power steering HONDA INTEGRA 1994 4.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 627 of 1413

Inspection and Adjustment

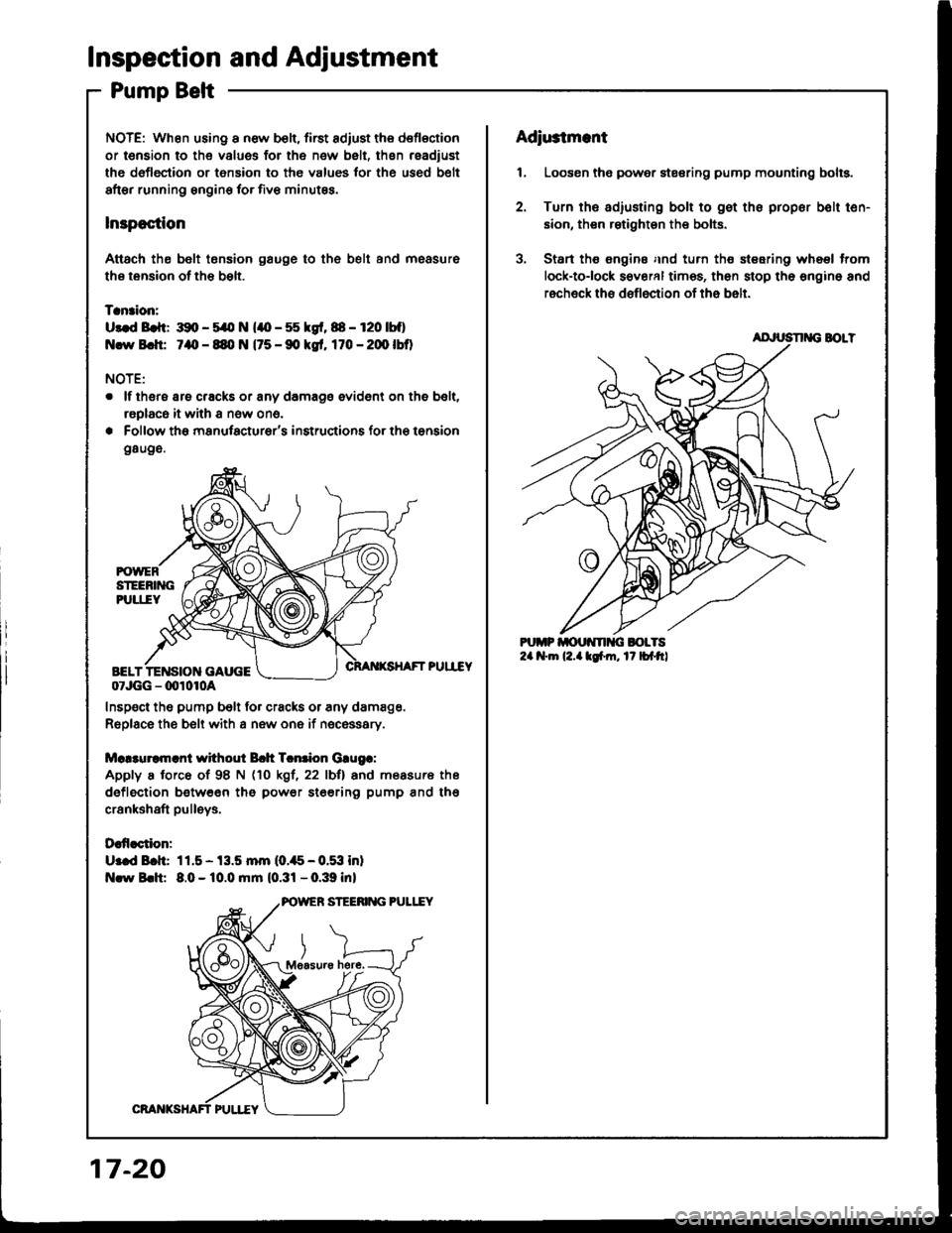

Pump Belt

NOTE: When using a new b€li, first adiust the deflection

or t€naion to the values for the new belt, thsn readiust

ths deflection or tension to the values tor the used b€lt

after running sngine for five minutss.

lnspoction

Attach th€ belt tonsion gauge to th6 belt and measure

ths tension of the bslt.

Tanaion:

U3.d Brft: 391, - 5/O N (lO - 55 kgf, 88 - r20 |bf)

Ncw Bch: 7aO - 89, N (75 - 90 kgt, 170 - 20O lbO

NOTE:

. lf thsre are cracks or any damage evident on the belt,

raplaca it with a now ono.

. Follow the manufacturer's insructions for the tonsion

g8uge.

PUII"EY

07JGG - 00r0r0a

Inspect the pump belt for cracks or any damage.

Replace the belt with a new one if nec€ssary.

Mc!3uramrnl without Bch Tcntion Grugr:

Apply a torce of 98 N (10 kgl, 22 lbll and measure ths

deflection between tho power ste€rin9 pump and tho

crankshaft pulleys.

Daffaction:

U:ed Bch: 11.5- 13.5 mm (0.,t5-0.53 inl

Nlw Brh: 8.0 - 10.0 mm (0.31 - 0.39 inl

here,

17-20

Adiu3tmant

1, Loosen the power stesring pump mounting bolts.

2. Turn ths adiusting bolt to gst the propor bolt ten-

sion, then rstighten the bolts.

3, Start ths €ngine and turn the steering wheel trom

lock-tolock s€veral times, then stop the engino and

recheck ths deflection of the belt.

