high mount HONDA INTEGRA 1994 4.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 1091 of 1413

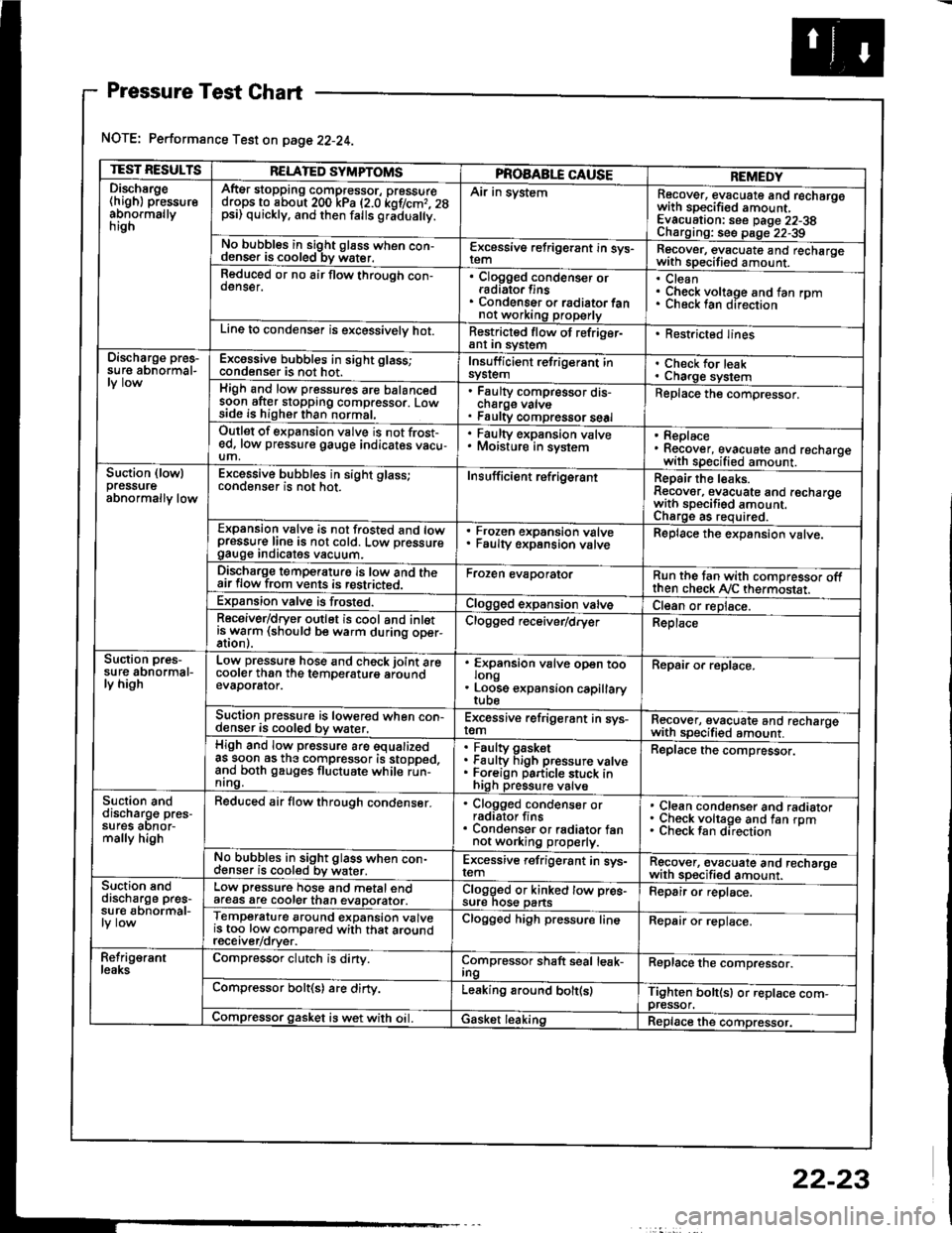

Pressure Test Chart

NOTE: Performance Test on page 22-24.

TEST RESULTSRELATED SYMPTOMSPROAABLE CAUSEREMEDYDischsrge(high) pressureabnormallynrgn

AftEr stopping compressor, pressuredrops to about 200 kPa (2.0 kof/cmr. 28psi) quickly, and then falls gr;dua y.

Air in systemRecover, evacuate and recharqowith sDecified amount. -

Evacuation: see Daqe 22-38Charoino: se6 D;op--2?-?qNo bubbles in sight g16ss when con-denser is cooled bv water.E-\cessive refrigerant in sys-Recover, evacuate and recharqewith specitied amount. -

Reduced or no air flow through con-oenser.Clogged condenser orradiato. finsCondenser o. radiator fannot working properly

CleanCheck voltage and fan rpmunecK lan ofeclton

Line to condenser is excessivelv hot.Restricted flow of refriger-ant In syslem. Restricted lines

Discharge pres-su re abnormal-Excossive bubbles in sight glass;condenser is not hot.Insuff icient refrigerant insyslemCheck for leakCharge systemHigh and low pressures are balancedsoon after stopping compressor. Lowside is higher than normal,

Faulty compressor dis-cnarge vaNsFaulty compressor seal

Replace the compressor.

