eld HONDA INTEGRA 1994 4.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 184 of 1413

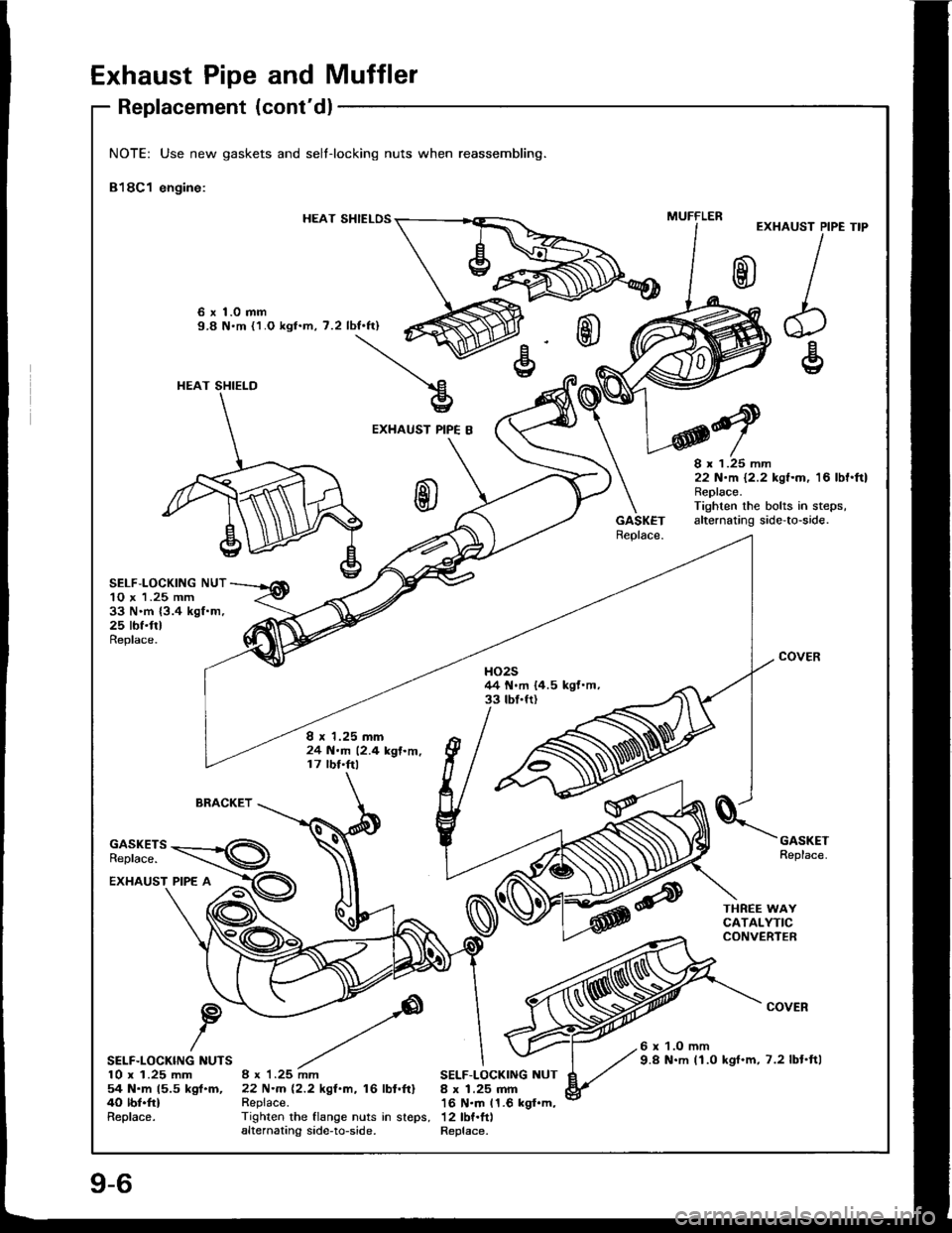

Exhaust Pipe and Muffler

Replacement (cont'dl

NOTE: Use new gaskets and selt-locking nuts when reassembling.

818C1 engine:

HEAT SHIELOSEXHAUST PIPE

I

h€

TIP

6 x 1.0 mm9.8 N'm {1.O kgt.m, 7.2 lbf.ft)

EXHAUST PIPE B

GASKETReplace.

8 x 1.25 mm22 N.m 12.2 kgf.m, 16 lbf'ftlReplace.Tighten the bolts in steps,alternating side'to-side.

SELF,LOCKING NUT10 x 1.25 mm33 N.m {3.4 kgf.m,25 tbf.frlReplace.

COVERHO2544 N.m {4.5 kgf.m,33 tbf.fr)

I r 1.25 mm24 N.m 12.4 kgf.m,17 lbf.ftl

BRACKET

GASKETSReplace.

GASKETReplace.

EXHAUST PIPE A

COVER

SELF.LOCKING NUTS10 x 1.25 mm54 N.m 15.5 kgl.m,40 lbf.frlReplace.

6 x 1.O mm9.8 N.m (1.0 kgf.m, 7.2 lbt'ft|8 x 1.25 mm22 N.m 12.2 kgf.m, 16 lbl.ftlRepiace.

SELF-LOCKING NUT8 x 1.25 mm16 N.m 11.6 kgf.m,Tighlen rhe flange nuts in sreps, 12lbf.ftlalternating side-to-side. Replace.