AD'USN G BOLT

Page 628 of 1413

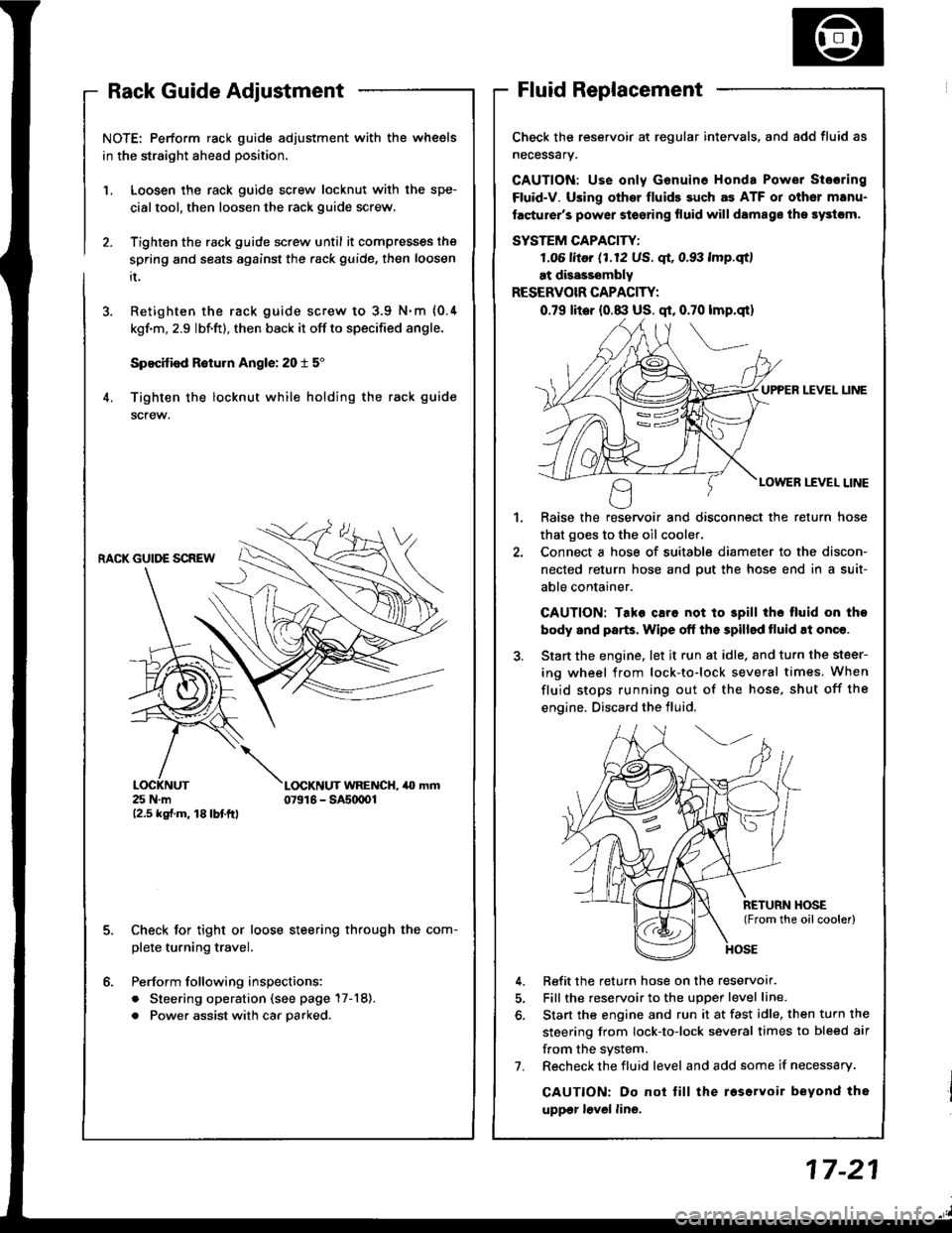

NOTE: Perform rack guide adjustment with the wheels

in the straight ahead position.

Loosen the rack guide screw locknut with the spe-

cialtool, then loosen the rack guide screw.

Tighten the rack guide screw until it compresses the

spring and seats against the .ack guide, then loosen

it.

Retighten the rack guide screw to 3.9 N.m {0.4

kgf'm, 2.9 lbf.ft), then back it off to specified angle.

Specified R6turn Angle: 20 t 5"

Tighten the locknut while holding the rack guide

screw.

1.

6.

RACK GUIDE SCREW

25 N.m12.5 kgf.m, 18lbtftl

L(rcKNUT WRENCH, 40 mm07916 - SAs(xtOl

Check for tight or loose steering through the com-

plete turning travel.

Perform following inspections:

. Steering operation (see page 17-18).

. Power assist with car parked.

Check the reservoir at regular intervals. and add fluid as

necessary.

GAUTION: Use only Genuine Honda Power Stosring

Fluid-V. Using othsr fluids such as ATF or other manu-

facturer's power stoering fluid will damags ths systcm,

SYSTEM CAPACITY:

LO6 litor (1.12 US. qt, 0.93 lmp.qtl

at disasssmbly

RESERVOIR CAPACITY:

0.79 lit6r (0.8:l US. qt, 0.70 lmp.qt)

UPPER LEVEL UNE

LOWER LEVEL LINE

,l

Raise the reservoir and disconnect the return hose

that goes to the oil cooler.

Connect a hose of suitable diameter to the discon-

nected return hose and put the hose end in a suit-

able container.

CAUTION: Tako caro not to 3pill tho tluid on tho

body and parts. Wipe off the spilled tluid at onqe.

Start the engine. let it run at idle. and turn the steer-

ing wheel from lock-to-lock several times. When

fluid stops running out of the hose, shut off the

engine. Discard the fluid,

Refit the return hose on the reservor.

Fill the reservoir to the uDoer level line.

Start the engine and run it at fast idle, then turn the

steering from lock-to-lock several times to bleed air

f.om the system.

Recheck the fluid level and add some if necessary.

CAUTION: Do not lill the roservoir beyond tho

uppgr lovel line.

7.

