fuel HONDA INTEGRA 1994 4.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 301 of 1413

![HONDA INTEGRA 1994 4.G Repair Manual Fuel Supply System

PGM-Fl Main Relay (contdl

BLU

BLU/wHt

Bt-xNOTE:. M/T: Clutch pedal mustbe depressed.. A/T: Transmission in

N or E] position.

BLK/ YEL/YEL BLK

Tloubloshooting

{To page 11 113}

- Eng HONDA INTEGRA 1994 4.G Repair Manual Fuel Supply System

PGM-Fl Main Relay (contdl

BLU

BLU/wHt

Bt-xNOTE:. M/T: Clutch pedal mustbe depressed.. A/T: Transmission in

N or E] position.

BLK/ YEL/YEL BLK

Tloubloshooting

{To page 11 113}

- Eng](/img/13/6067/w960_6067-300.png)

Fuel Supply System

PGM-Fl Main Relay (cont'dl

BLU

BLU/wHt

Bt-xNOTE:. M/T: Clutch pedal mustbe depressed.. A/T: Transmission in

N or E] position.

BLK/ YEL/YEL BLK

Tloubloshooting

{To page 11 113}

- Engino will not sran.- Inspection oI PGM-FI main re-lay and rolay ha.n6!a.

Check lor continuitv between BLKterminal @ and body ground.

Rapair open in BLK wire botwoonPGM-FI main.el6y and GIO'l llo-catod at thormostot housingl.

Measure the voltage betweenYELMHT terminal @ and bodyground.- Roplaco th. ECU IECMI(15 Allus6 in tho under-hood fu!o/r6-lay box.- Ropair opan or short in theYEL/WHT wil6 botwosn thePGM-FI main rolay and the ECU

{EcMl 115 A} luso.

ls there battery voltage?

Turn the ignition switch ON.

Measure the voltage betweenBLK/YEL terminal @ and bodyground.- Reolac. ths No. 24 ACG {ALT}{lcl {15 A:81881 6ngino, 20A: Bl8Cl engin6) tuse in thoundor-dash fuso/rolaY box.- Ropaii op6n or rhon in thoBLK/YEL wiro botwoen thoPGM-FI main ielay and th€ No.24 ACG {ALT) flG} {'�15 A:818Bi ongine, 20 A: 818Cionginol fuso.Turn the ignition switch to theSTART position.

Measure the voltage betweenBLUMHT terminsl @ and bodyground.

- Replaco the l\lo. 18 STARTERSIGNAL {7.5 A} fuso in thoundor-dash fuaa/rolay box.- R6pai. open or short in thoBLU/WHT wire botweon thsPGM-FI main relay and tho No.1A STARTER SIGNAL I7.5 AIluse.

