starter HONDA INTEGRA 1994 4.G Owner's Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 1187 of 1413

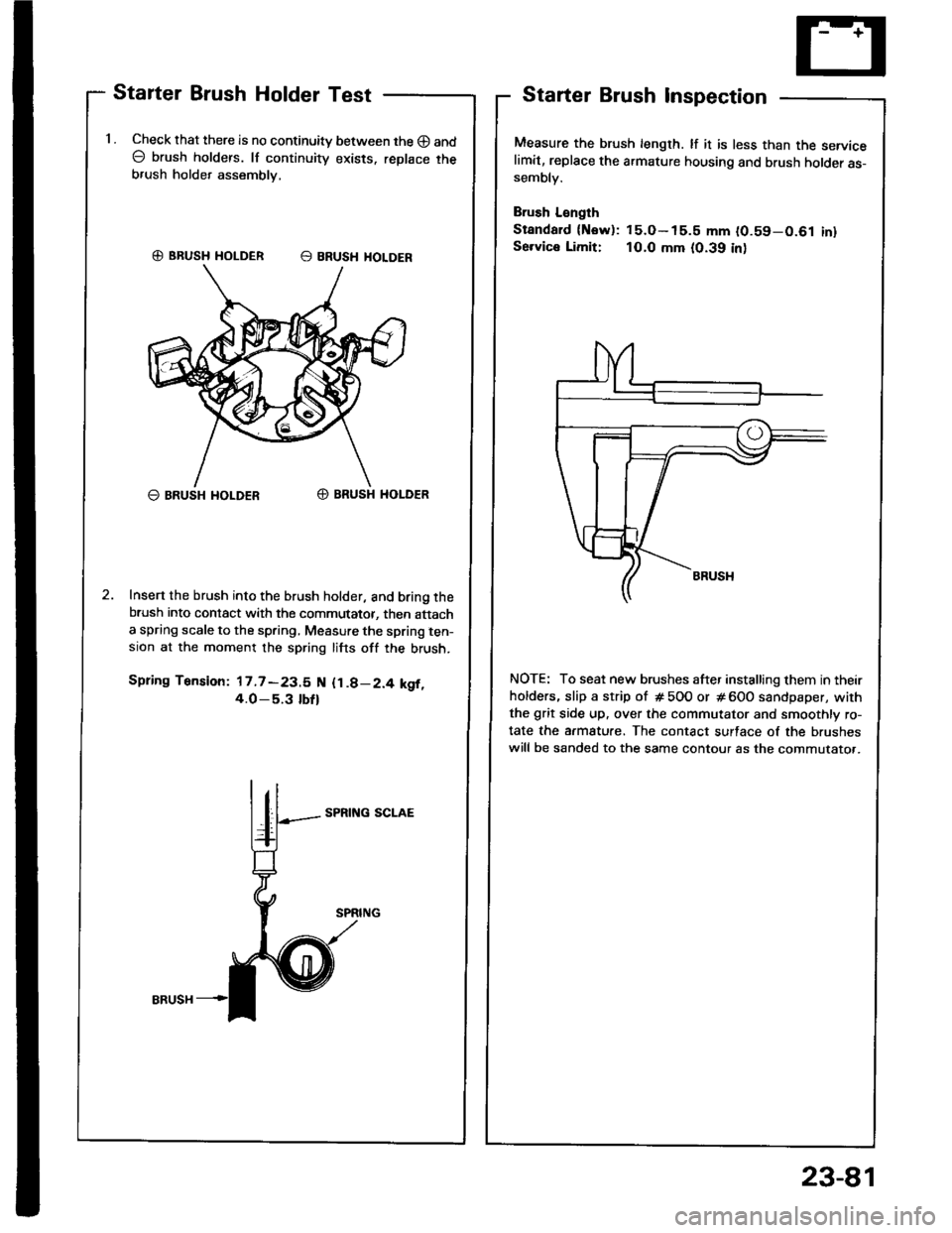

Starter Brush Holder Test

1 . Check that there is no continuity between the O and

O brush holders. lf continuity exists. replace theb,ush holder assembly,

G) BRUSH HOLDER E BRUSH HOLOER

O BRUSH I{OLDERO BRUSH HOLDER

Insert the brush into the brush holder, and bring thebrush into contact with the commutator, then attacha spring scale to the spring, Measure the spring ten-sion at the moment the spring lifts off the brush.

