eld HONDA INTEGRA 1994 4.G Service Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 1030 of 1413

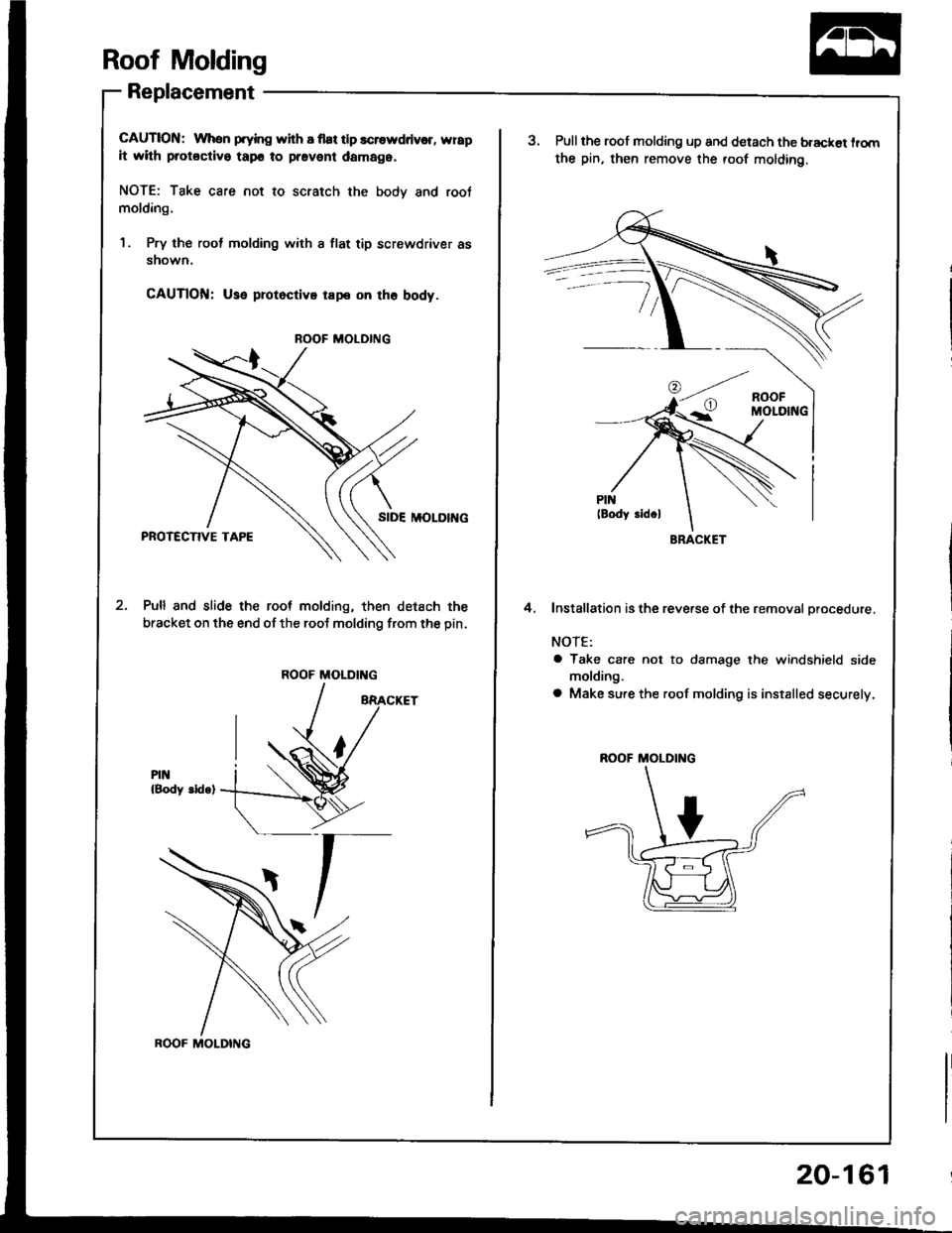

Roof Molding

Replacement

CAUTION: When prying with I flat tlp scrowddv€r, wrap

it with protoctivo tapo to pravent damag6.

NOTE: Take care not to scratch the bodv and root

molding.

1 . Pry the rool molding with a flat tip screwdriver as

snown.

CAUTlOfil: Use protoctivo rape on tho body.

SIDE MOLOII{G

Pull and slide the root molding, then detach the

bracket on the end of the roof molding from the pin.

PIN{Body ddq)

ROOF MOLDING

ROOF MOLDING

ROOF MOLDING

20-161

BRACKET

aPull the roof molding up and detach the bracket lrom

the pin, then remove the roof molding.

Installation is the reverse of the removal orocedure.

NOTE:

a Take care not to damage the windshield side

molding.

a Make sure the roof molding is installed securely.

4.

