wiring HONDA INTEGRA 1994 4.G Owner's Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 1232 of 1413

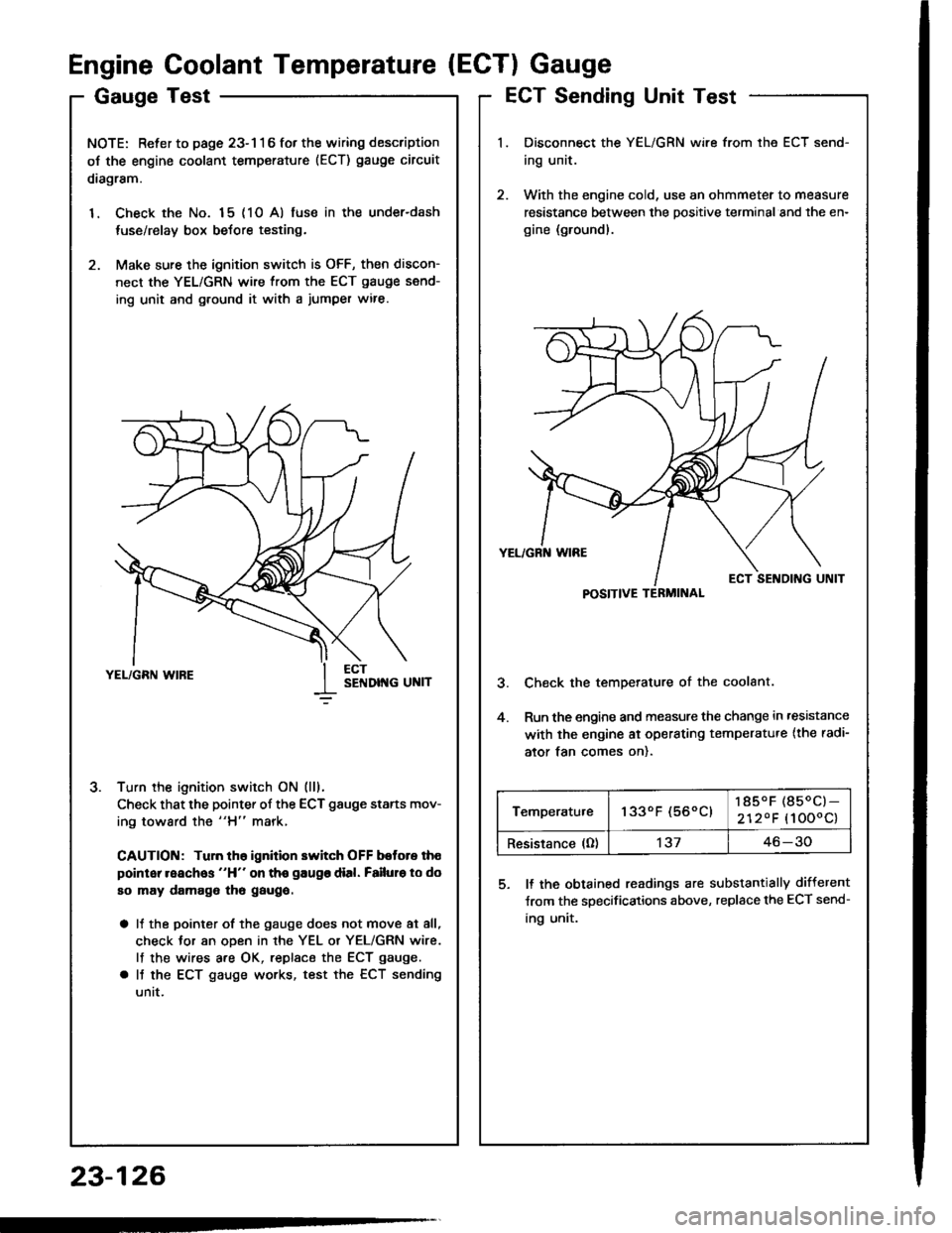

GaugeTest

NOTE: Refer to page 23-116 fot the wiring description

oJ the engine coolant temperature (ECT) gauge circuit

diagram.

1. Check the No. 15 (10 A) fuse in the under-dash

tuse/relay box before testing.

2. Make sure the ignition switch is OFF, then discon-

nect the YEL/GRN wire from the ECT gauge send-

ing unit and g.ound it with a jumper wire.

Turn the ignition switch ON (lll.

Check that the pointer of the ECT gauge starts mov-

ing toward the "H" mark,

CAUTION: Tuln th6 ignition switch OFF botore th€

point reaches "H" on tho gaugo dial. Failuro to do

so may damago tho gaugo.

a It the pointer of the gauge does not move at all,

check Jor an oDen in rhe YEL or YEL/GRN wire.

lf the wires are OK, replsce the ECT gauge.

a It the ECT gauge works, test the ECT sending

untt.

J.

Engine Coolant Temperature (ECTI Gauge

ECT Sending Unit Test

Disconnect the YEL/GRN wire from the ECT send-

ing unit.

With the engine cold, use an ohmmeter to measure

resistance between the positive terminal and the en-

gine (ground).

Check the temperature of the coolant.

Run the engine and measure the change in ,esistance

with the engine ai operating temperatu.e {the radi-

ator tan comes on).

5. ll the obtained readings are substantially different

Jrom the specifications above, replace the ECT send-

ing unit.

