check engine HONDA INTEGRA 1994 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 6 of 1413

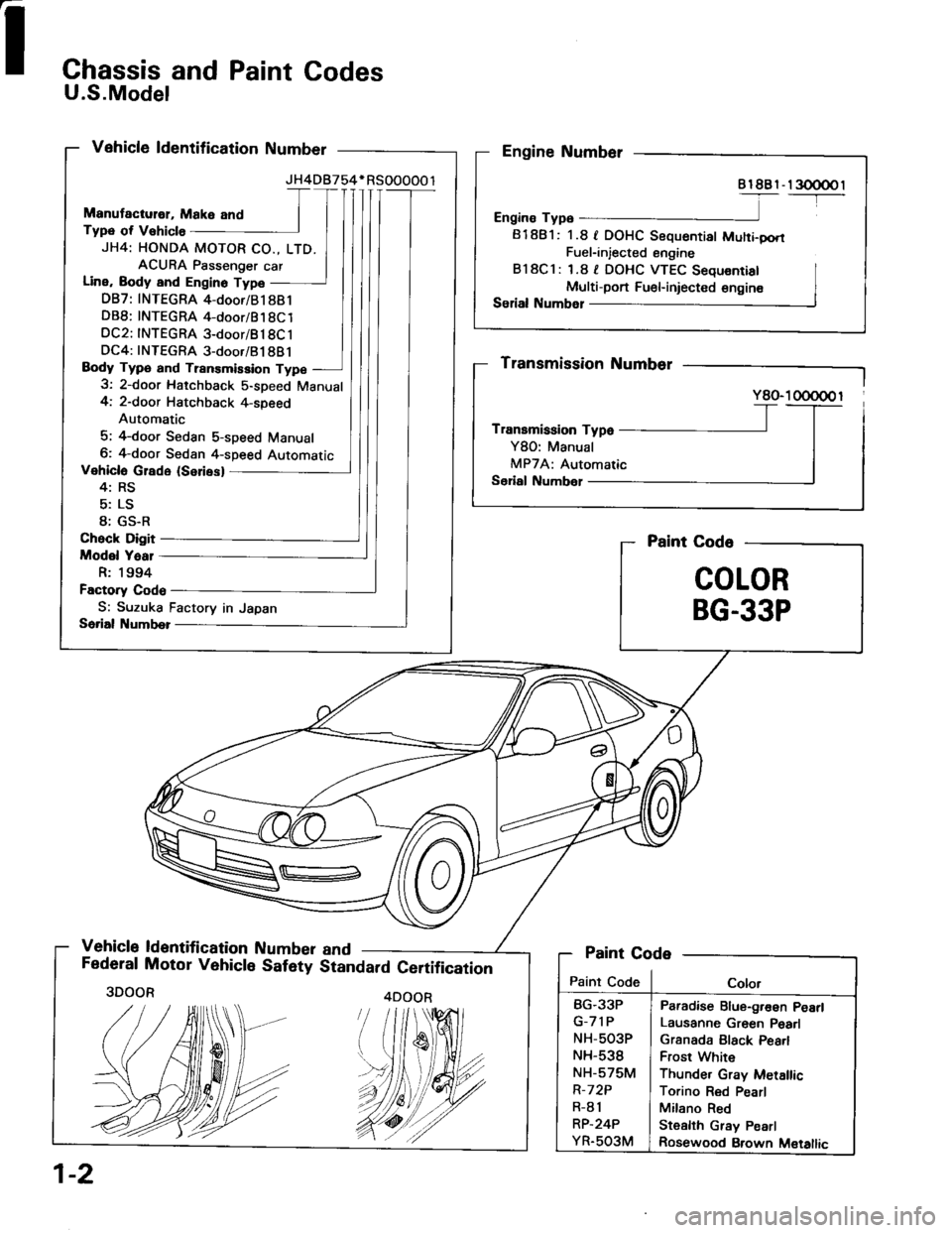

Chassis and Paint Codes

U.S.Model

Vehicle ldentification Number

Manutactulol, Make and

Typ€ of Vshicle

JH4: HONDA MOTOR CO., LTD.