R(X)F MOLDING

Page 1035 of 1413

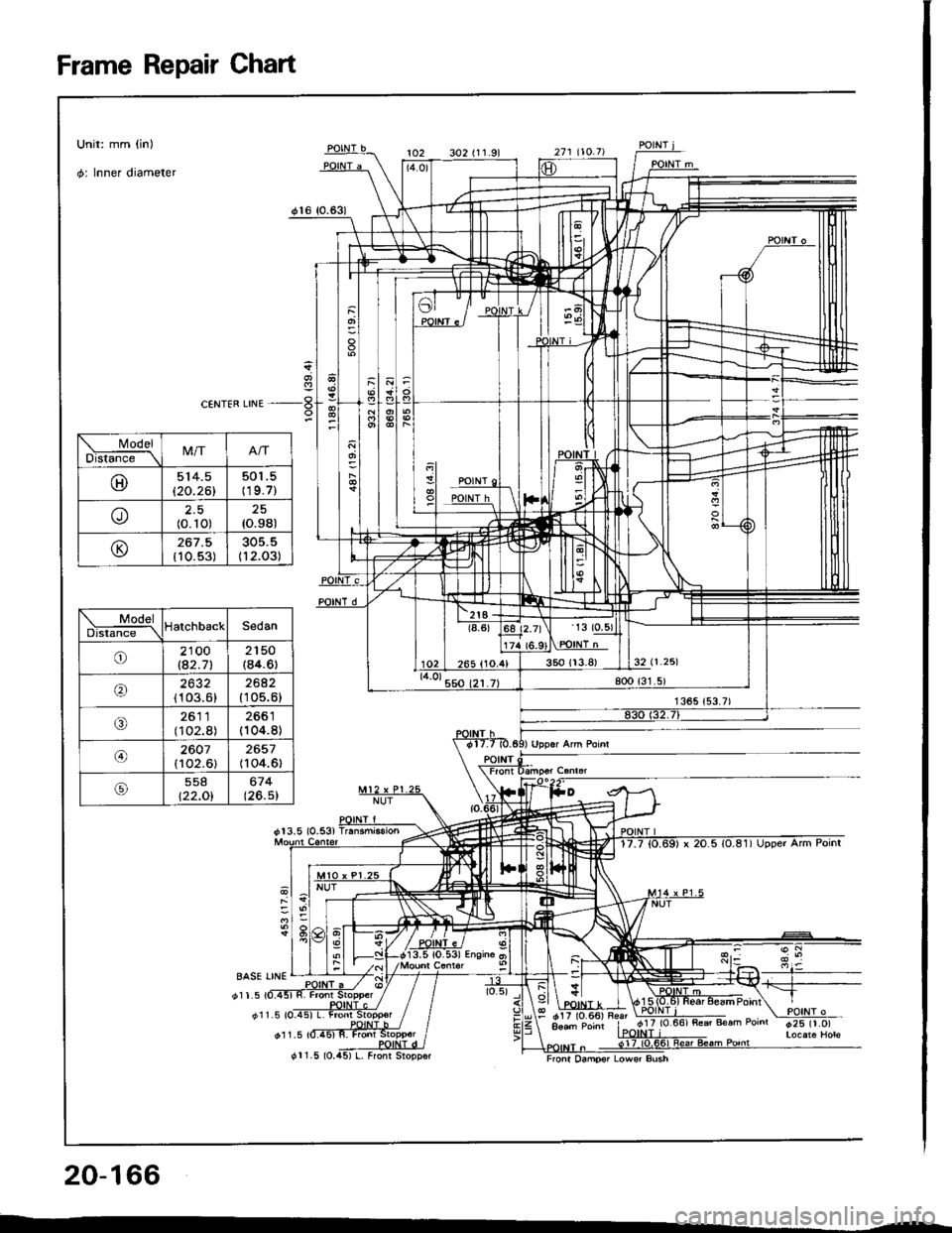

Frame Repair Ghart

1

ar"tr*,,,ua -!

BASE LINE

d11.5

dl 1.5 tO_

011.5

I cir (o-36;E;

y+, Aoad Poinr | 9rl lv

Front Osmpsr Lowsr Bush

20-166

cr1.5 (0.

ModelDls6ft-\M/T

@514.5

120.261

501 .5(19.7)

U-)2.5(0.10)25{o.98)

(J{10.53)112.03)

\---!e!s!SedanDistance \

o2100lE2.712150(84.6t

2632{103.6)

2642{105.6}

J5261 1(102.8)(104.8)

@2607(102.6)2657(104.6)

t22.Ol674(26.5)

