Bearing HONDA INTEGRA 1994 4.G Service Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 378 of 1413

Clutch Housing Bearing

Replacement

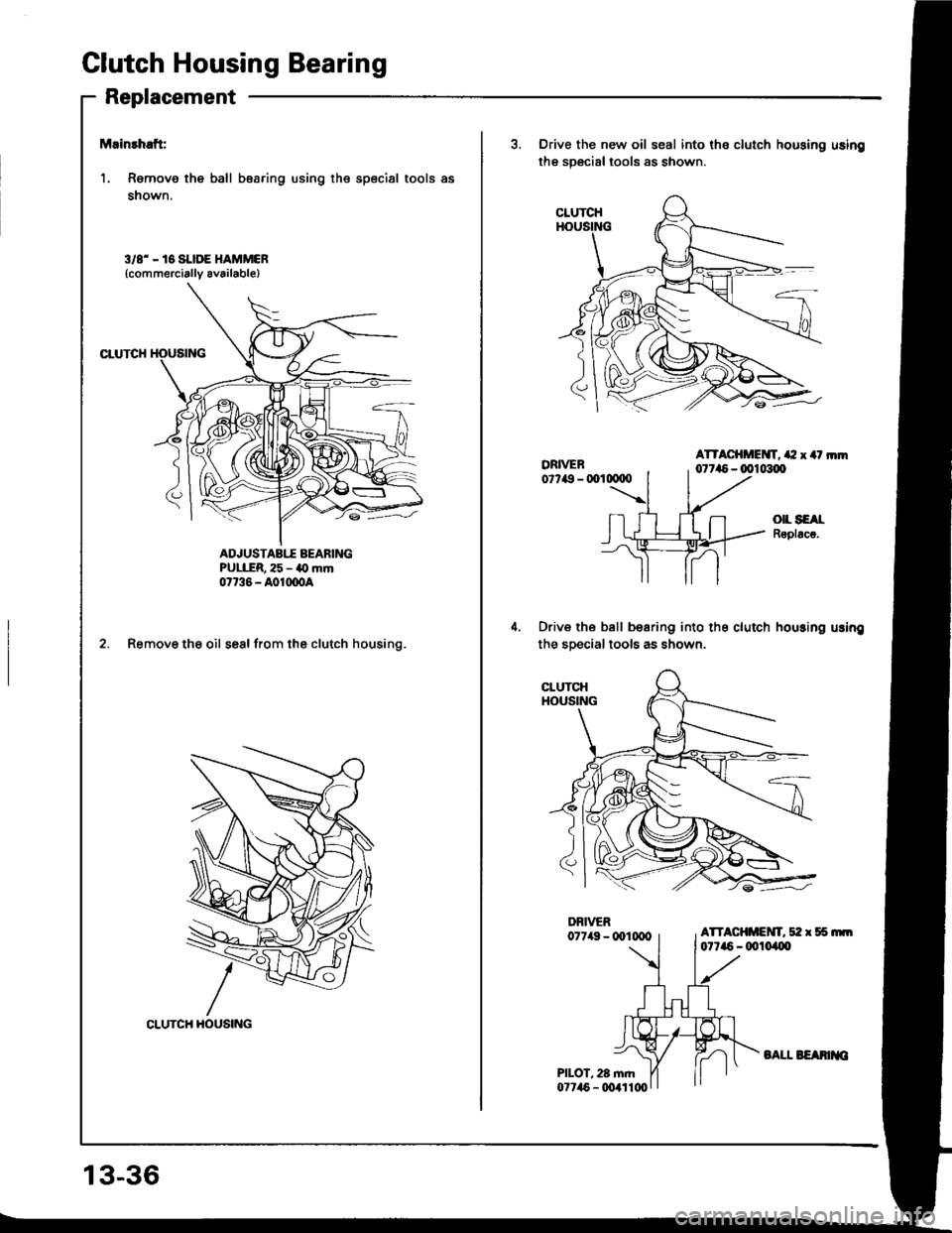

Mainrhaft:

1. Remove the ball bearing using the special tools as

shown.

3/8' - 16 SI.IDE HAMMCR(commercially av6ilable)

CTUTCH

ADJUSTABIT AEARINGPULER, 25 - a0 mrn07736 - A01moA

2. Remove the oil seal from the clutch housing.

CLUTCH HOUSING

3. Drive the new oil seal into the clutch housing using

the specialtools as shown.

ATTACHMEIVT, a2 x 4t rnm0r7a5 - 0010300

()|L SEAIRoplacs.

Drive the ball bearing into the clutch housing usin!

the sDecial tools as shown.

13-36

BATI. BEAMIO

Page 379 of 1413

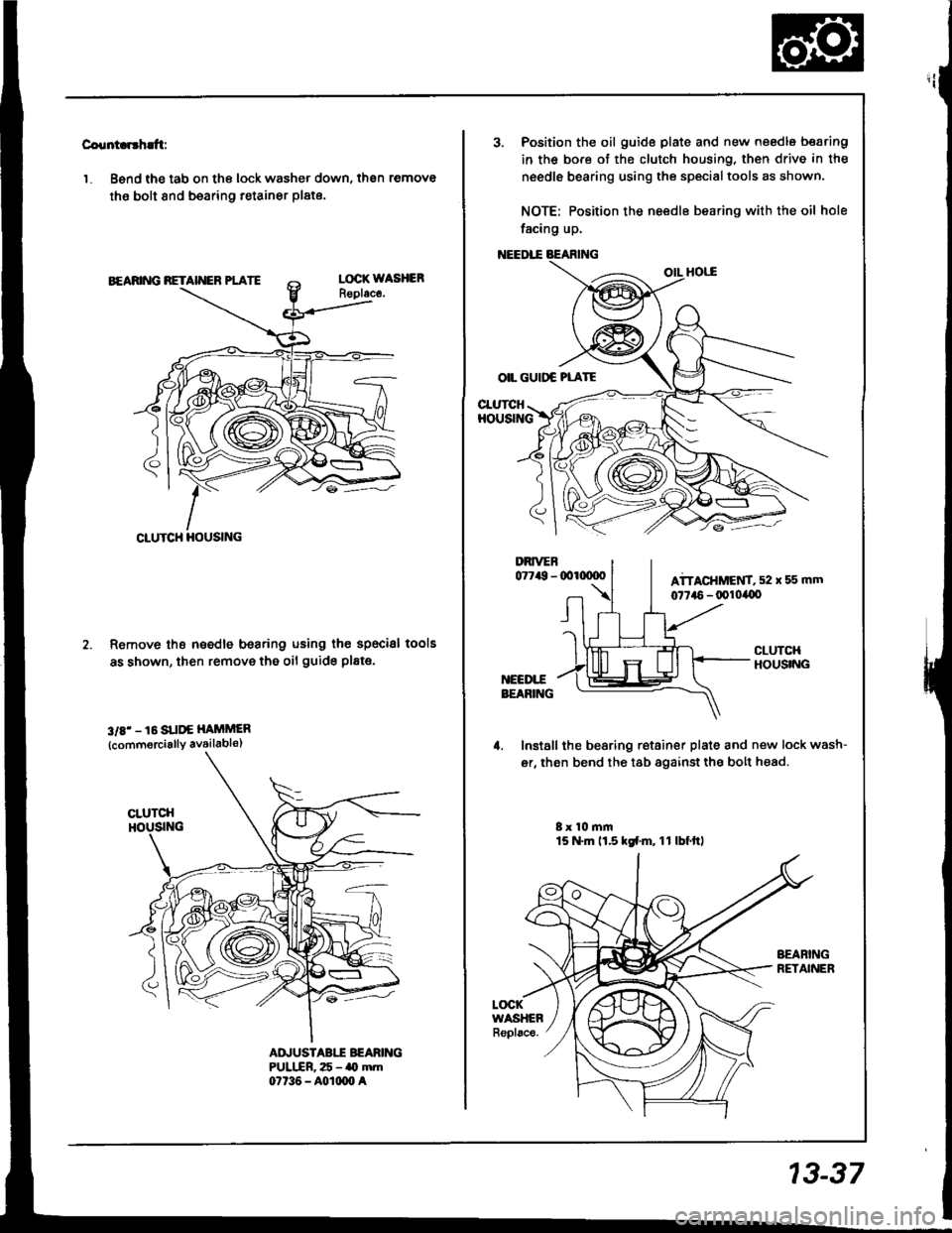

Countcr'h!ft:

'1. Bsnd the tab on the lock washer down, then remove

the bolt 8nd bearing retainer plate.

