idle air control HONDA INTEGRA 1994 4.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 315 of 1413

a

Intake Air System

Intake Air Bypass (lABl Control Valve IB18C1 enginel

Trlting

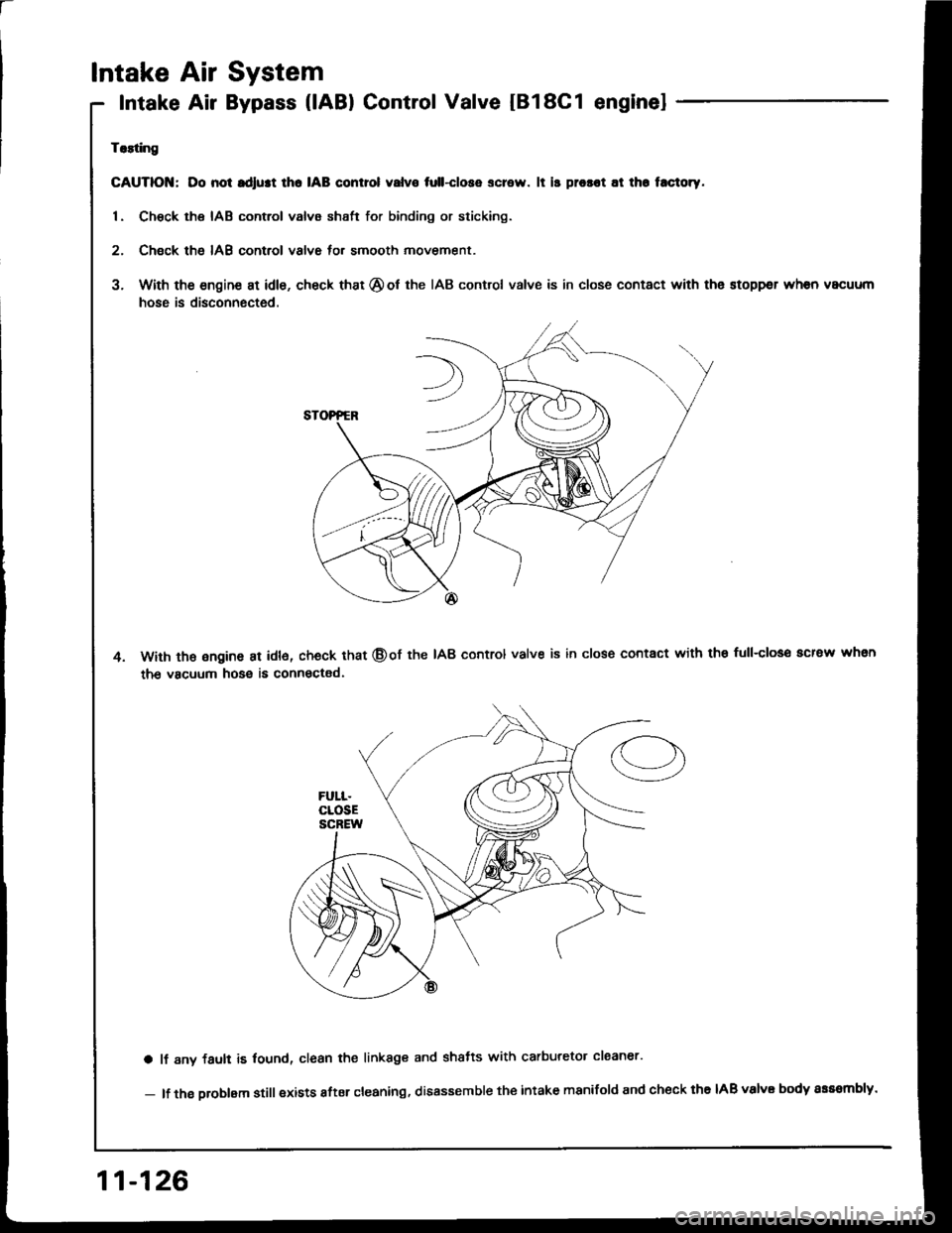

GAUTIOI{; Do not rdlust lho IAB control valvo tull-close screw. lt is prosot at th. t.ctoty.