23-126

POSITIVE TERMINAL

Temperatu.e1330F (560C)185.F (850C)-

2120F (1000c)

Resistance (O)'t3746-30

Page 1234 of 1413

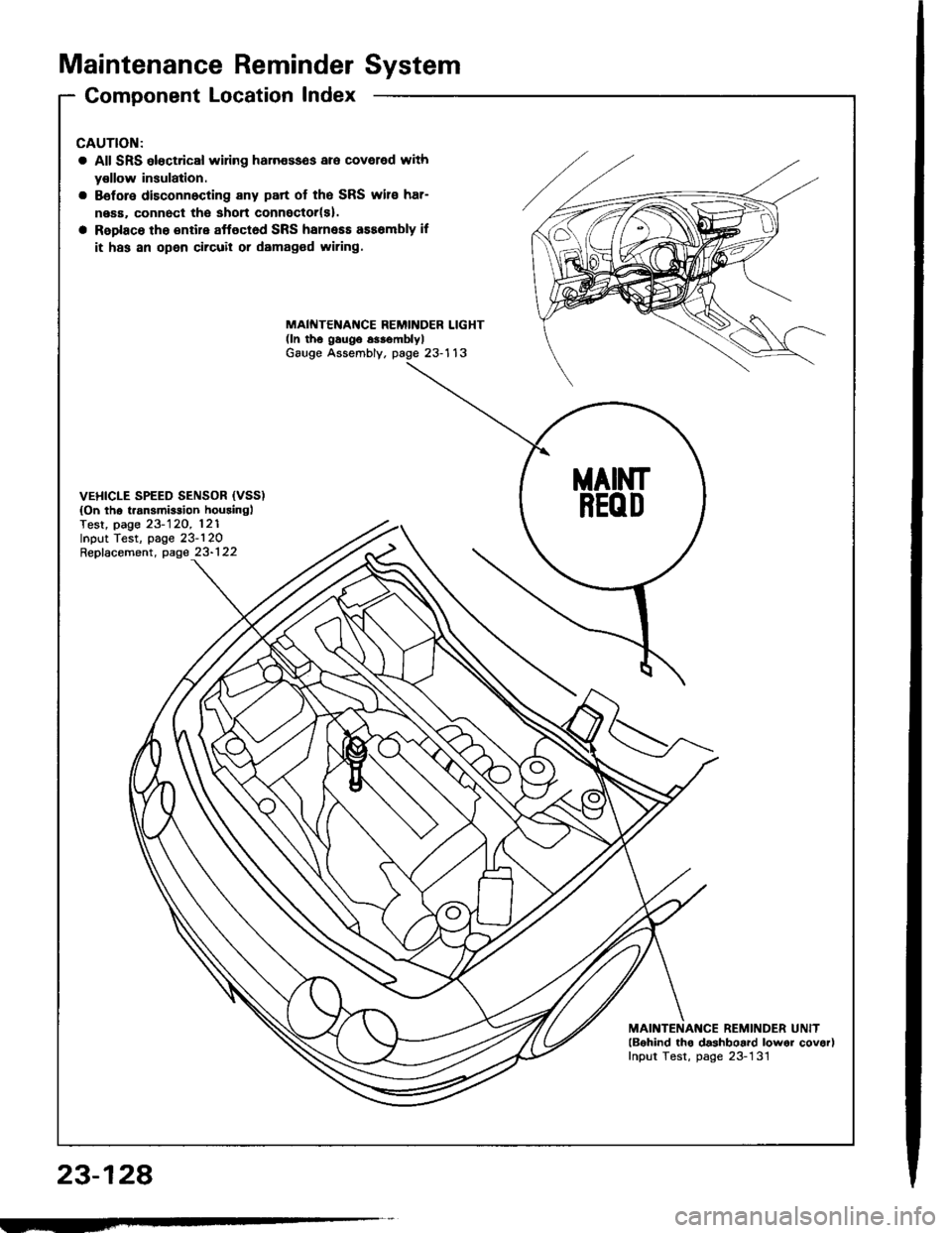

Maintenance ReminderSystem

Gomponent Location Index

23-128

CAUTION:

a All SRS eloctrical wiring haln€sses are coveled with

y€llow insulation.

a Bsfore disconnocting any part of the SRS wire har-

ne6a, connect tho shon connoctor(s).

a Replace the entire affoctod SRS hsrness ass6mbly if

it has an open circuil or damag€d wiring.

MAINTENAf{CE REMINDER LIGHT(ln th6 gaugo 63.smblylGauge Assembly. page 23-113

VEHICLE SPEED SENSOR {VSS){On the t.ansmirsion houainglTest, page 23-120, 121Input Test, page 23-120Repfacement, page 23-122

MAINTENANCE REMINDER UNITlBohind tho dashboard lowor covor)Input Test, page 23-131