Remove th€ needle bearing using the specisl

as shown, then remove the oil guide pl8te.

3rE' - 16 SUI'€ HAiiMER

{commorcially availabls)

lools

AD.'USTABII BEARIITGPULIIR, 25 - ao mm07t36 - A0rm0 a

CLUTCH HOUSING

3. Position the oil guide plate and new needle bearing

in the bore of the clutch housing, then drive in the

needle bearing using the specialtools as shown.

NOTE: Position the needle bearing with the oil hole

facing up.

OIL GUIDC PLATE

CI-UTCHHOUSING

Install the bearing retainer plate and new lock wash-

er, then bend the tab againstthe bolt head.

8x 10 mm15 N.m ll.5 kd.m, 11 lbf.ttl

LOCKWASHEARepl6ce.

13-37

Page 380 of 1413

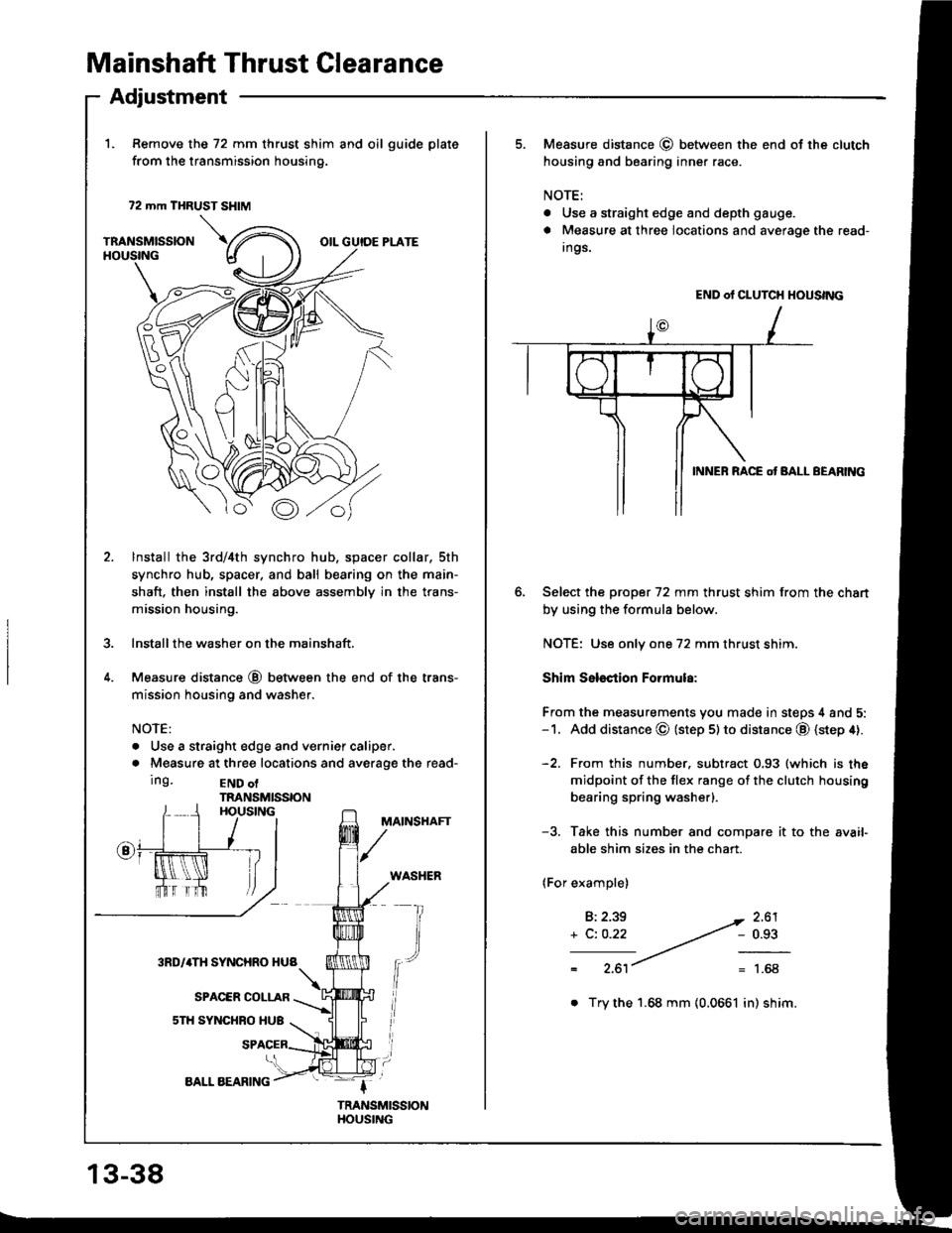

Mainshaft Thrust Glearance

1. Remove the 72 mm thrust shim and oil guide plate

from the transmission housing.

72 mm THRUST SHIM

TRANSMISSIONHOUSINGOIL GUIDE PLATE

Adjustment

\.u

o

Bo

lnstall the 3rd/4th synchro hub, spacer collar, sth

synchro hub, spacer, and ball bearing on the main-

shaft. then install the above assembly in the trans-

mission housing.

Installthe washer on the mainshaft.

Measure distance @ between the end of the trans-

mission housing and washer.

NOTE:

. Use a straight edge and vernief caliper.

. Measure at three locations and averaoe the read-

Ing.END olTRANSMISSIONHOUSINGMAINSHAFT

WASHER

fr

13-38

AALL AEARING

. Try the 1.68 mm (0.0661 in) shim.

5. Measure distance @ betlveen the end of the clutch

housing and bearing inner race.

NOTE:

. Use a straight edge and depth gauge.

a Measure at three locations and average the read-

Ings.

Select the prcpet 72 mm thrust shim from the chart

by using the formula below.

NOTE: Use only one 72 mm thrust shim.

Shim Sslsction Formula:

From the measurements you made in steps 4 and 5:-1. Add distance @ (step 5lto distance @ (step 4).

-2. From this number. subtract 0.93 (which is the

midpoint of the flex range of the clutch housing

bearing spring washerl.

-3. Take this number and compare it to the avaif

able shim sizes in the chart.