Spring Tension: 17.7 -23.5 N {1.8-2.4 kgf,4.O_5.3 tbfl

SPRING SCLAE

Starter Brush Inspection

Measure the brush length. lf it is less than the servicelimit, replace the armature housing and brush holder as-sembly.

Brush L€ngth

Standard {Now): 15.O- 15.5 mm (0.59-0.61 inlSe.vice Limit: 10.0 mm (0.39 inl

NOTE: To seat new brushes after installing them in their

holders, slip a strip of # 5OO or # 600 sandpaper, with

the grit side up. over the commutator and smoothly ro-

tate the armature. The contact surface of the brushes

will be sanded to the same contour as the commutato..

23-81

Page 1190 of 1413

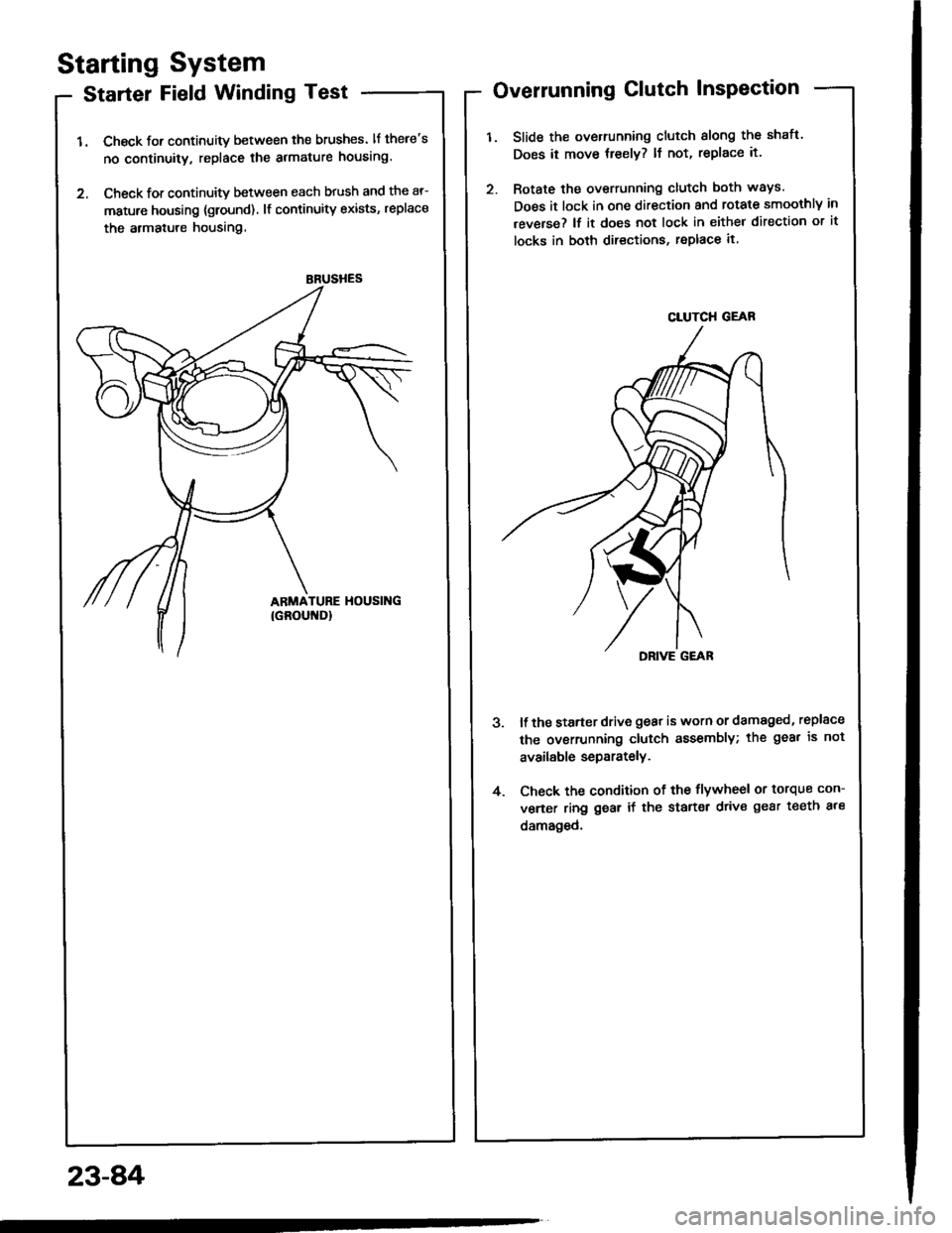

BRUSHES

Starting System

Starter Field Winding Test

1. Check for continuity between the brushes. lf there's

no continuity, replace the armature housing.

