HONDA INTEGRA 1994 4.G Workshop Manual

Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 341 of 1413

spection

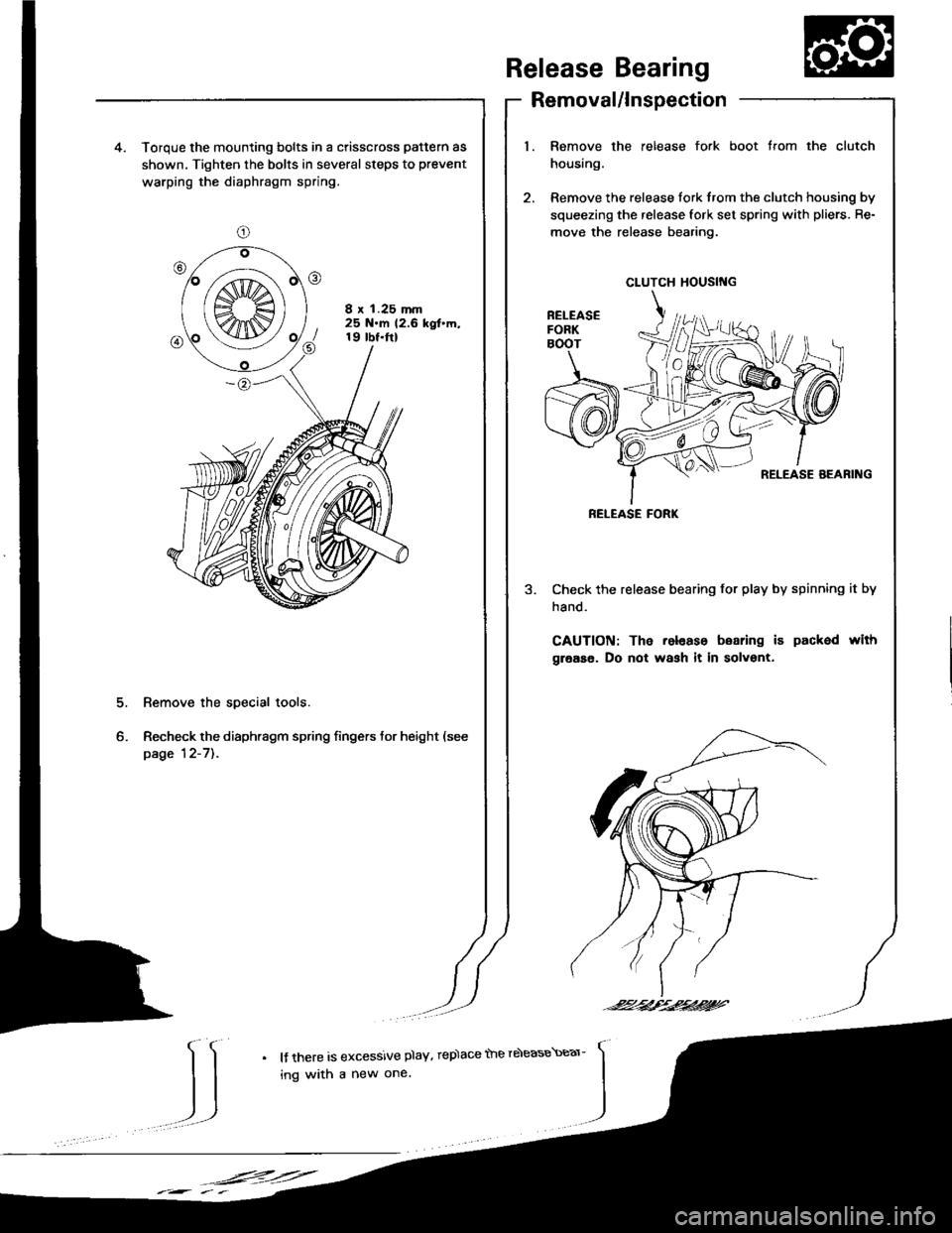

release fork boot trom the clutch4. Torque the mounting bolts in a crisscross pattern as

shown. Tighten the bolts in several steps to prevent

warping the diaphragm spring.

8 x 1.25 mm25 N.m 12.6 kgt'm,19 tbt.ftl

2. Remove the release tork trom the clutch housing by

squeezing the release fork set spring with pliers. Re-

move the release bearing.

Check the release bearing for play by spinning it by

hand.

CAUTION: The release boaring i6 packed with

grease. Do not wash it in solvent.

Remove the special tools.

Recheck the diaphragm spring fingers tor height (see

page 12-7]..

Release Bearing

Removal/ln

1. Remove the

housing.

CLUTCH HOUSING

RELEASE FORK

-24/--2,t'.2424?'

IJ

l{ there is excessive plaY, rep)ace the rdease\Ear-

ing with a new one.

