ECU HONDA INTEGRA 1994 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 93 of 1413

14.

16.

Installthe timing belt {see page 6-12).

Adjust the valve clea.ance (see page 6-31.

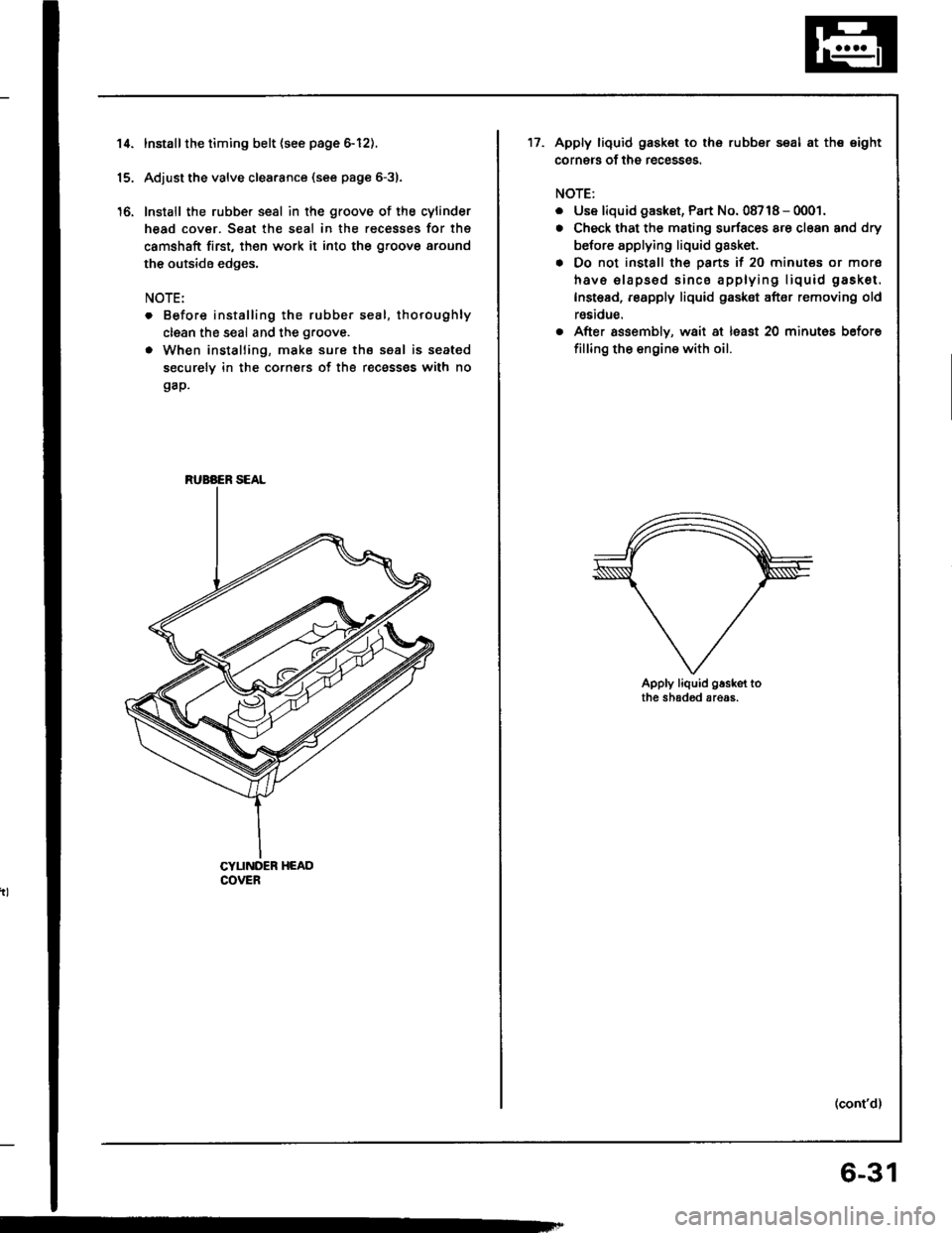

Install the rubber seal in the groove of the cylinder

head cover. Seat the seal in the recesses for thg

camshaft first, th€n work it into the groove around

the outside edges,

NOTE:

. Before installing the rubber seal, thoroughly

clean the seal and the groove.

. When installing, make sure the seal is seated

securely in the corners of the recass€s with no

gap.

CYUNDER HEADCOVER

RUBAER SEAL

17.Apply liquid gask€t to the rubber seal at the eight

corners of the recesses.

NOTE:

. Use liquid gaskst, Part No. 08718 - 0001.

. Check that the mating surfaces are cl€an and dry

before applying liquid gasket.

. Do not install the parts if 20 minutes or mor6

havs elapsod sinco applying liquid gasket.

Instead, reapply liquid gasket after removing old

reaidue.

. After assembly, wait at lsast 20 minutes before

filling the engine with oil.

Apply liquid g.sket tothe shaded areas.

(cont'd)

6-31

Page 139 of 1413

11.

12.

13.

Cylinder Head

Installation lcont'd)

lnstallthe timing belt lsee page 6-51).

Adjust the valve clearance (see page 6-44).

