HONDA INTEGRA 1994 4.G Workshop Manual

Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 351 of 1413

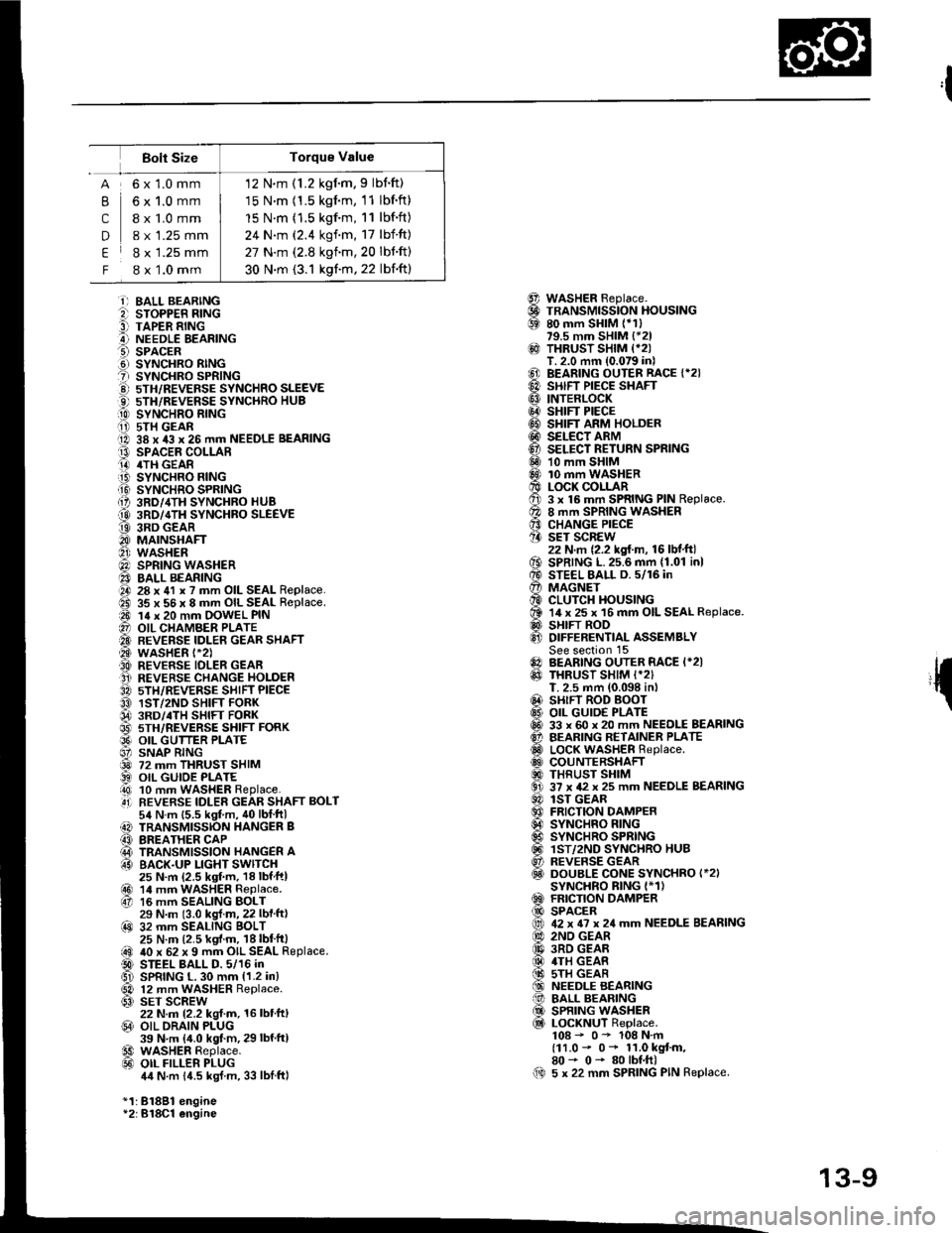

12 N.m (1.2 kgim,9 lbnft)

15 N.m (1.5 kgnm, 11 lbf.ft)

15 N.m (1.5 kgf.m, 11 lbf.ft)

24 N.m (2.4 kgf.m, 17 lbf'ft)

27 N.m (2.8 kgnm,20 lbnft)

30 N.m (3.1 kgf.m, 22 lbf'ft)

Bolt Size

,l

{

@@69

@

@@@@@@@@6Dq0

o€xv0@

@0!@@@@al

61@

B

c

D

E

F

6x1.0mm

6x1.0mm

I x 1.0 mm

8 x 1.25 mm

8 x 1.25 mm

8 x 1.0 mm

i) BALL BEARINGe sroPPER R|NG9 TAPER RINGA NEEDLE EEARINGO SPACER.d SYNCHRO RINGt sYNcHRo SPR|NG!) 5TH/REVEFSE sYNcHRo SLEEVEO 5TH/REVERSE SYNCHRO HUB[0 sYrucxao nlrucii i) 5TH GEARO 38 x 43 x 26 mm NEEDLE BEARINGt3 SPACEE COLLARO 4TH GEAR.iB SYNCHRO FING.Ii9 SYNCHRO SPRING{, 3RD/,ITH SYNCHRO HUB

@ 3RD/4TH SYNCHBO SLEEVEt9 3RD GEARO MAINSHAFTO wasHER@) SPRING WASHER40 BALL BEARINGO 28 x 41 x ? mm OIL SEAL Replace.ad 35 x 56 x 8 mm OIL SEAL Replace.a0 14 x 20 mm OOWEL PIN@ OIL CHAMBER PLATE'A BEVERSE IDLEN GEAR SHAFT@ wasHER t-2).A REVERSE IDLER GEAFO REVERSE CHANGE HOLDER3A sTH/REVERSE SHIFT PIECEO 1ST/2ND SHIFT FORK04 3RD/.TH sHlFr FoRK@ 5TH/REVERSE SHIFT FORKO9' OIL GUTTER PLATE6' SNAP RING@ 72 mm THRUST SHIM) OIL GUIOE PLATEi!0 10 mm WASHER Replace..4i] REVERSE IDLER GEAR SHAFT BOLT54 N.m {5.5 kgt m, 40lblftl) TRANSMISSION HANGER B(3 BREATHER CAP@ TRANSMISSION HANGER A63 BACK.UP LIGHT SWITCH25 N.m (2.5 ksf.m, 18lbfftl@r 14 mrn waSHER Replace.67 16 mm SEALING BOLT29 N.m (3.0 kgl.m, 22 lbf ft)@ 32 mm SEALING BOLT25 N.m (2.5 kgf.m. 18lbt'ft|@ 40 x 62 x 9 mm OIL SEAL Replace.D STEEL BALL D. 5/16 inGl SPRING L. 30 mm {1.2 in}