11-112

Page 303 of 1413

Fuel Supply System

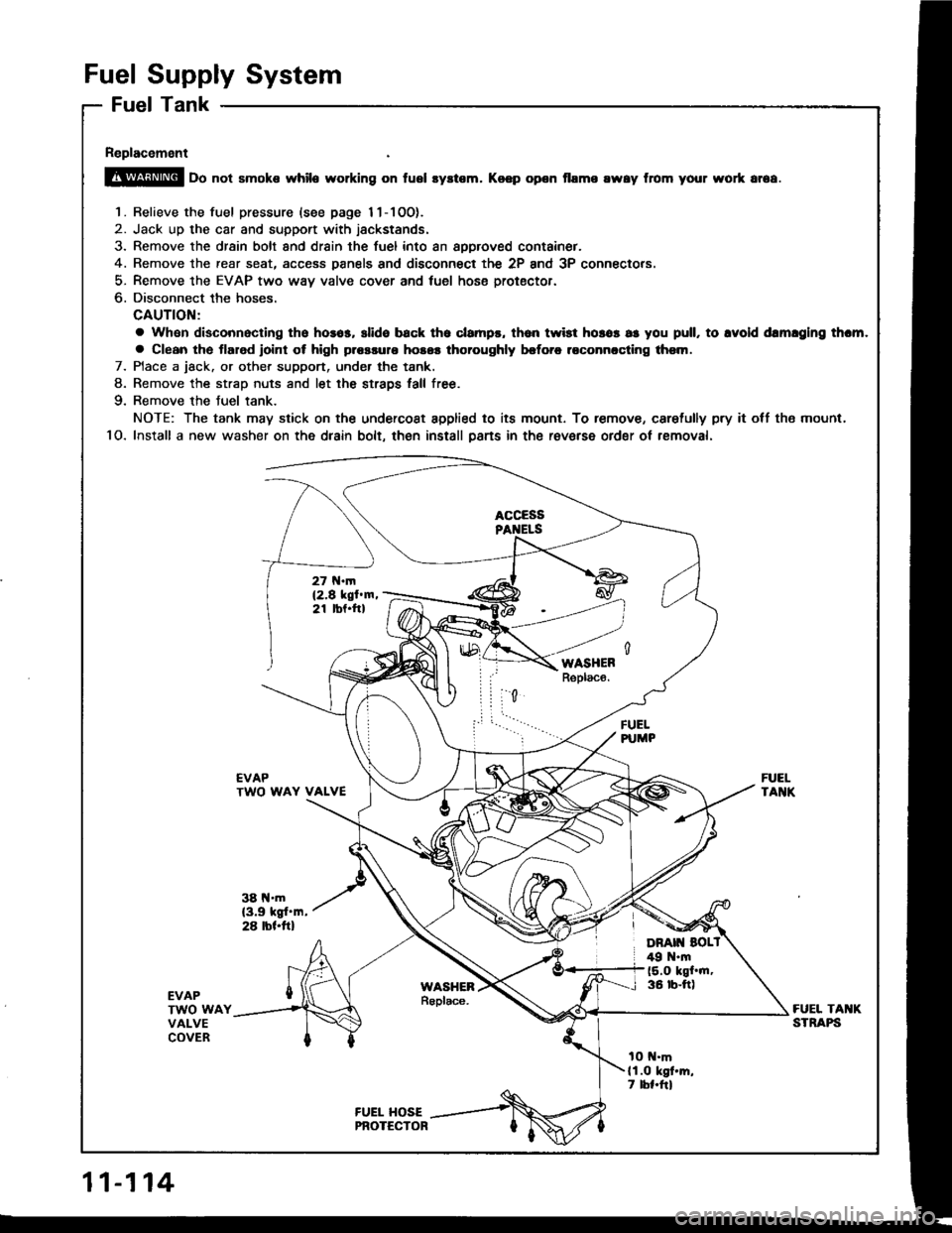

Fuel Tank

Replacement

@ oo not smoke while working on fusl syltem. Koep opon flame rway from your wort ar6a.

1. Relieve the fuel pressure {see page 11-1OO).

2. Jack up the car and support with jackstands.

3. Remove the drsin bolt and drain the fuel into an approved container.

4. Remove the rear seat, access Danels and disconnect the 2P and 3P connectors.

5- Remove the EVAP two way valve cover and tuel hose protector.

6. Disconnect the hoses.

CAUTION:

a Whan disconnacling tho hosos, slide back tho clampr, th6n twist horos as you pull, to lvold drmlglng thcm.

a Clean the tlarod roint ot high plossulo hosos thoroughly brforc roconnccling thsm.

7. Place a jack. or other support, under the tank.

8. Remove the strao nuts and let the straDs tall free.

9. Remove the Juel tank.

NOTE: The tank may stick on the undercoat applied to its mount. To remove, caretully pry it off tho mount,

1O. Install a new washer on the dlain bolt, then install psns in the raverse ordgr ot rsmoval.

FUELPUMP

EVAPTWO WAY VALVE

38 l{.m(3.9 kgt'm,28 rbl.ftl

FUELTANK

EVAPTWO WAYVALVECOVER

FUEL TAI{KSTRAPS

tO t{.mll.O kgt'm,7 lbl.frl

11-114

Page 324 of 1413

A.

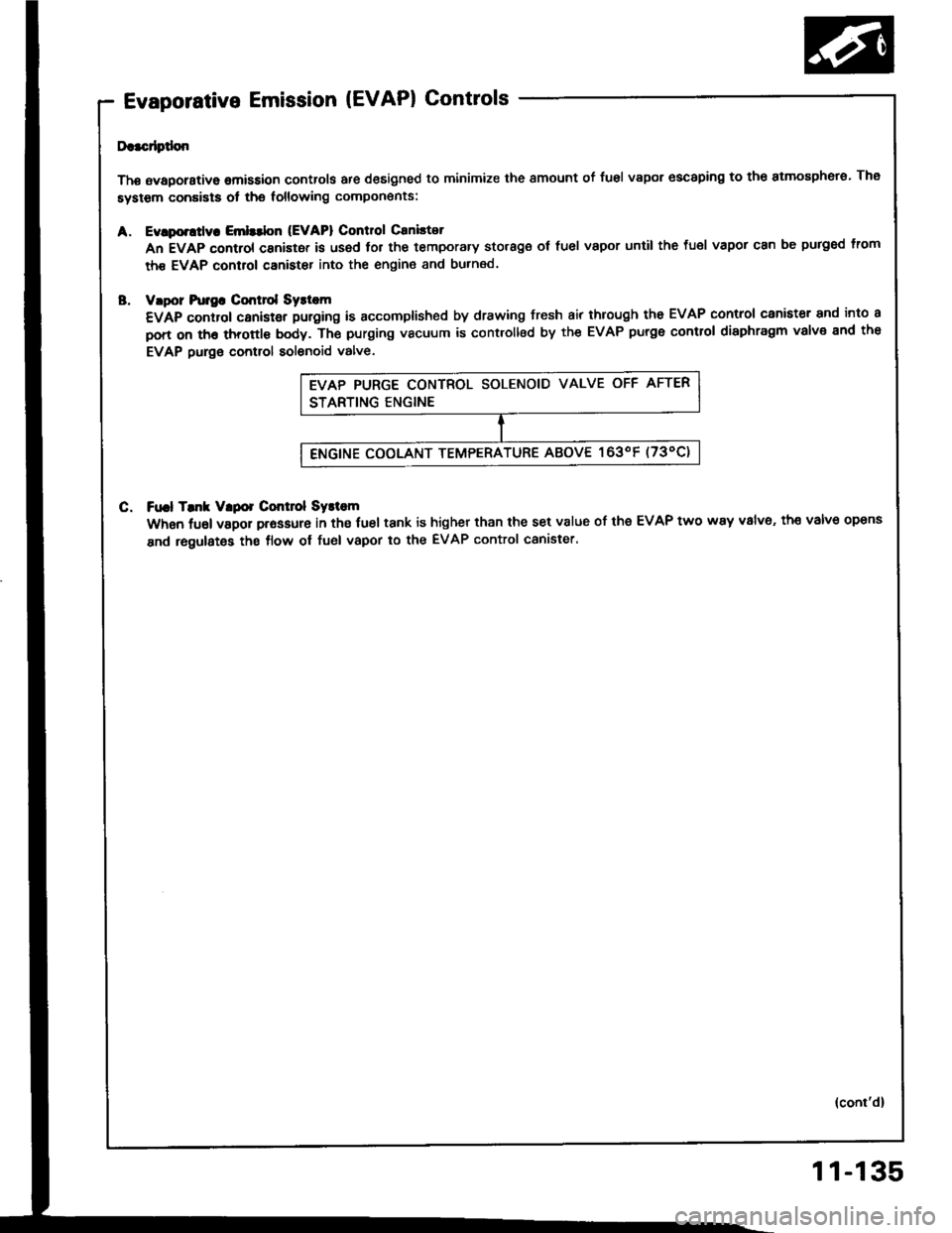

Evaporative Emission (EVAPI Controls

Da.cdptlon

Thg avaporstive omission controls are designed to minimize the smount of fusl vapor escaping to the atmosphero. The

system conaists ot the following compon€nts:

Evlporttly. Emlttbn (EVAPI Control Caniltot

An EVAP control canistor is used lor the temporary storage ot fuel vapor until the fuel vapor can be purged lrom

th€ EVAP control canister into the engin€ and burned.

vlpor hr]gG Cmt]ol Syst m

€VAp control canistgr puroing is accomplished by drawing fresh air through tho EVAP control canister and into a

pon on th6 throttl€ body. Th€ purging vacuum is controllsd by the EVAP purge control diaphragm valve end the

EVAP purge control solenoid valve.

C. Ft|.l Tmk Vlpor Control Systom

When fuel vapor prassure in the fuel tank is higher than the set v8lue of the EVAP two way v8lv6, th€ valve opens

and regulates the flow ol fuel vapor to the EVAP control canister.

(cont'd)

11-135

Page 325 of 1413

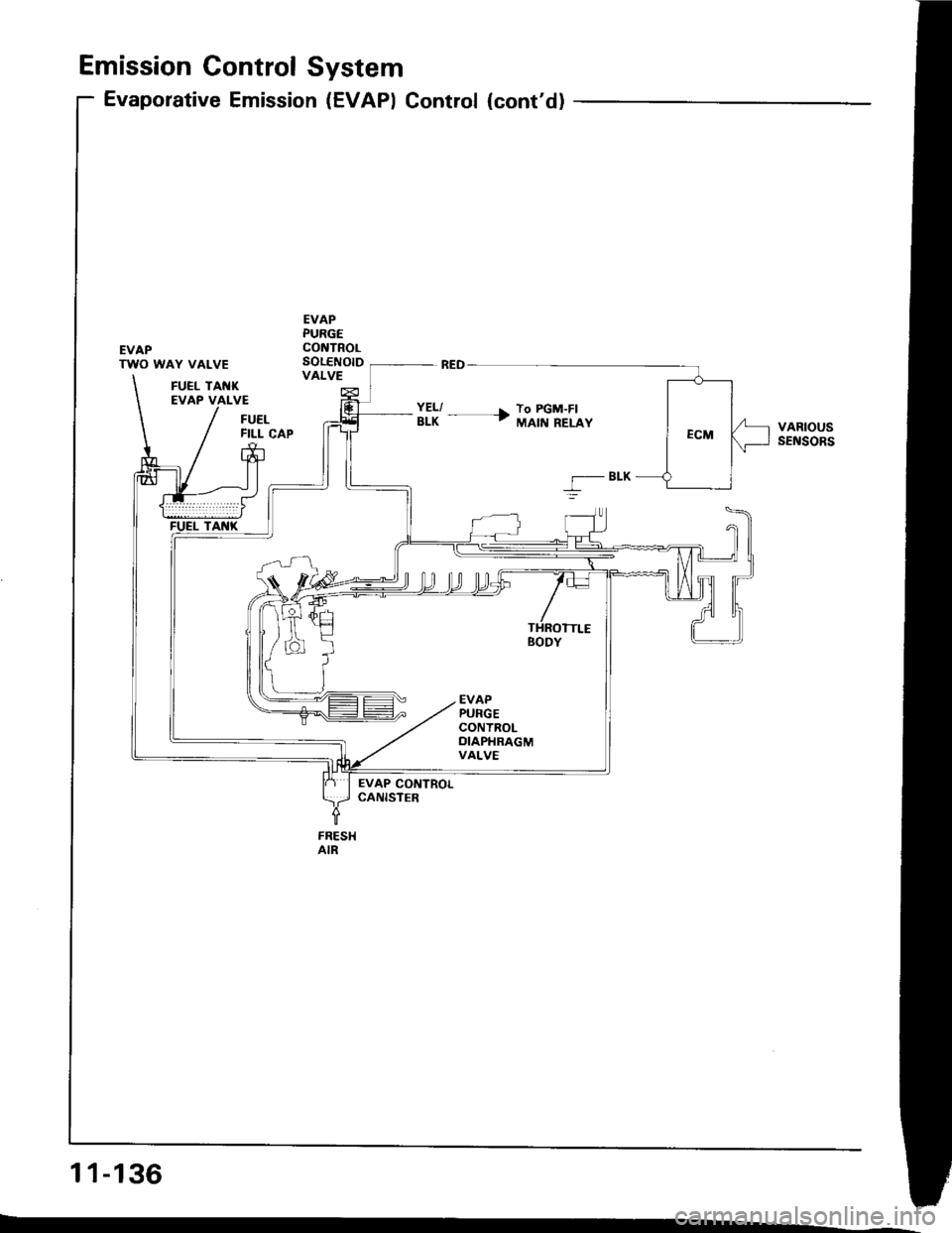

Emission Gontrol System

Evaporative Emission (EVAPI Control (cont'd)