Page 1098 of 1413

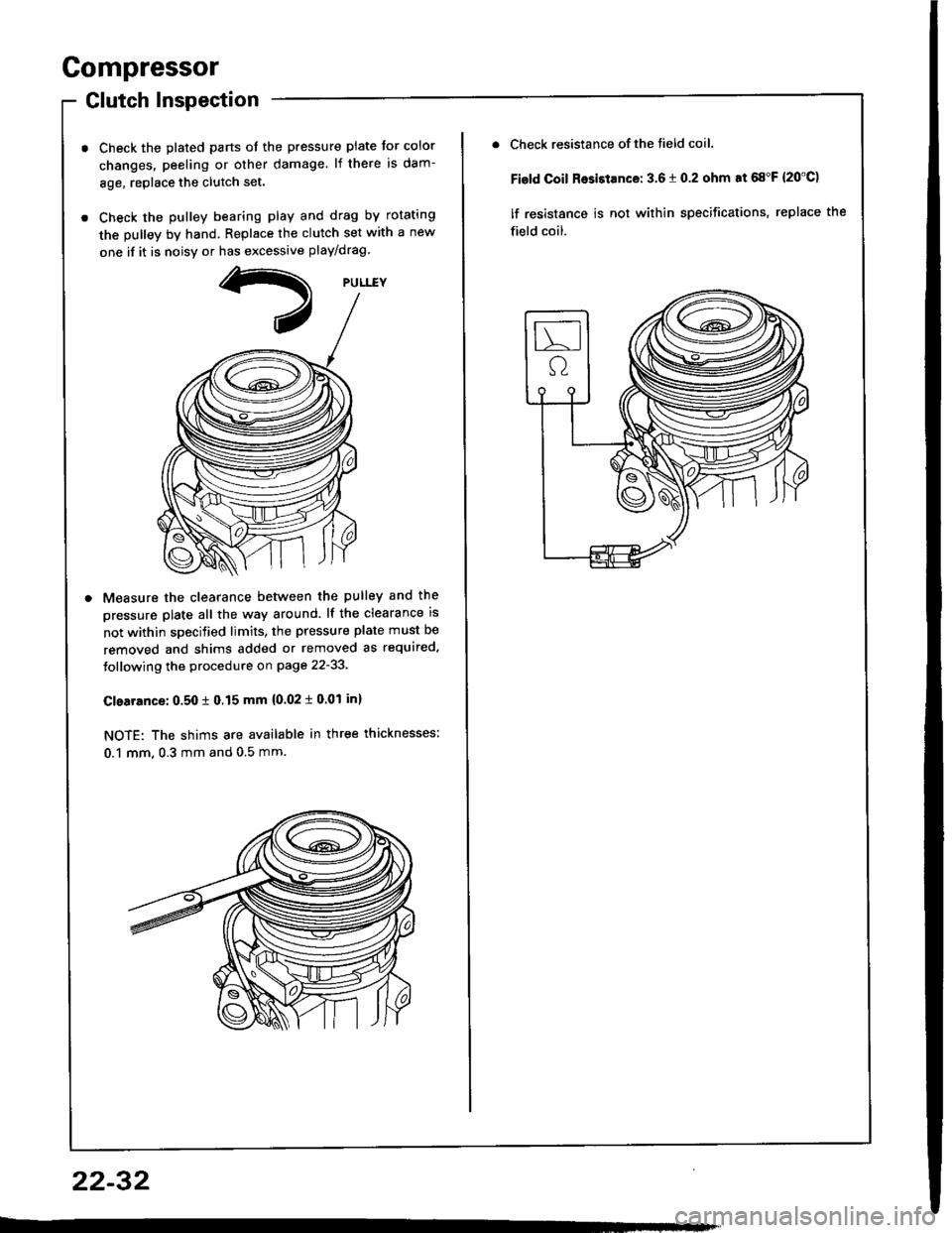

Compressor

Glutch Inspection

Check the plated parts ot the pressure plate tor color

changes. peeling or other damage. lf there is dam-

8ge, replace the clutch set.

Check the pulley bearing play and drag by rotating

the pulley by hand. Replace the clutch set with a new

one if it is noisv or has excessive play/drag

Measure the clearance betlveen the pulley and the

pressure plate all the way around. lf the clearance is

not within specified limits, the pressure plate must be

removed and shims added or removed as required.

Jollowing the procedure on page 22-33.

Clearrnce: 0.50 t 0.15 mm {0.02 i 0.01 inl

NOTE: The shims are available in three thicknesses:

0.1 mm, 0.3 mm and 0.5 mm.

22-32

Check resistance of the tield coil.

Fisld Coil Rosistance: 3.6 t 0.2 ohm at 68"F {20'C)

lf resistance is not within specifications, replace the

field coil.

Page 1100 of 1413

and com

it with a

a

a

a

a

4t l\-N

r-

-l/

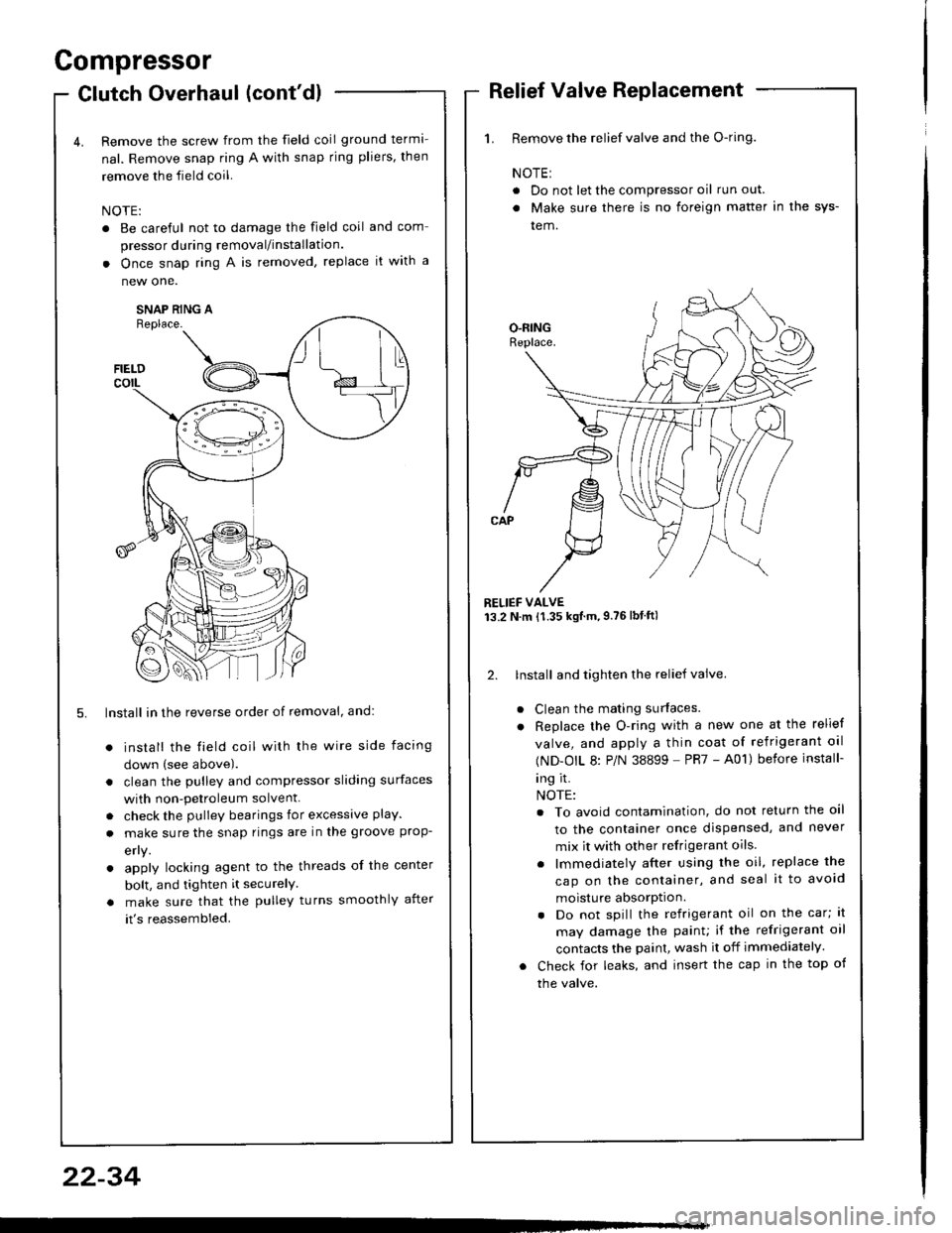

Compressor

Clutch Overhaul (cont'dl

Remove the screw from the field coil ground terma-

nal. Remove snap ring A with snap rjng pliers, then

remove the field coil.

NOTE:

. Be careful not to damage the field coil

pressor during removal/installation.

. Once snap ring A is removed, replace

new one.