Page 629 of 1413

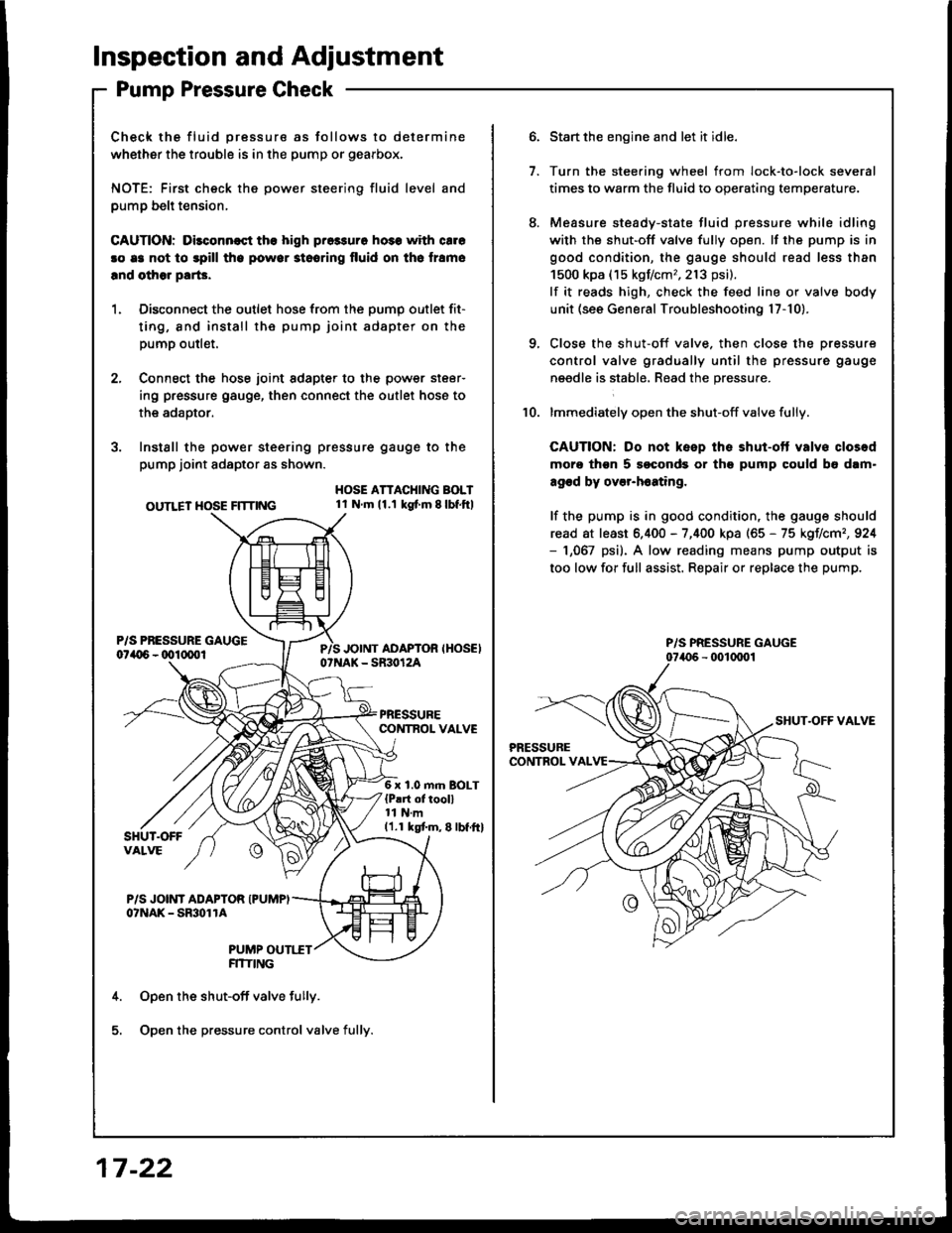

lnspection and Adjustment

Pump Pressure Check

Check the fluid pressure as follows to determine

whether the trouble is in the pump or gearbox.

NOTE: First check the power steering fluid level and

pump belt tension,

CAUnON: Dilconn€st the high pros3uro ho3s with cale

!o e3 not to spill tho powor stooring fluid on th6 lramo

lnd olhor parG.

1. Disconnect the outlet hose from the oumo outlet fit-

ting, 8nd install the pump joint adapter on the

pump outlet.

2, Connect the hose joint sdapter to the power steer-

ing pressure gauge, then connect the outlet hose to

the adaotor.

3. Instsll the power steering pressure gauge to the

pump joint adaptor as shown.

OUTLET HOSE FlTnNG

HOSE ATTACHING BOLT1l Nm11.1 kg{ m 8lbf.ftl

6 x 1.0 m.n BOLT{P!rt of tooll11 N.m11.1 kgtm,8lbf.ftl

P/S JOINT ADAPTOR IPUMPIo?NAK - SmolrA

PUMP OUTI.TTFITIING

Open the shut-off valve fully.

Open the pressure control valve fully.

17 -22

1.

Start the engine and let it idle.

Turn the stee.ing wheel from lock-to-lock several

times to warm the fluid to operating temperature.

Measure steady-state fluid pressure while idling

with the shut-off valve fully open. lf the pump is in

good condition, the gauge should read less than

1500 kpa (15 kgf/cm,,213 psi).

lf it reads high, check the feed line or valve body

unit (see General Troubleshooting l7-10).

Close the shut-off valve. then close the pressure

control valve gradually until the pressure gauge

needle is stabl6, Read the pressure.

lmmediately open the shut-off valve fully.

CAUTION: Do not keep the shut-ott valvs closod

moro thgn 5 soconds or th9 pump could b6 dam"

agod by over-h6ating,

lf the pump is in good condition, the gauge should

read at least 6.400 - 7,400 kpa (65 - 75 kgIlcm,,924- 1,067 psi). A low reading means pump output is

too low for full assist. Repair or replace the pump.

10.