,F=:=

Page 342 of 1413

Release Bearing

Installation

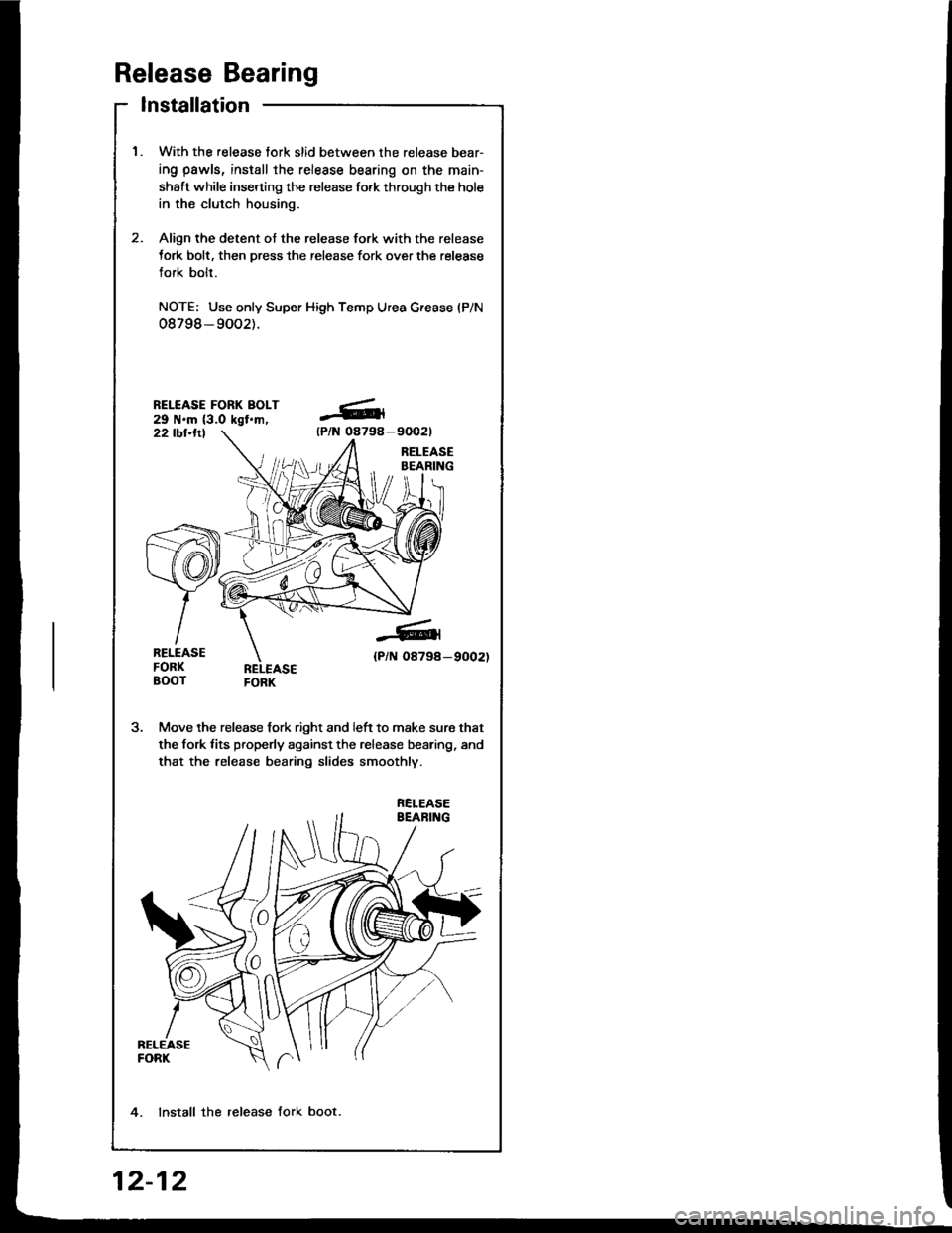

1.With the release tork slid between the release bear-

ing pawls, install the release bearing on the main-

shaft while inserting the release fo.k through the hole

in the clutch housing.

Align the detent ot the release fork with the release

tork bolt, then press the release fork over the release

fork bolt.

NOTE; Use only Super High Temp Urea G.ease (P/N

08798- 9002).

2.

-611

lPlN 08798-

-6

{P/N 0879a-9002)

Move the release fork right and left to make sure that

the fork tits properly against the release bearing, and

that the release bearing slides smoothly.

4. lnstall the release fork boot.

