hose HONDA INTEGRA 1994 4.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 78 of 1413

Gylinder Head

Removal

I

t

Engine removal is not required for this procedure.

CAUTION: To avoid damaging tho cylinder head, wait

until tho ongino coolant temporature drops bolow 100"F

{38"C) beforo loo36ning the rotainin0 bolts.

NOTE:

. Inspect the timing belt before removing the cylinder

neao.

. Turn the crankshaft pulley so that the No. 1 piston is

at top dead center (TDCI (page 6-12).

. Mark all emissions hoses before disconnecting them.. Anti-theft radios have a coded theft protection circuit.

Be sure to get the customer's code number before.- Disconnecting the battery.- Removing the No. 32 (7.5 A) fuse irom the under-

hood fuse/relay box.- Removing the radio.

After service, reconnect oower to the radio and turn it

on.

When the word "CODE" is displayed, enter the cus-

tomer's 5-digit code to restore radio operation.

1. Disconnect the negative terminalfrom the battery.

2. Drain the engine coolant (see page 10-5).

. Remove the radiator cap to speed draining.

3. Relieve fuel pressure (see Section 1 1).

@ Do not smoke whils working on tusl

systom, keep opon flame or spark away trom work

area. Drain fuol only inlo an approvod containsr.

4. Disconnect the fuel feed hose.

SERVIC€ BOLT

WASHERSReplace.

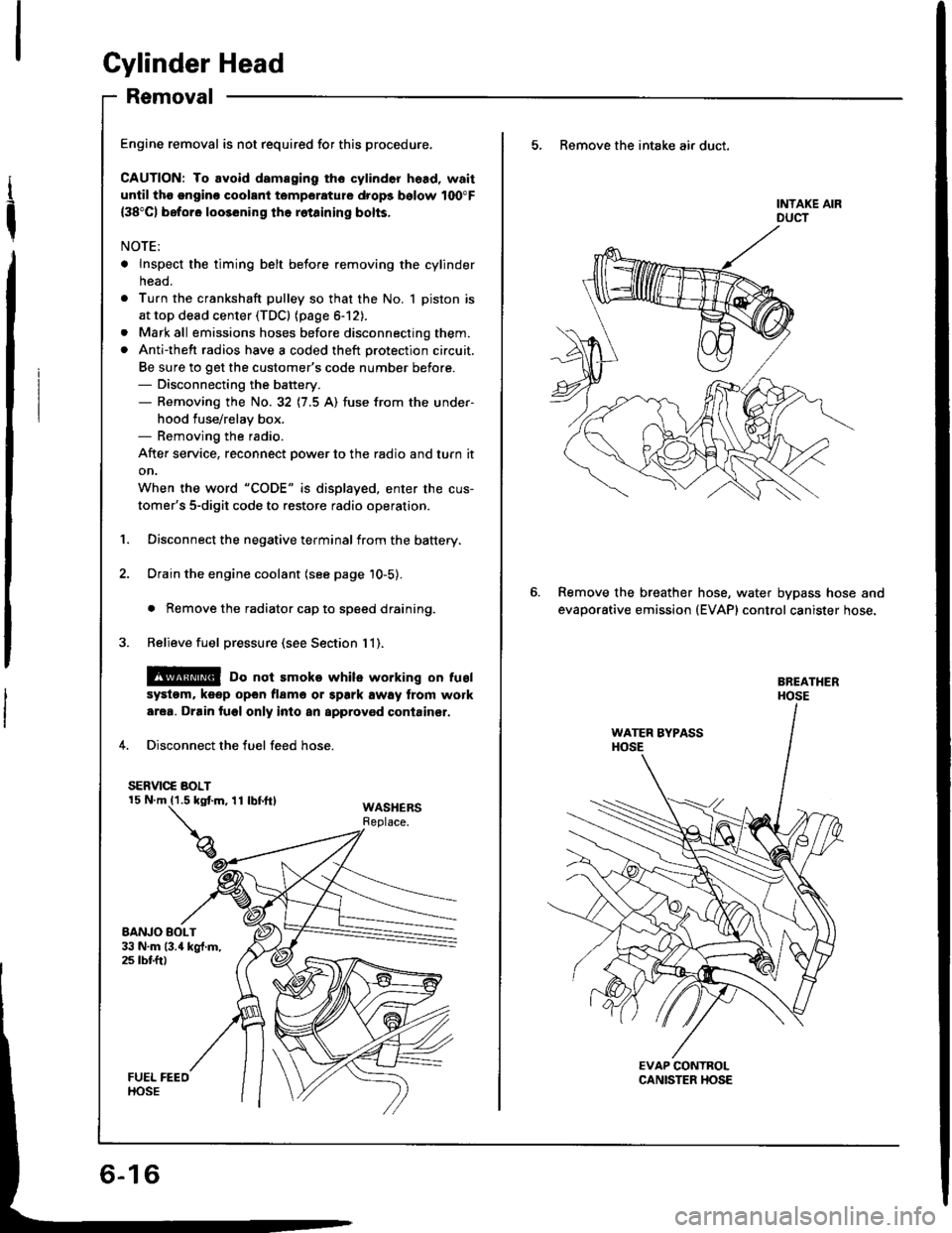

5, Remove the intake air duct.

Remove the breather

evaporative emission

hose, water bypass hose and(EVAP) control canister hose.

