fuel HONDA INTEGRA 1994 4.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 78 of 1413

Gylinder Head

Removal

I

t

Engine removal is not required for this procedure.

CAUTION: To avoid damaging tho cylinder head, wait

until tho ongino coolant temporature drops bolow 100"F

{38"C) beforo loo36ning the rotainin0 bolts.

NOTE:

. Inspect the timing belt before removing the cylinder

neao.

. Turn the crankshaft pulley so that the No. 1 piston is

at top dead center (TDCI (page 6-12).

. Mark all emissions hoses before disconnecting them.. Anti-theft radios have a coded theft protection circuit.

Be sure to get the customer's code number before.- Disconnecting the battery.- Removing the No. 32 (7.5 A) fuse irom the under-

hood fuse/relay box.- Removing the radio.

After service, reconnect oower to the radio and turn it

on.

When the word "CODE" is displayed, enter the cus-

tomer's 5-digit code to restore radio operation.

1. Disconnect the negative terminalfrom the battery.

2. Drain the engine coolant (see page 10-5).

. Remove the radiator cap to speed draining.

3. Relieve fuel pressure (see Section 1 1).

@ Do not smoke whils working on tusl

systom, keep opon flame or spark away trom work

area. Drain fuol only inlo an approvod containsr.

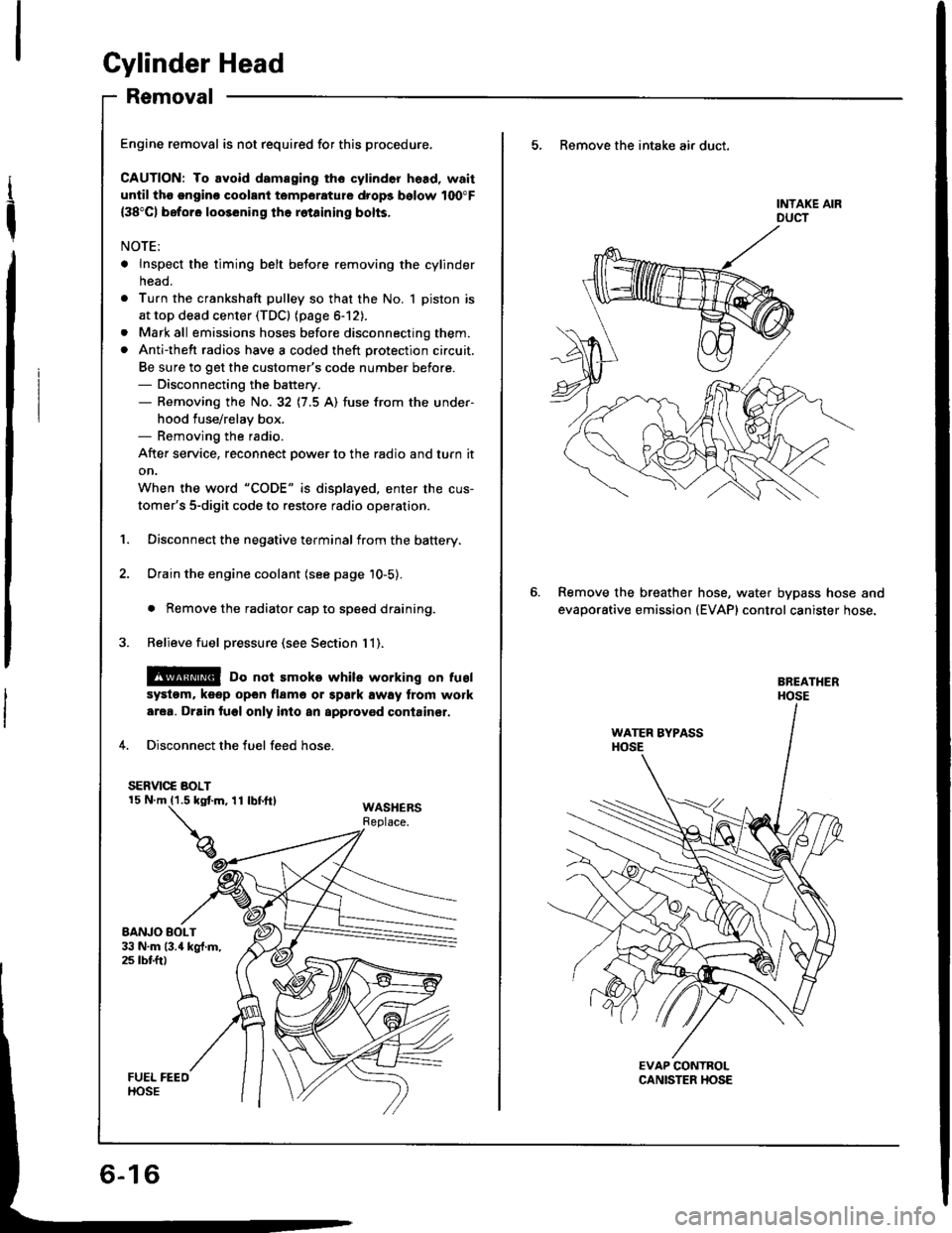

4. Disconnect the fuel feed hose.

SERVIC€ BOLT

WASHERSReplace.

5, Remove the intake air duct.

Remove the breather

evaporative emission

hose, water bypass hose and(EVAP) control canister hose.