(For example)

B:2.39

+ C: O.22

2.61- 0.93

1.68

END of CLUTCH HOUSING

INNEB RACE ot BALL BEARltac

Page 381 of 1413

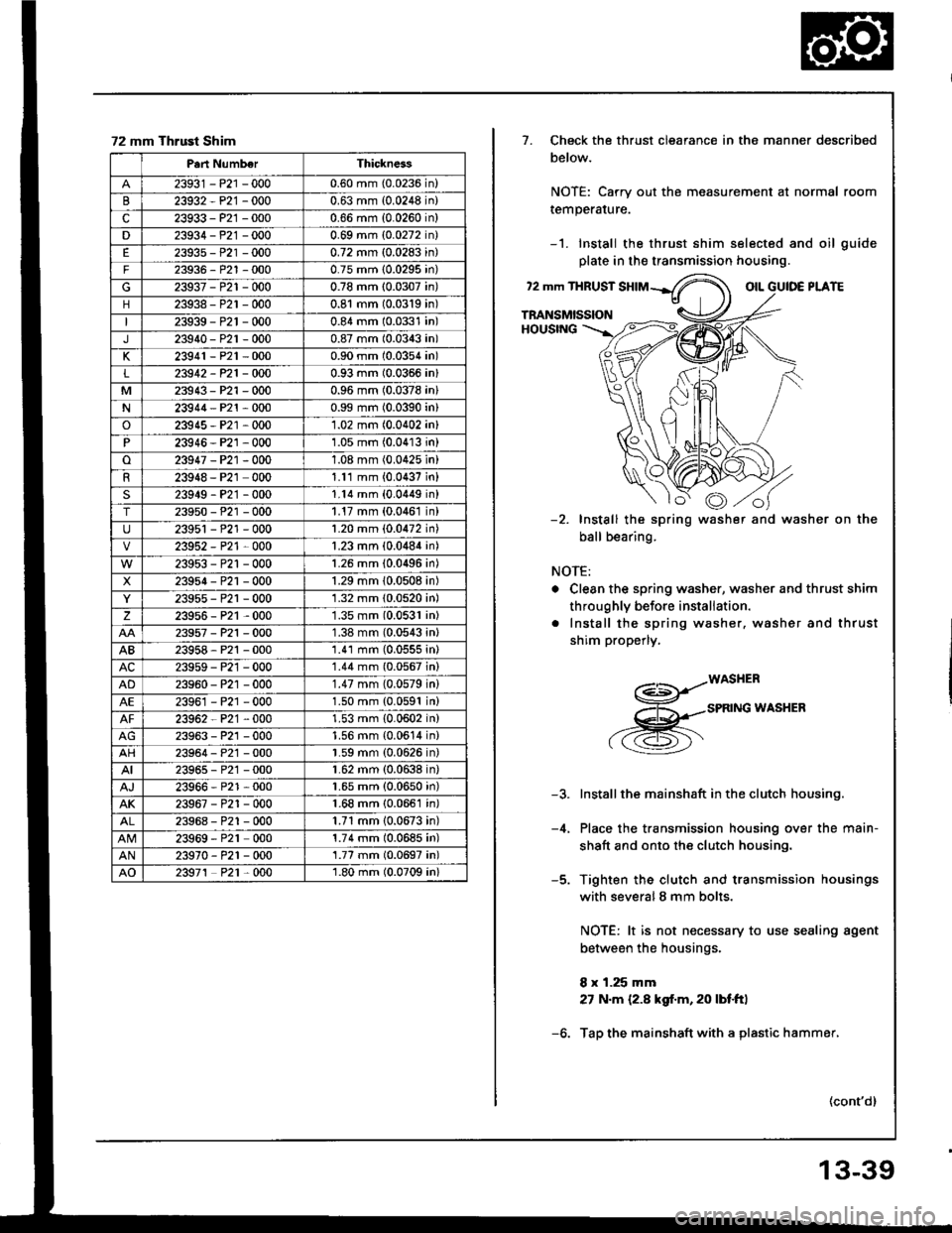

72 mm Thrust Shim

Part NumberThickness

23931 - P21 -0000.60 mm (0.0236 in)

23932-P21 -0000.63 mm (0.0248 in)

c23933 - P21 -0000.66 mm {0.0260 in}

D23934-P21 -0000.69 mm (0.0272 in)

23935 - P21 -0000.72 mm (0.0283 in)

F23936-P21 -0000.75 mm (0.0295 in)

23937-P21 -0000.78 mm (0.0307 in)

23938-P21 -0000.81 mm (0.0319 in)

23939-P21 -0000.84 mm (0.0331 in)

J23940-P2r-0000.87 mm (0.0343 in)

K23941 - P21 -0000.90 mm (0.0354 in)

L23912-P21-OOO0.93 mm (0.0366 in)

M23943-P21 -0000.96 mm (0.0378 in)

N23944-P21 -0000.99 mm (0.0390 in)

o23915 - P21 -0001.02 mm (0.0402 in)

P23946 - P21 ,0001.05 mm (0.04'13 in)

o23947 -P21 -0001.08 mm (0.0425 in)

23948 - P21 0001.11 mm {0.0437 in}

s23919-P21 -0001.14 mm (0.0449 inl

T23950-P21 -0001.17 mm (0.0461 in)

23951 - P21 -0001.20 mm {0.0472 in)

23952 - P21 0001.23 mm {0.0484 in)

23953-P21 -0001.26 mm (0.0496 in)

X23954-P2r-0001.29 mm 10.0508 in)

23955-P21 -0001.32 mm 10.0520 in)

z239s6-P21 ,0001.35 mm (0.0531 in)

23957-P21 -0001.38 mm (0.0543 inl

AB23958 - P21 -0001.41 mm (0.0555 in)

AC23959 - P21 -0001.44 mm (0.0567 in)

AD23960 - P21 -0001.47 mm (0.0579 in)

AE23961 -P21 -0001.50 mm {0.0591 in)

23962 P21 ,0001.53 mm {0.0602 in)

23963-P21 -0001.56 mm {0.0614 in}

AH23964 - P2'1 -0001.59 mm (0.0626 in)

AI23965 - P2'1 -0001.62 mm (0.0638 in)

23966-P21 -0001.65 mm (0.0650 in)

AK23967-P21 -0001.68 mm {0.0661 in)

23968 - P21 -0001.71 mm 10.0673 in)

23969 - P21 0001.74 mm (0.0685 in)

AN23970-P21 -000'1.77 mm (0.0697 in)

AO23971 P21 0001.80 mm (0.0709 in)

7. Check the thrust clearance in the manner described

below.

NOTE: Carry out the measurement at normal room

remperarure.

-1. Install the thrust shim selected and oil guide

plate in th€ transmission housing.

?2 mm THRUSTotLPLATE

TRANSMISSIONHOUSING

Install the spring

ball bearing.

washer and washer on the

NOTE:

. Clean the spring washer, washer and thrust shim

throughly before instaliation.

. Install the spring washer. washer and thrust

shim properly.

a-=s-.r*os".^

.,,-B*^INGWASHER

-4.

Installthe mainshaft in the clutch housing.

Place the transmission housing over the main-

shaft and onto the clutch housing.

Tighten the clutch and transmission housings

with severalS mm bolts.

NOTE: lt is not necessary to use sealing agent

between the housings.

8 x 1.25 mm

27 N.m {2.8 kgf.m, 20 lbf.ft}

Tap the mainshaft with a plastic hammer,

(cont'd)

13-39

Page 386 of 1413

Transmission

Reassembly (cont'd)