Page 79 of 1413

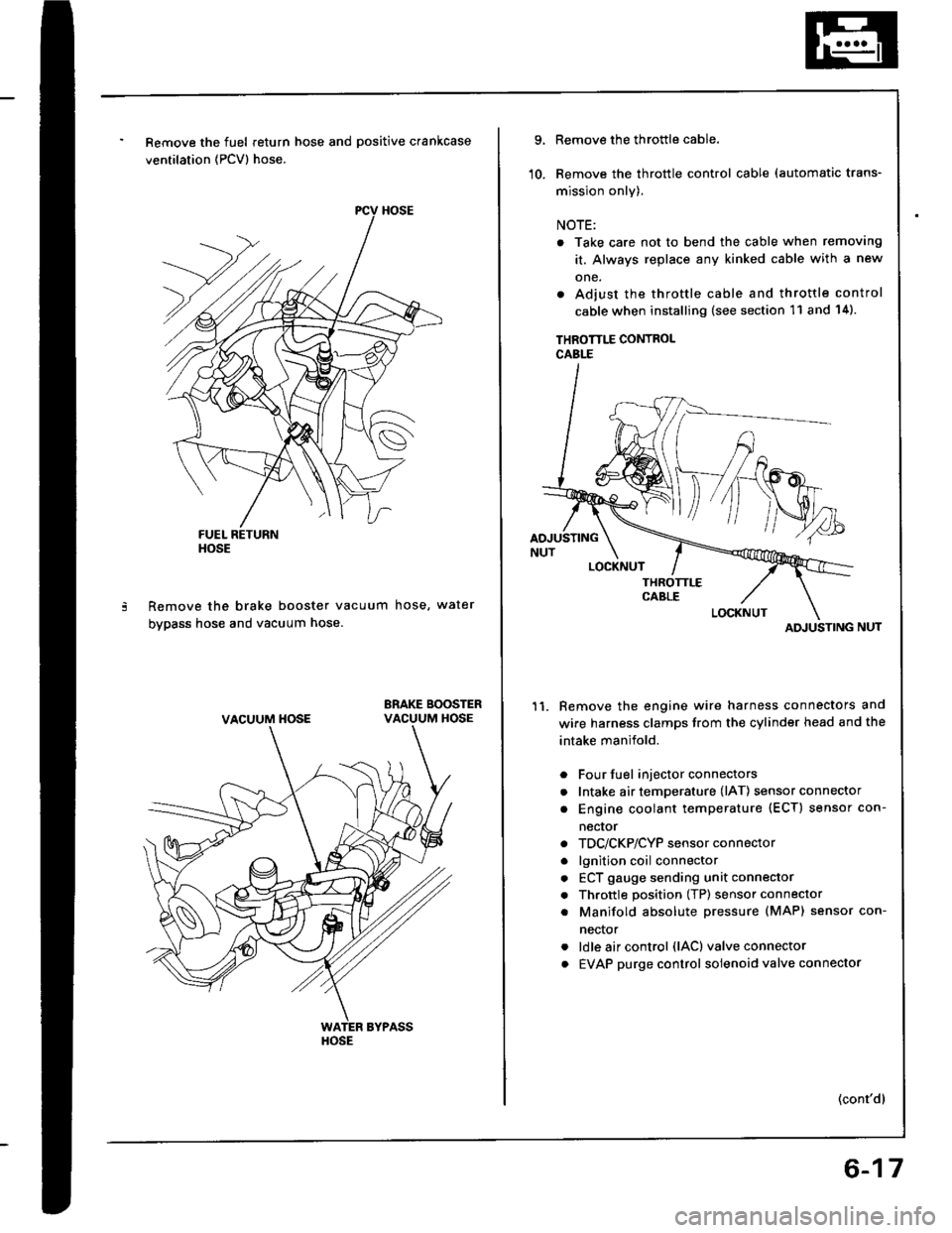

Remove the fuel return hose and positive crankcase

ventilation (PCV) hose.

Remove the brake booster vacuum hose, water

bypass hose and vacuum hose.

ERAKE BOOSTERVACUUM HOSE

HOSE

VACUUM HOSE

HOSE

9.

10.

Remove the throttle cable.

Remove the throttle control cable (automatic trans-

mission only).

NOTE:

. Take care not to bend the cable when removing

it. Always replace any kinked cable with a new

one.

. Adjust the throttle cable and throttle control

cable when installing (see section 11 and 14).

THROTTLE CONTROLCABLE

Remove the engine wire harness connectors and

wire harness clamps trom the cylinder head and the

intake manifold.

Four fuel injector connectors

Intake air temperature (lAT) sensor connector

Engine coolant temperature (ECT) sensor con-

necror

TDC/CKP/CYP sensor connector

lgnition coil connector

ECT gauge sending unit connector

Throttle position (TP) sensor connector

Manifold absolute Dressure (MAP) sensor con-

nector

ldle air control (lAC) valve connector

EVAP purge control solenoid valve connector

11.