ACURA Psssenger car

Line, Body and Engino Type

DB7: INTEGRA 4-door/B1 881

DB8: INTEGRA 4-door/81 8Cl

DC2: INTEGRA 3-door/B18C 1

DC4: INTEGRA 3-door/B1 8B j

Body Type and Trsnsmission Type

3: 2-door Hatchback S-speed Manual

4: 2-doot Hatchback 4-speed

Automatic

5; 4-door Sedan s-speed Manual

6: 4-door Sedan 4-speed Automatic

Vehicle Glado (Seriesl

4: RS

5: LS

8; GS-R

Check Digit

Model Yaal

R: 1994

Factory Code

S: Suzuka Factory in Japan

Serial Numb€l

Vehicle ld€ntification Number and

JH4DB754* RSOOOOO 1

I

Engine Number

8l8Br-r300@l-----T-----

Engine Typ6

81881: 1.8 f DOHC Sequentiat Muhi-pori

Fuel-injected engine

B l8Cl : 1.8 | DOHC VTEC Sequ€nrial

Multi-port Fu€l-iniected €ngin€

Se al Numbel

Paint Code

COLOR

BG.33P

Federal Motor Vehicle Safety Standard Certification

Transmission Numbsr

Y80- 1 000@ I

Transmission Type

Y80: Manual

MPTA: Automatic

Serial Numbel

Paint Code

Paint CodeColor

BG.33P

G-71P

NH-5O3P

NH-538

NH-575M

R-7 2P

R-81

RP.24P

YR.5O3M

Paradise Blue-g.€en PeErl

Lausanne Gr6en Pead

Grsnada Black Pea.l

Frost White

Thunder Grav Metallic

Torino Red Pearl

Milano Red

Stealth Gray Pearl

Rosewood Brown M€tallic

1-2

3DOOR4DOOR

Page 7 of 1413

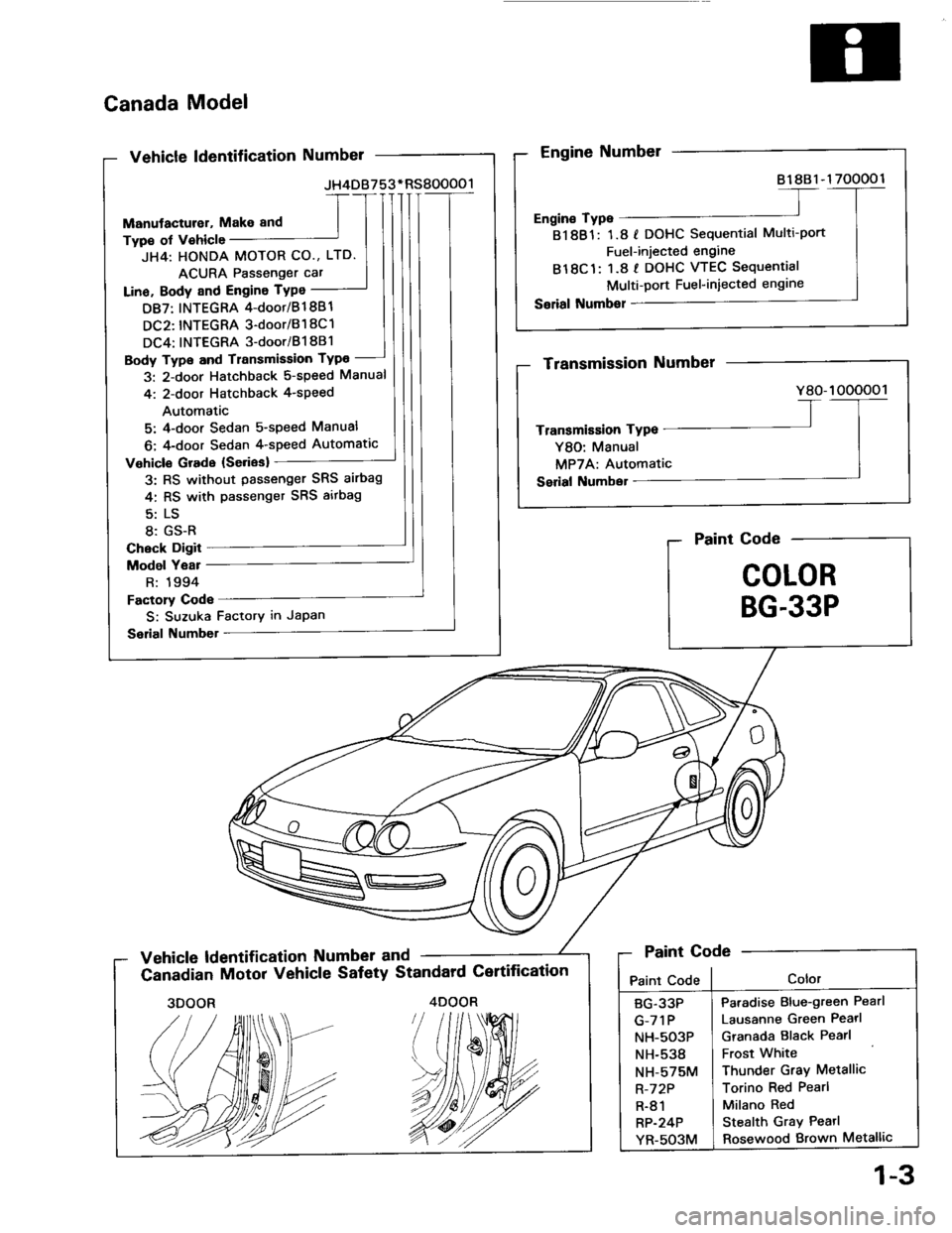

Canada Model

Vehicle ldentification Numbel

Manutacturer, Makeand

Type of v€hicle

JH4: HONDA MOTOR CO., LTD.

ACURA Passenger car

Lino. Body and Engine TYPo

D87: INTEGRA 4-doot/Bl 881

DC2: INTEGRA 3-dootBl 8C1

DC4: INTEGRA 3-doori B18B1

Body Type and Transmission TYPo

3: 2-door Hatchback 5-speed Manual

4'. 2-door Hatchback 4-speed

Automatic

5: 4-door Sedan s-speed Manual

6: 4-door Sedan 4-speed Automatic

Vehicle Grade {Sedes}

3: RS without passenger SRS airbag

4: RS with passenget SRS aitbag

8: GS-R

Check Digit

Model Yeat

R: 1994

Factory Code

S: Suzuka Factory in Japan

Serial Numbel

JH4DB753. RS800001

Engine Number

81881-1 700001

Engin€ Type

81881: 1.8 I DOHC Sequential Multi-port

Fuel-injected engine

B18C1: 1.8 I DOHC VTEC Sequential

Multi-Dort Fuel-iniected engrne

Serial Number

Paint Code

COLOR

BG.33P

Vehicle ldentification Number and

Canadian Motor Vehicle Safety Standard Certification

Transmission Number

Y80-1000001

Transmission Type

Y80: Manual

MPTA: Automatic

Serial Numbel

Paint Code

Paint CodeColor

Paradise Blue-green Pearl

Lausanne Green Pearl

Granada Elack Pearl

Frost White

Thunder Gray Metallic

Torino Red Pearl

Milano Red

Stealth Gray Pearl

Rosewood Brown Metallic

BG.33P

G-71P

NH-5O3P

NH-538

NH-575M

R-72P

R-81

RP-24P

YR-503M

3DOOR4DOOR

1-3

Page 11 of 1413

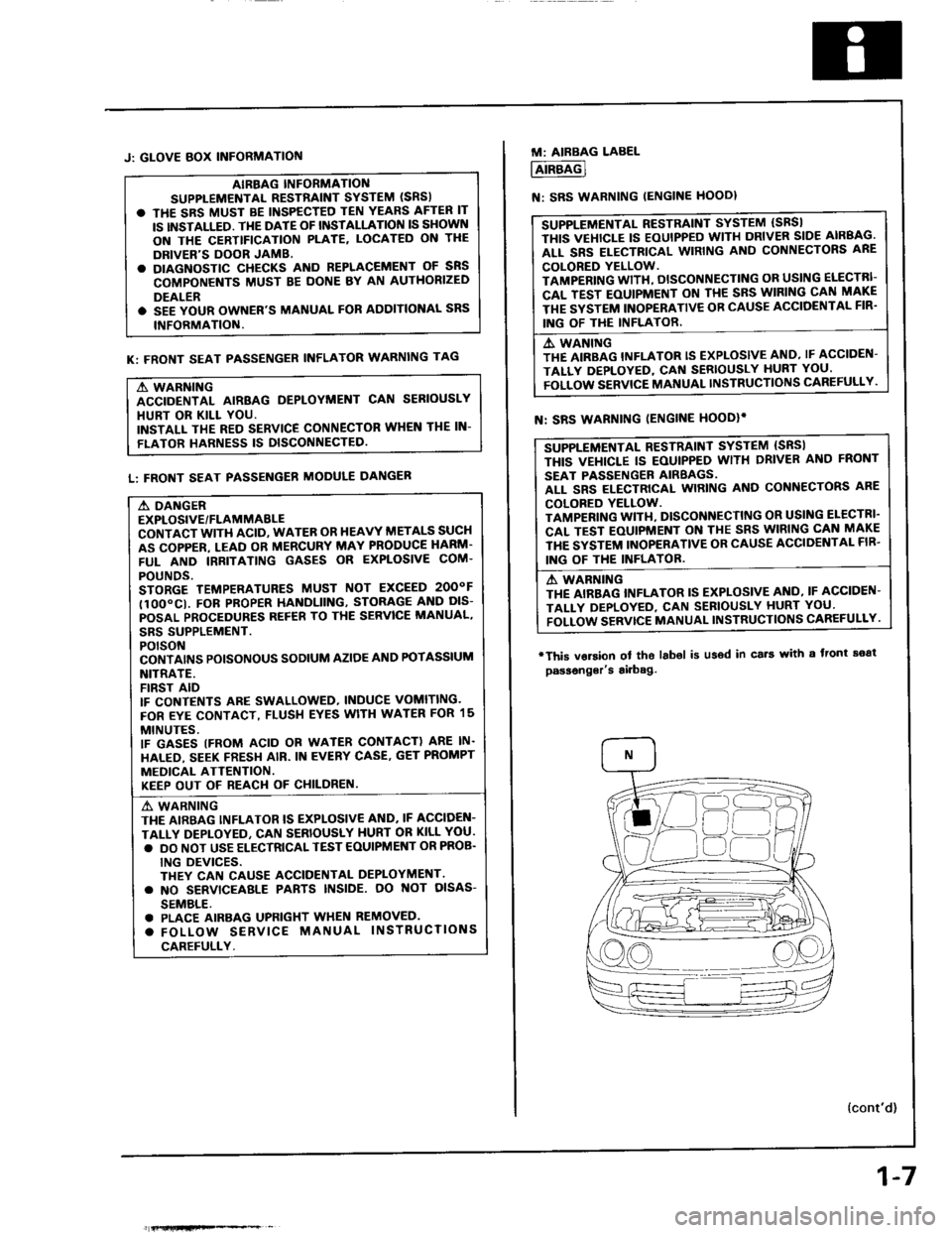

J: GLOVE BOX INFORMATIOf{

AIBBAG INFORMANO

SUPPLEMENTAL RESTiAINT SYSTEM (SRS)

. THE SRS MUST BE INSPECTED TEN YEARS AFTER IT

IS INSTALLED. TI{E DATE OF INSTALLATION IS SHOWN

ON THE CERTTFICATION PLATE, LOCATED ON THE

DRIVER'S DOOR JAMB.