MAINT

REOD

Page 1238 of 1413

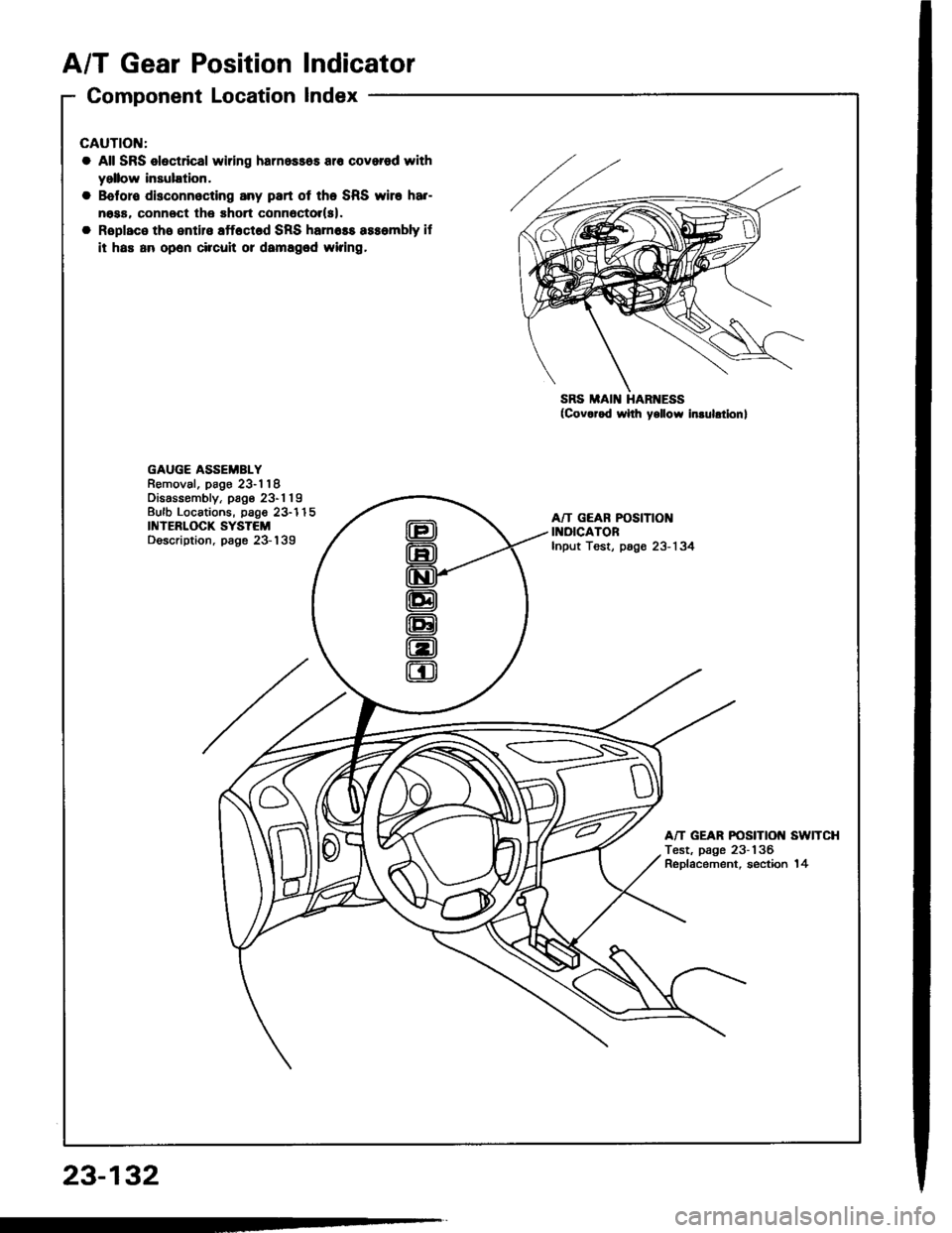

A/T Gear PositionIndicator

Component Locationlndex

23-132

cAUTtOt{:

a All SRS olectdcal wiring harnossos a16 covarod with

yellow insulation.

Boforo disconnocting any part ot the SRS wlr. har-

noaa, conngct the short conn6ctor(sl.

Roplaco tho entire aff6ct6d SRS harn$s assombly il

it has an op6n cilcuit or damagod wiling,

SRS MAIN HARI{ESS(Cov.rod whh ygllow io.ul.tlonl

GAUGE ASSEMBLYBemoval, page 23-1 18Disassombly, pag€ 23'1 19Bulb Locations, pago 23-1 15IiIIERLOCK SYSTEMDGscription. page 23-139

A/T GEAR POSITIONIlTDICATORInput Test, pago 23-134

A/T GEAR P('SITIOI{ SWITCHTest, page 23-136ReDlacement, 6ection 14

Page 1240 of 1413

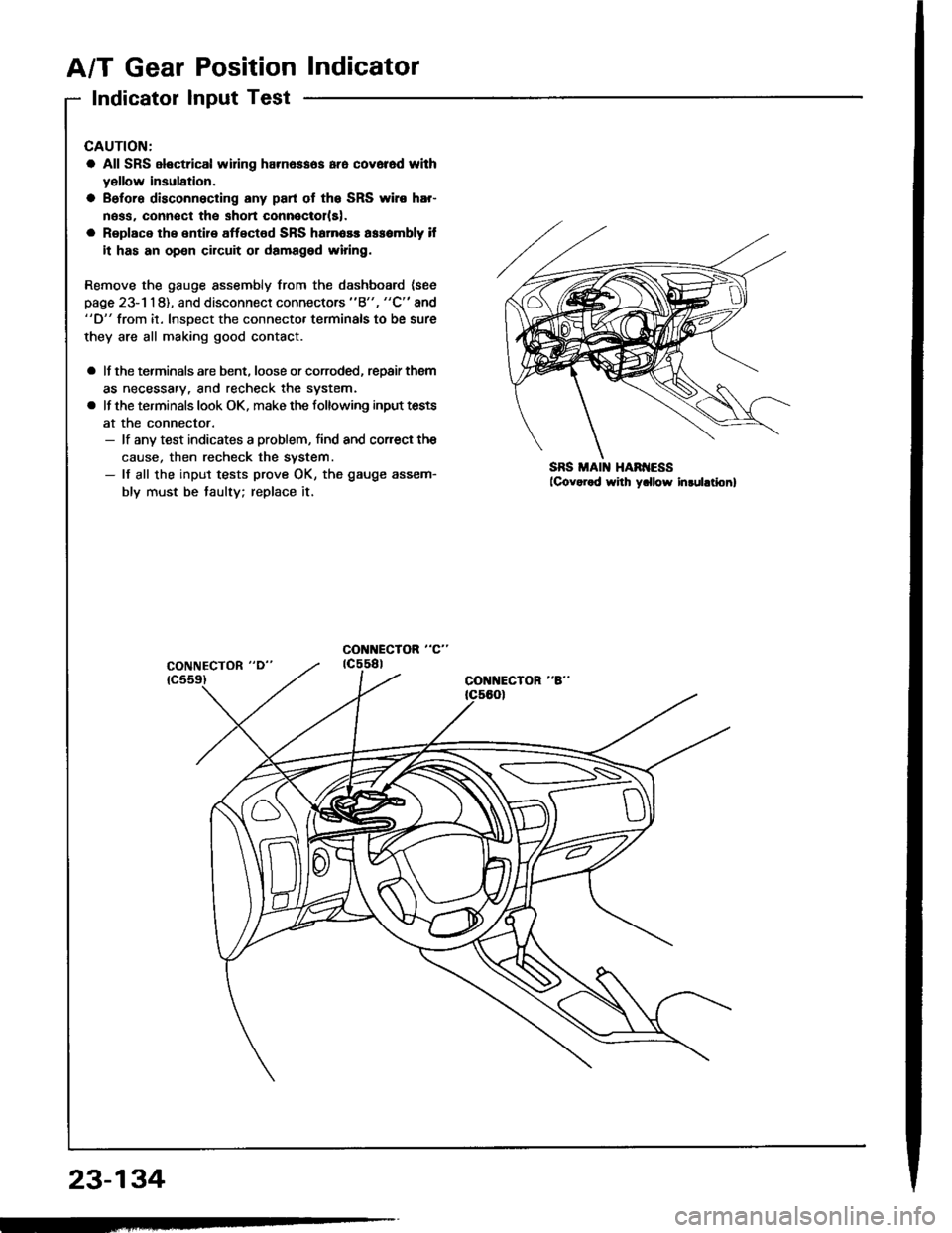

A/T Gear Position Indicator

Indicator Input Test

CAUTION:

a All SRS electrical widng harn6ssos ara cov6r6d whh

yellow insulation.

a Before disconnecting any part ot the SRS wiro hEr-

ness. connect the shon connoctolls).

a Replace the entire affectod SRS harnosr assombly il

it has an op€n circuit or damaged wiring.