1. Chsck the IAB control valve shsft for binding or sticking.

2. Check th6 IAB control valve for smooth movement.

3. With the engine at idle, check that @ot the IAB control valve is in close contact with the stoppsr when vacuum

hose is disconnected.

With th€ ongine at idl6, check that @of the IAB control valve is in close contact with the full-closo acrew whsn

the vacuum hose is connectad.

a lf 8ny fault is lound, clean the linkage and shatts with carburetor claaner'

- lf the oroblam still exists after cleaning, disassemble the intake manifold and check the IAB valvE body sss8mbly.

11-126

Page 319 of 1413

Emission Control System

SystemDescription

The emission control system includes a Three Way Cata-

lytic Convener (TWC), Positive Crankcase Ventilation(PCV) system and Evaporstive Emission {EVAP) Contfol

syst€m. The emission control system is designed to meet

federsl and stats emission standards.

Tailpipe Emission

Inspection

f!fifil oo nor amoro ou]rng rnr! Foacqurr. ^!op

any open flame away from yout wotk atca.

Start the engine. Hold the engine at 3,OOO rpm with

no load (A/T in @ or@ position, M/T in neutral) until

the radiator fan comes on, then let it idle,

Connect a tachometer.

Check and adiust the idle speed, if necessary (sss

page 1 1-95).

Warm up and calibrate the CO meter according to

the meter manutacturer's inst.uctions.

Check idle CO with the headlights, hester blower,

rear window defogger, cooling fan, and air condition-

er otf.

NOTE: (Canada) Pull the parking br8ke lever up.

Stan the engine, then check that the headlights are

off.

CO meter should indicate 0.1 maximum.

