tdc HONDA INTEGRA 1994 4.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 113 of 1413

Timing Belt

Installation (cont'dl

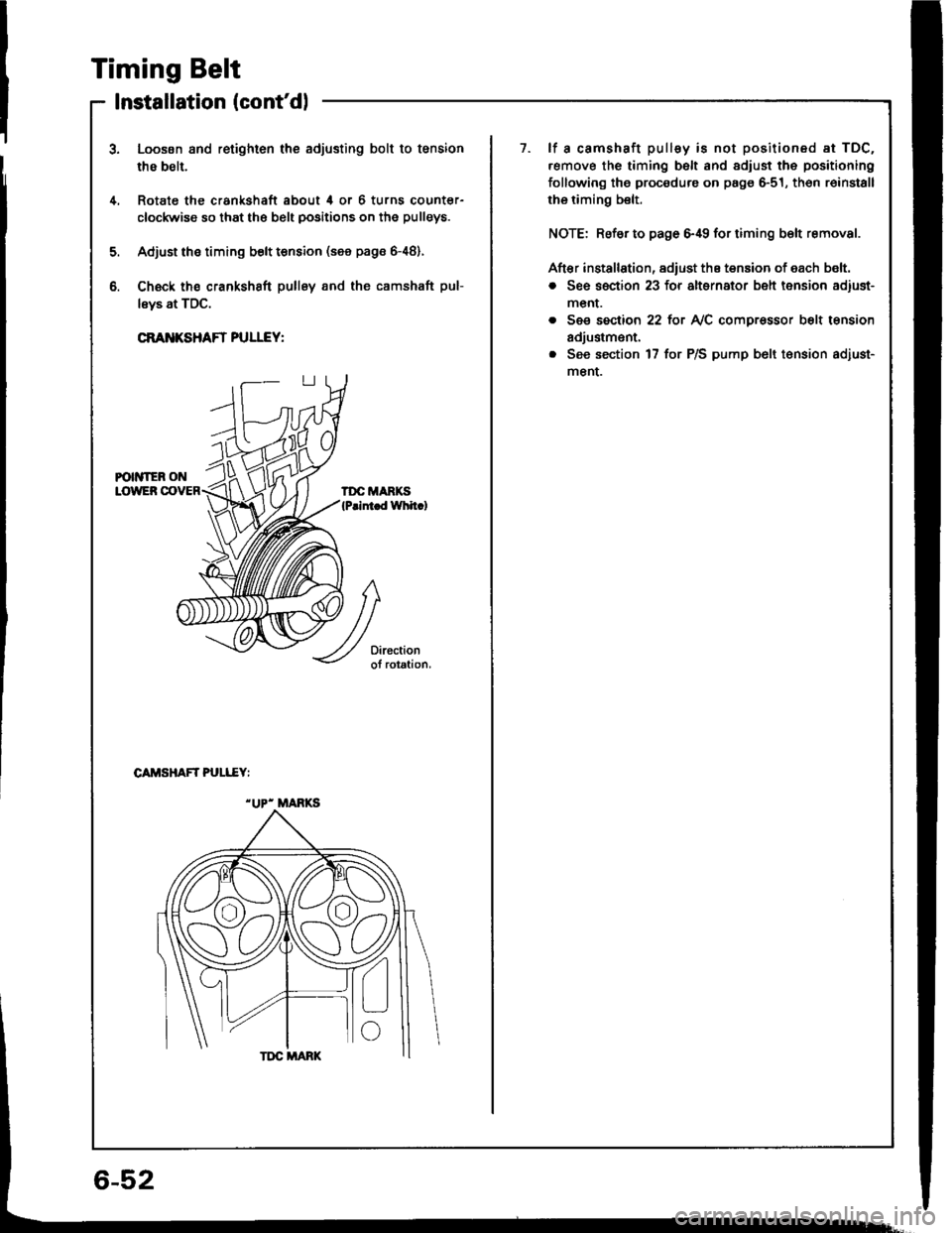

1Loosen and retighten the adjusting bolt to tsnsion

thB belt.

Rotate the crankshaft about 4 or 6 turns countsr-

clockwise so that the belt positions on the pulleys.

Adjust ths timing bolt tension (see pags &48).

Ch€ck ths crankshaft pullsy and the camshaft pul-

lsys at TDC.

CRANKSHAFT PULLEY:

1.lf a camshaft pulley is not positioned at TDC.

.emove the timing belt and adiust the positioning

following the procedure on page 6-51, th6n r6install

rhe riming belt.

NOTE: Refsr to page 6,19 for timing b€lt removal.

Aft€r installation, adiust the tension of each b€lt.

o See section 23 for alternator belt tension adiust-

menr.

. See section 22 tot NC compr€ssor b6lt tension

adjustm€nt.

. See section 17 for P/S pump b6lt t€nsion adiust-

menL

4.

5.

b.

CAMSHAFT PULI..EY:

"UP- MANKS

6-52

Page 116 of 1413

Cylinder Head

Removal

Engine removal is not required or this procedure.

CAUTION: To avoid damaging tho cylinder head, wail

u[tilths.nginc coolant tsmperaturo drops bolow 100"F(38'Cl bafore loos6ning tho retaining bolts.

NOTE;

. Inspect the timing belt before removing the cylinder

head.

Turn the crankshaft pulley so that the No. 1 piston is

at top dead center (TDc) {page 6-51).

Mark all emissions hoses betore disconnecting them.

Anti-theft radios have a coded theft protection circuit.

Be sure to get the customer's code number before- Disconnecting the battery.- Removing the No.32 (7.5 A) fuse trom the under-

hood fuse/relay box.- Removing the radio.

After service, reconnect power to the radio 8nd turn it

on.

When the word "CODE" is displaved. enter the cus-

tomer's 5-digit code to restore radio operation,

Disconnect the negative terminal from the battery.

Drain the engine coolant (see page 10-5).

. Remove the radiator cap to speed draining.