SNAP RING AReplace.

FIELDcorL

5. lnstall in the reverse order of removal, and:

install the field coil with the wire side facing

down (see above).

clean the pulley and compressor sliding surfaces

with non-petroleum solvent.

check the pulley bearings for excessive play.

make sure the snap rings are in the groove prop-

efly.

apply locking agent to the threads of the center

bolt, and tighten it securelY

make sure that the pulley turns smoothly after

it's reassembled.

1. Remove the relief valve and the O-ring.

NOTE:

. Do not let the compressor oil run out.

. Make sure there is no foreign matter in the sys-

tem.

RELIEF VALVE13.2 N.m {1.35 kgtm,9.76lbtftl

2. lnstall and tighten the relief valve.

Clean the mating surfaces.

Replace the O-ring with a new one at the relief

valve, and apply a thin coat of refrigerant oal

(ND-OIL 8: P/N 38899 - PR7 - A01) before install-

ing it.

NOTE:

. To avoid contamination, do not return the oil

to the container once dispensed, and never

mix it with other refrigerant oils.

. lmmediately after using the oil, replace the

cap on the container, and seal it to avoid

moisture absorption.

. Do not spill the refrigerant oil on the car; lt

may damage the painu if the refrigerant oil

contacts the paint, wash it off immediately.

Check for leaks, and insert the cap in the top of

the valve.

22-34

Page 1113 of 1413

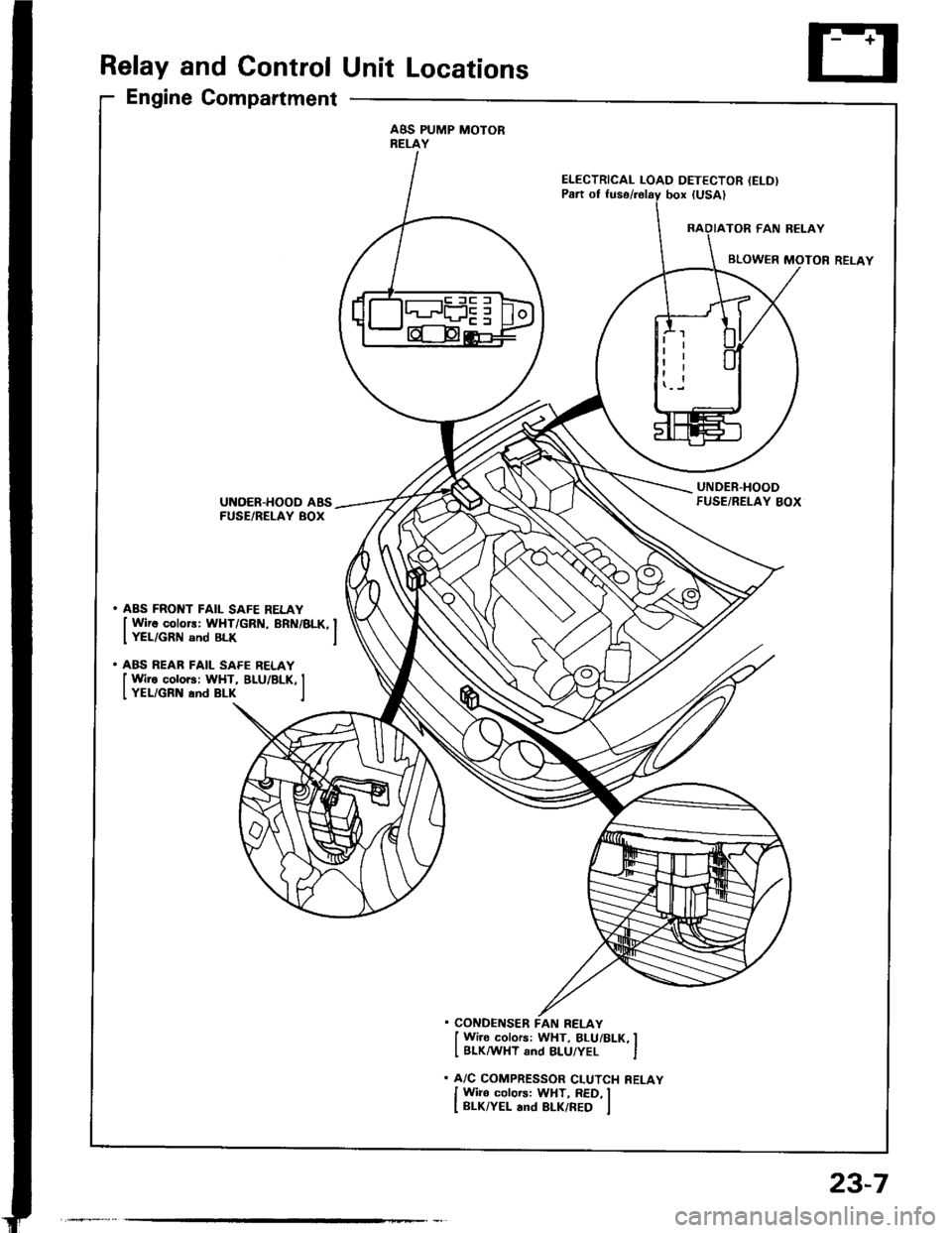

Relay and Control Unit Locations

Engine Compartment

ABS PUMP MOTORRELAY

ELECTRICAL LOAD DETECTOR (ELD)

