starter HONDA INTEGRA 1994 4.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 388 of 1413

Transmission Assembly

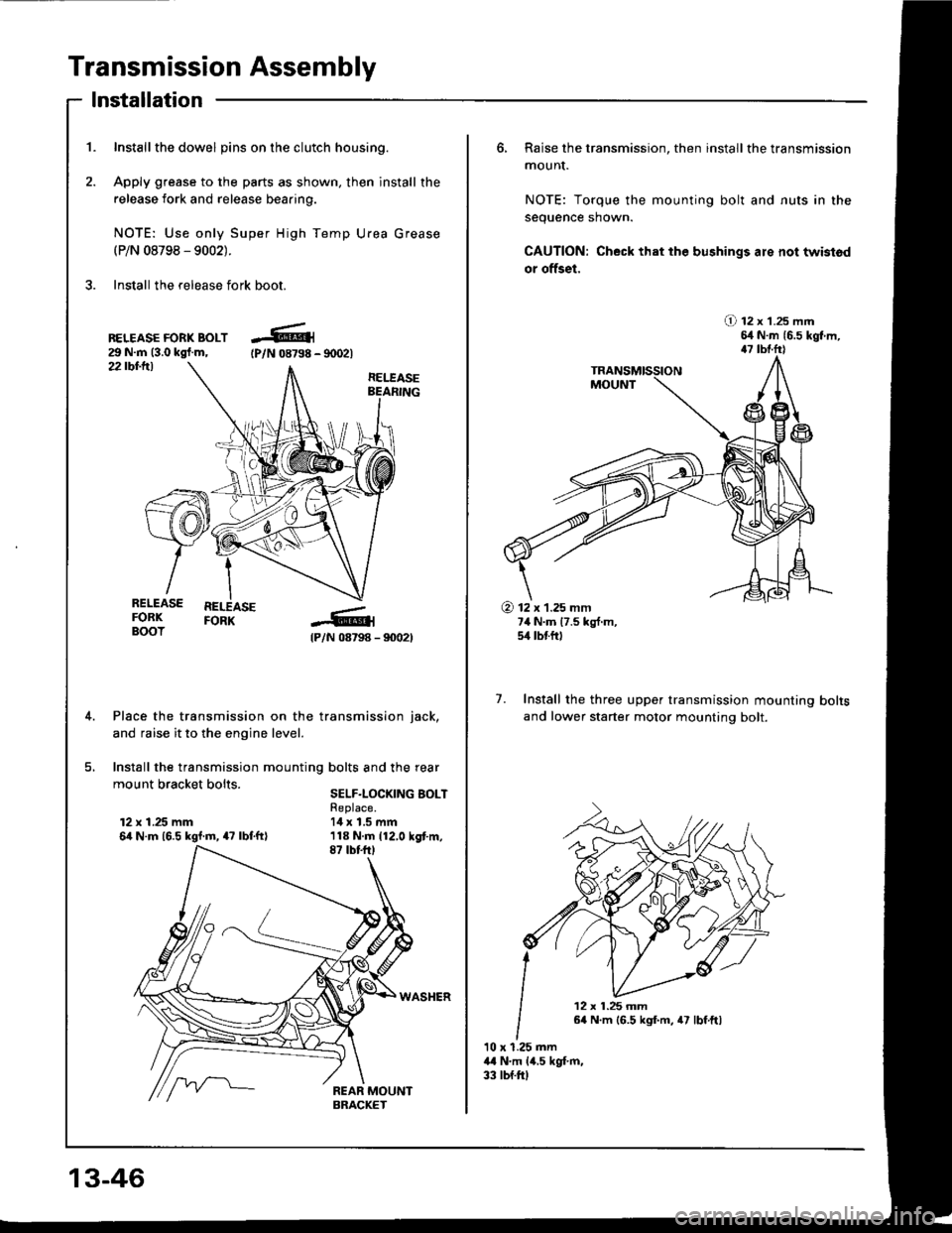

1. Inst€llthe dowel pins on the clutch housing.

2. Apply grease to the parts as shown, then install the

release fork and release beaaing.

NOTE: Use only Super High Temp Urea Grease(P/N 08798 - 9002).

3. Install the release fork boot.

lnstallation

22 tbt-ttl

BELEASE FORK BOLT29 N.m (3.0 kgl.m,tPlN 08798 - 90021

RELEASEBEARING

@

I

{P/N 08798 - 90021

Place the transmission on the transmission iack,

and raise it to the engine level.

Install the transmission mounting bolts and the rear

mount bracket bolts sELF-LocKrNG BoLT

RELEASE REEASEFORK FORKBOOT

12 x 1.25 mm6it N.m 16.5 kgl.m, 47 lbf.ftl

Replace.14 x 1.5 mm

13-46

6, Raise the transmission, then install the transmission

mounI.

NOTE: Torque the mounting bolt and nuts in the

sequence shown.

CAUTION: Check that the bushings are not twistod

or offset,

O 12 x 1.25 mm54 N.m {6.5 kgt m,47 tbtfrl

7. Install the three upper transmission mounting

and lower starter motor mounting bolt.