2. Check for continuity between each brush and the ar-

mature housing {ground) lf continuity exists, replace

the armatule housing.

Overrunning Clutch InsPection

Slide the overrunning clutch slong the shatt.

Does it move treely? ll not, replace it.

Rotate the overrunning clutch both ways.

Does it lock in one direction and rotate smoothly in

reverse? lf it does not lock in either direction or it

locks in both directions, replace it.

DRIVE G€AR

ll the starter drive gear is worn or damaged, replsce

the ovsrrunning clutch assembly; the gea. is not

available separately.

Check the condition of the flywheel or torque con-

verter ring gear if the starter drive gear teeth ale

damaged.

4.

23-8,4

CLUTCH GEAR

Page 1191 of 1413

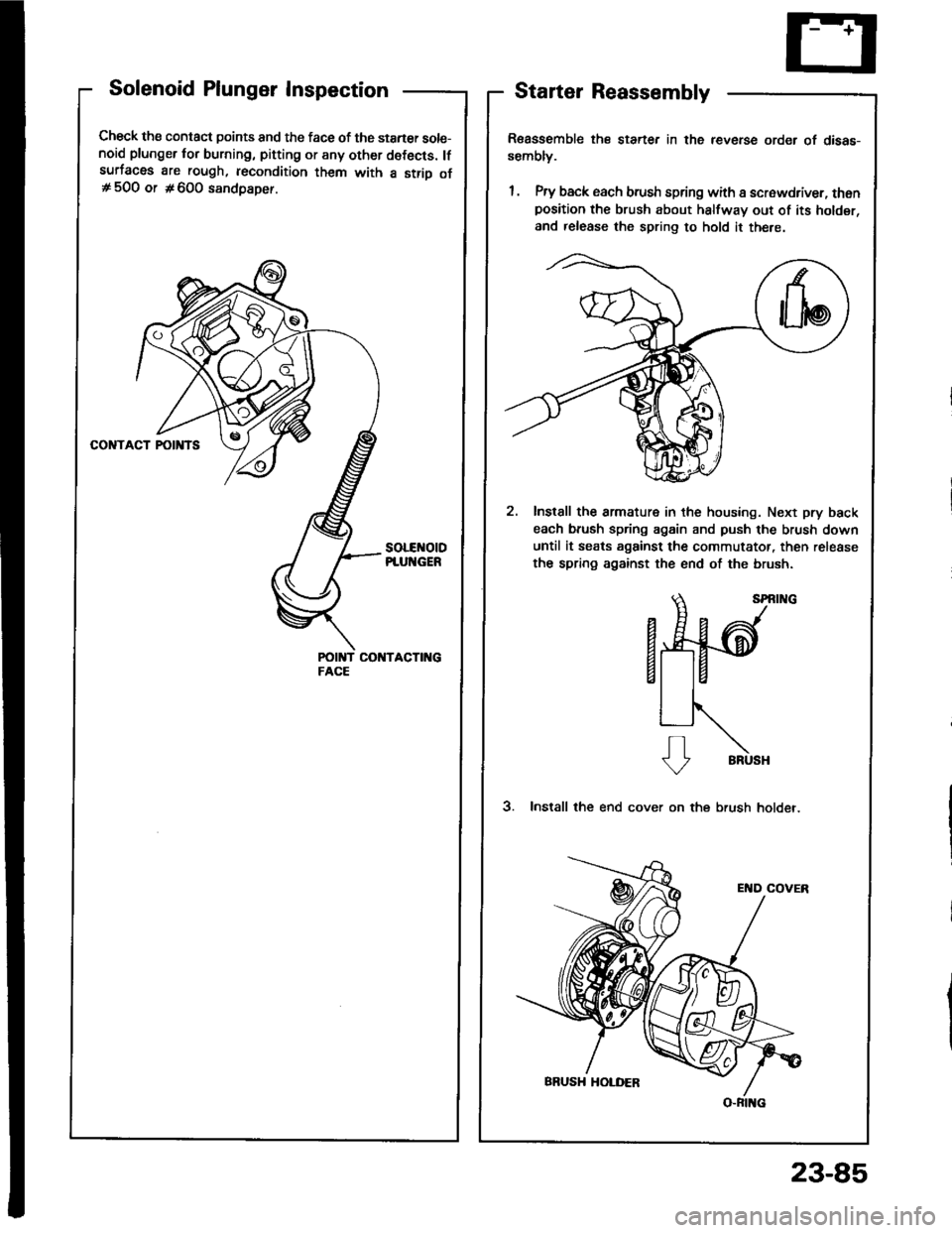

Solenoid Plunger Inspection

Check the contact points and the face of the staner sole-noid plunger for burning, pitting or any other defects. lfsurfacas are rough, recondition them with a strio of# 500 or #600 sandpaper.

soLEr{otDPIUNGER

Starter Reassembly

R€assemble the starter in the reverse order of disas-sembly.

1. Pry back each brush spring with a screwdriver, thonposition the brush about halfway out of its holder,

and release the spring to hold it there.

2. Instsll the armature in the housing. Next pry back

each brush spring again and push the brush down

until it seats against the commutator, then release

the spring against the end of the brush.

a&T&'

s..