. DIAGNOSTIC CHECKS AND REPLACEMENT OF SNS

COMPONENTS MUST BE DONE BY AN AUTHORIZED

DEALER

. SEE YOUR OWNER'S MANUAL FOR AODITIONAL SRS

INFORMATION.

K: FRONT SEAT PASSENGER INFLATOR WARNING TAG

A WARNING

ACCIDENTAL AIRBAG DEPLOYMENT CAN SERIOUSLY

HURT OR KILL YOU.

INSTALL THE RED SERVICE CONNECTOR WHEN THE IN-

FLATOR HARNESS IS DISCONNECTED

L: FRONT SEAT PASSENGER MODULE DANGER

A DANGER

EXPLOSIVE/FLAMMABLE

CONTACT WITH ACID, WATER OR HEAVY METALS SUCH

AS COPPER. LEAD OR MERCURY MAY PRODUCE HARM'

FUL AND IRRITATING GASES OR EXPLOSIVE COM.

POUNDS.

STORGE TEMPERATURES MUST NOT EXCEED 2OOOF

tlOO"CI. FOB PROPER HANDLIING, STORAG€ AND DIS-

POSAL PROCEDURES REF€B TO THE SERVICE MANUAL,

SBS SUPPLEMENT.

POTSON

CONTAI'\'S POISONOUS SODIUM AZIOE AND POTASSIUM

NITRATE.

FIRST AID

IF CONTENTS ARE SWALLOWED, INDUCE VOMITING.

FOR EYE CONTACT, FLUSH EYES WITH WATER FOR 15

MINUTES.

IF GASES (FROM ACID OR WATER CONTACT) ARE IN.

HALED, SEEK FRESH AIR. IN EVERY CASE. GET PROMPT

MEDICAL ATTENTION.

KEEP OUT OF REACI.I OF CHILDREN.

A' WARNING

THE AIRBAG INFLATOR IS EXPLOSIVE AND. IF ACCIDEN-

TALLY DEPLOYEO, CAN SERIOUSLY HURT OR KILL YOU.

. DO NOT USE ELECTRICAL TEST EOUIPMENT OR PROB.

ING DEVICES.

THEY CAN CAUSE ACCIOENTAL DEPLOYMENT.

. NO SERVICEAALE PABTS INSIDE. OO NOT OISAS-

SEMBLE.

. PLACE AIRBAG UPFIGHT WHEN REMOVED.

. FOLLOW SERVICE MANUAL INSTRUCTIONS

CAREFULLY.

fi{lHfiFe*% _

1-7

M: AIRBAG LABEL

AIRBAG

N: SRS WARNING IENGINE HOODI

SUPPLEMENTAL RESTRAINT SYSTEM (SBSI

THIS VEHICLE IS EOUIPPED WITH DRIVER SIDE AIRBAG.

ALL SRS ELECTRICAL WIRING AND CONNECTORS ARE

COLORED YELLOW.

TAMPERING WITH, DISCONNECTING OR USING ELECTRI-

CAL TEST EOUIPMENT ON TI{E SRS WIRING CAN MAKE

THE SYSTEM INOPERATIVE OB CAUSE ACCIOENTAL FIR'

ING OF THE INFLATOR.

A. WANING

THE AIRBAG INFLATOR IS EXPLOSIVE AND, IF ACCIDEN-

TALLY DEPLOYED, CAf{ SERIOUSLY HURT YOU'

FOLLOW SERVICE MANUAL INSTRUCTIONS CAREFULLY.

SUPPLEMENTAL RESTRAINT SYSTEM {SRSI

THIS VEI{ICLE IS EOUIPPED WITH DRIVER ANO FRONT

SEAT PASSENGER AIRBAGS.

ALL SRS ELECTRICAL WIRING AND CONNECTORS ARE

COLORED YELLOW.

TAMPENING WITI{, DISCONNECTING OR USI G ELECTRI'

CAL TEST EOUIPMENT ON THE SRS WIRING CAN MAKE

THE SYSTEM INOPERATIVE OR CAUSE ACCIDENTAL FIB'

ING OF THE INFLATOB.

A WABNING

THE AIRBAG INFLATOR IS EXPLOSIVE AI{O, IF ACCIDEN-

TALI-Y DEPLOYED, CAN SEBIOUSLY HURT YOU'

FOLLOW SERVTCE MANUAL INSTRUCTIONS CAREFULLY.

N: SRS WARNING IENGINE HOODIi

'This vorsion

passonger's

ol tho labol is u36d in cs.t with a front soat

airbag.

{cont'd)