P/S PRESSURE GAUGE

Page 641 of 1413

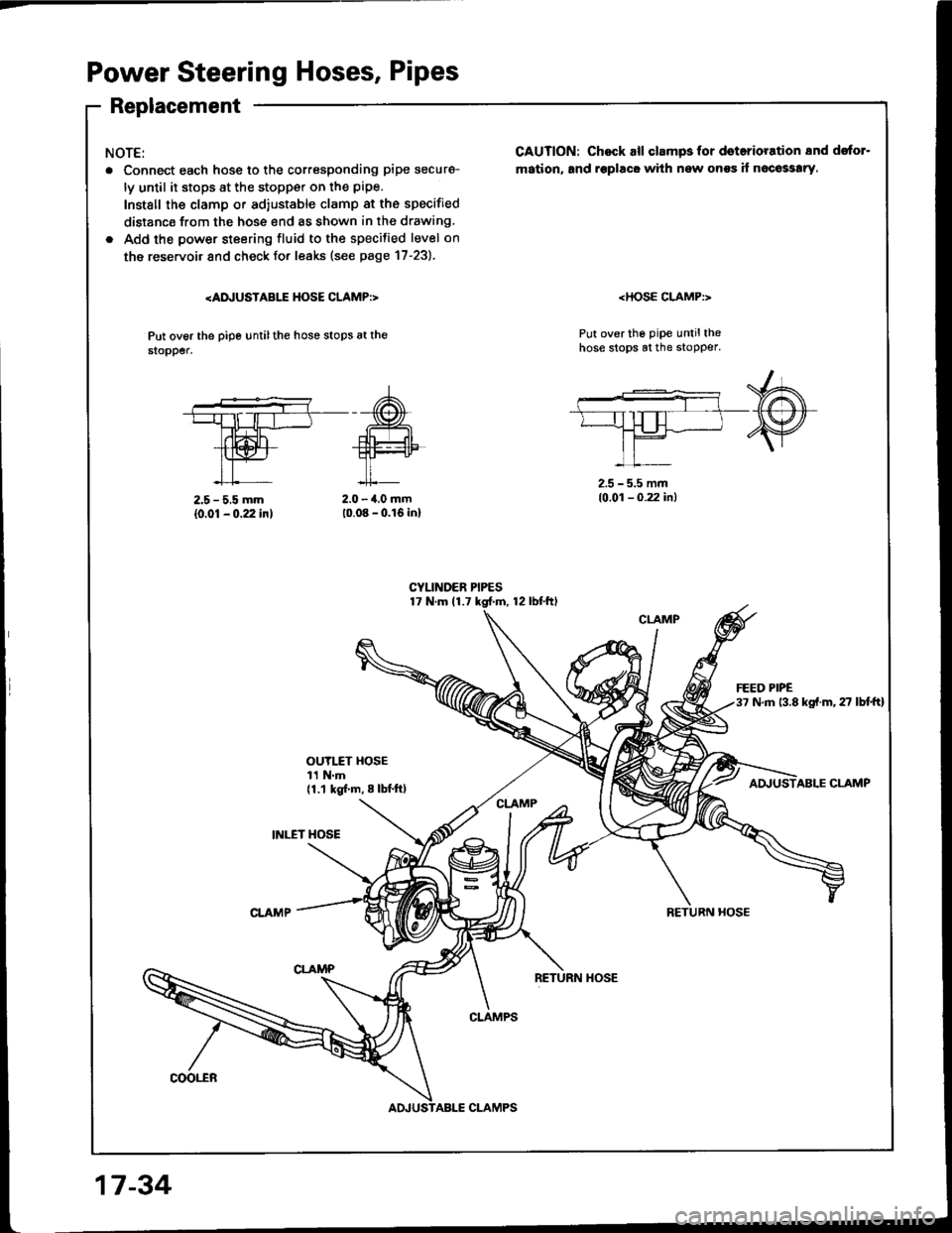

Power Steering Hoses, Pipes

Replacement

NOTE:

. Connect each hosg to the corresponding pipe securg-

ly until it stops at the stopp€r on the pipe.

Install the clamp or ad,ustable clamp at the specified

distancs from the hose end as shown in the drawing.

. Add the power steering fluid to the specilied level on

the reservoir and check fo. leaks (see page 17-23).

Put ov6r the pipe untilthe hose stops at the$opper.

CAUTION: Chock all clampsfor doterioration 8nd dstor-

mation, and rsplacG with new onss if n6co33!ry,

Put over the pipe untilthehose stops at the stopper.

2.5 - 5.5 mm

{0.01 - 0.22 inl2.0 - 4.0 mm10.08 - 0.16 inl

2.5 - 5.5 mm10.01 - 0.22 in)

OUYI.fT HOSE11 N.m{1.1 kgl.m, 8 lbl.ftl

INI."ET HOSE

ABLE CLAMP

RETURN HOSE

coot"ER

CLAMPS

17 -34

CLAMPS

Page 642 of 1413

OUTI.TT HOSE

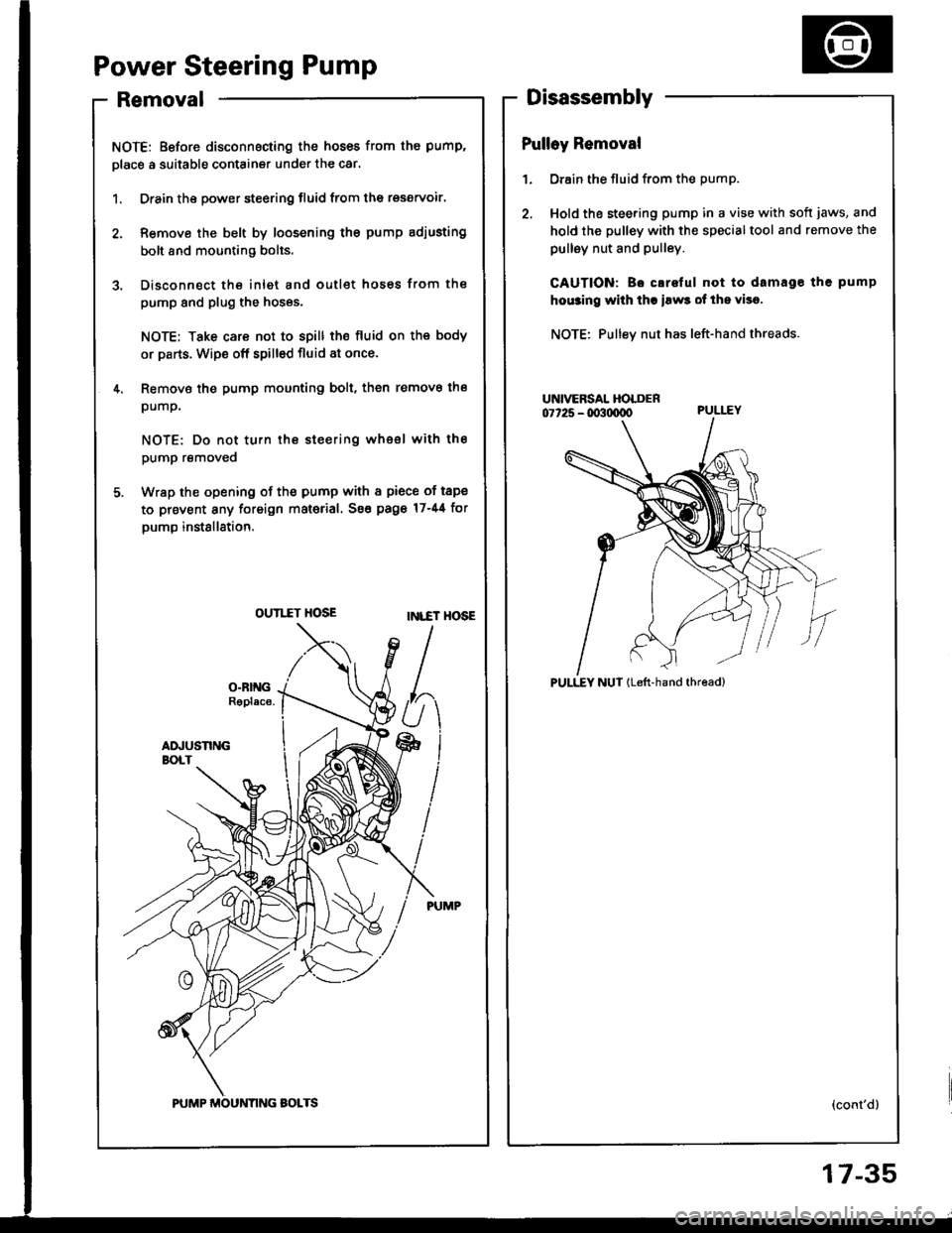

Power Steering Pump

Removal

NOTE: Before disconnecting the hoses from the pump,

place a suitable containsr under the car.

1. Drain the power steering fluid from the rsservoir.

2. Remove the belt by loosening the pump adjusting

bolt and mounting bolts.

3. Disconnect the inlet and outlet hoses from the

pump and plug the hoses.