EVAPTWO WAY VALVE

EVAPPURGECONTROLSOLENOIDVALVEFUEL TANKEVAP VALVE

FUELFILL CAPVARIOUSsEt{soRs

BLK

5

EVAP CONTROLCANISTEB

FRESHAIR

11-136

Page 329 of 1413

Emission Control System

Evaporative Emission Controls

(cont'dl

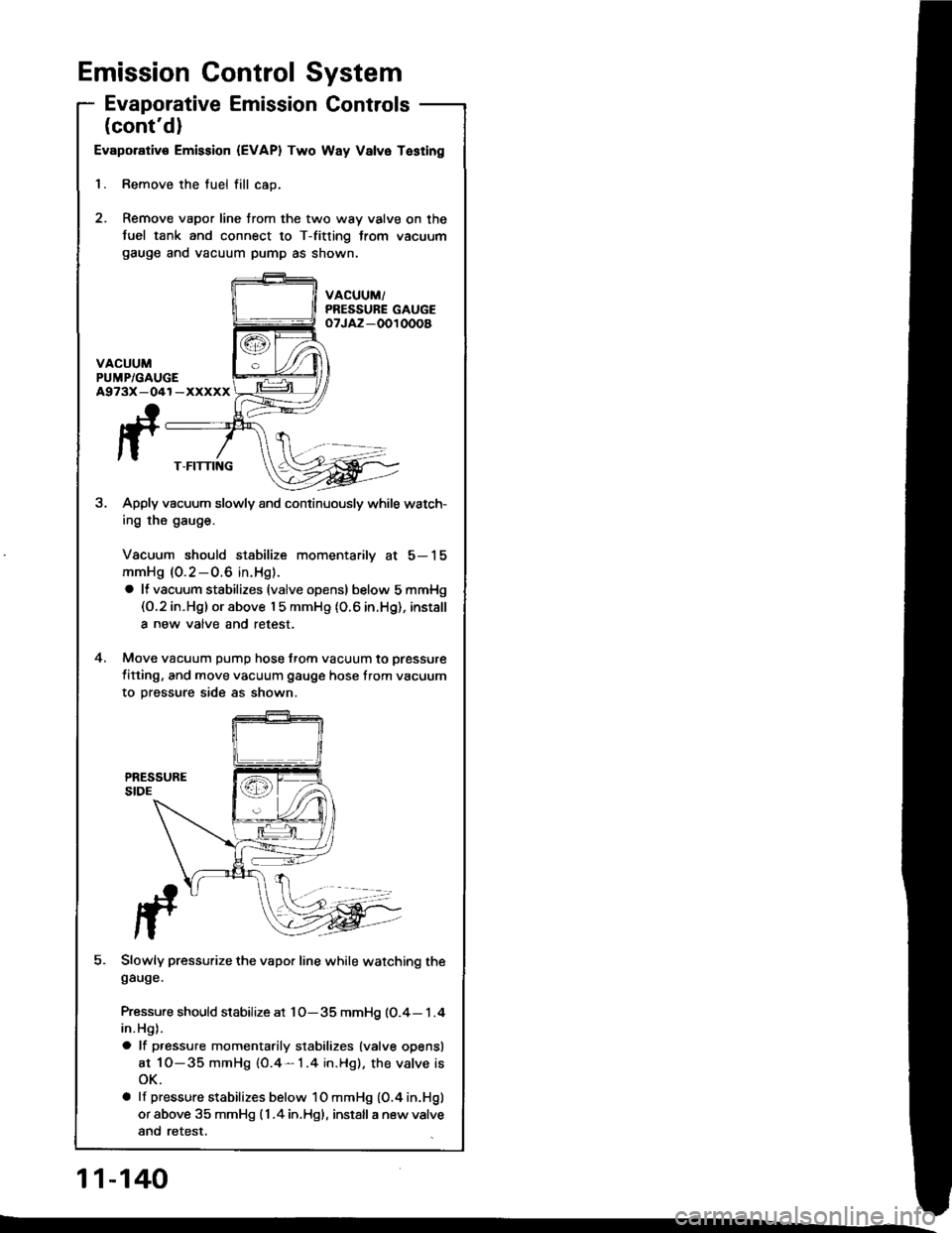

Evaporativ€ Emission {EVAPI Two Way Valvo Tasting

l. Remove the tuel fill cao.

2. Remove vapor line trom the two way valve on the

fuel tank and connect to T-fitting trom vacuum

gauge ano vacuum pump as snown.

VACUUM/PRESSURE GAUGEoTJAZ-OOI OOOa

A973X-041-XXXXX

fT-FITTING

Apply vacuum slowly and continuously while watch-

ing the gauge.

Vacuum should stabilize momentarilv at 5-15

mmHg (0.2-0.6 in. Hg).

a It vacuum stabilizes (valve opensl below5mmHg(O.2 in.Hg) or above I 5 mmHg (O.6 in.Hg), install

a new valve and retest.

Move vacuum pump hose from vacuum to pressure

titting, and move vacuum gauge hose trom vacuum

to oressure side as shown.

Pressure should stabilize at 1O-35 mmHg (0.4- 1 .4

in. Hg).

a lf p.essure momentarily stabilizes {valve opensl

at 1O-35 mmHg (O.4- 1.4 in.Hg), the valve is

oK.

a lf pressure stabilizes below 10 mmHg {O.4 in.Hg)

or above 35 mmHg (1 .4 in.Hgl, install a new valve

and retest.

4.

J-.

fF . -,-/ asr^:

,T 4?e

Slowly pressurize the vapor line while watching thegauge.