Page 26 of 1413

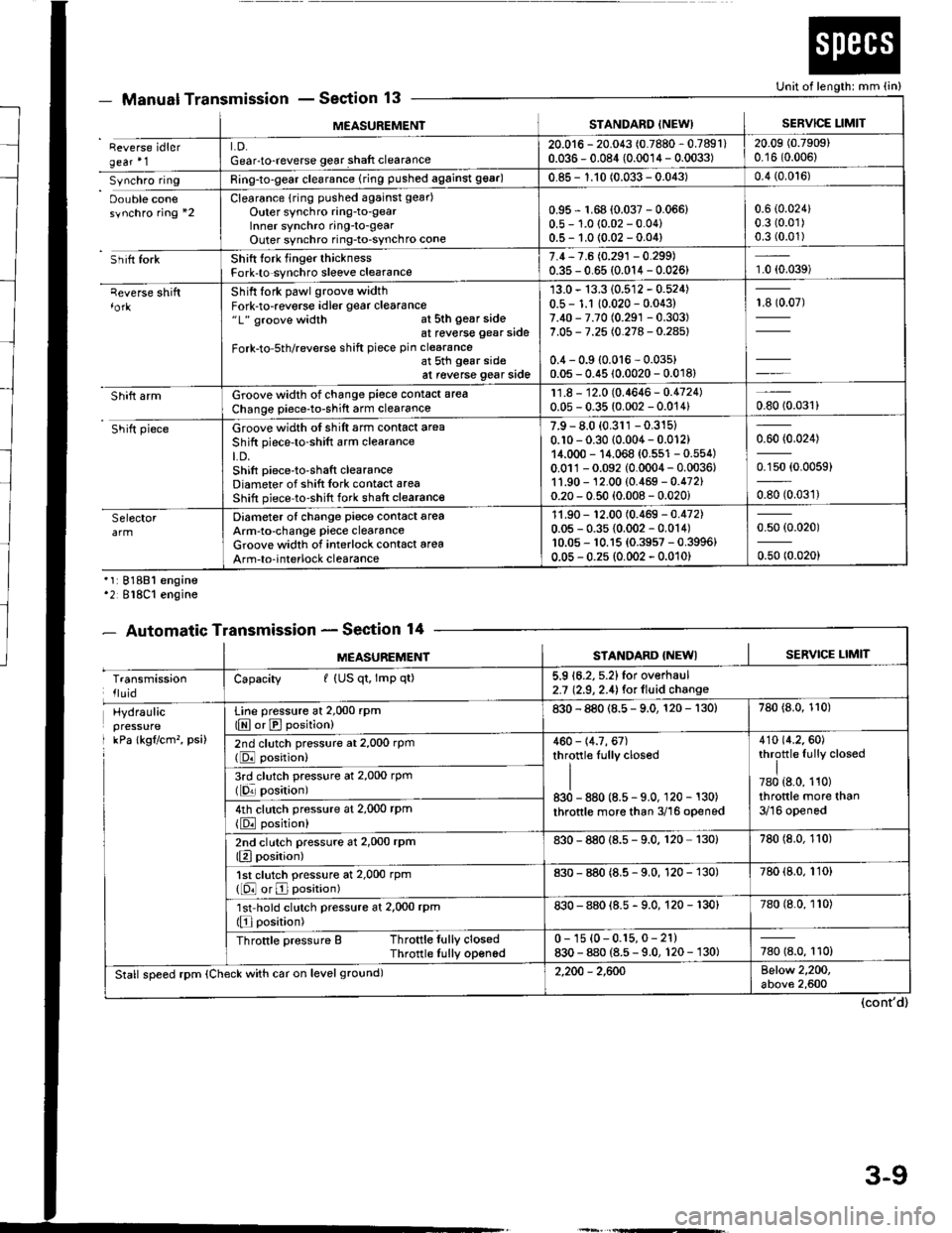

MEASUREMENISTANDARD INEW)SERVICE LIMIT

Reverse idlergear'1LD.Gear-to-reverse gear shaft clearance20.016 - 20.043 (0.7880 - 0.7891)0.036 - 0.084 (0.0014 - 0.0033)20.09 (0.7909)

0.16 (0.006)

Synchro ringRing-to-gear clearance (ring pushed against 99ar)0.85 - 1.10 (0.033 - 0.043)0.4 (0.0't6)

Oouble conesynchro ring *2Clearance {rin9 pushed against gear)

Outer synchro ring-to-gearlnner synchro ring-to-gearOuter synchro ring-to-synchro cone

0.95 r 1.68 (0.037 - 0.066)0.5 - 1.0 (0.02 - 0.04)0.5- 1.0 {0.02 -0.04)

0.6 (0.024)

0.3 (0.01)

0.3 (0.01)

Sh itt forkShift tork finger thicknessFork-to synchro sleeve clearance7.4,7.6 (0.291 - 0.299)0.35 - 0.65 (0.014 - 0.026)1.0 (0.039)

qeverse shiftShift fork pawl groove widthFork-to-reverse idler gear clearance"1" groove width at sth gear sideat reverse gear side

Fork-to-5th/reverse shift piece pin clearanceat 5th gear sideat reverse gear side

13.0 - 13.3 (0.512 - 0.524)0.5 - 1.1 10.020 - 0.043)7.40 - 7.70 (0.291 -0.303)

7.05 - 7.25 (0.278 - 0.28s)

0.4 - 0.9 {0.016 - 0.03s)0.05 - 0.45 (0.0020 - 0.018)

13907)

Shift armGroove width of change piece contact area

Change piece-to-shift arm clearance11.8 - 12.0 (0.4646- 0.4724)0.05 - 0.35 (0.002 - 0.014)0.8010.031)

Shift pieceGroove width of shift arm contact area

Shift piece'to-shift arm clearanceLD.Shift piece-to-shaft clearanceDiameter of shift Iork cont6ct areaShift piece-to-shift fork shaft clearance

7.9 - 8.0 (0.311 -0.315)

0.10 - 0.30 (0.004 - 0.012)14.000 - 14.068 {0.551 - 0.554)0.011-0.092 (0.0004 - 0.0036,1'1.90 - 12.00 (0.469 - 0.472)0.20 - 0.50 (0.008 - 0.020i

0.60 (0.024)

0.150 (0.0059)

oso to.oart

SelectorDiameter of change piece contact areaArm-to-change piece clearanceGroove widlh of interlock contact area

Arm-to-interlock clearance

11.90 - '�t2.00 (0.469 - 0.472)0.05 - 0.35 {0.002 - 0.014)10.05 - 10.15 {0.3957 - 0.3996}0.05 - 0.2s (0.002 - 0.010)

0.50 (0.020)

0.50 (0.020)

Manual TransmissionSection 13

'1:81881 engine'2 818C1 engine

- Automatic TransmissionSection 14

Unit of length: mm (in)

(cont'd)

- oEutrlrrl rr

MEASUREMENTSTANDARD {NEWISERVICE LIMIT

TransmissionlluidCapacity I (US qt, lmp qt)5.9 16.2, 5.2)for overhaul2.7 (2.9, 2.4) for lluid change

Hydraulicpressure

I kPa lkgflcm'�, psi)

Line pressure at 2,000 rpm(E or E position)830 - 880 (8.5 - 9.0, 120 - 130)780 {8.0, 110)

2nd clutch pressure at 2,000 rpm(DJ position)460 - 14.7, 67)throttle Iully closed

II830 - 880 (8.5 - 9.0, 120 - 130)

throttle more than 3/16 opened

410 {4.2.60)throttle fully closed

I780 {8.0, 110)throttle more than3/16 opened

3rd clutch pressure at 2,000 rpm(lqr posirion)

4th clutch pressure at 2,000 rPm

{E position)

2nd clutch pressure at 2,000 rPm(Elposition)830 - 880 {8.s - 9.0. 120 130)780 (8.0, 110)

1st clutch pressure at 2,000 rpm([O or E position)830 - 880 (8.5 - 9.0, 120 - 130)780 (8.0, 110)

'lst'hold clutch pressure at 2,000 rpm(Elposition)830 - 880 {8.5 - 9.0, 120 - 130}780 (8.0, 110)

Throttle pressure B Throttle fully closedThrotlle Iully opened0 - 1s {0-0.15,0- 21)830 - 880 (8.5 - 9.0, 120 - 130)780 18.0, 110)

Stall speed rpm (Check with car on level ground)2,200 - 2,600Below 2,200,above 2,600