MUFFLER

HEAT SHIELD

Page 196 of 1413

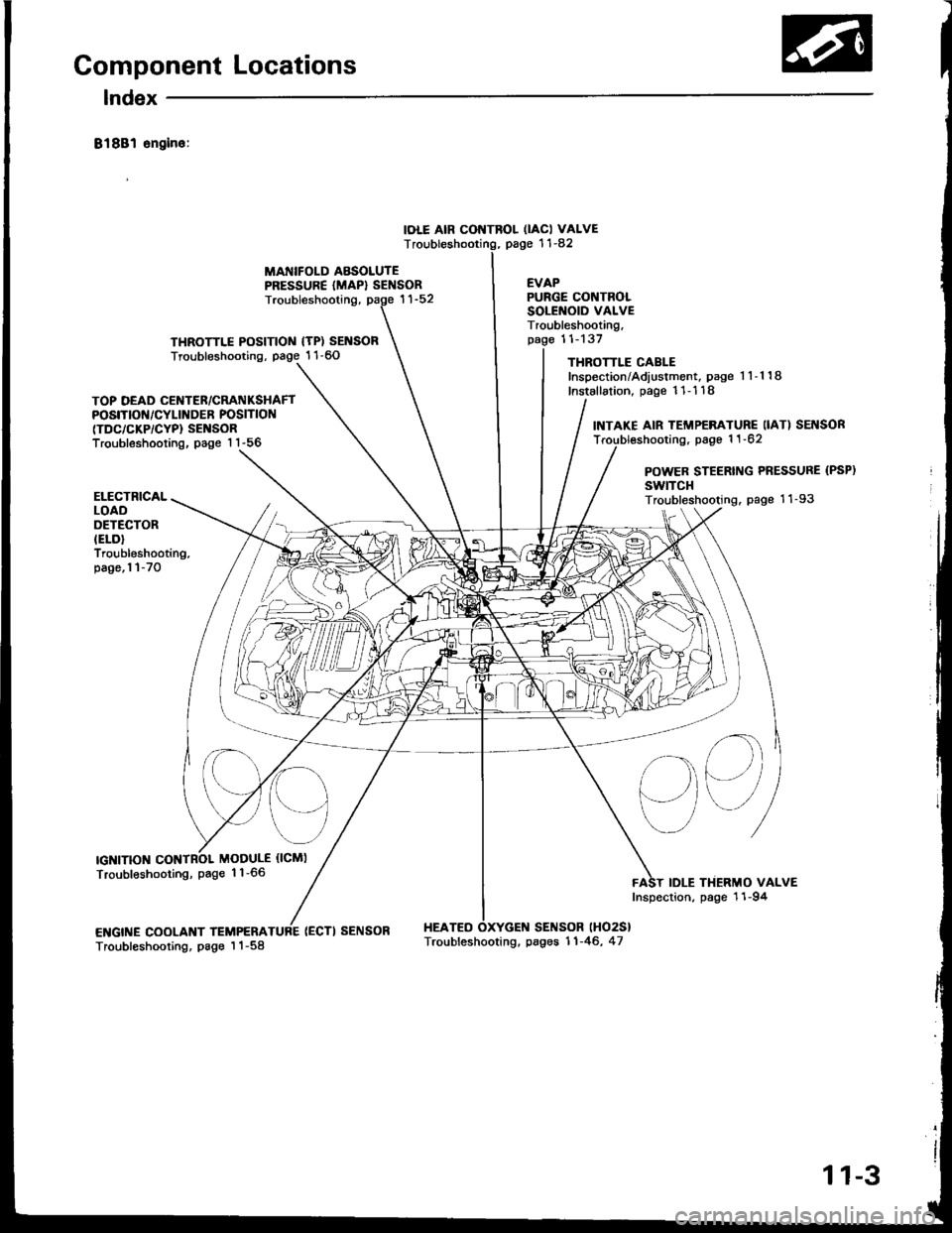

Component Locations

lndex

81881 sngin6:

IOLE AIR CONTROL OACI VALVEpage '11-82T

MANIFOLD ABSOLUTEPRESSURE {MAP} SENSOREVAP

THROTTLE POSITIOIII {TP) SENSORTroubleshooting, page 1 1-60

Troubleshooting,

(ECTI SENSOR HEATEO

PURGE CONTROLSOLENOID VALVETroubleshooting,11-137

THROTTLE CABLEInspection/Adiustment, page 1 1-1 18

Installation, page 11- 1 18

SENSOR lHO2S}

TOP DEAD CENTER/CRATIIKSHAFTPOSITIOf{/CYLINDER POSITION(TDC/CKP/CYP} SENSORTroubleshooting, page 1 1-56

INTAKE AIR TEMP€RATURE IIAT) SEI{SORTroubl€shooting, page 1 1 -62

POWER STEERING PRESSURE (PSP)

swtTcHTroubleshooting. page 11-93

sq

IDLE THERMO VALVEInspection, page 11-94

ELECTRICALLOADOETECTORIELD}Troubleshooting.page,l l-70

IGNITIONMODULE {ICMI

Troubleshooting, page 1 1-66

ENGINE COOLANT TEMPERATroubleshooting, page I 1-58Troubleshooting. pages 11-46, 47