@ 12 mm WASHER Replace.63) SET SCREW22 N.m 12.2 kgl.m, 16 lbt'ft,@ OIL ORAIN PLUG39 N.m {4.0 kgt.m, 29 lbf'ftl€9 WASHER Replace.@ oIL FILLER PLUG4,1N.m 14.5 kgJ m, 33 lblftl

*1:81881 engine*2:B18Cl engine

WASHER Beplace.TRANSMISSION HOUSING80 mm SHIM (*1)79.5 mm SHIM {*21THRUST SHIM {*2IT. 2.0 mm (0.079 in)BEARING OUTER RACE {*2}SHIFT PIECE SHAFTINTERLOCKSHIFT PIECESHIFT ARM HOLDERSELECT ARMSELECT RETURN SPRING10 mm SHIM10 mm WASHERLOCK COLLAR3 x 16 mm SPRING PIN Replace.8 mm SPRING WASHERCHANGE PIECESET SCREW22 N.m {2.2 kgf.m, 16 lbf.ft}SPRING L.25.6 mm {1.01 inlSTEEL BALL D. 5/16 inMAGNETCLUTCH HOUSING14 x 25 x 16 mm OIL SEAL Replace.SHIFT RODDIFFERENTIAL ASSEMBLYSee section 15BEARING OUTER RACE I*2ITHRUST SHIM I*2)T. 2.5 mm (0.098 in,SHIFT ROD BOOTOIL GUID€ PLATE33 x 60 x 20 mm NEEDLE BEARINGBEARING RETAINER PLATELOCK WASHER Replace.COUNTERSHAFTTHRUST SHIM37 x 42 x 25 mm NEEDLE BEARINGlST GEARFRICTION DAMPERSYNCHRO RINGSYNCHRO SPRINGlST/2ND SYNCHRO HUBREVERSE GEARDOUBLE CONE SYNCHRO I*2ISYNCHRO BING I*1)FRICTION DAMPERSPACER42 x 6? x 24 mm NEEDLE BEARING2ND GEAR3RD GEAR4TH GEAS5TH GEARNEEDLE BEARINGBALL BEARINGSPRING WASHERLOCKNUT Replace.108 - 0- 108 N.m(11.0 - 0* 11.0 kgt m,80- 0- 80lbf.ft)5 x 22 mm SPRING PIN Replace.00

13-9

Page 352 of 1413

Transmission Housing

Removal

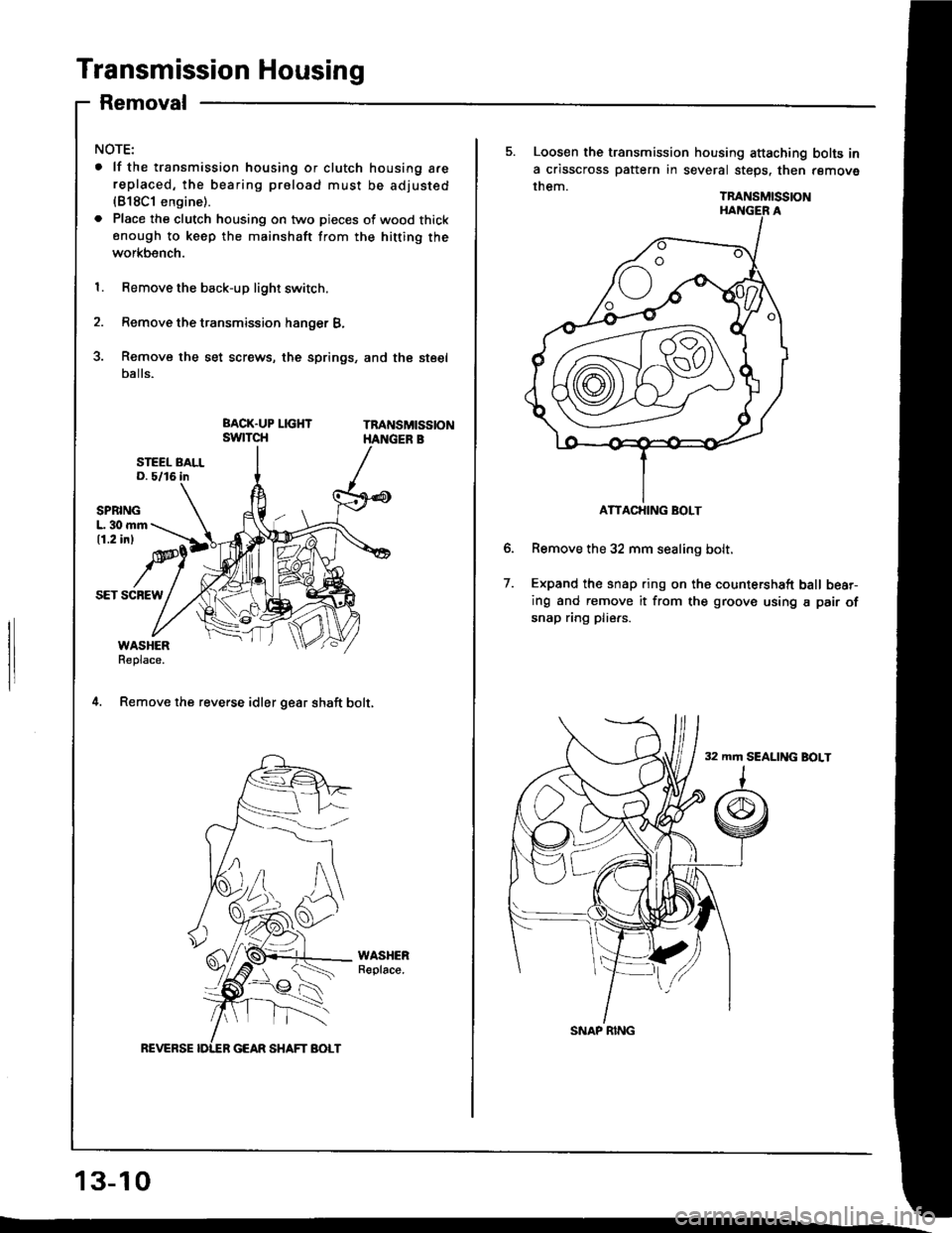

NOTE:

. lf the transmission housing or clutch housing a.ereplaced, the bearing proload must be adjusted(818C1 engine).