Relieve fuel pressure (see section 111.

l@ Do not 3moke whilo working on fuel

a

a

'1.

systgm. ko6p opon tlamo ot Spark away trom work

aroa. Drain fugl only into an approved containsr,

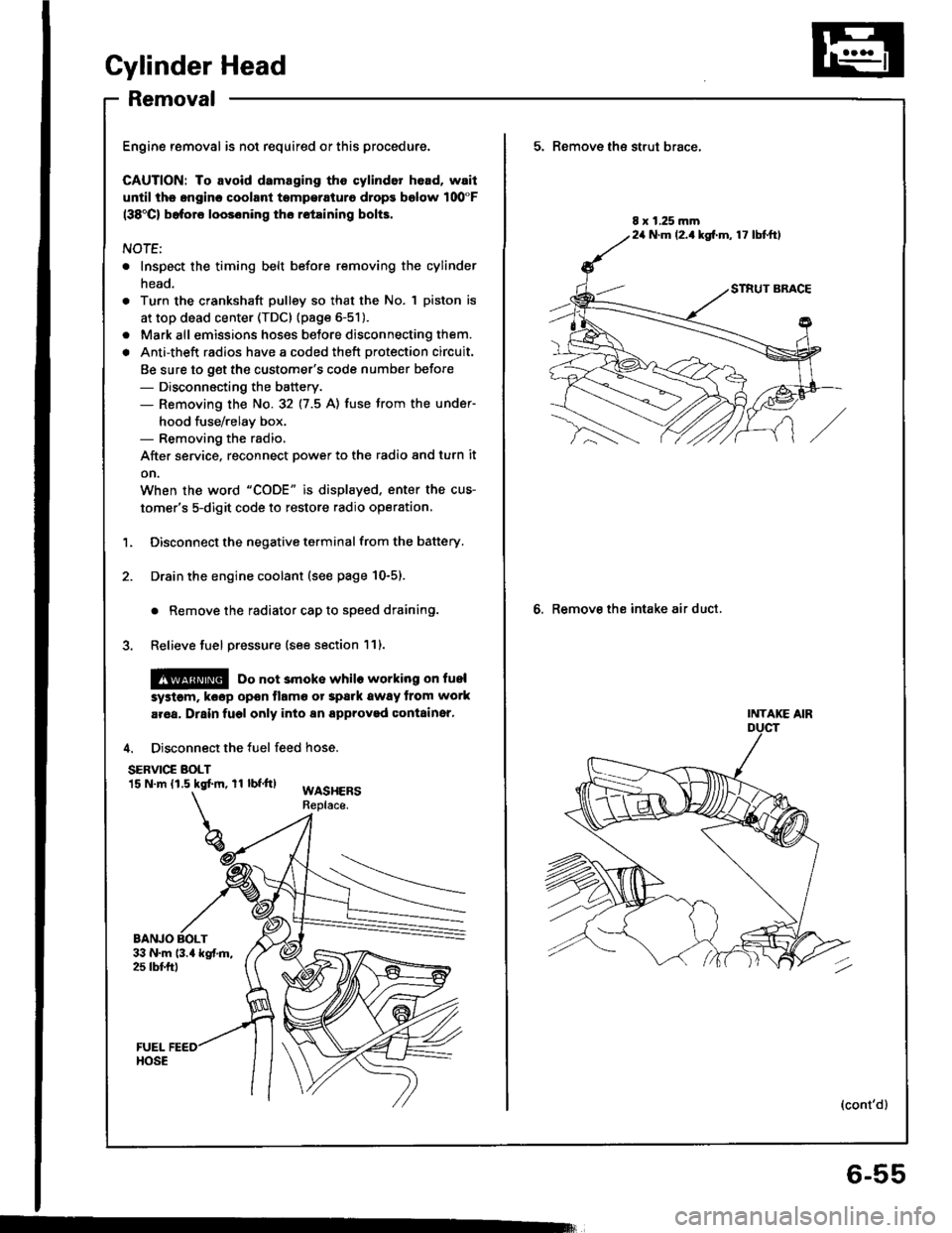

4. Disconnect the fuel feed hose.

SERVIC€ BOLT15 N.m (1.5 kgtm, rl bf.tt)WASHERSReplace.

BANJO BOLT

5. Remove th€ strut brace,

6. Remove the intake air duct.

8 x 1.25 mm24 N.m (2.1kg[.m, 17 lbtftl

INTAKE AIR

(cont'd)

6-55

Page 118 of 1413

ll.Remove the engine wire harness connectors and

wi.e ha.ness clamps from the cylinder head and the

intake manitold.

Four fuel injector connectors

Intake air tempe.ature {lAT) sensor connector

Engine coolant temperature (ECT) sensor con-

nector

TDC/CKP/CYP sensor connector

lgnition coil conn€ctor

ECT gauge sending unit connector

Throttle position (TP) sensor connector

VTEC solenoid valve connector

VTEC Dressure switch connector

Manifold absolute pressure (MAP) sensor con-

nector

ldle air control {lAC) sensor connector

EVAP purge controlsol€noid valvo connector

Intake air bypass {lABl control solenoid valve

conneclor

a

o

a

o

a

a

a

a

a

a

a

a

a

12.

13.

Remove the spsrk plug caps and distributor from

the cylinder head.