11-3

Page 197 of 1413

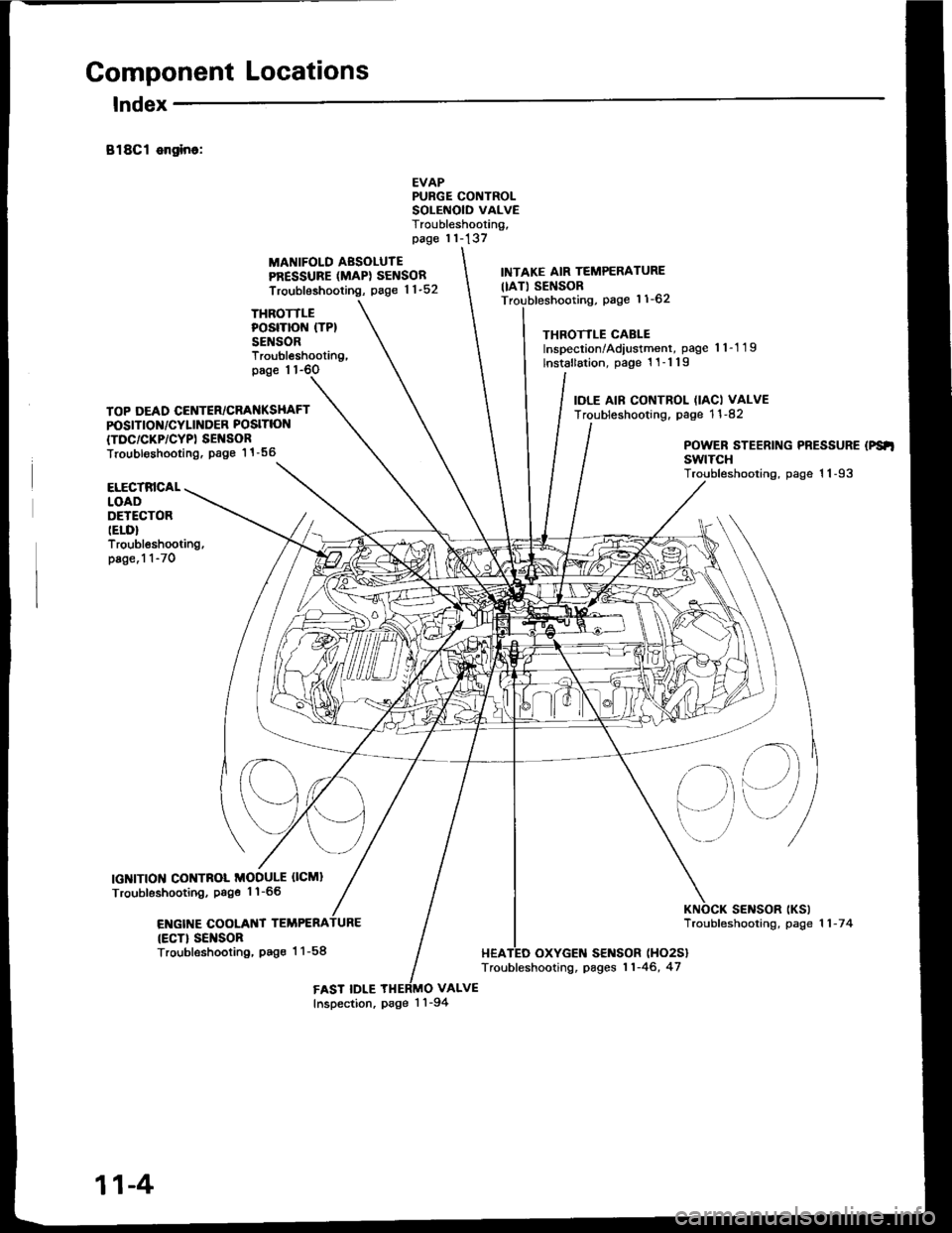

Component Locations

lndex

B18Cl ongino:

THROTTLEPOSITION (TP}

SENSOR

MANIFOLD AESOLUTEPRESSURE (MAPI SENSOR

Troubleshooting, page 1 1-52

EVAPPURGE CONTROLSOLEiIOID VALVETroubleshooting,page 11-137

VALVE

INTAKE AIR TEMPERATURE

IIAT) SENSORpage 11-62

THROTTLE CABLEInspection/Adiustment, page 'l 1-1 19

lnstallation, page 1 1-1 19

IOLE AIF CONTROL (IACI VALVETroubleshooting. page 1 1 -82

Troubleshooting,page 1 1-6O

TOP DEAD CENTER/CRANKSHAFTPOSITION/CYLINDER POSITION

{TDC/CKP/CYPI SEI{SORTroubl€shooting. Page 1 1 -56POWER STEERING PRESSURE (PS'I

swtTcHTroubleshooting, page 1 1-93ELECTRICALLOADDETECTORIELD}Troubleshooting,page.1 1-70

IGNITION CONTNOL MODULE OCMI

Troubleshooting, Psge 1'l-66

ENGIT{E COOLANT TEMPERA

{ECT} SEI{SORTroubleshooting, Pag€ 1 1-58

sElrlsoR tKslTroubfeshooting, page 1 1 -7 4

HEATED OXYGEN SENSOR (HO2S}

Troubleshooting, pages 11-46, 47

FAST IDLEInspection, page 1 'l -94

11-4

Page 228 of 1413

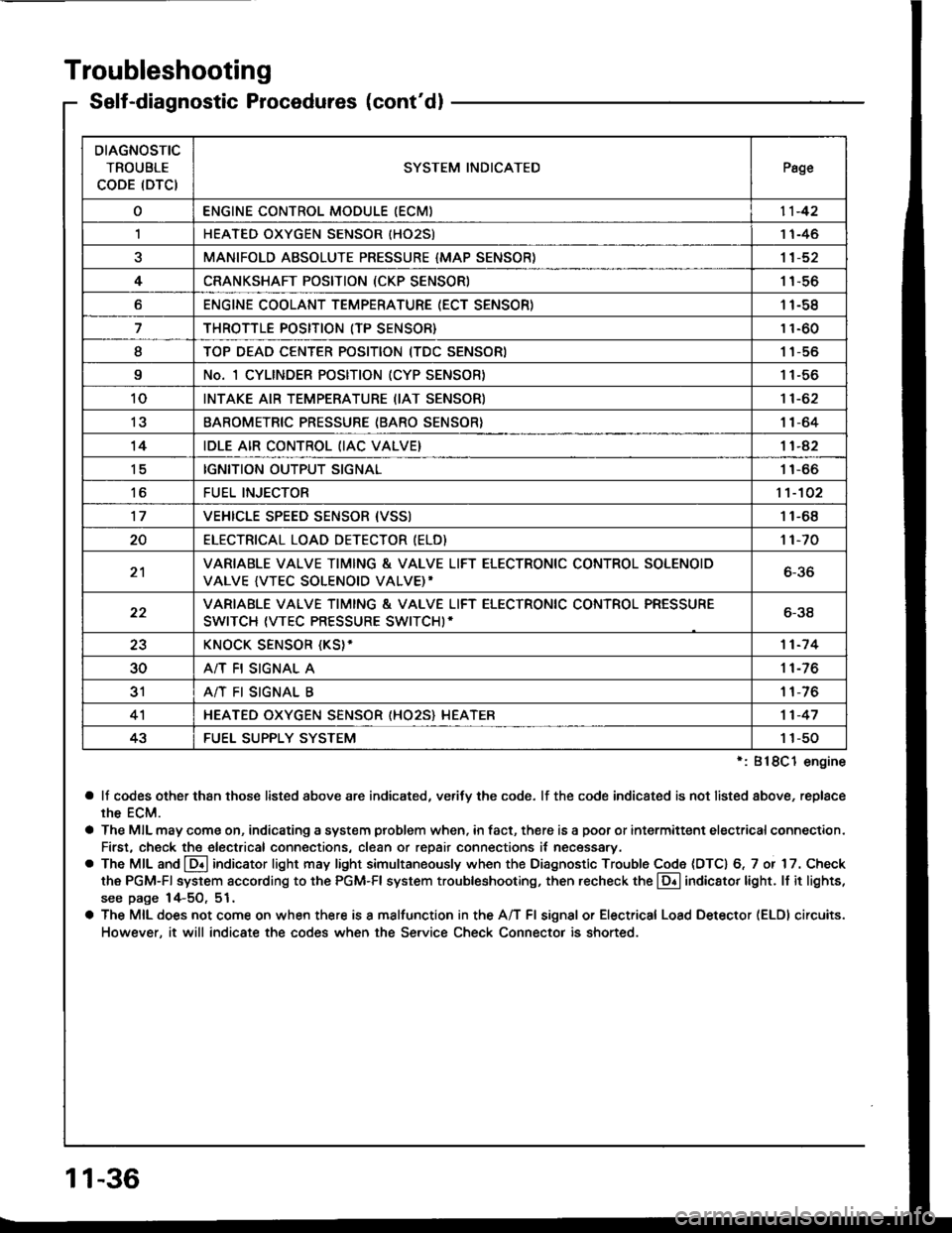

Troubleshooting

Self-diagnostic Procedures (cont'dl

':818C1 engine

a lf codes other than those listed above are indicated, verifv the code. lf the code indicated is not listed above, replace

rhe ECM.

a The MIL may come on, indicating a system problem when, in fact, there is a poor or intermittent electricalconnection.