. Place the clutch housing on two pieces of wood thickenough to keep the mainshaft from the hitting the

workbench.

1. Remove the back-up light switch.

2. Remove the transmission hanger B,

3. Remove the set screws, the springs, and the steel

balls.

Tna sMtsstoN

SPBINGL. 30 mm11.2 inl

SET SCBEW

WASHERReplace.

4. Remov€ the reverse idler gear shaft bolt,

WASHERReplace.

REVERSE

L

13-10

ATTACHING BOLT

5. Loosen the transmission housing attaching bolts in

a crisscross pattern in several steps. then remove

them.TRANSMISSION

Remove the 32 mm sealing bolt.

Expand the snap ring on ths countershaft ball bear-

ing and remove it from the groove using a pair of

snap ring pliers.

32 mm SEALING BOLT

7.

SNAP RING

Page 353 of 1413

Reverse Change Holder,

Reverse ldler Gear

Clearance Inspection

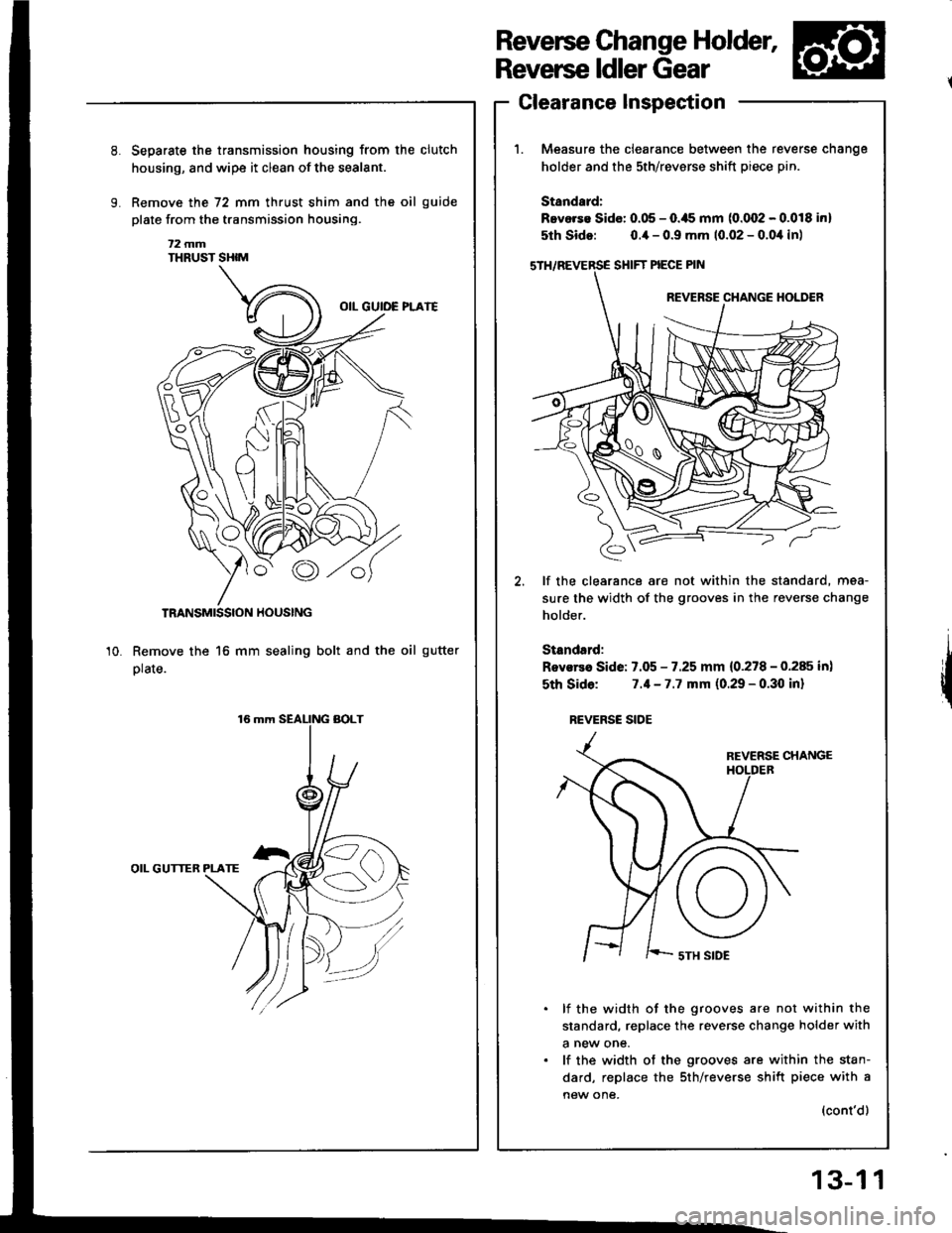

Measure the clearance between the re

holder and the sth/revsrse shift piece p

Standard:

Bevorse Sido: 0.05 - O.ils mm (0.002 - (

5th Sido: o.ia - 0.9 mm 10.02 - 0.0,1

SHIFT PIECE PIN

REVERSE CHANGE

€,

lf the clearance are not within the sti

sure the width of the grooves in the re

holder.

Standsrd:

Rovsrea Side: 7.05 - 7.25 mm {0.278 - (

sth Sido: 7.1-7.7 mm (0.29 - 0.30

REVERSC SIOE

REVERSE

I ' '-- sTH SIDE

lf the width of the grooves are n

standard, replace the reverse chan€

a new one.

lf the width of the grooves are wi

dard, replace the sth/reverse shift

new one,

Separste the transmission housing from the clutch

housing, and wipe it clean of the sealant.

Remove the 72 mm thrust shim and the oil guide

plate from the transmission housing.

t2 mmTHRUST SHIM

TRANSMISSION HOUSING

Remove the 16 mm sealing bolt and the oil gutter

plate.

OIL GUTTER PLATE

10.

reverse cnange

ptn.

