air condition HONDA INTEGRA 1994 4.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 629 of 1413

lnspection and Adjustment

Pump Pressure Check

Check the fluid pressure as follows to determine

whether the trouble is in the pump or gearbox.

NOTE: First check the power steering fluid level and

pump belt tension,

CAUnON: Dilconn€st the high pros3uro ho3s with cale

!o e3 not to spill tho powor stooring fluid on th6 lramo

lnd olhor parG.

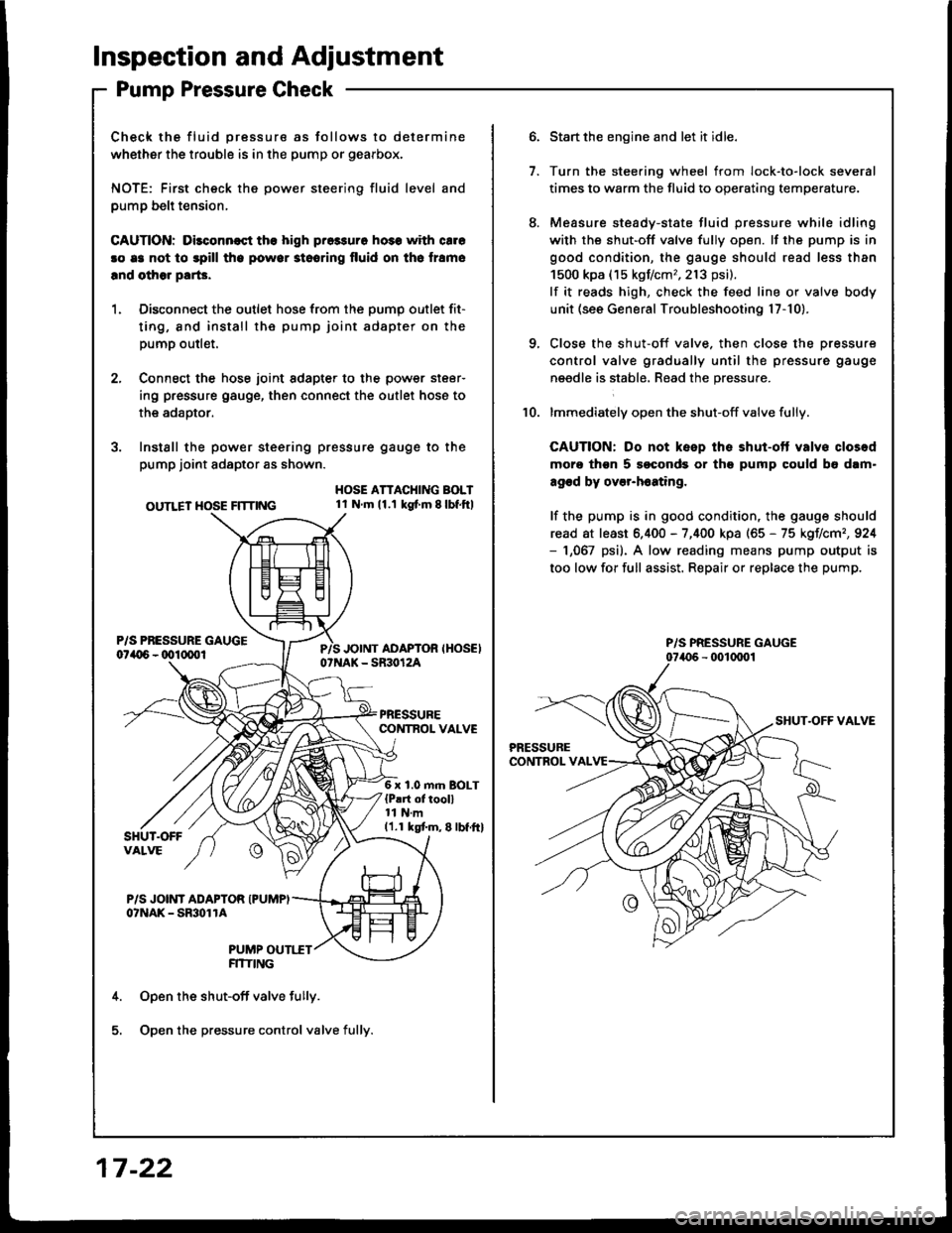

1. Disconnect the outlet hose from the oumo outlet fit-

ting, 8nd install the pump joint adapter on the

pump outlet.

2, Connect the hose joint sdapter to the power steer-

ing pressure gauge, then connect the outlet hose to

the adaotor.

3. Instsll the power steering pressure gauge to the

pump joint adaptor as shown.

OUTLET HOSE FlTnNG

HOSE ATTACHING BOLT1l Nm11.1 kg{ m 8lbf.ftl

6 x 1.0 m.n BOLT{P!rt of tooll11 N.m11.1 kgtm,8lbf.ftl

P/S JOINT ADAPTOR IPUMPIo?NAK - SmolrA

PUMP OUTI.TTFITIING

Open the shut-off valve fully.

Open the pressure control valve fully.

17 -22

1.

Start the engine and let it idle.

Turn the stee.ing wheel from lock-to-lock several

times to warm the fluid to operating temperature.

Measure steady-state fluid pressure while idling

with the shut-off valve fully open. lf the pump is in

good condition, the gauge should read less than

1500 kpa (15 kgf/cm,,213 psi).

lf it reads high, check the feed line or valve body

unit (see General Troubleshooting l7-10).

Close the shut-off valve. then close the pressure

control valve gradually until the pressure gauge

needle is stabl6, Read the pressure.

lmmediately open the shut-off valve fully.

CAUTION: Do not keep the shut-ott valvs closod

moro thgn 5 soconds or th9 pump could b6 dam"

agod by over-h6ating,

lf the pump is in good condition, the gauge should

read at least 6.400 - 7,400 kpa (65 - 75 kgIlcm,,924- 1,067 psi). A low reading means pump output is

too low for full assist. Repair or replace the pump.

10.