UNDER.HOODFUSE/RELAY BOXUNOER-HOOD ABSFUSE/BELAY BOX

. ABS FRONT FAIL SAFE RELAY

I Wirc colors: WHT/GRN, BRN/BLK, IIYEL/GRN snd BLK I

. ABS REAR FAIL SAFE RELAY

I Wire colors: WHT, BLU/BLK, II YEL/GRN and BLK I

. CONDENSER FAN RELAY

I Wi]o colors: WHT, BLUi BLK, II BLKMHT and 8LU/YEL I

. A/C COMPRESSOR CLUTCH RELAY

I Wiro colors: WHT, RED, II BLK/YEL and BLK/RED I

23-7

Page 1126 of 1413

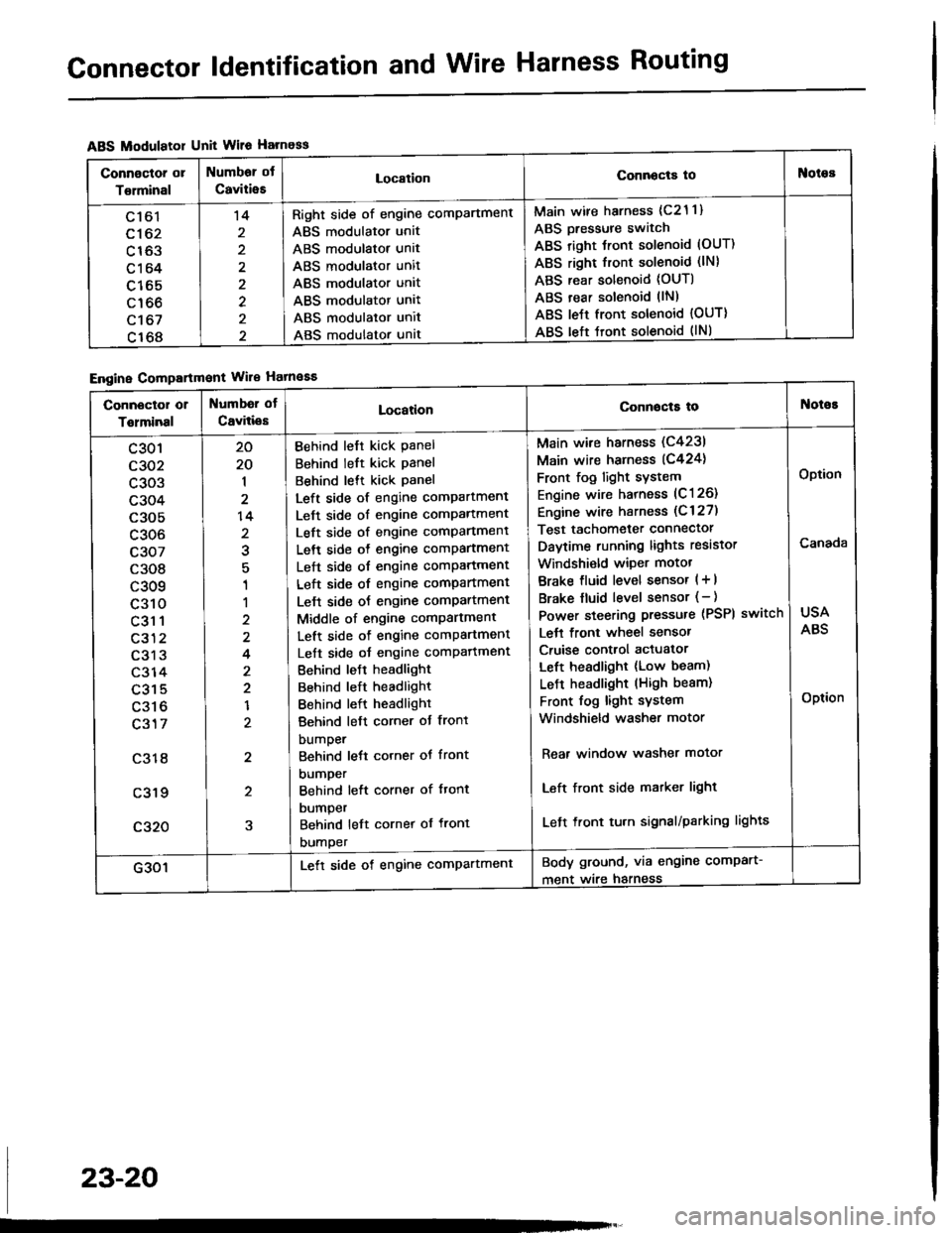

Connector ldentification and Wire Harness Routing

ABS Modulatol Unit Wile Harness

Engine Compartmont Wile Hatnaaa

Connoctor or

Torminal

Numbor ot

CaviiieELocationConnocta tooies

Ltol

c162

c163

c164

c165

c166

c't 67

c168

't4

2

2

Right side of engine comPartment

ABS modulator unit

ABS modulator unit

ABS modulator unit

ABS modulator unit

ABS modulator unit

ABS modulator unit

ABS modulator unat

Main wire harness (c21 1)

ABS Dressure switch

ABS right Jront solenoid (OUT)

ABS right front solenoid (lN)

ABS rear solenoid (OUT)

ABS rear solenoid llN)

ABS le{t front solenoid {OUT)

ABS left tront solenoid (lNl

Connector or

Tolminal

Numbd of

CaviliesLocationConnocta tot{oioE

c301

c302

c303

c304

c305

c306

c307

c308

c309

c310

c31 1

c312

c313

c314

c315

c316

c317

c318

c319

c320

20

20

1

2

14

2

1

1

2

4

2

2

1

2

2

5

Behind left kick Panel

Behind left kick panel

Behind lett kick Panel

Left side of engine compartment

Left side of engine comPartment

Left side of engine comPartment

Left side o{ engine comPartment

Left side of engine comPartment

Left side of engine compartment

Lelt side oJ engine comPartment

Middle of engine comPartment

Left side of engine comPartment

Left side oJ engine comPafiment

Behind leJt headlight

Behind left headlight

Behind left headlight

Behind left corner ot front

bumper

Behind lett corner ot front

DUmper

Behind left corner of ftont

DUmper

Behind left cornet of front

DUmper

Main wire harness (C4231

Main wire harness (C424)

Front fog light sYstem

Engine wire harness (C126)

Engine wire harness (C 127)

Test tachometer connector

Daytime running lights resistor

Windshi€ld wiper motot

Brake fluid level sensor ( + |

Brake fluid level sensor (- )

Power steering pressure (PSPI

Lett front wheel sensor

Cruise control actuator

Left headlight (Low beam)

LeJ-t headlight (High beam)