12-12

Page 343 of 1413

Manual Transmission

Special Toofs ............. 13-2

Maintenance

Transmission Oi1,...,........,........,.,..... 13-3

Back-up Light Switch

Replacement ......... 13-3

Transmission Assembly

Removal ..,.......,...... 13-4

lllustrated Index ................................... 13-8

Transmission Housing

Removal ...........,..... 13-10

Reverse Change Holder, Reverse ldler Gear

Glearance lnspestion ....................... 13-1 1

Removaf ................. 13-12

Change Holder Assembly

Clearance Inspection ....................... 1 3-1 3

Removal ................. 13-15

Disassembly/Reassembly ............... 13-16

Mainshaft, Gountershaft, Shift Fork

Removal ...,............. 13-17

Shift Rod

Removal ................. 13-18

Shift Fork Assembly

Index ................ ...... 13-19

Clearance Inspection ....................... 13-20

Mainshaft Assembly

Index ................ ...... 13-21

Clearance f nspection ....................... 13-22

Disassembly .......... 13-25

Inspection .............. 13-26

Reassembly ........... 13-21

Countershaft Assembly

Index ................ ...... 13-28

Clearance Inspection ....................... 13-29

Disassembly .......... 13-30

Inspection .............. 13-31

Reassembly ........... 13-32

Synchro Sleeve, Synchro Hub

Inspection .............. 13-34

Installation ............. 13-34

Synchro Ring, Gear

lnspection .............. 13-35

Clutch Housing Bearing

Replacement ......... 13-36

Mainshaft Thrust Clearance

Adiustment ............ 13-38

Transmission

Reassembly ........... 13-tl1

Transmission Assembly

lnstallation ............. 13-46

Gearshift Mechanism

Overhaul ................ 13-50

Page 344 of 1413

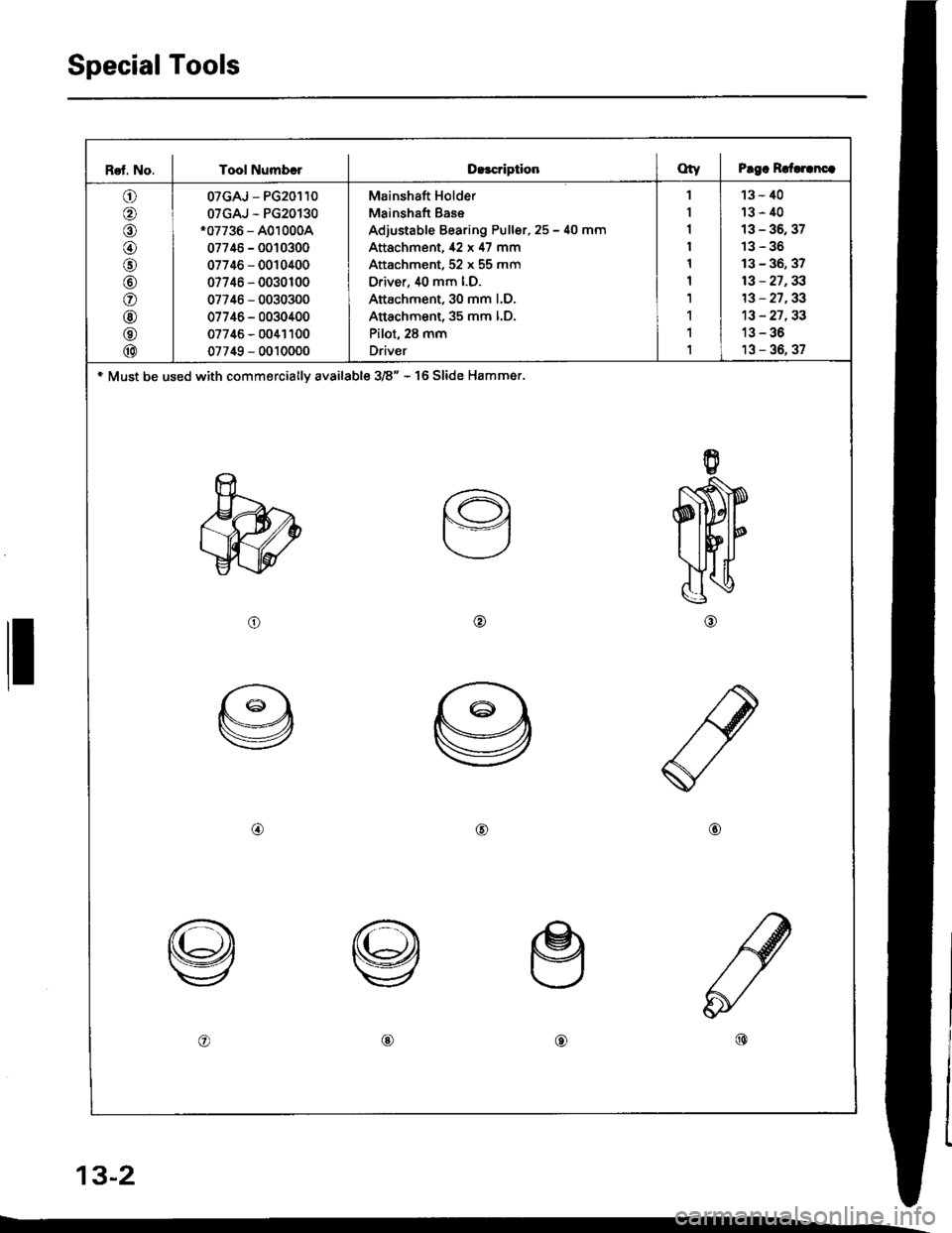

Special Tools

Rsf. No. I Tool NumbrrD!3criptionOty I Prgc R.{.rcnc.

o

o

o

o

@

@

@

@

@

07GAJ - PG20110

07GAJ - PG20130.07736 - A010004

07746 - 0010300

07746 - 0010400

07746 - 0030r00

07746 - 0030300

07746 - 0030400

07745 - 0041100

07749 - 0010000

Mainshaft Holder

Mainshaft Bas€

Adjustable Bearing Puller, 25 - 40 mm

Attachment, 42 x 47 mm

Attachment, 52 x 55 mm

Oriver, 40 mm l.D.

Attachment, 30 mm l.D.

Attachment, 35 mm l.D,

Pilot, 28 mm

Driver

1

1

1

1

1

1

1

1

1

1

'13 - 40

13-40

13 - 36, 37

13-36

13 - 36, 37

13 - 27,33

13 - 27,33

13 - 27,33

13-36

13 - 36, 37

* Must be used with commerciallv available 3/�8" - 16 Slide Hammer.