P/S PRESSURE GAUGE

Page 1037 of 1413

Heater and Air Conditioning

Heater ........ 21-1

Air Conditioning .......... ..22-1

SUPPLEMENTAL RESTRAINT SYSTEM {SRS}

The Integra SRS includes a driver's airbag, located in the steering wheel hub. In addition. all models except the

RS model for Canada have a front passenge.'s airbag located in the dashboard above the glovs box. Information

necessary to safely service the SRS is included in this Service Manual. ltems msrk€d with an asterisk (') on the

conlents page include, or are located near, SRS components. Servicing, disassembling or,eplacing thes€ items

will require special precautions and tools, and should therefore be done by an authorized Acura dealer.

a To avoid r6nd6dng tho SRS inoporativo. which could lead to personal injury or dealh in tho svont ot a sevele

frontal collision, all SRS servica work musl b€ portormed by an authorized Acura dealer.

a lmpropor sorvico procaduro3, including incorrect romoval and installatlon of tho SRS, could load to porsonal iniu-

ry causod by uninlonlional activation of tho ailbag8.

a All SRS eloctdcal widng harnossos are covored with yollow in3ulation. Relatsd compononts a.o locatod in tha

stsering column, flont console, daehboard, and dashboafd low6r pan6l, and in lhe dsshboa.d above lh€ glove

box. Do not uao electdcal tost equipmont on theae circuhs.

NOTE: The original radio has a coded theft protection circuit. Be sure to get the customer's code number beto.e

- disconnecting the battery.- removing the No. 32 (7.5 A) luse from the under-hood fuse/relay box.- removing the radio.

After service, reconnect power to the radio and turn it on. When the word "CODE" is displayed, enter the cus-

tomer's 5-digit code to restore radio operation.

Page 1045 of 1413

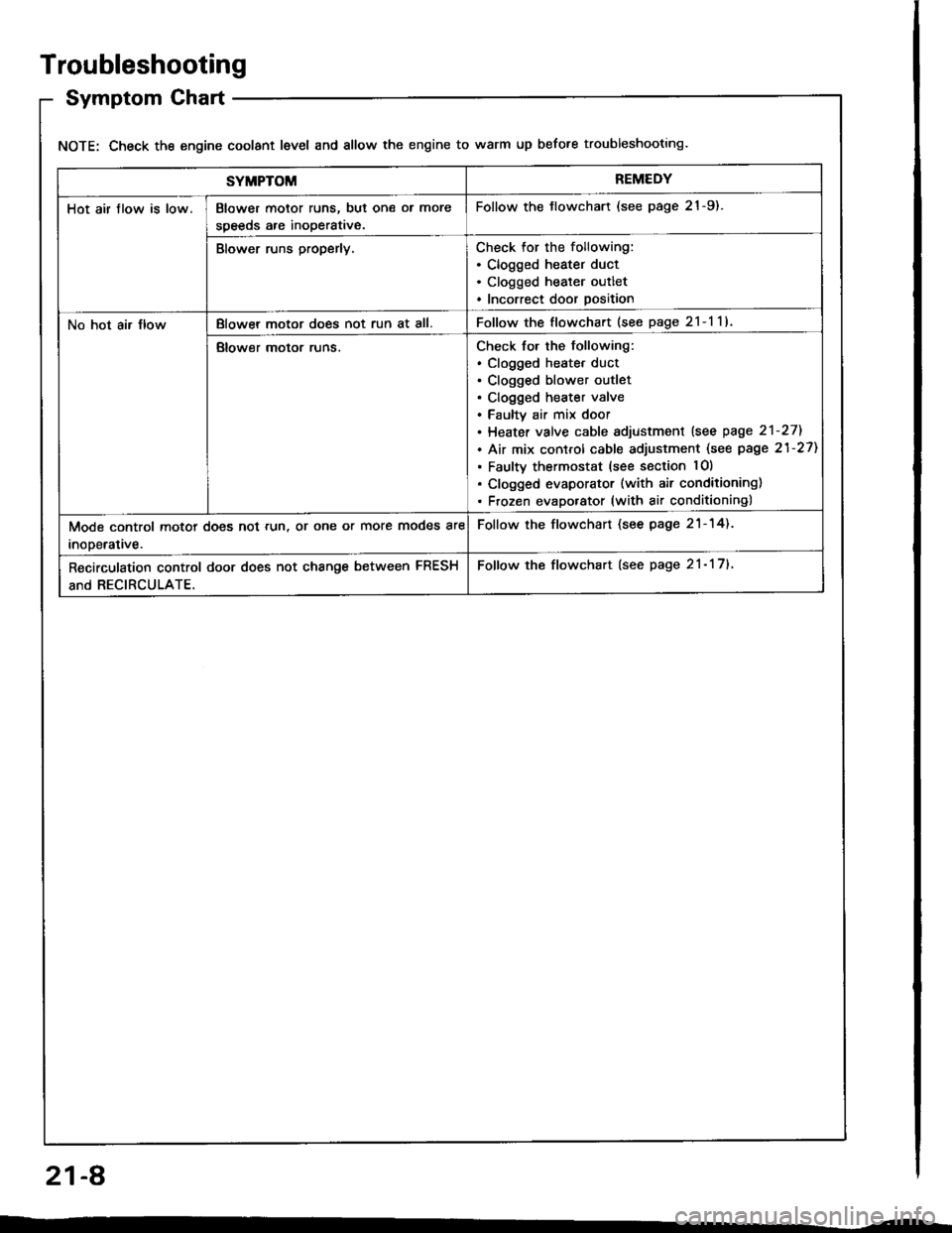

Troubleshooting

Symptom Chart

NOTE: Check the engine coolant level and allow the engine to warm up before troubleshooting.

SYMPTOMREMEDY

Hot air flow is low.Blower motor runs, but one ol more

speeds are inoperative.

Follow the tlowchart (see page 21-9).

Blower runs properly.Check for the following:. Clogged heater duct. Clogged heater outlet. Incorrect door position

No hot air JlowBlowel motor does not run at all.Follow the flowchart (see page 2l-l1l

Blower motor runs.Check for the following:. clogged heatet duct. Clogged blower outlet. Clogged heater valve. Faultv air mix door. Heater valve cable sdjustment lsee page 2'l-271

. Air mix control cable adjustment (see page 21-27)

. Faulty thermostat (see section lO)

. Clogged evaporator (with air conditioning). Frozen evaporator (with air conditioning)

Mode control motor does not run, or one or more modes are

inooerative.