11-130

Page 323 of 1413

Emission Control System

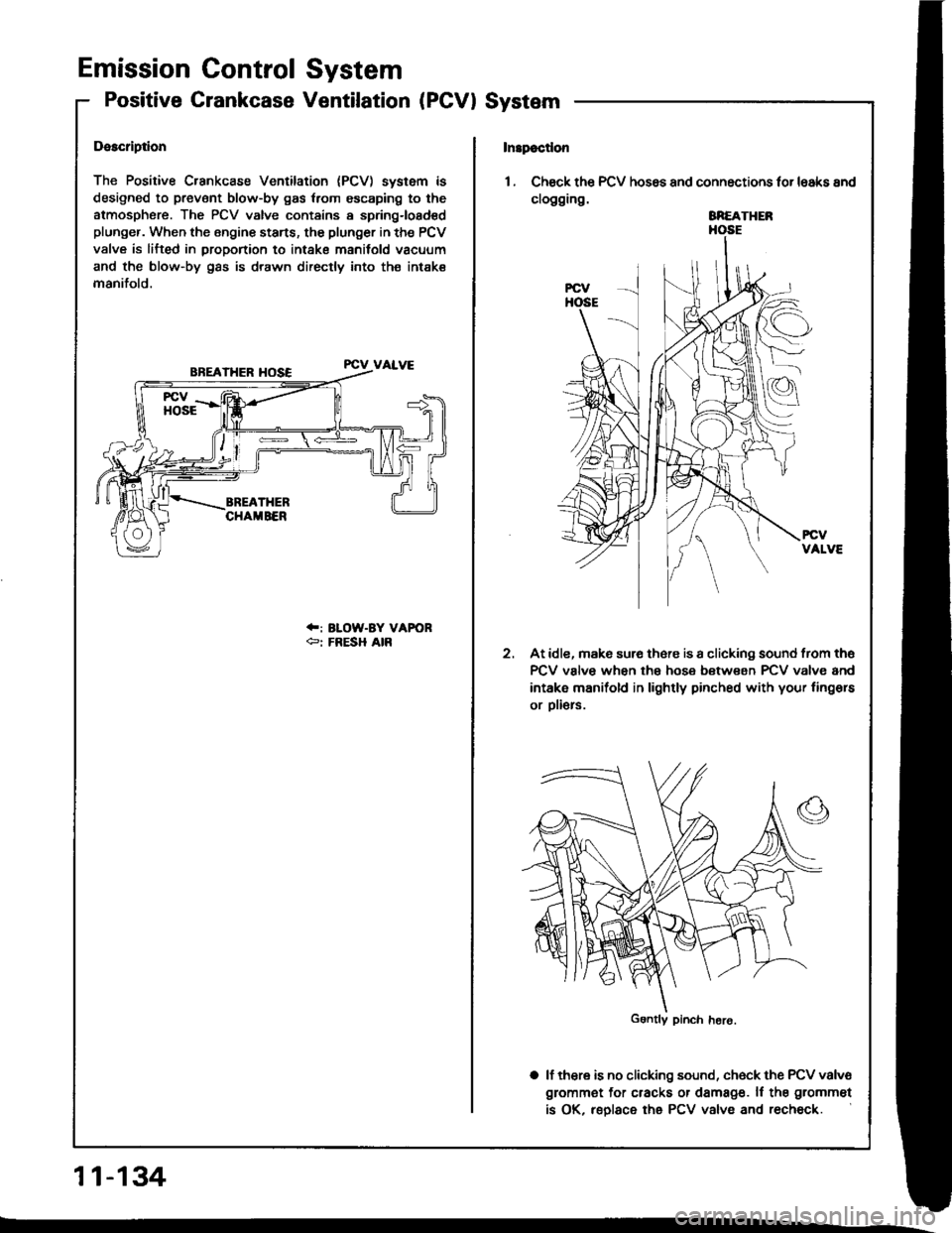

Positive Crankcase Ventilation (PCVI System

Description

The Positive Crankcase Ventilation (PCV) system is

designed to prevent blow-by gas {rom escaping to the

atmosphsre. The PCV valve contains a spring-loadsd

plunger. When the Bngine starts, the plunger in the PCV

valve is lifted in proportion to intake manifold vacuum

and the blow-by gas is drawn directly into th€ intak€

manifold.

FCV VALVE

.F: ILOW-BY VAFORer FRESH AIR

11-134

Insp€cdon

1. Check th€ PCV hos6s and connections tor lsaks and

clogging.

At idle, mak6 sur€ th6fe is a clicking sound from th6

PCV valve when the hose between rcV valve and

intake manifold in lightly pinched with your fingors

or oli€rs.

a lf thera is no clicking sound, ch6ck the PCV valve

grommet for cracks or damage. ll the grommet

is OK, reolace the PCV valve and recheck.

2.

SREATHER

Gontly pinch hero.