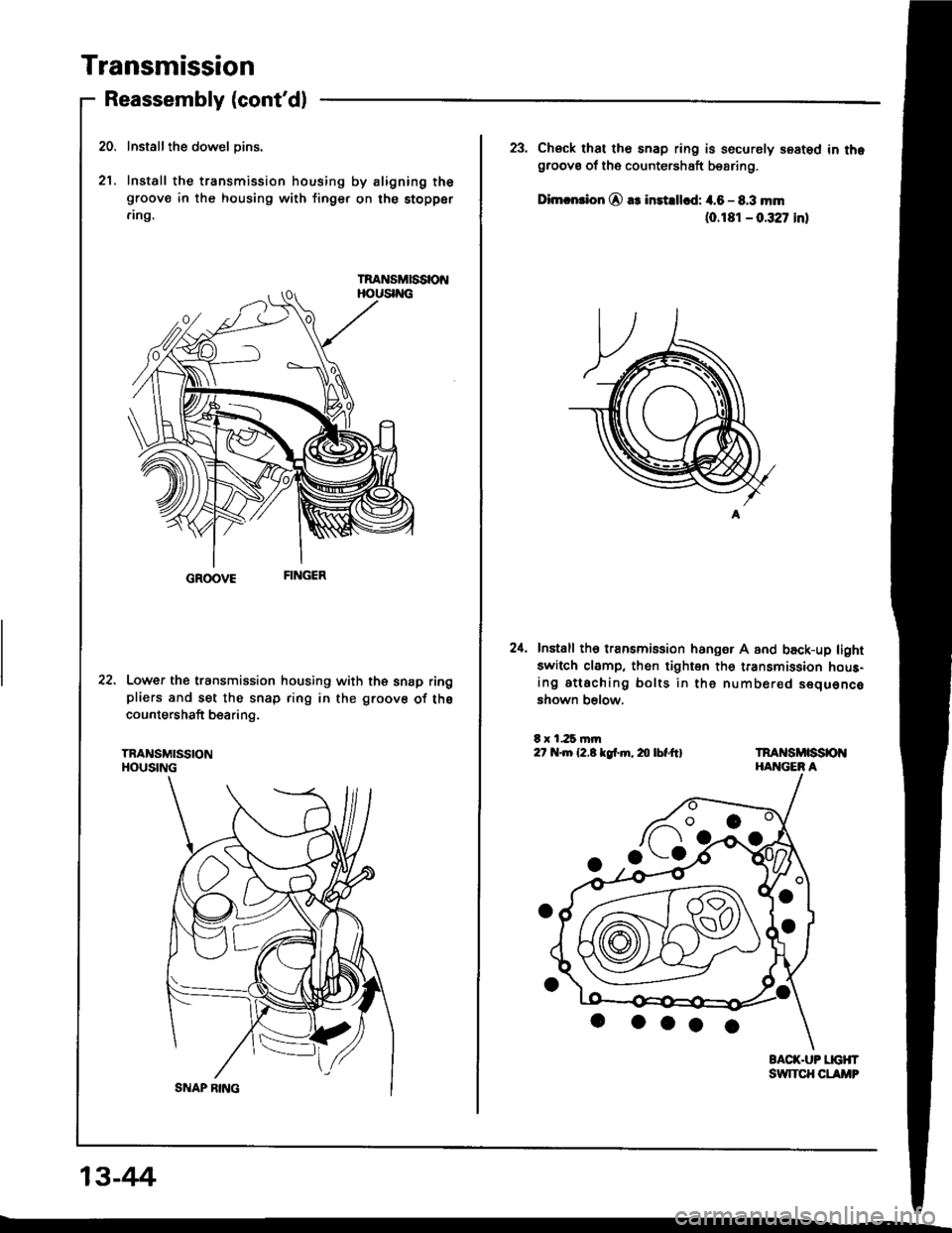

Installthe dowel oins.

Install the transmission housing by aligning thegroove in the housing with finger on the stopper

.ing.

GROOVE

22. Lower the transmission housing with the snap ringpliers and set the snap ring in the groove of tha

countershaft bearing.

TNANSMISSIONHOUSING

20.

21.

13-44

23, Check that the snap ring is securely seated in thegroova of th€ countershaft bearing.

Dimcntion O as inst.lbd: il.6 - 8.3 mm(0.181 - 0.327 inl

Install th6 transmission hang€r A and back-up light

switch clamp, thon tighten th6 transmission hous-ing attaching bolts in the number€d sequonco

shown below.

6 | i.25 mrn2t .m l2.8 lgf.m, 20 lbf.ftl

Page 388 of 1413

Transmission Assembly

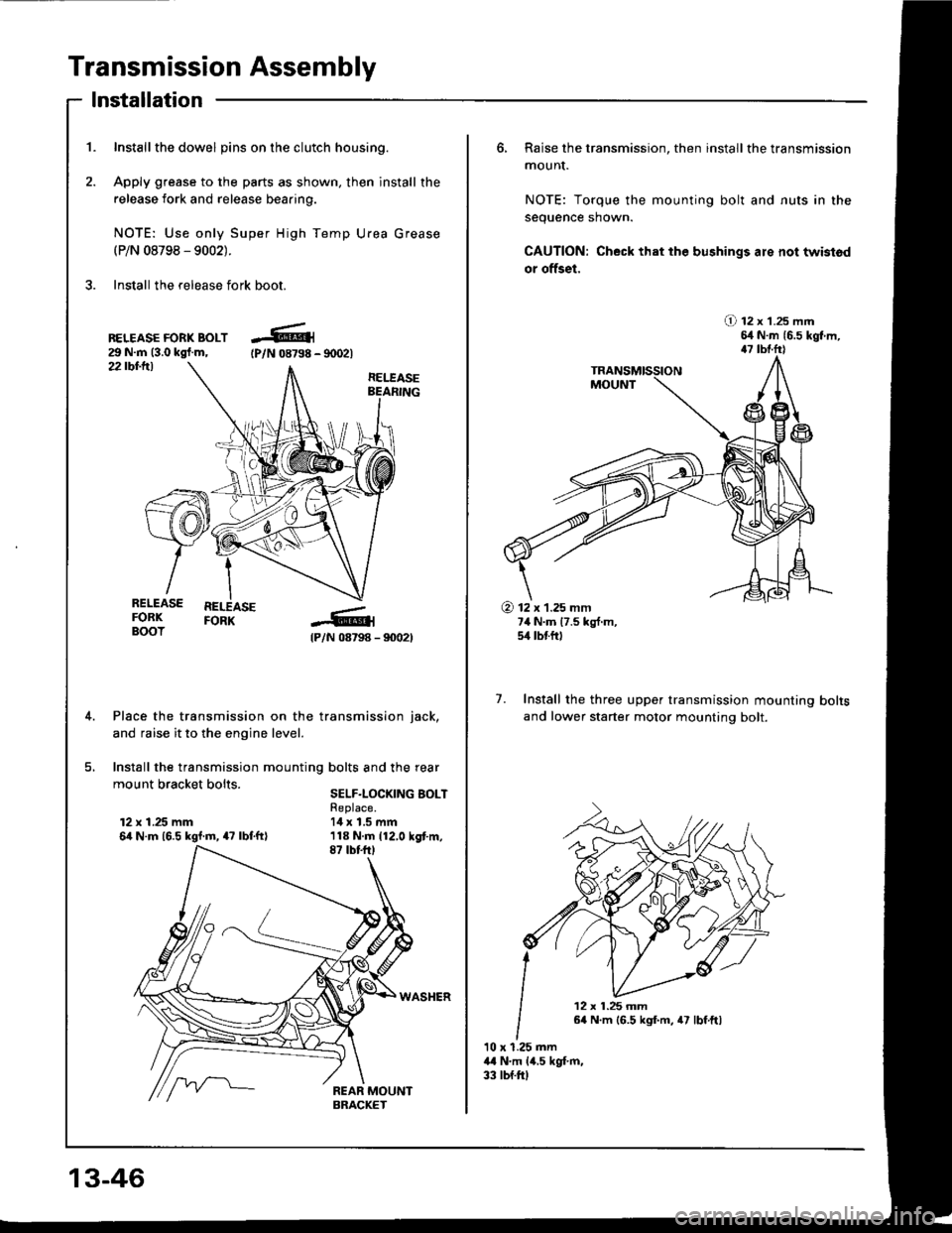

1. Inst€llthe dowel pins on the clutch housing.

2. Apply grease to the parts as shown, then install the

release fork and release beaaing.

NOTE: Use only Super High Temp Urea Grease(P/N 08798 - 9002).

3. Install the release fork boot.

lnstallation

22 tbt-ttl

BELEASE FORK BOLT29 N.m (3.0 kgl.m,tPlN 08798 - 90021

RELEASEBEARING

@

I

{P/N 08798 - 90021

Place the transmission on the transmission iack,

and raise it to the engine level.