Follow the flowchart (see page 21-14).

Recirculation control door does not change between FRESH

and RECIRCULATE.

Follow the flowchart (see page 21- 17).

21-A

Page 1057 of 1413

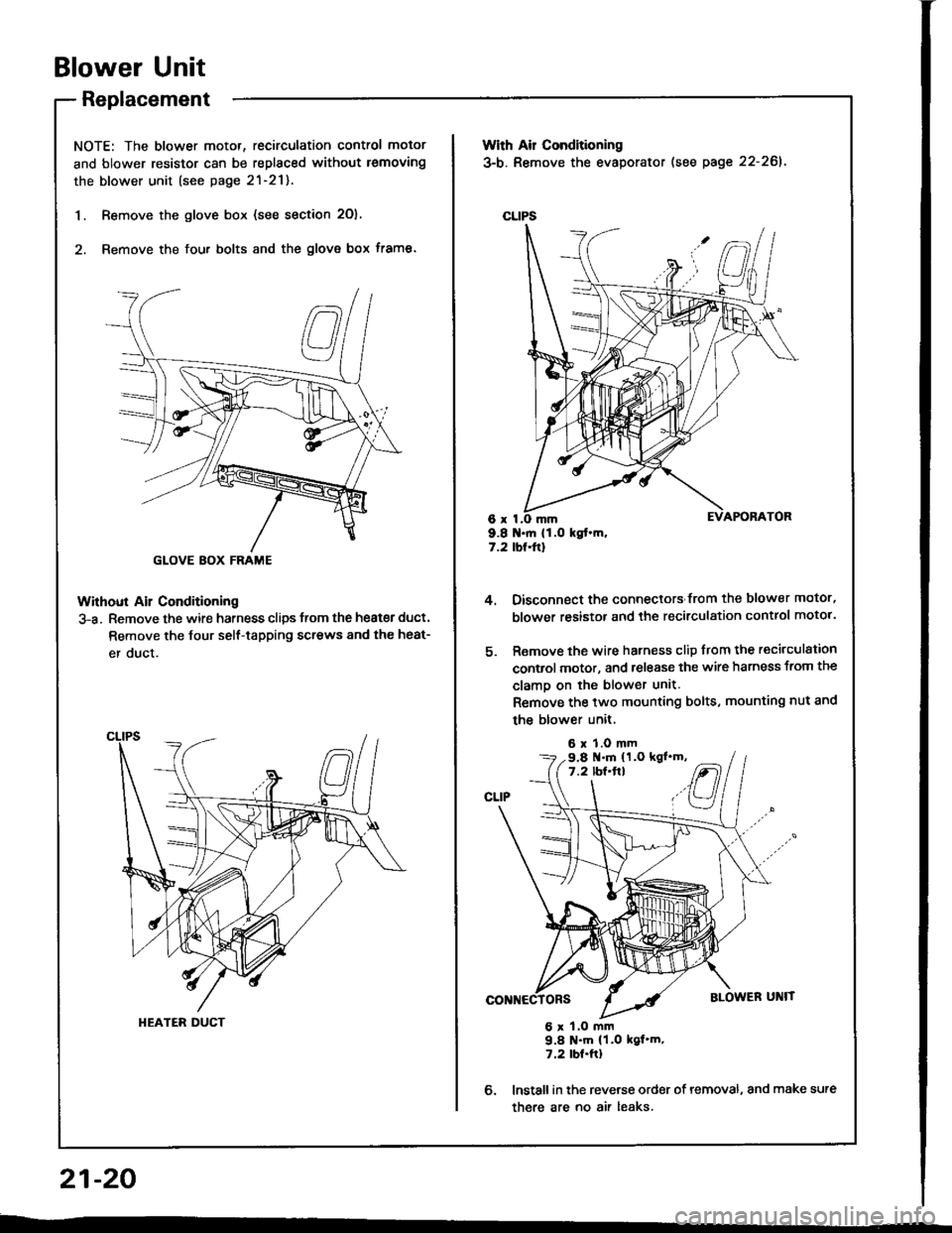

Blower Unit

Replacement

NOTE: The blower motor, recirculation control motor

and blower resistor can be replaced without lemoving

the blower unit (see page 2l-21).

1. Remove the glove box (see section 2O),

2. Remove the fou. bolts and the glove box frame.

Without Ail Conditioning

3-a. Remove the wire harness clips trom the heat€r duct.

Remove the Jour self-tapping screws 8nd the heat-

er duct.

GLOVE BOX FRAME

HEATER DUCT

With Air Conditioning

3-b. Remove the evaporator (see page 22-261.

CLIPS

6x I9.8 .ft 11.O kgt.m,7.2 tbt.ftl

4.

6.

Oisconnect the connectors from the blower motor,

blower resistor and the recirculation control motor.

Remove the wire harness clip from the recirculation

control motor, and release the wire harness from the

clamo on the blower unit.

Remove the two mounting bolts, mounting nut and

the blower unit,

6 x 1.0 mm

6 x 1.O mm9.8 N'm (1.0 kgf'm.7.2 tbt.ftl

lnstall in the reverse order of removal, and make sure

there are no air leaks.

9.8 .m (1.O kgl'm,7.2 lbf'ft}

21-20

--

Page 1069 of 1413

Air Conditioning

*Evaporator

Repf acement .........22-26

Overhauf ................ 22-27

Compressor

Description ............ 22-28

fffustrated fndex ............................... 22-29

Replacement .........22-30

Cf utch lnspection ....................... ...... 22-32

Cf utch Overhaul ............................... 22-33

Ref ief Vaf ve Replacement ............... 22-34

A/C Compressor Belt

Repf acement .........22-35

Adiustment ............22-36

Condenser

Replacement ......... 22-37

A/C System Service

Evacuation ....,.......,22-38

Charging ................ 22-39

Leak Test ...............22-40

+: Read SRS precautions before working in

this area.