Page 327 of 1413

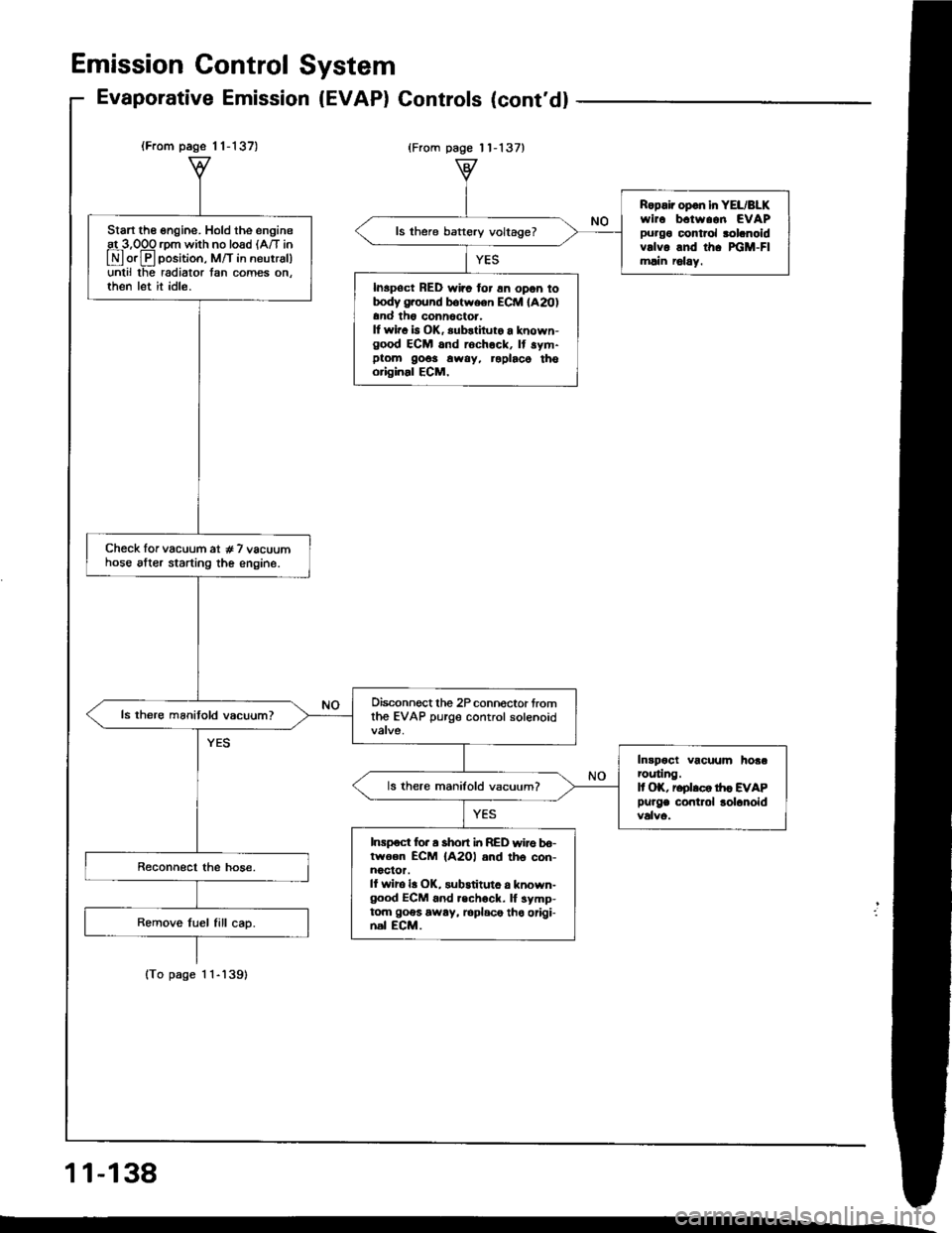

(From page 1 1-137)

lTo page 1 1-'l39)

Start the engine. Hold the engineat 3,OOO rom with no load lA/T in

E orE position, M/T in neutrsl)unlil lhe radiator tan comes on.then let it idle.

Check lor vacuum at # 7 vacuumhose alter starting the engine.

Oisconnect the 2P connoctor fromthe EVAP purge control solenoid

Intpoct vacuum hoaarcuting.It OK, reolrco tr|c EVAP

Purge contlol lolanoid

ls there manifold vacuum?

Inrpoct for a short i|t RED wire bo-lwoen ECM {A2Ol and th6 con-noclor.ll wiro la OK, substituto a known-good ECM 6nd .echock. lf symp-tom goes away, loplace tho origi-nal ECM.

Ropair opon in YEL/BLKwirc b.tw..n EVAPpurgo control rolanoidvrlvo and th. xiM-Flmlin r6lay.

ls there baftery voltage?

Inspoct RED wirc for 6n opon totrody g.ound botween ECM lA20)and th6 conn6ctor.It wir. b OK, substiluto a known-good ECM and rochock, It sym-ptom 9o6s away, roplaco thooriginal ECM,

Emission Gontrol System

Evaporative Emission (EVAP) Gontrols (cont'd)