Remove the gauge assembly from the dashboard (see

page 23- l 1 8), and disconnect connectors "8", "C" and"D" from it. lnsoect the connecto. terminals to be sure

they are all making good contact.

a lf the terminals are bent. loose or corroded, repair them

as necessary, and recheck the system.

a lf the terminals look OK, make the following input tests

at the connector.- lf any test indicates a problem, find and corect the

cause, then recheck the system.- lf all the input tests prove OK, the gauge assem-

bly must be taulty; replace it.

CONI{ECTOR "8"

SS

23-134

Page 1244 of 1413

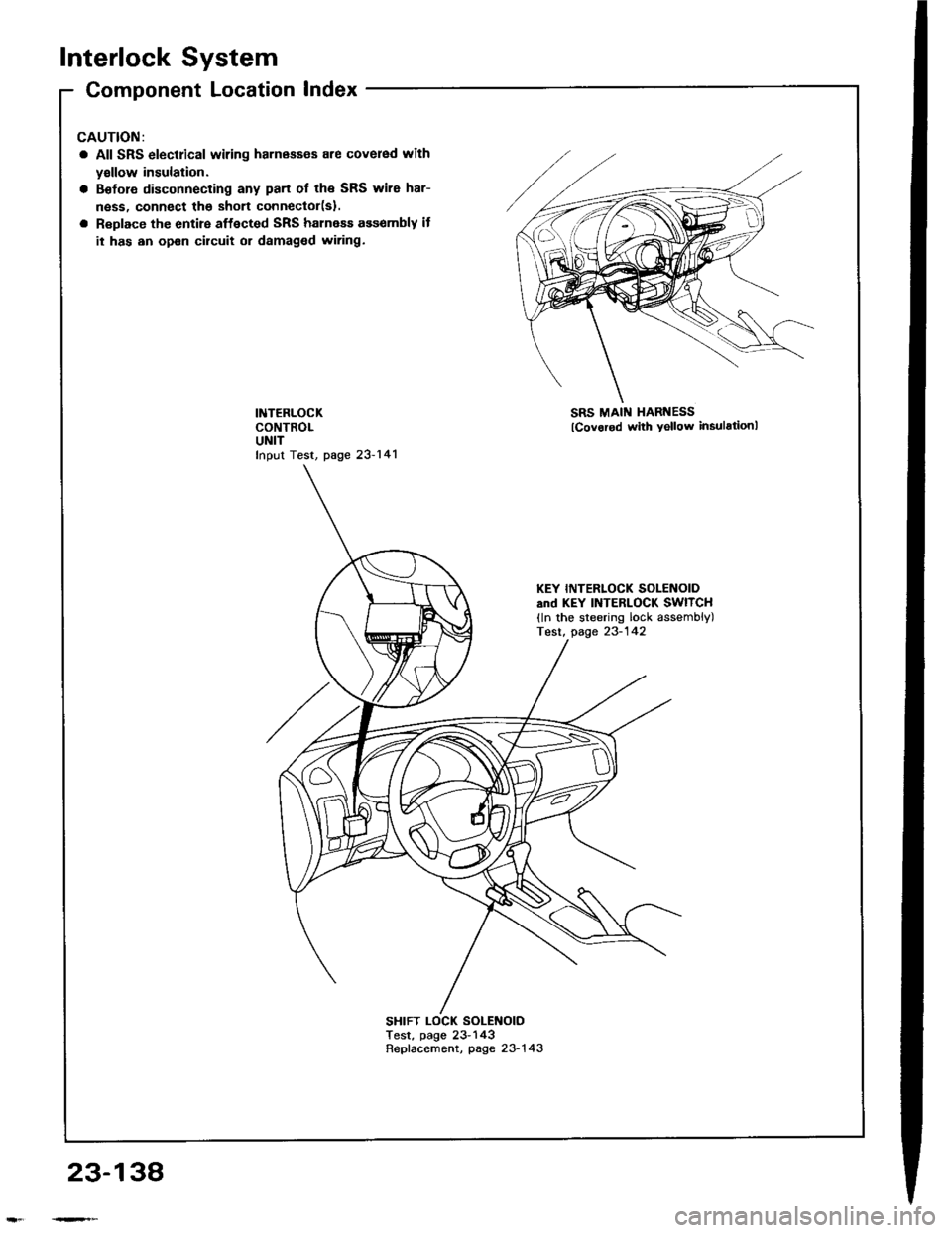

Interlock System

Component Location Index

All SRS electrical wiring harnass€s are covered with

yallow insulation.

Before disconnecting any part of the SRS wire har-

ness, connect the shon connector(sl.

Replace the entire affected SRS halness ass€mbly it

it has an open circuit or damaged wiring.

INTERLOCKCONTROLUNITfnput Test, page 23-141

SRS MAI[{ HARNESS

lcovorod with yellow insulstionl

SHIFT LOCK SOLENOIOTest, page 23- 143Repfacement, page 23-1 43

KEY INTERLOCK SOLENOIDsnd KEY INTERLOCK SWITCH(ln the steering lock assembly)Test, page 23-142