Page 79 of 1413

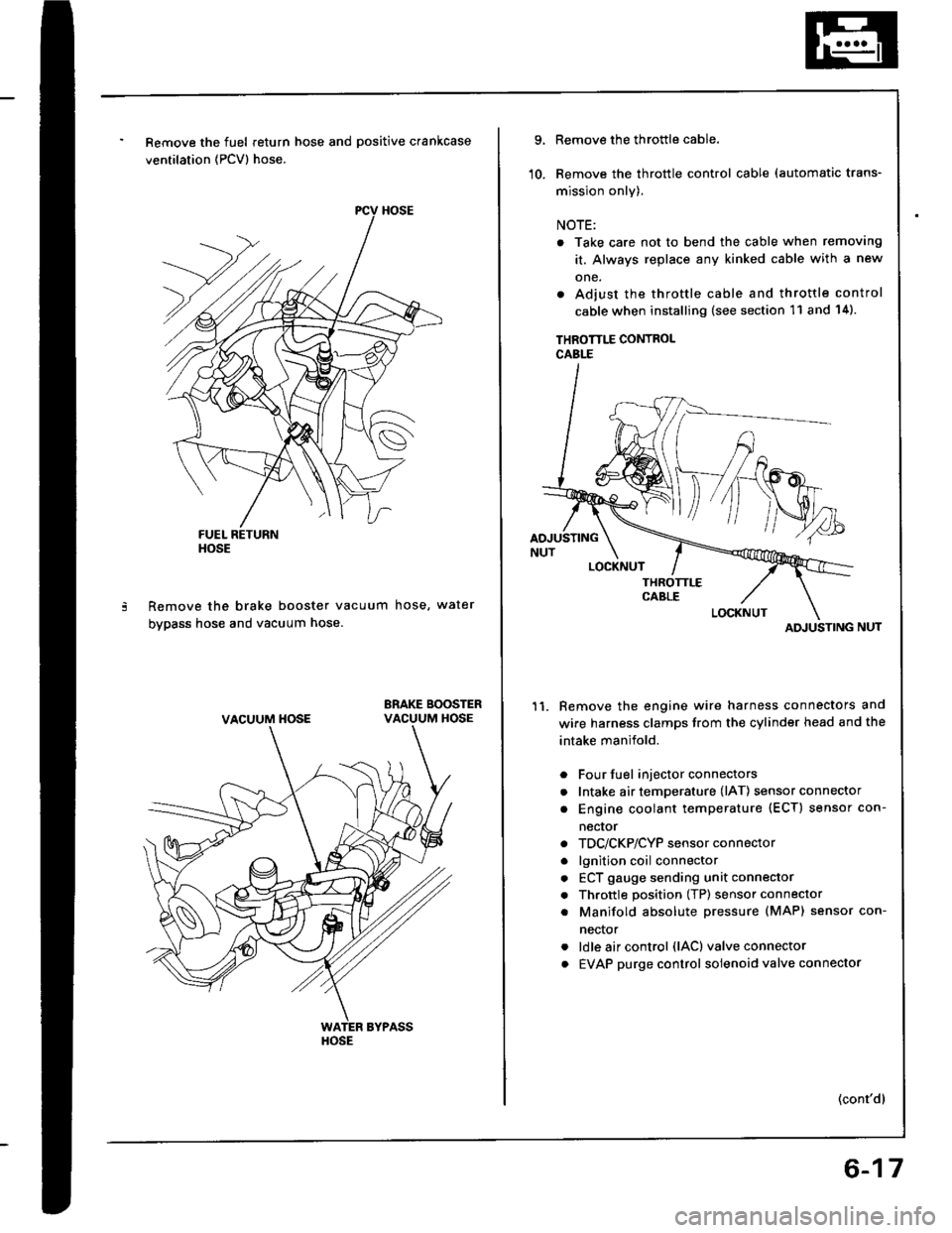

Remove the fuel return hose and positive crankcase

ventilation (PCV) hose.

Remove the brake booster vacuum hose, water

bypass hose and vacuum hose.

ERAKE BOOSTERVACUUM HOSE

HOSE

VACUUM HOSE

HOSE

9.

10.

Remove the throttle cable.

Remove the throttle control cable (automatic trans-

mission only).

NOTE:

. Take care not to bend the cable when removing

it. Always replace any kinked cable with a new

one.

. Adjust the throttle cable and throttle control

cable when installing (see section 11 and 14).

THROTTLE CONTROLCABLE

Remove the engine wire harness connectors and

wire harness clamps trom the cylinder head and the

intake manifold.

Four fuel injector connectors

Intake air temperature (lAT) sensor connector

Engine coolant temperature (ECT) sensor con-

necror

TDC/CKP/CYP sensor connector

lgnition coil connector

ECT gauge sending unit connector

Throttle position (TP) sensor connector

Manifold absolute Dressure (MAP) sensor con-

nector

ldle air control (lAC) valve connector

EVAP purge control solenoid valve connector

11.