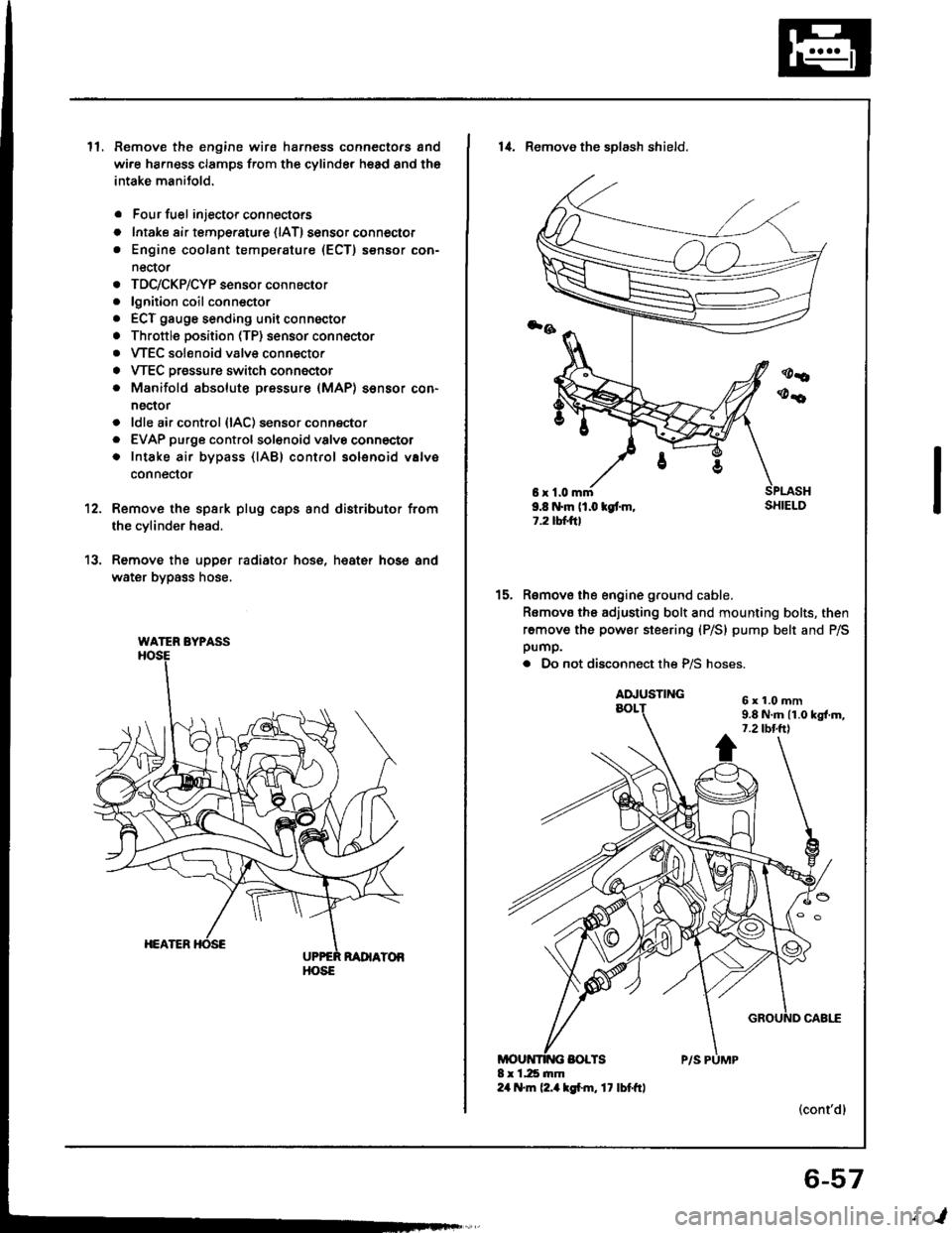

Remove the upper radiator hose, heat€r hose and

water bypass hose.

WATER BYPASS

HOSE

6r1.0mm9.8 N.m (1.0 kgt m,1.2 tbtftl

14. Remove the sDlash shield.

Remove the engine ground cable.

Romovo the adjusting bolt and mounting bolts, then

remove the power steering (P/S) pump belt and P/Spump.

. Do not disconnect the P/S hoses.

(cont'dl

15.

6x1.0mm9.8 N.m 11.0 kgl.m,7.2 tbt.ttl

6-57

,l

Page 136 of 1413

lnstallation

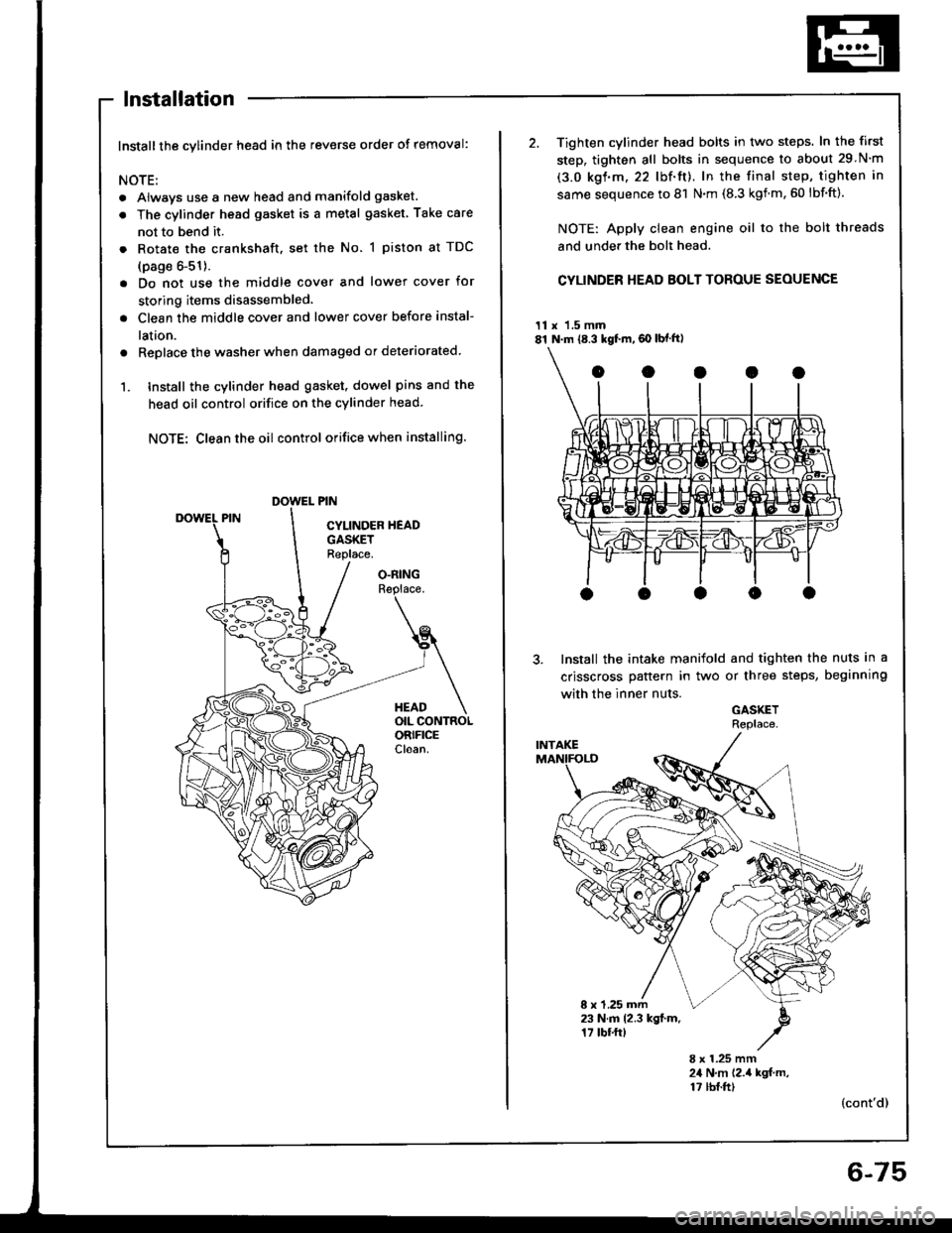

Installthe cylinder head in the reverse order of removal:

NOTE:

. Always use a new head and manifold gasket.

. The cylinder head gasket is a metal gasket Take care

not to bend it.

. Rotate the crankshaft, set the No. 1 piston at TDC

(page 6-51).