bolts

10 x 1.25 mm44 N.m lil,s kgt m,33 tbf.ftl

@ 12 x 1.25 mm7,1 N.m 17.5 kg{.m,5/r lbtftl

12 x 1.25 mm64 N.m 16.5 kgf.m, 47 lbf.ftl

Page 391 of 1413

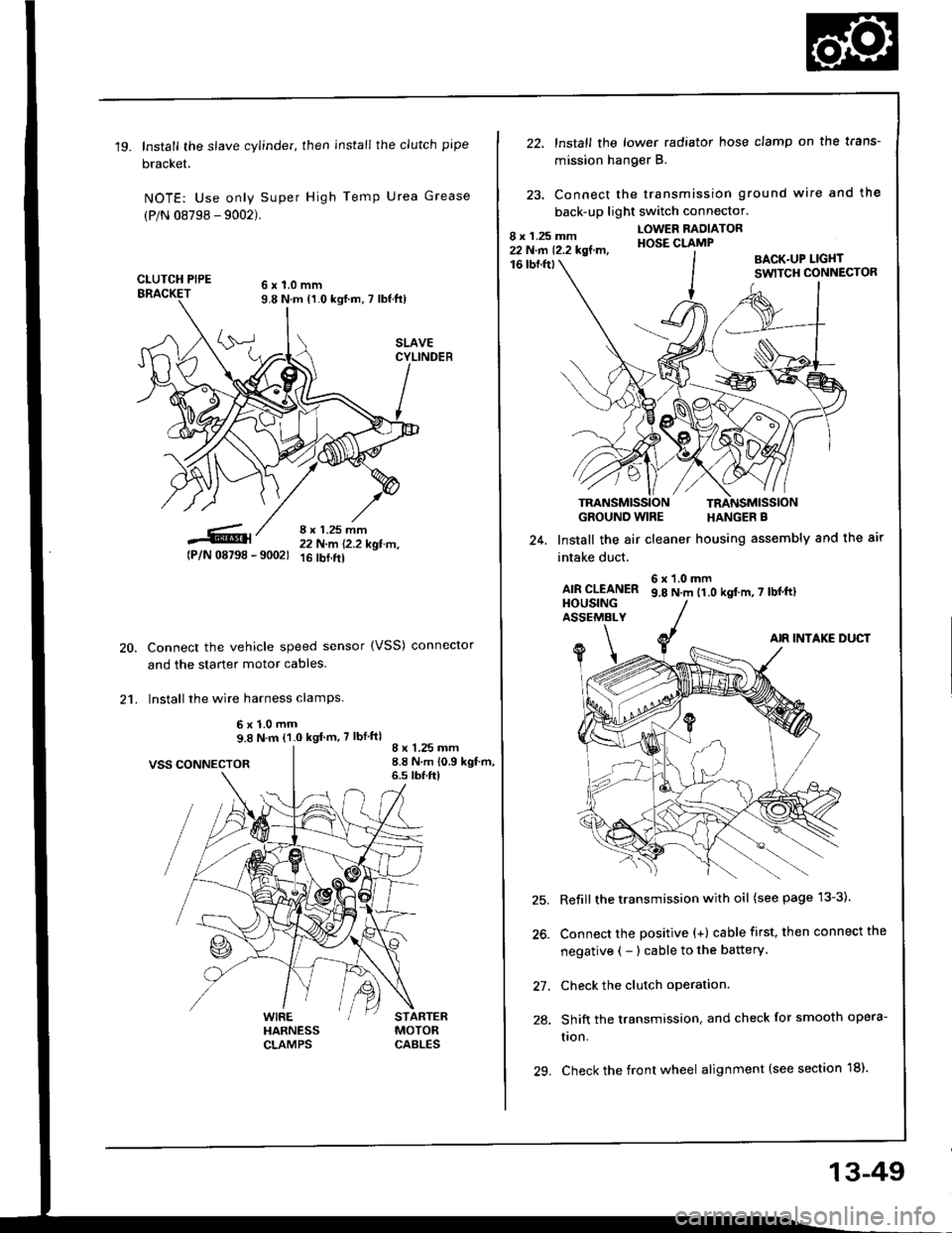

'19.Install the slave cylinder, then install the clutch pipe

bracket.

NOTE: Use only Super High Temp Urea Grease

(P/N 08798 - 9002).

CLUTCH PIPE6x1.0mm9.8 N.m {1.0 kgf.m, 7 lbf ft)

8 x 1.25 mm22 N-m 12.2 kgl.tr't,16 rbf.ftl

20.

21.

tPlN 08798 - 90021

VSS CONNECTOR

Connect the vehicle speed sensor (VSS) conneclor

and the starter motor cables.

Install the wire harness clamPs.

6x1.0mm9.8 N.m (1.0 kgt m,7 lbf ftl

WIREHARNESSCLAMPS

8 x 1.25 mm8.8 N.m 10.9 kgf.m,6.s tbf.ft)

STARTERMOTORCABLES

22, lnstall the lower radiator hose clamp on the trans-

mission hang€r B.

23. Connect the transmission ground wire and the

back-up light switch connector.

16 tbf.fttBACK.UP LIGI{TSWITCH CONNECTOR

GROUND WIRE HANGER B

Install the air cleaner housing assembly and the air24.

intake duct.

AIR CLEANERHOUSINGASSEMALY

6x1.0mm9.8 N.m 11.0 kgt'm,7 lbtftl

AIR INTAKE DUCT

Refill the transmission with oil (see page 13-3).

Connect the positive (+) cable first, then connect the

negative ( - ) cable to the battery.

Check the clutch operation.

Shift the transmission. and check for smooth opera-

tron.

29. Check the front wheel alignment (see section 18).

9\

\<

27.

28.