3-9

Page 56 of 1413

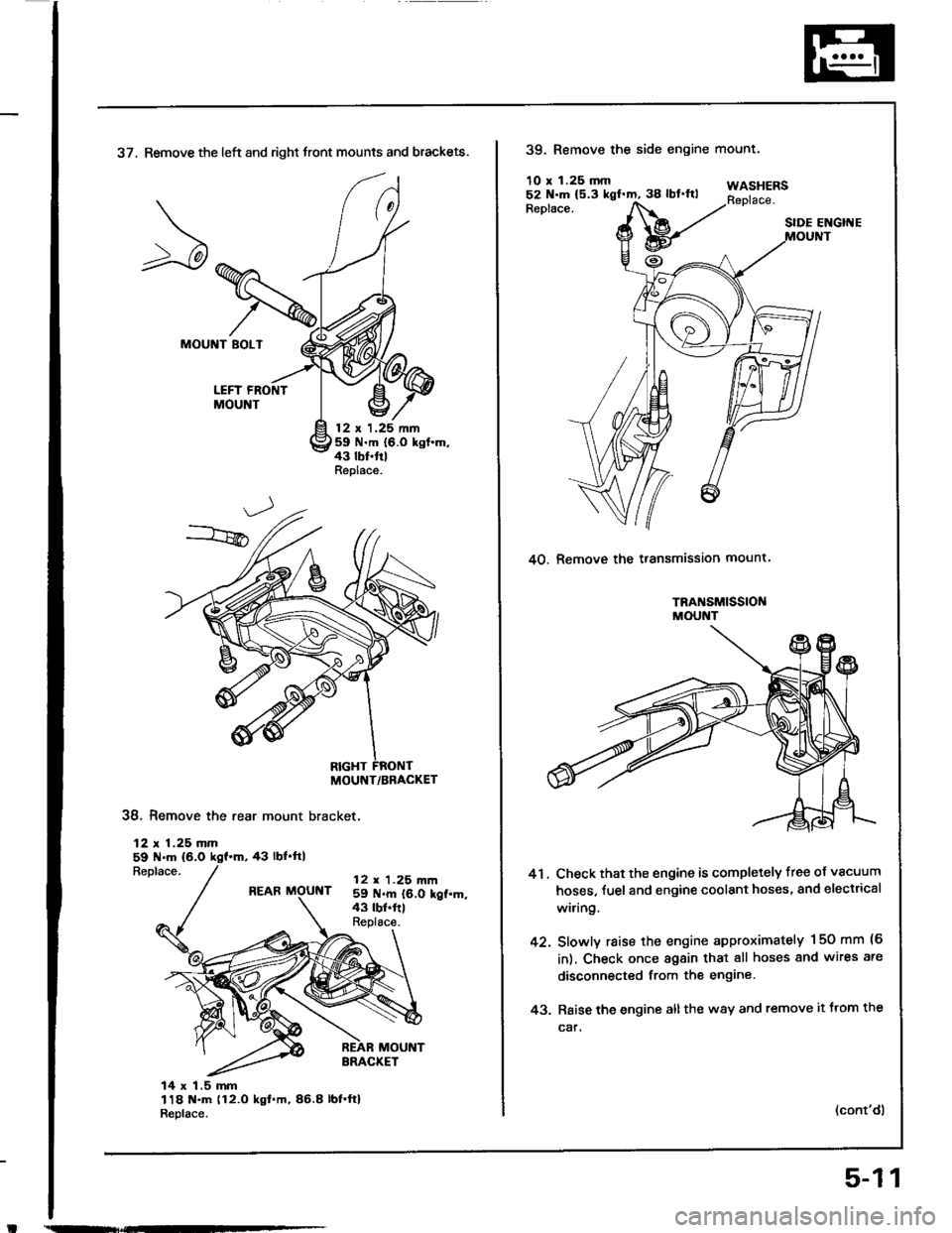

37, Remove the left and right front mounts and brackets.

MOUNT BOLT

LEFT FRONTMOUNT

12 t 1.25 nn59 N.m {6.0 kgt.m,43 lbf.trlReplace.

38. Remove the rear mount bracket,

12 r 1.25 mm59 N.m (6.0

Replace.43 rbf.ftl

REAR MOUNT12 r 1.25 m|n59 N.m {6.0 kgt.m,43 tbt.frlReplace.

14 x 1.5 mm118 t{.m (12.O kgt.m,86.8 lbl.ft}R6place.

MOUNT/BRACKET

39. Remove the side engine

10 r 1.25 mm

mounr.

WASHERSReplace.Replace.SIDE ENGIITE

40. Remove the transmission mount

TRA SM|SS|OI{MOUNT

41. Check that the engine is completely free of vacuum

hoses, fuel and engine coolant hoses, and electrical

wi.ing.

42. Slowly raise the engine approximately 150 mm (6

in), Check once again that all hoses and wires are

disconnected from the engine

43. Raise the engine all the w8y and remove it trom the

car.

(cont'dl

5-11

Page 90 of 1413

t

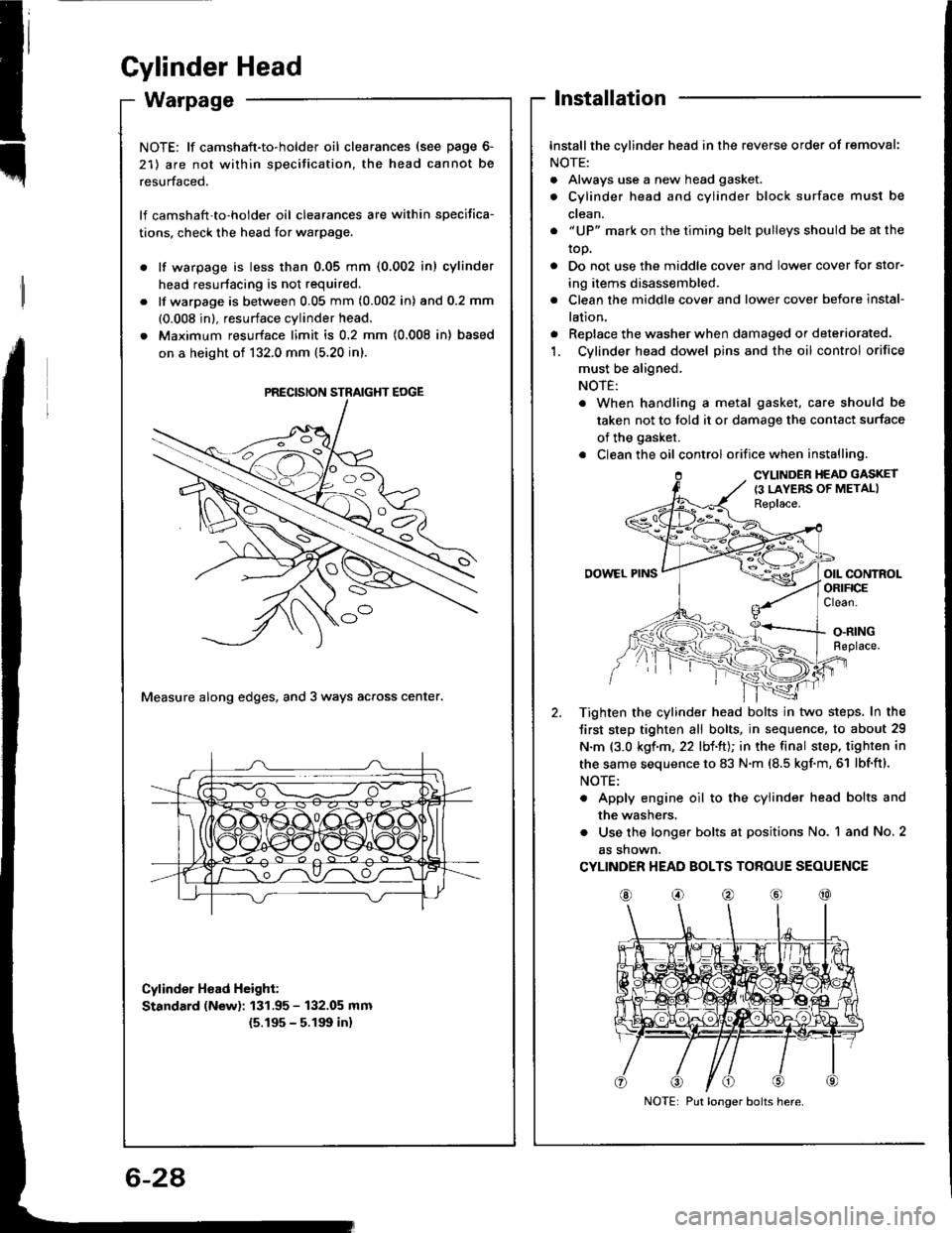

Gylinder Head

Installation

Installthe cylinder head in the reverse order of removal:

NOTE:

. Always use a new head gasket.