Front fog light system

Windshield washer motor

switch

Rear window washer motor

Left front side matker light

Left front tu.n signal/parking lights

USA

ABS

Option

Canada

Option

G301Lett side of engine comPartmentBody ground, via engine comPart-

ment wire harness

23-20

Page 1155 of 1413

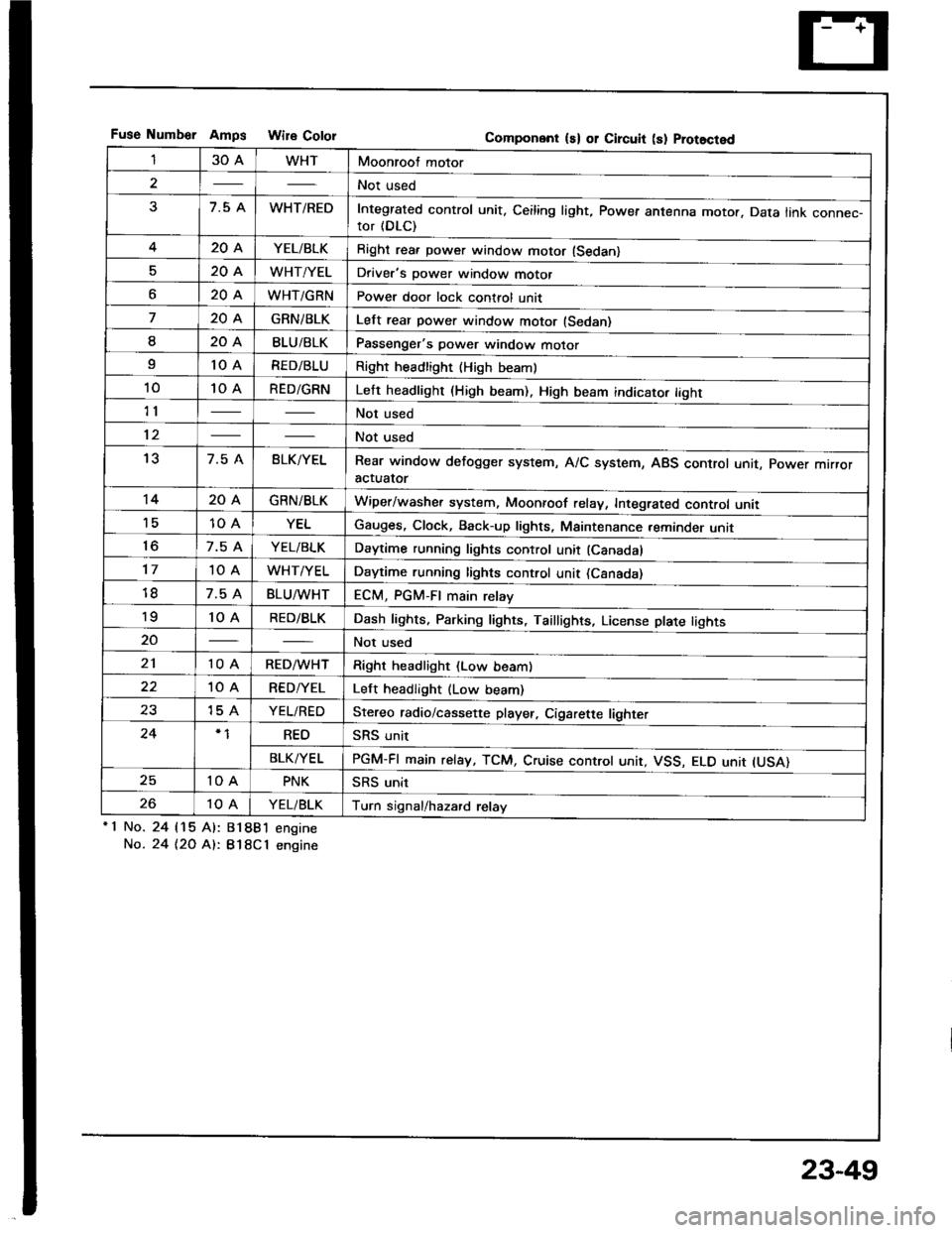

Fuse Numb€r AmDs Wire CololGomponent ls) or Circuit (s) Prot8cted

130AWHTMoonroof motor

2Not used

37.5 AWHT/REDIntegrated control unit, Ceiling light, Power antenna motor. Data link connec-tor (DLC)

420AYEL/BLKRight rea. power window motor (Sedan)

520AWHT/YELDriver's power window motor

o20AWHT/GRNPower door lock control unit

720AGRNiBLKLelt rear power window motor (Sedan)

I20ABLU/BLKPassenger's power window motor

I10 ARED/BLURight headlight {High beaml

1010 ARED/GRNLeft headlight (High beam). High beam indicato. tight

11Not used

12Not used

137.5 ABLK/YELRear window defogger system, A/C system, ABS control unit, power mrrroractuator

1420AGRN/BLKWiper/washer system, Moonroof relay, Integrated control unii'1510 AYELGauges, Clock, Back-up lights, Maintenance reminder unit

to7.5 AYEL/BLKDaytime running lights control unit (Canadal

1710 AWHT/YELDaytime running lights control unit (Csnada)

7.5 ABLU^tvHTECM, PGM-FI main relay'to10 ARED/BLKDash lights, Parking lights, Taillights, License plate tights

20Not used

2110 ARED/WHTRight headlight (Low beam)

10 ARED/YELLeft headlight (Low beam)

2315 AYEL/REDStereo radio/cassette player, Cigarette lighter

24REOSRS unit

BLK/YELPGM-FI main relay, TCM, Cruise controt unit, VSS, ELO unit IUSA)

2510 APNKSRS unit

2610 AYEL/BLKTurn signal/hazard relay'1 No.

No.

24 115 Al:

24 t2O At:.