23-138

Page 1248 of 1413

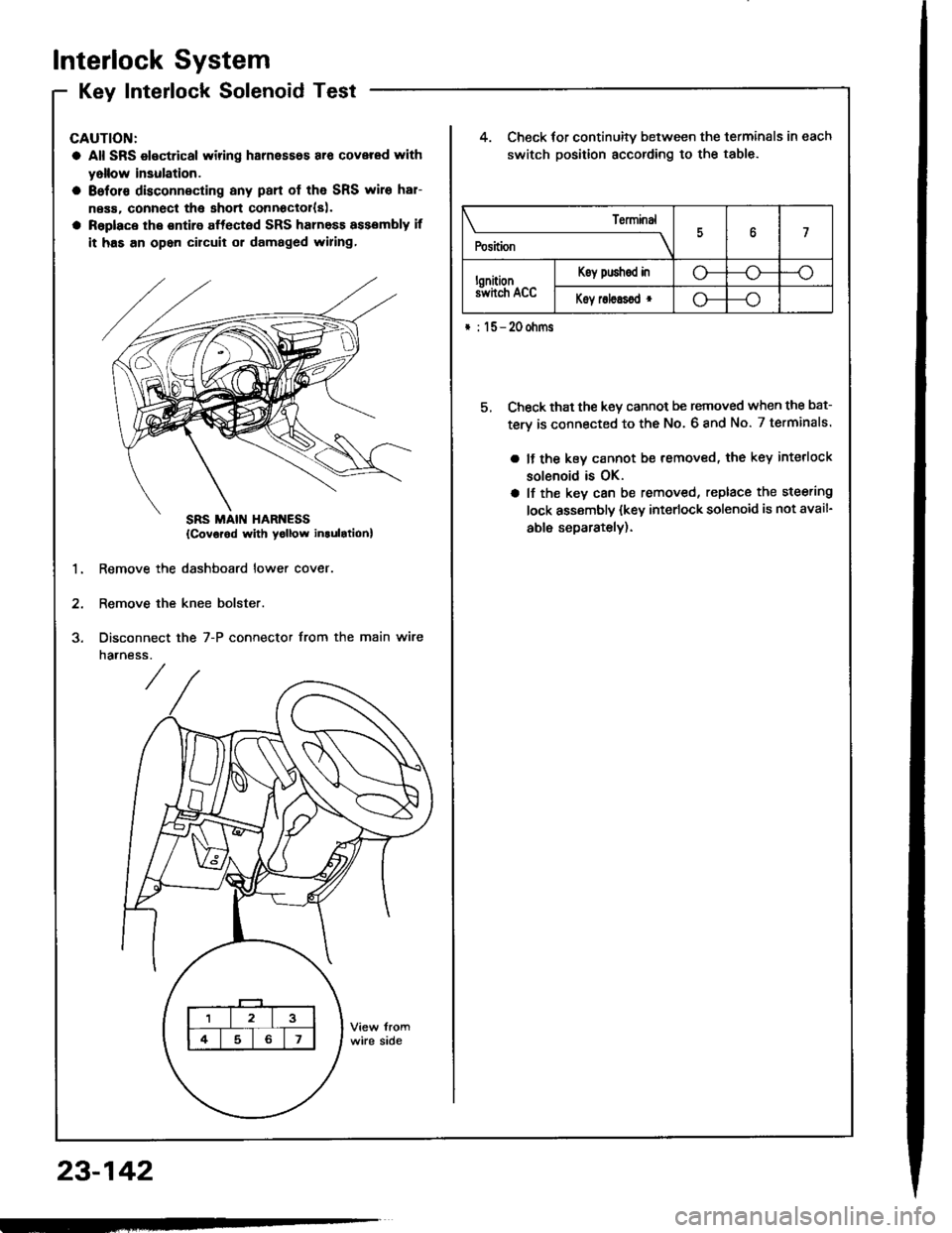

Interlock System

Kev Interlock SolenoidTestKey IntenocK Dorenoro I esr -

CAUTION:

a All SRS electrical wiring harnesses ar€ covered rYith

yollow insulation.

a 8eforc disconnecting any pan of the SRS wire har-

ness. connecl tha short connoclol{s|.

a Raplace the ontire affected SRS harness assembly if

it has an opon circuit or damaged wiring,

4. Check for continuitv between the terminals in each

switch position according to the table.

5, Check that the key cannot be removed when the bat-

tery is connected to the No. 6 8nd No. 7 terminals.

a It the kev cannot be removed, the key interlock

solenoid is OK.

a lf the key can be removed, replace the steering

lock assembly (key interlock solenoid is not avail-

able separately).

1.Remove the dashboard lower cover

Remove the knee bolster.

Disconnect

narness.