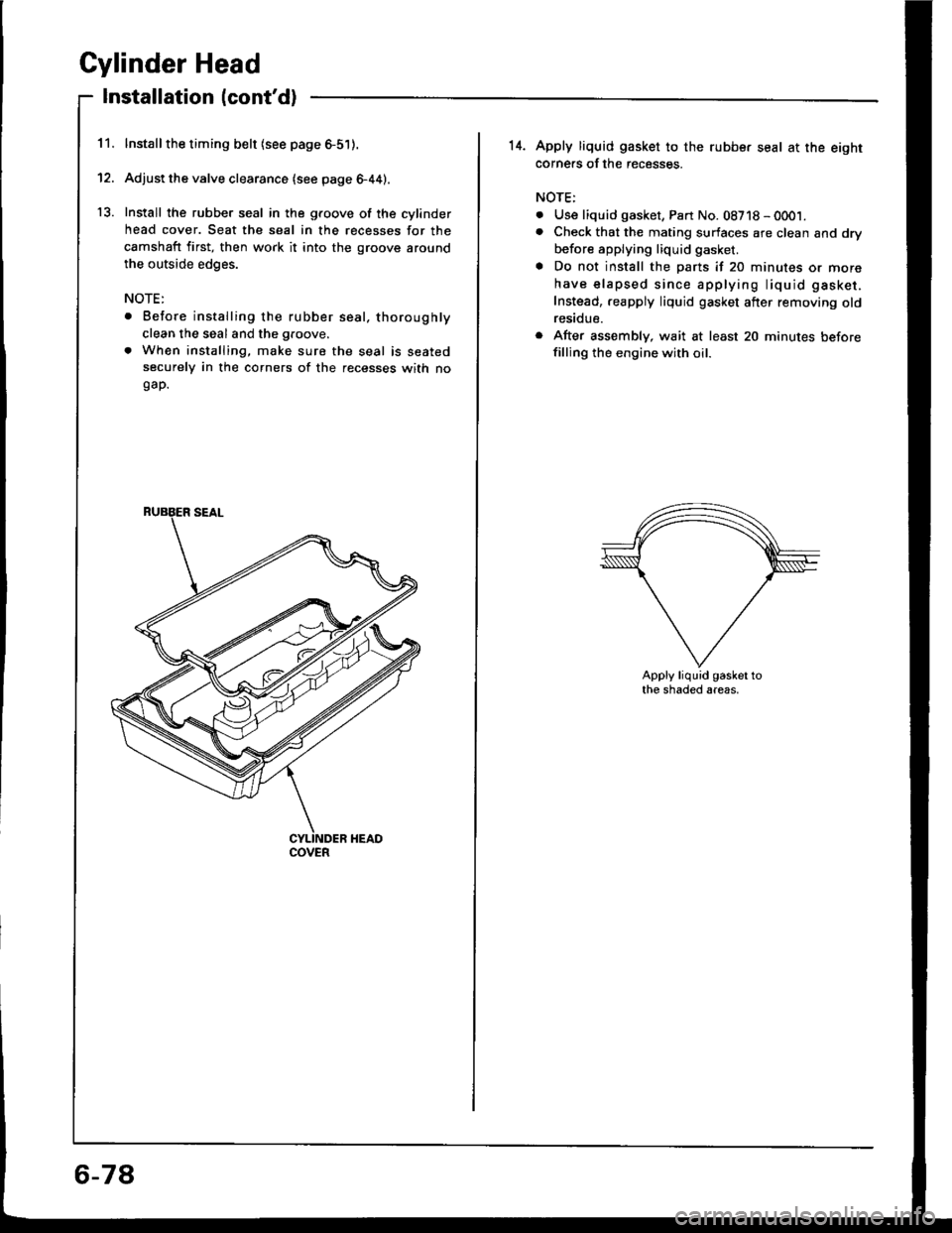

Install the rubber seal in the groove of the cylinder

head cover. Seat the seal in the recesses for the

camshaft first, then work it into the groove around

the outside edges.

NOTE:

. Before installing the rubber seal. thoroughly

clean the seal and the groove.

. When installing, make sure the seal is seatedsecurely in the corners of the recesses with nogap.

COVER

6-78

14. Apply liquid gasket to the rubbe. seal at the eightcorne.s of the recesses.

NOTE:

. Use liquid gasket, Part No. 08718 - 0001.. Check that the mating surfaces are clean and dry

before applying liquid gasket.

a Do not install the parts if 20 minutes or more

have elapsed since applying liquid gasket.

Instead,.eapply liquid gasket after removing oldresidue.

r After assembly, wait at least 20 minutes beforefilling the engine with oil.

Apply liquid gasket tothe shaded areas.