Page 1071 of 1413

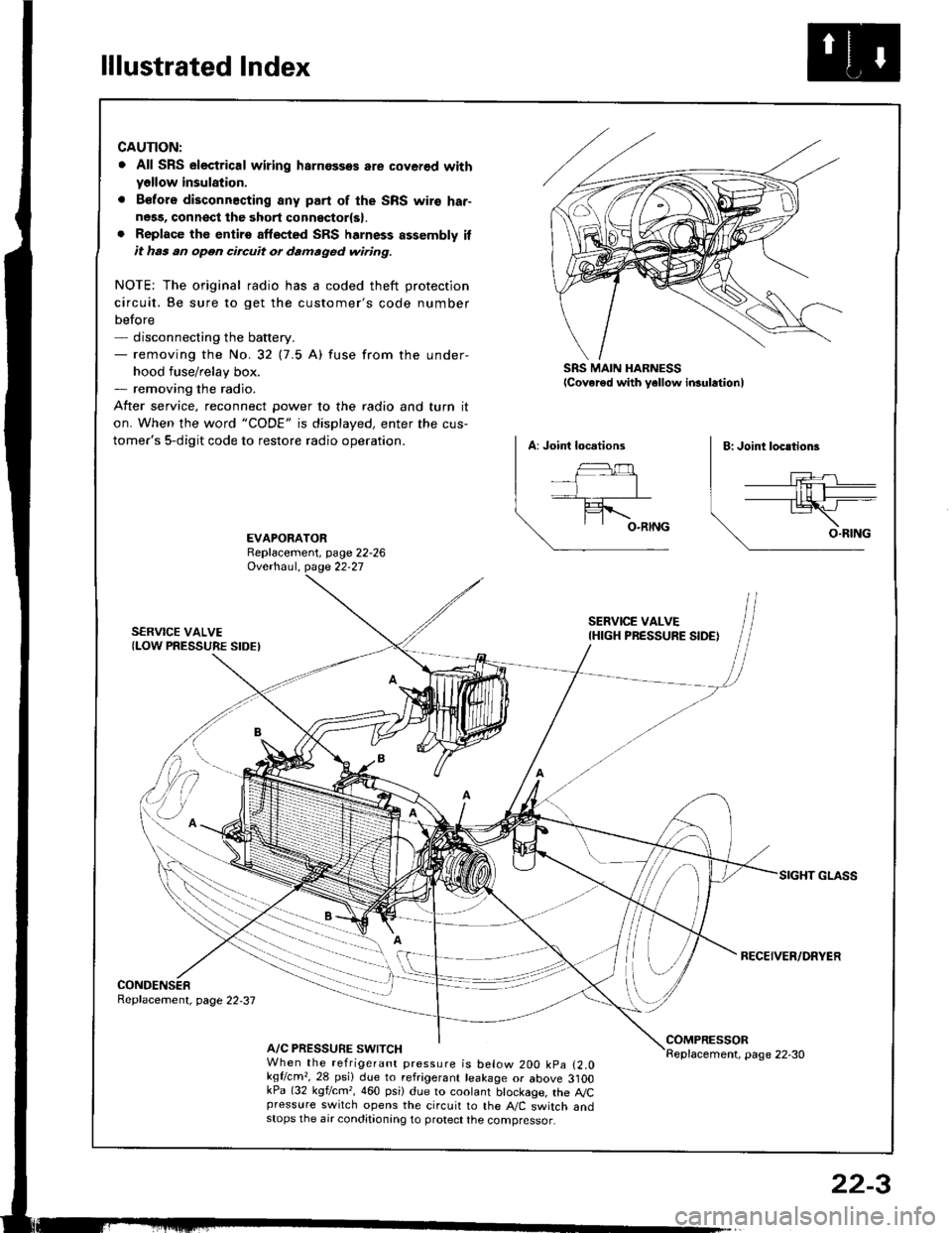

lllustrated Index

CAUTION:

. All SRS electrical wiring harnossos are cover€d withyellow insulation.

. B€fors disconnacting any part of the SRS wire har-ness, connsct the 3hort connsctor(s).. Replace the entirs affscted SRS harness assembly itit has an open circuit or damaged wiring.

NOTE; The original radio has a coded theft protection

circuit. Be sure to get the customer's code number

before- disconnecting the battery.- removing the No.32 (7.5 A) fuse from the under-

hood fuse/relay box.- removing the radio.

After service, reconnect Dower to the radio and turn it

on. When the word "CODE" is displayed, enter the cus-

tomer's 5-digit code to restore radio operation.

SRS MAIN HARNESSlcover€d with yellow insulationl

EVAPORATORReplacement, page 22-26Ovethaul. Oase 22.27

SERVICE VALVE(LOW PRESSURE SIDEI

SERVICE VALVEIHIGH PRESSURE SIDE)

RECEIVER/DRYER

CONDENSERReplacement, page 22,37

A/C PRESSURE SWITCHCOMPRESSORReplacement, page 22-30When the refrigerant pressure is below 200 kpa (2.0kqflcm,,28 psi) due to refrigerant leakage or above 3]OOkPa (32 kgf/cm,, 460 psi) due to coolant btockage, the A,/Cpressure switch opens the circuit to the A"/C switch andstops the air conditionang to protect the compressor.