NOTE; Take care not to spill ths tluid on the body

or parts. Wipe off spillod fluid at once.

4. Remove the pump mounting bolt, then remove th€

pump

NOTE: Do not turn the steering whesl with the

pump removeo

5. Wrap the opening of th€ pump with a piece of taps

to provent any foreign mat€rial. Se6 pags 17-44 for

oumD instsllstion,

tNt.€T HOSE

Disassembly

Pulley Removal

1. Drain the fluid from the pump.

2, Hold the stee.ing pump in a vise with soft iaws, and

hold the pulley with the specialtool and remove the

pulley nut and pulley.

CAUTION: Bo clrstul not to damage the pump

ho$ing with thr iaw3 of ths vise.

NOTE: Pullev nut has left-hand threads.

PULLEY NUT {Left-hand thread)

(cont'dl

17-35

Page 643 of 1413

Power Steering Pump

Disassembly (cont'dl

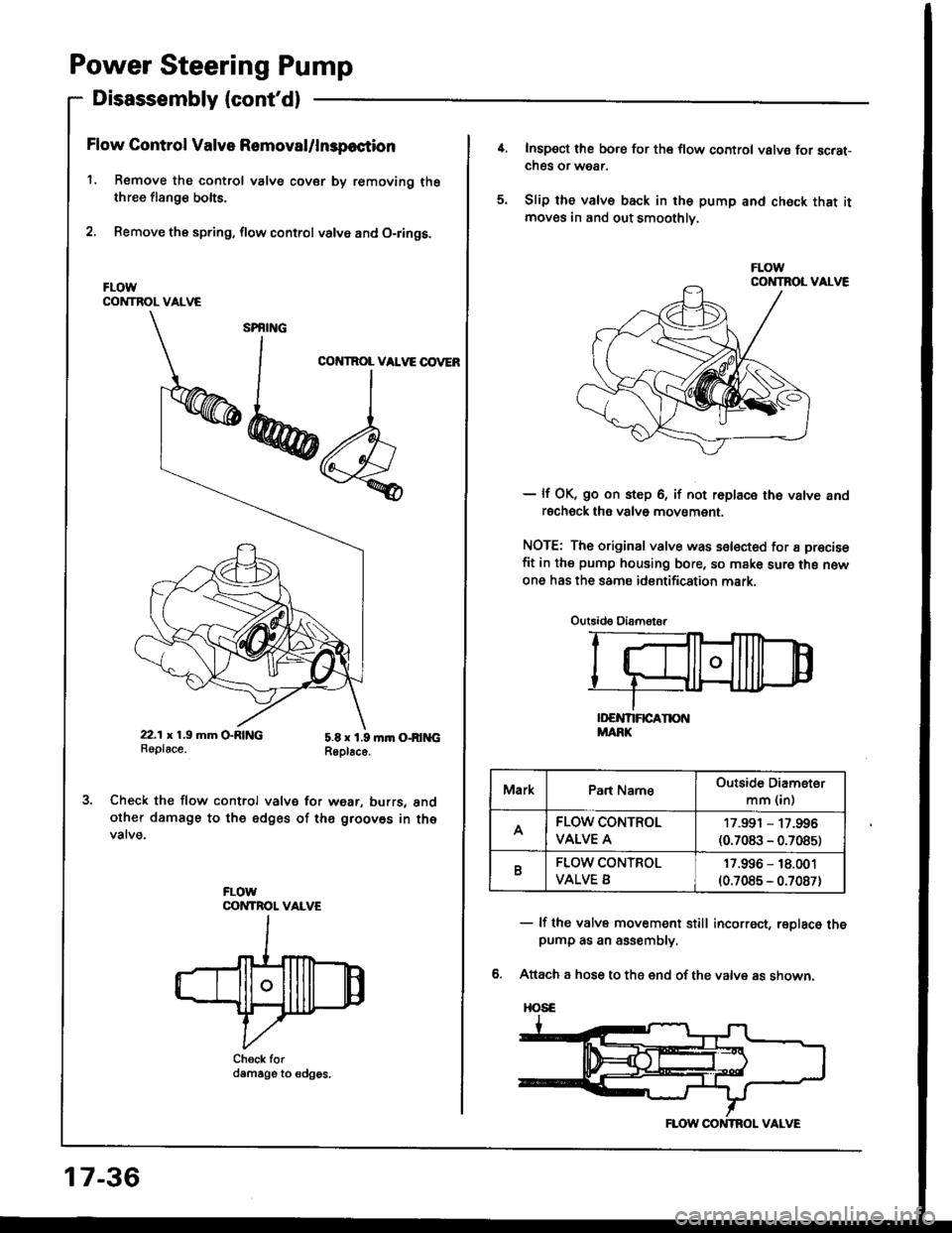

Flow Gontrol Valve Removal/lnspoction

l. Rsmove the control valve cov€r by romoving thethree flange bolts.

2. Remove the spring, flow control valve and O-rings.

FLOWCONTROL VALVE

Check the flow control valvg for wgar, burrs, andother damage to the edges of th€ groovos in tho

FLOWOONTROL VALVE

Ch6ck fordamags to €dgos.

17-36

il. Inspect the bore for the flow control valvs for scrat-ches or wear.

5. Slip the valve back in the pump and chock that itmoves in and out smoothly.

- lf OK, go on step 6, if not replace th6 valve androchsck the valve movsment.

NOTE: The original valve was selected for a precise

fit in the pump housing bore, so make sure ths n€w

on6 has the same identification mark.

Outsid€ Oiam€ter

- lf the valve movement still incorr€ct, replaco thepump as an assembly.

6. Attach a hose to the end of the valve as shown.

HOSE

MarkPart NameOutside Diameter

mm (in)

AFLOW CONTROL

VALVE A

17.991 - 17.996(0.7083 - 0.7085)