. Cylinder head and cylinder block surface must be

ctean.

. "UP" mark on the timing belt pulleys should be at the

top.

. Do not use the middle cover and lower cover for stor-

ing items disassembled.

. Clean the middle cover and lower cover before instal-

lation.

. Replace the washer when damaged or deteriorated.'1. Cylinder head dowel pins and the oil control orifice

must be aligned,

NOTE:

. When handling a metal gasket, care should be

taken not to told it or damage the contact surface

of the gasket.

. Clean the oil control orifice when installing.

CYLINDER HEAD GASKET

{3 LAYERS OF METALIReplace.

OOWEL PINSorl coNtnolORIFICEClean.

O.RINGReplace.

Tighten the cylinder head bolts in two steps. In the

Jirst step tighten all bolts, in sequence, to about 29

N.m {3.0 kgf.m, 22 lbl.ltJ; in the final step, tighten in

the same sequence to 83 N.m (8.5 kgf.m, 61 lbf'ft).

NOTE:

. Apply engine oil to the cylinder head bolts and

the washers.

. Use the longer bolts at positions No. 1 and No. 2

as shown.

CYLINDER HEAD BOLTS TOROUE SEOUENCE

@o@@@

NOTE: lf camshaft-to-holder oil clearances (see page 6-

21) are not within specitication, the head cannot be

resurfaced.

lf camshaft'to-holder oil clearances are within specifica-

tions, check the head for warpage.

lf warpage is less than 0.05 mm (0.002 in) cylinder

head resurtacing is not required.

lf warpage is between 0.05 mm (0.002 in) and 0.2 mm

(0.008 in), resurface cylinder head.

Maximum resurface limit is 0.2 mm (0.008 in) based

on a height of 132.0 mm (5.20 in).

Measure along edges, and 3 ways across center.

Cylinder Hoad Height:

Standard (New): 131.95 - 132.05 mm

{5.195 - 5.191t in}

PRECISION STRAIGHT EOGE

Put longer bolts here.

Page 93 of 1413

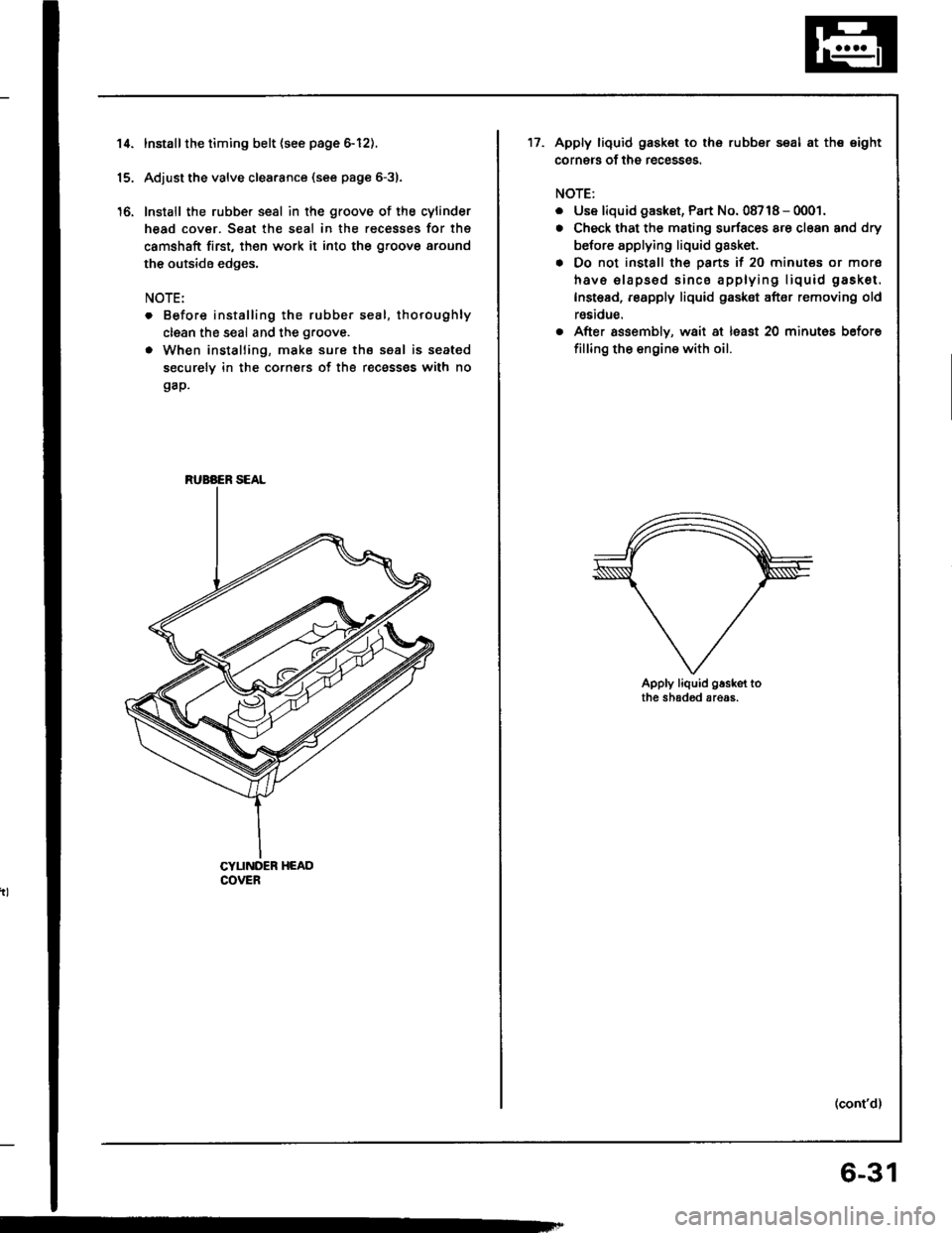

14.

16.

Installthe timing belt {see page 6-12).

Adjust the valve clea.ance (see page 6-31.

Install the rubber seal in the groove of the cylinder

head cover. Seat the seal in the recesses for thg

camshaft first, th€n work it into the groove around

the outside edges,

NOTE:

. Before installing the rubber seal, thoroughly

clean the seal and the groove.

. When installing, make sure the seal is seated

securely in the corners of the recass€s with no

gap.

CYUNDER HEADCOVER

RUBAER SEAL

17.Apply liquid gask€t to the rubber seal at the eight

corners of the recesses.

NOTE:

. Use liquid gaskst, Part No. 08718 - 0001.

. Check that the mating surfaces are cl€an and dry

before applying liquid gasket.

. Do not install the parts if 20 minutes or mor6

havs elapsod sinco applying liquid gasket.

Instead, reapply liquid gasket after removing old

reaidue.

. After assembly, wait at lsast 20 minutes before

filling the engine with oil.

Apply liquid g.sket tothe shaded areas.