{From page 11-137}

11-138

Page 617 of 1413

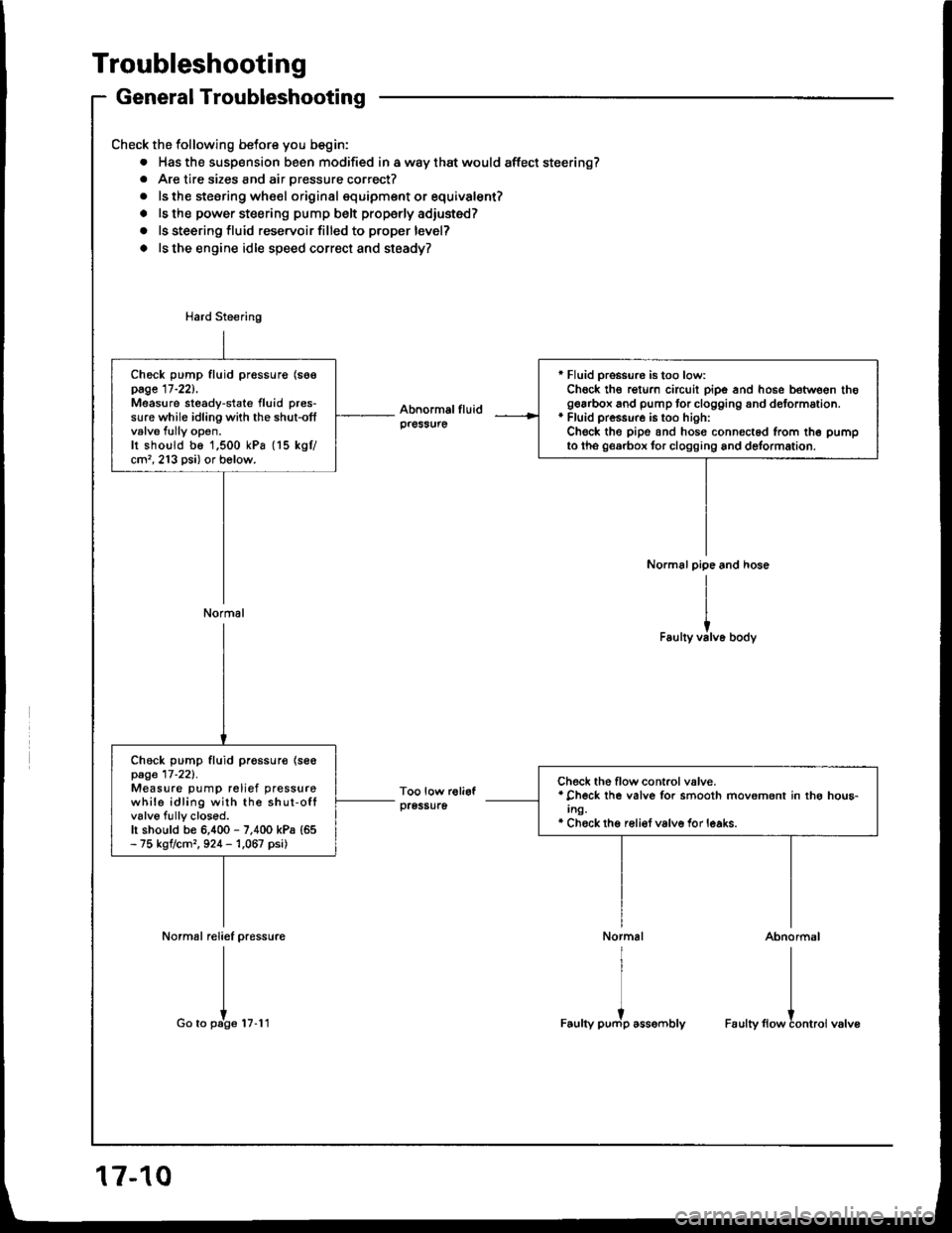

Troubleshooting

General Troubleshooting

Check the following betore you begin:

. Has the susp€nsion been modified in a way that would affect steering?. Are tire sizes and air pressure correct?

. ls the steering whe€l original squipment or equivalent?

. ls the power steering pump belt properly adiusted?

o ls steering fluid reservoir filled to proper level?

o ls the engine idle speed correct and steady?

Normal reliel pressure

I

I

Go to pate tu.l t

r Fluid pro$ure is too low:Chock th€ rgturn circuit pipe and hose between thogearbox and pump tor clogging and dotormation.* Fluid pressure is too hioh:Check the pipe and hosg connected from th6 pumpto tho georbox tor clogging and delormation.