FLOW CONTROL

VALVE B

17.996 - 18.001

{0.7085 - 0.7087}

FLOW CONTROL VALVE

Page 645 of 1413

Power Steering Pump

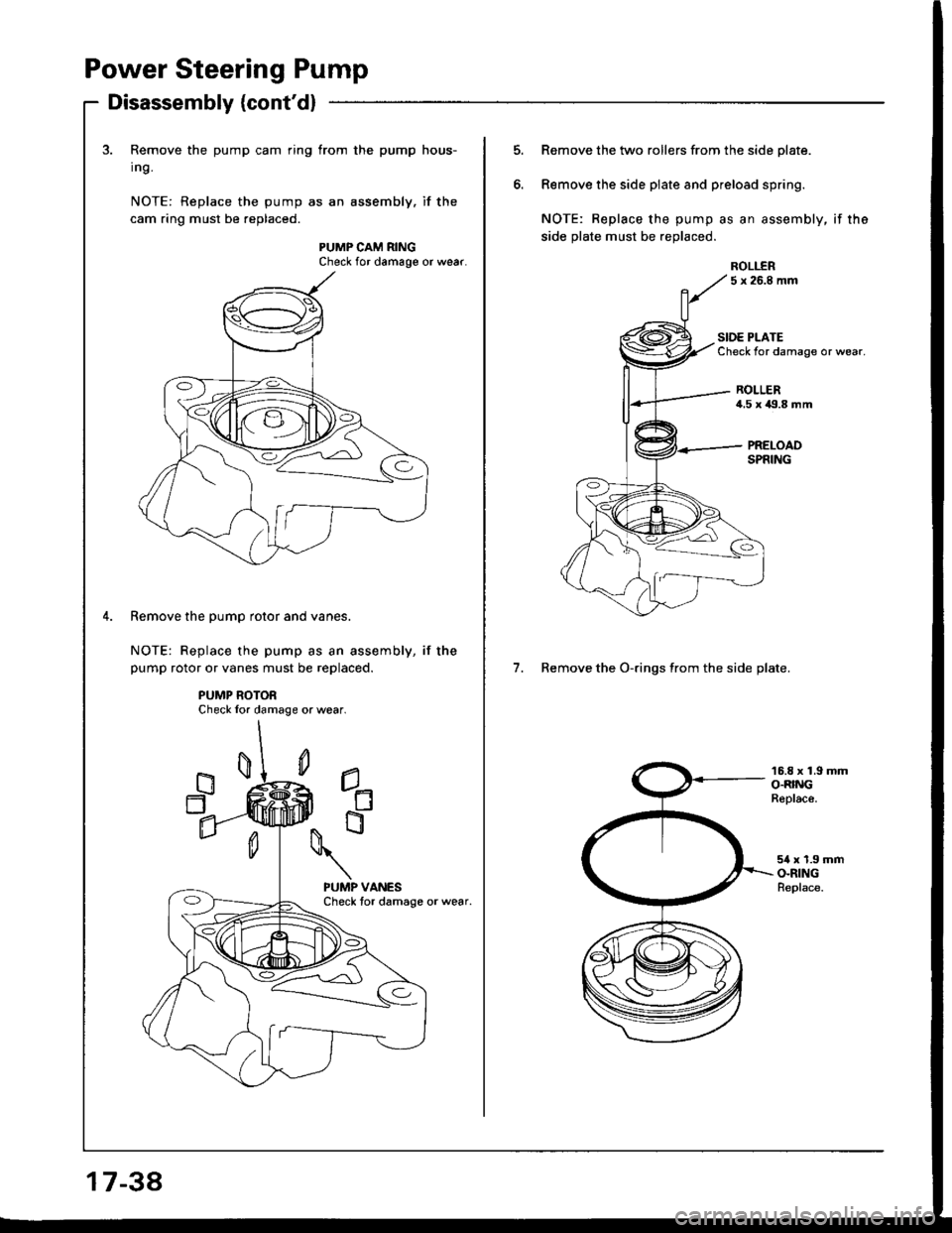

Disassembly {cont'd}

3. Remove the pump cam ring from the pump hous-

Ing.

NOTE: Replace the pump as an assembly. if the

cam ring must be replaced.

PUMP CAM RINGCheck for damage or wear.

Remove the pump rotor and vanes.

NOTE: Replace the pump as an assembly, if the

pump rotor or vanes must be replaced.

PUMP ROTORCheck lor damage or wear.

1734

Remove the two rollers from the side plate.

Remove the side piate and preload spring.

NOTE: Replace the pump as an assembly, if the

side plate must be replaced.

5 x 26.8 mm

7. Remove the O-rings from the side plate.

SIDE PLATECheck for damage or wear.

ROLLER4,5 x 119.8 mm

16.8 x 1.9 mmO.RINGReplace.

54 x 1.9 mmO-RINGReplace.