a

a

a

a

a

a

a

a

a

(cont'dl

ATI'USTING

6-17

Page 116 of 1413

Cylinder Head

Removal

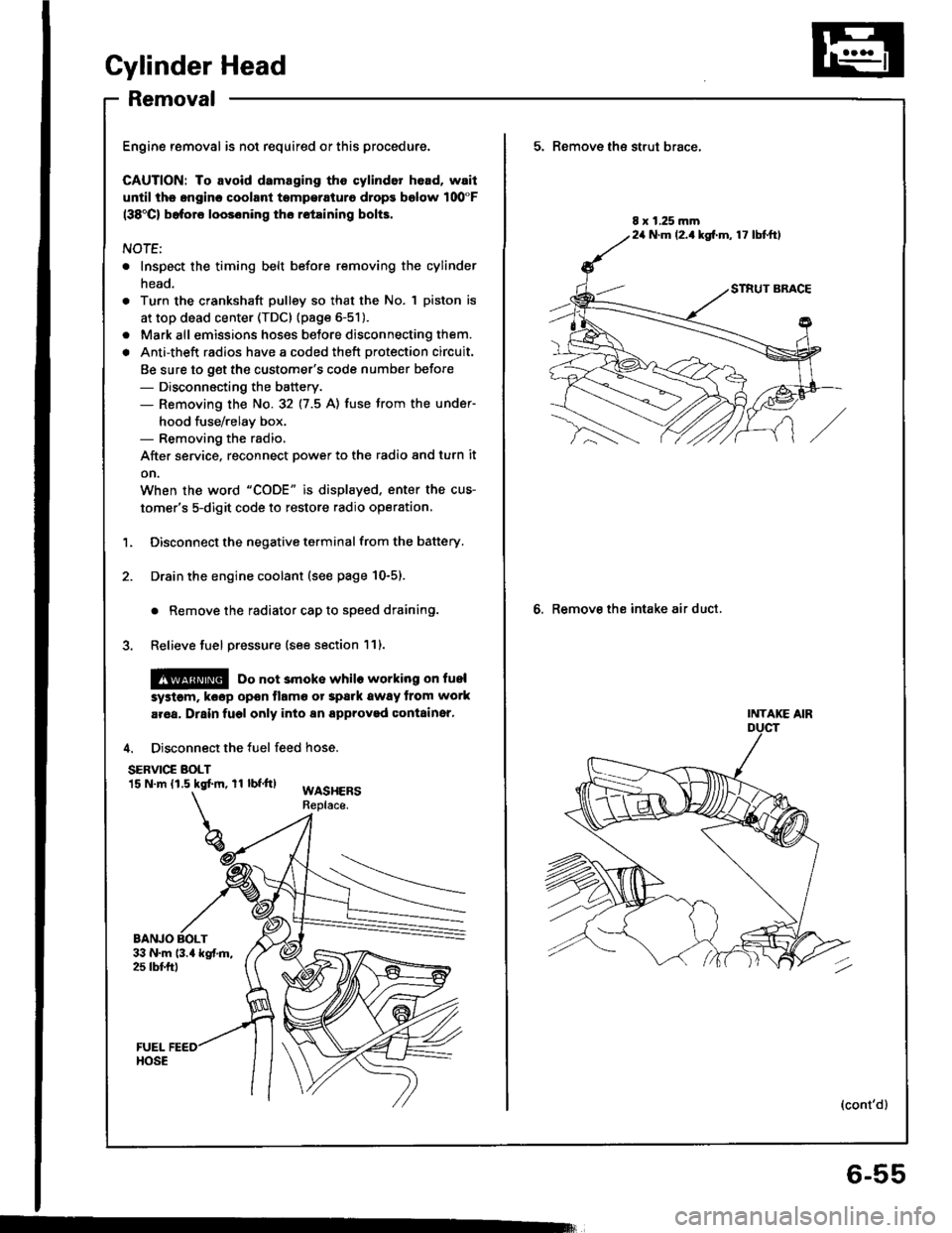

Engine removal is not required or this procedure.

CAUTION: To avoid damaging tho cylinder head, wail

u[tilths.nginc coolant tsmperaturo drops bolow 100"F(38'Cl bafore loos6ning tho retaining bolts.

NOTE;

. Inspect the timing belt before removing the cylinder

head.

Turn the crankshaft pulley so that the No. 1 piston is

at top dead center (TDc) {page 6-51).

Mark all emissions hoses betore disconnecting them.

Anti-theft radios have a coded theft protection circuit.

Be sure to get the customer's code number before- Disconnecting the battery.- Removing the No.32 (7.5 A) fuse trom the under-

hood fuse/relay box.- Removing the radio.

After service, reconnect power to the radio 8nd turn it

on.

When the word "CODE" is displaved. enter the cus-

tomer's 5-digit code to restore radio operation,

Disconnect the negative terminal from the battery.

Drain the engine coolant (see page 10-5).

. Remove the radiator cap to speed draining.

Relieve fuel pressure (see section 111.

l@ Do not 3moke whilo working on fuel

a

a

'1.

systgm. ko6p opon tlamo ot Spark away trom work

aroa. Drain fugl only into an approved containsr,

4. Disconnect the fuel feed hose.

SERVIC€ BOLT15 N.m (1.5 kgtm, rl bf.tt)WASHERSReplace.

BANJO BOLT

5. Remove th€ strut brace,

6. Remove the intake air duct.

8 x 1.25 mm24 N.m (2.1kg[.m, 17 lbtftl

INTAKE AIR

(cont'd)

6-55

Page 118 of 1413

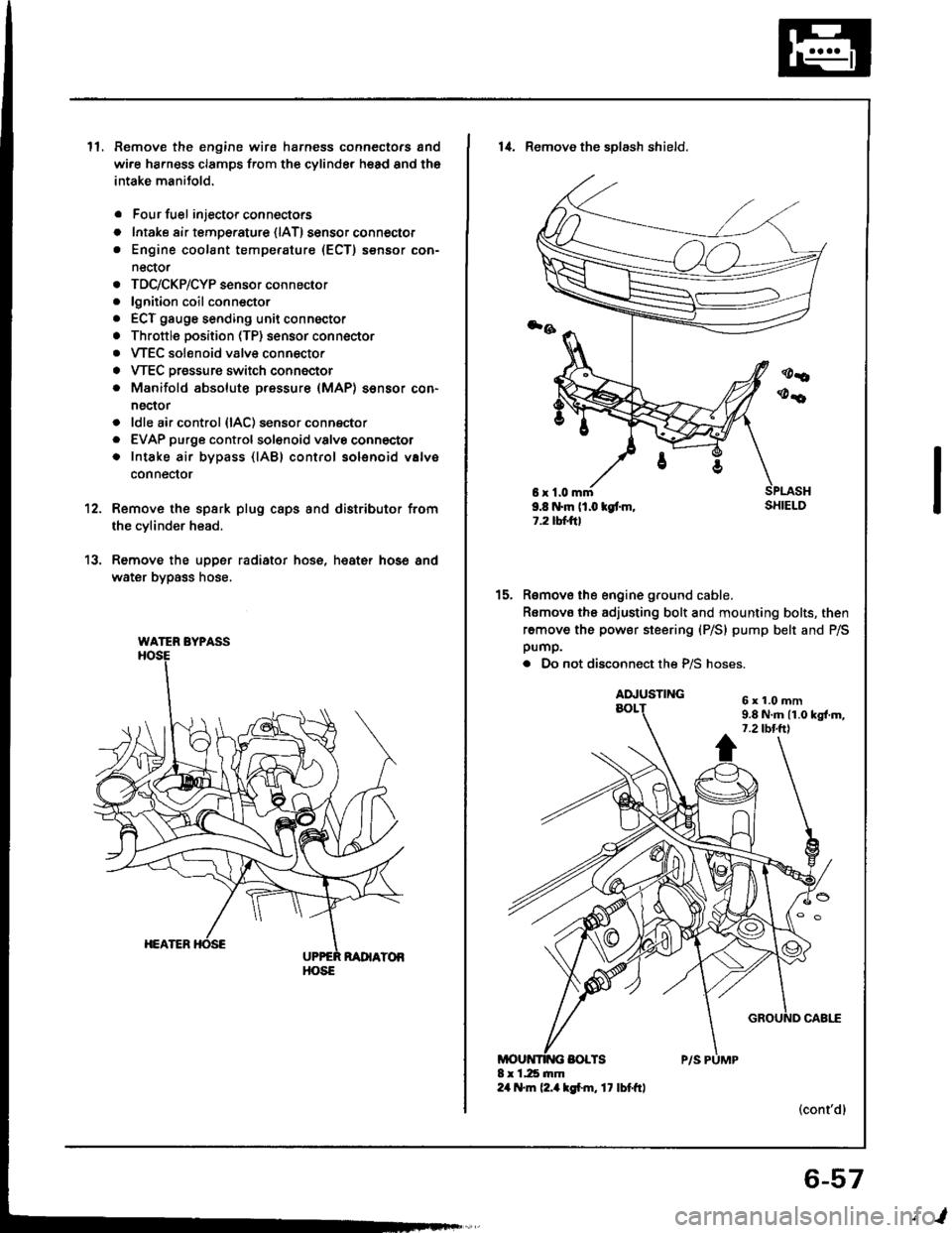

ll.Remove the engine wire harness connectors and

wi.e ha.ness clamps from the cylinder head and the

intake manitold.