o@

@@@

o@@

ll

13-2

Page 345 of 1413

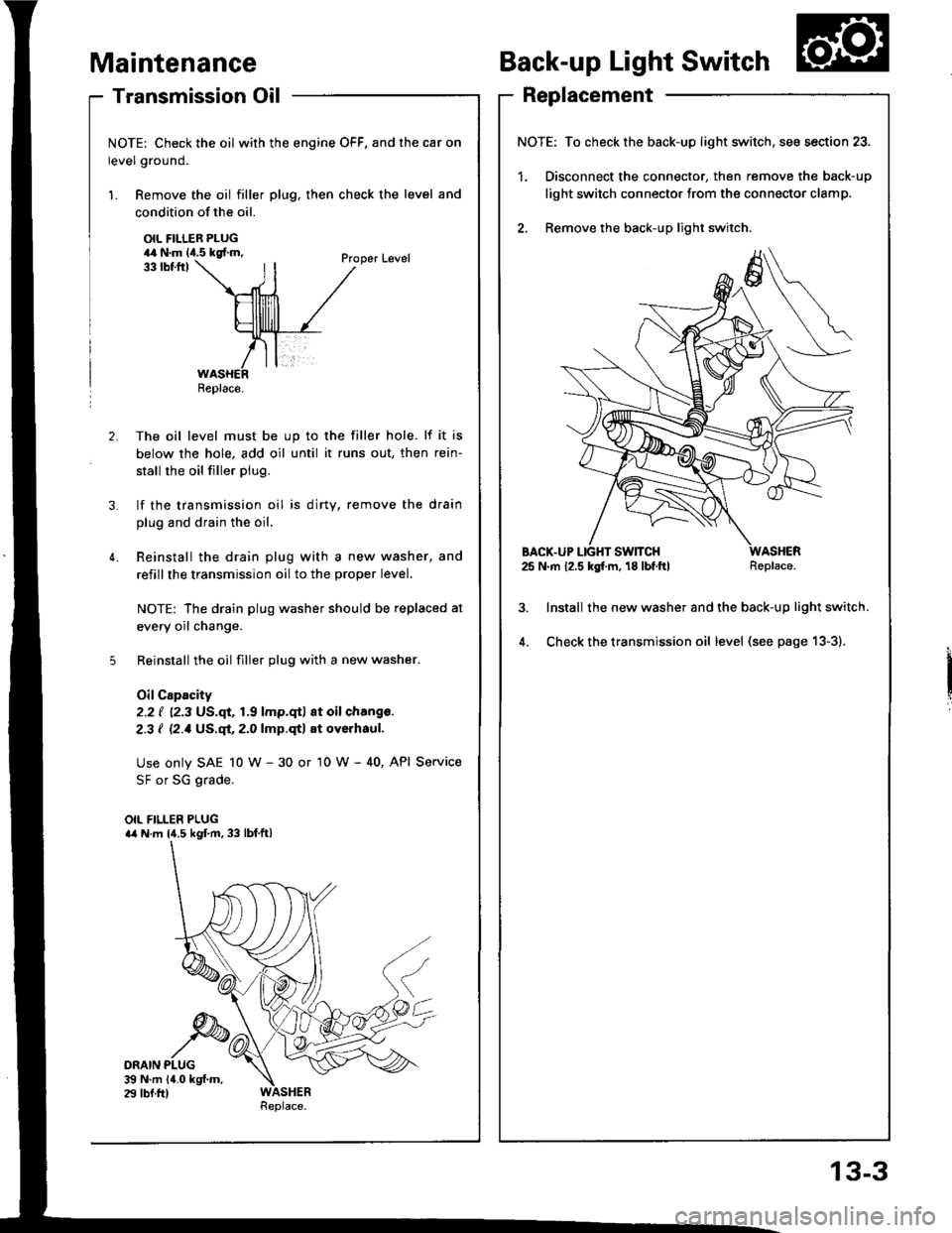

- Transmission Oil

NOTE: Check the oil with the engine OFF, and the car on

level ground.

1. Remove the oil filler plug, then check the level and

Maintenance

condition of the oil.

OIL FILLER PLUG44 N.m lia.5 kgf.m,

ORAIN PLUG$ N.m 14.0 kgf.m.29 lbf.fr)

33 tbtftlProper Level

2. The oil level must be up to the filler hole. lf it is

below the hole. add oil until it runs out, then rein-

stall rhe oil filler plug.

3. lf the transmission oil is dirty, remove the drain

plug and drain the oil.

4. Reinstall the drain plug with a new washer, and

refillthe transmission oil to the proper level.

NOTE: The drain plug washer should be replaced at

every oil change.

5 Reinstall the oil filler plug with a new washer.

OilCapacity

2.2 ( ''2.3 US.qt,1.9 lmp.qt) at oil chang€.

2-3 I l2.1Us.ql,2.0lmp.qtl at oyerhaul.

Use only SAE 10 w - 30 or '10 W - 40, API Service

SF or SG grade.

OIL FILLER PLUGa4 N.m l{.5 kgf.m, 33 lbf.ftl

Back-up Light Switch

Replacement

NOTE: To check the back-up light switch,

1. Disconnect the connector, then rem(

light switch connector trom the conn

2. Remove the back-up light switch.

BACX-UP LIGHT SWITCH25 N.m 12.5 kg[.m, 18 lbf.ftl

lnstall the new washer and the back-

Check the transmission oil level (see

Replace.

/itch, see section 23.

remove the back-up

]onnector clamp.

-up light switch.

) page 13-3).

Replace.