First, check the electrical connections, clean or repair connections it necessary.

o The MIL and @ indicator light may light simultaneously when the Diagnostic Trouble Code (DTC) 6, 7 or 17. Check

the PGM-Fl system according to the PGM-Fl system troubleshooting, then recheck the l!! indicator light. ll it lights,

see page 14-5O, 51.

a The MIL does not come on when there is a malfunction in the A/T Fl signal or Electrical Load Detector (ELDI circuits.

However, it will indicate the codes when the Service Check Connector is shorted.

DIAGNOSTIC

TROUBLE

CODE (DTCISYSTEM INDICATEDPsge

oENGINE CONTROL MODULE IECM)11-42

,lHEATED OXYGEN SENSOR IHO25)1 1-46

aMANIFOLD ABSOLUTE PRESSURE {MAP SENSOR)11-52

4CRANKSHAFT POSITION (CKP SENSOR)1 1-56

oENGINE COOLANT TEMPERATURE (ECT SENSOR)11-58

THROTTLE POSITION (TP SENSOR}11-60

ITOP DEAD CENTER POSITION (TDC SENSORI1 1-56

9No. 1 CYLINDER POSITION (CYP SENSOR)1 1-56

10INTAKE AIR TEMPERATURE (IAT SENSOR)11-62

13BAROMETRIC PRESSURE (BARO SENSOR}1|-64

14IDLE AIR CONTROL (IAC VALVE}11-42

tcIGNITION OUTPUT SIGNAL11-66

toFUEL INJECTOR1't-102

17VEHICLE SPEED SENSOR {VSSI11-68

20ELECTRICAT LOAD DETECTOR (ELD)'t 1-70

21VARIABLE VALVE TIMING & VALVE LIFT ELECTRONIC CONTROL SOLENOID

VALVE {VTEC SOLENOID VALVE)'6-36

22VARIABLE VALVE TIMING & VALVE LIFT ELECTRONIC CONTROL PRESSURE

SWITCH (VTEC PRESSURE SWITCHI-6-38

23KNOCK SENSOR {KS}-11-7 4

30A/T FI SIGNAL A11-76

3'rA/T FI SIGNAL B1 1-76

4'lHEATED OXYGEN SENSOR (HO25} HEATER11-47

43FUEL SUPPLY SYSTEM1 1-50

11-36

Page 232 of 1413

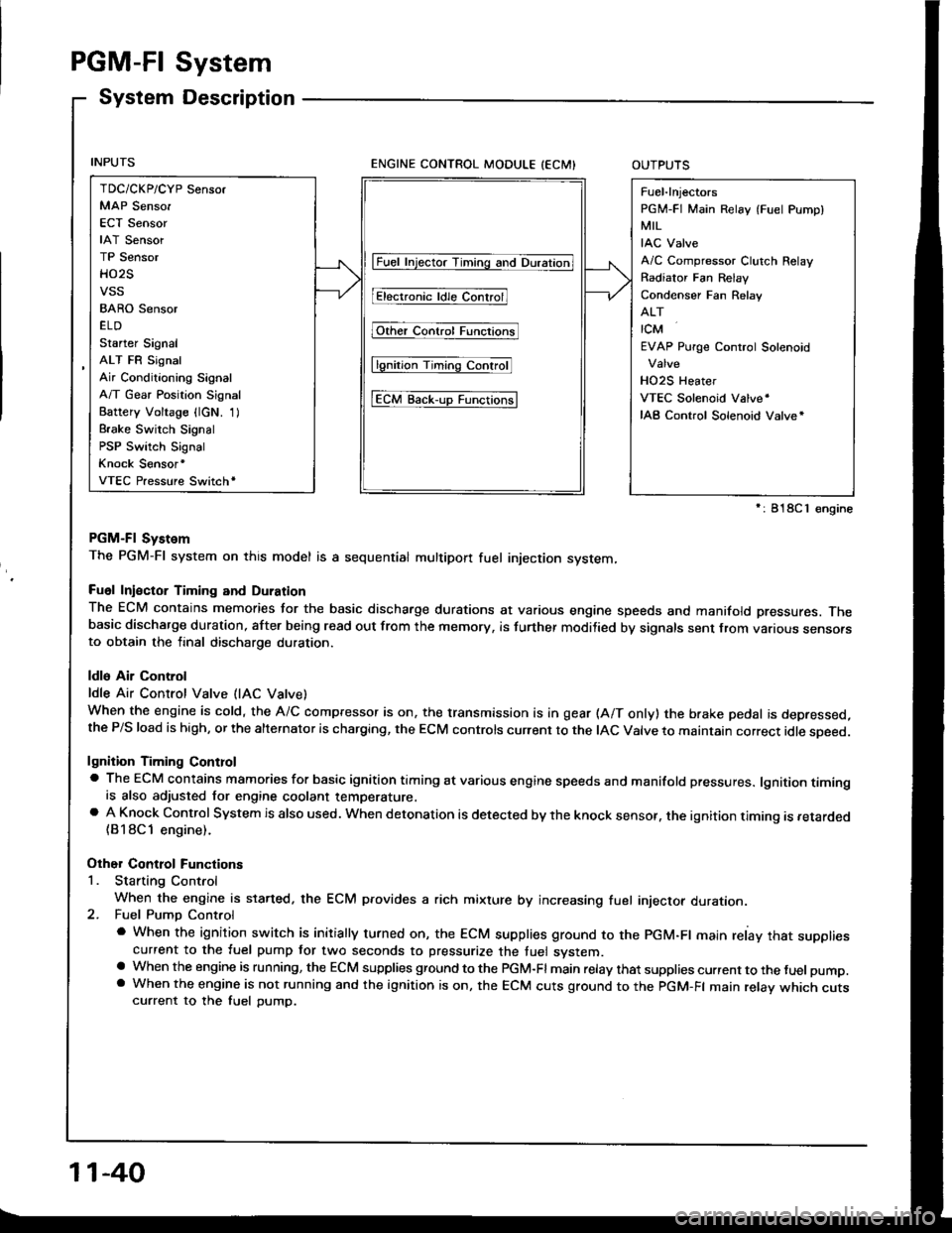

PGM-FI System

System Description

ENGINE CONTROL MODULE (ECMIOUTPUTS

PGM-Fl System

The PGM-Fl system on this model is a sequential multipon fuel injection system,

Fuol Iniector Timing and Duration

The ECM contains memories tor the basic discharge durations at various engine speeds and manifold pressures. Thebasic discharge duration, after being read out from the memory, is turther modilied by signals sent from vanous sensofsto obtain the final discharge duration.

ldle Air Control

ldle Air Control Valve (lAC Vatve)

When the engine is cold, the A/C compressor is on, the transmission is in gear (A/T only) the brake pedal is depressed,the P/S load is high, or the alternalor is charging, the ECM controls current to the IAC Valve to maintain correct idle soeed.

lgnition Timing Controla The ECM contains mamories for basic ignition timing at various engine speeds and manifold pressures. lgnition timingis also adjusted for engine coolant temperature.a A Knock Control System is also used. when detonation is detected by the knock sensof. the ignition timing is retarded(B18Cl engine).

Other Control Functions

1. Starting Control

When the engine is started. the ECM provides a rich mixture by increasing fuel injector duration.2. Fuel Pump Control