Four fuel injector connectors

Intake air tempe.ature {lAT) sensor connector

Engine coolant temperature (ECT) sensor con-

nector

TDC/CKP/CYP sensor connector

lgnition coil conn€ctor

ECT gauge sending unit connector

Throttle position (TP) sensor connector

VTEC solenoid valve connector

VTEC Dressure switch connector

Manifold absolute pressure (MAP) sensor con-

nector

ldle air control {lAC) sensor connector

EVAP purge controlsol€noid valvo connector

Intake air bypass {lABl control solenoid valve

conneclor

a

o

a

o

a

a

a

a

a

a

a

a

a

12.

13.

Remove the spsrk plug caps and distributor from

the cylinder head.

Remove the upper radiator hose, heat€r hose and

water bypass hose.

WATER BYPASS

HOSE

6r1.0mm9.8 N.m (1.0 kgt m,1.2 tbtftl

14. Remove the sDlash shield.

Remove the engine ground cable.

Romovo the adjusting bolt and mounting bolts, then

remove the power steering (P/S) pump belt and P/Spump.

. Do not disconnect the P/S hoses.

(cont'dl

15.

6x1.0mm9.8 N.m 11.0 kgl.m,7.2 tbt.ttl

6-57

,l

Page 172 of 1413

Englne Oil

Replacement {cont'd)

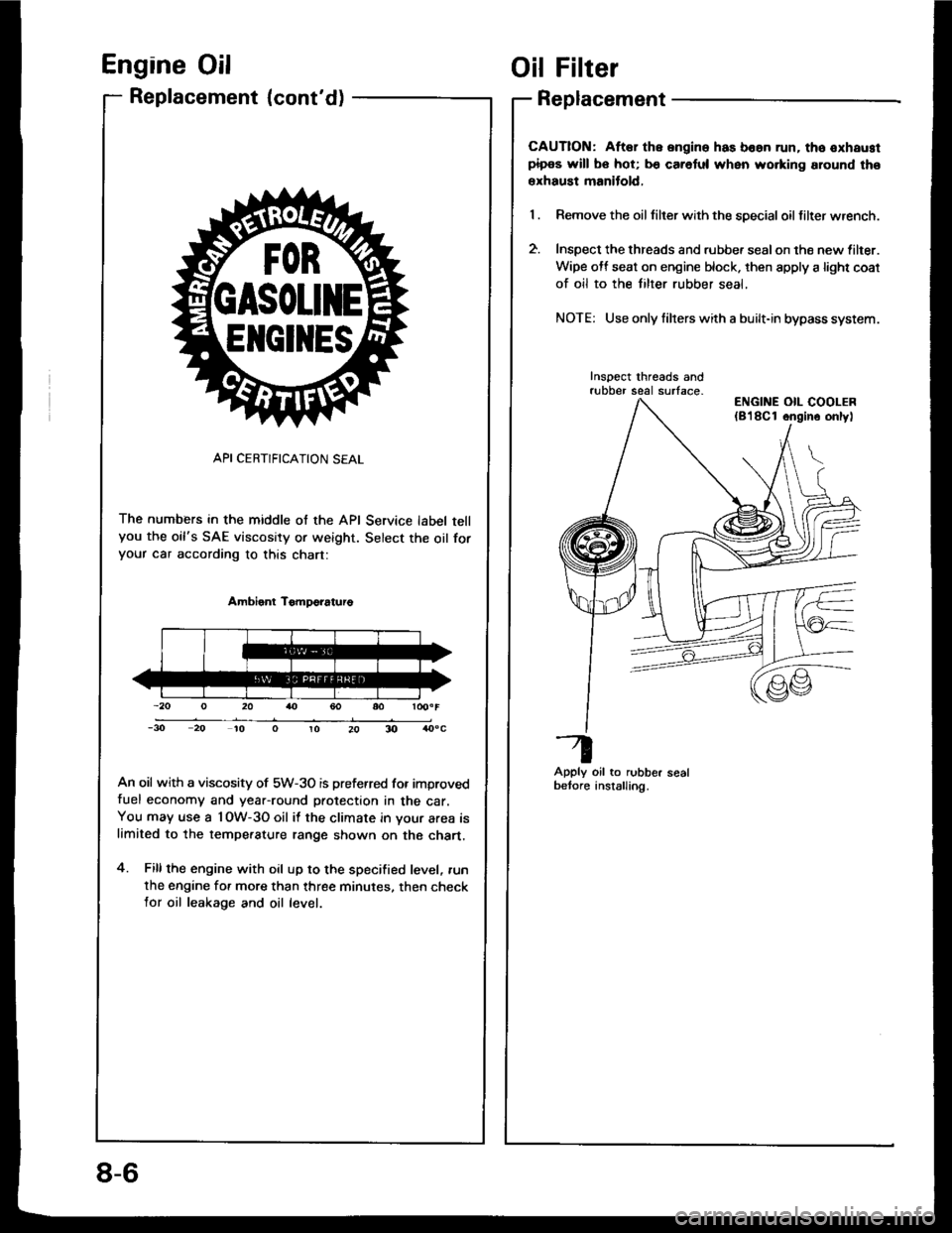

API CERTIFICATION SEAL

The numbers in the middle of the API Service label tellyou the oil's SAE viscosity or weight. Select the oil foryour car according to this chart:

Ambient TomDo?aturo

An oil with a viscosity of 5W-3O is preferred for improvedfuel economy and year-round protection in the car.You may use a l OW-3O oil it the climate in your area islimited to the tempe.ature range shown on the chart.