22-3

Page 1074 of 1413

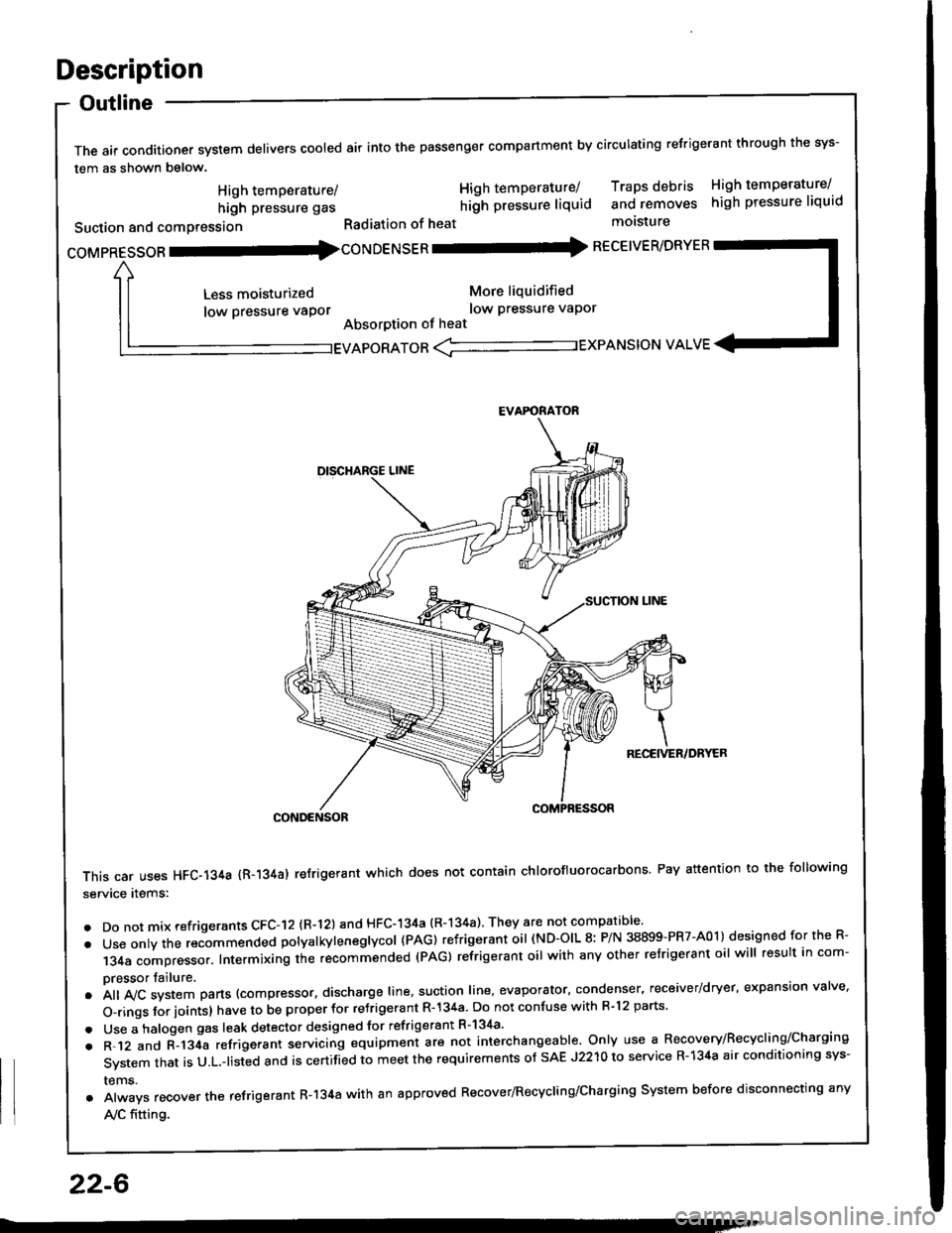

Description

Outline

The air conditioner system delivers cooled air into the passenger compartment by circulating refrigerant through the sys-

tem as shown below.

CONDENSOR

This car uses HFC-134a {R-134a) refrigerant which does not contain chlorofluorocarbons Pay attention to the following

service items:

. Do not mix refrigerants CFC-I2 (R-l21 and HFC-134a (R-134a) They are not compatible'

. Use onty the recommended potyatkytenegtycol {PAG) refrigerant oil (ND-OIL 8: P/N 38899-PR7-A01) designed for the R-

134a compressor. Intermixing the recommended (PAG) refrigerant oil with any other refrigerant oil will result in com-

pressor tailure.

.A||lvcsystemparts(compressor.dischargeIine,suotionIine,evaporator,condenser.receiver/dryer,expansionva|ve.

o-ringsforioints}havetobeproperforre'rigerantR-l34a.DonotconfusewithR.l2parts.

. Use a halogen gas leak detector designed for refrigerant R-134a'

. R-.12 and C-l34a refrigerant servicing equipment are not interchangeable. Only use a Recovery/Recyclins/Charging

System that is U.L.-listed and is certifLd to meet the requirements of sAE J2210 to service R-134a air conditioning sys-

rems.

. Always recover the refrigerant R-134a with an approved Recover/Recycling/Charging System before disconnecting any

A,/C fitting.