Install the transmission mounting bolts and the rear

mount bracket bolts sELF-LocKrNG BoLT

RELEASE REEASEFORK FORKBOOT

12 x 1.25 mm6it N.m 16.5 kgl.m, 47 lbf.ftl

Replace.14 x 1.5 mm

13-46

6, Raise the transmission, then install the transmission

mounI.

NOTE: Torque the mounting bolt and nuts in the

sequence shown.

CAUTION: Check that the bushings are not twistod

or offset,

O 12 x 1.25 mm54 N.m {6.5 kgt m,47 tbtfrl

7. Install the three upper transmission mounting

and lower starter motor mounting bolt.

bolts

10 x 1.25 mm44 N.m lil,s kgt m,33 tbf.ftl

@ 12 x 1.25 mm7,1 N.m 17.5 kg{.m,5/r lbtftl

12 x 1.25 mm64 N.m 16.5 kgf.m, 47 lbf.ftl

Page 393 of 1413

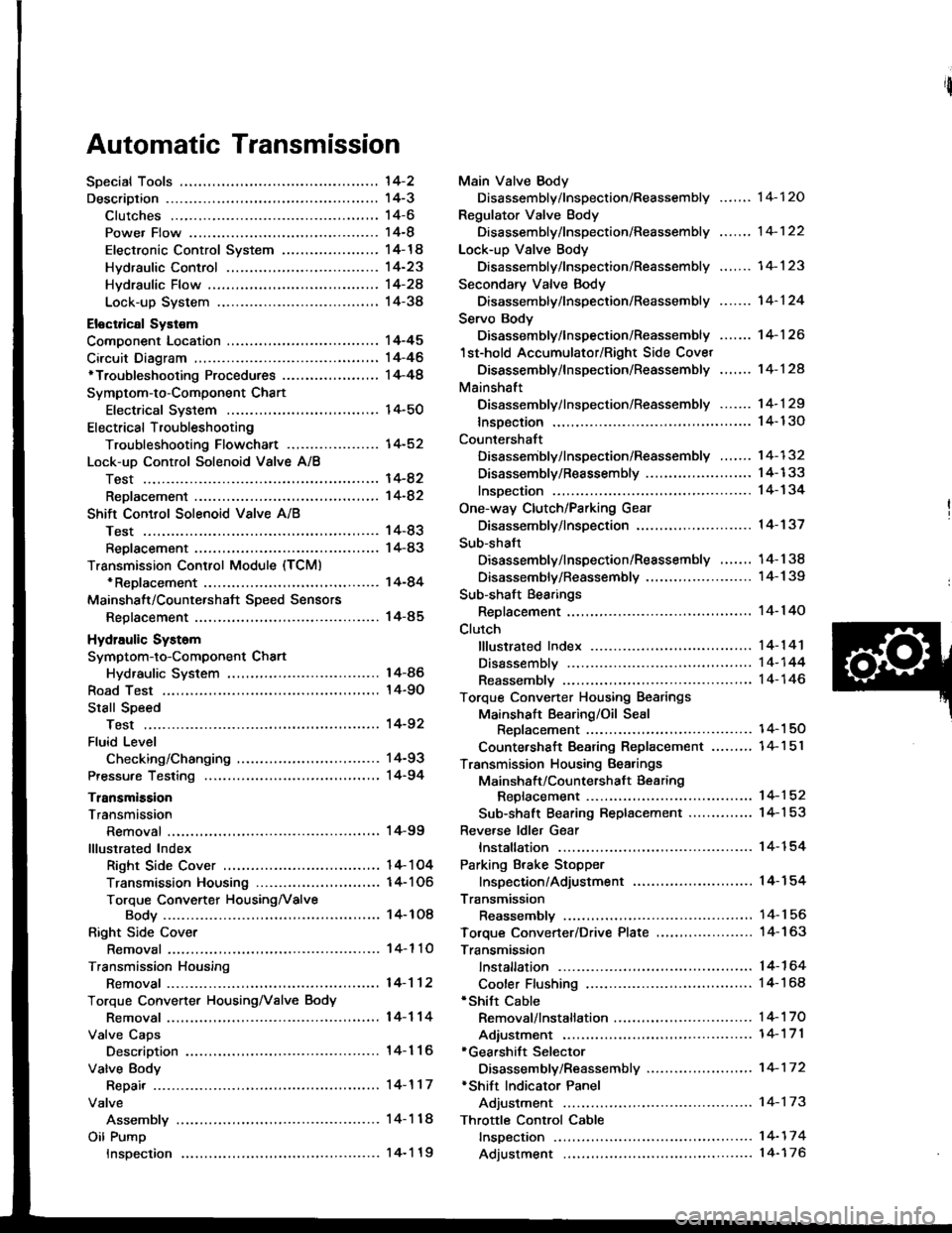

Automatic Transmission

'l4-2

14-3't 4-6

14-8

14-14

14-23

Hvdraulic Flow ...--...... 14-24

Lock-up System ........ 14-38

Eloctrical Systom

Component Location ............,...,................ I 4-45

Circuit Diagram ............. 14-46'Troubleshooting Procedures ........,..........., l4-48

Symptom-to-Component Chart

Electrical System ...... 14-50

Electrical Troubleshooting

Troubleshooting Flowchart .................... 14-52

Lock-uo Control Solenoid Valve A/8

Test .................. --.... \4-82

ReDlacement ,...,...,..,. 14-82

Shift Control Solenoid Vslve A/B

Test .................. ...... 14-83

Reolacement .............. 14-83

Transmission Control Module (TCM)*ReDlacement ........... 14-84

Mainshalt/CountershaJt SDeed Sensors

Reolacement ............. 14-85

Hydraulic Systom

Symptom-to-Component Chart

Hydraulic System

Road Test

Slall Speed

Test ..................

Fluid Level

Checking/Changing

Pressu.e Testing

Transmission

Transmission

Removal ............. ...... 14-99

lllustrated Index

Right Side Cover .................................. 1 4- 1 04

Transmission Housin9 ..................,,....... I 4-1 06

Torque Converter HousingNalve

Body .................. ... 14- 1O8

Right Side Cover

Removal ............. ...... 14-110

Transmission Housing

Removal ............. .-..-. 14-112

Torque Convener HousingNalve Body

Removal ............. ...... 14-114

Valve Caps

Description ................ 14-116

Valve Body

Repair ................ ...-.. 14-117

Valve

Assembly ...........

Oil Pump

Main Valve Body

Disassembly/lnspection/Reassembly

Regulator Valve Body

Disassembly/lnspection/Reassembly

Lock-up Valve Body

Disassembly/lnspection/Reassembly .......

Secondary Valve Body

Disassembly/lnspection/Reassembly .......

Servo Body

Disassembly/lnspection/Reassembly .......

1st-hold Accumulator/Right Side Covet

Oisassembly/lnspection/Reassembly .,..,..