13-3

Page 346 of 1413

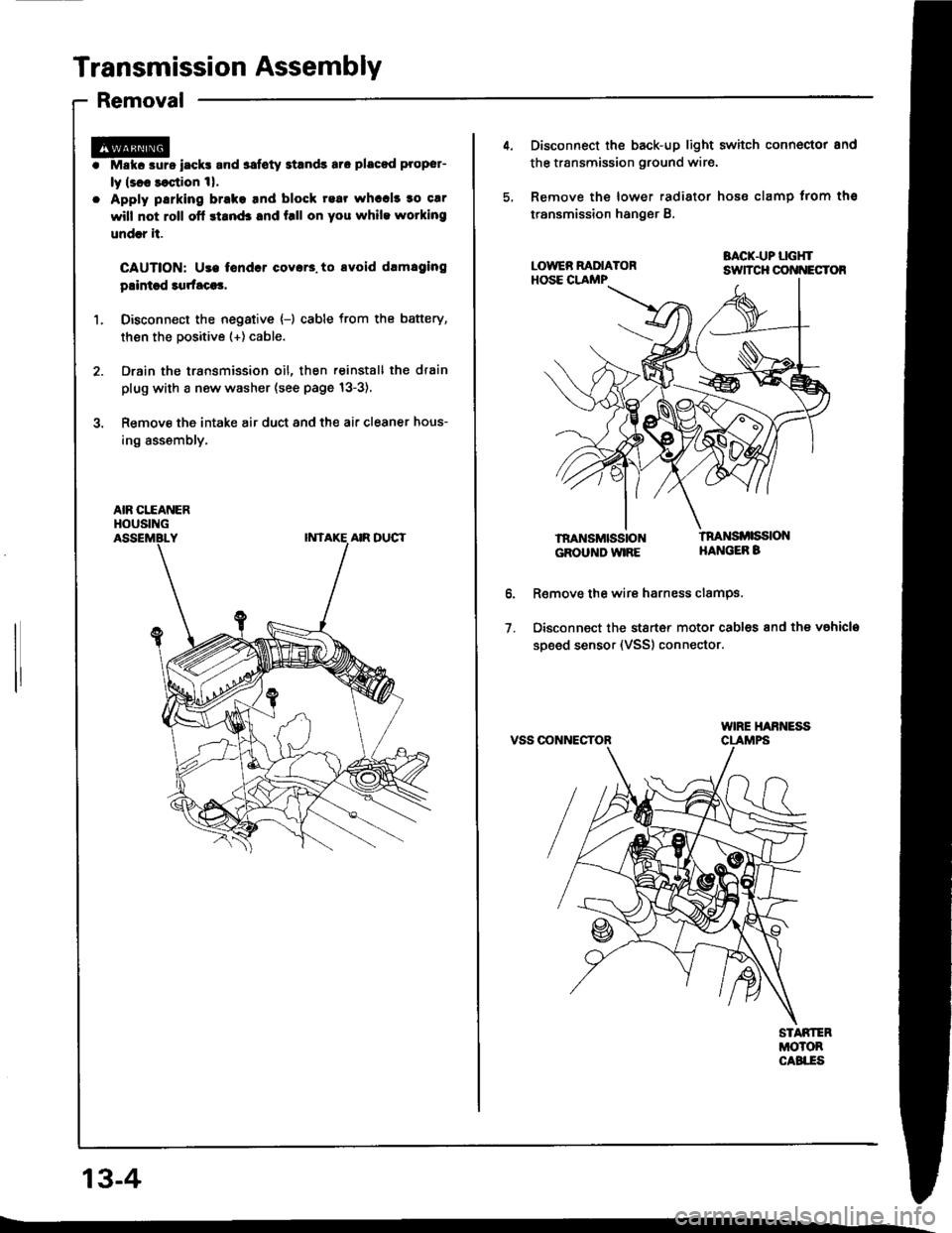

Transmission Assembly

Removal

Mskc aurs iack! and safoty Etands aro placod proper-

ly lsl8 saqtion 1|.

Apply parking brake tnd block rear whccl! to car

will not roll ofl stand3 and f.ll on you while wotking

undrr it.

CAUTION: Use tondcr coyar3. to avoid drmlging

plintsd 3qrfaca3,

Disconn€ct the negative {-) cable from the battery,

then the positive (+) cable.

Drain the transmission oil, then reinstall the drain

plug with a new washer (see page 13-3),

Remove the intake air duct and the air cleaner hous-

ing assembly,

AIR CITANERHOUSING

13-4

4. Disconnect the back-up light switch connoctor and

the transmission ground wir€.

5, Remove the lower radiator hose clamp trom ths

transmission hanger B.

BACK.UP LGHTsuTcH cot{t{EcToR

lnaNsMttistoNGROUND WIRE

tnaNsi ssloNHANGEB B

o.

1.

R€move the wire harness clamPs.

Disconnect the stsrt€r motor cables and the vahicla

soeed sensor (VSS) connector.