13-49

Page 395 of 1413

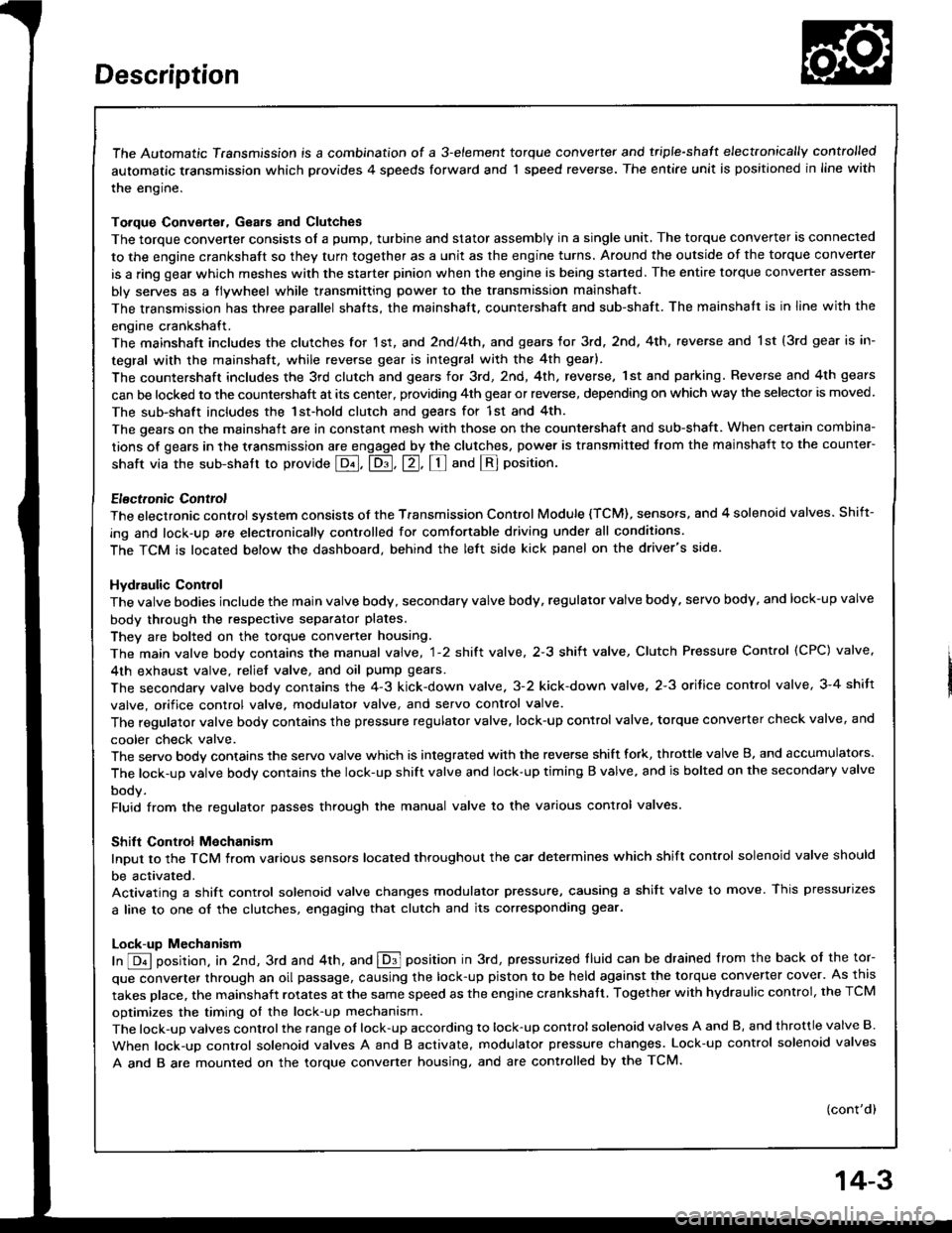

The Automatic Transmission is a combination of a 3-e,ement torque convefter and triple-shaft electfonically controlled

automatic transmission which provides 4 speeds forward and 1 speed reverse. The entire unit is positioned in line with

the engine.

Torque Converter, Gears and Clutches

The torque converter consists of a pump, turbine and stator assembly in a single unit, The torque converter is connected

to the engine crankshaft so they turn together as a unit as the engine turns. Around the outside of the torque converter

is a ring gear which meshes with the starter pinion when the engine is being staned. The entire torque converter assem-

bly serves as a flywheel while transmitting power to the transmission mainshaft.

The transmission has three parallel shafts, the mainshaft. countershaft and sub-shaft. The mainshatt is in line with the

engine crankshaft.

The mainshaft includes the clutches for 1 st, and 2ndl4th, and gears for 3rd. 2nd, 4th, reverse and l st (3rd gear is in-

tegral with the mainshaft, while reverse gear is integral with the 4th gear).

The countershaft includes the 3rd clutch and gears Ior 3rd, 2nd,4th, reverse, lst and parking. Reverse and 4th gears

can be locked to the countershaft at its center, providing 4th gear or reverse, depending on which way the selector is moved.

The sub-shaft includes the lst-hold clutch and gears for 1st and 4th

The gears on the mainshait are in constant mesh with those on the countershaft and sub-shaft. When certain combina-

tions of gears in the transmission are engaged by the clutches, power is transmitted from the mainshaft to the counter-

shaft via the sub-shatt to provide @, E, tr. tr and @ position.

Electronic Control

The electronic control system consists of the Transmission Control Module {TCM), sensors, and 4 solenoid valves. Shift-

ing and lock-up are electronically controlled for comfortable driving under all conditions.

The TCM is located below the dashboard, behind the left side kick panel on the driver's side.

Hydraulic Control

The valve bodies include the main valve body, secondary valve body, regulator valve body. servo body, and lock-up valve

body throuqh the respective separator plates.

They are bolted on the torque converter housing.

The main valve body contains the manual valve, 1-2 shift valve, 2-3 shift valve, Clutch Pressure Cont.ol (CPC) valve,

4th exhaust valve, relief valve, and oil pump gears.

The secondary valve body contains the 4-3 kick-down valve,3-2 kick-down valve,2-3 orifice cont.ol valve, 3-4 shitt

valve, orifice control valve. modulator valve, and servo control valve

The regulator valve body contains the pressure regulator valve. lock-up control valve, torque converter check valve, and

cooler check valve.

The servo bodv contains the servo valve which is integrated with the reverse shift fork, throttle valve B, and accumulators.

The lock-ug valve bodv contains the lock-up shift valve and lock-up timing B valve. and is bolted on the secondary valve

body.

Fluid from the regulator passes through the manual valve to the various control valves.

Shitt Control Mochanism

Input to the TCM i.om various sensors located throughout the car determines which shift control solenoid valve should

be activated.

Activating a shift control solenoid valve changes modulator pressure, causing a shift valve to move. This pressurizes

a line to one of the clutches. engaging that clutch and its corresponding gear.

Lock-up Mechanism

In @ position. in 2nd, 3rd and 4th, and E position in 3rd, pressurized tluid can be drained from the back of the tor-

que converter through an oil passage, causing the lock-up piston to be held against the torque converter cover. As this

takes Dlace, the mainshaft rotates at the same speed as the engine crankshatt. Together with hydraulic control, the TCM

optimizes the timing ol the lock-up mechanism.

The lock-up valves control the range of lock-up according to lock-up control solenoid valves A and B, and throttle valve B

When lock-up control solenoid valves A and B activate, modulator pressure changes. Lock-up control solenoid valves

A and B are mounted on the torque converter housing, and are controlled by the TCM.

(cont'd)