11-140

Page 440 of 1413

![HONDA INTEGRA 1994 4.G Repair Manual Troubleshooting Procedures

when the TcM senses an abnormality in the input or output systems. the E]indicator light in the gaugo assembly willblink.

when the service check Connector {located under the HONDA INTEGRA 1994 4.G Repair Manual Troubleshooting Procedures

when the TcM senses an abnormality in the input or output systems. the E]indicator light in the gaugo assembly willblink.

when the service check Connector {located under the](/img/13/6067/w960_6067-439.png)

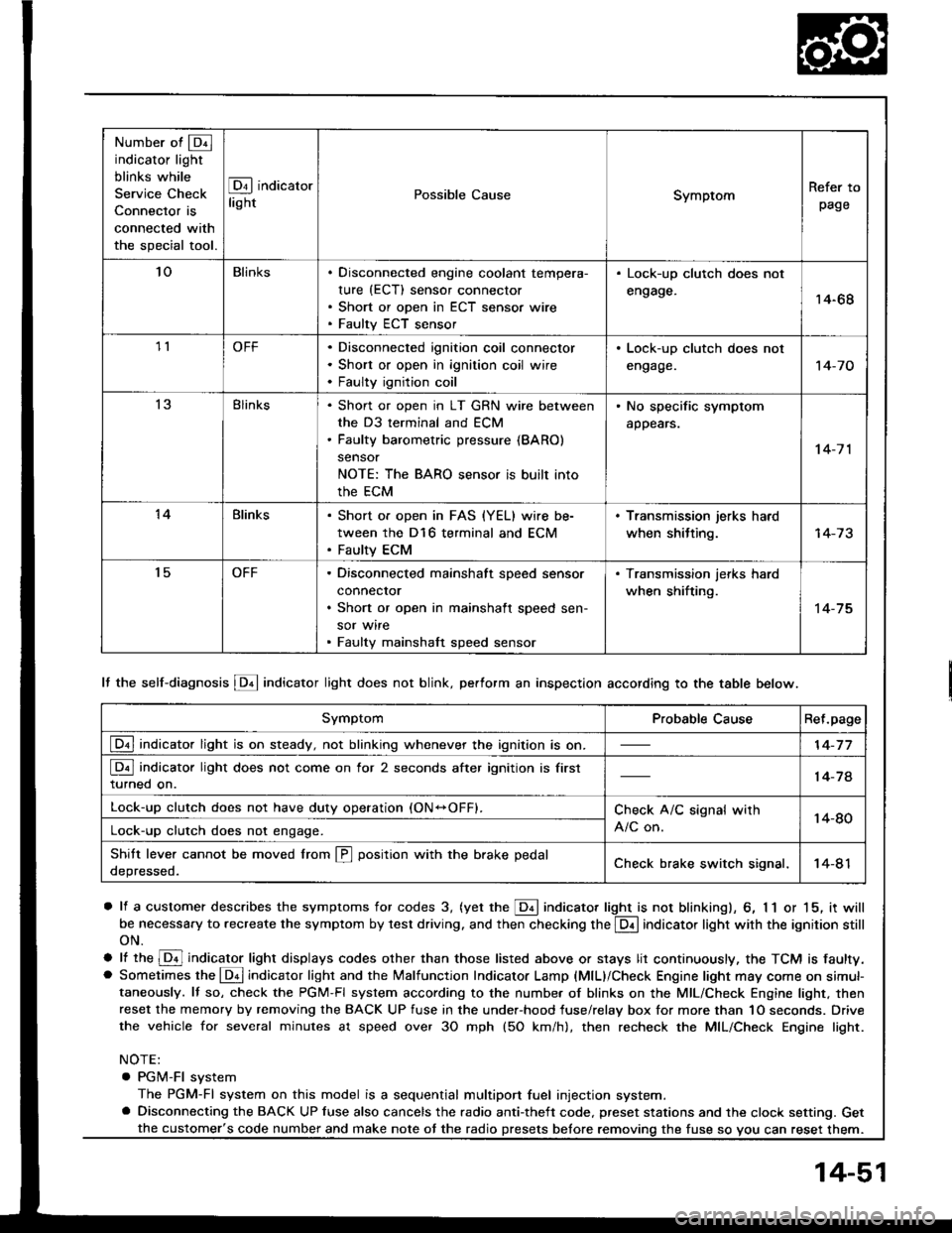

Troubleshooting Procedures

when the TcM senses an abnormality in the input or output systems. the E]indicator light in the gaugo assembly willblink.

when the service check Connector {located under the dash on the passenger side} is connected with the specaat toolas shown, the E] indicator light will blink the Diagnostic Trouble iode {DTCI when the ignition switch is turned on.

When the lDil indicator light has been reported on, connect the service check connector with the special tool.Then turn on the ignition switch and observe the @ indicator light.

GAUGE ASSEMSLY

)'t

DAI'A LI]TKcor{r{EcToR (3P)NOTE:Do not atlachjumpe. wire.

Sc. DTCI

So. DTC2

S.. DTC14

scs sHoRT CO[{]{ECTORoTPAZ-OOl0too

codes 1 through I are indicated by individual short blinks, codes 1o through 1 5 are indicated by a series of tong andshon blinks. one long blink equals l0 short blinks. Add the long and short blinks together to dete;mins the cod€. Aft6rdetermining the code, refer to the erectricar system symptom-to-component chart on pages 14-5o and 51.

ahon

f"l

some PGM-FI problems will also make the @ indicator light come on. After repairing the pGM-Fr system, disconnectthe BACK UP tuse (7.5 Al in the under-hood fuse/relay box tor more than 1o seconds to reset the TcM memorv.

NOTE:

a PGM-FI svstem

The PGM-FI system on this model is a sequential multipon fuel iniection svstem.' Disconnecting the BACK UP tuse also cancels the radio anti-theft code, preset stations and the clock setting. G6tthe customer's code numbe. and make note of the radio presets befote temoving the fuse so you can reset them.