Outlet of expansion vslve is not frost-ed, low pressure gauge indicates vacu-um,

. Faulty expansion valve. Moisture in sysiem. Replace. Recover, evacuate and recharoewith specified amount. -

Suction (lowlpressureabnormally low

Excessive bubbles in sight glass;conqenser rs not hot_Insuff icient ref rigerantReoair the leaks.Reaover, evacuate and recharoewith sDecifisd amount. -

Charqe as required.Expansion valve is not trosted and lowpressur€ line is not cold. Low pressuregauge Inorcates vacuum.

Frozen expansion valveFaulty expansion valveReplace the expansion valve.

Discharge temperaturg is low and theair flow from vents is restricted.Froren evaporatorRun the tan with comoressor oftthen check Ay'C thermostat.Expansion valve is frost€d.Clogged expansion valveCl€an or replace.Receiver/dryer outlet is cool and inletisrryarm (should be warm during oper-Clogged r€ceiver/dry€rReplace

Suction pres-su re abnormal-ly high

Low pressure hose and check joint arecooler than the temDeraturo aroundevaDorator.

'

ffin"nsion u"lu" oD"n too

. Loose expansion capillary

Repair or replace.

Suction pressure is lowered when con-denser is cooled by water,Excessive refrigerant in sys-remRecover, evacuate and recharqewith sDecifi€d amount. -

High and low pressure are equalizedas soon as the compressor is stopped,and both gauges fluctuate while run-nrng.

Faultv oasketFaulty Figh pressure valveForeign particle stuck inhigh pressure valve

Replace the compressor.

Suction anddischarg€ pres-sufes aonor-mally high

Reduced air flow through condenser.. Clogged condenser orradiator fins. Condenser or radiator fannot working properly.

Clean condenser and radiatorCheck voltage and fan rpmCheck fan direcrion

No bubbles in sight glass when con-cl€nser is cooled bv water.Excessive refrigerant in sys-remRgcover, €vacuate and recharoewith sp€cified amount.Suction snddischarge pres-su r€ abnormal-

Low pressure hose and metal endafeas are cooler than evaDorator.Clogged or kinked tow pre€-sure nos€ pansFepair or replace.

Temperature around expansion valveis too low compared with that aroundrecerver/orver.

Clogged high pressure lineRepair or replace.

Refrig€rantleaksCompressor clutch is dirty.Compressor shaft seal leak-IngReplace the comDressor.

Compressor bolt(s) are dirty.Leaking around bolt(s)Tighten bolt(sl or replace com-pressor.Compressor gasket is wet with oil. IGasket leakingReplace the compressor.