14-3

Page 399 of 1413

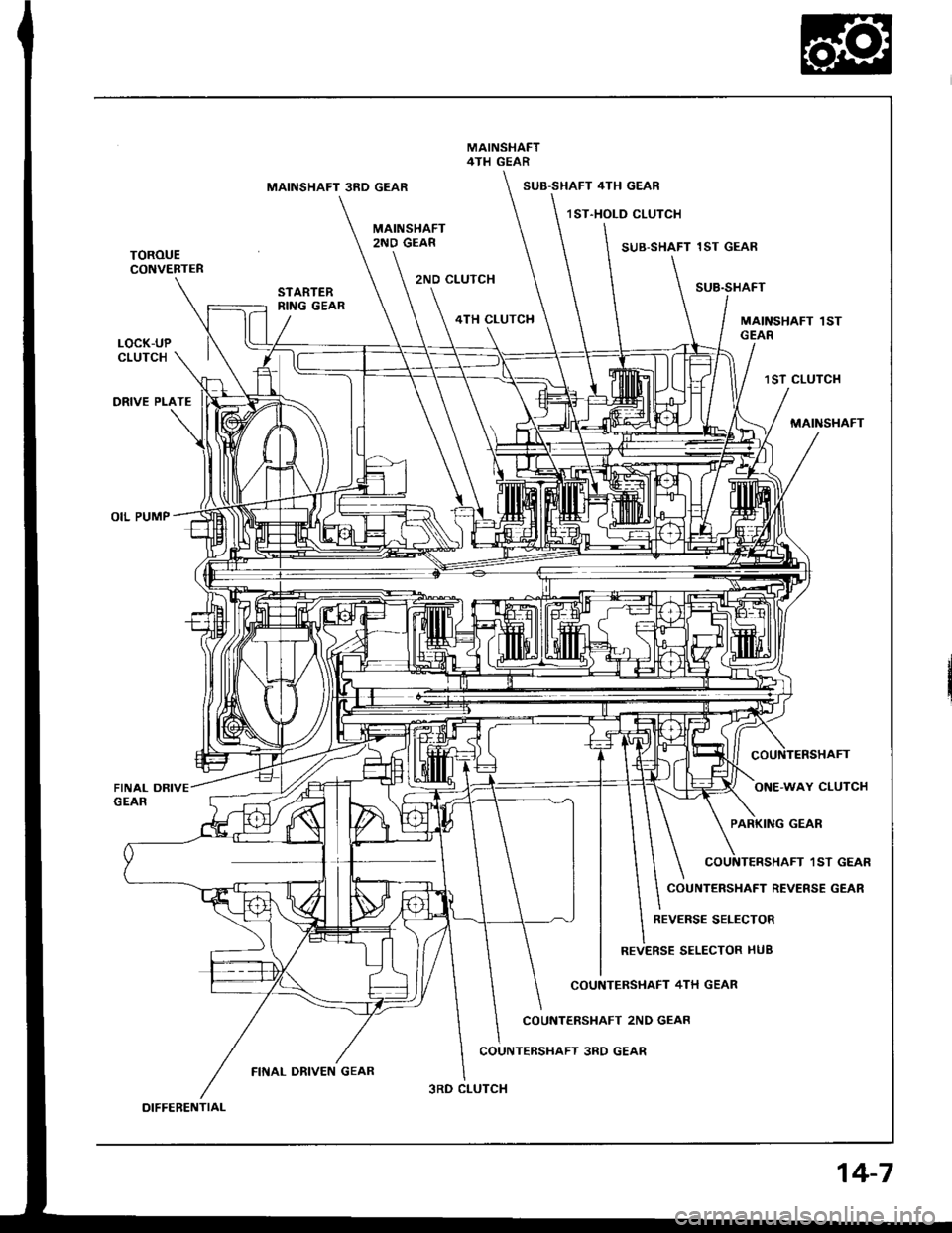

MAINSHAFT4TH GEAR

MAINSHAFT 3RD GEARSUB.SHAFT 4TH GEAR

lST,HOLD CLUTCHMAINSHAFT2ND GEARTOROUECONVERTER

SUB-SHAFT 1ST GEAR

SUB.SHAFT2ND CLUTCHSTARTERNING GEAR

LOCK-UPCLUTCH

4TH CLUTCHMAINSHAFT 1STGEAR

DRIVE PLATE

1ST CLUTCH

MAINSHAFT

ONE-WAY CLUTCH

PARKING GEAR

,I ST GEAR

COUNTERSHAFT REVERSE GEAR

REVERSE SELECTOR

REVERSE SELECTOR HU8

COUNTERSHAFT 4TH GEAR

COUNTERSHAFT 2ND GEAR

COUNTERSHAFT 3RD GEAR

DIFFERENTIAL

FINAL DRIVEN GEAR

3RD CLUTCH

14-7

Page 491 of 1413

Transmission

Removal

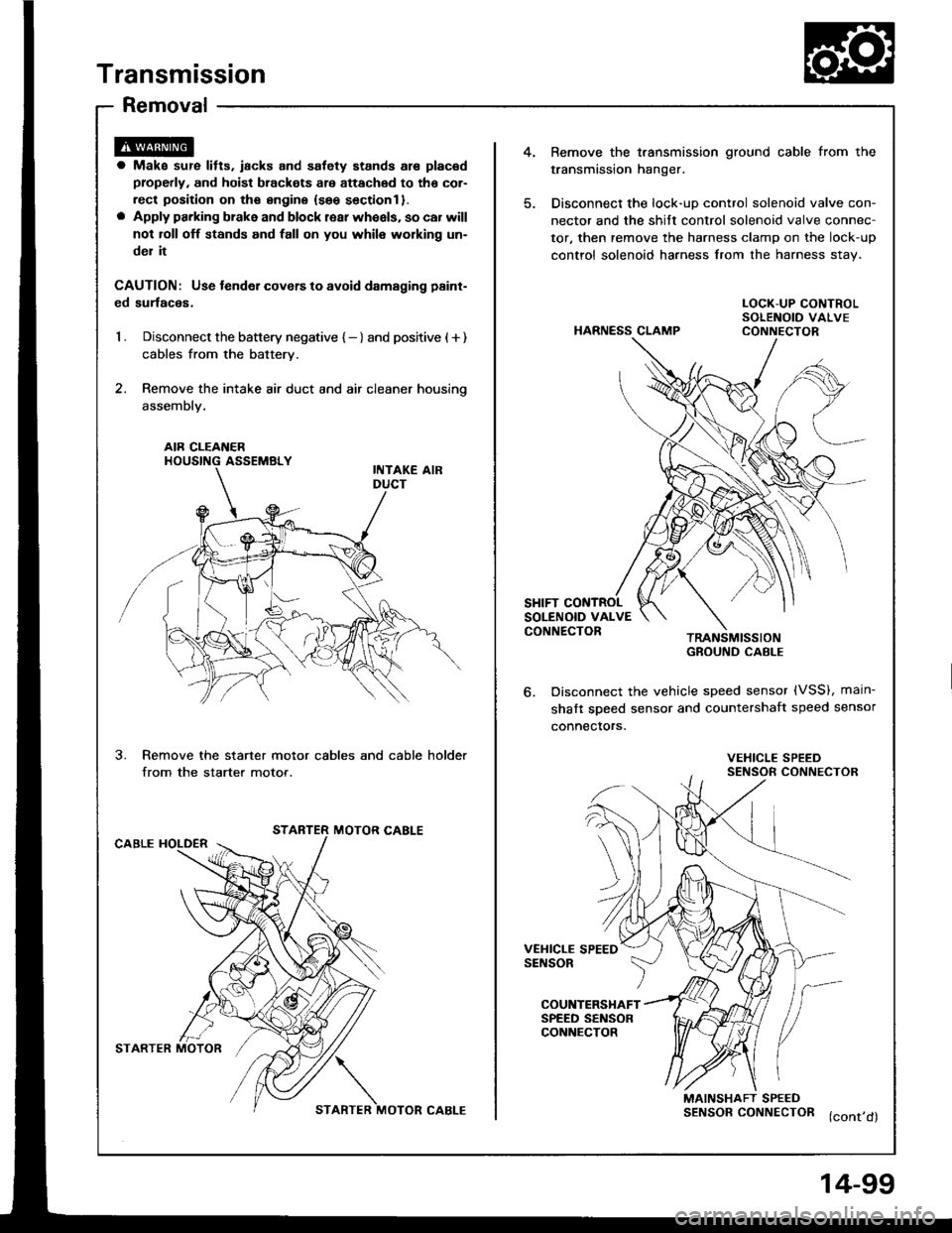

4.Bemove the t.ansmission ground cable from the

transmission hanger.

Disconnect the lock-uD control solenoid valve con-

nector and the shitt control solenoid valve connec-

tor, then remove the harness clamp on the lock-up

control solenoid harness from the harness stav.

a Make sur€ lifts. iacks and safety stands are placad

properly, and hoist brackots are attachod to tho cor-