ROLI..ER

Page 647 of 1413

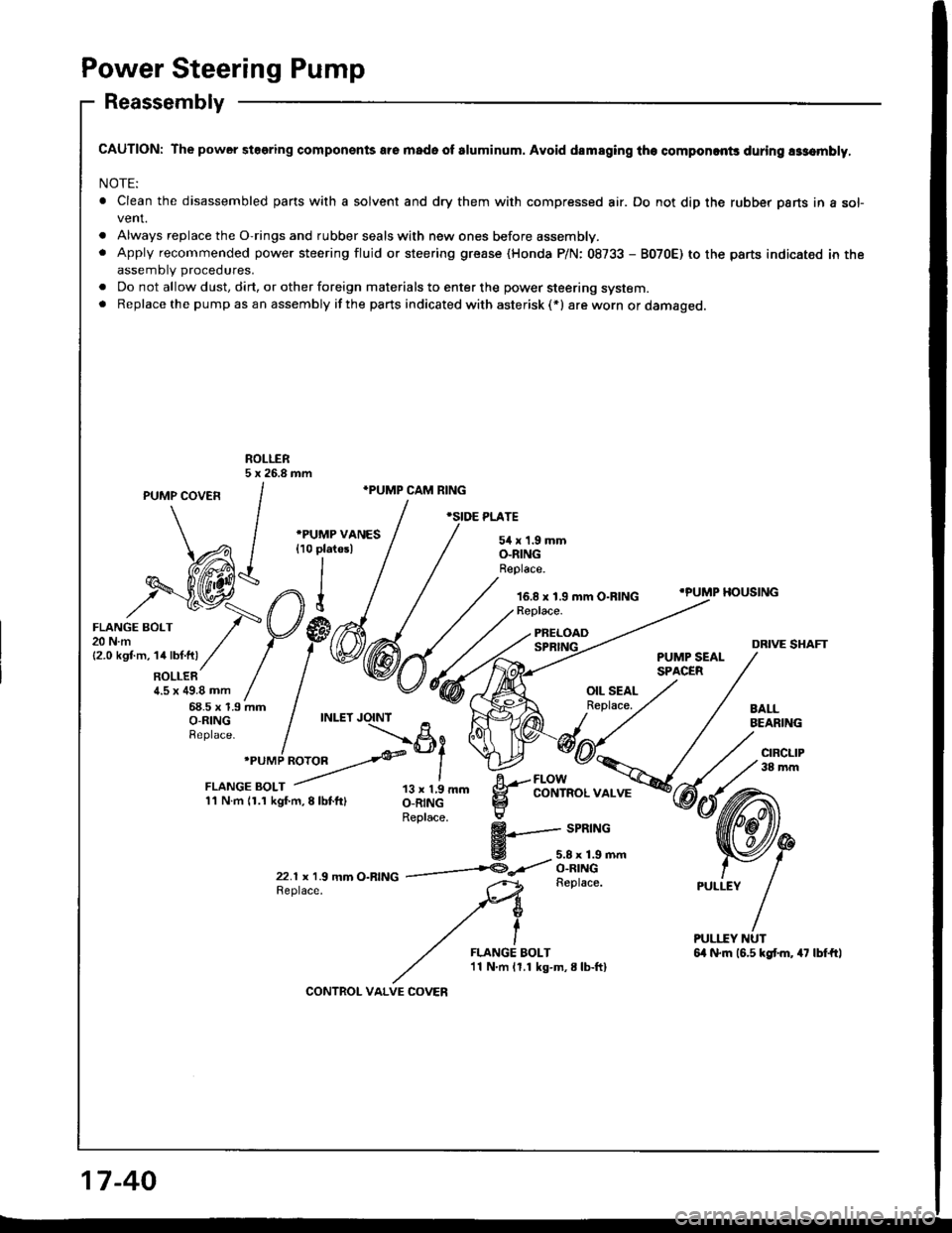

Power Steering Pump

Reassembly

CAUTION: The power steering componsnts are mado of sluminum. Avoid dsmaging th€ componcnts during assombly,

NOTE:

. Clean the disassembled pans with a solvent and dry them with compressed air. Do not dip the rubber parts in a sofvent.

. Always replace the O-rings and rubber seals with new ones before assembly.. Apply recommended power steering fluid or steering grease (Honda P/N: 08733 - B070E) to the parts indicated in theassemblv procedures.

. Do not allow dust, dirt, or other foreign materials to enter the power steering system.. Replacethe pump asan assembly ifthe parts indicated with asterisk (*) are worn or damaged.

ROLLER5 x 26.8 mm

PUMP covEn /

."'MP cAM RING

, / .",or r*r,

^ / -e^urrae vrues / / sirx1.smm

\Al {ro pratesl I / o_nrNc

dA-h1//EZil*l///'^ee'ace

o-ntNGReplace.

16.8 x 1.9 mm O-RING

\A I {ro Platesl

,h$;@:",n1

i'"otr

/-V#mtt.m,1a|t�t.fti// / / \E

RoLLER / |a.5 x ag.a mm / |68.5 x 1.9 mm Io-RING / INLET

Reptace.

I

.PUMP HOUSING

xf:.i'/pp@6{fr;ryDRIVE SHAFTPUMP SEALSPACERROLLER /1.5 x 49.8 mm /68.5 x 1.9 mmO-R|NG / INLET JO-INT

Replace.

I'PUMP ROTOR>ei

iiij:f:,ll-T;-,",,,, ll;il'- g--lblY""."*";

Replace. :

$+--- srntnc

E -5.8x1.9mm

22.r x r.9 mm o-RfNG ------t@-<'t o^::t:\-GReplace.Replace.

FLANGE BOLT'11 N.m 11.1 kg-m,8lb-ftI

17-40

CONTROL VALVE COVEN

Page 648 of 1413

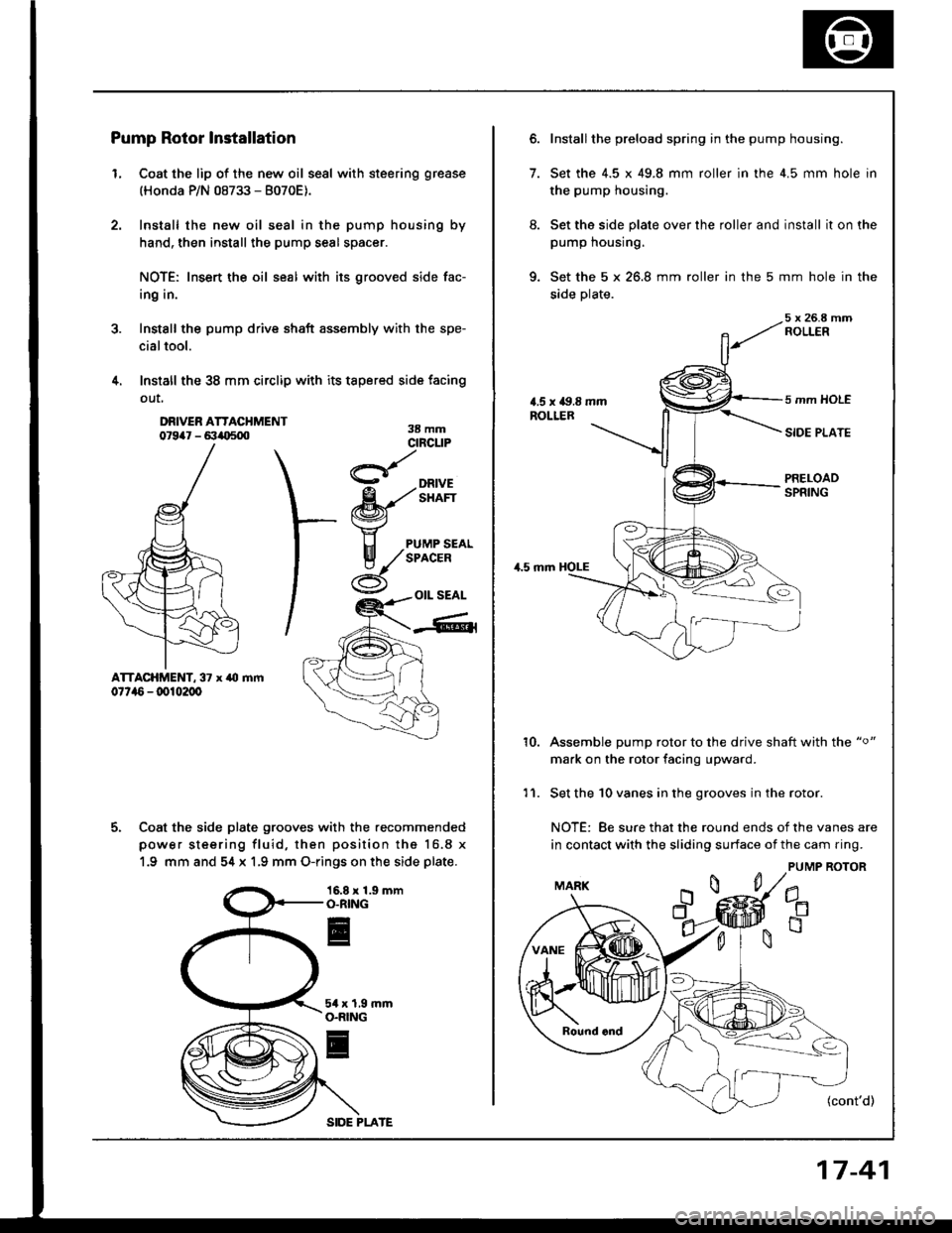

Pump Rotor Installation

L Coat the lip of the new oil seal with steering grease

(Honda P/N 08733 - 8070E).