a When the ignition switch is initially turned on, the ECM supplies ground to the PGM-Fl main relay that suppliescurrent to the fuel pump tor two seconds to pressurize the tuel system.a When the engine is running, the ECM supplies gfound to the PGM-Fl main relay that supplies current to the fuel pump.a When the engine is not running and the ignition is on, the ECM cuts ground to the PGM-FI main relav which cutscurrent to the fuel pump.

TDC/CKP/CYP Sensor

MAP Senso.

ECT Sensor

IAT Sensor

TP Sensor

HO2S

vss

BARO Sensor

ELD

Starter Signal

ALT FR Signal

Air Conditioning Signal

A/T Gear Position Signal

Battery Voltage {lcN. 1)

Brake Switch Signal

PSP Switch Signal

Knock Sensor'

VTEC Pressure Switchr

Fuel-lnjectors

PGM-FI Main Relay (Fuel Pump)

MIL

IAC Valve

A/C Compressor Clutch Relay

Radiator Fan Relav

Condenser Fan Relav

ALT

rcM

EVAP Purge Control Solenoid

HO2S Heater

VTEC Solenoid Valve'

IAB Control Solenoid Valve*

lFuet tnjector Timing and Duration]

I Electr..l"ldle Contr;il

Fit'e' contr; Funcrfit

l6tio; Ttntrlg c..trol

tEcM aack-,rp Functiorlsl

': 818C 1 €ngine

11-40

Page 260 of 1413

![HONDA INTEGRA 1994 4.G User Guide PGM-FI System

Electrical Load Detector (ELDI

tft;-]/ The Maltunction Indicaror Lamp (MlL) indicatss Diagnostic Trouble Code IDTC) 20: A probtem in-Li!- tne Electrical Load Detecror {ELD} circuit.

With HONDA INTEGRA 1994 4.G User Guide PGM-FI System

Electrical Load Detector (ELDI

tft;-]/ The Maltunction Indicaror Lamp (MlL) indicatss Diagnostic Trouble Code IDTC) 20: A probtem in-Li!- tne Electrical Load Detecror {ELD} circuit.

With](/img/13/6067/w960_6067-259.png)

PGM-FI System

Electrical Load Detector (ELDI

tft;-]/ The Maltunction Indicaror Lamp (MlL) indicatss Diagnostic Trouble Code IDTC) 20: A probtem in-Li!- tne Electrical Load Detecror {ELD} circuit.

With lho SCS lhon connectolconnoctod {ree pago 11-34}, cod.20 is indicatod.

Do the ECM B6set Procedurs {seepage 1 'l-35).

Start engine and keep engin€speed at idle.Turn on headlights.

lntennlna tlllure, lyrtom lt Ol(!t irl. dm. (lgtt driv. mly [email protected] for Door connactlona oaloota wiro. rt C218 IELD, lndEctrt.

Ooes the MIL indicato code 20?

Romove the undgr-hood fusg/relay box and remove the tus6/relav box lowet cover.

Turn lhe ignition switch ON.

Measure voltage betw€on BLK/YEL (+l terminal and BLK (-)terminal.

Msasuro voltag€ b€tweon BLK/Y€L {+) terminal snd bodvground.ls there bartory voltagel

Rcpir oo.n in BLK wir.batwaan lha 3P connrc-tor lnd G2Ol {loc.t.dtroit ot angh|. comprn-m.r dghl .ld.l,

B.p.lr op.n in BLKrYEL wlrr b.-tw..n o.24ACG (ALn flcl115A: Bl88l .ngln!, 20 A:818C1cnginol fu!. In thr und.r{..htu.o/r.lly bor lnd tho 3P con-rcclo?.

View tromwire side

BLK (-)

(To page 11-7'l)