.0.018 inl

),1in)

standard, mea-

reverse change

0.285 in)

I inl

not within the

Inge holder with

within the stan-

rift piece with a

(cont'd)

13-1 1

Page 354 of 1413

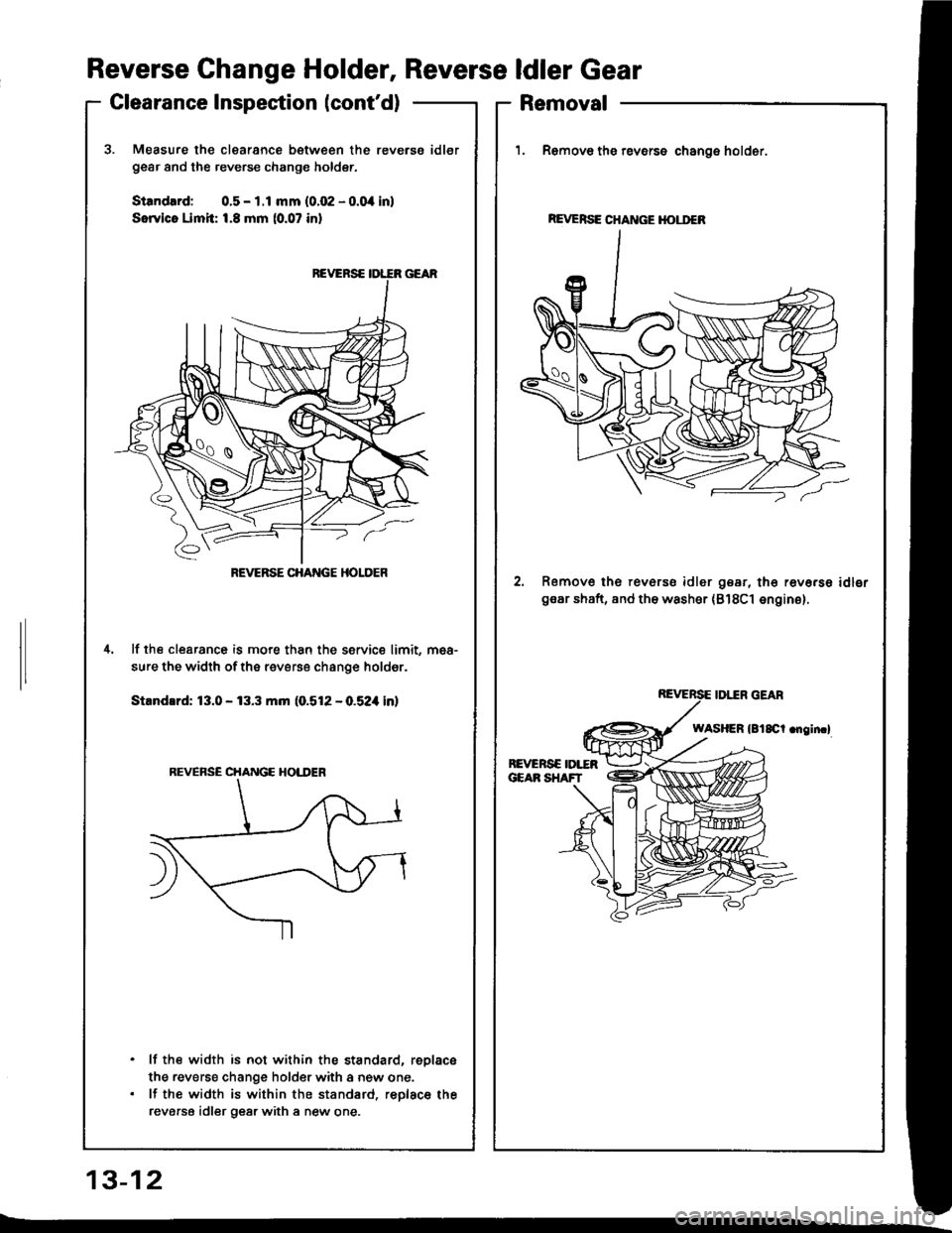

Measure the clearance between the reverss idler

gear and the reverse change holder.

Standard: 0.5 - 1.1 mm (0.02 - 0.04 inl

Sorvico Limit: 1.8 mm (0.07 inl

4.lf the clearance is more than the service limit, mea-

sure the width ofthe reverse change hold6r.

St.ndrrd: 13.0 - 13.3 mm (0.512 - 0.52/t inl

lf the width is not within the standard, replace

the reverse change holder with a new one.

lf the width is within the standard, reolaco the

reversa idler gear with a new one.