Install the new oil seal in the pump housing by

hand, then install the pump seal spacer.

NOTE: Insert the oil seal with its grooved side fac-

ing in.

Install the pump drive shaft assembly with the spe-

cialtool.

Install the 38 mm circlip with its tapered side facing

out,

3.

4.

DRIVER ATTACHMENT07947 - 6:1io50038 mmcrncuP

- DRIVE

fu'/'i,Ert\=zl4

I"J PUMP SEALIf /sprcen

x,tY -ot seal

-Gll

ATTACHMENT, 37 x ,r0

07t,16 - dt102d,

5. Coat the side plate grooves with the recommended

power steering fluid, then position the 16.8 x

1.9 mm and 54 x 1,9 mm O-rings on the side plate.

16.8 x 1.9 mmO.RING

5a x 1,9O.RING

l

SIDE PLATE

17-41

6. Install the preload spring in the pump housing.

7. Set the 4.5 x 49.8 mm roller in the 4.5 mm hole in

the pump housing.

8. Set the side plate over the roller and install it on the

pump housrng.

9. Set the 5 x 26.8 mm roller in the 5 mm hole in the

side plate.

5 x 26.8 mmROLLER

5 mm HOLE

SIDE PLATE

PRELOADSPRING

,1.5 mm

10.Assemble pump rotor to the drive shaft with the "o"

mark on the rotor facing upward.

Set the 10 vanes in the grooves in the rotor.

NOTE: 8e sure that the round ends of the vanes are

in contact with the sliding surface of the cam ring.

PUMP ROTOR

(cont'd)

11.

Page 649 of 1413

Power Steering Pump

Reassembly (cont'dl

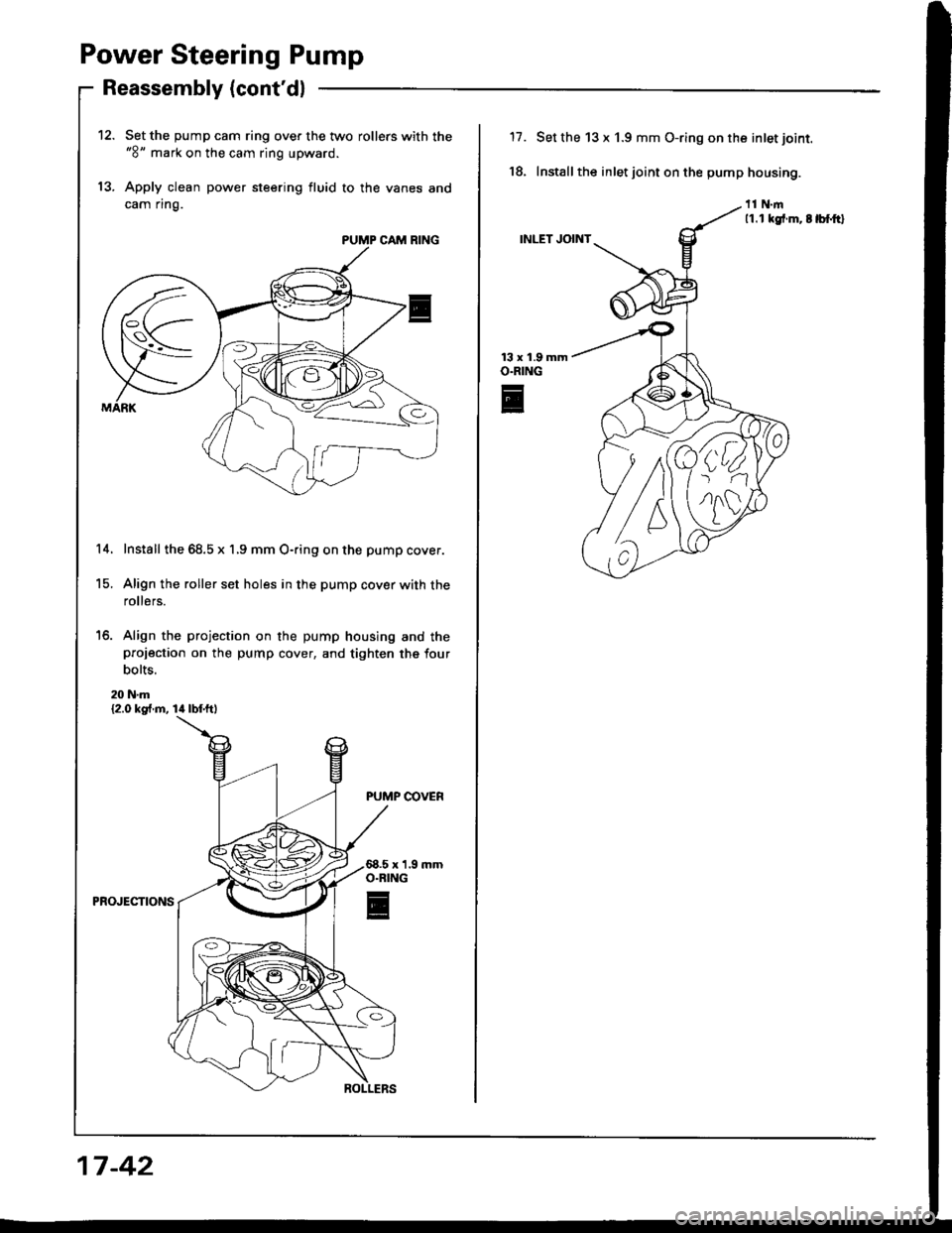

Set the pump cam ring over the two rollers with the"8" mark on the cam ring upward.

Apply clean power steering fluid to the vanes and

cam ring.

Install the 68.5 x 1,9 mm O-ring on the pump cover.

Align the roller set holes in the pump cover with the

rollers.

'16. Align the projection on the pump housing and theprojection on the pump cover, and tighten the four

bolts.

20 N.m{2.0 kg .m, lil lbf.ftl

PUMP COVER

PROJECTIONS

13.

PUMP CAM RING

14.

15.

17 -42

17.

18.

13 x 1.9O.RING

E

Set the 13 x 1.9 mm O-ring on the inlet joint.

Install the inlet joint on the pump housing.

11.1 kgt.m. t lbf.ftl

INLET JOINT

T9