Check pump fluid pressurg (soepage 17-221,Measure steady-state fluid pres-sure while idling with the shut-offvalve fully open.Ir shoutd be 1,500 kPa (15 kgtcm'�, 213 psi) or bolow.

Normal

Check pump fluid pr€ssur€ {se€page 17-221.Measure pump relief pressurewhile idling with the shut-offvalve fully closod.h should be 6,400 - 7,400 kPa {65- 75 kgtcm,, 924 - 1,067 psi)

Check the flow control valve.* Check lhe valve for smooth movement in thg hou6-Ing.* Chock thg reli€f valve for leaks.

Abnormal

I

I

Faulty flowtontroi valve

17-10

Page 620 of 1413

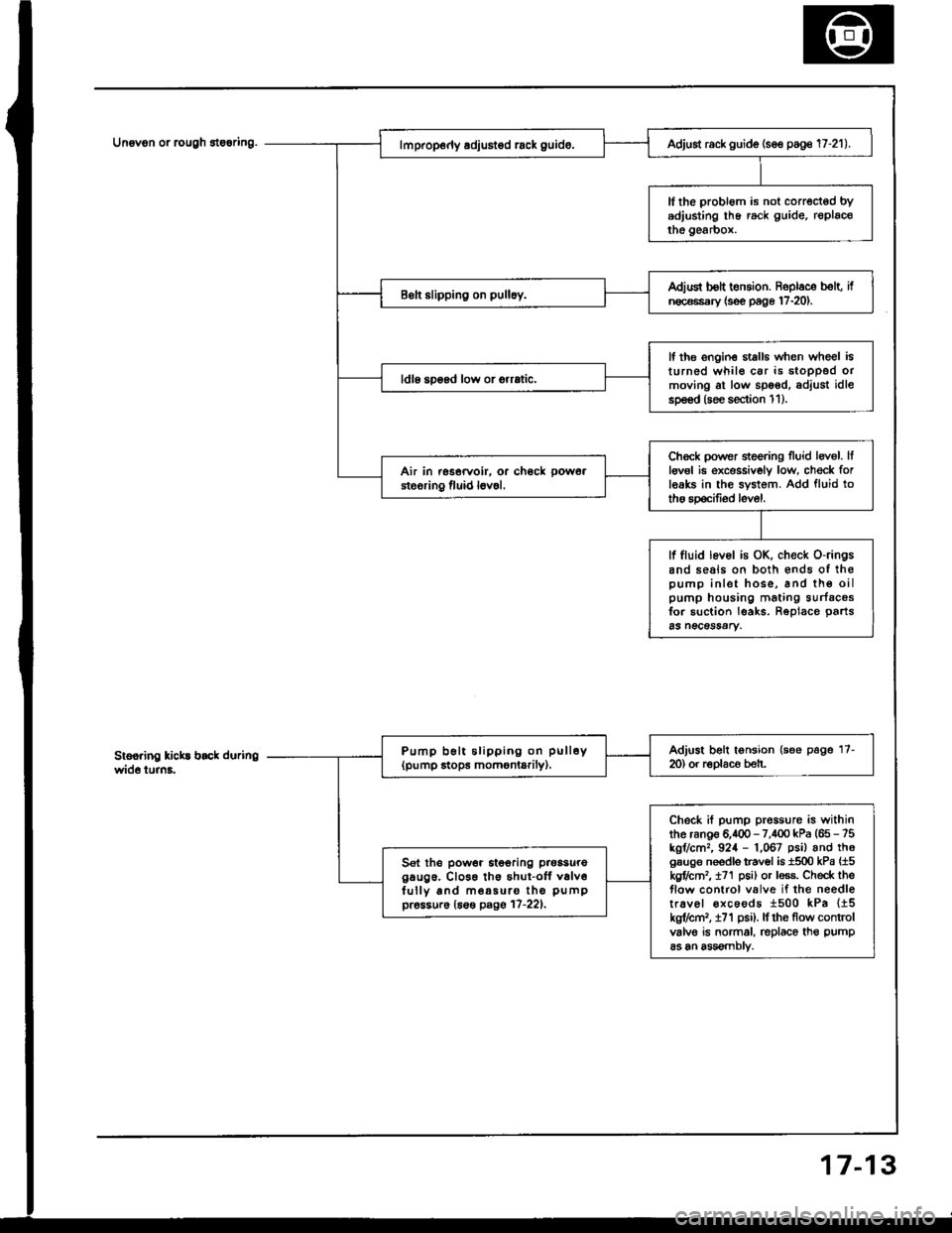

Unovon or rcugh 8te6ring.