22-23

Page 1106 of 1413

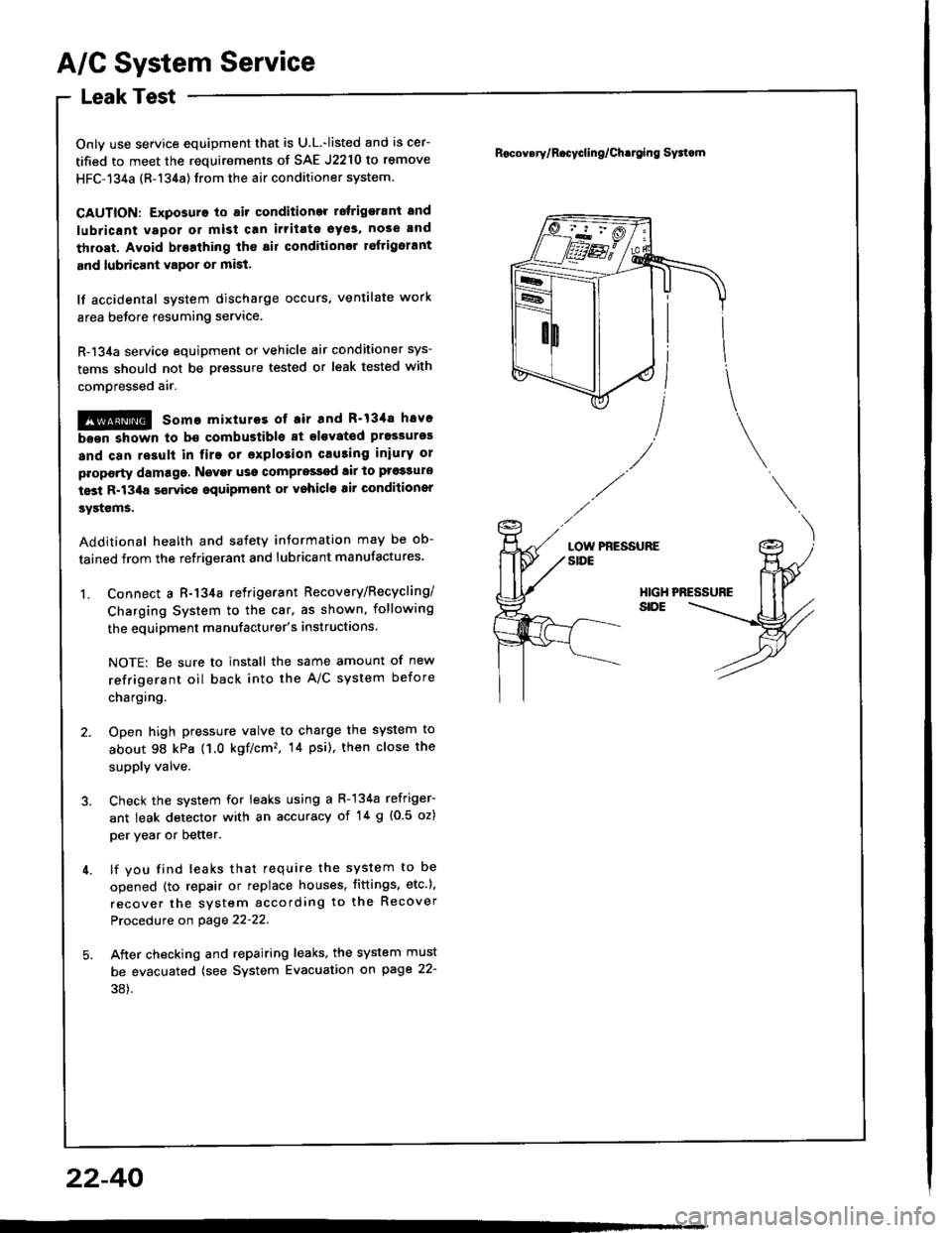

A/C System Service

Leak Test

Only use service equipment that is U.L.-listed and is cer-

tified to meet the requirements of SAE J2210 to remove

HFC-134a (R-134a) from the air conditioner system.

CAUTION: Exposura to air condition ratrigerant and

lubaicant vapor or mist can irritato oyes. nose and

throat. Avoid br€athing tho sir conditionsr reftigolant

and lubricant vapor or mist.

lf accidental svstem discharge occurs, ventilate work

area before resuming service.

R-134a service equipment or vehicle air conditioner sys-

tems should not be pressure tested or leak tested with

comoressed air.

@ some mixturos ot air and R'13'la have

b.6n shown to b€ combustible at glsvated pressur€s

and can result in firo or sxplo3ion causing iniury or

proporty damage. Ngvar uso compress€d tir to pro33ure

tost R-134a $rvics oquipmont or vohicl€ air Gonditionsr

systcms.

Additional health and satetY information may be ob-

tained from the refrigerant and lubricant manufactures'

1. Connect a R-134a retrigerant Recovery/Recycling/

Charging System to the car. as shown, following

the equipment manufacturer's instructions.

NOTE: Be sure to install the same amount of new

refrigerant oil back into the A/C system before

chargtng.

2. Open high pressure valve to charge the system to

about 98 kPa (1.0 kgf/cm'�, 14 psi), then close the

supply valve.

3. Check the system for leaks using a R-134a refriger-

ant leak detector with an accuracy of '!4 g {0.5 oz)

per year or better.

4. lf you find leaks that require the system to be

opened (to repair or replace houses, fittings, etc.),

recover the system according to the Recover

Procedure on page 22-22.

5. Aiter checking and repairing leaks, the system must

be evacuated (see System Evacuation gn page 22-

38).