VSS OONNECTOR

Page 347 of 1413

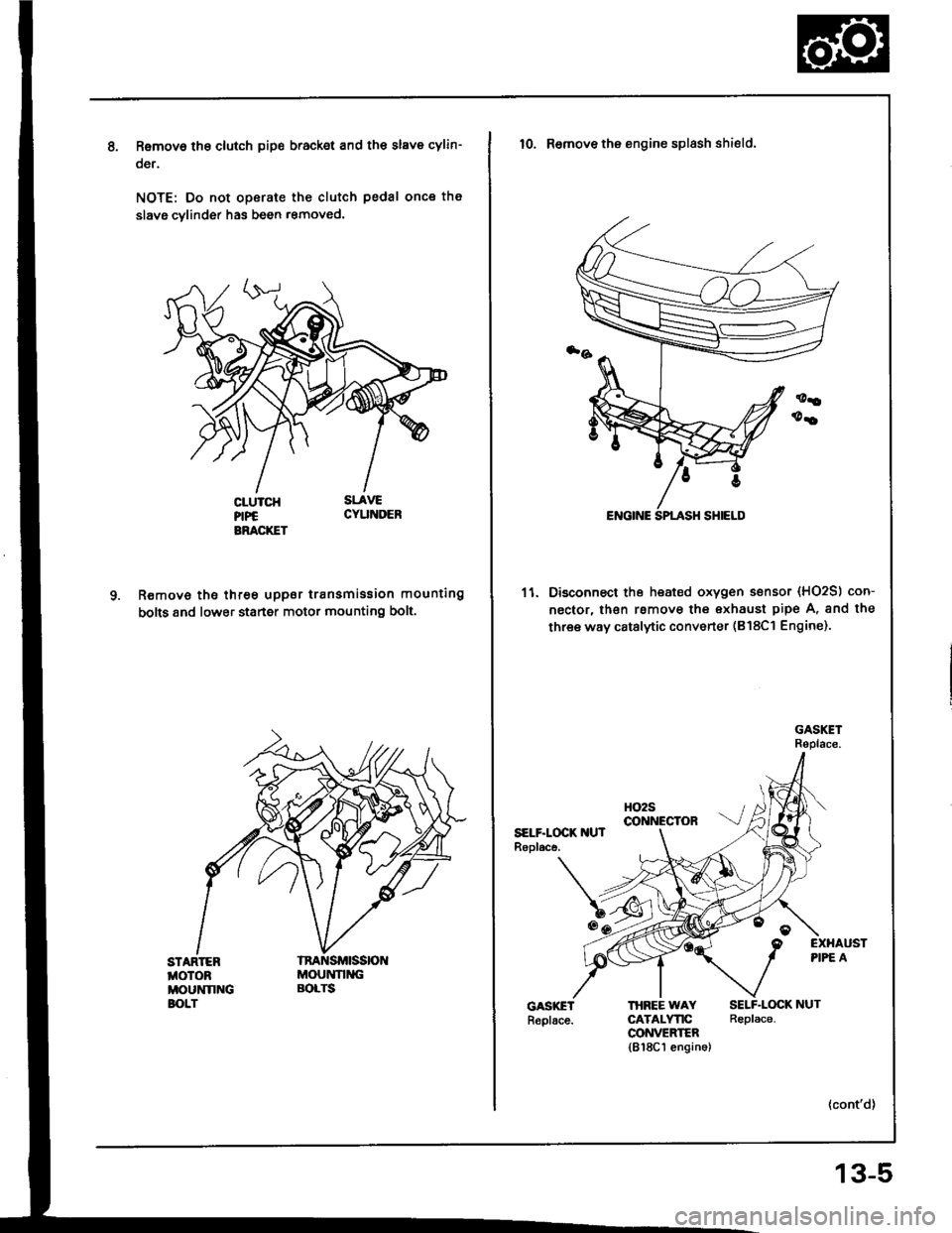

Removo tho clutch pip€ bracket and th€ slave cylin-

oer.

NOTE: Do not operate the clutch pedal once th€

slavg cvlinder has been r€moved.

R€move the three uppor transmission mounting

bolts 8nd lower staner motor mounting bolt.

STARTEBMOTOBMOUNNNGBOLT

MOUNNNGBOLTS

10. Remove the engine splash shield.

11. Disconnect the heated oxygen sensor (HO2S) con-

nector, lhsn rsmove the exhaust pipe A, and the

three way catalytic converter (B18Cl Engine).

HO2Sco NEctoRSELF.LOCK IIUTRopl.ce.

EXHAUSTPIPE A

THBEE WAYCATALYTICCONVEEIER1818C1 engin6)

SELF.LOCK NUTReplace.