Page 156 of 1413

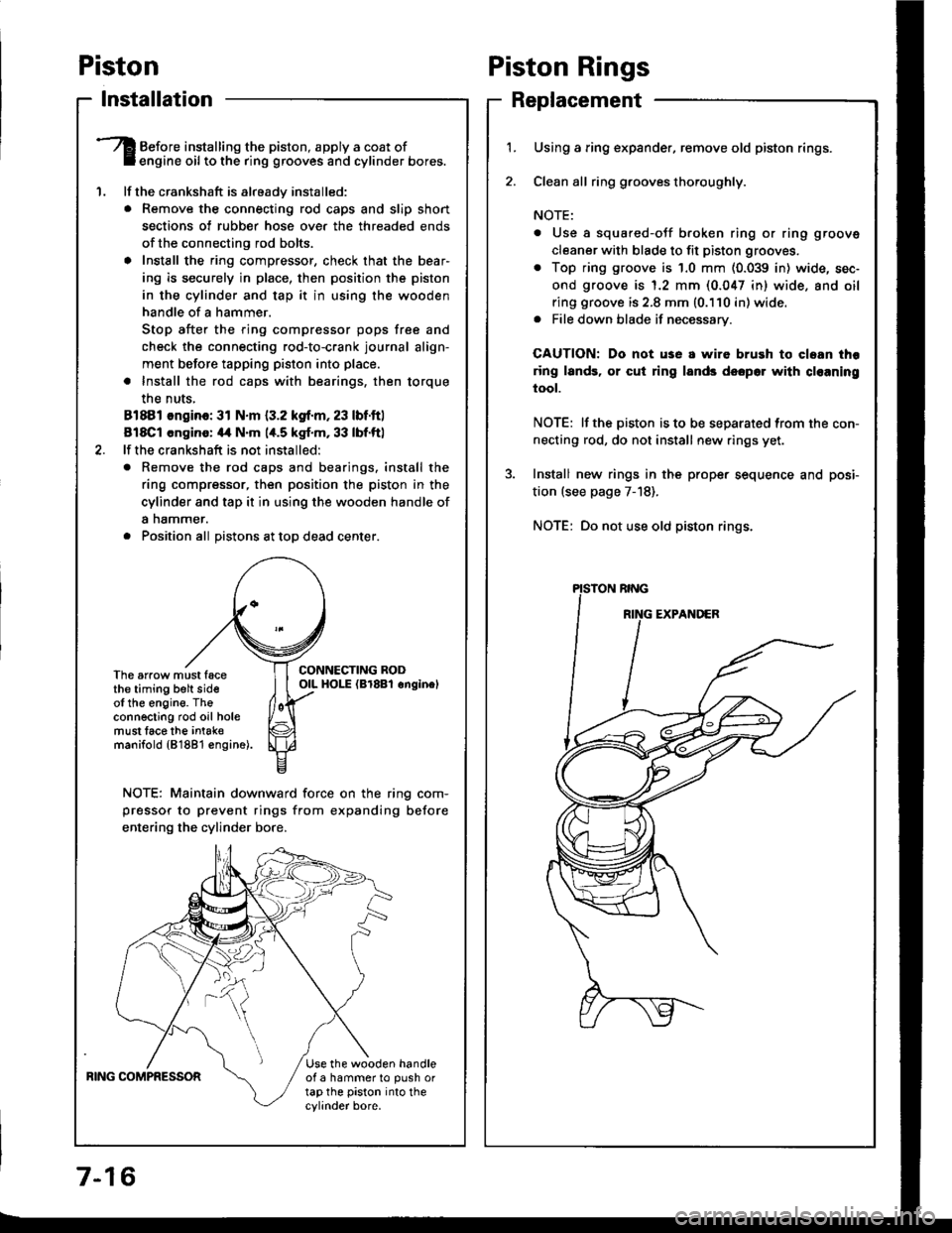

Piston

lnstallation

'1.

Before installing the piston, apply a coat ofengine oil to the ring grooves and cylinder bores.

lf the crankshaft is already installed:

. Remove the connecting rod caps and slip short

sections of rubber hose ove. the threaded ends

of the connecting rod bolts.

a Install the ring compressor, check that the bear'

ing is securely in place, then position the piston

in the cylinder and tap it in using the wooden

handle of a hammer.

Stop after the ring compressor pops free and

check the connecting rod-to-crank journal align-

ment before tapping piston into place.

. Install the rod caps with bearings, then torque

the nuts,

81881 ongino: 31 N.m {3.2 kgf.m, 23 lbf.ftl

818C1 cngino: 44 N'm 1,t.5 kgf.m, 33 lbf.ftl

lf the crankshaft is not installed:

o Remove the rod caps and bearings. install the

ring compressor, then position the piston in the

cylinder and tap it in using the wooden handle of

a nammer.

. Position all Distons at toD dead center.

CONNECTING RODOIL HOI-E (Br8Bl onginelThe arrow must facethe timing belt sideof the engine. Theconnecting rod oil holemust lace the intak€manifold {81881 €ngine).

NOTE: Maintain downward force on the ring com-

pressor to prevent rings from expanding before

entering the cylinder bore,

BING COMPRESSORUse the wooden handleof a hammer to push ortap the piston into thecylinder bore.

Piston Rings

Replacement

1.Using a ring expander, remove old piston rings.

Clean all ring g.ooves thoroughly.

NOTE:

. Use a squared-oJf broken ring or ring groove

cleaner with blade to fit piston grooves.

. Top ring groove is 1.0 mm (0.039 in) wide, sec-

ond groove is 1.2 mm (0.047 in) wide. and oil

ring groove is 2.8 mm (0.110 in) wide.. File down blade if necessary.

CAUTION: Do not use a wire brush to cloan thr

ring lands, or cut ring lands dsopo. with cl€aning

tool.

NOTE: lf the piston is to be separated from the con-

necting rod, do not install new rings yet.

Install new rings in the prope. sequence and posi-

tion (see page 7-18).

NOTE: Do not use old piston rings.