Rocov.ry/R.cycling/Ch.tging Sy3tcm

LOW PRESSURESIDE

HIGHSIDE

22-40

Page 1136 of 1413

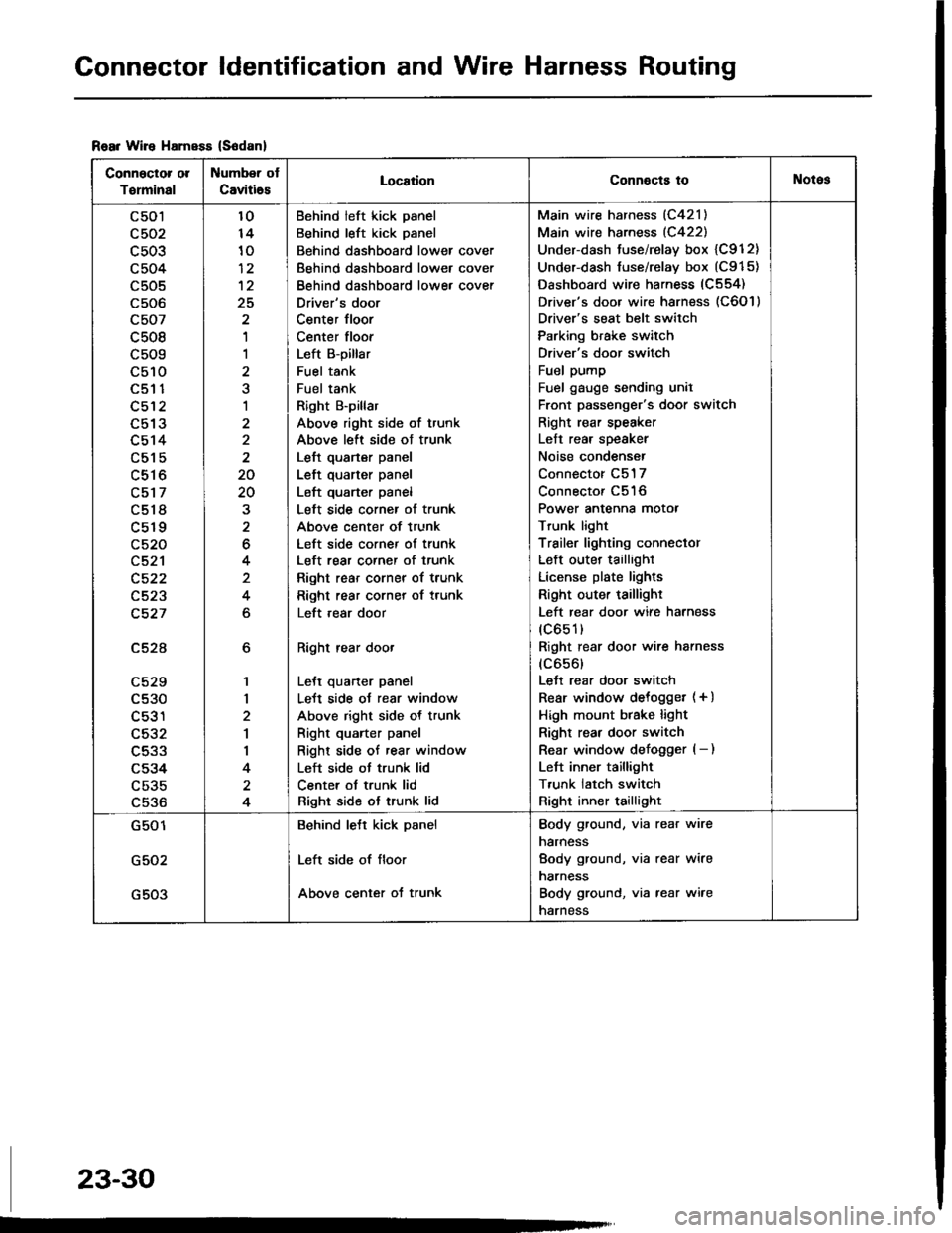

Connector ldentification and Wire Harness Routing

Rear Wire HamsEs (S6danl

Connector ol

Torminal

Number ot

Caviti6sLocaiionConnocts toNotos

c501

c503

c504

c505

c506

c507

c508

c509

c510aEt t

c512

L9 IJ

c514

c515

c516

c517

c518

c519

c520

c521

c522

c523

c527

c52A

LCZY

c530

c531

c532

c533

c534

c535

c536

6

1,|

2

1

I

4

4

10

10

12

25

'I

1

a

1

2

2

20

20

2

6

4

4

6

Behind left kick panel

Behind left kick panel

Behind dashboard lower cover

Behind dashboard lower cover

Behind dashboard lowe, cover

Driver's door

Center floor

Center floor

Left B-pillar

Fuel tank

Fuel tank

Right B'pillar

Above right side of trunk

Above left side ot trunk

Left quarter panel

Left quarter panel

Left quarter panel

Left side corner of trunk

Above center of trunk

Left side corner of trunk

Left rear corner of trunk

Right rear corner of trunk

Right rear corner of trunk

Left ,ear door

Right rear door

LeJt quarter panel

LeJt side oJ rear window

Above right side of trunk

Right quarter panel

Right side of rear window

Left side ot trunk lid

Center ot trunk lid

Right side ot trunk lid

Main wire harness (C421)

Main wire harness (C422)

Under-dash tuse/relay box {C912}

Under-dash fuse/relay box (C915)

Dashboard wire harness (C554)

Driver's door wire harness (C6O l )

Driver's seat belt switch

Parking brake switch

Driver's door switch

Fuel pump

Fuel gauge sending unil

Front passenger's door switch

Right rear speaker

Left rear speaker

Noise condenser

Connector C517

Connector C516

Power antenna motor

Trunk light

Trailer lighting conneclor

Left outer taillighr

License plate lights

Right outer taillighr

Left rear door wire harness

(c651)

Right rear door wire harness

(c656)

Lett rear door switch

Rear window delogget (+ )

High mount btake light

Right rear door switch

Rear window defogger (- )