13-5

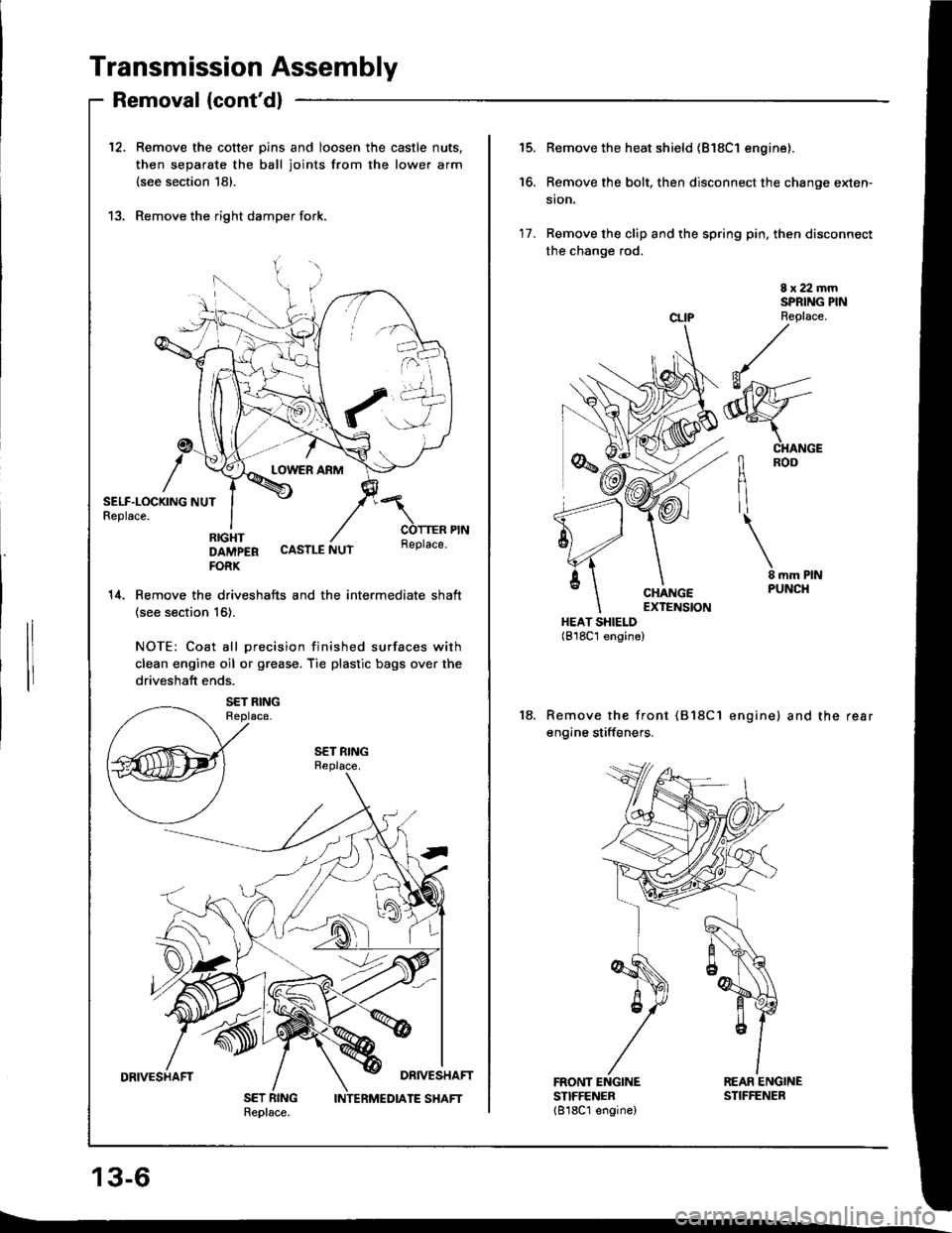

Page 348 of 1413

Page 349 of 1413

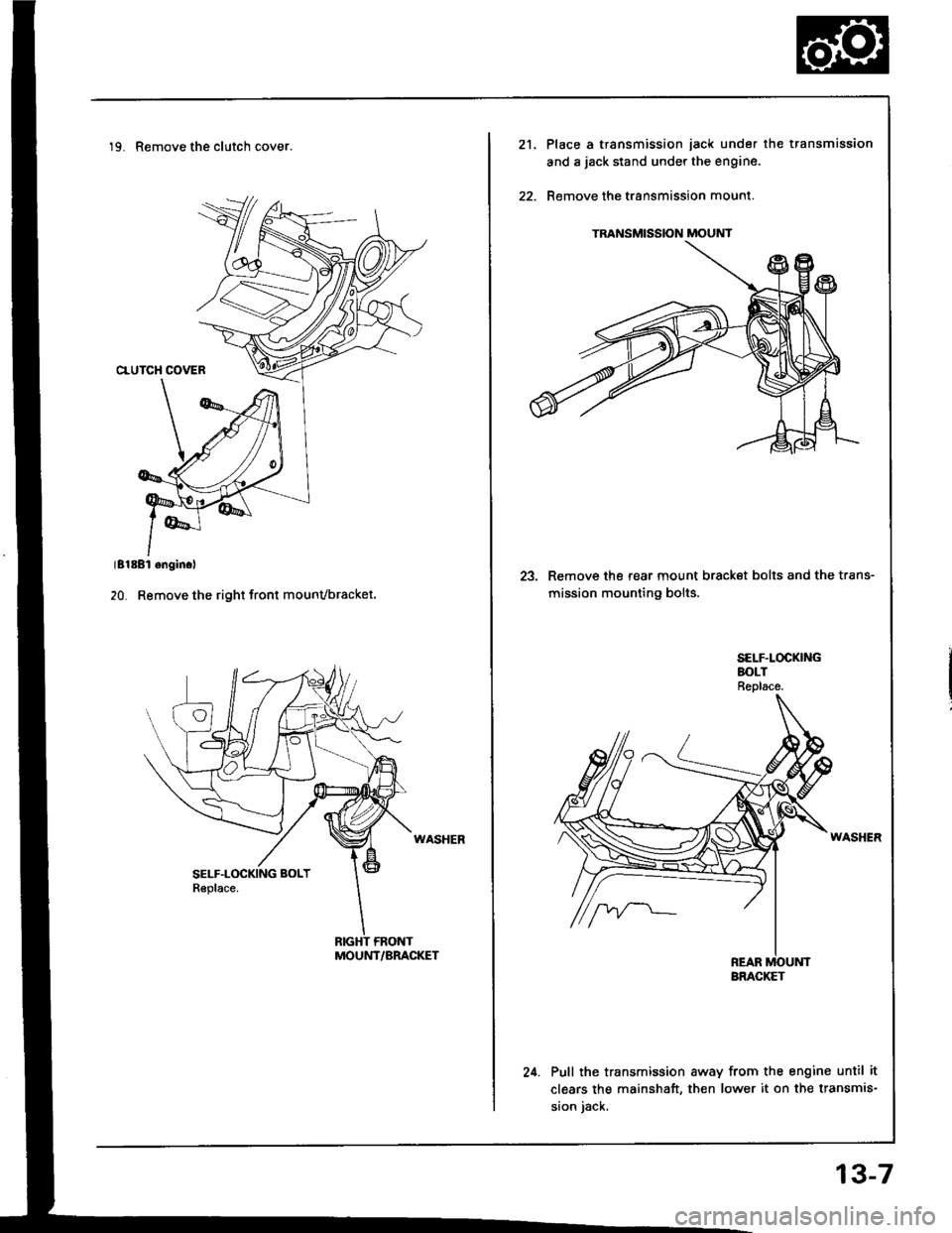

19. Remove the clutch cover.

MOUNT/BRACKET

TRANSMISSION MOUNT

21.Place a transmission iack under the transmission

and a jack stand under the engine.