V BRUSH

3. Install the end cover on the brush holder.

23-85

Page 1192 of 1413

Starting System

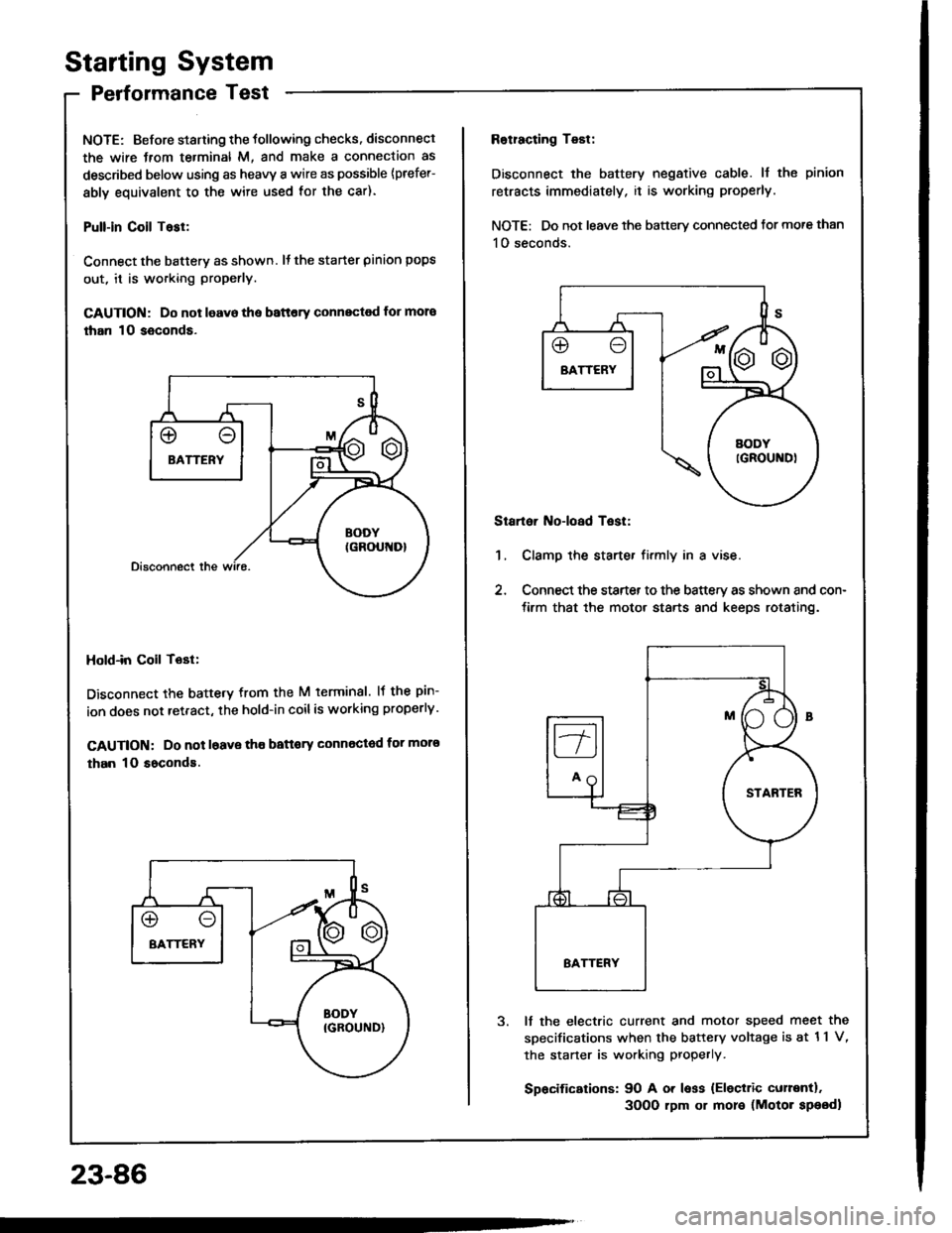

Performance Test

NOTE: Before staning the tollowing checks. disconnect

the wire Jrom te.minal M, and make a connection as

described below using as heavy a wire as possible {prefer-

ably equivalent to the wire used for the car).

Pull-in Coil Tasl:

Connect the batterv as shown. It the starter pinion pops

out, it is working properly.

GAUTION: Do not leavo the battery connectod for mora

than 10 seconds.

Hold-in Coil Tost:

Disconnect the battetv from the M terminal. lf the pin-

ion does not retract, the hold-in coilis working properly.

CAUTION: Do not l6ave tho battory Gonnected for moro

than 10 soconds.

23-86

Rotracting Test:

Disconnect the battery negative cable. ll the pinion

retracts immediately, it is working properly.

NOTE: Do not leave the battery connected tor more than

1O seconds.

Startoi Noioad Test:

1, Clamp the starte. firmly in a vise.

2, Connect the starter to the battery as shown and con-

tirm that the motor starts 8nd keeps rotating.

It the electric current and motor speed meet the

sDecifications when the battery voltage is at 11 V,

the staner is working properly.

Spacifications: 90 A or less {Eleciric curentl.