the 7-P connector from the main wire

\______________rry

Position7

lonitionS hch Acc

Koy push€d ino---o

Koy roleEsod r--o

* : l5-20ohms

{Covorod with yollow inlulrtionl

23-142

Page 1258 of 1413

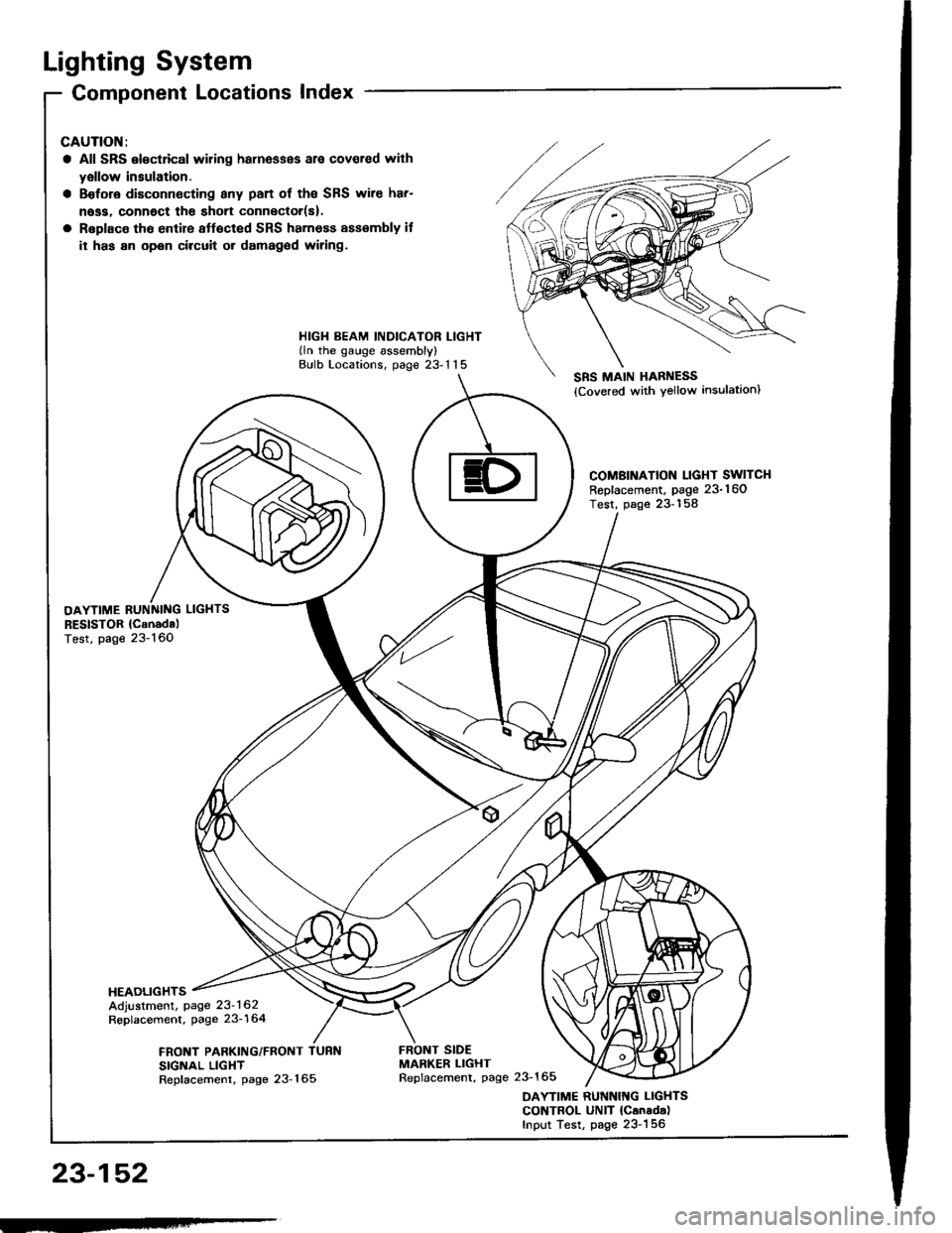

Lighting System

OAYTIMERESISTOR lC.nodalTest, page 23-160

HEAOLIGHTSAdjustment, page 23-162Replacement, page 23-164

Component Locations Index

All SRS el€ctrical wiring harnesses ale covered with

yallow insulation.

B€fore disconnocting any pan of th€ SBS wire har-

ness, connect the short connactor(sl.

Replac€ th6 entire affocted SRS harness assembly it

it has an open circuit or damagod wiring.

HIGI{ BEAM INDICATOR LIGHT(ln the gauge assembly)Bulb Locations, page 23-1 15

COMBINATION LIGHT SWITCHReplacement, page 23-160Test, page 23- l58

FRONT PARKING/FRONT TURNSIGNAL LIGHTReplacement, page 23-165

FRONT SIDEMARKER LIGHTReplacement, page 23-165

DAYTIME RUNNIT{G LIGHTSCONTROL UNIT {C6nada)Input Test, page 23-156

23-152

-

Page 1264 of 1413

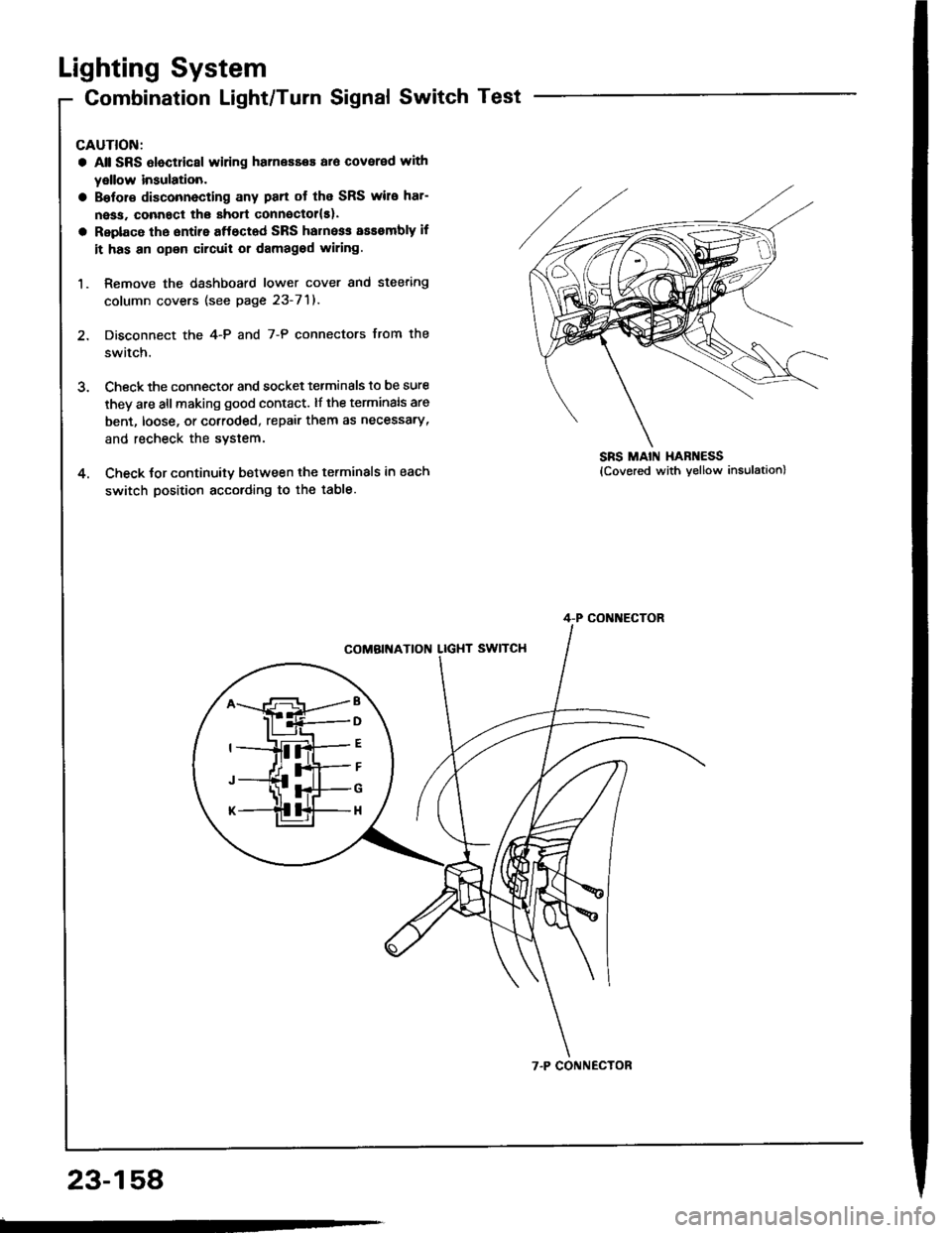

Lighting System

Combination Light/Turn Signal Switch Test

CAUTION:

a Atl SRS Oloctricsl wiring harnesses ar6 covered with

yellow insulation.