14-48

Page 443 of 1413

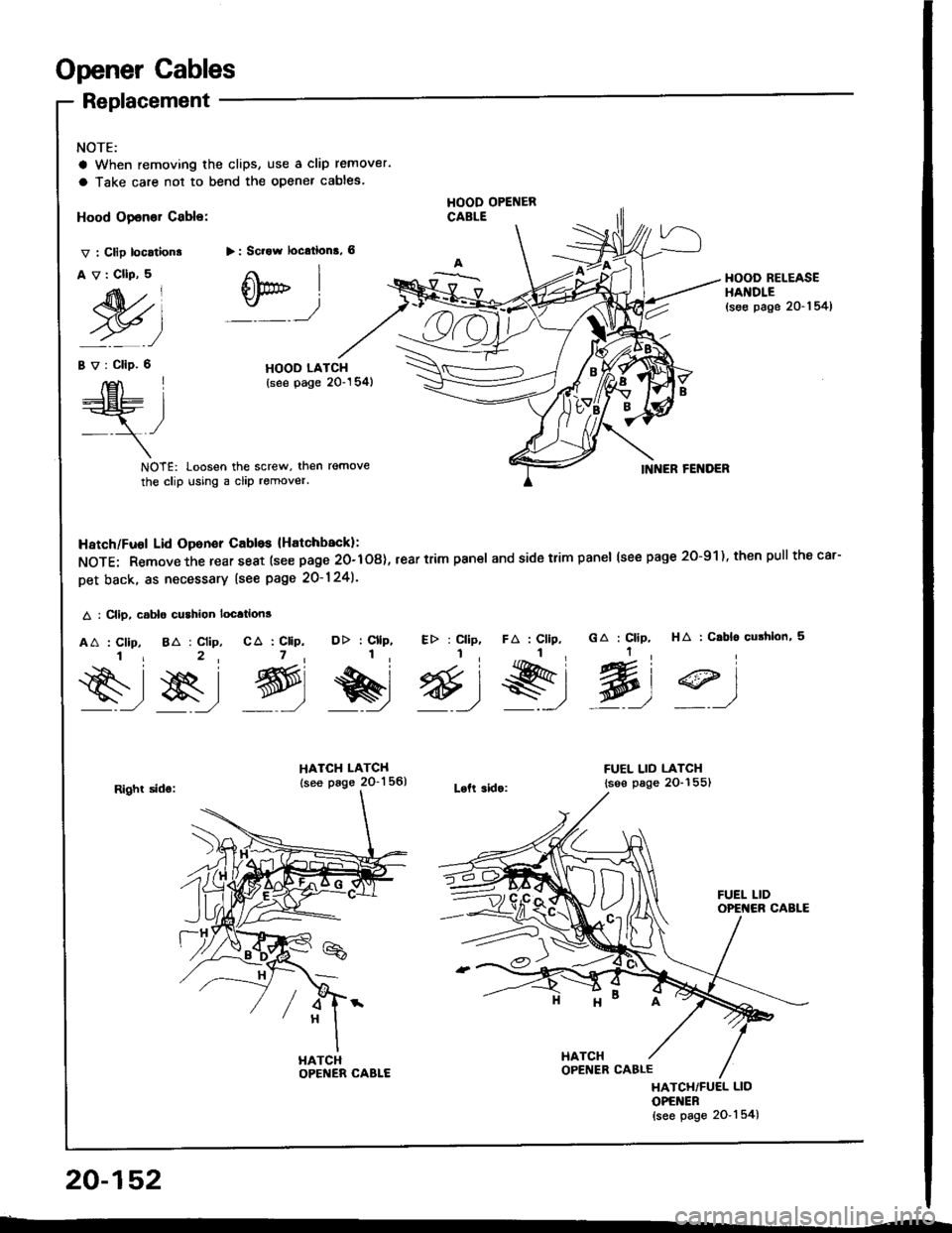

Number of @indicator light

blinks while

Service Check

Connector is

connected with

the special tool.

@ indicator

lightPossible CauseSymptomRefer to

page

'loBlinksDisconnected engine coolant tempera-

rure (ECT) sensor connector

Short or open in ECT sensor wire

Faulty ECT sensor

Lock-up clutch does not

engage.14-68

1lOFFDisconnected ignition coil connector

Short or open in ignition coil wire

Faulty ignition coil

. Lock-up clutch does not

engage.'t 4-7 0

13Blinks. Shon or open in LT GRN wire between

the D3 terminal and ECM. Faulty barometric pressure {BARO)

sensor

NOTE: The BARO sensor is built into

the ECM

. No specific symptom

appears.

14-7 1

14Blinks. Short of open in FAS {YEL} wire be-

tween the D16 terminal and ECM. Faulty ECM

. Transmission jerks hard

when shitting.

't5OFFDisconnected mainshaft speed sensor

connecror

Short or open in mainshaft speed sen-

sor wire

Faulty mainshaft speed sensor

. Transmission jerks hard

when shifting.

14-75

SymptomProbable CauseRet.page

LQ! indicator light is on steady, not blinking whenever the ignition is on.14-77

[Q3] indicator light does not come on for 2 seconds after ignition is first

turned on.14-78

Lock-up clutch does not have duty operation (ON-OFFI.Check A/C signal with

A/C on.14-80Lock-up clutch does not engage.

Shitt leve. cannot be moved lrom @ position with the brake pedal

depressed.Check brake switch signal,14-41

It the self-diagnosis LQ4 indicator light does not blink, perform an inspection according to the table below.

a lf a customer describes the symptoms for codes 3, (yet the LQ! indicator light is not blinkingl, 6, 1 1 or 15, it will

be necessa.y to recreate the symptom by test driving. and then checking the @ indicator light with the ignition still

oN.

e lt ttre @ indicator light displays codes olher than those listed above or stays lit continuously, the TCM is faulty.. Sometimes the Lqd indicator light and the Malfunction Indicator Lamp (MlL)/Check Engine light may come on simul-taneously. lf so, check the PGM-Fl system according to the numbe. of blinks on the MIL/Check Engine light. thenreset the memory by removing the BACK UP fuse in the unde.-hood fuse/relay box for more than 1O seconds. Drive

the vehicle for several minutes at speed over 30 mph (5O km/h), then recheck the MIL/Check Engine light.