Left inner taillight

T,unk latch switch

Right inner taillight

G501

G502

G503

Behind lett kick panel

Left side of floor

Above center of trunk

Body ground, via rear wire

narness

Body ground, via rear wire

narness

Body ground, via rear wire

narness

23-30

Page 1150 of 1413

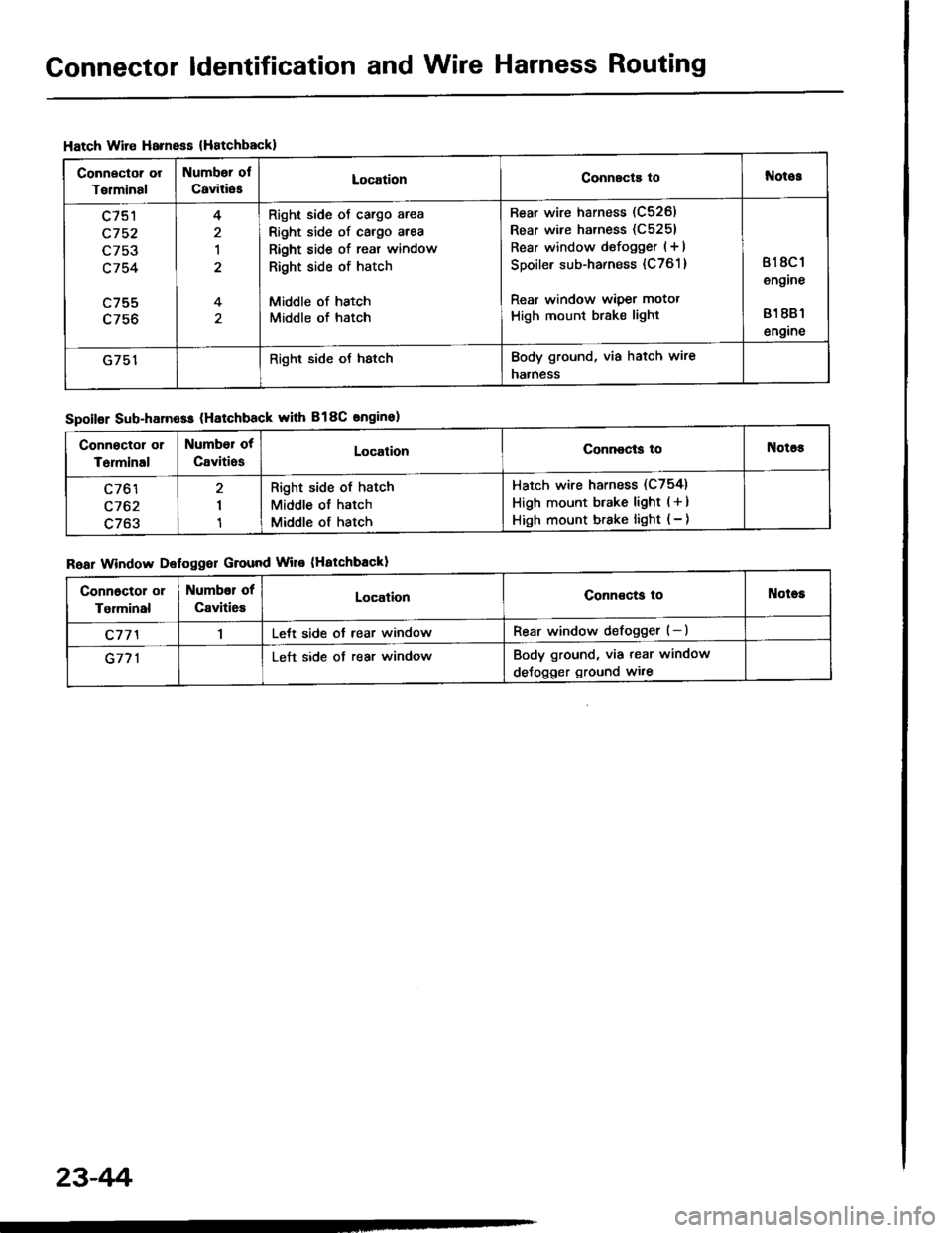

Connector ldentification and Wire Harness Routing

Hatch Wire Harnsss {Hatchbackl

Connector or

Torminal

Numbor ol

CaviliesLocationConnscts tol{otos

c751

c752

L/5J

c754

c755

4

1

4

Right side oJ cargo area

Right side of cargo area

Right side of reat window

Right side of hatch

Middle of hatch

Middle of hatch

Rear wire harness (C526)

Rear wire harness (C5251

Rear window defogger (+ I

Spoiler sub-harness (C761 )

Rear window wiper motot

High mount brake light

818C 1

engine

81 881

engine

G751Right side oJ hstchBody ground, via hatch wire

naaness

Spoilor Sub-harn6ss (Hatchback with B18C snginel

Roar Window Defoggor Ground Wire (Hatchbackl

Connoctor or

Terminal

Number ot

CavitiosLocalionConnocls toNotos

c761

c762

c763

I

1

Right side of hatch

Middle of hatch

Middle of hatch

Hatch wire harness (C754)

High mount btake light ( + )

High mount brake light ( - )

Connoctol or

Tgrminal

Numbor of

Caviti6sLocationConnoctg toNotes

c77'l1Lett side ot rear windowRear window defogger (-)