4. Fillthe engine with oil up to the specified level, .un

the engine for more than three minutes. then checklor oil leakage and oil level.

ElrclltEs

Oil Filter

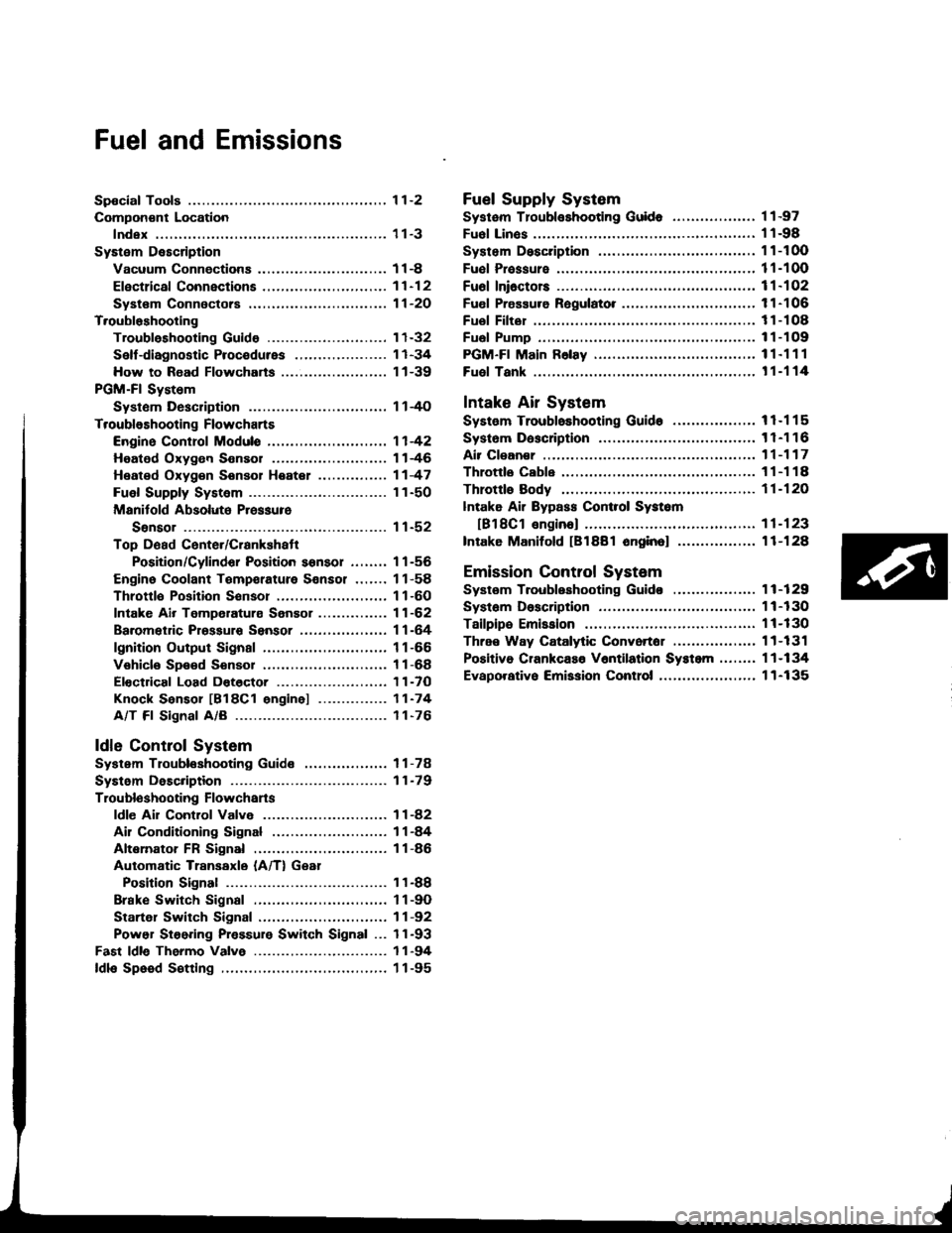

Replacement

CAUTION: Aftar the ongine has boan run. tho oxhaustpipos will bo hot; b€ caretul when wo.king around tho

erhaust manitold,

Remove the oil tilter with the special oil filter wrench.

Inspect the threads and rubbe. sealon the new lilter.

Wipe off seat on engine block. then apply a light coat

of oil to the tilter rubber seal,

NOTE: Use only filrers with a built-in bypass system.

Inspect threads andrubber seal surface-

Apply oil to rubber sealbetore anstalling.