REVERSE CHA'{GE HOLDER

REVERSE CHANGE HOTI'ER

Reverse Change Holder, Reverse ldler Gear

Clearance Inspection lcont'd)Removal

1. Removo the reverse change holder.

2. Remove the revorss idler g€ar, th€ rev6rs6 idlsrgear shaft, and the washor {B18Cl engine}.

REVERSE IDI.TRGEAF SHAFT

13-12

REVERSE CHAMiE HOII'ER

Page 355 of 1413

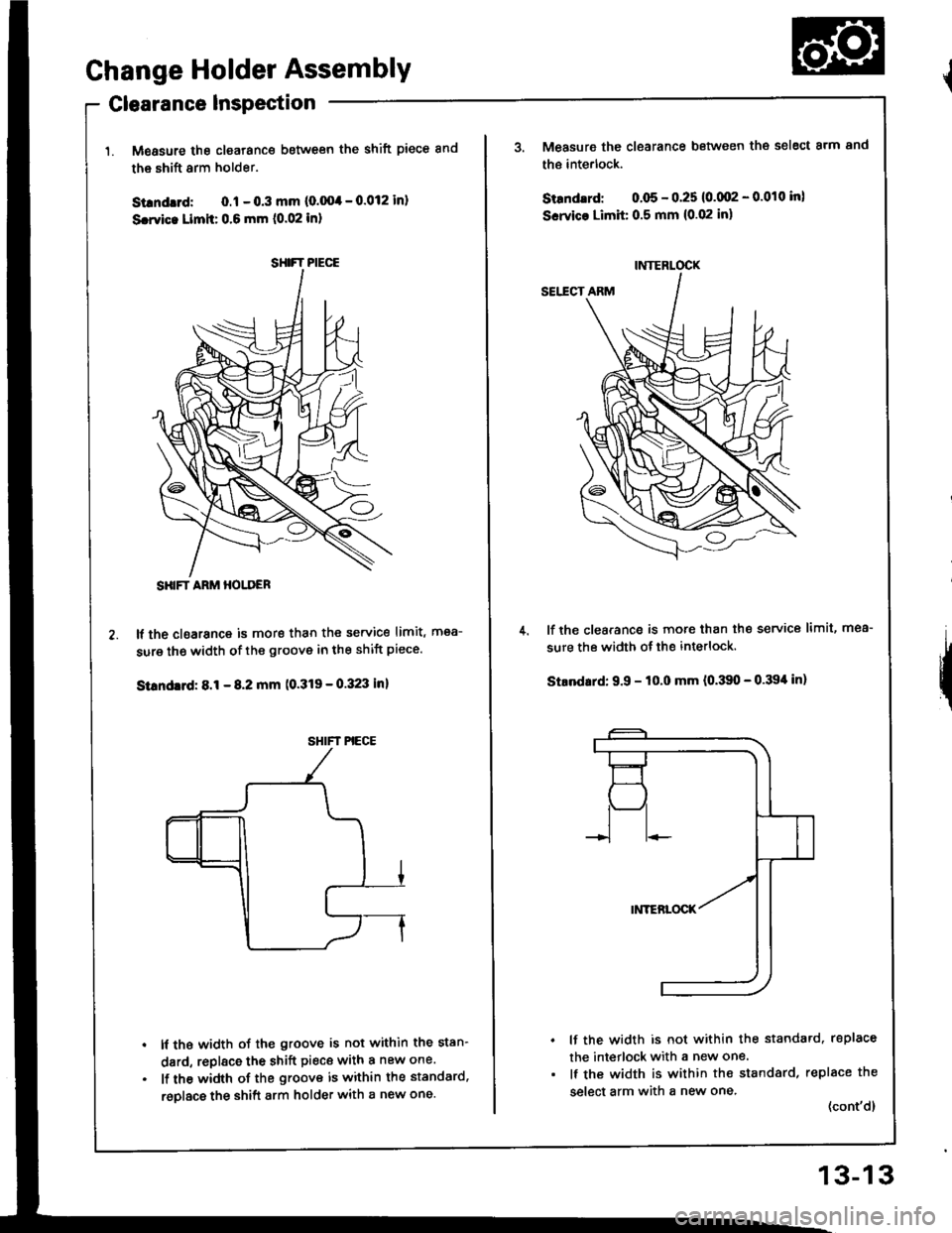

Change Holder Assembly

Clearance Inspection

Measure the clearance between the shift piece and

the shift arm holder.

Silndrd: 0.1 - 0.3 mm (0.004 - 0.012 inl

Scwic. Limit: 0.6 mm (0.02 inl

It the cloarance is more than the service limit, mea-

sure th€ width of the groove in the shift piece.

Stlndffd: 8.1 - 8.2 mm (0.319 - 0.323 inl

ll the width of the groove is not within the stan-

dard, replsce the shift piecs with a new one.

lf the width of the groove is within the standard.

roolace the shift arm holder with a new one.

SHIFT PIECE

SHIFT ARM HOI.I'ER

SHIFT PIECE

INTERLOCK

{

3. Measure the clearance between the select 8rm and

the interlock.

Standlrd: 0.05 - 0'25 (0.002 - 0.010 in)

Scrvica Limit 0.5 mm (0.02 in)

4. lf the clearance is more than the service limit, mea-

sure the width ot the interlock.

Stlndrrd: 9.9 - 10.0 mm (0.391t - 0.39a in)

lf the width is not within the standard. replace

the interlock with a new one.

lf the width is within the standard, replace the

select arm with a new one.(cont'd)

13-13

Page 356 of 1413

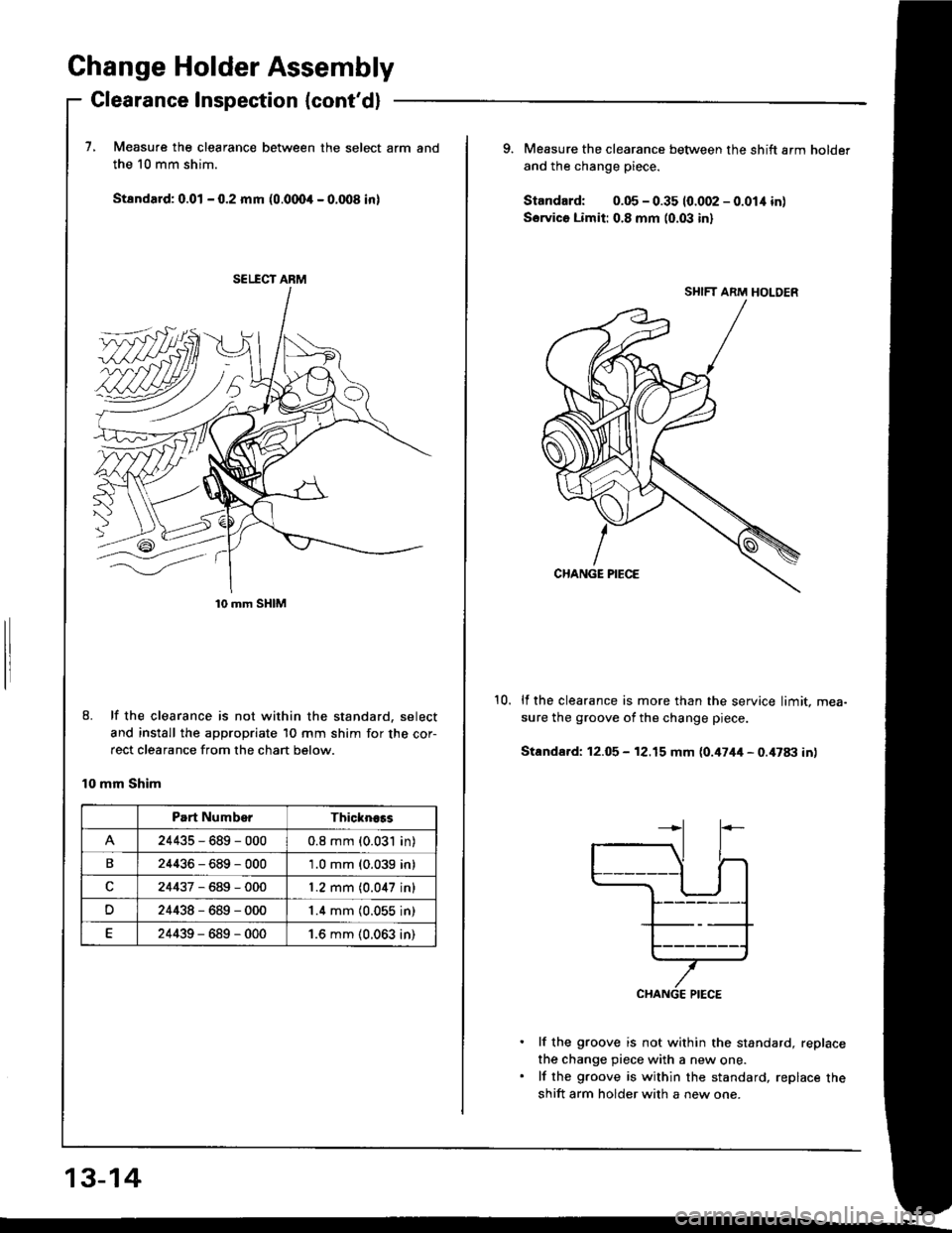

Change Holder Assembly

Clearance Inspection {cont'd}

7, Measure the clearance between the select arm

the 10 mm shim.