a

a

a

a

a

a

a

a

a

(cont'dl

ATI'USTING

6-17

Page 80 of 1413

Cylinder Head

Removal (cont'dlI

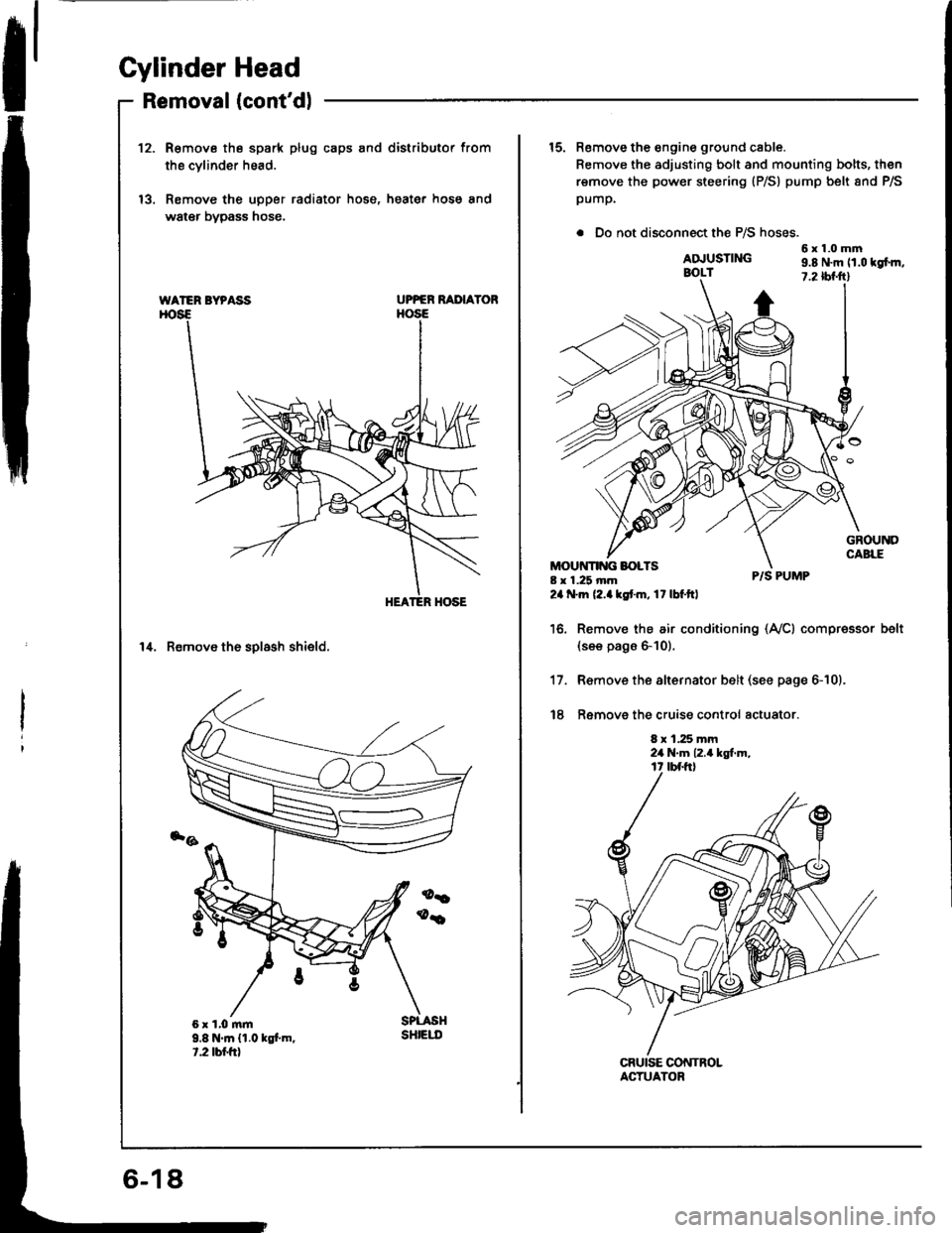

12.R€move the spark plug caps and distributor from

the cvlinder head.

Remove the upper radiator hose, heater hose and

water bypass hose.

UPPER RAI'IAYOR

14. Remove th6 solash shield.

WATER BYPASS

9.8 N.m {1.0 kgt m.t.2 tbr.frt

sHtEut

15. Remove the engine ground cable.

Remove the adjusting bolt and mounting bolts, then

remove the power steering (P/S) pump belt 8nd P/S

pump.

. Do not disconnect the P/S hoses.

6x1.0mmADJUSTINGBOLT9.8 N.m 11.0 tgfm,7.2 tbf.ftl

8 x 1.25 mm24 .m (2.akstm, 17lbf.ftl

P/S PUMP

Remov€ the air conditioning (Ay'Cl compressor(see pags 6-10).

R€move the alternator belt (see page 6-10).

Ramove the cruise control actuator.

8 x 1.25 mm2a N.m 12.4 kgt m,

belt

17.

t8

ACTUATOR

Page 94 of 1413

Gylinder Head

lnstallation (cont'dl

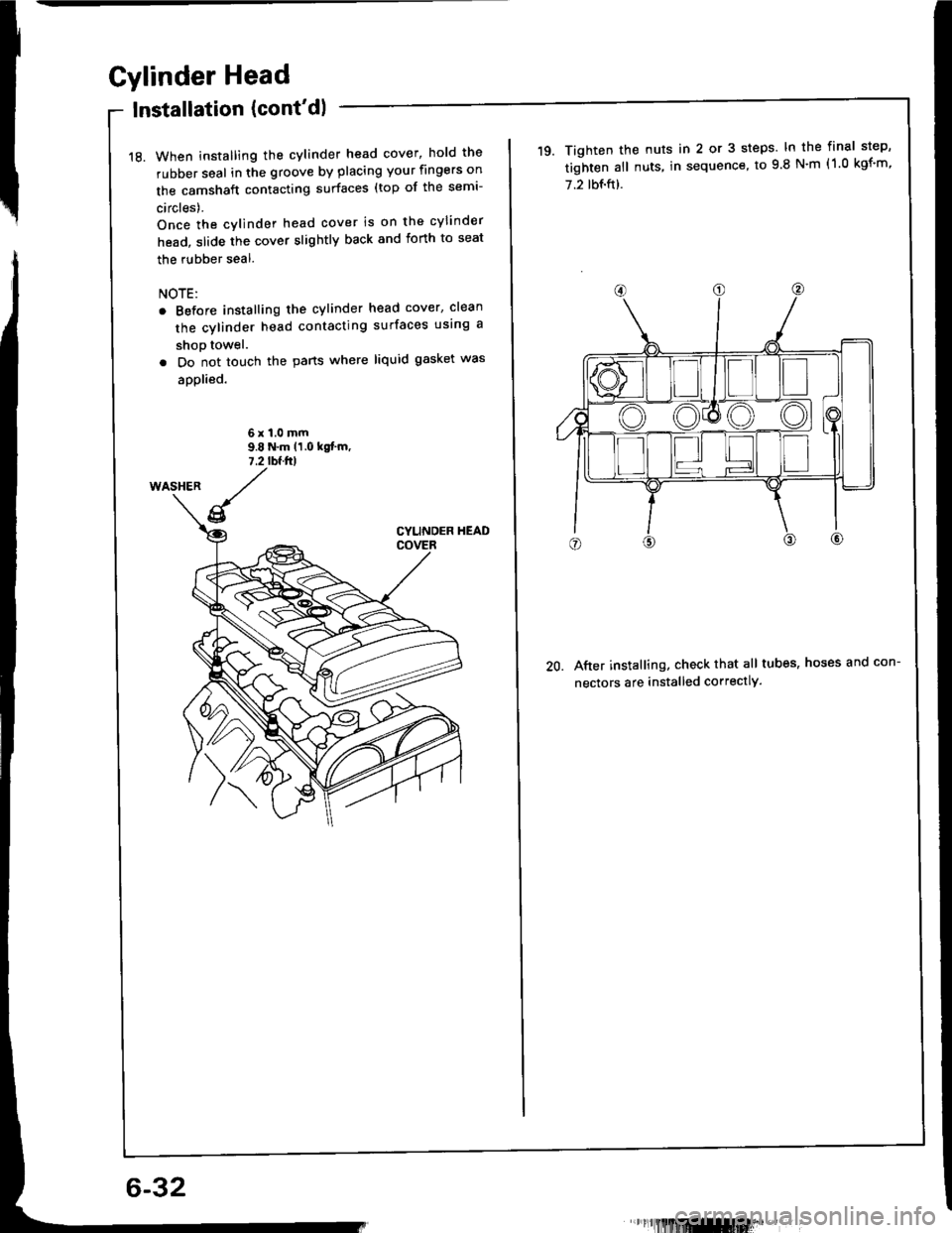

18. When installing the cylinder head cover, hold the

rubber seal in the groove by placing your fingers on

the camshaft contacting surfaces (top of the semi-

circles).