ENGINE OIL COOLER(8'l8Cl ongino onlyl

8-6

Page 194 of 1413

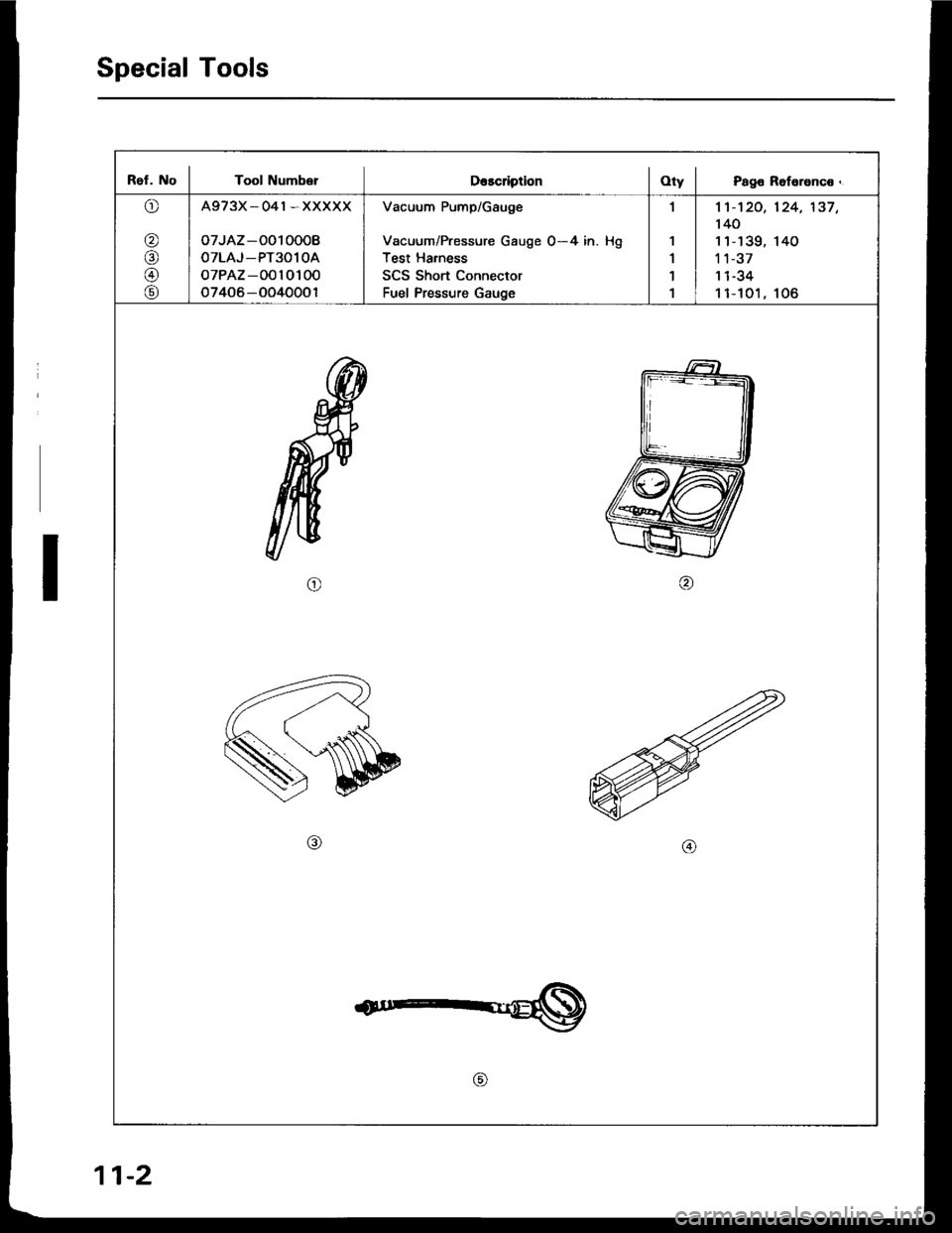

Fuel and Emissions

Spocial Tools ................ 1 1-2

Compon€nt Location

lndex ................. ...... 11-3

System Description

Vacuum Connectiona .......,.................... 1 1 -8

Efectrical Connections ....,.,.,......,...,,.....,'11-12

Syst€m Connectors ...,...,.................-.--. 11-2O

T.oubloshooting

Troubleshooting Guido .......................... 1 1-32

Self -diagnostic Procedures .,..,............... 1 1 -34

How to Road Flowcharts ...................,... 11-39

PGM-Fl System

Systom Description .............................. 1 l-4O

Troubleshooting Flowcharts

Engine Control Moduls ............... ........... 1 1 -42

Heated Oxygon Sensor ......,.................. 1 1-46

Heated Oxyg€n Sonsol Heatel .....,......... 1 1 -47

Fuel Supply System ..............-............... 1 1-50

Manitold Absolute Pressure

Ssnsor ............................................ 1 1-52

Top D6ad Cente./Crankshatr

Position/Cylindor Position sonsor ........ 1 1 -56

Engine Coolant Tempsrature Sonsor ....... 11-58

Throttlo Position Sonsor ........,..,,........... 1 1-60

Intake Air Temperaturs Sensor ............... 11-62

Baromet c Prsssuro Sensor ......,...,...,..,. 11-64

lgnition Output Signal ........................... 1 1 -66

Vehicle Spe€d Sensor ........................... 1 1 -68

Electdcal Load Dotector ....,...,..........,.... 1 1 -7O

Knock Sensor [818C1 engine] ............... 11-74

A/T Fl Signal A/B ................................. 1 1-76

ldle Contlol System

System Troubleshooting Guide .................. 1 1 -78

Systom Description ........ 11-79

Troubloshooting Flowchans

ldl€ Ail Control Valve ........................... 1 1 -82

Ail Conditioning Signal ......................... 1 1 -84

Altemator FR Signal ............................. 1 1 -86

Automatic Transaxle (A/T) Gear

Position Signal ......... 11-88

Brake Switch Signal ............................. 1 1 -9O

Startel Switch Signal ............................ 11-92

Power Steering Pressure Switch Signal ... 11-93

Fast ldle Thermo Valve ...................,......... 1 1 -94

ldls Speed S€tting .................................... 1 1 -95

Fuel Supply System

Systam Tloubloshooting Guid. .................. 1 1 -97

Fuol Linos ...................... 1'l -98

System Description ........ 11-100

Fuol Prassure ................. 11-100

Fu6l Ini6ctors ................. 11-102

Fuel Pressure Ragulato. .,. 11-106

Fuel Filter ...................... 11-108

Fual Pump ..................... 11-109

PGM-Fl Main F6lay ................................... 1 1"1 1 1

Fuel Tank ...................... t 1-114

Intake Air System

System Troubloshooting Guido .................. 1 1 -1 1 5

Systom Dascription ........ 11-116

Air Clean€r .................... 11-117

Throttls Cable ................'11-118

Throttl8 Body ................ 11-120

lntake Air Bypass Cont.ol Systsm

[B18Cl enginal .,......... 11-123

Intake Manilold [B1881 onginol ................. 11-128

Emission Control System

Systsm Troubleshooting Guido .................. 1 1 -1 29

Systam Doscription ........ 11-130

Tailpips Emission ........... 11-130

Thrae Way Catalytic Convortor ...,...,........., 11-131

Positiva CrankcaEo V6ntilation Systcm .,....., 11-134

Evaporativo Emission Contro|,..,..,.,.,,.,,..,.., 1 1-135

Page 195 of 1413

Special Tools

Ref. No I Tool Numb€rDescription I OtV I Page Reference.