Stsndard: 0.01 - 0.2 mm (0.0004 - 0.008 inl

8. lf the clearance is not within the standard. select

and install the appropriate 10 mm shim for the cor-

rect clearance from the chan below.

10 mm Shim

SETICT ABM

10 mm SHIM

Part NumbsrThickn€ss

24435-689-0000.8 mm (0.03'l in)

B24436-689-000'1.0 mm (0.039 in)

24437-689-0001.2 mm (0.047 inl

24438-689-0001.4 mm {0.055 in)

24439-689-0001.6 mm (0.063 in)

13-14

SHIFT ARM HOLDER

9. Measure the clearance between the shift arm holder

and the change piece.

Standard: 0.05 - 0.35 10.002 - 0.01i1 in)

Sorvico Limit: 0.8 mm (0.03 in)

ll the clearance is more than the service limit. mea-

sure the groove of the change piece.

Standafd: 12.05 - 12.15 mm {0.47ilil - 0.iU83 in)

lf the groove is not within the standard, replace

the change piece with a new one.

lf the groove is within the standard, replace the

shift arm holder with a new one.

10.

Page 357 of 1413

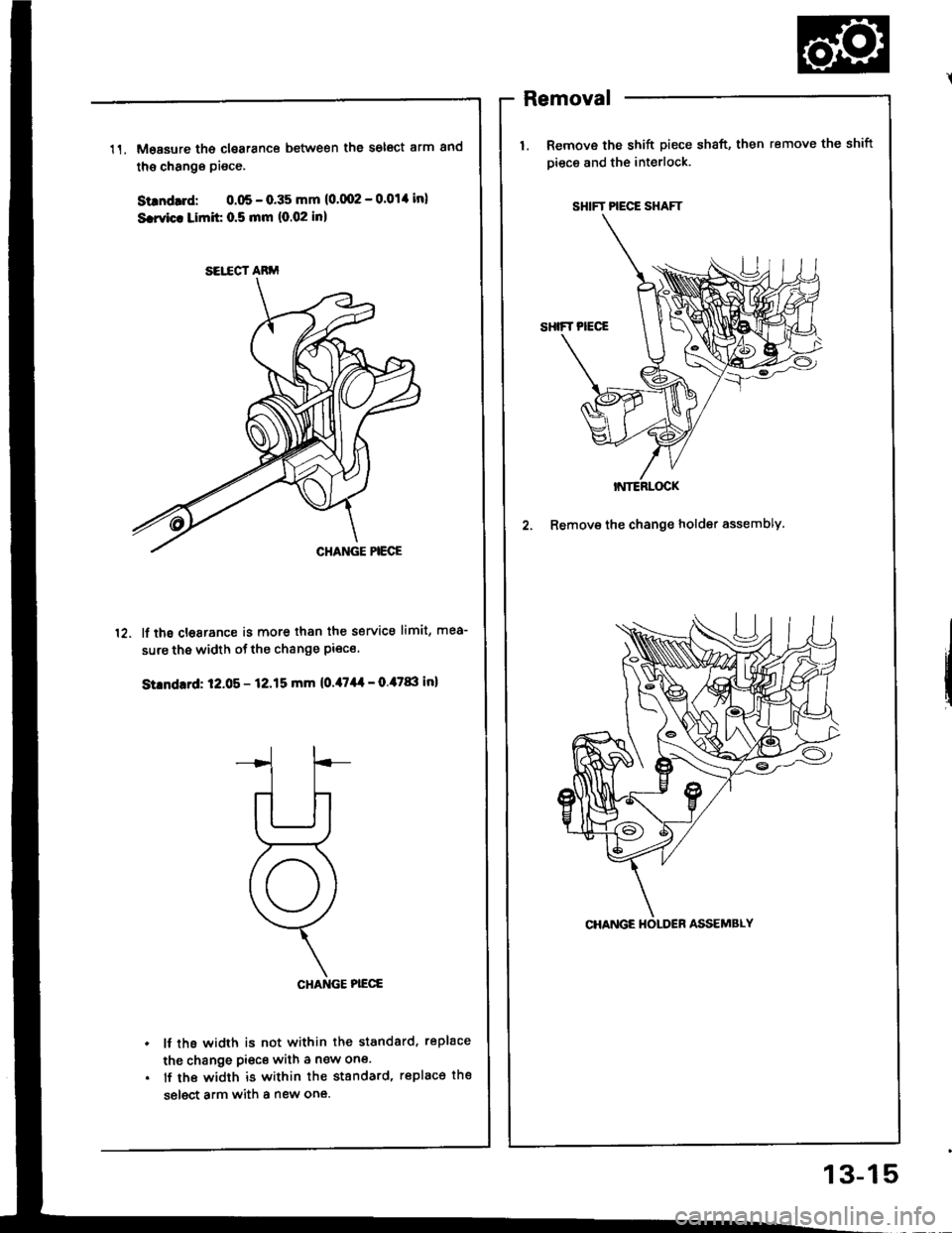

11.Moasure th€ clsarance between the s6l6ct arm 8nd

tho change piece.

Sundrrd: 0.05 - 0.35 mm (0'002 - 0'014 in)

S.rvic. Limit 0.5 mm 10.02 Inl

lf the clesrance is more than the service limit, mea-

sure the width ofthe change Piece.

Strndrrd: 12.05 - 12.15 mm {0./17,11 - o.'U&l in)

CHANGE PIECE

lf ths width is not within the standard, replace

the change piec€ with a n€w one.

lf the width is within the standard, replaco th€

select arm with a new one.

Removal

Removs the shift piece shaft, then remove the shift

pieca and the interlock.

SHIFT PIECE SHAFT

2. Remove the change holder assembly.

12.