Once the cvlinder head cover is on the cylinder

head, slide the cover slightly back and forth to seat

the rubber seal.

NOTE:

. Before installing the cylinder head cover, clean

the cylinder head contacting surfaces using a

shop towel.

. Do not touch the pans where liquid gasket was

aDplied.

6x1.0mm9.8 N.m 11.0 kgt'm,7.2 tbf.trl

6-32

'lllllllllmlmti'""

Tighten the nuts in 2 or 3 steps. In the final step,

tighten all nuts, in sequence, to 9.8 N'm (1 0 kgf'm,

7.2 tbf.ft).

20. After installing, check that all tubes, hoses and con-

nectors are installed correctlY.

Page 116 of 1413

Cylinder Head

Removal

Engine removal is not required or this procedure.

CAUTION: To avoid damaging tho cylinder head, wail

u[tilths.nginc coolant tsmperaturo drops bolow 100"F(38'Cl bafore loos6ning tho retaining bolts.

NOTE;

. Inspect the timing belt before removing the cylinder

head.

Turn the crankshaft pulley so that the No. 1 piston is

at top dead center (TDc) {page 6-51).

Mark all emissions hoses betore disconnecting them.

Anti-theft radios have a coded theft protection circuit.

Be sure to get the customer's code number before- Disconnecting the battery.- Removing the No.32 (7.5 A) fuse trom the under-

hood fuse/relay box.- Removing the radio.

After service, reconnect power to the radio 8nd turn it

on.

When the word "CODE" is displaved. enter the cus-

tomer's 5-digit code to restore radio operation,

Disconnect the negative terminal from the battery.

Drain the engine coolant (see page 10-5).

. Remove the radiator cap to speed draining.

Relieve fuel pressure (see section 111.

l@ Do not 3moke whilo working on fuel

a

a

'1.

systgm. ko6p opon tlamo ot Spark away trom work

aroa. Drain fugl only into an approved containsr,

4. Disconnect the fuel feed hose.

SERVIC€ BOLT15 N.m (1.5 kgtm, rl bf.tt)WASHERSReplace.

BANJO BOLT

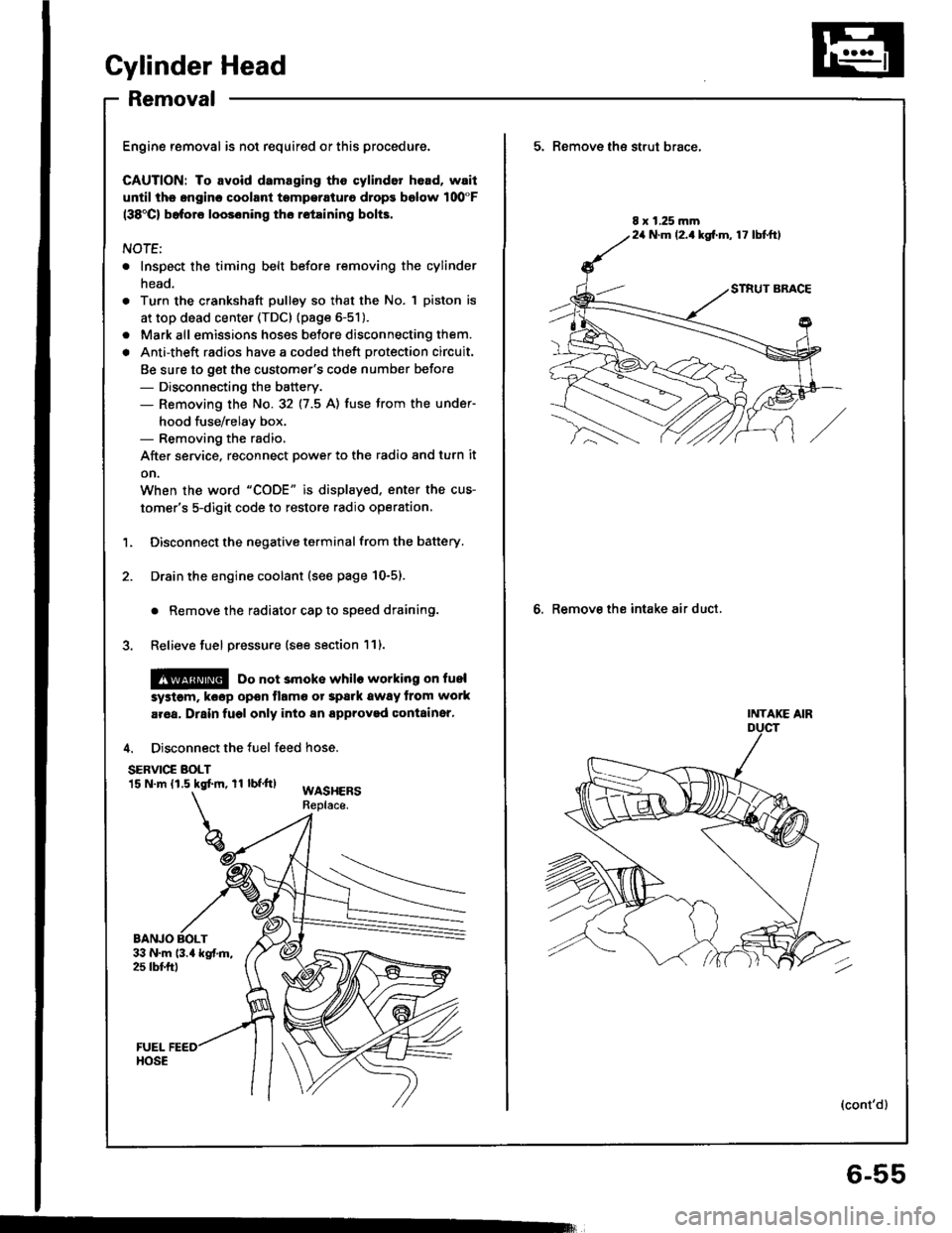

5. Remove th€ strut brace,

6. Remove the intake air duct.

8 x 1.25 mm24 N.m (2.1kg[.m, 17 lbtftl

INTAKE AIR

(cont'd)

6-55

Page 117 of 1413

Cylinder Head

Removal (cont'd)