Page 188 of 1413

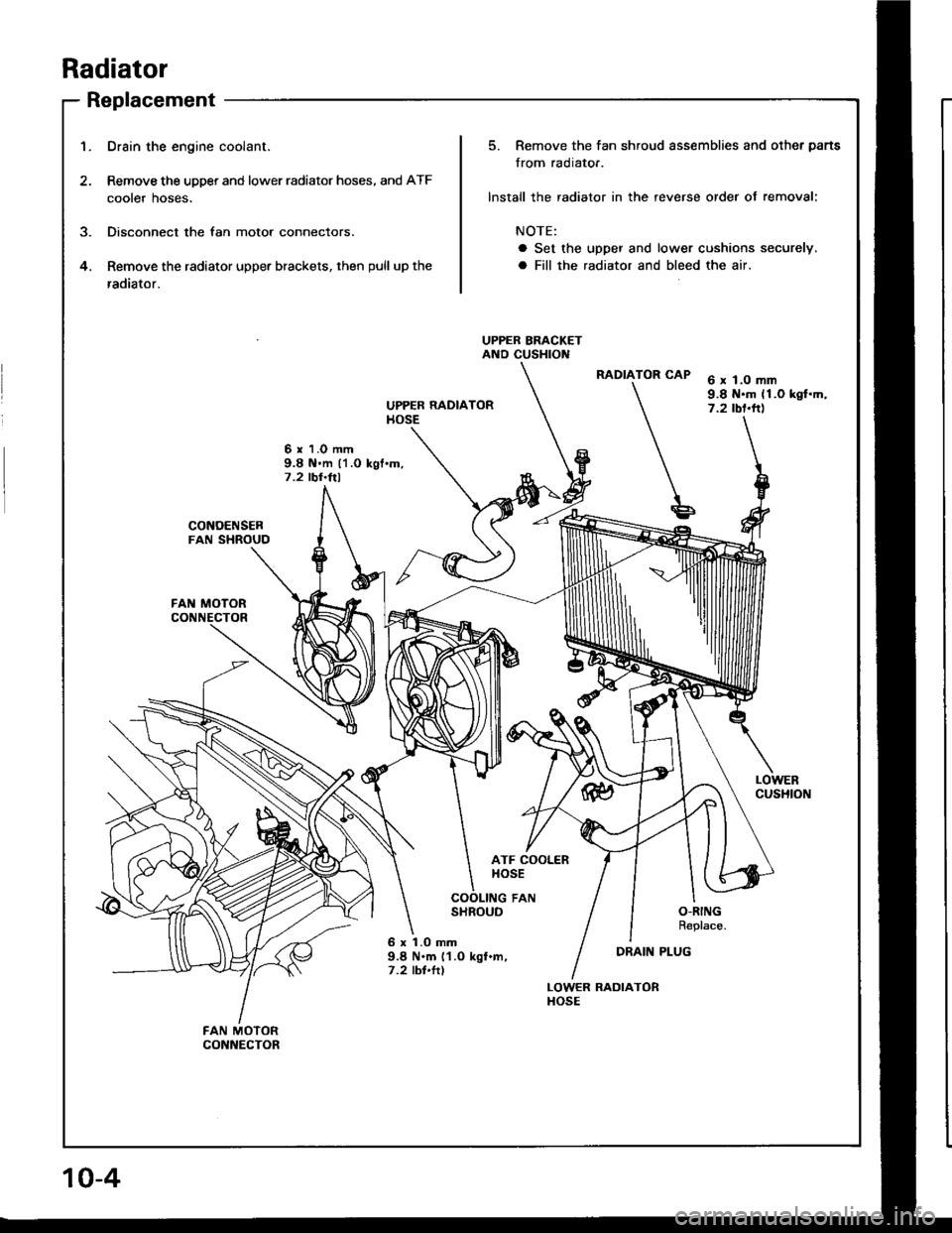

Radiator

Replacement

1.Drain the engine coolant.

Remove the upper and lower radiator hoses, and ATF

cooter noses.

Disconnect the fan motor connectors.

Remove the radiator upper brackets, then pull up the

radiator.

5. Remove the fan shroud assemblies and other parts

from radiato..

lnstall the radiator in the reverse order of removal:

NOTE:

a Set the upper and lower cushions securely.

a Fill the radiator and bleed the air.4.

UPPER BRACKETAND CUSHTOl{

RADIATOR CAP

t

e

6 x l.O mm9.8 N.m (1.O kgt.m,7.2 rbf.ft)

6 x 1.0 mm9.8 il.m 11.O kgt'm,7.2 lbr.ftl

FAN MOTOR

CUSHION

SHROUDO-RINGReplace.