. Do not use the middle cover and lower cover for

storing items disassembled.

. Clean the middle cover and lower cover before instal-

lation.

a Replace the washer when damaged or deteriorated

1. tnstall the cylinder head gasket. dowel pins and the

head oil control orifice on the cylinder head

NOTE: Clean the oil control orifice when installing.

O.RINGReplace.

HEADOIL CONTROLORIFICECloan.

2. Tighten cylinder head bolts in two steps. In the first

step, tighten all bolts in sequence to about 29 N'm

(3.0 kgf.m.22 lbf'ft). In the final step, tighten in

same sequence to 81 N.m (8.3 kgnm.60 lbf'ft).

NOTE: Apply clean engine oil to the bolt threads

and under the bolt head.

CYLINDER HEAD BOLT TOROUE SEOUENCE

11 x 1.5 mm81 N.m {8.3 kgf.m,60 lbf ft)

Install the intake manifold and tighten the nuts in a

crisscross pattern in two or three steps, beginning

with the inner nuts.

GASKETRePlace

8 x 1.25 mm23 N.m 12.3 kgl.m.17 tbf.ftt

8 x 1.25 mm24 N,m 12.,4 kgf m,17 tbf.ft)(cont'd)

6-75

Page 194 of 1413

Fuel and Emissions

Spocial Tools ................ 1 1-2

Compon€nt Location

lndex ................. ...... 11-3

System Description

Vacuum Connectiona .......,.................... 1 1 -8

Efectrical Connections ....,.,.,......,...,,.....,'11-12

Syst€m Connectors ...,...,.................-.--. 11-2O

T.oubloshooting

Troubleshooting Guido .......................... 1 1-32

Self -diagnostic Procedures .,..,............... 1 1 -34

How to Road Flowcharts ...................,... 11-39

PGM-Fl System

Systom Description .............................. 1 l-4O

Troubleshooting Flowcharts

Engine Control Moduls ............... ........... 1 1 -42

Heated Oxygon Sensor ......,.................. 1 1-46

Heated Oxyg€n Sonsol Heatel .....,......... 1 1 -47

Fuel Supply System ..............-............... 1 1-50

Manitold Absolute Pressure

Ssnsor ............................................ 1 1-52

Top D6ad Cente./Crankshatr

Position/Cylindor Position sonsor ........ 1 1 -56

Engine Coolant Tempsrature Sonsor ....... 11-58

Throttlo Position Sonsor ........,..,,........... 1 1-60

Intake Air Temperaturs Sensor ............... 11-62

Baromet c Prsssuro Sensor ......,...,...,..,. 11-64

lgnition Output Signal ........................... 1 1 -66

Vehicle Spe€d Sensor ........................... 1 1 -68

Electdcal Load Dotector ....,...,..........,.... 1 1 -7O

Knock Sensor [818C1 engine] ............... 11-74

A/T Fl Signal A/B ................................. 1 1-76

ldle Contlol System

System Troubleshooting Guide .................. 1 1 -78

Systom Description ........ 11-79

Troubloshooting Flowchans