Mainshaft

Disassembly/lnspection/Reassembly -.. -... 1 4- 1 29

lnsDection ................. 14- 130

Countershaft

Disassembly/lnspection/Reassembly ....... 14-132

Disassembly/Reassembly ....................... 1 4-1 33

lnsDection ................. 14-134

One-way Clutch/Parking Gear

Disassembly/lnspection .................... -.. -. 1 4-137

Sub-shaft

Disassembly/lnspection/Reassembly ....... 14-138

Disassemblv/Reassemblv ....................... 1 4-1 39

Sub-shaft Bearings

Replacement ............. l4-140

Clutch

fllustrated lndex ................. -..-...-.......... 14-1 41

Disassembly ,,,.,,........ 14-144

Reassembly .............. 14-146

Torque Converter Housing Bearings

Mainshaft Bearing/Oil Seal

Reolacement ......... 14-1 50

Countershaft Bearing Replacement .......,, 14-1 5l

Transmission Housing Bearings

Mainshsft/Countershaft Bearing

Repfacement ...-..-..14-152

Sub-shaft Bearing Replacement .............. 1 4-1 53

Reve.se ldler Gear

lnstallation ................ 14-154

Parking Brake Stopper

lnspection/Adjustment ..........................'14-'154

Transmission

Reassemblv .............,. .14_156

Toroue Converter/Drive Plate ..,..,............... 1 4- 1 63

Transmission

14-120

14-122

14-123

14-124

14-126

14-124

14-86

14-90

't4-92

14-93

14-94

lnstallation

Cooler Flushing'Shitt Cable

Removal/lnstallation ..............................

Adiustment ...-..-......-. 14-'171*Gearshift Selector

Disassembly/Reassembly .....................,. 1 4-17 2*Shift Indicator Panel

Adjustment -..........-...14-173

Throttle Control Cable

fnspection .......,..,...... 14-17 4

Adjustment .............. 14-176

14-164

14-168

14-'t 7 0

Inspection

Page 394 of 1413

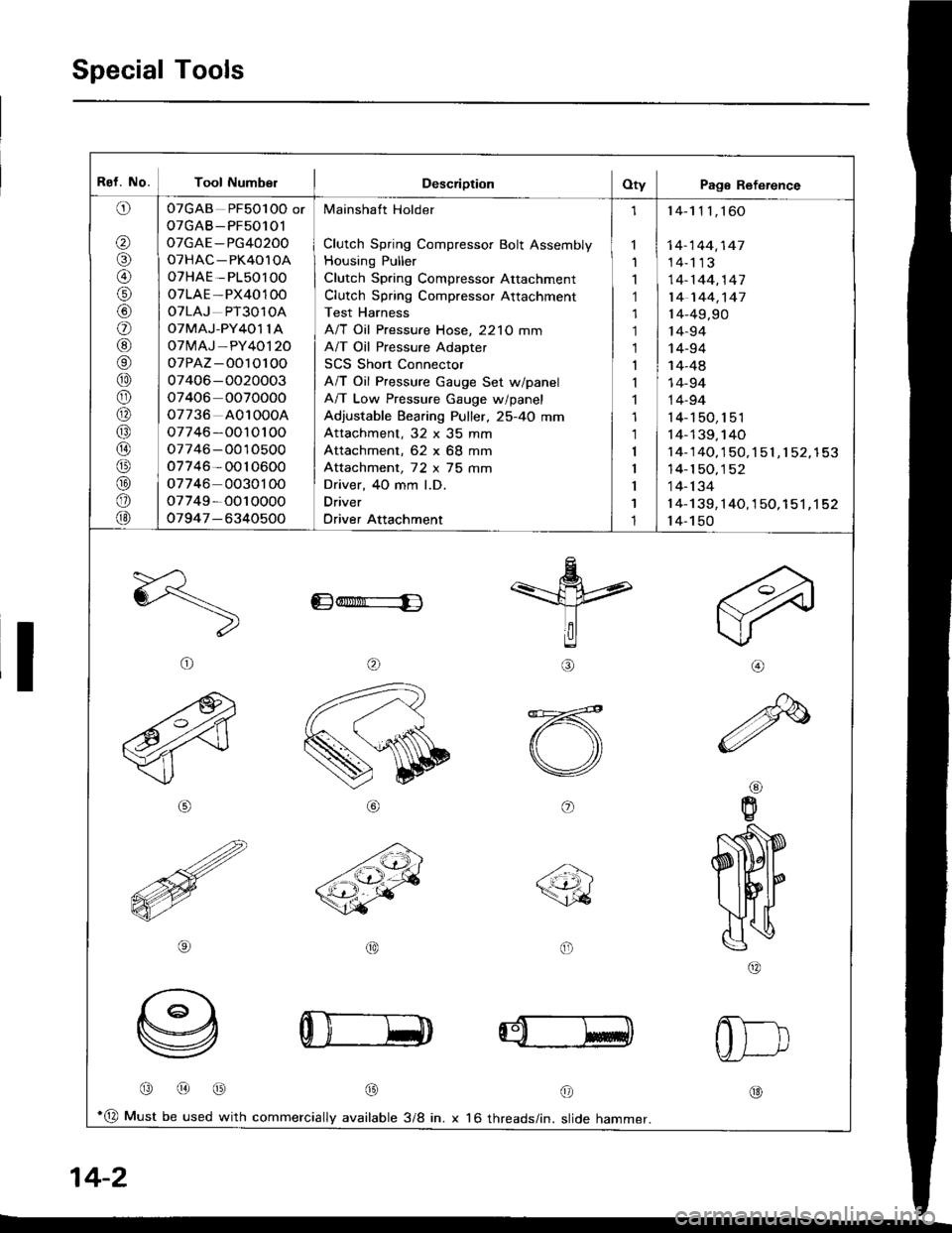

Special Tools

Rol. No. Tool NumbslDescriptionOty Page Reference

o

IA\

,6\

@

€/

o

@rt)

@

@

\9

@

@

@

@

@

@

OTGAB PF50l OO

oTGAB-PF50101

oTGAE-PG40200

oTHAC-PK4010A

oTHAE-PL50lOO

oTLAE-PX40100

OTLAJ PT30l OA

OTMAJ-PY4O'I 1A

oTMAJ-PY40120

oTPAZ -OO10100

07406-OO20003

o7406 0070000

07736 A01000A

o7746-O010100

o7746-O010500

07746-OO10600

07746 0030100

o7749-O010000

07947-6340500

Mainshatt Holder

Clutch Spring Compressor Bolt Assembly

Housing Puller

Clutch Spring Compressor Attachment

Clutch Spring Compressor Attachment

Test Harness

A/T Oil Pressure Hose, 221O mm

A/T Oil Pressure Adapter

SCS Short Connector

A/T Oil Pressure Gauge Set w/panel

A/T Low Pressure Gauge w/panel

Adjustable Bearing Puller, 25-40 mm

Attachment, 32 x 35 mm

Attachment, 62 x 68 mm

Attachment, 72 x 75 mm

Driver, 40 mm l.D.

Driver

Oriver Attachment

'I

I

1

1,1

1

1

1,|

1

1

1

1

1

I

I'I

1

14-1 1 1.160

14-144,147

14-1 1 3

14- 144,147

14 144,'t47

14-49,90

14-94

14-94't 4-44

14-94

14-94

14-150,151

14-139,140

14-140.1 50,1 51,1 52, 1 53

14-150,152

14-134

1 4-1 39,'140, 1 50.1 51,1 52

14,150

Edrn$r--€

o

a)

a6l@o

@@@@(r)

*@ Must be used with commercially available 3/8 in. x 16 threads/in. slide hammer.