Remove the transmission mount.

23. Remove the rear mount bracket bolts and the trans-

mission mounting bolts.

24. Pull the transmission away from the engine until it

clears the mainshaft, then lower it on the transmis-

sion iack.

BRACKET

13-7

Page 350 of 1413

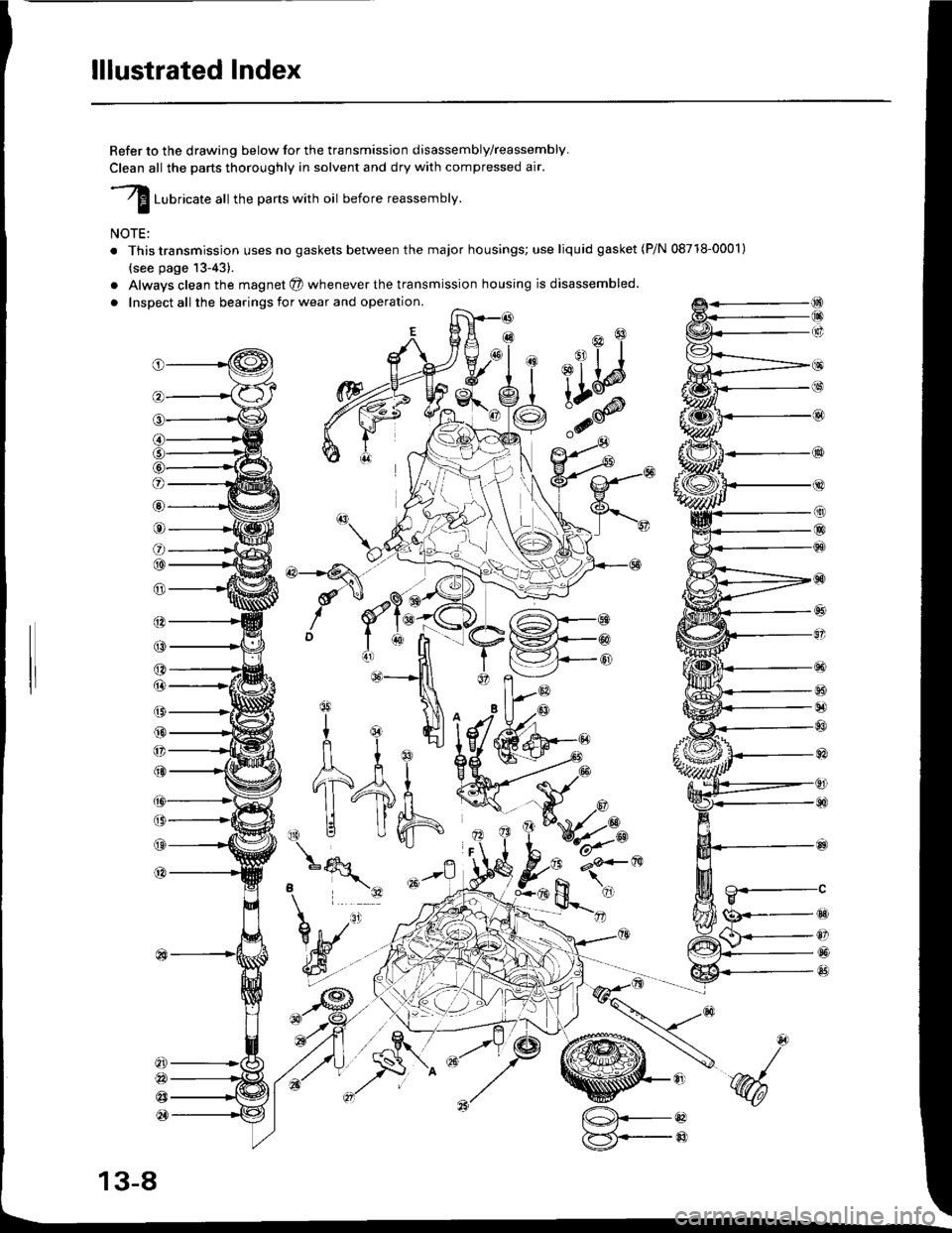

lllustrated Index

Refer to the drawing below for the transmission disassembly/reassembly.

Clean all the parts thoroughly in solvent and dry with compressed air.

I ruurlcate att the parts with oil before reassembly.

NOTE:

. This transmission uses no gaskets between the major housings; use liquid gasket (P/N 08718-0001)

{see page 13-43).

a

a

Alwavs clean the magnet @ whenever the transmission housing is disassembled.

Inspect all the bearings for wear and operation.

(9

@

@

tqqlnl^'1ult I Ej

nl

11-4fi

,\|j Uh

o

@

o

@@

@

@

(3

(,

@

@

@

a

@

@

@

@

B

tg

Y

o

@

@

@

*N

13-8

[@.--oaF5i,--@:7