coMpRESsoR -coNDENSER - RECEIVER/DRYER

High temperature/

high pressure gas

Suction and comPression

Less moisturized

low pressure vaPor

High temperature/ Traps debris High temperature/

hilh pressure liquid and removes high pressure liquid

Radiation of heat molsture

More liquidified

low Pressure vaPor

Absorption of heat

EVAPORATOR <-'----------.- EXPANSION VALVE

EVAFORATOR

22-6

Page 1089 of 1413

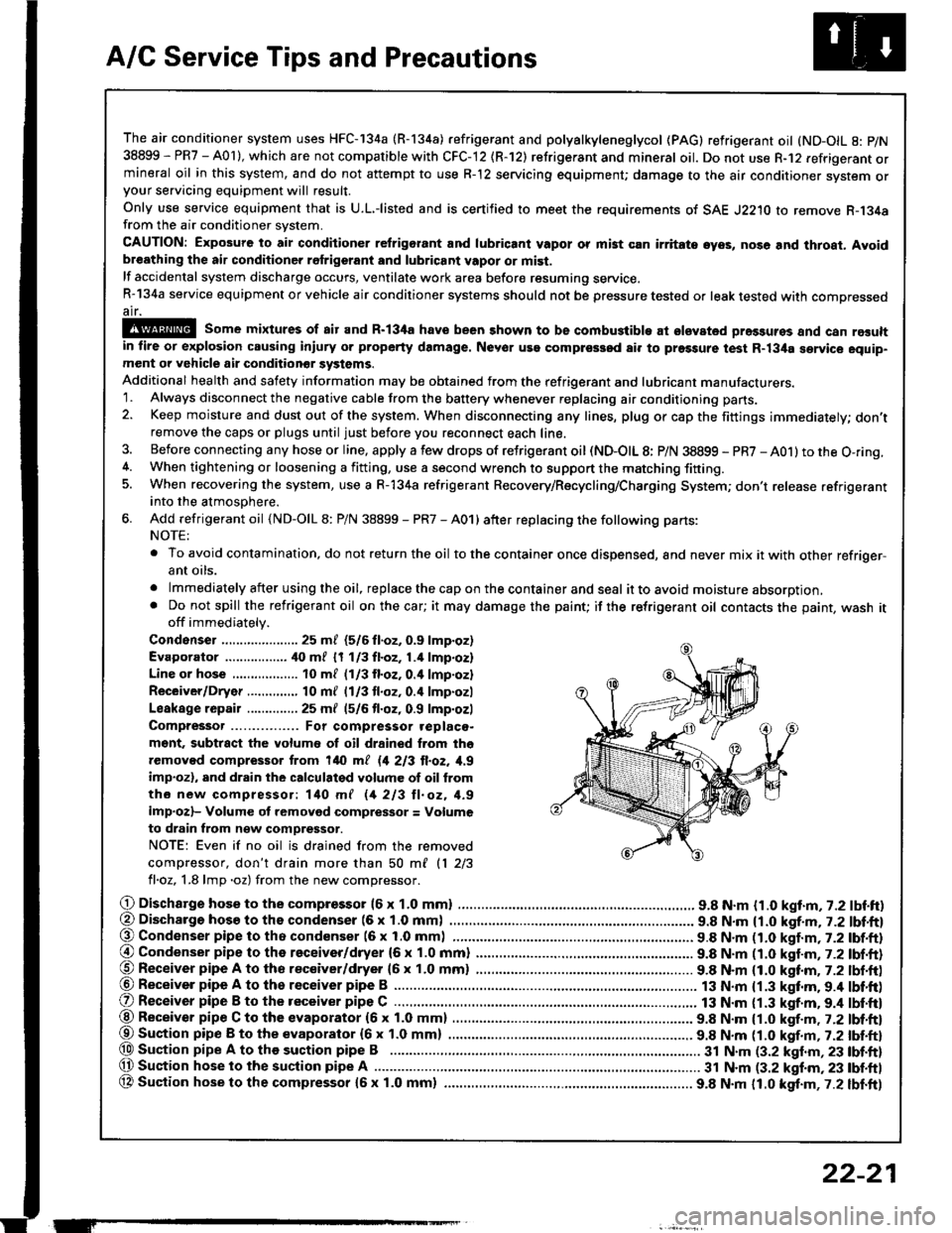

A/C Service Tips and Precautions

The air conditioner system uses HFC-134a (R-134a) .efrigerant and polyalkyleneglycol (PAG) retrigerant oil (ND-OIL g: p/N

38899 - PR7 - A0l ), which are not compatible with CFC-12 \R-'12) refrigerant and mineral oil. Do not use R-12 refrigerant ormineral oil in this system, and do not attempt to use R-'12 servicing equipment; damage to the air conditioner system oryour servicing equipment will result.

only use service equipment that is u.L,-listed and is certified to meet the requirements of sAE J2210 to remove R-134afrom the air conditioner svstem.

CAUTION: Exposure lo air conditioner refrigorant and lubricanl vapor or mi3t cln irritato gyos, nose and throat. Avoidbreathing lhe air conditioner refrigerant and lubricant vapor or mist.

lf accidental system discharge occurs, ventilate work area befor€ resuming service.R-134a service equipment or vehicle air conditioner systems should not be pressure tested or leak tested with compressedair.

@ some mirtures of air and R-l3ifa have been 3hown to be combu3tible at slsvated prossuros and can relultin fire or explosion causing inlury or property damage. Never use complessod ai. to prgssure t€|st R-134a service equip-ment or vehicle air conditiongr systems.

Additional health and safety information may be obtained from the refrigerant and lubricant manufacturers.'1. Always disconnect the negative cable from the battery whenever replacing air conditioning pans.

2. Keep moisture and dust out of the system. When disconnecting any lines, plug or cap the fittings immediately; don'tremove the caps or plugs until just before you reconnect each line.

3. Before con necting a ny hose or line, apply a few drops of refrigerant oil (ND-OIL 8: P/N 38899 - PR7 - AO1) to the O-ring.4. When tightening or loosening a fitting, use a second wrench to support the matching fitting.5. When recovering the system, use a R-134a refrigerant Recovery/Recycling/Charging System; don't release refrigerantinto the atmosDhere.

6. Add refrigerant oil (ND-OlL 8: P/N 38899 - PR7 - A01) after replacing the following parts:

NOTE:

. To avoid contamination, do not return the oil to the container once dispensed, and never mix it with other refriqer-ant orls.

. lmmediately after using the oil, replace the cap on the container and seal ittoavoid moisture absorption,. Do not spill the refrigerant oil on the car; it may damage the paint; if the re{rigerant oil contacts the paint, wash itoff immediately.

Condenser ..................... 25 m/ (5/6 fl.oz, 0.9 lmp.oz)

Evaporator ................. ilo mf 17 113fl.oz,1.4 lmp.oz)

Line or hose 10 ml (1/3 fl.oz. o.il lmp'ozl

Receiver/Dryer .....,.,,...., 10 m{ l1l3 tl.oz, 0.4 lmp.ozl

Leakage repair .............. 25 mf (5/6 fl.oz, 0.9 lmp.ozl

Compressor For compressor .eplaco-

m€nt, subtract the volumo of oil drained from tho

removed compressor trom 140 ml 11 213 ll.oz, 1,9

imp.ozl, and drain the calculalgd volume of oil from

tho new compressor: 140 mf 11 213 ll. oz, 1.9

imp.ozl- Volume ot removod compressor = Volume

to drain from n€w compressor.

NOTE: Even if no oil is drained from the removed

compiessor, don't drain more than 50 ml 11 213

fl.oz, 1.8 lmp .oz) from the new comDressor.

O Dischargo hose to the compresso. (6 x 1.0 mml .............................. 9.8 N.m {1.0 kgt.m, 7.2 lbf.ft)(, Discharge hosa to ths condenser (6 x 1.0 mm) . 9.8 N.m {1.0 kgf.m, j.Z lbl.ftl@ Condenser pipe to tho condenser (6 x 1.0 mml 9.8 N.m n.O kaf.m,t-2tbl.ftl

@ Condenser pipe to the receiver/dryer (6 x 1.0 mm) ......................... 9.8 N.m (1.0 katm,7.2 lbf.ft)@ Receiver pipe A to tho receiver/dryer 16 x 1.0 mm) ......................... 9.8 N.m (1.0 kttm. 7.2 lbt.ft)@ Receiver pipe A to th6 receiver pipe B ......................................