SEI.ECT ARl,l

CHANGE HOLDER ASSEMBLY

13-15

Page 358 of 1413

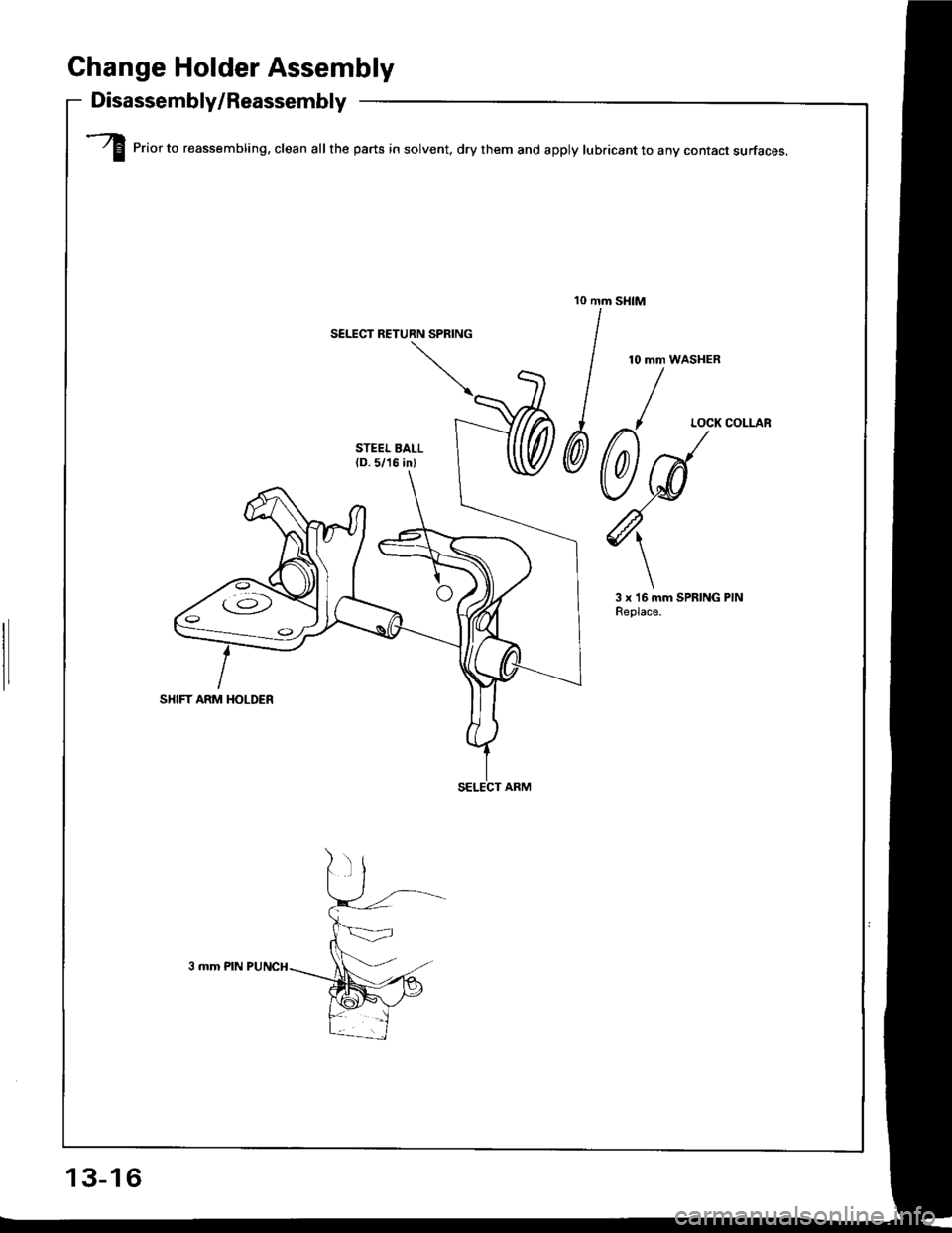

Change Holder Assembly

Disassembly/Reassembly

I erior to reassembling. clean all the parts in solvent, dry them and apply lubricant to any contact surfaces.