81881 engine

B18Cl engine

23-49

Page 1172 of 1413

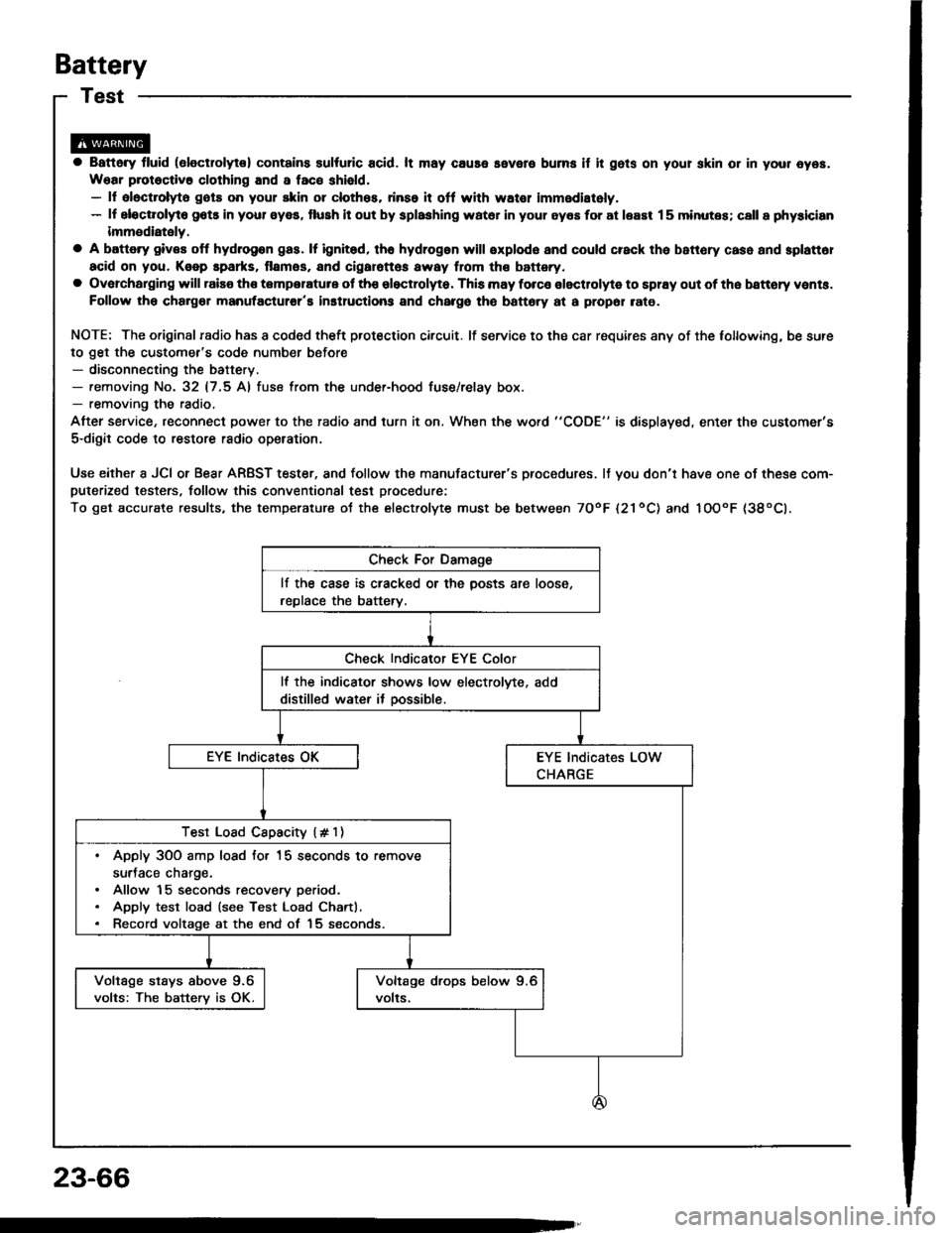

Battery

a Battory tluid (6lectrolyt€l contains sulturic acid. lt may cauaa aevere burns iI it gots on your skin or in youl oyos.

Woar protoctivo clothing and I fac€ shield,- ll aloctrolyt6 gots on youl skin or clothos, rimo it off with wator immediately,- lf eloclrolyto g6ts in your oyos, tlush it out by splashing wat6r in youl eyes for at least 15 minutes; call a physiclan

immediately,

a A battery gives off hydrogon gas, lf ignit6d. tha hydrogsn will orploda and could crack tho baflory cas6 and splattor

acid on you. Koep spa*s. flames, and cigarottos away from the baftery.

a Overcharging will raiso ths tempelature ot th€ electrolyte. This may force electrolyte to splay out of the battery venta.

Follow lhe chargor manutacturer's instluctions and chargo tho battory at a prop61 rate.

NOTE: The original radio has a coded theft protection circuit. lt service to the car requires any of the lollowing, be sure

to get the customer's code number before- disconnecting the battery.- removing No. 32 (7.5 Al fuse from the under-hood fuse/relay box- removing the radio,

After service, reconnect power to the radio and turn it on. When the word "CODE" is displayed, enter the customer's

s-digir code to restore radio operation,

Use either a JCI or Bear ARBST tester, and follow the manufacturer's procedures. It you don'r have one of these com-puterized testers, follow this conventional test procedure:

To get accurate results, the temperature ot the electrolyte must be between TOoF l21ool and IOOoF {38oCl.

lf the case is cracked or the posts are loose,

replace the battery.

lf the indicator shows low electrolvte, add

distilled water it oossible.

Test Load Cspacity (# 1)

. Apply 3OO amp losd fo. 15 seconds to remove

surJace charge.. Allow 15 seconds recovery period.. Apply test load (see Test Load Chartl.. Record voltage at the end of 15 seconds.

Voltage stays above 9.6

volts: The batterv is OK.

23-66

Page 1183 of 1413

5. Check lor 8n op€n in the BLKMHT wire circuit be-

tween the staner and ignition switch, and con-

nectors.

6. Check the ignition switch (see page 23-70).

7, On cars with automatic transmission, check the A/Tgear position switch (neutral position switchl and

connector. On cars with manualtransmission, check

the staner cut relay, clutch interlock switch, and

connectors.

NOTE: Check the No. 39 (5O A) fuse in the under-hood

fuse/relay box for the starter cut relay.