6 x 1.0 mm9.8 N.m ('l.O kgl.m,7.2 tbl.ttl

DRAIN PLUG

LOWER RADIATORHOSE

Page 189 of 1413

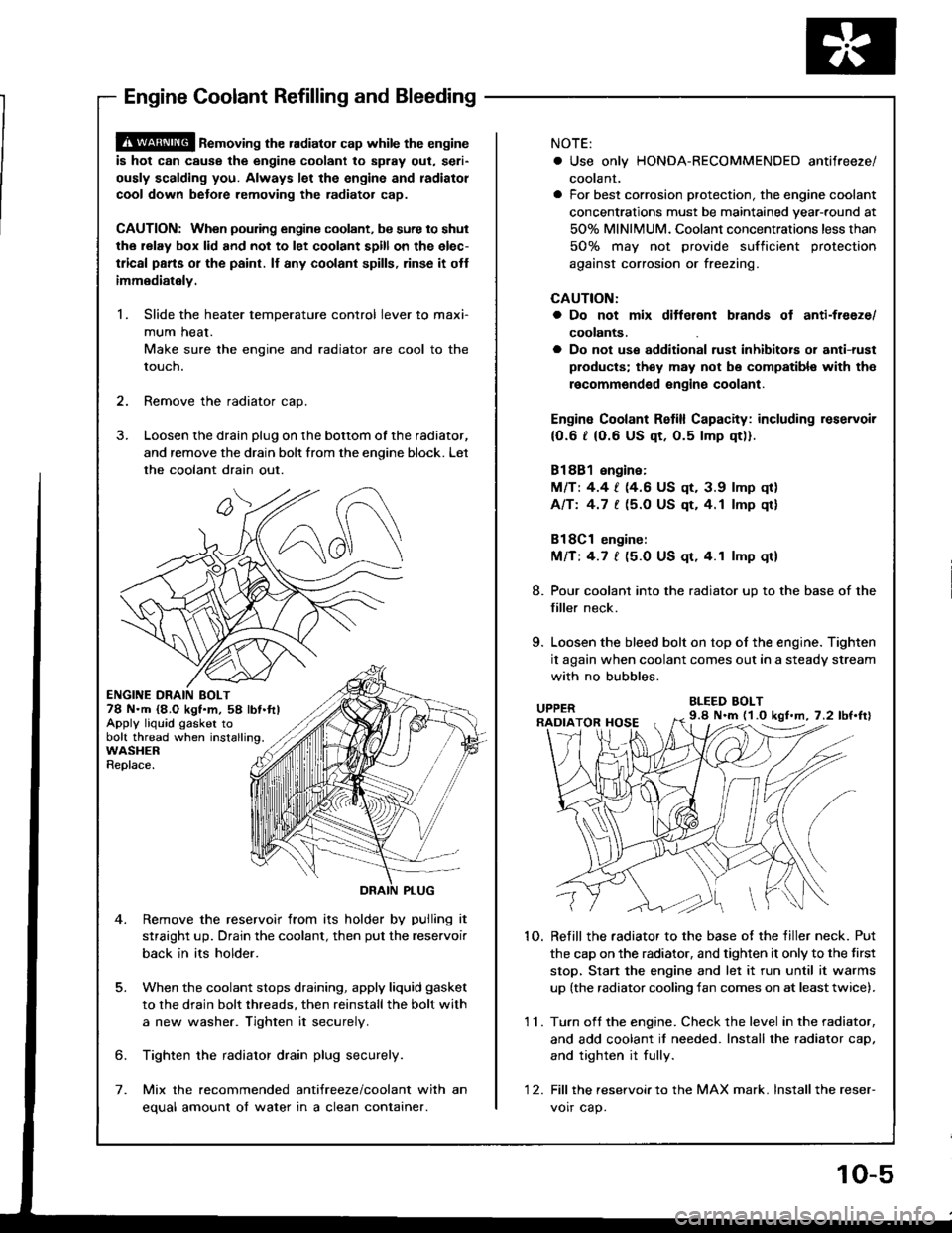

@ ne-oving the radiator cap while the engine

is hot can cause the engine coolant to splay out, seri-

ously scalding you. Always let the engine and radiatol

cool down betore removing the radiator cap.

CAUTION: When poudng engine coolant, be sure to shut

the relay box lid and not to let coolant spill on the elec-

tlical pans or the paint. ll any coolant spills, rinse it otf

immediately.

1. Slide the heater temperature control lever to maxi-

mum heat.

Make sure the engine and radiator are cool to the

touch.

2. Remove the radiator cao.

3. Loosen the drain plug on the bottom of the radiator,

and remove the drain bolt from the enoine block. Let

the coolant drain out.

ENGINE DRAIN BOLT78 N.m {8,O kgt.m, 58 lbt.ftlApply liquid gasker tobolt thread when installing.WASHERReplace.

5.

Remove the reservoir from its holder by pulling it

straight up. Drain the coolant, then put the reservoir

back in its holder.

When the coolant stops draining, apply liquid gasket

to the drain bolt threads, then reinstallthe bolt with

a new washer. Tighten it securely

6. Tighten the radiator drain plug securely.

7. Mix the recommended antifreeze/coolant with an

equal amount of water in a clean container.

NOTE:

. Use only HONDA-RECOMMENOED antifreeze/

coolant.

a For best corrosion protection, the engine coolant

concentrations must be maintained year-round at

50% MINIMUM. Coolant concentrations less than

50% may not provide sufficient protection

against corrosion or freezing.

CAUTION:

a Do not mix ditterent blands ot anti-freeze/

coolants.

a Do not use additional rust inhibitois or anti-rust

products; they may not bs compatibl€ with the

recommgndsd engins coolant.

Engin€ Coolant Retill Capacity: including reservoir

{0.6 t (0.6 US qt, 0.5 lmp qt)).

81881 engine:

MlTt 4.4 | (4.6 US qt, 3.9 lmp qr)

Afft 4.7 [ (5.O US qt,4.1 lmp qt]

Bl8Cl engine:

Mnt 4.7 | (5.0 US qt.4.1 lmp qt)

8. Pour coolant into the radiator up to the base of the

filler neck.

9. Loosen the bleed bolt on top of the engine. Tighten

it again when coolant comes out in a steady stream

with no bubbles.

BLEED BOLT

1O. Refill the radiator to the base of the tiller neck. Put

the cap on the radiator. and tighten it only to the tirst

stop, Stan the engine and let it run until it warms

up (the radiator cooling fan comes on at leasttwice).

11. Turn oft the engine. Check the level in the radiator,

and add coolant it needed. Install the radiator caD,

and tighten it fully.

'1 2. Fill thereservoirto the MAX mark. lnstallthe reser-

voir cap.