rect position on ths sngine {seo sectionl }.o Apply parking brake and block rear wheels, so car will

not roll off stands and fall on you whil6 working un-

del it

CAUTION: Use tender covers to avoid damsging paint-

ed surlaces,

1 . Disconnect the battery negative { - } and positive ( + )

cables from the battery.

2. Remove the intake air duct and air cleaner housino

assembly.

HARNESS CLAMP

LOCK-UP CONTROLSOLENOID VALVECONNECTOR

AIR CLEAI{ERHOUSING ASSEMBLY

SHIFT CONTROLSOLENOID VALVECONNECTORTRANSMISSIONGROUND CABI-E

Disconnect the vehicle speed sensor (VSS), main-

shaft sDeed sensor and countershaft speed sensor

connectors.

3.Remove the starter motor cables and cable holder

from the starter motor.VEHICLE SPEEDSENSOR CONNECTOR

STARTER MOTOR CABLECABLE HOLDER

VEHICLE SPEEDSENSOR

COUNTERSHAFTSPEED SENSORCONNECTOR

MAINSHAFT SPEEDSENSORCONNECTOR (cont,d)

STARTER MOTOR?/\

STARTER MOTOR CABLE

4-99

Page 554 of 1413

Transmission

Installation

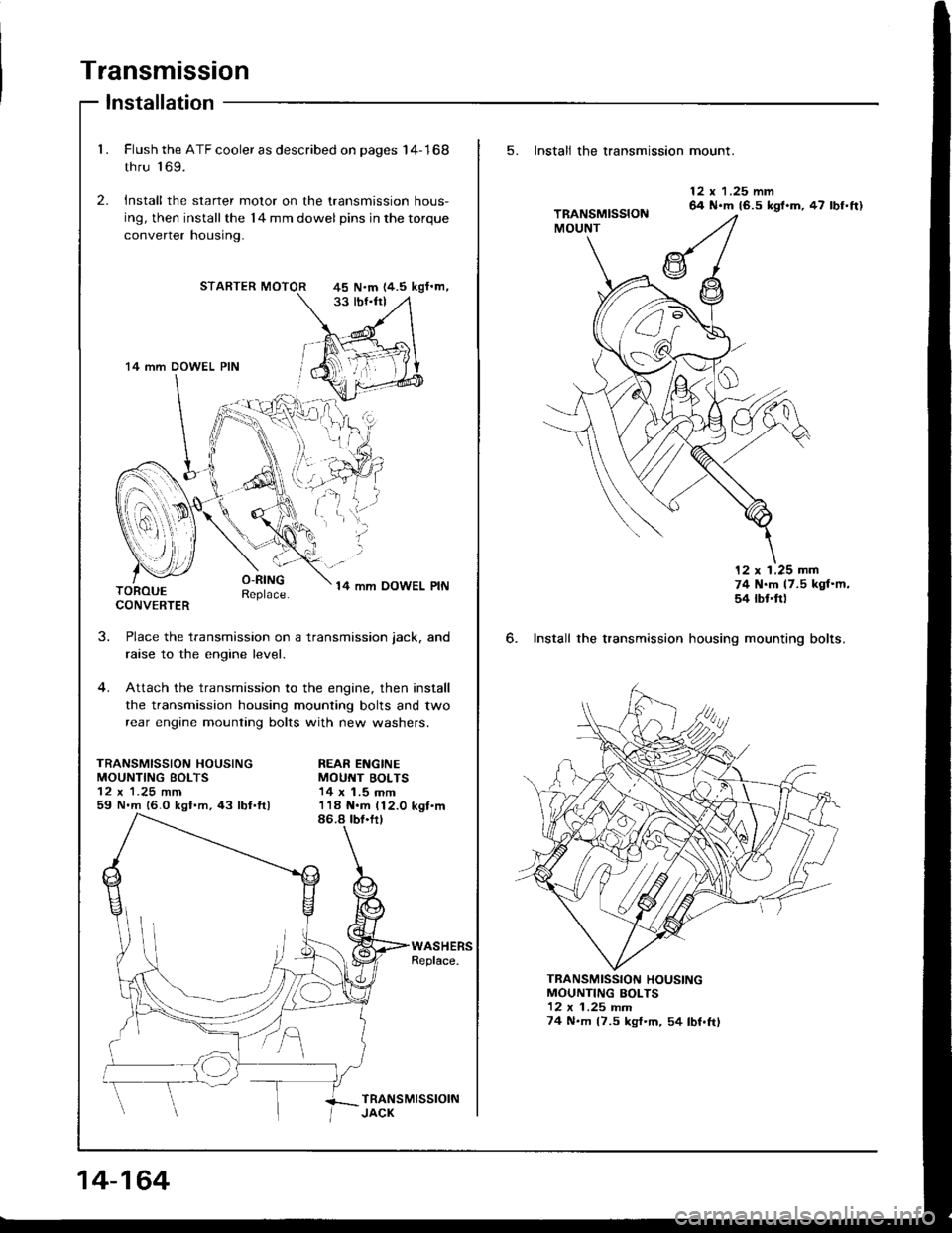

1. Flush the ATF cooler as described on pages I4-168

thru 'l 69.