(cont'd)

6-31

Page 99 of 1413

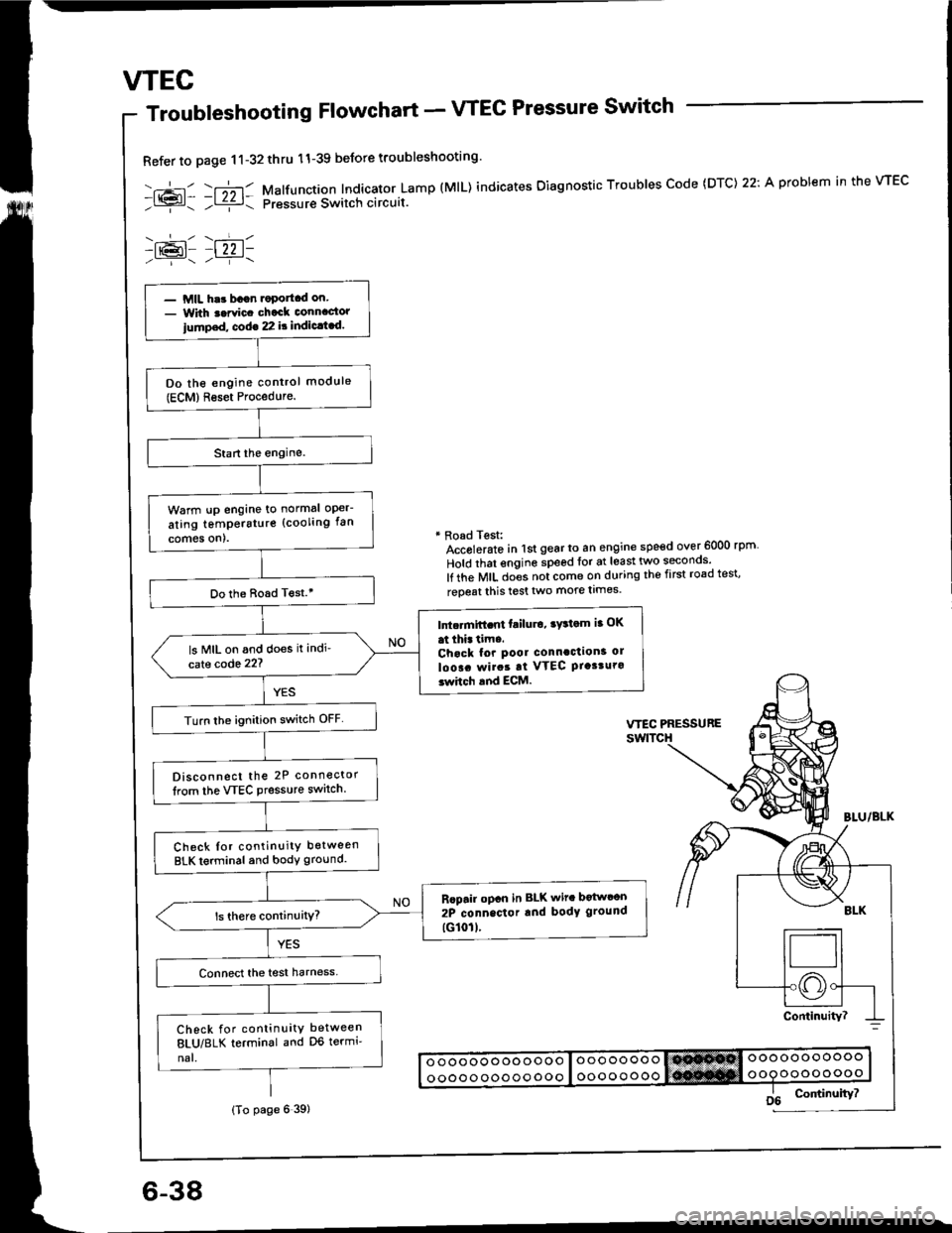

wEc

6-38

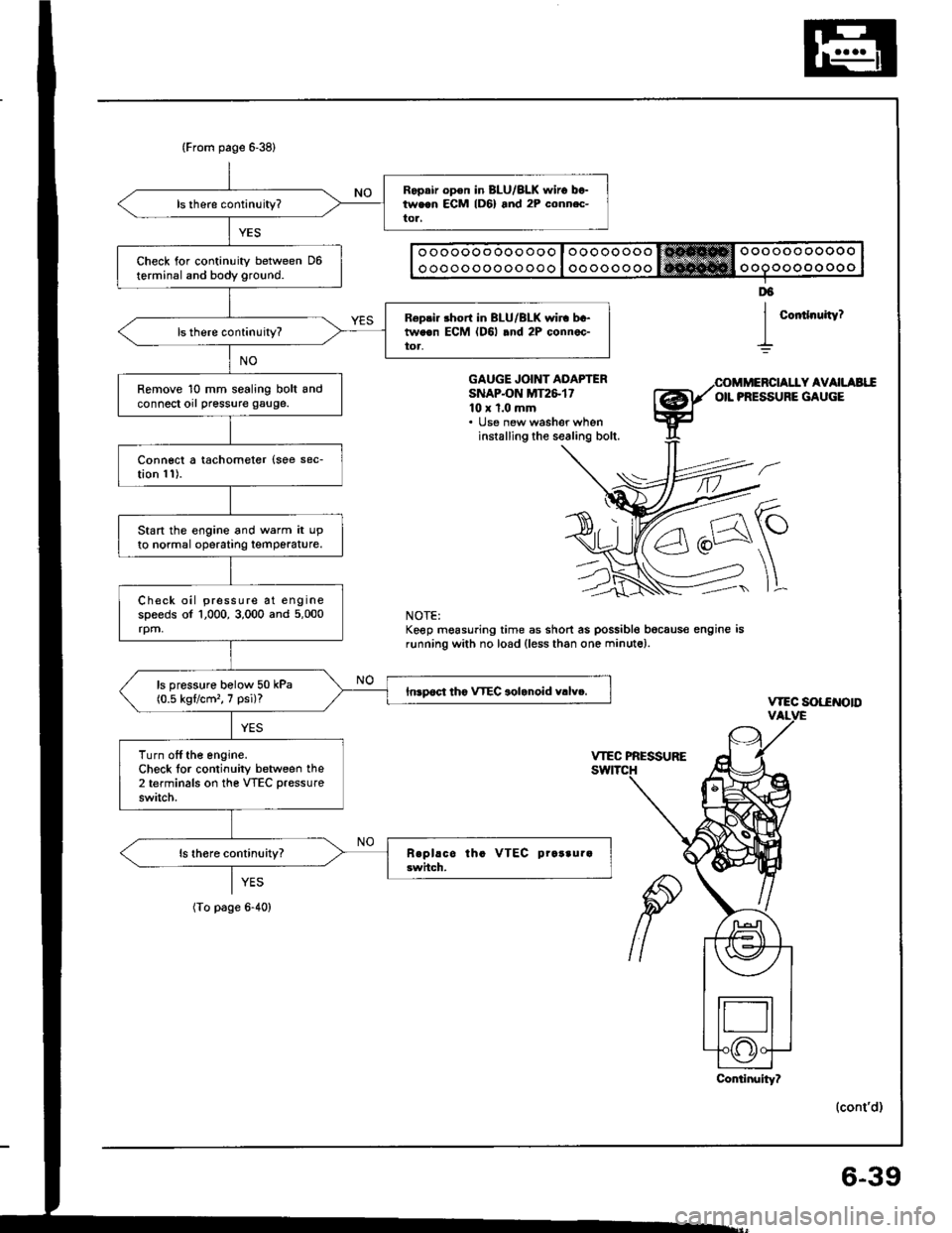

Troubleshooting Flowchart - VTEC Pressure Switch

Refer to page 11-32thru 11-39 beJore troubleshooting'

-.+- -r";-r- Malfunction Indicator Lamp (MlL) indicates Oiagnostic Troubles Code (DTC) 22: A problem in the VTEC- l{{?l- ;l ziz r: pressur€ Switch circuit.