@

14-2

Page 481 of 1413

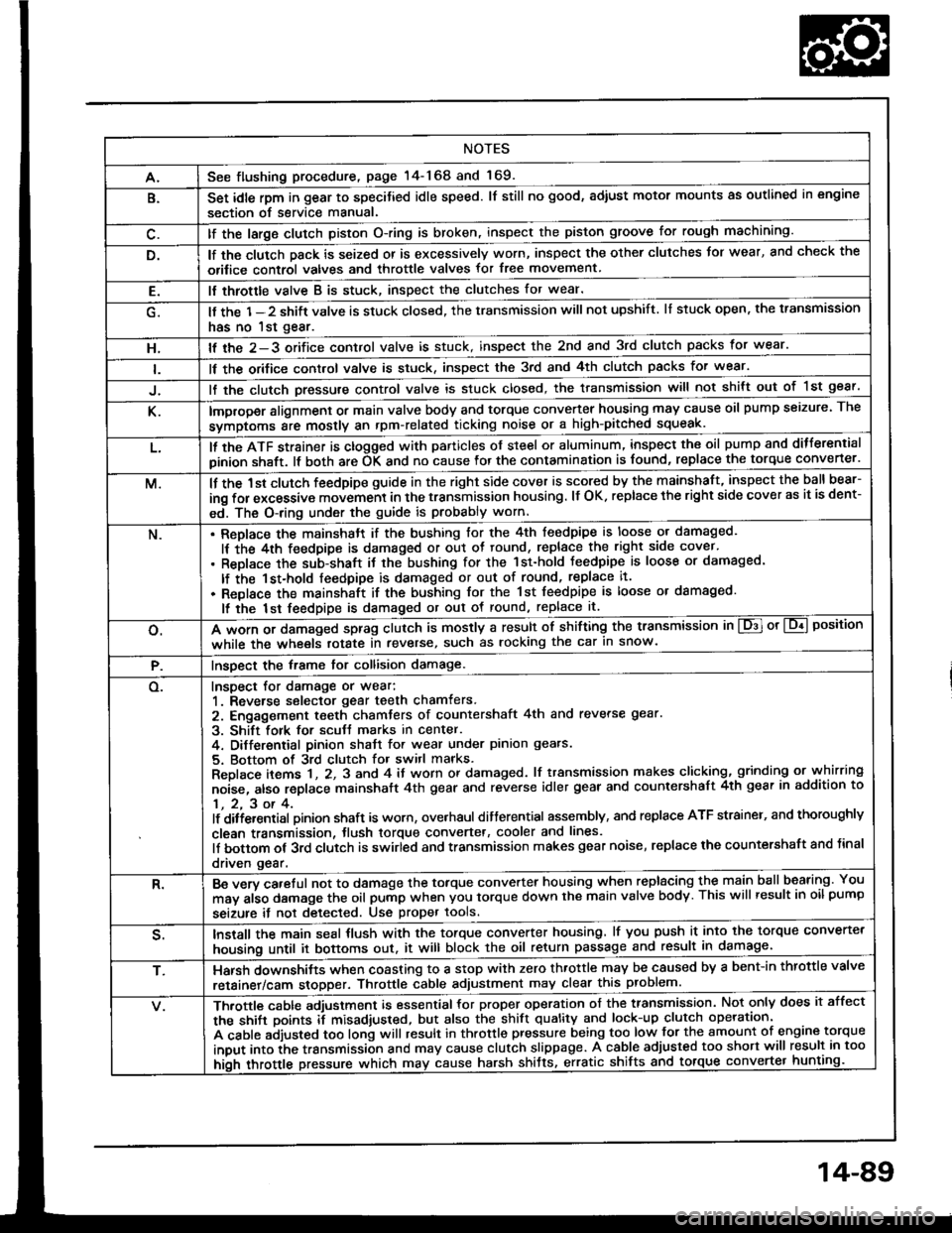

NOTES

A.See flushing procedure, page l4-168 and 169.

B.Set idle rpm in gear to specitied idle speed. lf still no good, adiust motor mounts as outlined in engine

section of service manual.

lf the large clutch piston O-ring is broken, inspect the piston groove for rough machining.

lf the clutch pack is seized or is excessively worn, inspect the other clutches Jor wear, and check the

orifice control valves and throttle valves for free movement.

E.It throttle valve B is stuck, inspect the clutches for wear.

lf the 1-2 shift valve is stuck closed, the transmission will not upshift. lI stuck open, the transmission

has no lst gear.

H.lf the 2-3 orifice control valve is stuck, inspect the 2nd and 3rd clutch packs for wear.

ll the orifice cont.ol valve is stuck, inspect the 3rd and 4th clutch packs for wear.

lf the clutch Dressure control valve is stuck closed, the transmission will not shilt out of 1st gear.

K.improper alignment or main valve body and torque converter housing may cause oil pump seizure. The

symptoms ale mostly an rpm-related ticking noise or a high-pitched squeak.

L.ll the ATF strainer is ctogged with panicles of steel or aluminum, inspect the oil pump and ditferential

pinion shaft. lt both are OK and no cause lor the contamination is found, replace the torque converter.

M.lf the 1st clutch feedpipe guide in the right side cover is scored by the mainshaft, inspect the ball bear-

ing for excessive movement in the transmission housing. lf OK. replace the right side cover as it is dent-

ed. The O-ring under the guide is probably worn.

N.ReDlace the mainshstt if the bushing for the 4th feedpipe is loose or damaged.

It the 4th feedpipe is damaged or out ot tound, replace the right side cover'

Replace the subjshaft it thtbushing for the 1st-hold Jeedpipe is loose or damaged.

lf the 1st-hold feedpipe is damaged or out of round, replace it.

Replace the mainshaft if the bushing lor the 1st feedpipe is loose or damaged.

lf the lst feedpipe is damaged or out ot round, replace it.

o.A *o- r, da."s"d "p-g clutch is mostly a result of shifting the transmission in El or Lq! position

while the wheels rotate in reverse, such as rocking the car in snow.

P.InsDect the frame for collision damage.

o.Inspect for damage or wear:

1. Reverse selector gear teeth chamfers.

2. Engagement teeth chamters of countershaft 4th and reverse gear.

3. Shift fork for scutt marks in center.

4. Differential Dinion shaJt for wear under pinion gears.

5. Bottom of 3rd clutch for switl marks.

Replace items 1 , 2, 3 and 4 it worn or damaged. lf transmission makes clicking, grinding or.whirring

noise, atso replace mainshaft 4th gear and reverse idler gear and countershaft 4th gear in addition to

1,2,3ot4.lf ditiersntial Dinion shaft is worn, overhaul differential assembly, and replace ATF strainel, and thoroughly

clean transmission, tlush torque convertet, cooler and lines.

lf bottom of 3rd clutch is swirled and transmission makes gear noise, replace the countershaft and tinal

driven gear.

R.Be wry careful not to dsmage the torque converter housing when replacing the main ballbearing. You

may al;o damage the oil pump when you torque down the main valve body. This will result in oil pump

seizure it not detected. Use proper tools.

qInstall the main seal tlush with the torque converter housing, lf you push it into the torque converter

housing until it bottoms out. it will block the oil return passage and result in damage.

T,Harsh do\/vnshiJt"\./l,'hen coasting to a stop with zero th.ottle may be caused by a bent-in throttle valve

retainer/cam stopper. Throttle cable adjustment may clear this problem.

ifuitle cable adjustment is essential for proper operation of the transmission. Not only does it affect

the shift points if misad,usted, but also the shift quality and lock-up clutch operation'

A cable adjusted too long will result in throttle pressure being too low for the amount of engine torque

input into ihe trsnsmission and may cause clutch slippage. A cable adjusted too short will result in too

hi;h throttle pressure which may cause harsh shitts, erratic shrfts and torque con