Check tor Woar and Damago:

The starter should crank the engine smoothly and stead-

ily. lf th€ startsr engages, but cranks the engine errati-

cally, remove it. Inspect the starter, drive gear, and

flywheel ring gesr for damage.

a Check the drive gear overunning clutch for binding

or slipping when the armature is rotated with the drivegear held. Replace the gesrs if damaged.

Check Cranking Voltago 8nd Current Draw:

Cranking voltage should be no less than 8.O volts.

Current draw should be no more than 360 amperes.

lf cranking voltag€ is too low, or current draw too high,

check for:

a Fully charged battery

a Open circuit in starter armature commutatot segments

a Starter armature dragging

a Shoned armature winding

a Excessive drag in engine

Chack Cranking rpm:

Engine spsod during cranking should be above 1O0 rpm.

lf spe6d is too low, ch€ck for:

a Loose battsry or starter teminals

a Excessively worn starter brushes

a Open circuit in commutator segments

a Dirty or damaged helical spline or drive gear

a Defective drive gear overrunning clutch

Chock StErtor Disongagomoni:

Press the clutch pedal allth€ way in (M/T), turn the ioni-

tion switch to "lll" and rolease to "11".

The starter drive gear should disengage from the tlywheel

ring gear. When you rolease the key.

lf the drive gear hangs up on th€ flywheel ring gear, check

for:

a Solenoid plunger and switch malfunction

a Dirty drive gear assembly or damaged overrunning

clutch

23-77

Page 1188 of 1413

Starting System

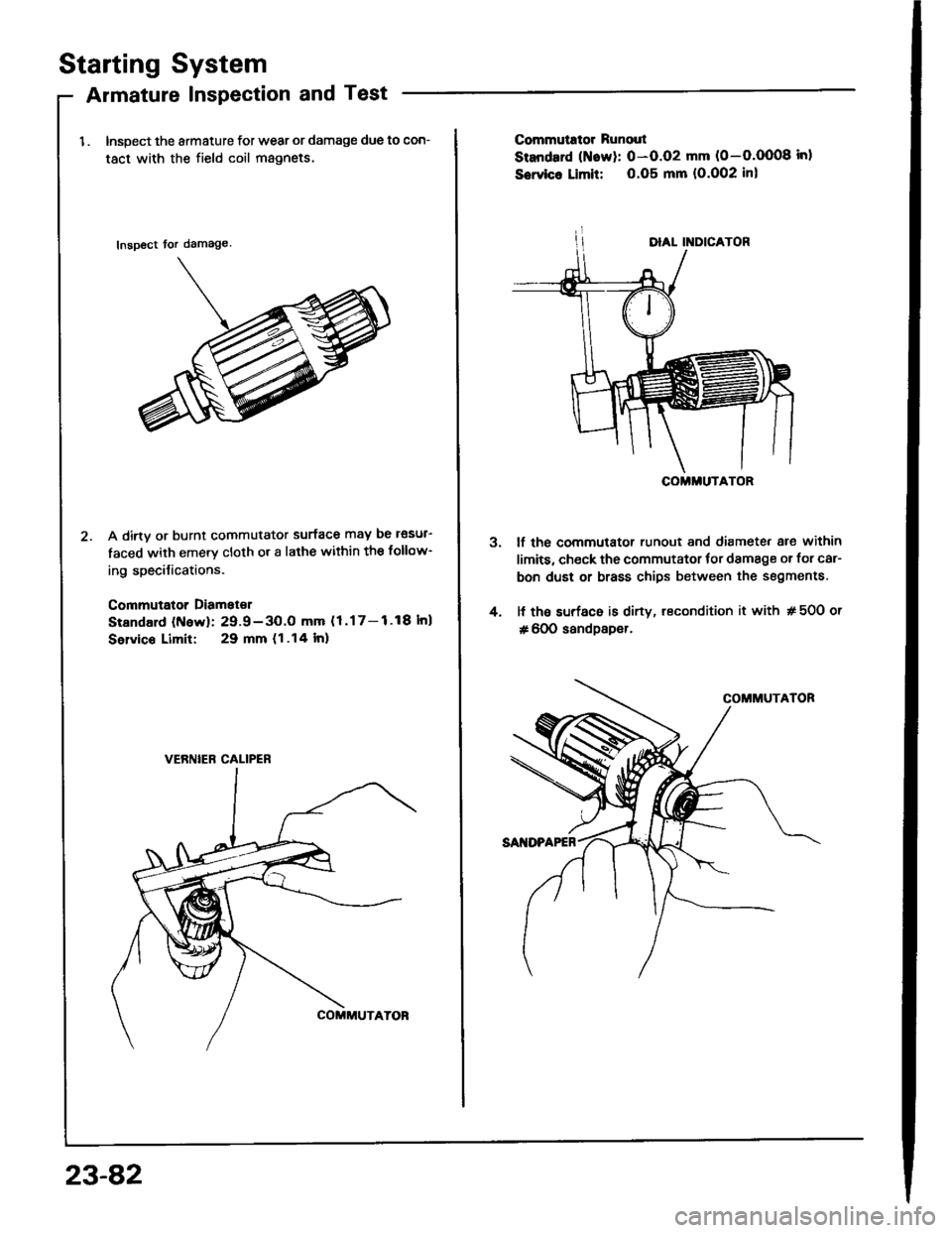

Armature Inspection and Test

1 . Inspect the armature for wear or damage due to con-

tact with the field coil magnets.

Inspect tor damage

A dirtv or burnt commutator surface may be l€sul-

faced with emery cloth or a lathe within the follow-

ing specilications.

Commutator Diamet€r

Stsndald (N6w): 29.9-3O.O mm (1.17-1.18Inl

Selvico Limit: 29 mm (1.14 lnl

VERNIEB CALIPER

23-82

3.

4.

Commutrtor Runout

Standard (Naw): 0-O.O2 mm (0-O.OO08 inl

Sowico Limit: 0.O5 mm (O.O02 inl

lf the commutator runout and diamete. are within

limits, check the commutator tor damage or for car-

bon dust or brass chips between the segments.

lf the surf6c6 is dirty, recondition it with # 50O or

# 600 sandpsper.

COMMUTATOR