-lr@l- |22 1-

* Road Test:Accolerato in lst gear to an engine speed over 6000 rpm

Hold that engine speed for at least two seconos'

lf the MIL does not come on during the first road test'

reoeat this test two more limes.

- MIL har bagn.oportcd on.- With t.rvic. chack connactor

iump.d, cod€ 22 it indic.t.d.

Do the engine control module(ECM)Reset Procedure.

Warm !p engine to normal oper-

ating temperstur€ (cooling fan

comes on).

Do the Boad T€st.'

Intc.mift.nt failu.o, ry3tom ia OK

at thi. tim..Chack for pool connaction3 ol

loo!. rvirat at VTEC Ptasturo3whch and ECM.

ls MIL on and does it indi'

cate code 22?

Turn lhe ignition switch OFF

Disconnect the 2P connector

lrom the VTEC Pressure switch.

Check Ior continuity between

BLK terminal and body ground.

Rcpair opcn in BLK wit. botwcon

2P connector rnd body ground

tG101l.

Check for continuity between

8LU/8LK terminal and D6 termi'

nal.

(To page 6 39)

Page 100 of 1413

(From page 6-38)

Ropair op€n in BLU/BLK $,iro between ECM lD6) and 2P conn.c-tor,

Check for continuity between D6terminal and body ground.

R6pri. short in BLU/BLK wir. bc-tweon ECM (D6l .nd 2P connec-toa,

Remove 10 mm sealing bolt andconnect orl pressure gauge.

Connect a tachometer {soe sec-tion 11).

Start the engine and warm it upto normal operatrng temperature.

Check oil pressure at enginespeeds of 1,000, 3,000 and 5,000rpm,

ls pressure bolow 50 kPa(0.5 kgflcm'�, 7 psi)?Inrpoct tho VTEC aolanoid v.lv..

Turn off the engine.Check lor continuity between the2 terminals on the VTEC pressure

switch.

o oooooo ooo ooo I oooooooo trt!*Hffi Oooooo ooooo

o oooo ooooo ooo I oo oooo ooo ooooo oo oo o

Coitlnuity?

D6

I

GAUGE JOINT ADAPTERSNAPON MT2&1710 x 1.0 mm. lJse new washer wheninstalling the sealing bolt.

Y AVAILAEIIOIL PRESSURE GAUGE

\-

]L

vtEc sot-€NotD

(cont'd)

NOTE:Keep mgasuring time as short as possible bocaus€ engine isrunning with no load (less than one minute).

YES

(To page 6-40)

Conlinuity?

6-39

Page 101 of 1413

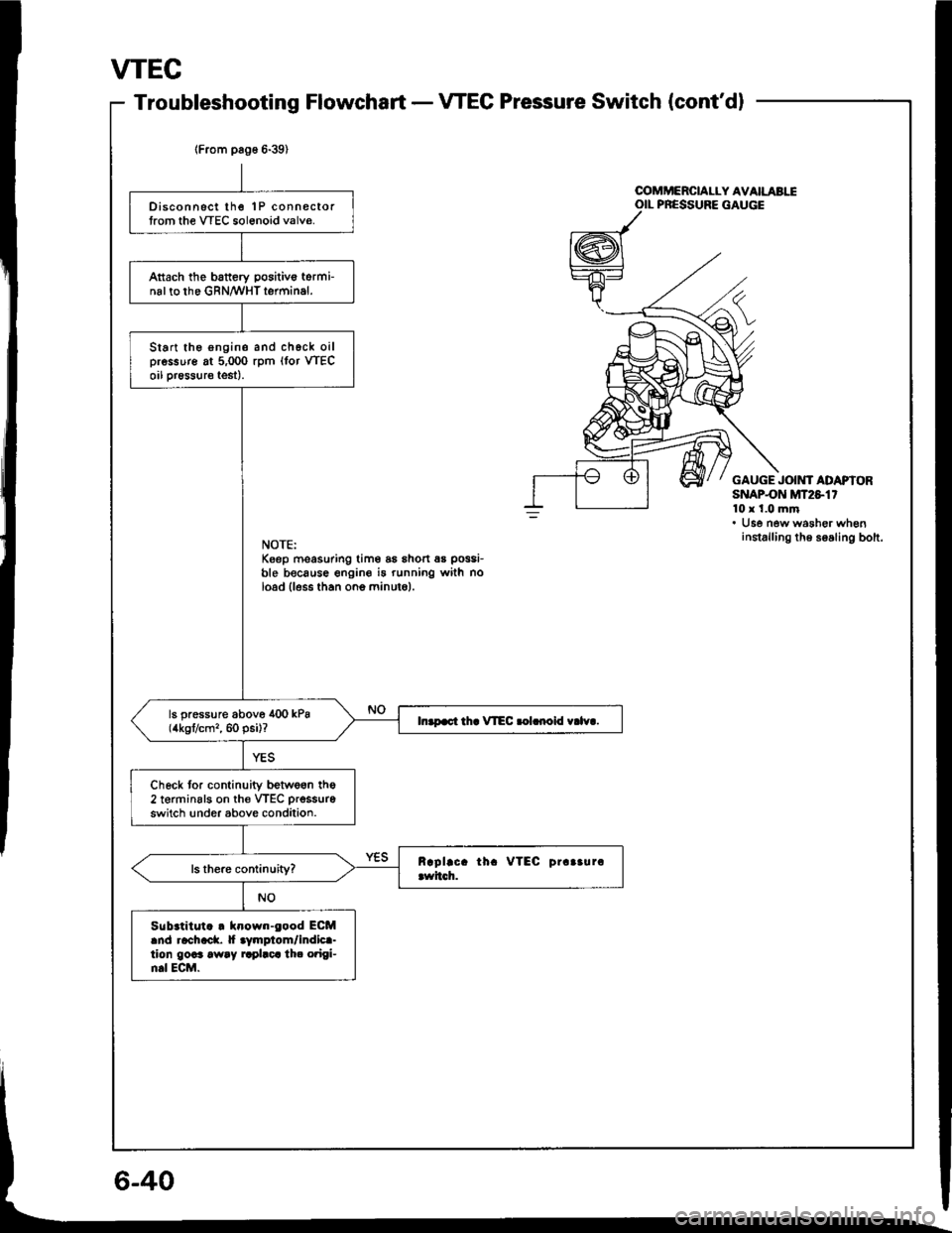

VTEC

Troubleshooting FlowchartVTEC Pressure Switch (cont'dl

lFrom pag6 6-39)

Disconnsct lhe 1P connectortrom the VTEC sol6noid valve.

Attach the battery positivo torminal to the GRN/WHT terminal.

Start the engine and chgck oilpressure at 5,000 rpm (lor VTECoil pr€ssure test).

ls pressure above 400 kPa(4kgt/cm,, 60 psi)?In.p.ct th. VIEC .olrnoid v.lv..

Check tor continuity betwe6n the2 terminsls on th€ VTEC prsssure

switch !nder above condition.

Sub.titut. . klown-eood ECMand rachack. |f aymplom/indica-tion goaa away rrplaca th. o?igi-n.l ECM.

u

OOMMERCIALLY AVAILABIIOIL PRESSURE GAUGE

GAUGE JOIMf ADAPIORSNAPON MT2S1'10x 1.0 mm. Use new washer wheninstalling th6 soaling bolt.NOTE:Keep moasuring tim6 as shon 6s possi-

ble because engine i5 running with noload lless than ono minuto).