9.8 N.m (1.O kgl.m, 7.2 lbf.ftl

Engine Coolant Refilling and Bleeding

10-5

Page 204 of 1413

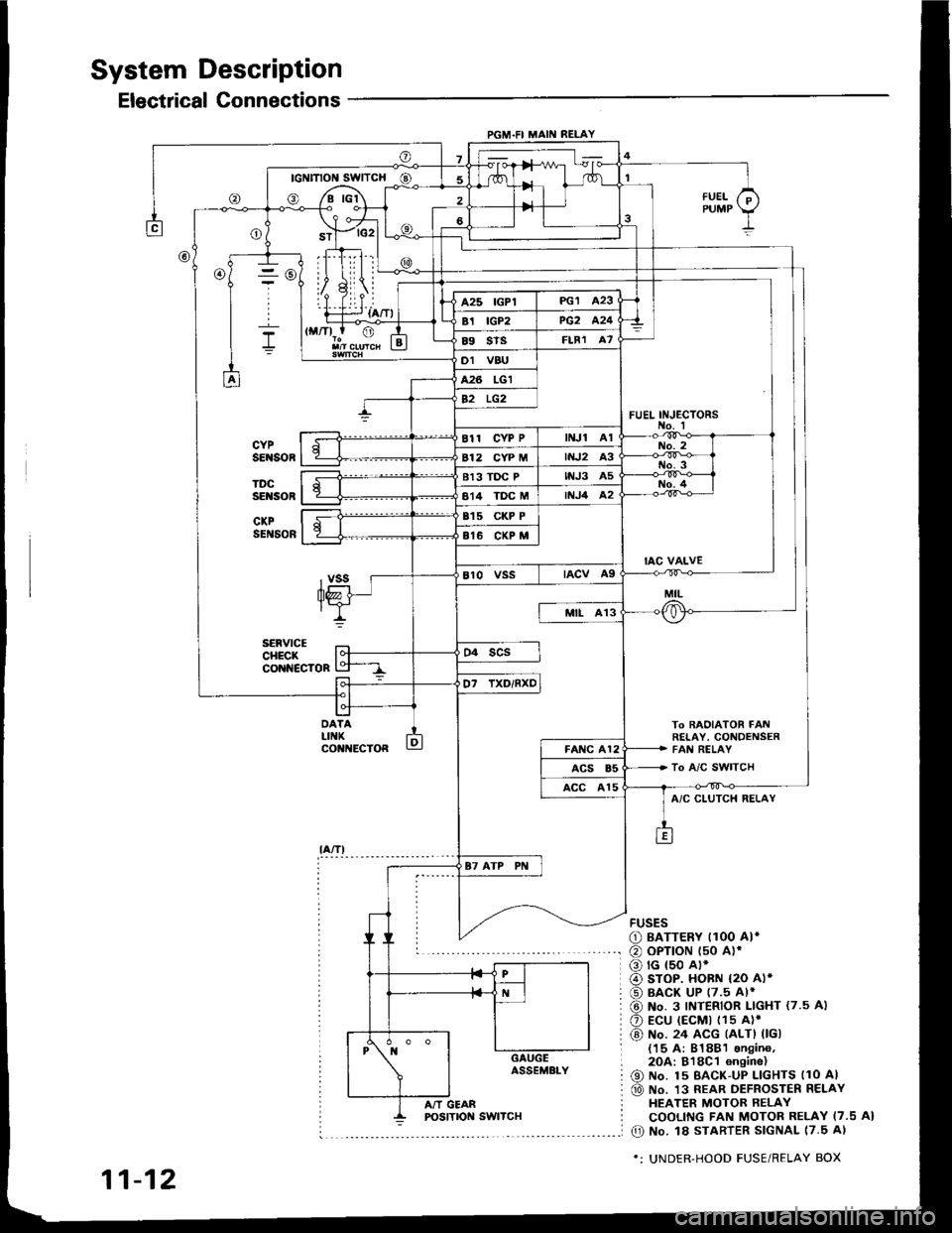

System Description

Electrical Connections

PGM.FI MAII{ RELAY

- rc2l L

IllLii |

ril.i--r {a/Tl

To BAOIATOR FAt!RETAY, CONDENSERFAI{ RELAY

To A/C SWITCH

FUEL INJ€CTORS

@

DATALIIIKco t{EcToR

fUELPUMP

A/C CLUTCH RELAY

FUSES

O BATTERY I1OO AI*

@ oPTroN t50 alr

o rG {50 A).

@ sroP. HoBN {2O Al*

@ BACK UP (7.5 Al*

@ No. 3 INTERIOR LIGHT {7.5 A)

O Ecu (EcMt (1s A)'

@) No. 24 ACG (ALTI 0Gl{15 A: 81881 sngin6,2OA:818C1 6n9ine)

@ No. 15 BAcK-uP LlcHTs llo Al

@ No. 13 REAR DEFROSTER RELAYHEATER MOTOR RELAYCOOLING FAN MOTOR RELAY I7.5 A}

O No. l8 STARTER SIGNAL 17.5 A)

*: UNDER-HOOD FUSE/RELAY BOX

11-12

A/T GEAR

Page 233 of 1413

3. Fuel Cut-oft Control

a During deceleration with the throttle valve closed, current to the {uel injectors is cut otJ to improve fuel economy

at speeds over tollowing rpm:

. 8188l engine: 91O tpm (Canada model: 1,O50 rpm)

. 818C1 engine: 95O tpm (Canada model: l,O5O rpm)

a Fuel cut-olf action also takes place when engine speed exceeds, 7,O0O rpm {81 8B1 engine), 8,1O0 rpm (B 18Cl

engine), regardless oI the position of the throttle valve, to protect the engine from ovet-revving.

A/C Compressor Clutch Relay

When the ECM receives a domand for cooling trom the air conditioning system, it del8ys the compressor from being

enetgized, and enriches the mixture to assure smooth transition to the A/C mode.

Evaporative Emission (EVAP) Purge Control Solenoid Valve

When the engine coolant tempersture is below 163oF {73"C), the ECM supplies a ground to the EVAP pu.ge control

solenoid valve which cuts vacuum to the EVAP purge control diaphragm valve.

Intake Air Bypsss (lAB) Control Sol€noid Valve

When the engine rpm is below 5,750 rpm, the IAB control solenoid valve is activated by a signal from the ECM,

intske air flows through the long intake path, then high torque is delivered. At spaeds highe. than 5,750 rpm, the

solenoid valve is deactivated by the ECM, and intake air flows through the short intake path in order to reduce the

resistance in airflow.