14-89

Page 496 of 1413

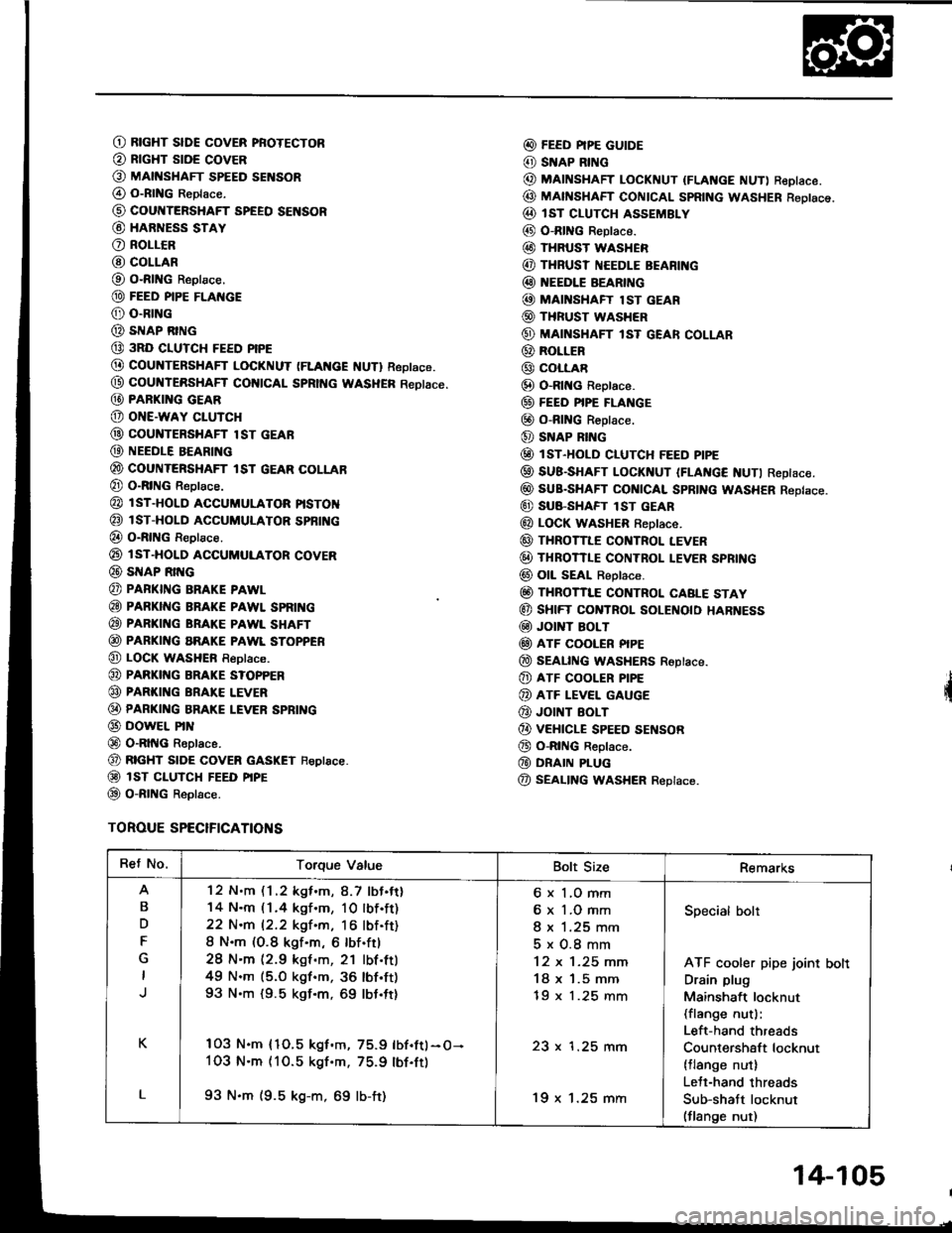

O RtcHT slDE covER pRoTEcToR

@ RrcHT stDE covER

O MAtt{sHAFr spEED sENsoR

@ o-RtNG Reptace.

@ cour{TERSHAFT SPEEO SENSOR

@ HARNESS STAY

O RoLLCR

@ COLLAR

O O-RING Reptace.

@ FEED PIPE FLAI{GE

@ o-RrNG

@ sIrlAP RING

@ 3RD CIUTCH FEED PIPE

@ COUNTERSHAFT LOCKNUT (FLAt{cE f{UTl Reptace.

@ coultTERsHAFf col{tCAL SpRtt{c WASHER Reotace.

@ PARKI G GEAR

@ oNE-waY cLUTcH

@ couNTERsHAFr lsr GEAR

@ NEEDLE BEARING

@ couNTERsHAFr tsr GEAR coLLAB

@ O-RING Reptace.

@ l sT-HoLD accuMuLAToR ptsToN

@ isT-HoLD ACCUMULAToR spBfi{c

@ o-RtNG Reptace.

@ rsT-HoLD ACGUMULAToR covER

@ SNAP Rrr{G

@ PAFKING BRAKE PAWL

@ PARKING BRAKE PAWL SPRII{G

@ PARKING BRAKE PAWL SHAFT

@ PARKING aRAKE PAWL SToPPER

@ LOCK wasHEn Reptace.

@ PARKI G BRAKE s?oPPER

@ PARKING BRAI(E LEVER

@ PARKI G BRAKE LEVER SPBING

@ DowEL PrN

@ O-RltIG Reptace.

@ RTGHT stoE covER GASKET Feptace.

@ isT ct-uTcH FEED ptpE

@ o-RtNG Reptace.

TOROUE SPECIFICATIONS

@ FEED PIPE GUIDE

@ SNAP RING

@ MAINSHAFT LocKNUT {FLANGE NUT) ReDIace.

@ MAfISHAFT CONTCAL SpRtNG WASHER Reotsce.

@ IsT cLUTcH ASSEMBLY

@ O-RING Reptace.

@ THRUST WASHER

@ THRUSI NEEDLE BEARI G

@ EEDLE BEARING

@ MAI'{SHAFT lsT GEAR

@ THRUST WASHER

@ MAINSHAFT lsT GEAR coLLAR

@ RoLLER

@ coLLAR

@ O-Rlt{c Reptace.

@ FEEo PIPE FLANGE

@ o-RING R€ptace.

@ SNAP RING

@ lsr-HoLD cLUTcH FEED ptpE

@ SUB-SHAFT LoCKNUT IFLAt{c€ NUTI Reptace.

@ suB-sHAFr cot{tcAl spRtNG WASHER Reptace.

@ SU8-SHAFT lST GEAR

@ LOCK WASHER f,eptace.

@ THRoTILE cor{TRoL LEVER

@ THRoTTLE coNTRoL I.EVER SPRING

@ oll sEAt Reptace.

@ THRoTTI"E coNTRoL CABLE STAY

@ sHtFT CONTROL SOLEI{O|O HARNESS

@ Jor T BoLT

@ ATF COOLER PIPE

@ SEAL|NG WASHERS Roptace.

@ ATF cooLER P|PE

@ ATF LEVEL GAUGE

@ JOINT EOLT

@ vEHtcLE spEED sEf{soR

@ o-RtNG Reptace.

@ DRAIN PLUG

@ SEALING WASHER Replace.

Ret No.Torque ValueBolt SizeRemarks

B

D

F

K

L

'12 N.m (1 .2 kgf .m, 8.7 lbJ.tt)

14 N.m (1.4 kgf.m, 10lbf.ft)

22 N.m 12.2 kgf.m, 16 lbf.ft)

8 N.m (O.8 kgf.m, 6 lbf.ftl

28 N'm (2.9 kgf .m, 21 lbf.ttl

49 N.m (5.O kgf.m, 36 lbf'ft)

93 N.m {9.5 kgf.m, 69 lbt.ft}

103 N.m {1O.5 kgf.m, 75.9 lbf.ftl-O-

1O3 N.m (10.5 kgf'm. 75.9 lbf.ft)

93 N.m (9.5 kg-m, 69 lb-ft)

6 x 1,O mm

6 x 1.O mm

I x 1.25 mm

5x0.8mm

12 x 1-25 mm

18 x '1.5 mm

tY x t.z5 mm

23 x 1.25 mm

'19 x 1.25 mm

Specialbolt

ATF cooler pipe joint bolt

Drain plug

Mainshaft locknut(flange nut):

Left-hand threads

Countershaft locknut(tlange nut)

Lett-hand threads

Sub-shatt locknut(flange nut)

14-105