G771Left side ot rear windowBody ground, via tear window

deJogger ground wi.e

23-4r'i

Page 1268 of 1413

Headlight

Adjustment

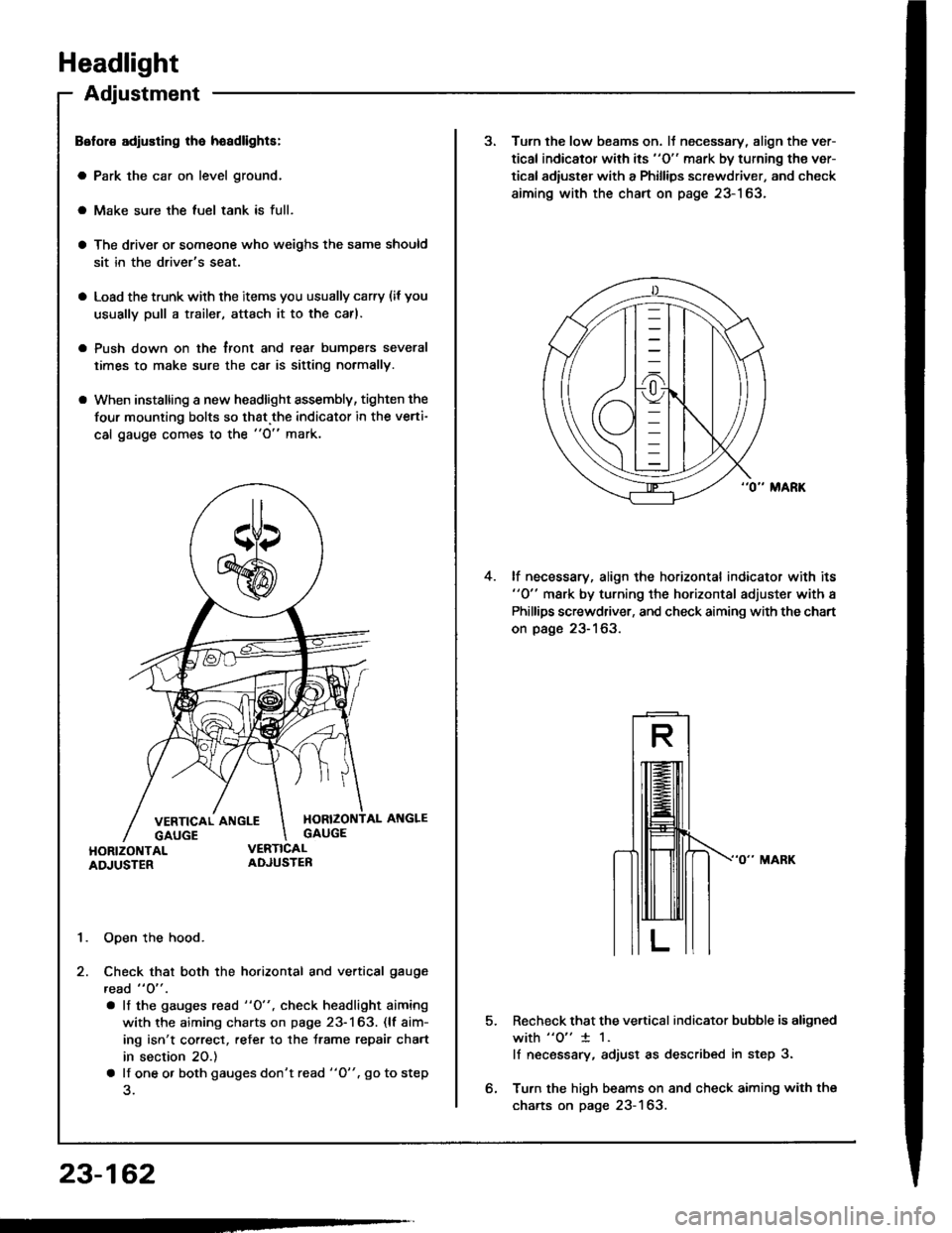

Belol€ adiusting lha hoadlights:

a Park the car on level ground.

a Make sure the luel tank is full.

a The driver or someone who weighs the same should

sit in the driver's seat.

a Load the trunk with the items you usually carry (if you

usually pull a trailer, attach it to the carl.

a Push down on the tront and rear bumDers several

times to make sure the car is sitting normally.

a When installing a new headlight assembly, tighten the

four mounting bolts so that.the indicator in the verti-

cal gauge comes to the "O" mark.

1. Open the hood.

2. Check that both the horizontal and vertical gauge

read " O" .

. lf the gauges rcad "O", check headlight aiming

with the aiming charts on page 23-163. (lf aim-

ing isn't correct, refer to the trame repair chart

in section 20.)

a lf one o. both gauges don't read "O". go to step

23-162

3. Turn the low beams on. lJ necessary, align the ver-

tical indicator with its "O" mark by turning the ver-

tical adiuster with a Phillips screwdriver, and check

aiming with the chart on page 23-163.

lf necessary, align the horizontal indicator with its"0" mark by turning the horizontal adjuster with a

Phillips screwdriver, and check aiming with the chart

on page 23-163.