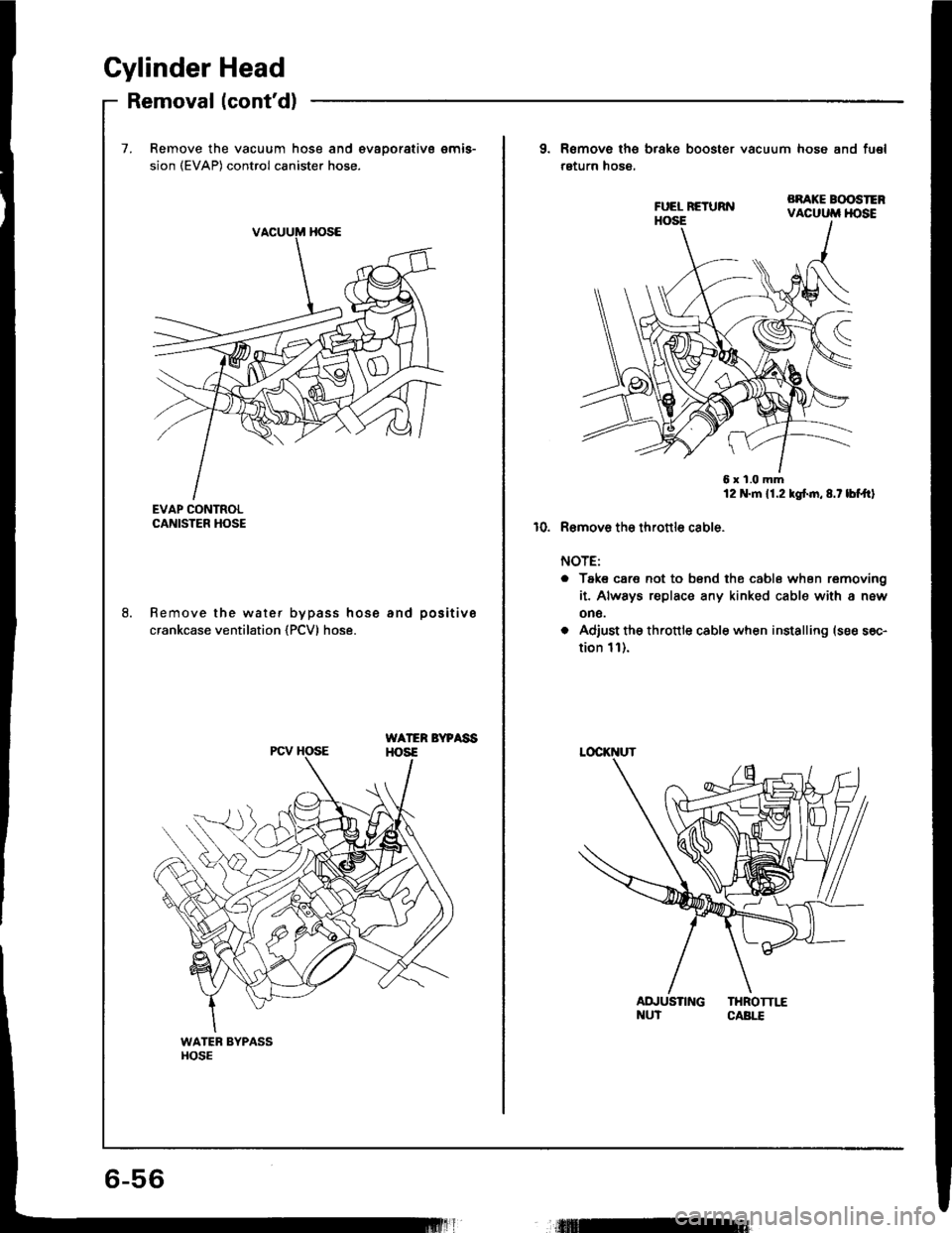

7. Remove the vacuum hose and €vaoorativs emis-

sion (EVAP) control canister hose.

EVAP CONTROLCANISTER HOSE

Remove the water bypass hose and positive

crankcase ventilation {PCV) hose.

WATER BYPAssHOS€PCV HOSE

9. Remove ths brake booster vacuum hose and fu€l

return hose,

BRAKE BOOSTERVACUUM HOSE

6x1.0mm12 N.m 11.2 kgf.n,8.t lbf.trl

10. R€mov6 tho thronlo cable.

NOTE:

o Taks care not to bsnd the cabl6 when removing

it. Always replace any kinked cable with a new

on6.

o Adiust the th.ottle cable when installing (see s6c-

tion 1l).