a Bslor€ disconnecting any pan ot the SRS wire har-

ness, connact the short connsctollsl.

a Replace the sntire aftectad SRS harne$ assembly if

it has an opon circuit or damagod wiring.

1. Remove the dashboard lower cover and steering

column covers (see page 23-71).

2. Disconnect the 4-P and 7-P connectors from the

switch.

3. Check the connector and socket tetminals to be sure

they are all making good contact. lf the terminals are

bent, loose, or cotroded, repair them as necessary,

and recheck the system.

4. Check tor continuitv between the terminals in each

switch position according to the table.

SRS MAIN HAR ESS

B

D

G

H

4-P CONI{ECTOR

7.P CONNECTOR

23-158

Page 1290 of 1413

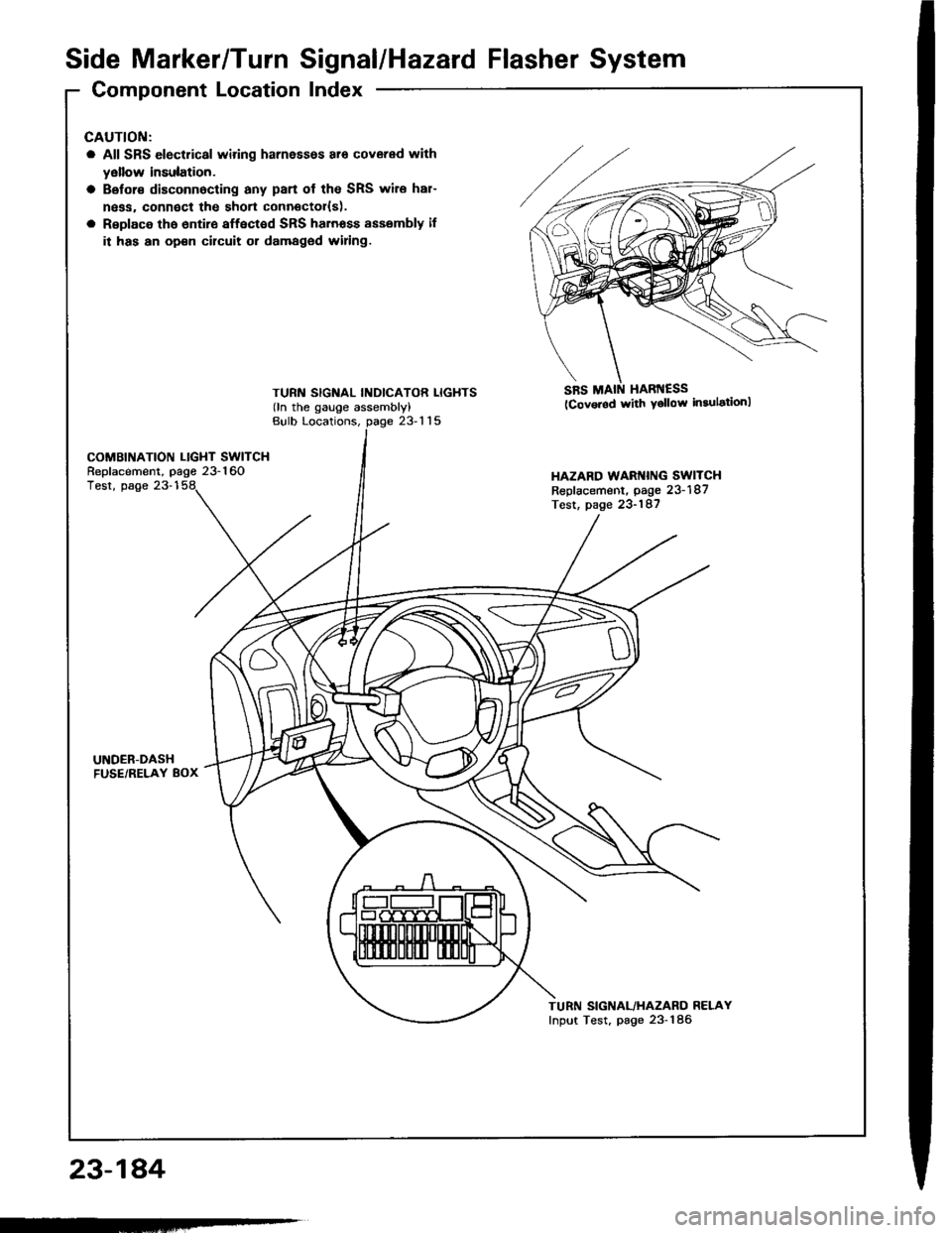

Side Marker/TurnSignal/Hazard Flasher System

Component LocationIndex

23-184

GAUTION:

a All SRS electrical wiring harnessos ar6 covered with

yellow insulation.

a Belor€ disconnocting any pan of the SRS wire har-

ngss, connoct the short connector{s).

a Rsplace tho 6ntir€ affect€d SRS harnoss sssembly il

it has an op€n cilcuit or damaged widng.