4.

5.Recheck that the vertical indicator bubble is aligned

with "o" 1 1.

lf necsssary, adjust as described in step 3.

Turn the high beams on and check aiming with the

charts on page 23-163.

Page 1288 of 1413

AB'|Frt

jr'li

CD

Brake Lights

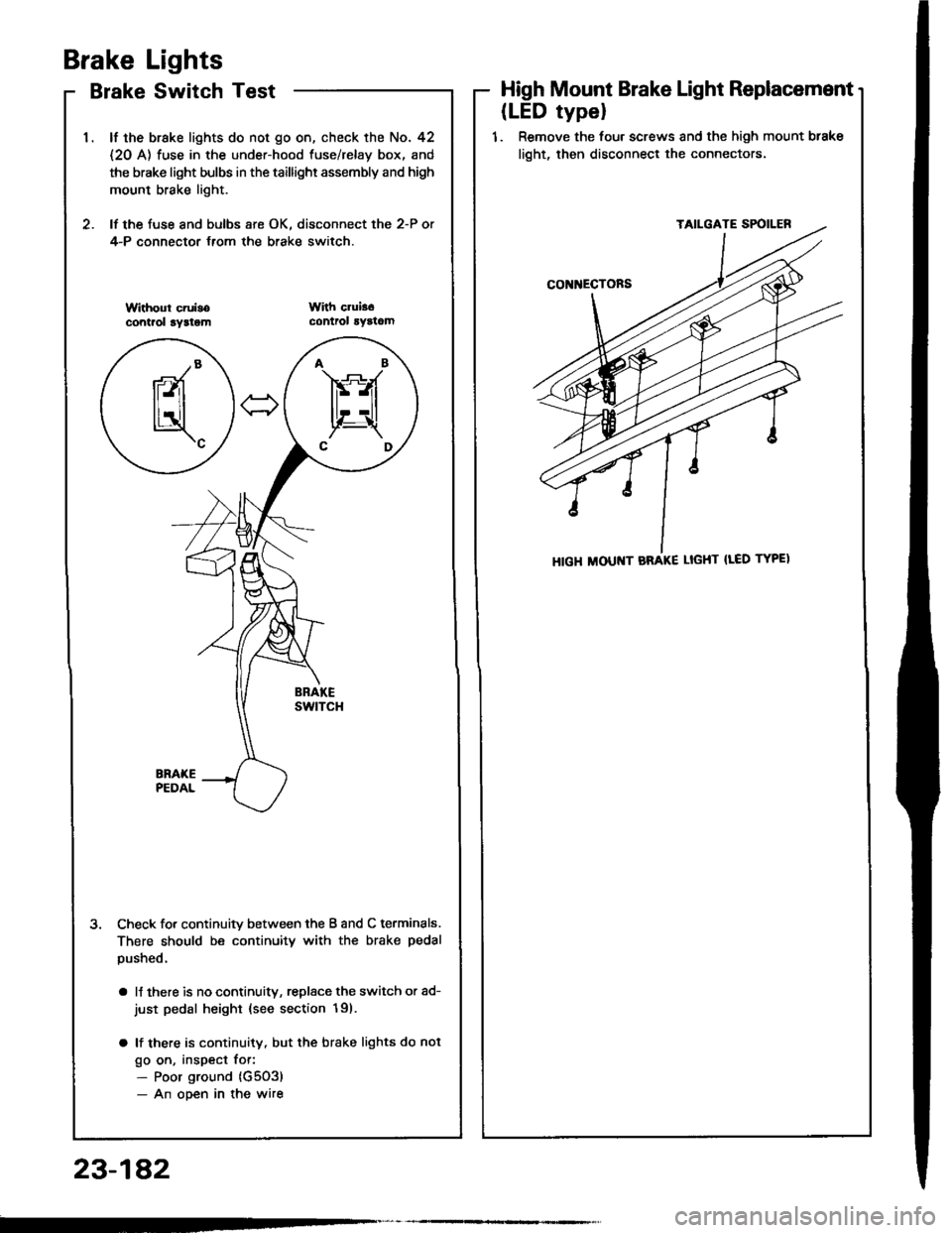

Brake Switch Test

lf the brake lights do not go on, check the No. 42

{2O A) fuse in the under-hood fuse/relay box, and

the brake light bulbs in the taillighr assembly and high

mount brake light.

lf the fuse and bulbs are OK. disconnect the 2-P or

4-P connector {rom the brake switch.

3. Check fo. continuitv between the B and C terminals.

There should be continuity with the brake pedal

pushed.

a lJ there is no continuitv, replsce the switch or ad-

just pedal height {see section 19).

a lf there is continuity, but the brake lights do not

go on, inspect for:- Poor ground (G5O3)

- An ooen in the wire

High Mount Brake Light Replacement

(LED typel

1. Remove the four screws and the high mount btake

light, then disconnect the connectors.