ldl€ Ail Control Valve ........................... 1 1 -82

Ail Conditioning Signal ......................... 1 1 -84

Altemator FR Signal ............................. 1 1 -86

Automatic Transaxle (A/T) Gear

Position Signal ......... 11-88

Brake Switch Signal ............................. 1 1 -9O

Startel Switch Signal ............................ 11-92

Power Steering Pressure Switch Signal ... 11-93

Fast ldle Thermo Valve ...................,......... 1 1 -94

ldls Speed S€tting .................................... 1 1 -95

Fuel Supply System

Systam Tloubloshooting Guid. .................. 1 1 -97

Fuol Linos ...................... 1'l -98

System Description ........ 11-100

Fuol Prassure ................. 11-100

Fu6l Ini6ctors ................. 11-102

Fuel Pressure Ragulato. .,. 11-106

Fuel Filter ...................... 11-108

Fual Pump ..................... 11-109

PGM-Fl Main F6lay ................................... 1 1"1 1 1

Fuel Tank ...................... t 1-114

Intake Air System

System Troubloshooting Guido .................. 1 1 -1 1 5

Systom Dascription ........ 11-116

Air Clean€r .................... 11-117

Throttls Cable ................'11-118

Throttl8 Body ................ 11-120

lntake Air Bypass Cont.ol Systsm

[B18Cl enginal .,......... 11-123

Intake Manilold [B1881 onginol ................. 11-128

Emission Control System

Systsm Troubleshooting Guido .................. 1 1 -1 29

Systam Doscription ........ 11-130

Tailpips Emission ........... 11-130

Thrae Way Catalytic Convortor ...,...,........., 11-131

Positiva CrankcaEo V6ntilation Systcm .,....., 11-134

Evaporativo Emission Contro|,..,..,.,.,,.,,..,.., 1 1-135

Page 196 of 1413

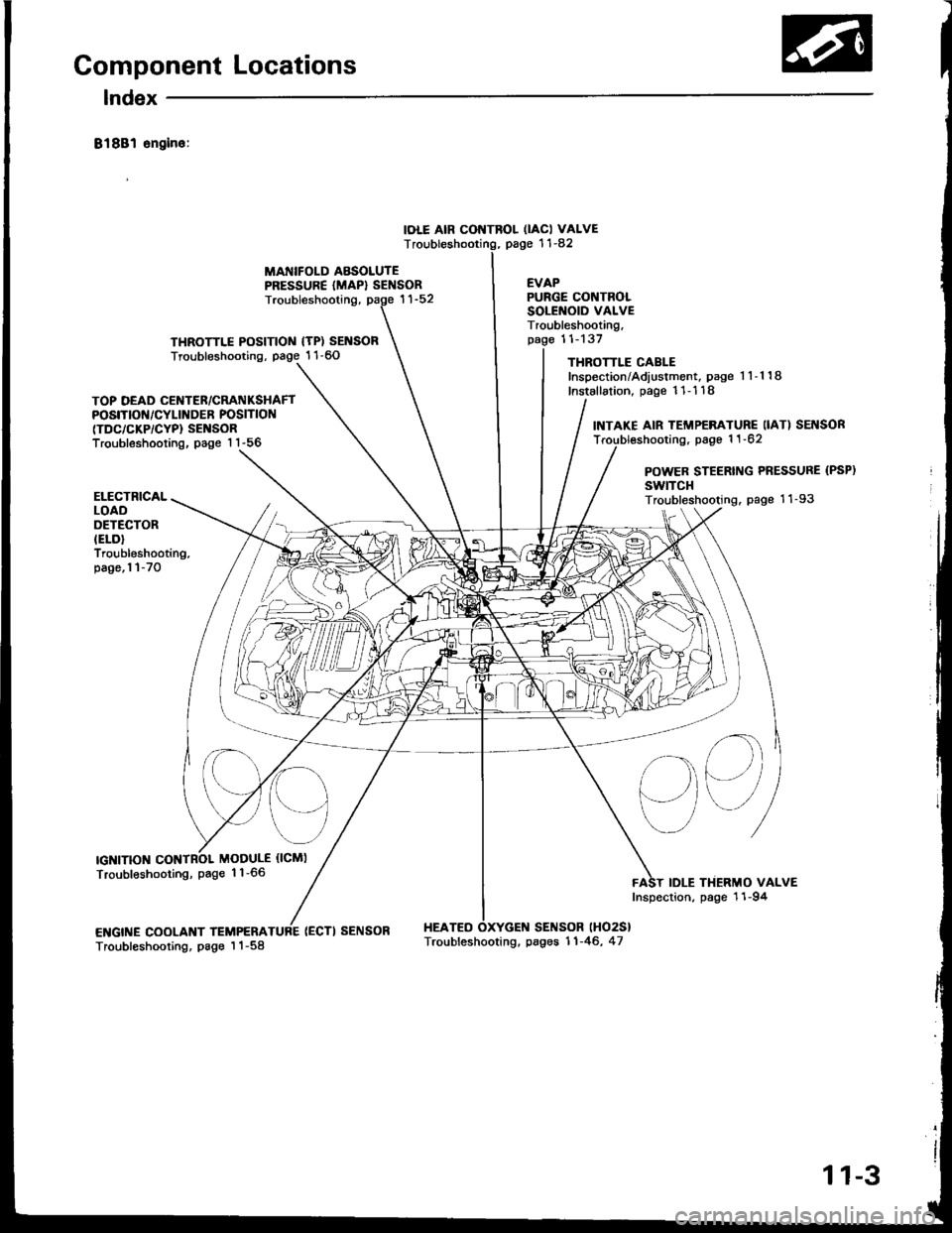

Component Locations

lndex

81881 sngin6:

IOLE AIR CONTROL OACI VALVEpage '11-82T

MANIFOLD ABSOLUTEPRESSURE {MAP} SENSOREVAP

THROTTLE POSITIOIII {TP) SENSORTroubleshooting, page 1 1-60

Troubleshooting,

(ECTI SENSOR HEATEO

PURGE CONTROLSOLENOID VALVETroubleshooting,11-137

THROTTLE CABLEInspection/Adiustment, page 1 1-1 18

Installation, page 11- 1 18

SENSOR lHO2S}

TOP DEAD CENTER/CRATIIKSHAFTPOSITIOf{/CYLINDER POSITION(TDC/CKP/CYP} SENSORTroubleshooting, page 1 1-56

INTAKE AIR TEMP€RATURE IIAT) SEI{SORTroubl€shooting, page 1 1 -62

POWER STEERING PRESSURE (PSP)

swtTcHTroubleshooting. page 11-93

sq

IDLE THERMO VALVEInspection, page 11-94

ELECTRICALLOADOETECTORIELD}Troubleshooting.page,l l-70

IGNITIONMODULE {ICMI

Troubleshooting, page 1 1-66

ENGINE COOLANT TEMPERATroubleshooting, page I 1-58Troubleshooting. pages 11-46, 47

11-3

Page 197 of 1413

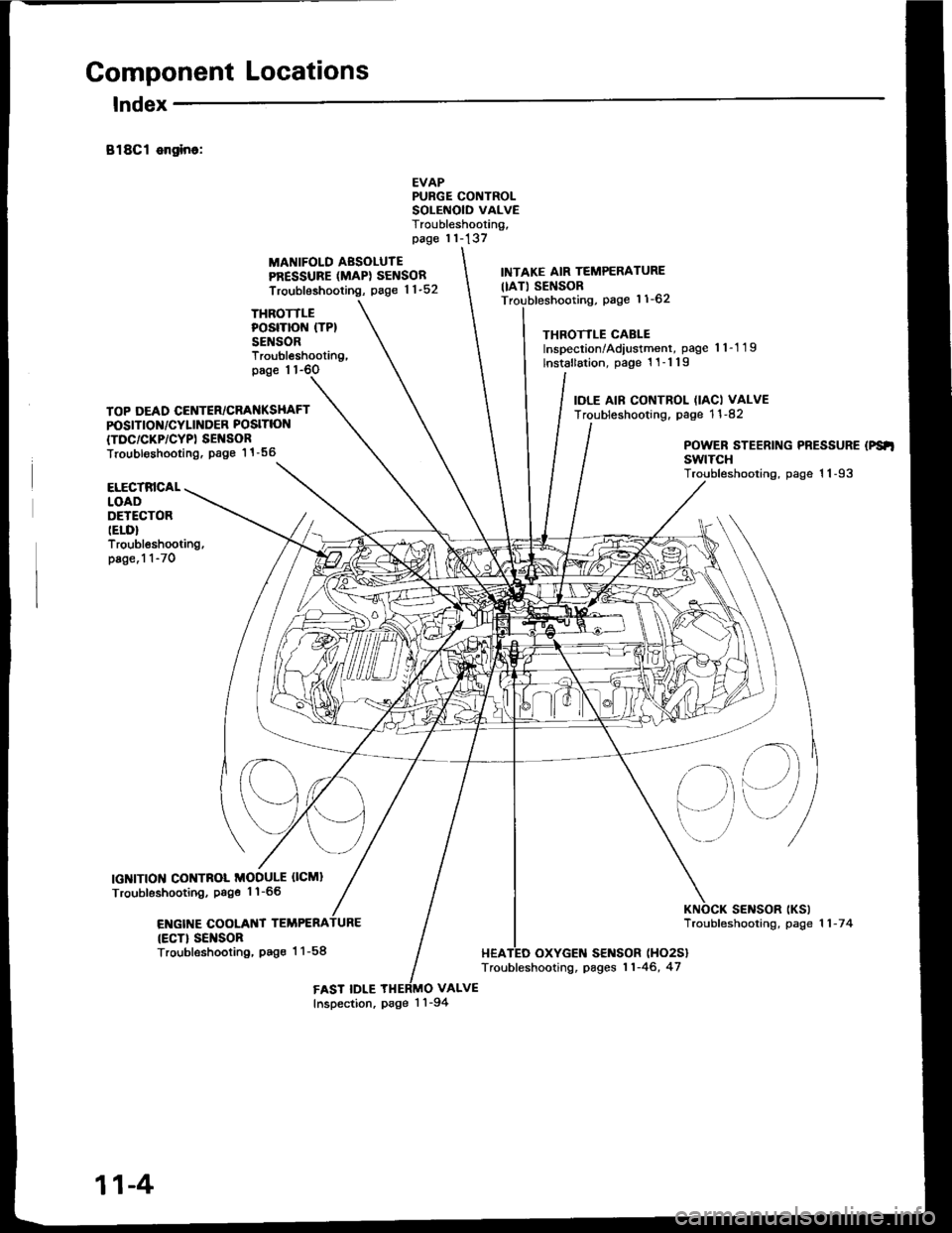

Component Locations

lndex

B18Cl ongino:

THROTTLEPOSITION (TP}

SENSOR

MANIFOLD AESOLUTEPRESSURE (MAPI SENSOR

Troubleshooting, page 1 1-52

EVAPPURGE CONTROLSOLEiIOID VALVETroubleshooting,page 11-137

VALVE

INTAKE AIR TEMPERATURE

IIAT) SENSORpage 11-62

THROTTLE CABLEInspection/Adiustment, page 'l 1-1 19

lnstallation, page 1 1-1 19

IOLE AIF CONTROL (IACI VALVETroubleshooting. page 1 1 -82

Troubleshooting,page 1 1-6O

TOP DEAD CENTER/CRANKSHAFTPOSITION/CYLINDER POSITION

{TDC/CKP/CYPI SEI{SORTroubl€shooting. Page 1 1 -56POWER STEERING PRESSURE (PS'I

swtTcHTroubleshooting, page 1 1-93ELECTRICALLOADDETECTORIELD}Troubleshooting,page.1 1-70

IGNITION CONTNOL MODULE OCMI

Troubleshooting, Psge 1'l-66

ENGIT{E COOLANT TEMPERA

{ECT} SEI{SORTroubleshooting, Pag€ 1 1-58

sElrlsoR tKslTroubfeshooting, page 1 1 -7 4

HEATED OXYGEN SENSOR (HO2S}

Troubleshooting, pages 11-46, 47

FAST IDLEInspection, page 1 'l -94

11-4

Page 207 of 1413

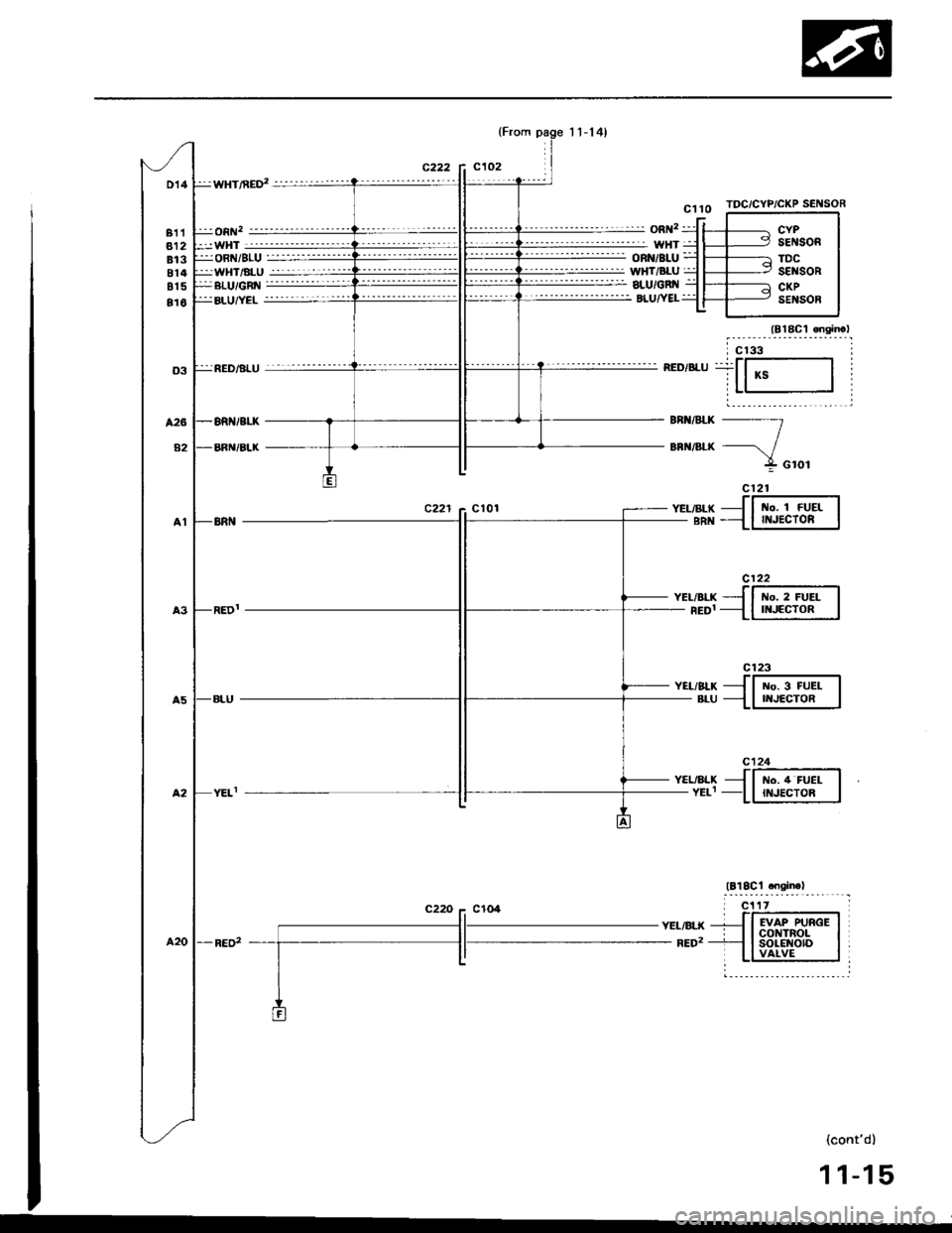

D14

811812813814815

816

:wHT/nED' -'-'--''''-''-'

:j:on 2-"''''-' '- -----

:-WHT--------'-''''-''''

TDC/CYP/CKP SENSOR

c122

t{o. 2 FUELII{JECTOR

c123

No. 3 FUELNJECTOR

c124

t{o. 4 FUELII{JECTOR

:ji oRNi sLU =::::i-:jjjjjjj:ji WHT/ALU jjji-::-:-:::i:jj

YEL/ALXYELI

YEL/BLK- RED2

(cont'd)