2. Install the starter motor on the transmission hous-

ing, then installthe l4 mm dowel pins in the torque

converrer nousrng.

STARTER MOTOR

O-RINGReplace.14 mm OOWEL PINTOROUECONVERTER

J.

TRANSMISSION HOUSINGMOUNTING BOLTS

59 N.m 16.0 kgf.m,43 lbl.ftl

Place the transmission on a transmission jack, and

raise to the engine level.

Attach the transmission to the engine, then install

the transmission housing mounting bolts and two

rear engine mounting bolts with new washers.

REAR ENGINEMOUNT BOLTS14 x 1.5 mm

45 N.m 14.5 kgf'm,

'14 mm DOWEL PIN

I

i.'l,i;

14-164

5. Install the transmission mount.

6. Install the transmission

12 x 1.25 mm64 N.m 16.5 kgl.m, 47 lbf.ft)

12 x 1.25 mm74 N.m 17.5 kgf'm,54 rbt'ft)

housing mounting bolts.

MOUNTING BOLTS12 x 1 .25 rnm74 N.m (7.5 kgf'm, 54 lbf.ftl

TRANSMISSION HOUSING

Page 557 of 1413

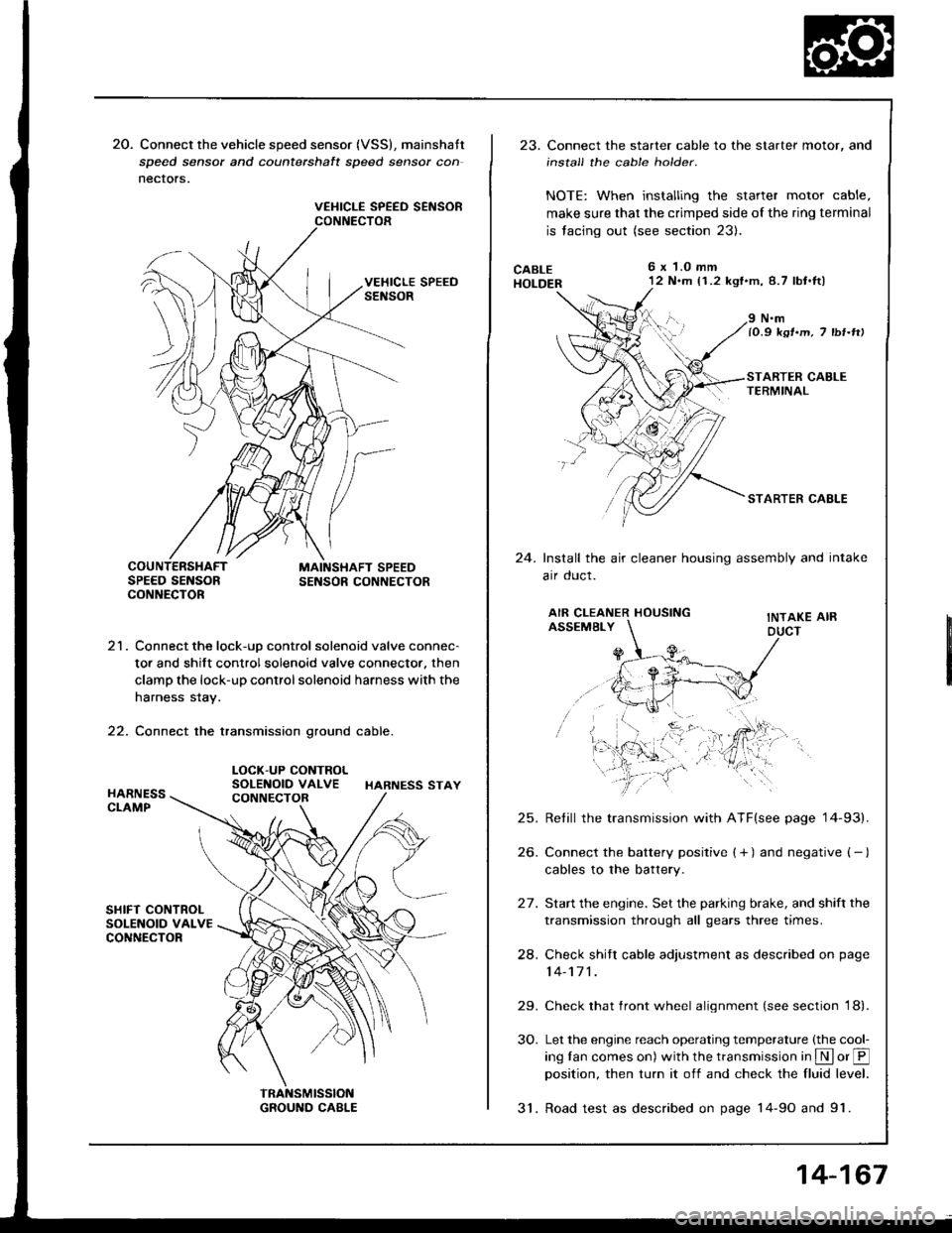

20. Connect the vehicle speed sensor (VSS), mainshatt

speed sensor and counterchalt speed sensor con

nectors.

VEHICLE SPEED SEiISORCONNECTOR

21. Connect the lock-uD control solenoid valve connec-

tor and shift control solenoid valve connector. then

clamp the lock-up control solenoid harness with the

harness stay.

22. Connect the transmission ground cable.

LOCK-UP CONTROLSOLENOID VALVE HARNESS STAY

23. Connect the starter cable to the starter motor, and

install the cable holder.

NOTE: When installing the starter motor cable,

make sure that the crimped side of the ring terminal

is facing out (see section 23).

CABLEHOLDER

6x 1.0 mm'12 N.m (1.2 kgf'm,8.7 lbt.tl)

24.

N.mlO.9 ksr.m, 7 tbr-rtt

STARTER CAELE

Install the air cleaner housing assembly and intake

arr oucl.

AIR CLEANER HOUSINGASSEMBLYINTAKE AIRDUCT

25.

26.

24.

29.

30.

Retill the transmission with ATF(see page '14-93).

Connect the battery positive ( + ) and negative ( - )

cables to the battery.

Start the engine. Set the parking brake, and shift the

transmission through all gears three times.

Check shitr cable adjustment as described on page

14-171 .

Check that front wheel alignment (see section 18).

Let the engine reach operating temperature (the cool-

ing tan comes on) with the transmission in S or @position, then turn it off and check the fluid level.