GRn/iED I - |

BLK/YEL I + I

11-70

Page 262 of 1413

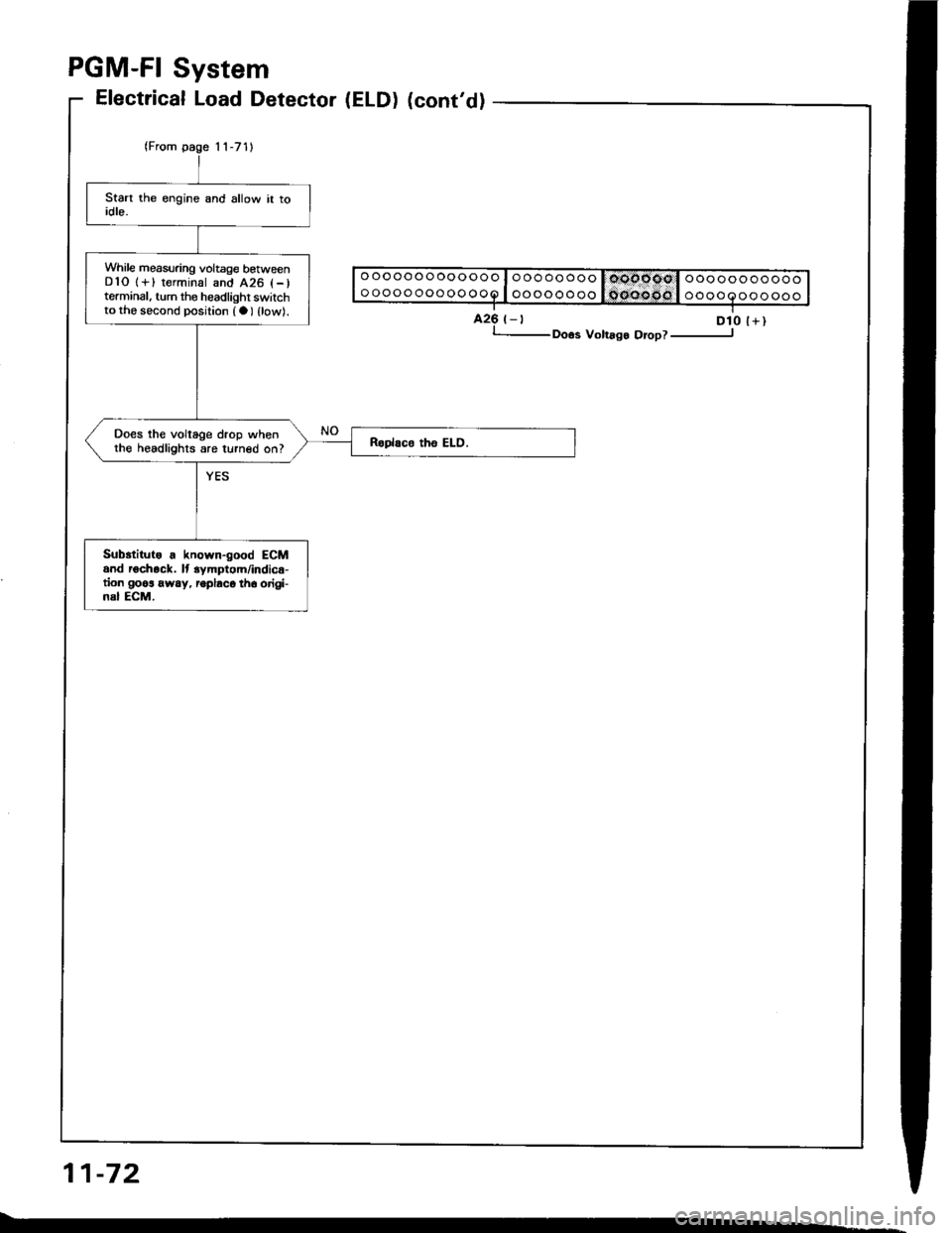

PGM-FI System

11-72

While measuring voltage betweenDlO 1+) terminal and 426 l-)terminal, turn the headlighr switchto the second position (a) {low).

Does the voltage drop whenthe headlights are turned on?

Subrtitute . known-good ECMand rochock. lt 3ymptom/indic€-tion goos away, ioplaco th6 origi-nal ECM.

Electrical Load Detector (ELD) (cont'd)