AD.'USTING THROTTI,"ENUT CABI.T

Page 118 of 1413

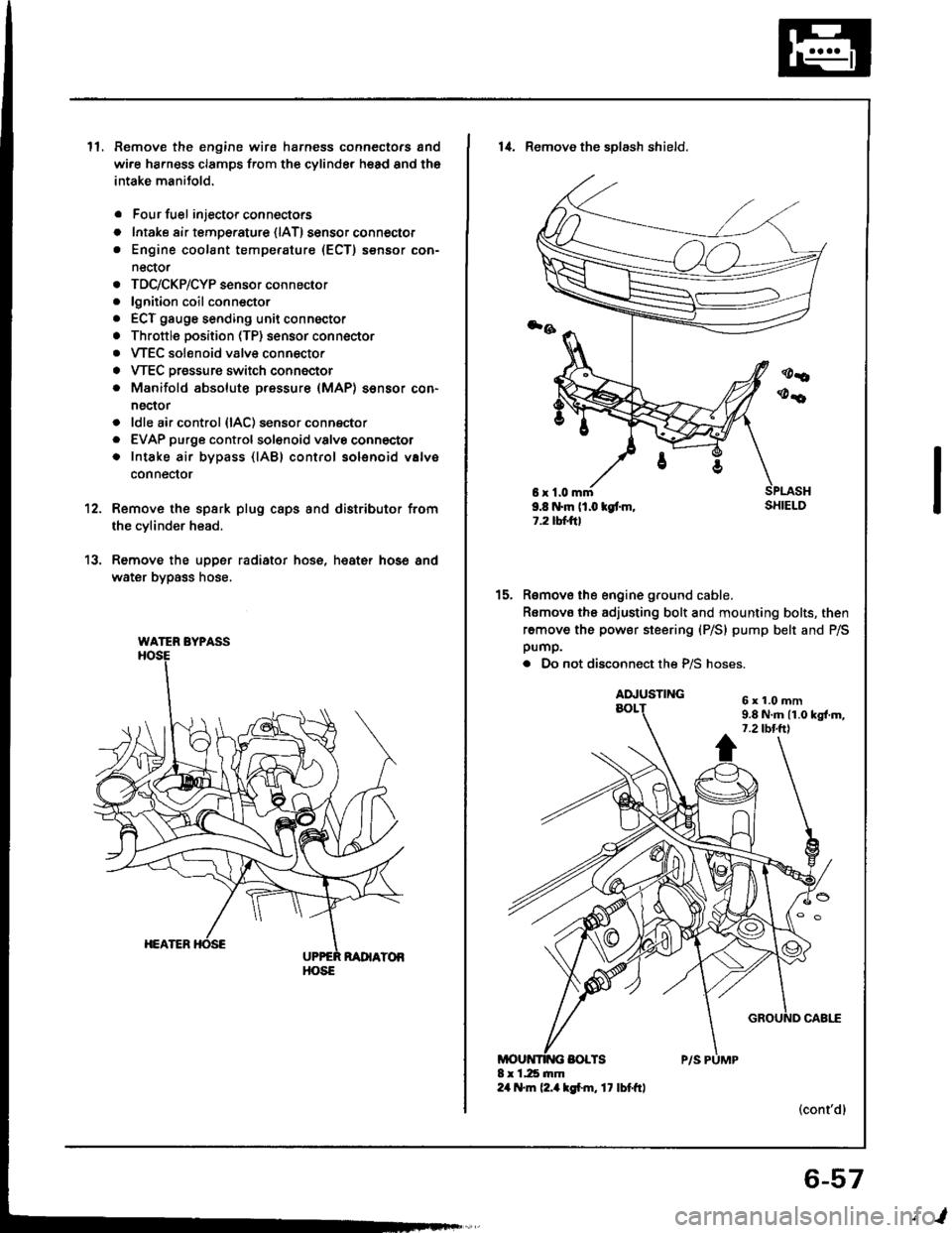

ll.Remove the engine wire harness connectors and

wi.e ha.ness clamps from the cylinder head and the

intake manitold.

Four fuel injector connectors

Intake air tempe.ature {lAT) sensor connector

Engine coolant temperature (ECT) sensor con-

nector

TDC/CKP/CYP sensor connector

lgnition coil conn€ctor

ECT gauge sending unit connector

Throttle position (TP) sensor connector

VTEC solenoid valve connector

VTEC Dressure switch connector

Manifold absolute pressure (MAP) sensor con-

nector

ldle air control {lAC) sensor connector

EVAP purge controlsol€noid valvo connector

Intake air bypass {lABl control solenoid valve

conneclor

a

o

a

o

a

a

a

a

a

a

a

a

a

12.

13.

Remove the spsrk plug caps and distributor from

the cylinder head.

Remove the upper radiator hose, heat€r hose and

water bypass hose.

WATER BYPASS

HOSE

6r1.0mm9.8 N.m (1.0 kgt m,1.2 tbtftl

14. Remove the sDlash shield.

Remove the engine ground cable.

Romovo the adjusting bolt and mounting bolts, then

remove the power steering (P/S) pump belt and P/Spump.

. Do not disconnect the P/S hoses.

(cont'dl

15.