31. Road test as described on page 14-9o and 91.

14-167

Page 1114 of 1413

![HONDA INTEGRA 1994 4.G User Guide Relay and Control Unit Locations

Dashboard and Door

CRUISE CONTROL UNIT

PGM-FIMAIN RELAY

STARTER CUT RELAY IMIT)

I wir. colo]s: BLKMHT, BLU/BLK II BLKMHT ANd BLK/RED I

Wirs colors:WHT,GBN/BLK,GRN 6nd HONDA INTEGRA 1994 4.G User Guide Relay and Control Unit Locations

Dashboard and Door

CRUISE CONTROL UNIT

PGM-FIMAIN RELAY

STARTER CUT RELAY IMIT)

I wir. colo]s: BLKMHT, BLU/BLK II BLKMHT ANd BLK/RED I

Wirs colors:WHT,GBN/BLK,GRN 6nd](/img/13/6067/w960_6067-1113.png)

Relay and Control Unit Locations

Dashboard and Door

CRUISE CONTROL UNIT

PGM-FIMAIN RELAY

STARTER CUT RELAY IMIT)

I wir. colo]s: BLKMHT, BLU/BLK II BLKMHT ANd BLK/RED I

Wirs colors:WHT,GBN/BLK,GRN 6nd BLK

MOONROOF RELAYREAR wlNDOW DEFOGGERFELAY

I Wiro colo6: II BLKA'EL, BLK/GBN, I

I BLUffEL 8nd BLK^^THT I

POWER WINDOWRELAY

IIORN RELAY

J wi.o color3: WHT/GRN, BLx,l

I BLU/GBN, and BLU/RED I

INTEGRATEOCONTROL UNIT

TURN SIGI{AL/HAZARDRELAY UNDEB-OASHFUSE/RELAY 8OX

23-8

Page 1119 of 1413

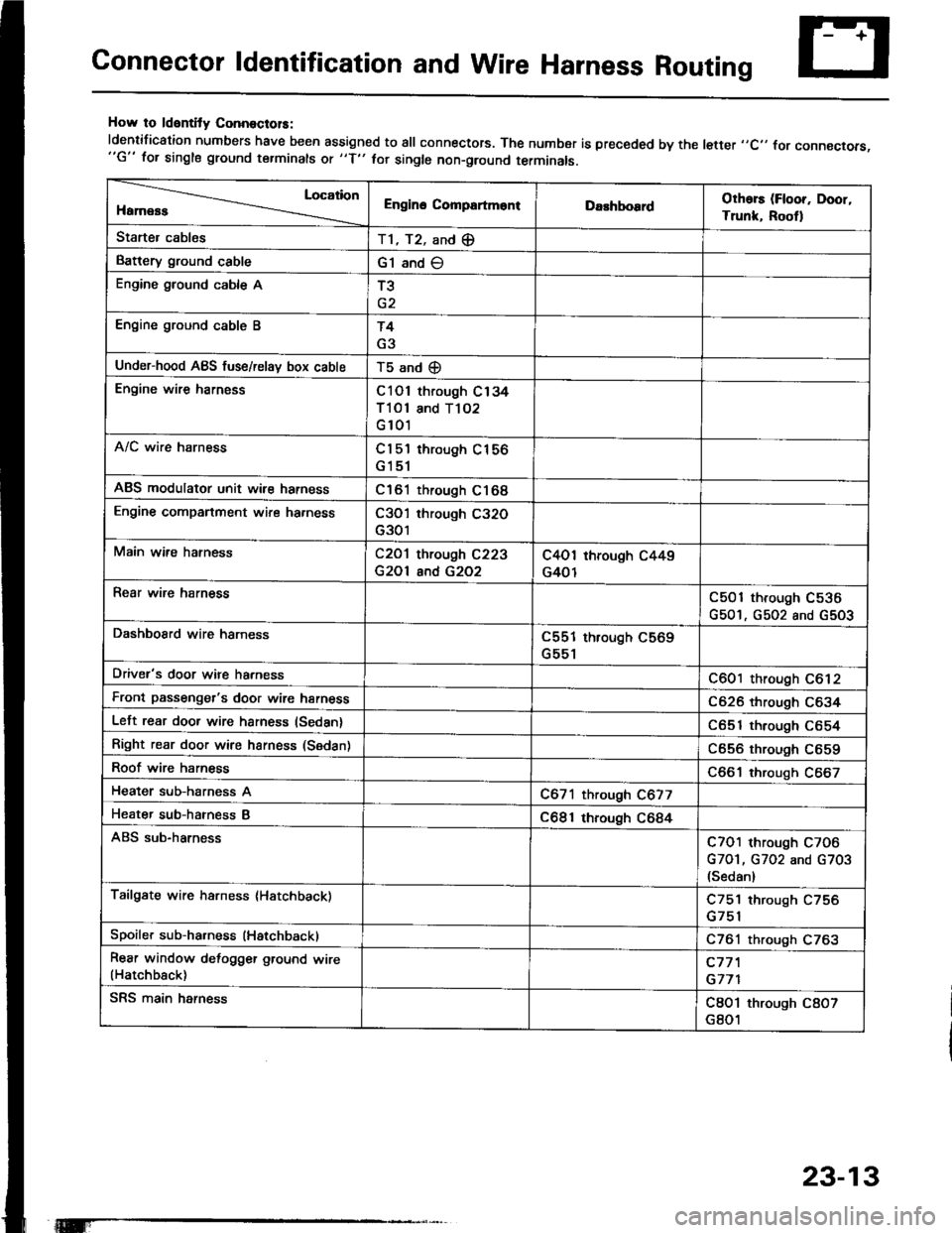

Connector ldentification and Wire Harness Routing

How to ldentity ConnoctolS:

ldentification numbers have been assigned to all connectors. The number is preceded by the letter ,,C,, for connecrors,"G" for single ground terminals ot "f" hr single non-ground terminals.