425 t-t D10 l+), Doos Volrago Orop? ----------------J

Page 321 of 1413

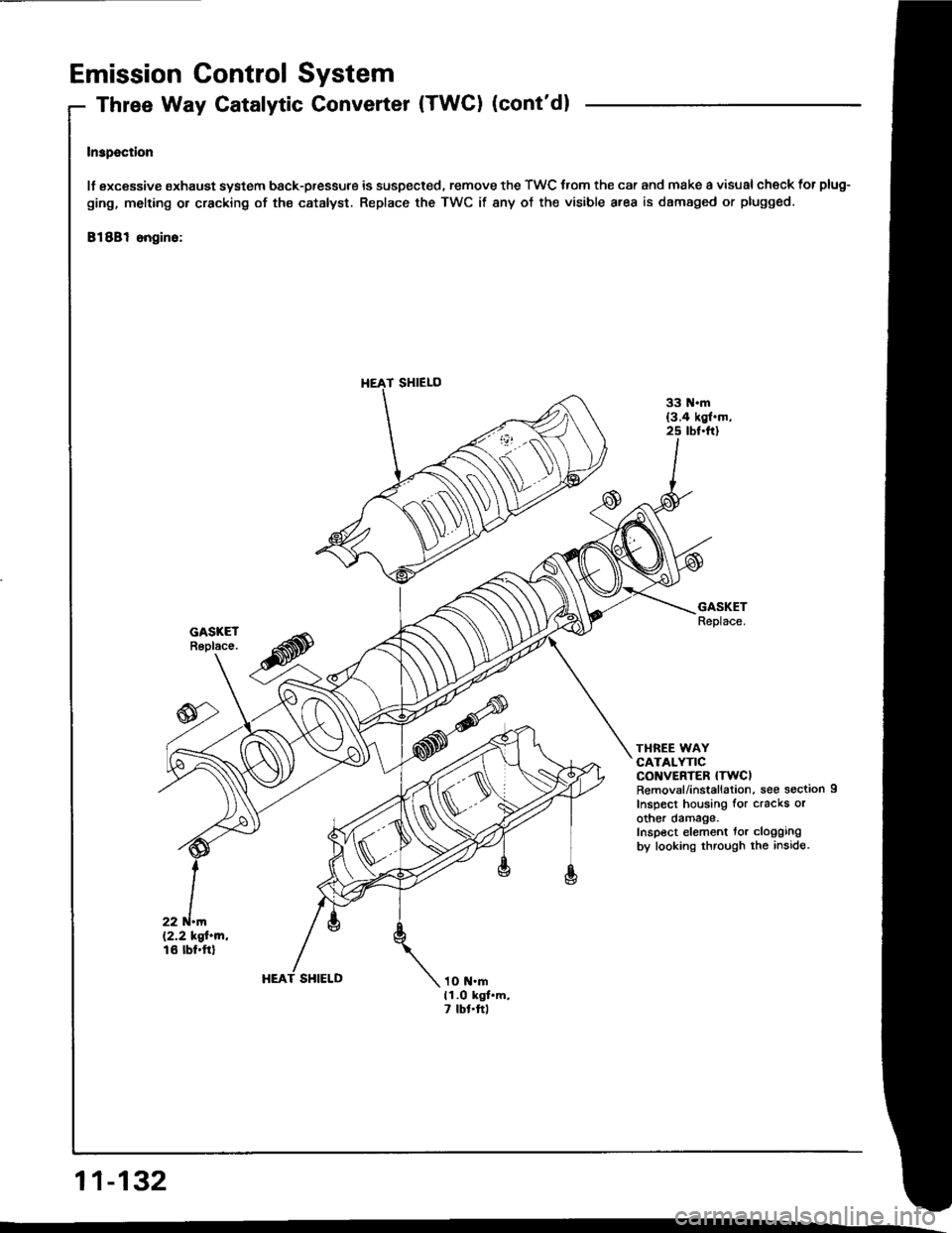

Emission Control System

Three Way Catalytic Converter (TWC) (cont'dl

Inspection

lf sxcessive oxhaust system back-pressure is suspected. remove the TWC trom the car and make a visual check for plug-

ging, melting or cracking of ths catalyst. Replace the TWC if any of the visible area is damaged or plugged.

81881 ongino:

TI{REE WAYCATALYTICCONVERTER {TWCIRemovsl/installation, see section 9

Inspect housing for cracks orother damage.Inspect element tor cloggingby looking through the inside.

HEAT SHIELD

11-132

T SHIELO

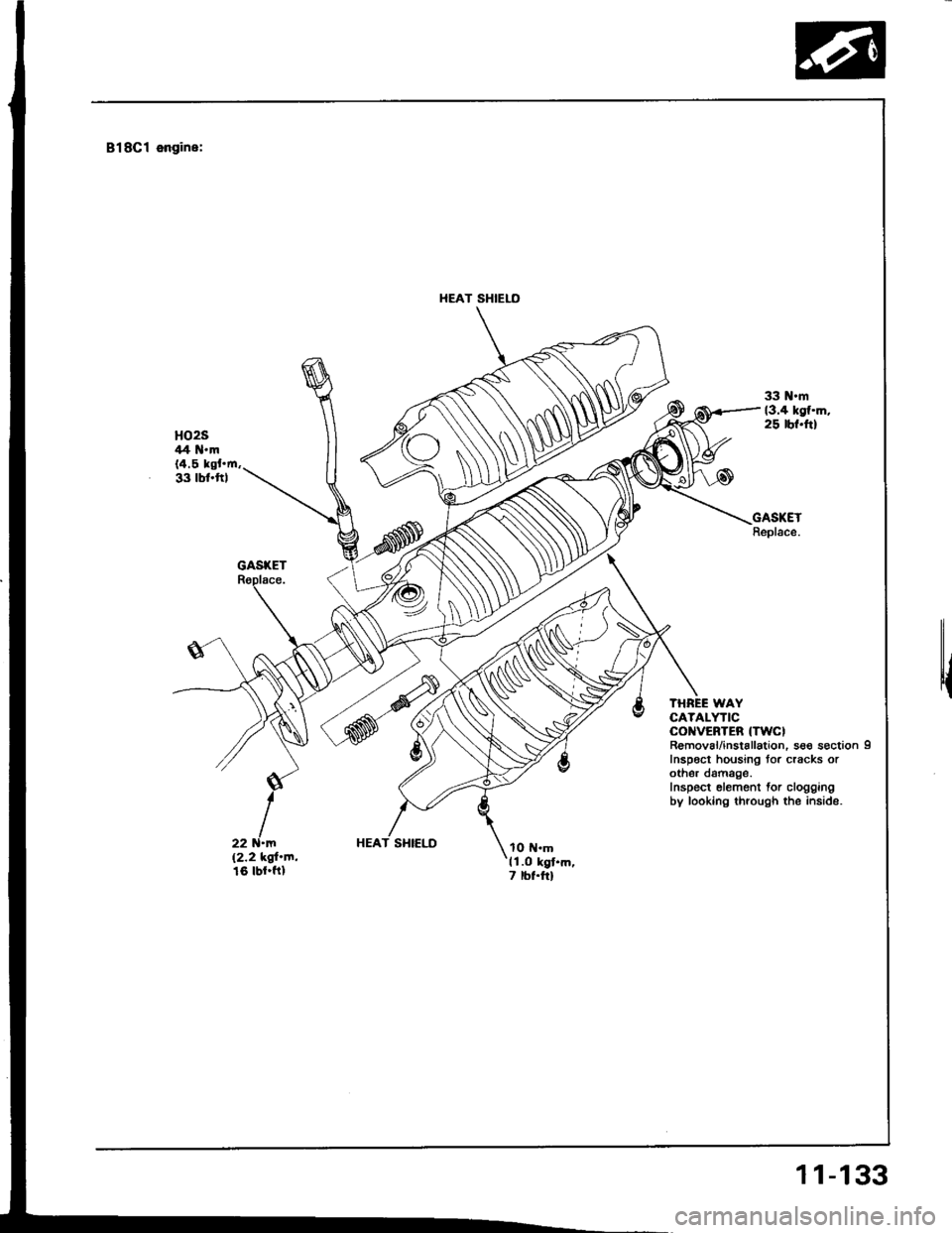

Page 322 of 1413

818Cl engine:

HEAT SHIELO

r{

THREE WAYCATALYTICCOI{VEBTEB {TWCIR€moval/installation. sso s€ction 9Inspoct housing tor cracks orothor damage.Inspect elemont for cloggingby looking through the inside.