11-15

KS

t{o. 1 FUEIII{JECTOR

EVAP PURGEcot{TRoLsoLE {otDVAIVE

Page 228 of 1413

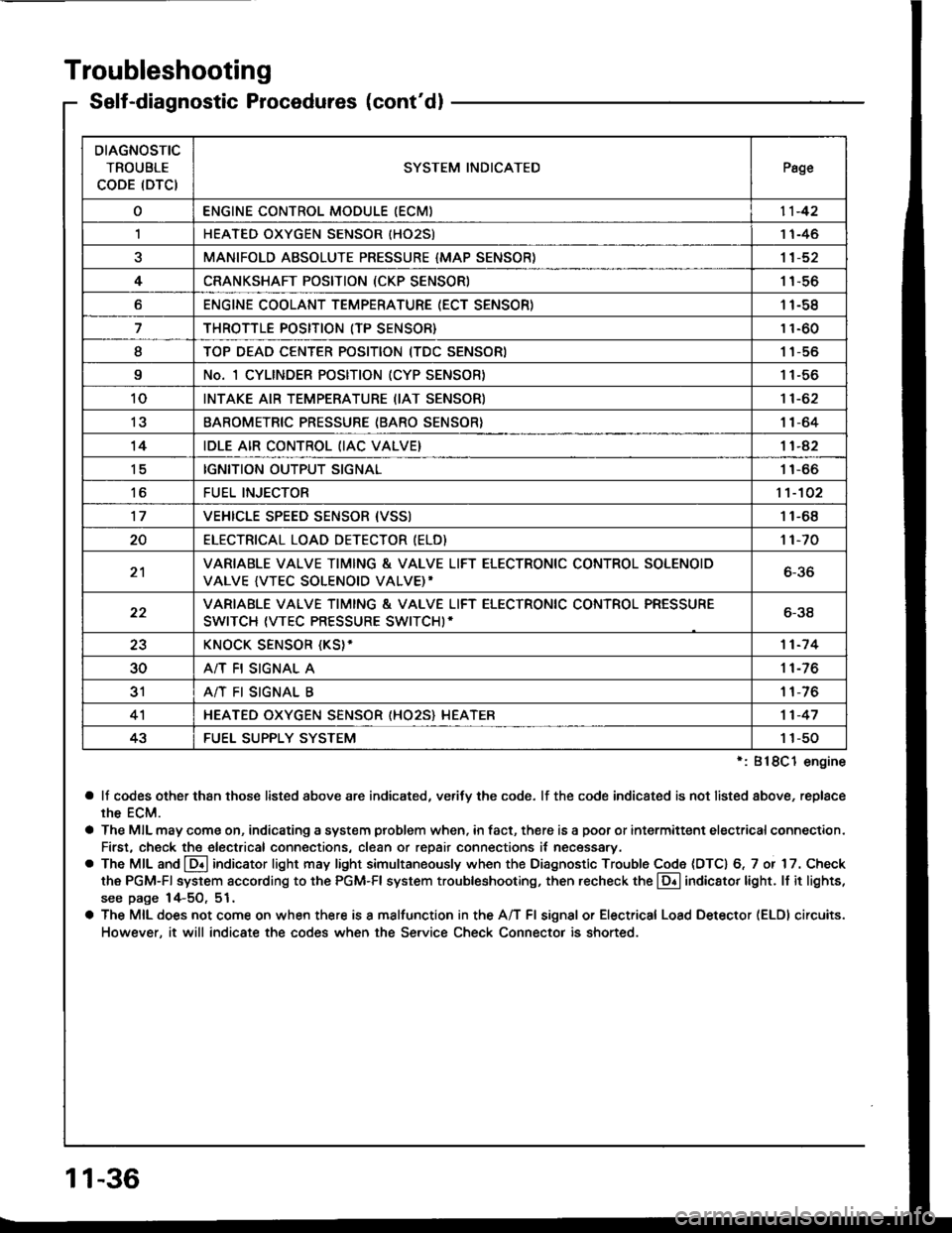

Troubleshooting

Self-diagnostic Procedures (cont'dl

':818C1 engine

a lf codes other than those listed above are indicated, verifv the code. lf the code indicated is not listed above, replace

rhe ECM.

a The MIL may come on, indicating a system problem when, in fact, there is a poor or intermittent electricalconnection.

First, check the electrical connections, clean or repair connections it necessary.

o The MIL and @ indicator light may light simultaneously when the Diagnostic Trouble Code (DTC) 6, 7 or 17. Check

the PGM-Fl system according to the PGM-Fl system troubleshooting, then recheck the l!! indicator light. ll it lights,

see page 14-5O, 51.

a The MIL does not come on when there is a malfunction in the A/T Fl signal or Electrical Load Detector (ELDI circuits.

However, it will indicate the codes when the Service Check Connector is shorted.