6x1.0mm9.8 N.m 11.0 kgl.m,7.2 tbt.ttl

6-57

,l

Page 138 of 1413

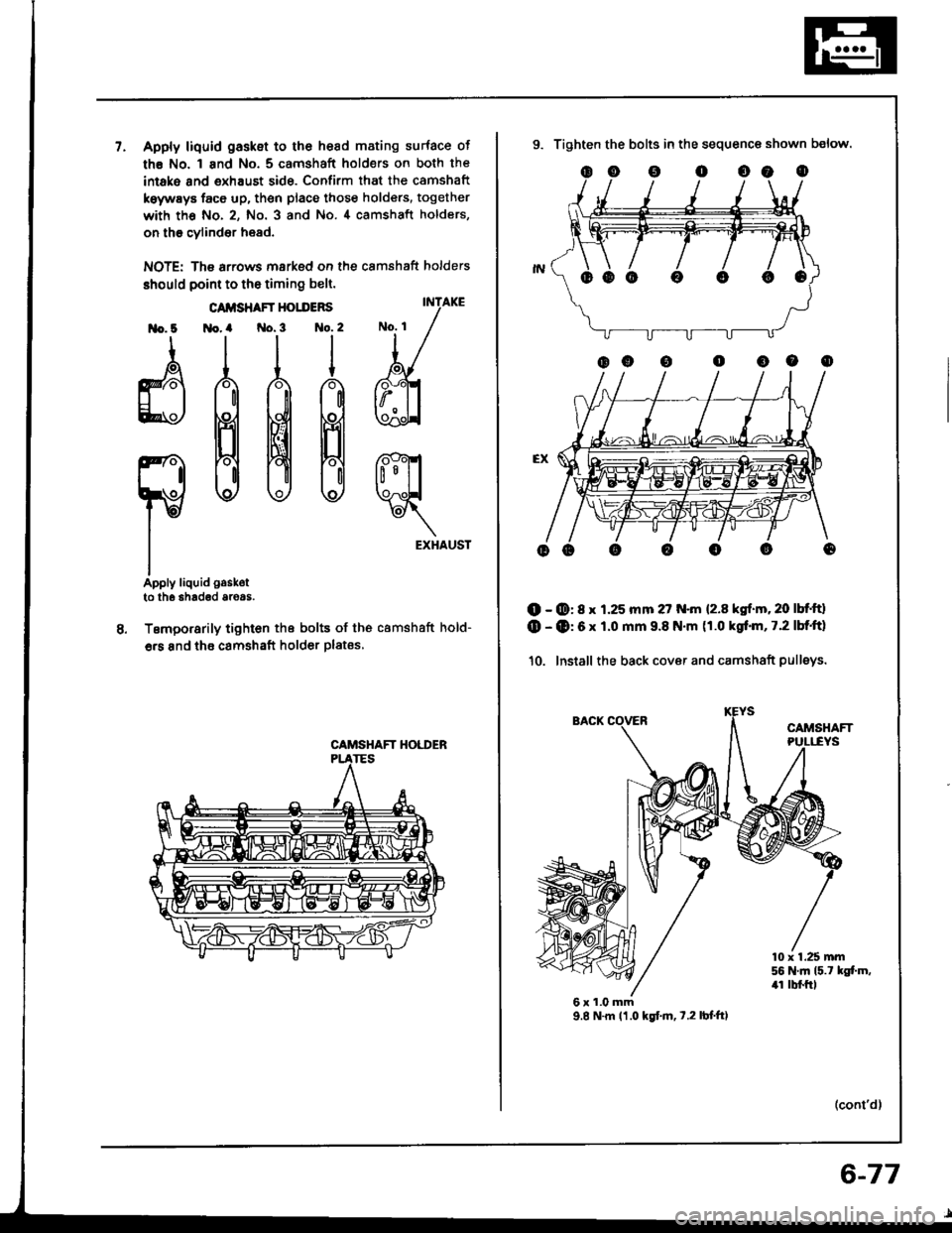

7.Apply liquid gasket to the hesd mating surface of

th€ No. 1 and No. 5 camshaft holders on both the

intako and exhaust side. Confirm that the camshaft

koywEys face up, then place those holders, together

with th€ No.2, No. 3 and No.4 camshaft holders,

on th€ cylind6r head.

NOTE: The arrows msrked on the camshaft holders

should point to the timing belt.

INTAKE

t/

bl

ffi

rfl?x

rt

EXHAUST

Apply liquid gaskot

to lh6 3had€d aroas.

Temporarily tighton the bolts of tho camshaft hold-

6rs and thE camshaft holder plates,

lrlo. 6

d

ro

I

CAIISHAFT HOIDERS

Ho. a No.3 1to.2

rllttt

888

CAMSHAFT HOI,I'ER

9. Tighten the bolts in the sequence shown below.

(D - @: 8 x 1.25 mm 27 N.m {2.8 kgf.m,20 lbt ttl

(D - (D: 6 x 1.0 mm 9.8 N.m (1.0 kgrl.m, 7.2 lbf'ft}

10. Install the back cover and camshaft pulleys.

CAMSHAFT

ooooo0o

10 x 1.25 mm56 N.ln l5.t kgf.m,4r lbl.trl

6x1.0mm9.8 N.m 11.0 kgtm, t.2lbf'ft)

(cont'd)

6-77

Page 140 of 1413

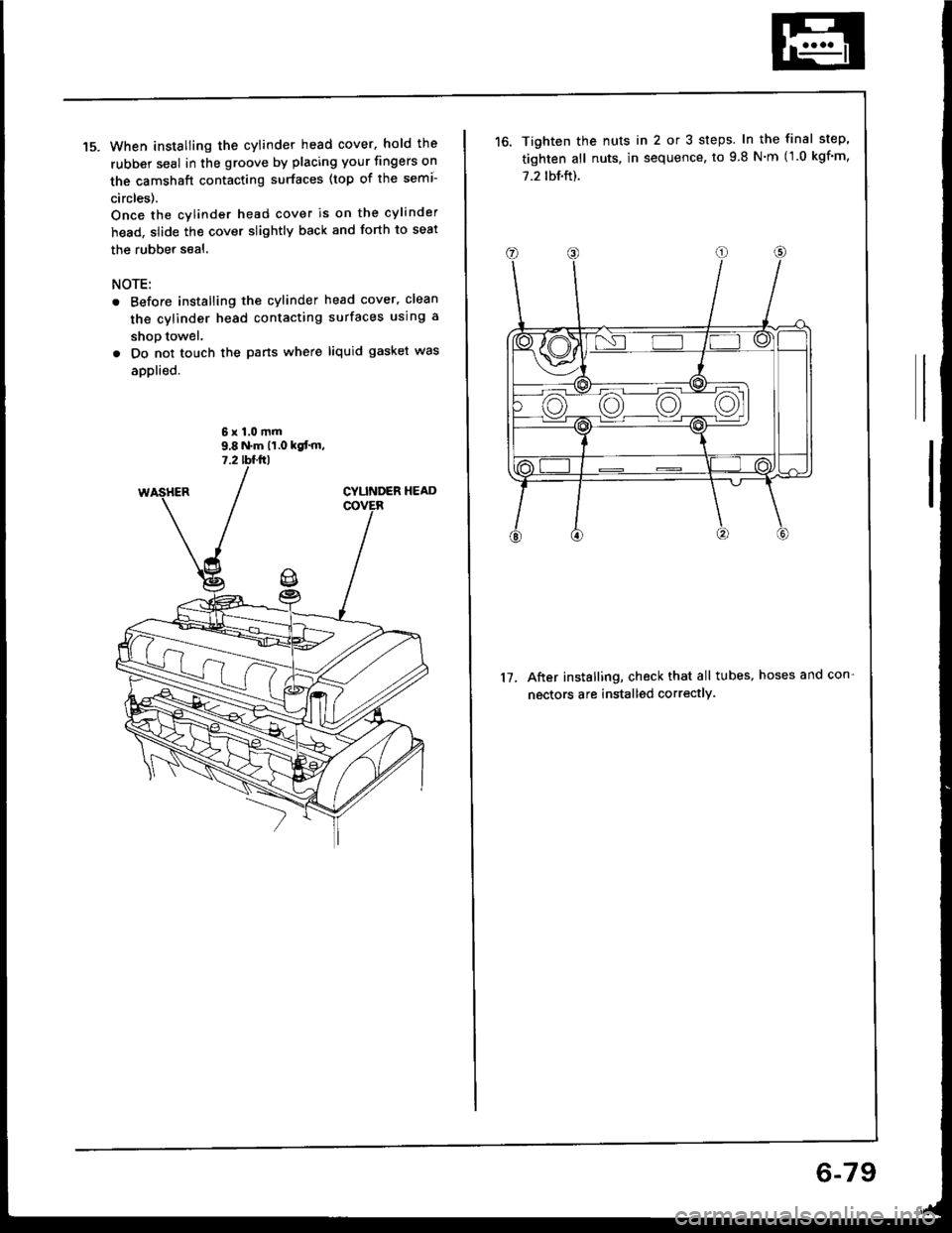

When installing the cylinder head cover. hold the

rubber seal in the groove by placing your fingers on

the camshaft contacting surfaces (top of the semi-

circles).

Once the cylinder head cover is on the cylinder

head, slide the cover slightly back and forth to seat

the rubber seal.

NOTE:

Before installing the cylinder head cover, clean

the cylinder head contacting surfaces using a

shop towel.