3OO0 rpm or more (Motor speodl

Page 1255 of 1413

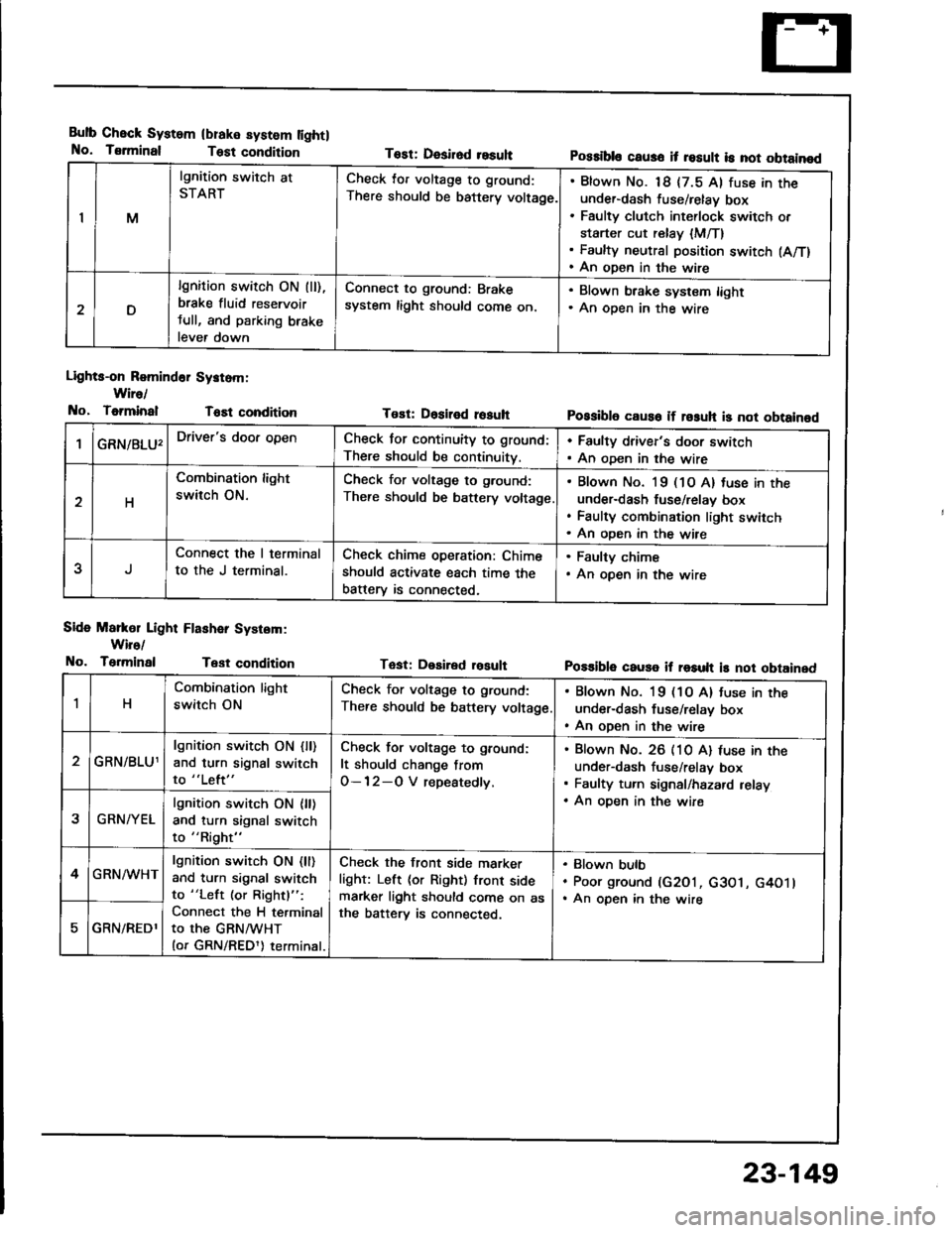

Bulb Check System

No. Tsrminal

(blake system lightl

Test condition

Lights-on Romind6r Systom:

Wire/

No, ToiminalT6Et condition

Side Markol Light Flashar System:

Wiro/

No. TerminalTest condition

Tost: Desirod resuhPossibls caus6 it result is not obtainod

Tost: Dositod rosuhPossibl6 caus6 if rosuh is not obtainod

Tast: Desired rosultPo$ible cause if result is not obtained

IM

lgnition switch at

STARTCheck lor voltage to ground:

There should be battery voltage.

Blown No. 18 {7.5 Al fuse in theunder-dash fuse/relay box

Faulty clutch int€rlock switch or

starter cut relay {M/T}Faulty neutral position switch (A/T)

An open in the wire

D

lgnition switch ON (ll),

brake fluid reservoir

tull, and parking brake

lever down

Connect to ground: Brake

system light should come on.

. Blown brake system light. An oDen in the wire

GRN/8LU'Driver's door openCheck for continuity to ground:

There should be continuity.

. Faulty driver's door switch. An oDen in the wire

H

Combination light

switch ON.

Check for voltage to g.ound:

There should be battery voltage

Blown No. l9 (1O A) tuse in the

under-dash fuse/relav box

Faulty combination light switch

An oDen in the wire

5

Connect the I terminal

to the J terminal.

Check chime operation: Chime

should activate each time the

batterv is connected,

. Faulty chime. An open in the wire

1H

Combination light

switch ON

Check for voltage to ground:

There should be battery voltage

. Blown No. 19 (1O A) tuse in the

under-dash fuse/relay box. An open in the wire

GRN/BLU1

lgnition switch ON {ll)and turn signal switch

to "Left"

Check for voltage to ground:

It should change from

O-12-O V repeatedly.

Blown No. 26 (10 A) luse in theunder-dash fuse/relav box

Faulty turn signal/hazard relay

An oDen in the wire2GRN/YEL

lgnition switch ON {ll)and turn signal switch

to "Right"

4GRN/WHTlgnition switch ON (ll)

and turn signal switch

to "Left (or Rightl":

Connect the H terminal

to the GRNMHT(or GRN/REDl) terminal.

Check the front side marker

light: Left (or Right) front sidemarker light should come on asthe batterv is connected.

Blown bulb

Poor ground (G2O1, c3O1, G4O1lAn open in the wire

GRN/REDl

23-149