DIAGNOSTIC

TROUBLE

CODE (DTCISYSTEM INDICATEDPsge

oENGINE CONTROL MODULE IECM)11-42

,lHEATED OXYGEN SENSOR IHO25)1 1-46

aMANIFOLD ABSOLUTE PRESSURE {MAP SENSOR)11-52

4CRANKSHAFT POSITION (CKP SENSOR)1 1-56

oENGINE COOLANT TEMPERATURE (ECT SENSOR)11-58

THROTTLE POSITION (TP SENSOR}11-60

ITOP DEAD CENTER POSITION (TDC SENSORI1 1-56

9No. 1 CYLINDER POSITION (CYP SENSOR)1 1-56

10INTAKE AIR TEMPERATURE (IAT SENSOR)11-62

13BAROMETRIC PRESSURE (BARO SENSOR}1|-64

14IDLE AIR CONTROL (IAC VALVE}11-42

tcIGNITION OUTPUT SIGNAL11-66

toFUEL INJECTOR1't-102

17VEHICLE SPEED SENSOR {VSSI11-68

20ELECTRICAT LOAD DETECTOR (ELD)'t 1-70

21VARIABLE VALVE TIMING & VALVE LIFT ELECTRONIC CONTROL SOLENOID

VALVE {VTEC SOLENOID VALVE)'6-36

22VARIABLE VALVE TIMING & VALVE LIFT ELECTRONIC CONTROL PRESSURE

SWITCH (VTEC PRESSURE SWITCHI-6-38

23KNOCK SENSOR {KS}-11-7 4

30A/T FI SIGNAL A11-76

3'rA/T FI SIGNAL B1 1-76

4'lHEATED OXYGEN SENSOR (HO25} HEATER11-47

43FUEL SUPPLY SYSTEM1 1-50

11-36

Page 232 of 1413

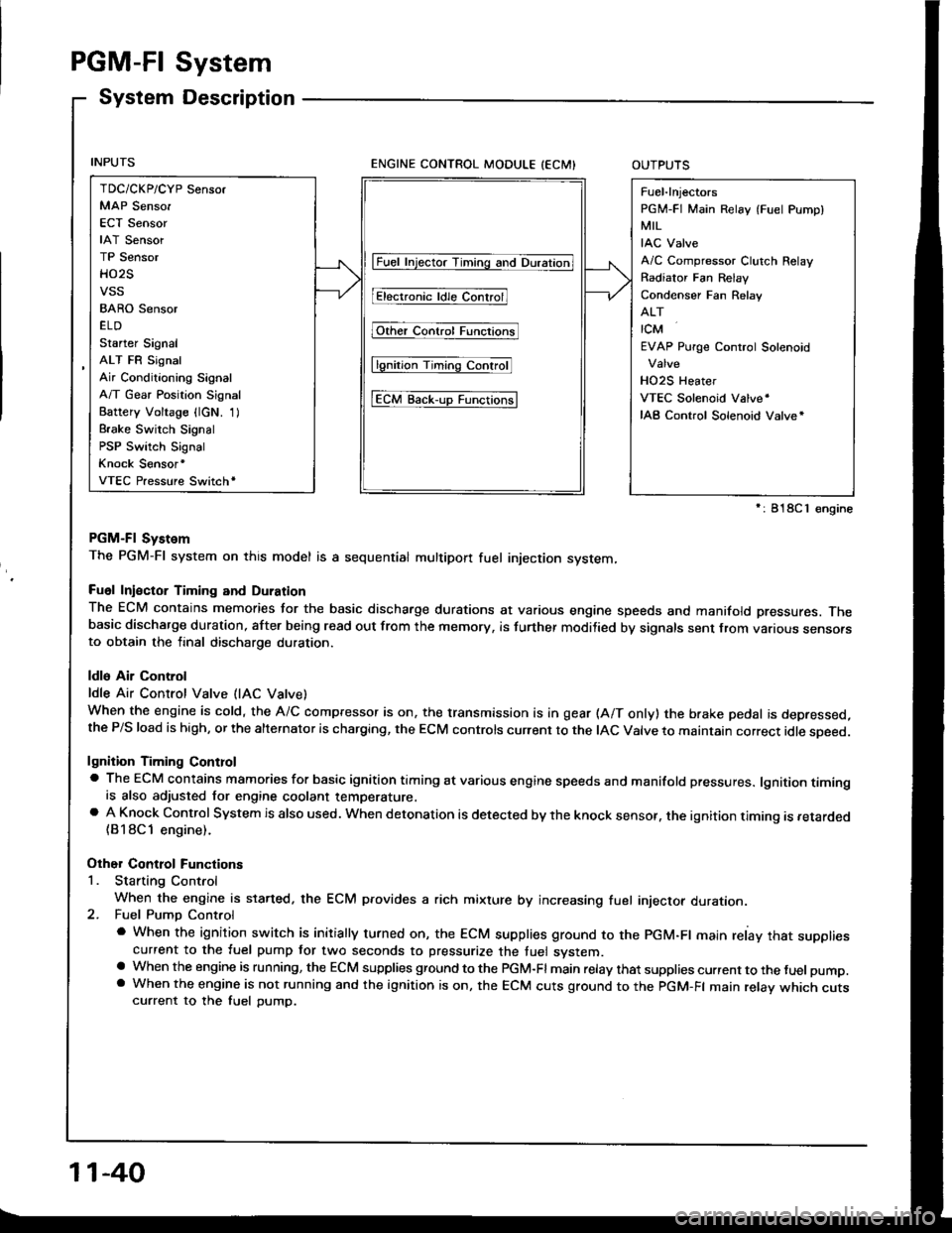

PGM-FI System

System Description

ENGINE CONTROL MODULE (ECMIOUTPUTS

PGM-Fl System

The PGM-Fl system on this model is a sequential multipon fuel injection system,

Fuol Iniector Timing and Duration

The ECM contains memories tor the basic discharge durations at various engine speeds and manifold pressures. Thebasic discharge duration, after being read out from the memory, is turther modilied by signals sent from vanous sensofsto obtain the final discharge duration.

ldle Air Control

ldle Air Control Valve (lAC Vatve)

When the engine is cold, the A/C compressor is on, the transmission is in gear (A/T only) the brake pedal is depressed,the P/S load is high, or the alternalor is charging, the ECM controls current to the IAC Valve to maintain correct idle soeed.

lgnition Timing Controla The ECM contains mamories for basic ignition timing at various engine speeds and manifold pressures. lgnition timingis also adjusted for engine coolant temperature.a A Knock Control System is also used. when detonation is detected by the knock sensof. the ignition timing is retarded(B18Cl engine).

Other Control Functions

1. Starting Control

When the engine is started. the ECM provides a rich mixture by increasing fuel injector duration.2. Fuel Pump Control

a When the ignition switch is initially turned on, the ECM supplies ground to the PGM-Fl main relay that suppliescurrent to the fuel pump tor two seconds to pressurize the tuel system.a When the engine is running, the ECM supplies gfound to the PGM-Fl main relay that supplies current to the fuel pump.a When the engine is not running and the ignition is on, the ECM cuts ground to the PGM-FI main relav which cutscurrent to the fuel pump.

TDC/CKP/CYP Sensor

MAP Senso.

ECT Sensor

IAT Sensor

TP Sensor

HO2S

vss

BARO Sensor

ELD

Starter Signal

ALT FR Signal

Air Conditioning Signal

A/T Gear Position Signal

Battery Voltage {lcN. 1)

Brake Switch Signal

PSP Switch Signal

Knock Sensor'

VTEC Pressure Switchr

Fuel-lnjectors

PGM-FI Main Relay (Fuel Pump)

MIL

IAC Valve

A/C Compressor Clutch Relay

Radiator Fan Relav

Condenser Fan Relav

ALT

rcM

EVAP Purge Control Solenoid

HO2S Heater

VTEC Solenoid Valve'

IAB Control Solenoid Valve*

lFuet tnjector Timing and Duration]

I Electr..l"ldle Contr;il

Fit'e' contr; Funcrfit

l6tio; Ttntrlg c..trol

tEcM aack-,rp Functiorlsl

': 818C 1 €ngine

11-40