Location

HamessEngino CompartmontDarhboardOthors (Floor, Door,

Trunk, Rootl

Starter cablesT1, T2, and (E

Battery ground cableG1 and O

Engine ground cable AT3

Engine ground cable BT4

G3

Under-hood ABS fuse/relav box cableT5 and (D

Engine wire harnessC101 through C134

Tl Ol and T102

G 101

A/C wire harnessCl 5'l through C156

G151

ABS modulator unit wir€ harnessC161 through C168

Engine companment wire ha.nessC3O'l through C32O

G301

Main wire hatnessC2O1 through C223

G2Ol and G2O2

C4O1 through C449

G401

Rear wire harnessC501 through C536

G501, G502 and G5O3

DashboSrd wire harnessC551 through C569

G551

Driver's door wire harnessC601 through C612

Front passenger's door wire harnessC626 through C634

Left rear door wire harness (Sedan)C651 through C654

Right rear door wire harness (Sedan)C656 through C659

Roof wire harnessC661 through C667

Heater sub-harness AC671 through C677

Heater sub-hatness BC681 through C684

ABS sub-harnessC7O1 through C7O6

G7O1, G702 and G703(Sedan)

Tailgate wire harness (Hatchback)C751 through C756

Spoiler sub-ha.ness (Hatchback)C761 through C763

Rear window defogger ground wire(Hatchback)c77'l

G771

SRS main harnessC8O1 through C8O7

G801

23-13

Page 1120 of 1413

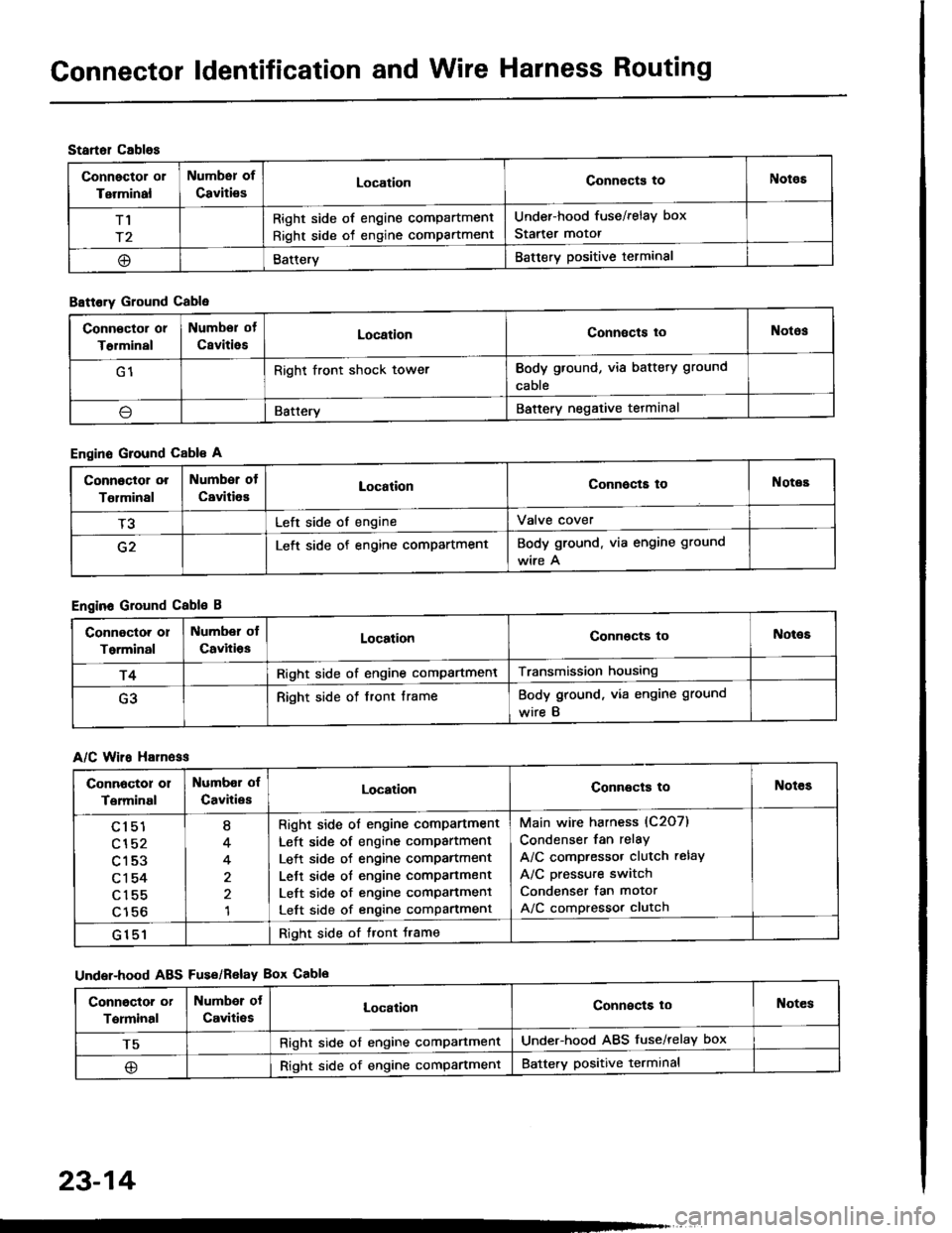

Gonnector ldentification and Wire Harness Routing

Startol cablos

Connector or

Terminal

Numbsr of

CavitiesLocationConnects toNotos

T1

r2

Right side of engine compartment

Right side of engine compartment

Under-hood fuse/relay box

Starter motor

@BatteryBattery positive terminal

B8ttory Ground Cable

Engine Ground Cable A

Engine Ground Cable B

A/C Wiro H81n6ss

Under-hood ABS Fus€/Relav Box Cablo

Conn€ctor or

T€rminal

Numbor of

CsvitiesLocationConnects toNotos

G1Right front shock towerBody ground, via battery ground

cable

\lBatteryBattery negative tetminal

Connoctor or

Tolminal

Number of

CavitiesLocationConnocta toNotes

T3Left side of engineValve cover

G2Left side of engine compartmentBody ground. via engine ground

wire A

Connoctor or

Torminal

Number ol

CavitiosLocationConnocts toNot€s

r4Right side of engine compartmentTransmission housing

G3Right side of front frameBody ground, via engine ground

wire B

Connoctor 01

Terminal

Numbor of

CavitiesLocationConnects toNotes

cl51

cl52

c153

c1 54

c155

c156

I

4

4

1

Right side ol engine comPartment

Left side of engine compartment

Left side of engine comPartment

Lett side ot engine compartment

Left side of engine comPanment

Left side of engine compartment

Main wire harness (C2O7)

Condenser fan relay

A/C compressor clutch relay

A/C pressure switch

Condenser fan motor

A/C compressor clutch

G151Right side of tront Jrame

Conngctor or

Terminal

Numbor ot

Caviti€sLocalionConnects loNotes

T5Right side of engine comPartmentUnder-hood ABS fuse/relay box

@Right side of engine compartmentBattery positive terminal

23-14