3

Adjust rack guide (se€ poge 17-21).

ll the probl6m is not corrected bYadjusting lhe rack guide. replacothe gearbox.

Adiud bolt t€nsion. Roplace b€lt, ifn€c€ssary {s€e page 17-20).

lf the ongin€ stalls when wheel isturned whil€ car is stoDPed ormoving at low spoed, adjust idlesp€€d (soe section 1 1 ).

ldl6 soosd low or orrrtic.

Chock power sieering Iluid levol. Itlgv6l ie excessivoly low, ch€ck forleaks in the system. Add fluid totho spocifiod level.

Air in rssorvoir. or ch€ck pow6a

steoring fluid l6v6l.

lf fluid lev6l is OK, check o-ringsand seals on both €nds of ihopump inlet hose, and th€ oilpump housing mating surfacosfor suction leaks. Reolace oarts65 n€CeSSAry.

Adjust belt tonsion (see page 17-m) or r€Dlaco beh.Pump b6lt slipping on pull6y(pump stops momontarily).

Check if pump prossure is withinthe ranoe 6.400 - 7,100 kPa (65 - 75kgr/cm,, 924 - 1,067 psil and th6gsuge needls travol is 1500 kPa {15kgflctn2, t71 p6i) or less. Check theflow control valve if the needletr.vel €xcoods 1500 kPa {15kg?cm,, i71 psi). lf rhe flow controlvalvo is normal, replace th€ pump

as an assomblv.

Sel the power itooring p.oasuregaug6. Cl066 th€ shut-off v6lv6fully and m€a5uro tho pumppr6ssur6 (6s€ pagg 17-221,