HIGH ltlOUt{T BRAKE LIGHT {LED TYPEI

23-1A2

Page 1289 of 1413

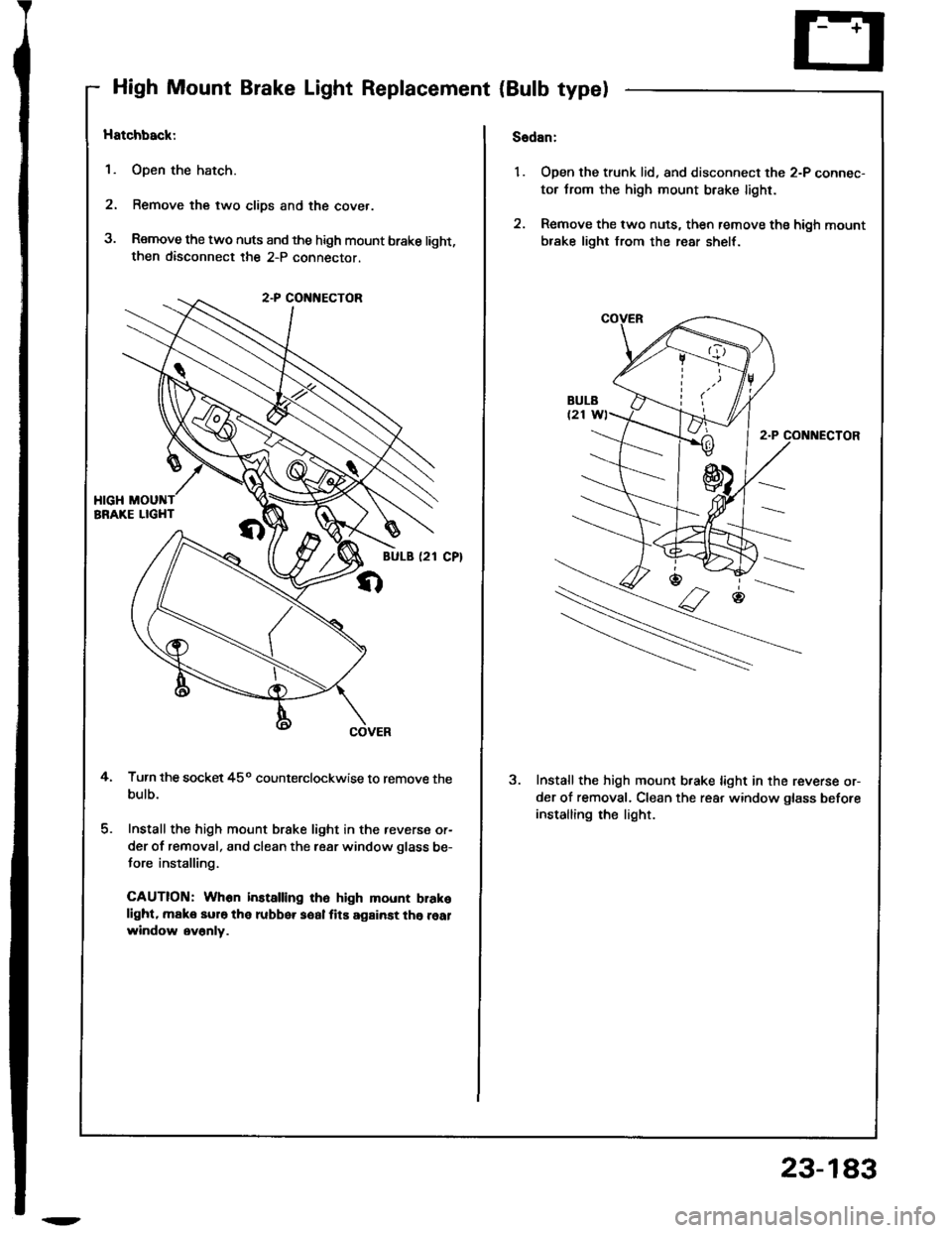

High Mount Brake Light Replacement {Bulb type)

Hatchback:

1. Open the hatch.

2. Remove the two clips and the cover.

3. Remove the two nuts and the high mount brake light,then disconnect the 2-P connector.

Turn the socket 45o counterclockwise to remove thebulb.

Install the high mount brake light in the reverse or-

der of removal, and clean the rear window glass be-

tore installing.

CAUTION: Whon installing ih6 high mount brakelight. make sur6 the rubber soal fits against the realwindow ev6nly.

4.

Sadan:

1. Open the trunk lid, and disconnect the 2-P connec-

tor trom the high mount brake light.

2. Remove the two nuts, then remove ths high mount

brake light from the rear shelt.

2-P CONt{ECTOR

Install the high mount brake light in the reverse or-

der of removal. Clean the rear window glass before

installing rhe light.

2

23-183