TURN SIGNAL INDICATOR LIGHTS(ln the gauge assembly)

SRS MAIN HARI{ESS(Cov.rod with Ysllow in3ulationl

Bulb Locations,23-115

COMBINATION LIGHT SWITCHReplacement, page 23-160HAZARD WARI{ING SWITCHReplacement, page 23-187Test, page 23-187

Test, page 23-1

UNDER-DASHFUSE/RELAY 8OX

TURN SIGNAL/HAZARO RELAYInput Test, page 23-186

-

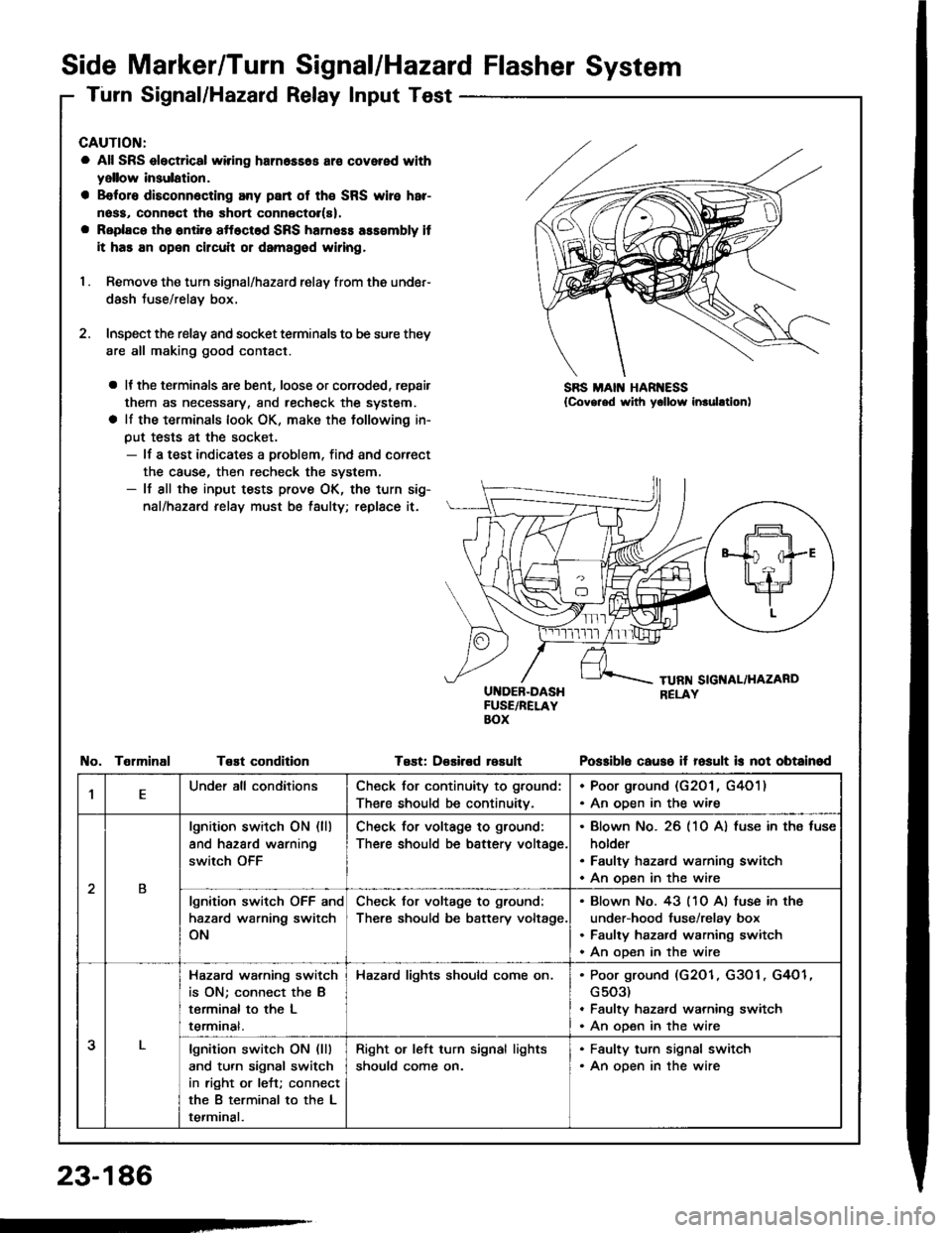

Page 1292 of 1413

Side Marker/Turn Signal/Hazard Flasher System

Turn Signal/Hazard Relay Input Test

CAUTION:

a All SRS electrical wiring harn6ss6s ar€ covered with

yellow insulation.

a B€foro disconn6cting any part of th€ SRS wire har-

noss, connoct tho short connector(s).

a Replaco tho ontiro sftoctod SRS harness ass€mbly it

it has an open circuit or damagod wiring,

I . Remove the turn signal/hazard relay from ths under-

dash Juse/relay box.

2. Inspect the relay and socket terminals to be sure they

are all making good contact.

a It the terminals are bent, loose or coroded, repair

them as necessary, and recheck the system.

a lf the terminals look OK, make the tollowing in-

put tests at the socket.- lf a test indicates a problem, find and correct

the cause, then recheck the system.- lf all the input tests prove OK, the turn sig-

nal/hazard relay must be taulty; replace it.

UI{DEB-DASHFUSE/RELAYBOX

Test: D€sired rosult

SBS MAIN HAR ESS{Covg.ed with yollow inrulltion)

TelminalTeEt conditionPo$iblo causo it fosult is not obtainod

,lEUnder all conditionsCheck for continuity to ground:

There should be continuitv.

. Poor ground (G201 , G4O1). An oDen in the wire

2B

lgnition switch ON (ll)

and hazard warning

switch OFF

Check for voltage to ground:

There should be battery voltage.

Blown No. 26 (10 A) fuse in ths fuse

holder

Faulty hazard warning switch

An open in the wire

lgnition switch OFF and

hazard warning switch

ON

Check for voltage to ground:

There should be battery voltage.

Blown No. 43 (10 Al fuse in the

under-hood fuse/relay box

Faulty hazard warning switch

An ooen in the wire

3

Hazard wa.ning switch

is ON; connect the B

terminal to the L

termrnat.

Hazard lights should come on.Poor ground (G2O1, G3O1, G4O1

G503)

Faulty hazard warning switch

An open in the wire

lgnition switch ON (lll

and turn signal switch

in right or left; connect

the B terminal to the L

terminal.

Right or left turn signal lights

should come on.

. Faulty turn signal switch. An open in the wire

23-186

-