O Receiver pipe B to the receiver pipe C .............................................. 13 N.m {1.3 kgt.m. 9.4 lbt'ft)

13 N.m {1.3 kgf.m.9.4 lbf'ft)@ Receiver pipe C to the evaporator (6 x 1.0 mm) 9.8 N.m {1.0 kgf.m , j.Zlbl.ftl

@Suaion pip€ B to the evaporator {6x 1.0 mm) ................ ................ 9.8 N.m tt.O t!f.-, r.Z tUt tt}@ Sustion pipe A to the suction pipe B .................. 3t N.m (3.2 klnm,23 lbf.ft)(, Suction hose lo the suction pipe A ................ ...... 31 N.m (3.2 kgf.m, 23 tbf.ftl

OA Suction hose to the compressor {5x 1.0 mm} ................ ................. 9.8 N.m 11.0 kgt.m,7.2 lbf.ft)

ET

22-21

Page 1090 of 1413

A/C System Service

Recovery

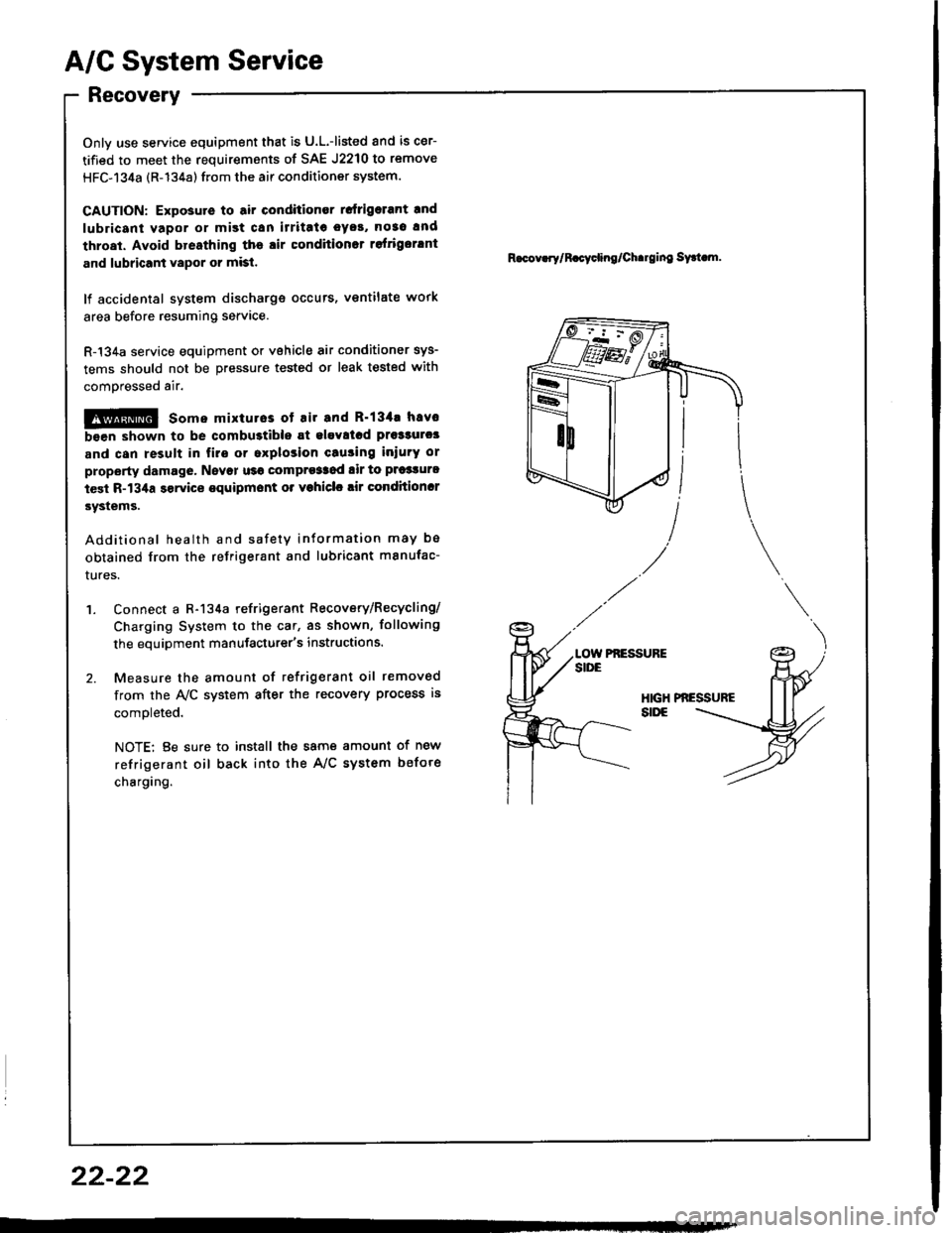

Onlv use service equipment that is U.L.-listed and is cer-

tified to meet the requirements of SAE J2210 to remove

HFC-134a (R-134a) from the air conditioner system.

CAUTION: Expo3ute to air conditioner rcfrigelant rnd

lubricant vapor or mist can irritatc oyo!, no3o and

throat. Avoid bresthing the lir condhionot rofrigorlnt

and lubricant vapor or misl.

lf accidental system discharge occuts, ventilate work

area before resuming service.

R-134a service equipment or vehicle air conditioner sys-

tems should not be pressure tested or leak tested with

comoressed air.

!!@ some mixturos ot Eir and R'134. hsvc

bsen shown to be combu3tible st elavllcd prs33urc3

and can result in fire or oxplosion cau3ing iniurY or

property damage, Nsvor u36 comprg3Sod lir to P|'�3turl

test R-134a servic€ equipmont o. vohiclc rir condhioncr

3ystems.

Additional health and safety information may be

obtained from the refrigerant and lubricant manufac-

rures.