o

@

@

@

@

A973X_041*XXXXX

oTJAZ -O010008

OTLAJ_PT3O1OA

oTPAZ-0010100

o7406-OO40001

Vacuum Pump/Gauge

Vacuum/Pressure Gauge 0-4 in. Hg

Test Harness

SCS Short Connector

Fuel Pressure Gauge

,l

1

1'l

1

1't -'t 20,

140

11-139,'t 1-37

I t -J.+

11-t01,

124,'137,

140

106

o

11-2

Page 199 of 1413

![HONDA INTEGRA 1994 4.G User Guide System Description

Index

FUEL FILTERReplacement, page 11- l OB

FUEL II{JECTORSTroubleshooting, page 1 1-102Replacemont, page 1 1-105

FUEL FEED PIPE

FUEL GAUGE SE]IIDING U]{ITTgsting, s€ction 23

FU� HONDA INTEGRA 1994 4.G User Guide System Description

Index

FUEL FILTERReplacement, page 11- l OB

FUEL II{JECTORSTroubleshooting, page 1 1-102Replacemont, page 1 1-105

FUEL FEED PIPE

FUEL GAUGE SE]IIDING U]{ITTgsting, s€ction 23

FU�](/img/13/6067/w960_6067-198.png)

System Description

Index

FUEL FILTERReplacement, page 11- l OB

FUEL II{JECTORSTroubleshooting, page 1 1-102Replacemont, page 1 1-105

FUEL FEED PIPE

FUEL GAUGE SE]IIDING U]{ITTgsting, s€ction 23

FU€L

FUEL PUMPT€sting. page 11- 1 10Roplscam€nt. page 11-l 10

FUEL FIIL CAP

FUEL TA KR6placomont,page l1-114

EVAFORATIVE EMISSIONIEVAP} TWO WAY VALVETesting, pag€ 11-140

EVAPORATIVEEMTSStOt{{EVAP} PURGECONTROL DIAPHNAGMVALVETroubleshooting, page'l 1-137

PNESSURE REGUIATORTesting, page 11-106Roplac€m€nt, page 1 1-107

FUEL RAIL

EVAFORATIVC EMISSION(EVAPI COI{TROL CANISTERTroubl6shooting. pag6 1 1-'l 37

FUEL VAFON APE

11-6

Page 201 of 1413

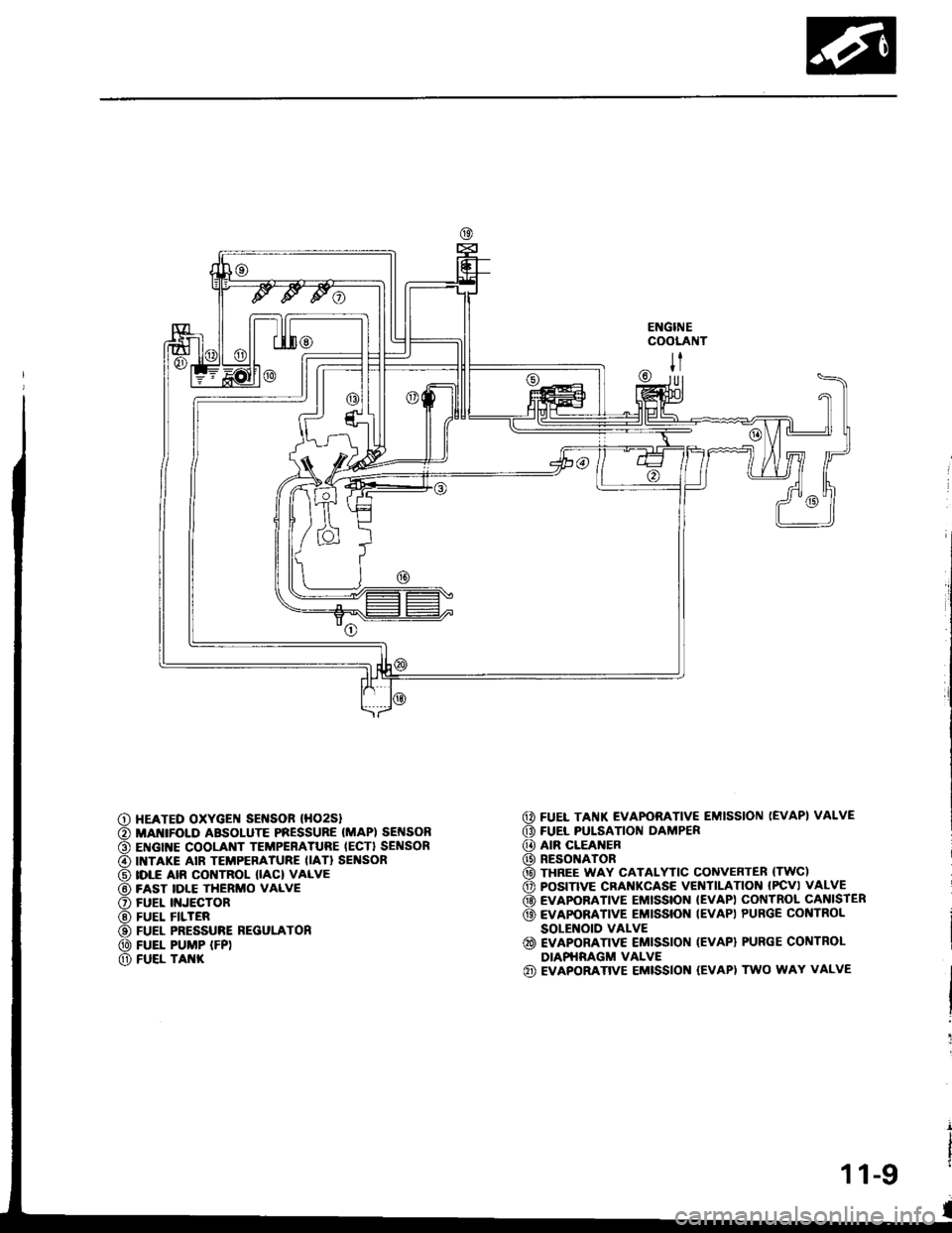

ENGINECOOLANT

@ FUEL TAI{K EVAPORATIVE EMISSION (EVAP} VALVE

G) FUEL PULSATION DAMPER

@ AIR CLEANER

@) RESONATOR

@ THREE WAY CATALYTIC CONVEnTER (TWC)

o POS|TIVE CRANKCASE VEITITILAT|ON IPCV) VALVE

@ EVAPOBATIVE EMISSION IEVAP) COI{TROL CANISIER

@ EvApoRATrvE EMrssroN IEVAP) PURGE coNTRoL

SOLENOID VALVE

@ EVAPORATTVE EMISSION (EVAP) PURGE CONTROL

DIAPHRAGM VALVE(iD EVAPORATIVE EMISSION (EVAPI TWO WAY VALVE

|l

U]