7-1

Page 629 of 1413

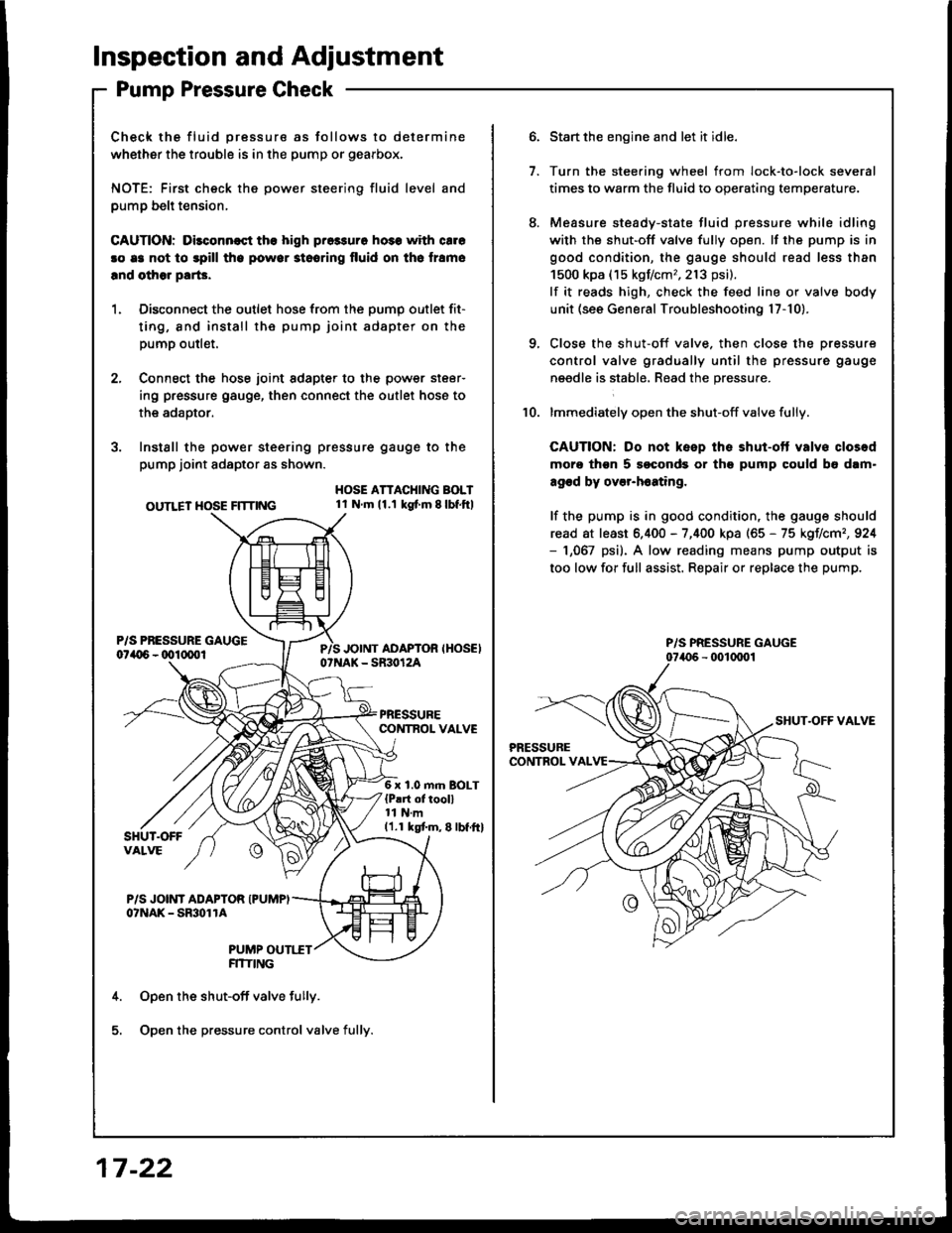

lnspection and Adjustment

Pump Pressure Check

Check the fluid pressure as follows to determine

whether the trouble is in the pump or gearbox.

NOTE: First check the power steering fluid level and

pump belt tension,

CAUnON: Dilconn€st the high pros3uro ho3s with cale

!o e3 not to spill tho powor stooring fluid on th6 lramo

lnd olhor parG.

1. Disconnect the outlet hose from the oumo outlet fit-

ting, 8nd install the pump joint adapter on the

pump outlet.

2, Connect the hose joint sdapter to the power steer-

ing pressure gauge, then connect the outlet hose to

the adaotor.

3. Instsll the power steering pressure gauge to the

pump joint adaptor as shown.

OUTLET HOSE FlTnNG

HOSE ATTACHING BOLT1l Nm11.1 kg{ m 8lbf.ftl

6 x 1.0 m.n BOLT{P!rt of tooll11 N.m11.1 kgtm,8lbf.ftl

P/S JOINT ADAPTOR IPUMPIo?NAK - SmolrA

PUMP OUTI.TTFITIING

Open the shut-off valve fully.

Open the pressure control valve fully.

17 -22

1.

Start the engine and let it idle.

Turn the stee.ing wheel from lock-to-lock several

times to warm the fluid to operating temperature.

Measure steady-state fluid pressure while idling

with the shut-off valve fully open. lf the pump is in

good condition, the gauge should read less than

1500 kpa (15 kgf/cm,,213 psi).

lf it reads high, check the feed line or valve body

unit (see General Troubleshooting l7-10).

Close the shut-off valve. then close the pressure

control valve gradually until the pressure gauge

needle is stabl6, Read the pressure.

lmmediately open the shut-off valve fully.

CAUTION: Do not keep the shut-ott valvs closod

moro thgn 5 soconds or th9 pump could b6 dam"

agod by over-h6ating,

lf the pump is in good condition, the gauge should

read at least 6.400 - 7,400 kpa (65 - 75 kgIlcm,,924- 1,067 psi). A low reading means pump output is

too low for full assist. Repair or replace the pump.

10.

P/S PRESSURE GAUGE