ECM fail-safe/bEck-up Functions

1. Fail-sate Function

When an abnormality occurs in a signal from a sensor, the ECM ignores that signal and assumes a pre-progtammed

value tor that sensor that allows the engine to continue to run.

Back-uD Function

When an abnormalitv occurs in the ECM itself, the fuel iniectors are controlled by a back-up citcuit independent of

the system in order to permit minimal driving.

Self-diagnosis Function IMaltunction Indicator Lamp {MlL)1

Wh6n an abnormality occurs in a signal from a sensor, the ECM supplies ground for the MIL and stores the code

in erasable memory. When the ignition is initially turned on, the ECM supplies ground tor the MIL tor two seconds

to check the MIL bulb condition.

Two Trio Detection Method

To prevent tals€ indications, th€ Two Trip Dstection Method is used for the HO2S and fuel metering-related self-

diagnostic tunctions. When an abnormslity occurs, the ECM stores it in its memo.y. Wh€n the ssme sbnormality

recurs alter the ignition switch is turned OFF and ON ag8in, the ECM informs the driver by lighting the MlL.

However, to ease troubleshooting, this function is canc€ll€d when you short the service check connector. The MIL

will then blink immedistelv when an abnormality occurs.

4.

6.

2

4.

11-41

Page 235 of 1413

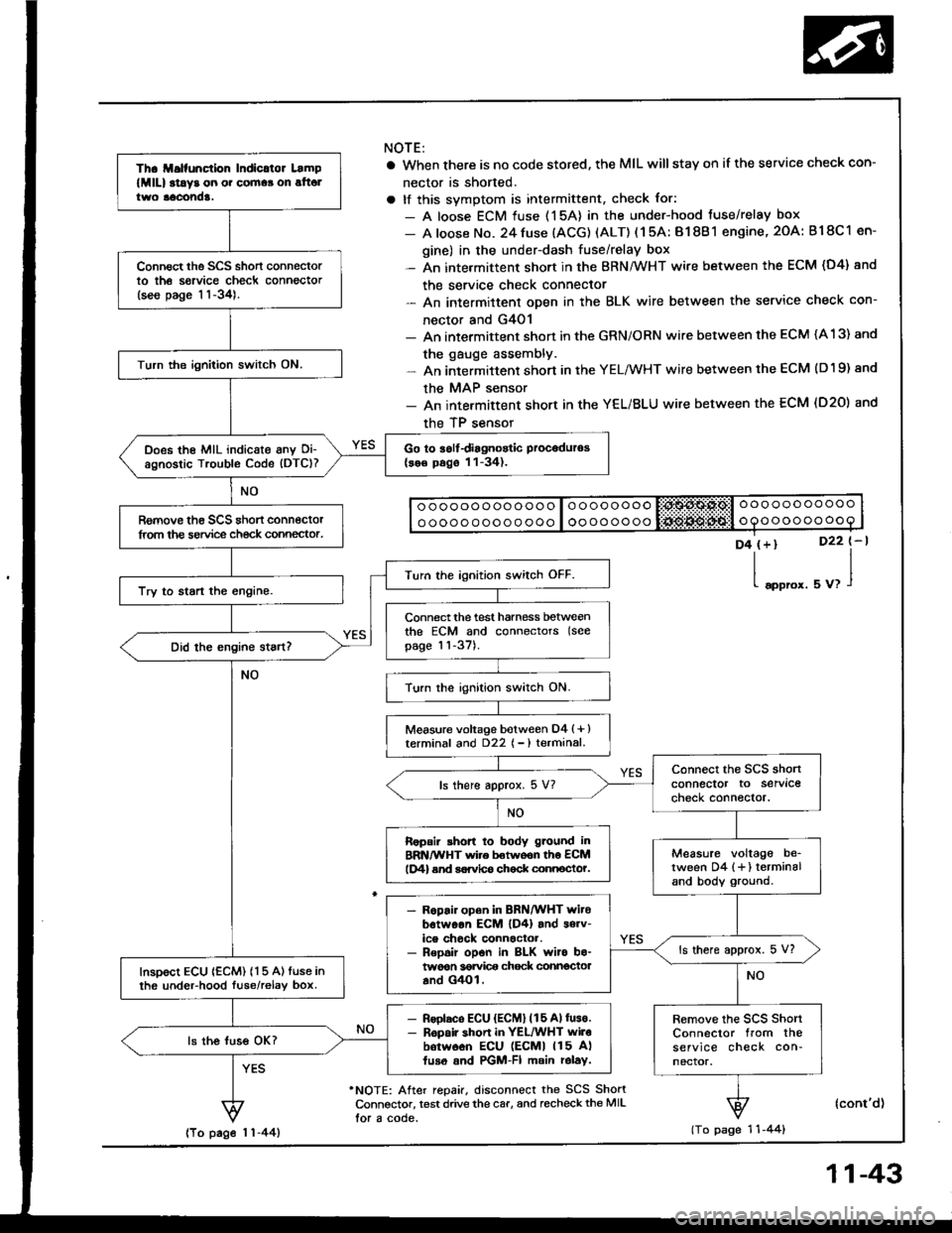

Th. ll.lfunction Indicltor Lamp

lMlll at!y3 on o. cornaa on alt6ltwo aacond!.

Connect the SCS short connectorto th6 sorvice check connector(see page 11-34).

Turn the ignition switch ON.

Go to iolfdiagnostic Proceduros(se€ pago 11-34).Does the MIL indicate anv Oi-agnostic Trouble Code (DTC)?

Romove th€ SCS shon connectorlrom the service ch€ck connector.

Turn the ignition switch OFF.

Try to start the engine.

Connect the test harness betweenthe ECM and connectors (see

page 11-37).