NOTE:

. PGM-FI system

The PGM-Fl system on this model is a sequential multiport fuel injection system.a Disconnecting the BACK UP luse also cancels the radio anti-theft code. preset stations and the clock setting. Get

the fuse so vou can reset them.the customer's code number and make note ot the radio

14-51

Page 1021 of 1413

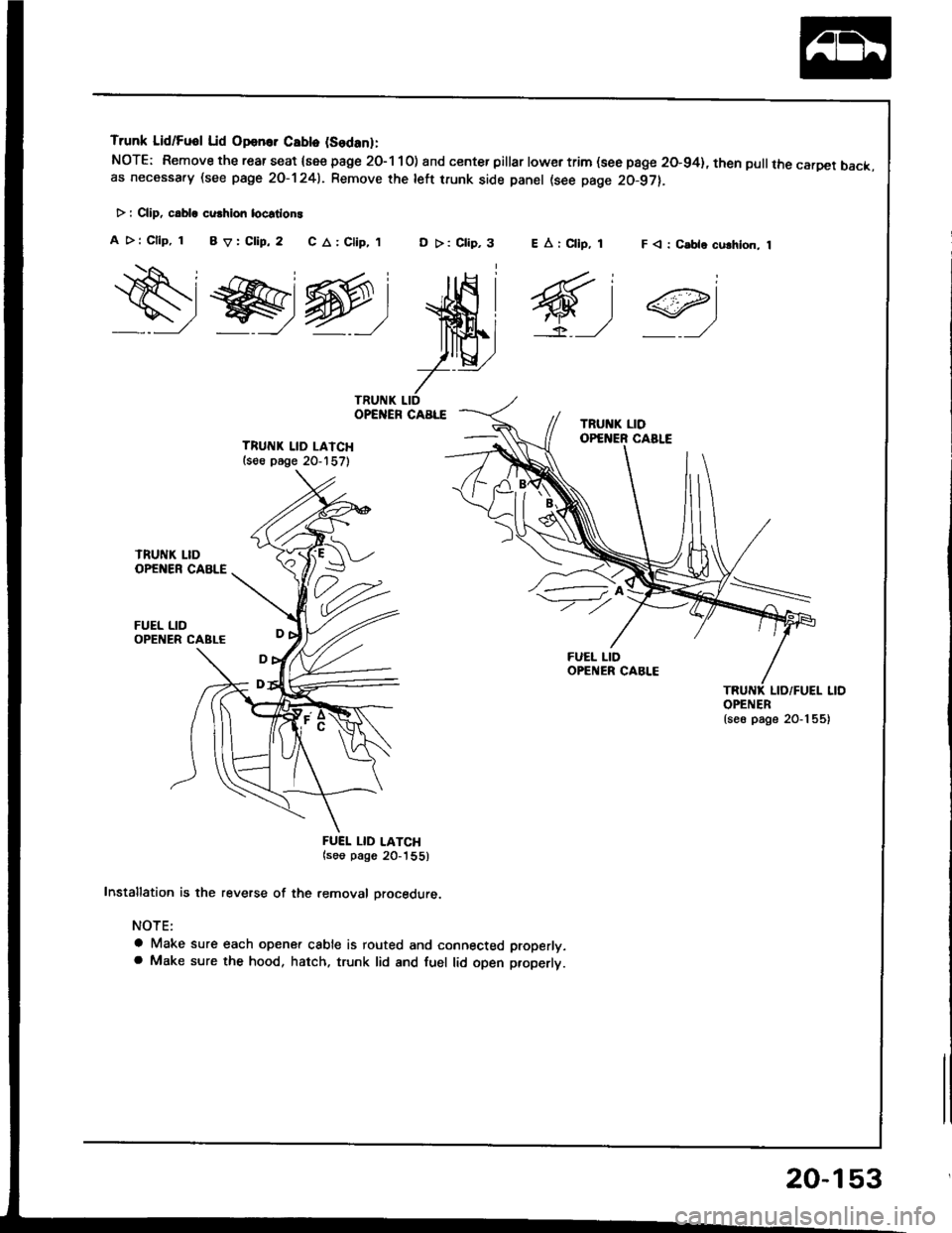

Opener Cables

NOTE:

a When removing the clips, use a clip remover.

a Take care not to bend the opener cables.

Replacement

Hood Opener Cable:

v : Clip location.

Av:CllP,5

M)

HOOD OPENERCABLE

> : Scrow locrtions, 6

Otr" I

:_ _)

HOOD RELEASEHAI{DLE(se€ page 20-1 54)

Bv:Clip.6HOOD LATCH(see page 20"154)E\I____lEt- L:=r

,/- -\-

NOTE: Loosen the screw, then remove

the clip using a clip remover.INNER FENDER

HA : C.bl6 cushlon, 5GA : Clip,

Wt

DD : Cllp, Etr : Cllp,1, I,

e&r @)9)

HATCH LATCH

lsee page 2O-1 56)Loft 3ido:

FUEL LID LATCH

lsse page 2O-155)

Hatch/Fuol Lid Oponer Cabls lHatchback):

NOTE: Remove the rear seat (see page 20-108), rear trim pan€l and side trim panel (see page 2O-91), then pull thecar-

Det back. as necessary lsee page 20-124).