HEAT SHIELD

11-133

Page 334 of 1413

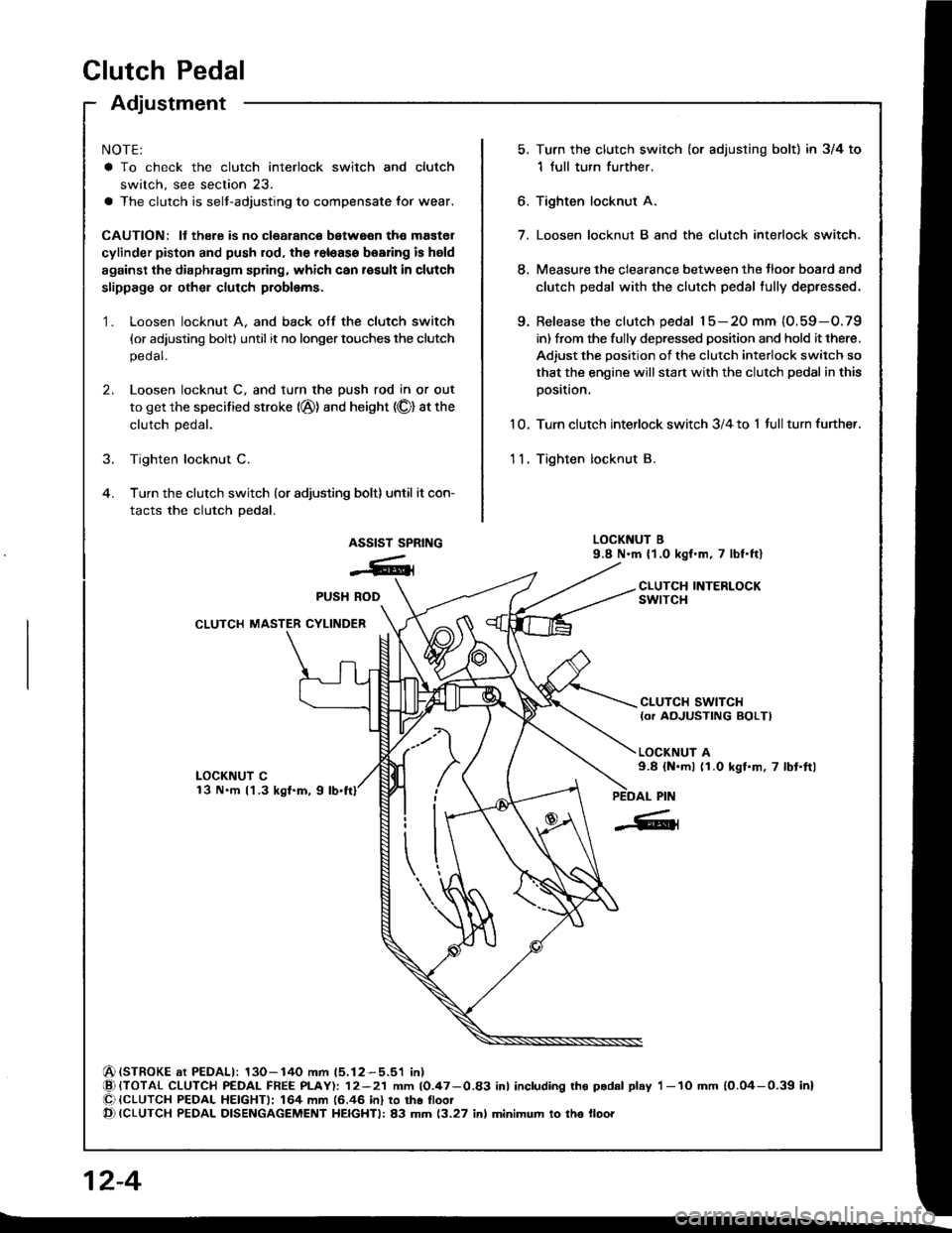

Adjustment

NOTE:

a To check the clutch interlock switch and clutch

switch, see seclion 23.

a The clutch is selt-adjusting to compensate for wear.

CAUTION: It there is no clearanco between the mastel

cylinder piston and push lod. the releaso boaring is held

againsl the diaphragm spring, which can result in clutch

slippage 01 othel clutch problems.

Loosen locknut A, and back otf the clutch switch

{or adjusting bolt) until it no longer touches the clutch

pedal.

Loosen locknut C, and turn the push rod in or out

to get the specified stroke (@) and height (O) at the

clutch pedal.

Tighten locknut C.

Turn the clutch switch (or adjusting bolt) until it con-

tacts the clutch pedal.

Turn the clutch switch (or adjusting bolt) in 3/4 to

1 full turn further.

Tighten locknur A.

7. Loosen locknut B and the clutch interlock switch.

8. Measure the clearance between the tloor board and

clutch pedal with the clutch pedal tully depressed.

9. Release the clutch pedal 15-20 mm {O.59-O.79

in) from the fully depressed position and hold it there.

Adiust the position of the clutch interlock switch so

that the engine will start with the clutch pedal in this

oosition.

1 0. Turn clutch interlock switch 3/4 to 1 tull turn funher.

11. Tighten locknut B.

LOCKNUT B9.8 N.m (1.0 kgf.m, 7 lbf.ftl

CLUTCH INTERLOCKswtrcH

6.

1.

2.

ASSIST SPRING

-6ll

LOCKNUT Cl3 N.m l'l.3 kgf.m, 9

CLUTCH SWITCH{or AOJUSTING BOLTI

LOCKNUT A9.8 {N.ml (1.0 kgl.m, 7 lbt.ftl

(STROKE at PEDALI: 130-140 mm 15.12-5.51 in){TOTAL CLUTCH PEDAL FREE PLAY): 12-21 mm 10.47-0.83 inl including tho p.dal play I -lO mm 10.04-0.39 inl{CLUTCH PEDAL HEIGHTI: 164 mm (6.46 in} to tho lloot{CLUTCH PEDAL DISENGAGEMENT HEIGHTI: 83 mm 13.27 inl minimum to tho lloo.

PUSH ROD

CLUTCH MASTER CYLINDER

Clutch Pedalctutch Pedat I

[-],ll'"-"" f

| :;i:'":fff*tr#:?iff:".,*::,::". | .#::J:::

sb''�'�'""

| |

| "orr,O", It there is no clearanco between the master | ,. aoo""n locknut B and the clutch intertoct switcl. | |cylinder piston and push lod. the releaso boaring is held | | Iagainst the diaphragm spring, which can result in clutch | 8. Measure tne clearance between the floor board and I Islippage 01 othel clutch problems.

I

clutch pedal with the clutch pedal tully deeressed.

I I1. Loosen locknut A, and back otf the clutch switch | 9. Release the clutch pedal 15-2O mm (O.59-O.79 I I

{or adiusting boltl until it no longer touches the clutch I int trom ttre fully depressed position and hold it there. I I

, ::":"" rocknut c, and rurn the push rod in or out | iliiiliffi:l1l:J"'1"-:H"l:tJ:i"i#fT: I I

. il*:*j':"'-(@)andheisht(olatthe

|

,:.;:,nterrockswitch3/4torrurrturnturtner.

I tf

,

::

***r**''

.,".,u"**;

|

'-"'"'';*1,,0*.,.-,.,*,

I I