Do not touch the pans where liquid gasket was

applied.

6x1.0mm9,8 N.m 11.0 kgt'm,7.2 tffirl

Tighten the nuts in 2 or 3 steps. In the final step'

tighten all nuts, in sequence, to 9.8 N'm (1.0 kgf'm,

7.2 tbf.ft).

After installing, check that all tubes, hoses and con-

nectors are installed correctly.

17.

6-79

Page 156 of 1413

Piston

lnstallation

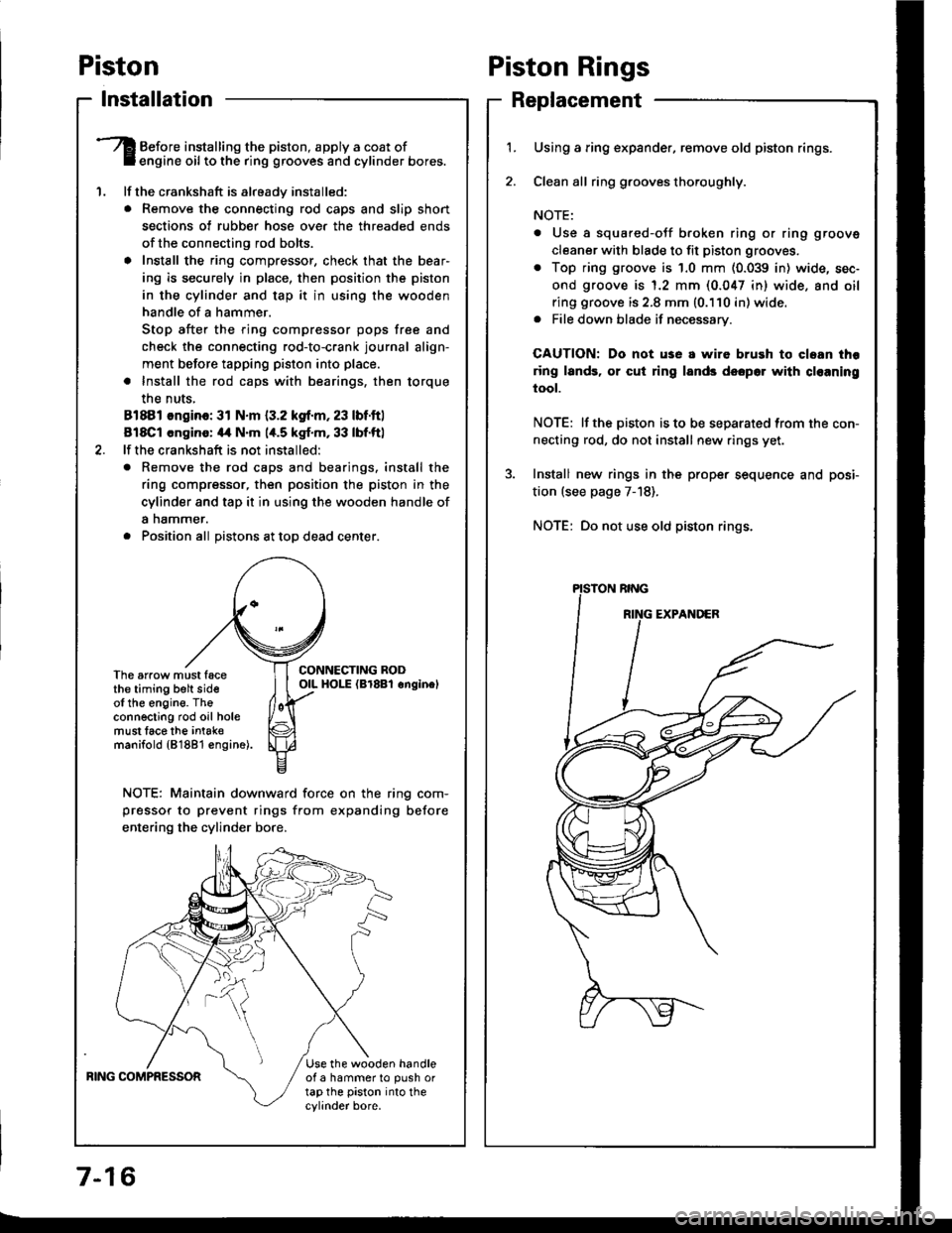

'1.

Before installing the piston, apply a coat ofengine oil to the ring grooves and cylinder bores.

lf the crankshaft is already installed:

. Remove the connecting rod caps and slip short

sections of rubber hose ove. the threaded ends

of the connecting rod bolts.

a Install the ring compressor, check that the bear'

ing is securely in place, then position the piston

in the cylinder and tap it in using the wooden

handle of a hammer.

Stop after the ring compressor pops free and

check the connecting rod-to-crank journal align-

ment before tapping piston into place.

. Install the rod caps with bearings, then torque

the nuts,

81881 ongino: 31 N.m {3.2 kgf.m, 23 lbf.ftl

818C1 cngino: 44 N'm 1,t.5 kgf.m, 33 lbf.ftl

lf the crankshaft is not installed:

o Remove the rod caps and bearings. install the

ring compressor, then position the piston in the

cylinder and tap it in using the wooden handle of

a nammer.

. Position all Distons at toD dead center.

CONNECTING RODOIL HOI-E (Br8Bl onginelThe arrow must facethe timing belt sideof the engine. Theconnecting rod oil holemust lace the intak€manifold {81881 €ngine).

NOTE: Maintain downward force on the ring com-

pressor to prevent rings from expanding before

entering the cylinder bore,

BING COMPRESSORUse the wooden handleof a hammer to push ortap the piston into thecylinder bore.

Piston Rings

Replacement

1.Using a ring expander, remove old piston rings.

Clean all ring g.ooves thoroughly.

NOTE:

. Use a squared-oJf broken ring or ring groove

cleaner with blade to fit piston grooves.

. Top ring groove is 1.0 mm (0.039 in) wide, sec-

ond groove is 1.2 mm (0.047 in) wide. and oil

ring groove is 2.8 mm (0.110 in) wide.. File down blade if necessary.

CAUTION: Do not use a wire brush to cloan thr

ring lands, or cut ring lands dsopo. with cl€aning

tool.

NOTE: lf the piston is to be separated from the con-

necting rod, do not install new rings yet.

Install new rings in the prope. sequence and posi-

tion (see page 7-18).

NOTE: Do not use old piston rings.