HEATED OXYGEI{ SEI{SOF (HO2S}

MANIFOI.D ABSOLUTE PRESSURE (MAP) SEI{SONENGINE COOLANT TEMPERATURE IECT} SENSORINTAKE AIR TEMPERATURE IIAT} SEI'ISORIDLE AIR CONTROL IIAC) VALVEFAST IDLE THERMO VALVEFUEL II{JECTORFUEL FILTERFUEL PRESSURE REGULATONFUEL PUMP IFP)FUEL TAI{K

11-9

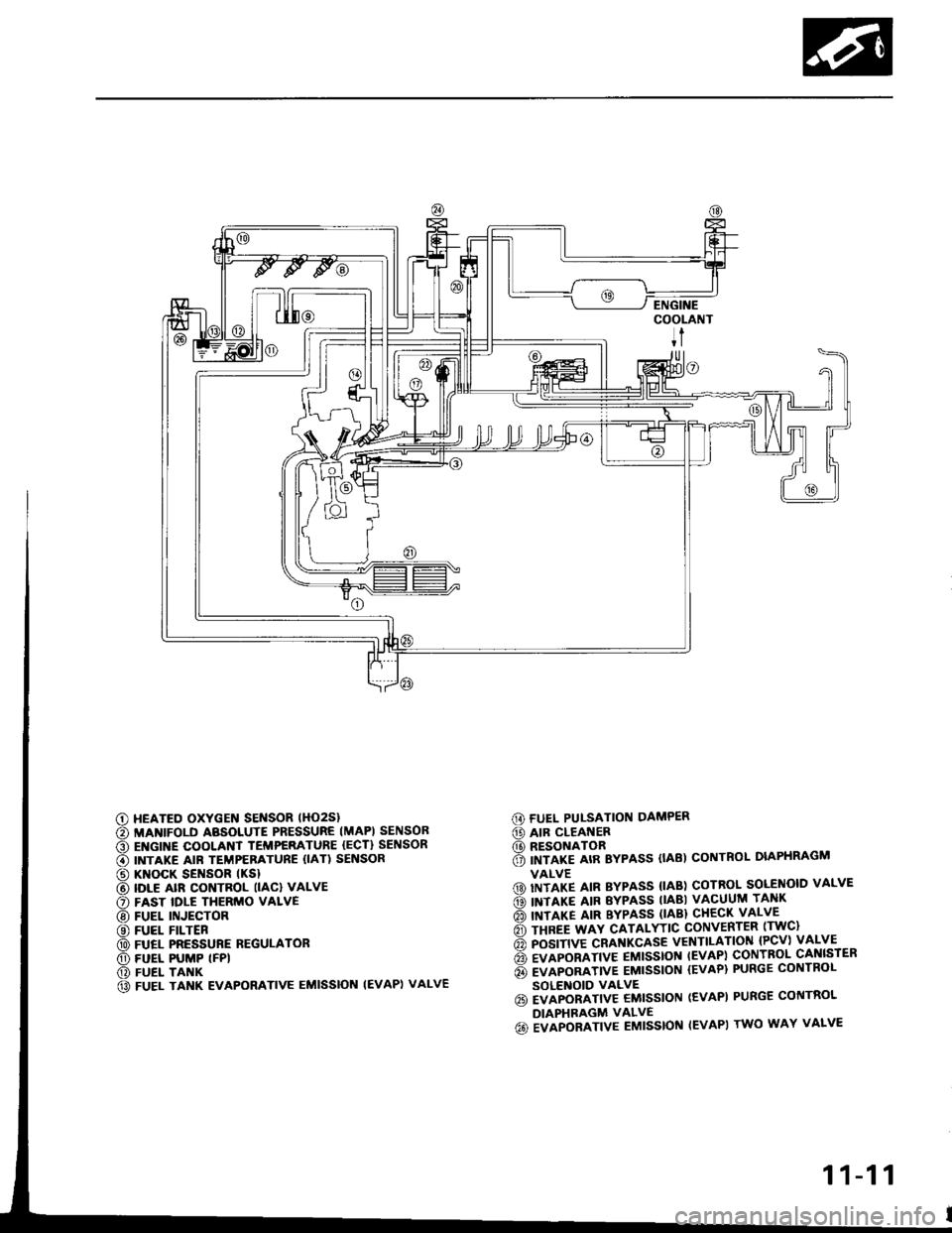

Page 203 of 1413

G) FUEL PUI-SATION DAMPER

@ AIR CLEANER(D RESONATOR6 imrlre arR Bypass (tAB) coNTRoL DIAPHRAGM

VALVE(D) IITITP IIN BYPASS {IAB) COTROL SOLENOID VALVE

ds) INTIXT AIR EYPASS TIABI VACUUM TANK

rio'l rnrarg ltn BYPASS (lABl cHEcK vALvE

6 rsnee wav cATALYTtc coNvERTER lrwc)

6 posrnve cRAf{KcAsE vENTILATIoN {Pcv) vALVE

6 evlponlrtve EMtsstot{ tEvAPl coNTBoL cANlsrER

6 evlponltvE EMtssloN {EvAP} PURGE coNTRoL

SOLENOID VALVE6i EVAPORATIV€ EMISSION (EVAPI PURGE CONTROL

DIAPHRAGM VALVE

6o ivlpoalrtve Eutsstof{ IEVAPI rwo wAY vALvE

c) HEATED OXYGEN SENSOR lHO2Sl

€) MANIFOLD ABSOLUTE PRESSURE IMAPI SENSOB

O EI{GINE COOLANT TEMPERATURE {ECT} SENSOR

€) INTAKE AIR TEMPERATURE {IAT) SENSOR

@ KNOCK SENSOR tKSl

@ IDLE alR coNTRoL llAcl vALvE

O FAST IDLE THERMO VALVE

@ FUEL INJECTOR

@ FUEL FILTER

@ FUEL PRESSURE REGULATOR

O) FUEL PUMP (FPI

@) FUEL TANK

@ FUEL TANK EVAPORATIVE EMISSION IEVAPI VALVE

11-11