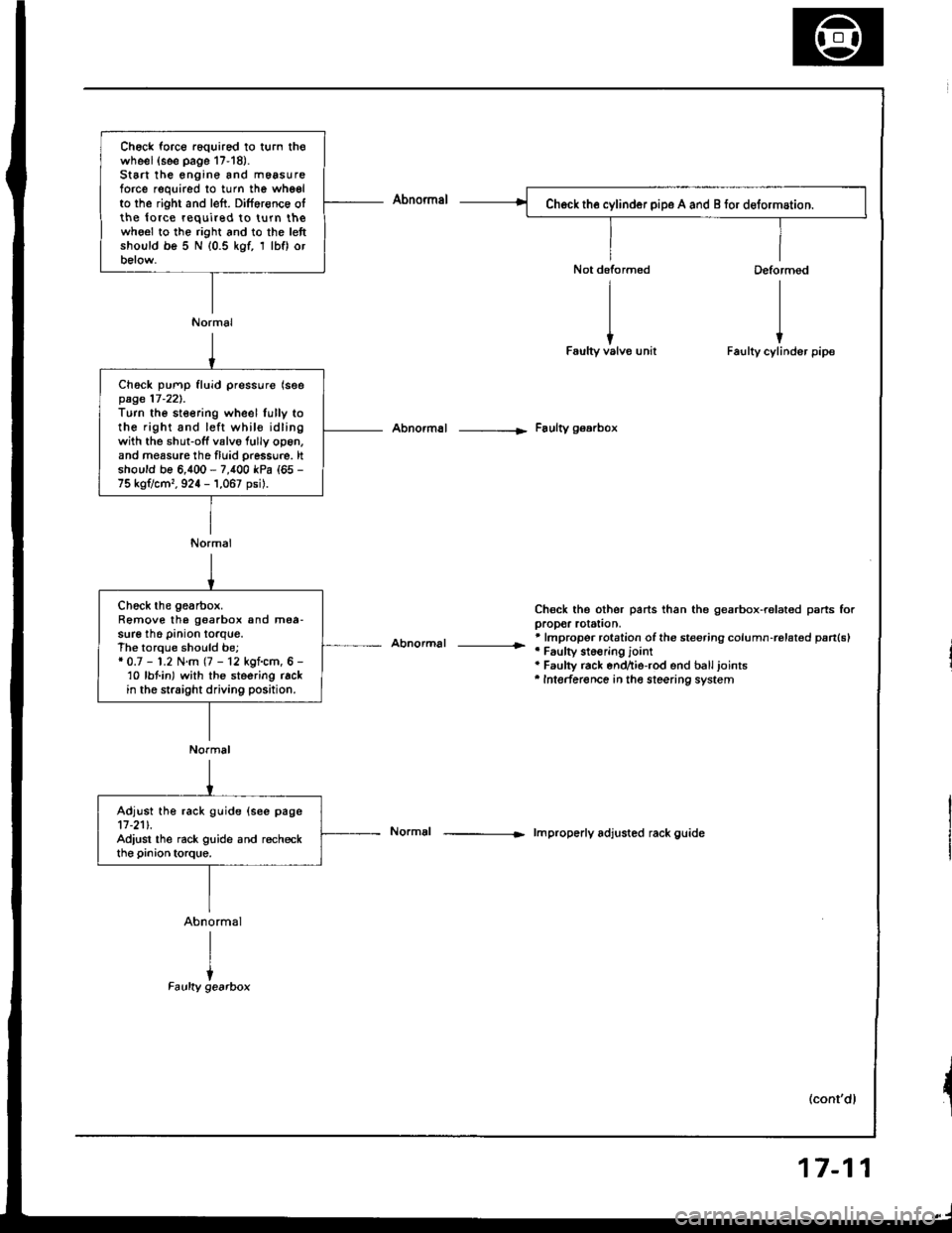

Ch6ck force r6quired to turn thowheel(see page 17-18).St6 the engine and m6asureforce required to turn the whgelto the right and left. Dilference olthe lo.ce required to turn thewho€l to the right and to the lettshould be 5 N (0.5 kgf, 1 lbf) orbelow.

Normal

Ch6ck pump fluid pressure (seepage 17-221.Turn the steering wheel lully tothe right and left whil€ idlingwith the shut-off valvo fully op6n,and measure tho fluid pressu.e. ltshould be 6,400 - 7,400 kPa (65 -

75 kg?cm,, 924 - 1,067 psil.

Normal

Abnormal -----|. Faulty gearbox

Abnormal |r

Chsck the other parts than the gearbox-ralated psrts forpropor rotstion,* lmpropor rotation ofthe steering column-rolat€d pan(sl'Faulty st6€ring jointa Faulty rack end^ie-rod end balljoints'Intederence in the steering system

lmproperly adjusted rack guide

(cont'dl

Chock the gearbox.Remove the goarbox and mea-sure the pinion torque.The torque should be;* 0.7 - 1.2 N.m (7 - 12 kgf.cm, 6 -'10 lbt in) with the steering rackin the straight driving position.

Normal

Adjust the rack guide (see page11-211.Adiust the rack guide and recheckthe pinion torque.

17-11