'1. Connect a R-134a refrigerant Recovery/Recycling/

Charging System to the car, as shown, following

the equipment manufacturer's instructions.

2. Measure the amount of refrigerant oil removed

from the A/C system after the recovery process is

comoleted.

NOTE: Be sure to install the same amount of new

refrigerant oil back into the A/C system befote

charging.

R.cov.rylR.cycling/Ch.rging sy.t m.

Pf,ESSUFE

22-22

Page 1092 of 1413

A/G System Service

Performance Test

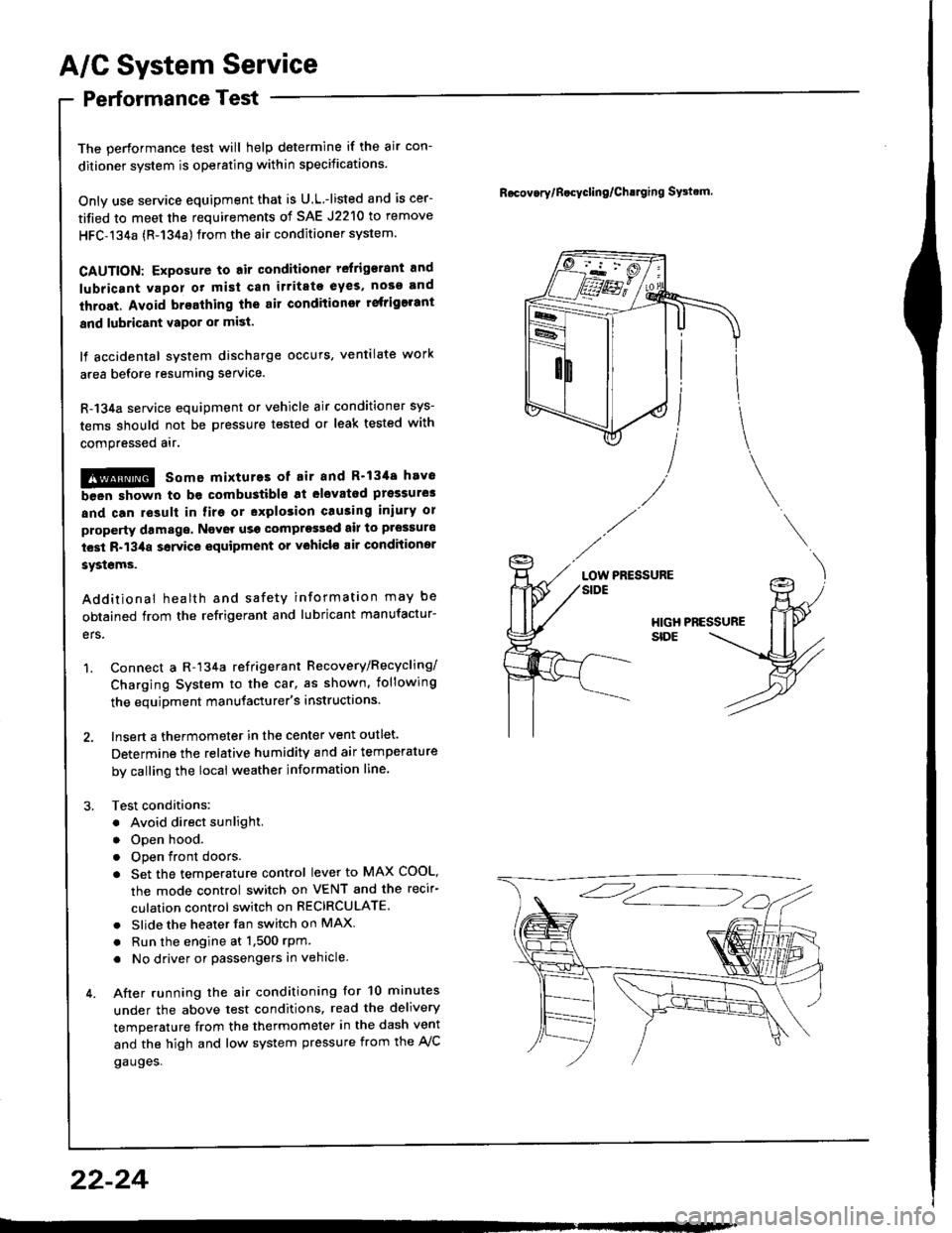

The performance test will help determine if the air con-

ditioner system is operating within specitications.

Only use service equipment that is U.L.-listed and is cer-

tified to meet the requirements of SAE J2210 to remove

HFC-134a {R-134a) from the air conditioner system.

CAUTION: Exposure to air conditioner relrig€rant and

lubricant vapor ot mist can irritate eyes, nose and

throat. Avoid breathing the air conditioner rstrigerant

and lubricant vapor or mi3t.

It accidental system discharge occurs, ventilate work

area before resuming service.

R-134a service equipment or vehicle air conditioner sys-

tems should not be pressure tested or leak tested with

comPressed atr.

!@ some mixtures ot air and R'1344 hrv6

been shown to be combustibls at elovatod prsssurel

and can result in firg or explosion causing iniury 01

property damage. Ngvor usg compregsed ail to prossuro

t€st R-134a ssrvice equipment or vohicl€ air conditioner

syst€ms.

Additional health and safety information may be

obtained from the refrigerant and lubricant manufactur-

ers.

1. Connect a R-134a refrigerant Recovery/Recycling/

Charging System to the car, as shown, iollowing

the equipment manufacturer's instructions.

2. Insert a thermometer in the center vent outlet.

Determine the relative humidity and air temperature

by calling the local weather information line,

3. Test conditions:

. Avoid direct sunlight.

. Open hood.

. Open front doors

. Set the temperature control lever to MAX COOL,

the mode control switch on VENT and the recir-

culation control switch on RECIRCULATE.

. Slide the heater fan switch on MAX

. Run the engine at 1,500 rPm

. No driver or passengers in vehicle.

4. After running the air conditioning for 10 minutes

under the above test conditions. read the delivery

temperature from the thermometer in the dash vent

and the high and low system pressure from the A,/C

gauges.

Rocov.rylB.cycling/Ch!lging SFtrm.

PRESSURELOW

22-24