A : Clip, csblo cushion location3

AA : Clip, 8A : Clip, CA : CliP,i r 2, 7,

s-,$, g,

FA : Cllp,

s,l

Right sids:

HATCHOPENER CABLE

HATCH/FUEL LID

OPENER{see page 2O-'l 54)

20-152

HATCH

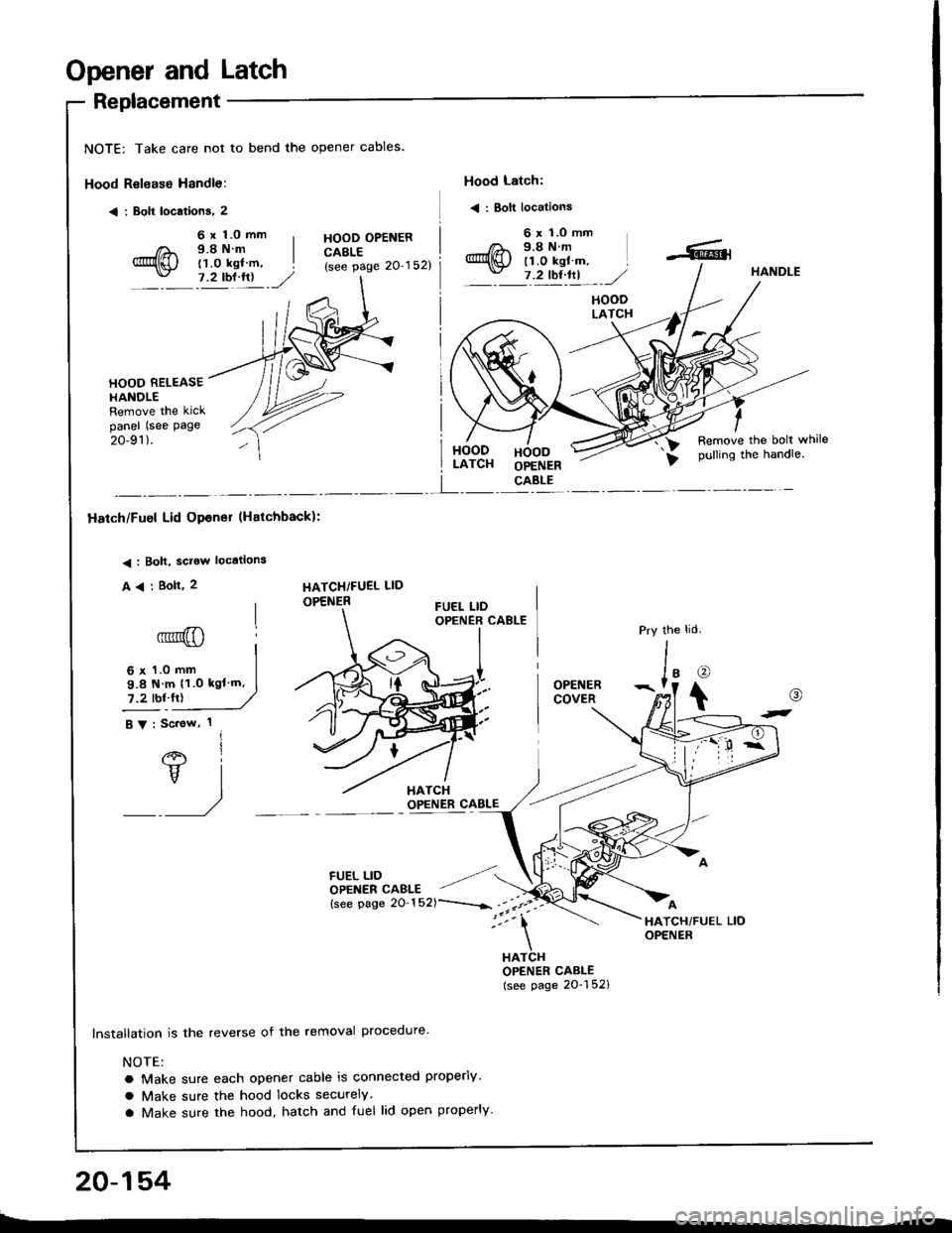

Page 1022 of 1413

Trunk Lid/Fuol Lid Opan.. Cablo (Sodanl:

NOTE: Remove the rear seat {see page 2O-1 10) and center pillar lowertrim (see page 20-94}, then pullthe carDet back.as necessa.y (see page 2O-1241. Remove rhe left trunk side panel (see page 20-97).

> : CliD, c.bla cu.hion locstlon!

A >: Cllp, 1 BV:Clip,2 C A: Clip,,tD >: Clip,3F < : C.ble culhlon, 1

ws@:

ffi;

7--

TRUITIK LID LAICH(s€e p6ge 20-157)

FUEL LID

FUEI. LID LATCH(soo pago 20_'|55)

Installation is the reverse of the removal orocedure.

NOTE:

a Make sure each opener cable is routed and connected properly.a Make sure the hood, hatch. trunk lid and fuel lid open properlt.

EArCllp, 1

6,1

OPENER{se6 page 20-1 55)

20-153

Page 1023 of 1413

Opener and Latch

Replacement

NOTE: Take care not to bend the opener cables.

Hood Relsase Handle:

< i Bolt locations, 2

Hood Latch:

< : Bolt locations

6 x 1.0 mm9.8Nm(1.0 kgl m,7.2 tbl.lrl

HOOD OPENERCABLE(see page 20'152)

6 x 'l.O mm9.8Nm11.0 kgl m,7 .2 tbt ftl,/HANDLE

HOODLATCH

HOOD RELEASEHANOLERemove the kickpanel (see page

20-91).HOODLATCHHOODOPENERCABLE

Remove the bolt whilepulling the handle.

I

Hatch/Fuel Lid Opener lHatchback):

< : Bolt, sclow locations

A

6' I

vl

/

HATCHiFUEL LID

OPENER

6 x 1.0 mm

9.8 N m 11.0 kgl'm,

7.2 tbl.fr)

FUEL LIDOPENER CAELE

lnstallation is the reverse of the removal procedure'

NOTE:

a Make sure each opener cable is connected properly

a Make sure the hood locks securely

a Make sure the hood, hatch and fuel lid open properly.

the

J'o

t

OPENERCOVER

HATCHOPENER CABLE(see page 20-152)

@

t-

20-154