10 mm SHIM

3 mm PIN

SELECT RETURN SPRING

13-16

Page 359 of 1413

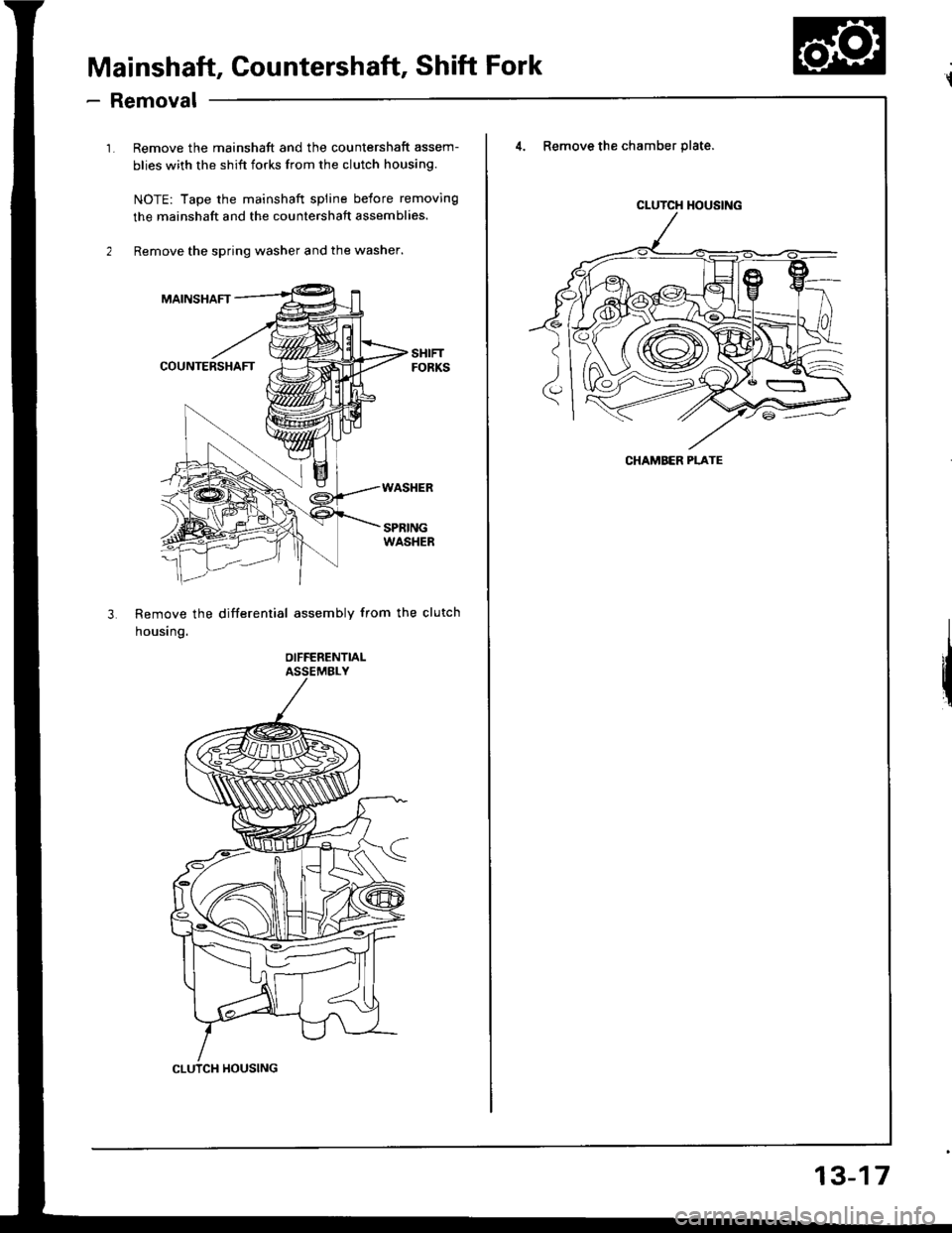

Mainshaft, Gountershaft, Shift Fork

- Removal

1. Remove the mainshaft and the countershaft assem-

blies with the shift forks from the clutch housing.

NOTE: Tape the mainshaft spline belore removing

the mainshaft and the countershaft assemblies.

2 Remove the spring washer and the washer.

Remove the differential assembly from the clutch

housing.

OIFFERENTIAL

CLUTCH HOUSING

13-17

4. Remove the chamber plate.

CLUTCH HOUSING

CHAMBCR PLATE

Page 360 of 1413

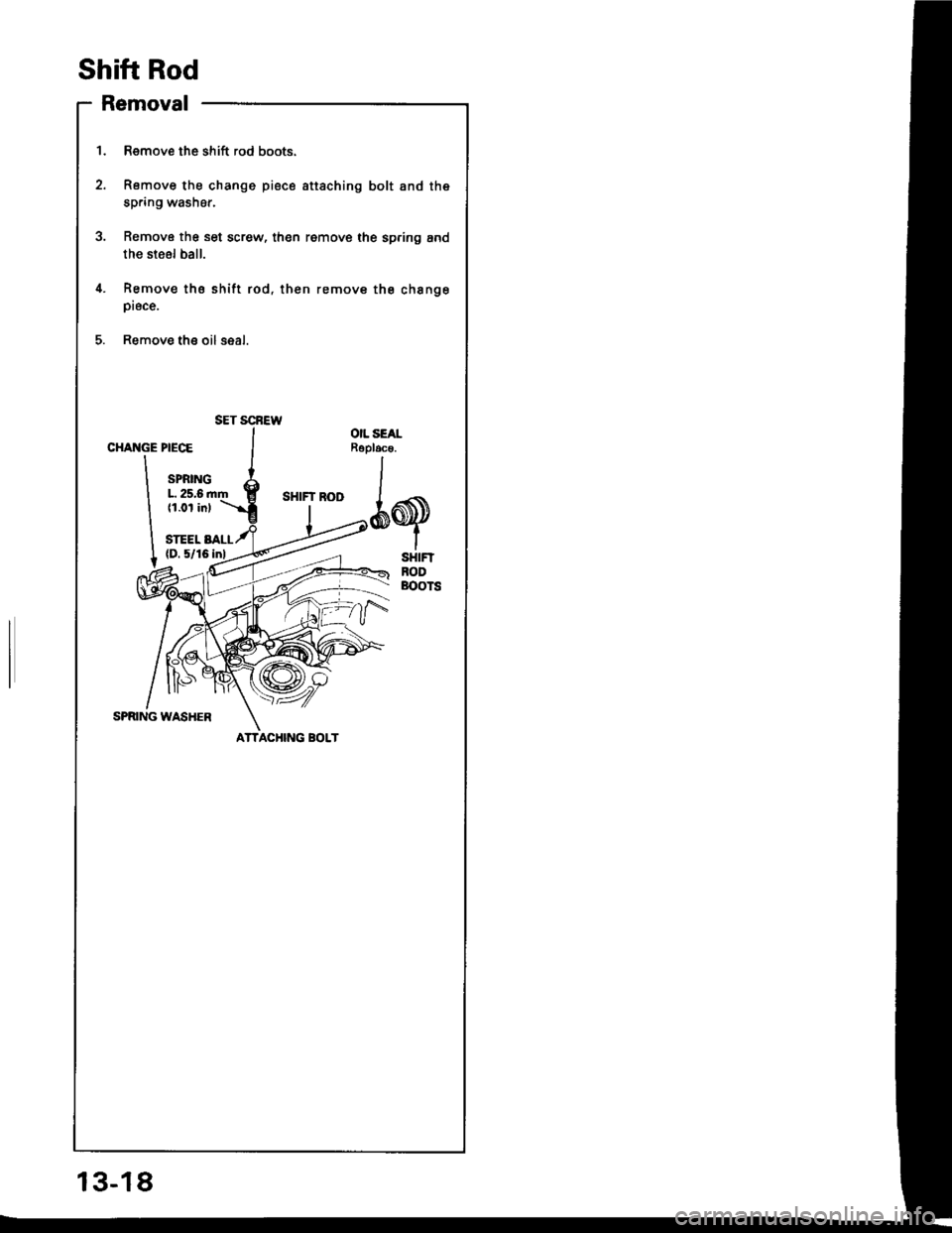

Shift Rod

CHANGE PIECE

SPRINGL 25.6ll.0r in,

STEEL AALL(D.5/16

SPRING WASHER

Removal

1. Remove the shift rod boots.

2. Romove the change piece sttaching bolt and the

spring washer.

3. Remove the set screw, then remove the spring and

the steol ball.

4. Remov€ tho shitt rod, then remove the chsngepiece.

5. Remove th€ oilseal.

OIL SEALRoploc€.

*q

ACHING BOLT

SET SCBEW

13-18