Turn the ignition switch ON.

Measure voltage botween D4 (+ )terminal and D22 { - ) terminal.

connect the SCS shonconnector to servlcecheck connector.ls there approx. 5 V?

Ropair shon to body g.ound inBRN/WHT wire betwoon th6 ECMlD4) end sorvlco chock connocto?.Measure voltage be_tween D4 {+} terminaland body ground.

- R6pair open in BRN/WHT witobotwoon EcM lD4) and s6rv-ice chock connactor.- Repoir opon in BLK wiro bo-twoon 36rvi@ chock connectoaand G4Ol.

ls there approx. 5 V?

InsDoct ECU {ECM) 115 A) tuse inth6 undeFhood luse/relav box.

- Rsolaco ECU {ECM} (15 Allus€.- R6pair shon in YEL/WHT wilobotw6on ECU lEcMl 115 A)fuso and PGM-FI main rolay.

Remove the scs shortConnector from theservice check con-nector.

ls the luss OK?

NOTE:

a When there is no code stored, the MIL willstay on if the service check con-

nector is shorted.

a tf this svmotom is intermittent, check for:

- A loose ECM fuse (15A) in the under-hood tuse/relay box

- A loose No. 24 fuse (ACG) (ALT) ( 1 5A: B1 8B 1 engine, 2OA: B18C 1 en-

gine) in the under-dash fuse/relay box- An intermittent short in the BRN/WHT wire between the ECM (D4) and

the service check connector- An intermittent oDen in the BLK wire between the service check con-

nector and G4O1- An intermittent shon in the GRN/ORN wire between the ECM (A 13) and

the gauge assembly.- An intermittent short in the YELMHT wire between the ECM (D19) and

the MAP sensor- An intermittent short in the YEL/BLU wire between the ECM (D20) and

the TP sensor

o ooooo ooo ooo o loooooooo liii:$A$.Ps,l o oo ooo ooooo

o oooo ooo o o ooo I oooooooooooooooooo

D4 (+)

l"oo,o'.

D22 t-l

uu,l

'NOTE: After repair, disconnect the SCS ShortConnsctor, test drive the car, and recheckthe MIL

lor a code.

(cont'd)

(To page 1 'l -44)lTo page 1 1-44)

11-43

Page 301 of 1413

![HONDA INTEGRA 1994 4.G Workshop Manual Fuel Supply System

PGM-Fl Main Relay (contdl

BLU

BLU/wHt

Bt-xNOTE:. M/T: Clutch pedal mustbe depressed.. A/T: Transmission in

N or E] position.

BLK/ YEL/YEL BLK

Tloubloshooting

{To page 11 113}

- Eng HONDA INTEGRA 1994 4.G Workshop Manual Fuel Supply System

PGM-Fl Main Relay (contdl

BLU

BLU/wHt

Bt-xNOTE:. M/T: Clutch pedal mustbe depressed.. A/T: Transmission in

N or E] position.

BLK/ YEL/YEL BLK

Tloubloshooting

{To page 11 113}

- Eng](/img/13/6067/w960_6067-300.png)

Fuel Supply System

PGM-Fl Main Relay (cont'dl

BLU

BLU/wHt

Bt-xNOTE:. M/T: Clutch pedal mustbe depressed.. A/T: Transmission in

N or E] position.

BLK/ YEL/YEL BLK

Tloubloshooting

{To page 11 113}

- Engino will not sran.- Inspection oI PGM-FI main re-lay and rolay ha.n6!a.

Check lor continuitv between BLKterminal @ and body ground.

Rapair open in BLK wire botwoonPGM-FI main.el6y and GIO'l llo-catod at thormostot housingl.

Measure the voltage betweenYELMHT terminal @ and bodyground.- Roplaco th. ECU IECMI(15 Allus6 in tho under-hood fu!o/r6-lay box.- Ropair opan or short in theYEL/WHT wil6 botwosn thePGM-FI main rolay and the ECU

{EcMl 115 A} luso.

ls there battery voltage?

Turn the ignition switch ON.

Measure the voltage betweenBLK/YEL terminal @ and bodyground.- Reolac. ths No. 24 ACG {ALT}{lcl {15 A:81881 6ngino, 20A: Bl8Cl engin6) tuse in thoundor-dash fuso/rolaY box.- Ropaii op6n or rhon in thoBLK/YEL wiro botwoen thoPGM-FI main ielay and th€ No.24 ACG {ALT) flG} {'�15 A:818Bi ongine, 20 A: 818Cionginol fuso.Turn the ignition switch to theSTART position.

Measure the voltage betweenBLUMHT terminsl @ and bodyground.

- Replaco the l\lo. 18 STARTERSIGNAL {7.5 A} fuso in thoundor-dash fuaa/rolay box.- R6pai. open or short in thoBLU/WHT wire botweon thsPGM-FI main relay and tho No.1A STARTER SIGNAL I7.5 AIluse.

11-112

Page 372 of 1413

Countershaft Assembly

Disassembly

13-30

't.Securely clamp the countershaft assembly in a

bench vise with wood blocks.

Raise the locknut tab from the groove in the coun-

tershaft, then remove the locknut and the spring

washer.

4,Remove the bearing outer .ace, then remove the

needle bearing using a bearing puller as shown.

2.

BEARING PULLER

BEARING

Remove the ball bearing using a bearing puller as

shown.

CAUTION: Romove the gclrs using a pross and tho

steol blocks rs shown. U3a of a l.w.typo pullor can

cau36 damagg to tho gsar iocth.

Support 4th gear on steel blocks. and press the

countershaft out of sth and 4th gears, as shown.

PULlTR

\-Y