Bearing HONDA INTEGRA 1994 4.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 333 of 1413

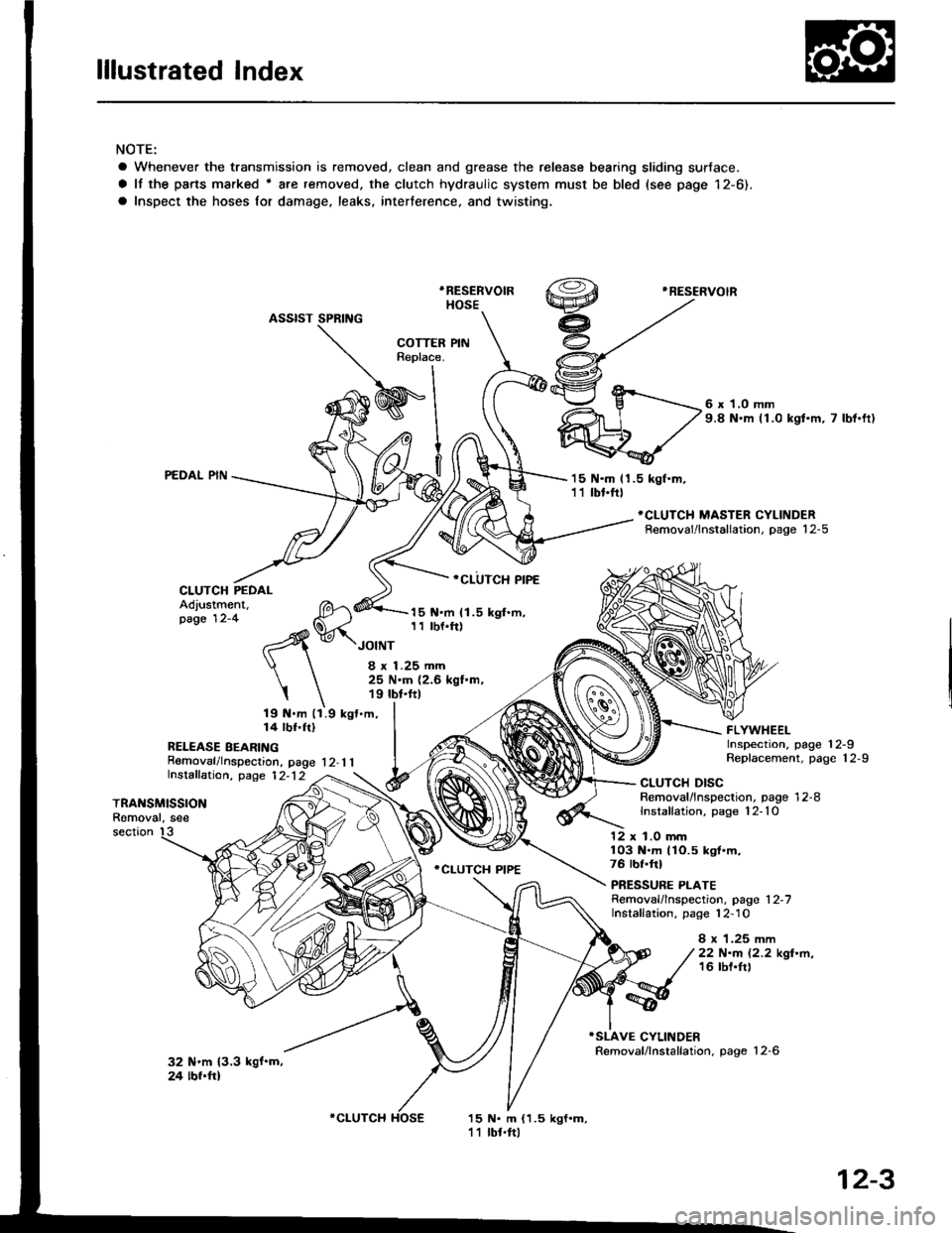

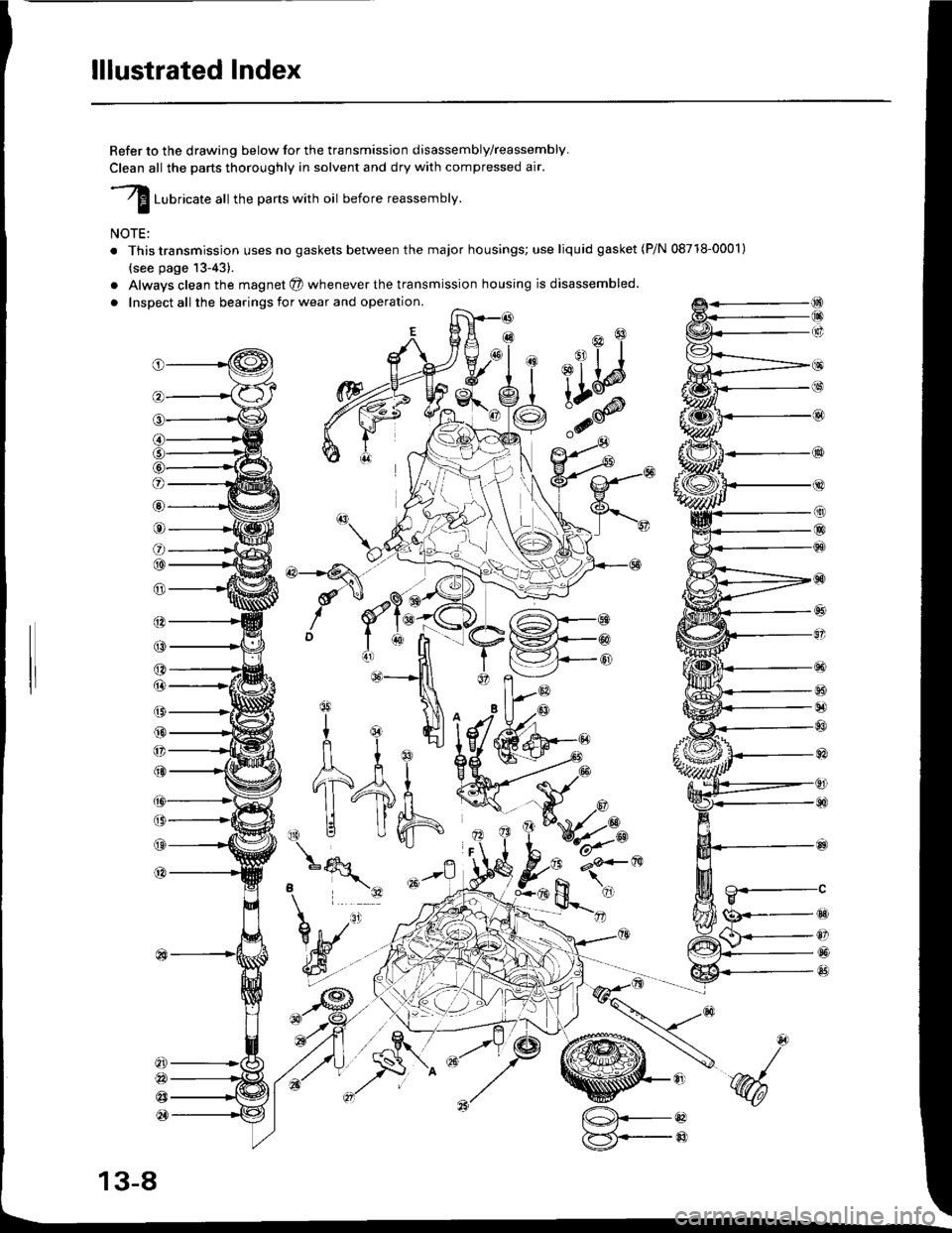

lllustrated Index

NOTE:

a Whenever the transmission is removed, clean and grease the release bearing sliding sudace.

a It the pans marked r are removed. the clutch hydraulic system must be bled (see page 12-6).

a Inspect the hoses lor damage, leaks, interterence, and twisting.

*RESERVOIR

HOSEASSISI SPRING

PEDAL PIN

CLUTCH PEDALAdjustment,page 12-4

15 N.m 11.5 kgl.m,11 tbt.ftl

6 x 1,0 mm9.8 N.m ll.0 ksf.m, 7 lbf.tt)

FLYWHEELInspection. page 12-9Replacement, page 12-9

TCLUTCH MASTER CYLINDERRemoval/lnstallation, page 1 2-5

19 N.m ll.9 kgt.m,14 lbf.ftl

.CLUTCH PIPE

15 N.m {1.5 kgl.m,1 1 rbf.ft)

ICLUTCH PIPE

JOtt{T

8 x 1.25 mm25 N.m (2.6 kgl.m,19 lbt.ttl

RELEASE BEARINGRomovaf /lnspection, page 1 2-1 1lnstaffation, page 1 2- 1 2

TRANSMISSIONRomoval. see

CLUTCH DISCRemoval/lnspection. page'1 2-8Installation, page 12-10

8 x 1.25 mm22 N.m (2.2 kgf.m.16 lbl.rr)

section 1312 x 1.0 mm103 N.m llO.5 kgt.m,76 rbf.ftl

PRESSURE PLATERemoval/lnspection. page 1 2-7Installation, page 12,10

TSLAVE CYLINDERRemovaf /lnstallation. page 1 2-632 N.m {3.3 kgf'm,24 tbf.ftl

15 N. m {1.5 kgf.m,'| I tbf.ftl

COTTERBeplace.

I

NInl

9t

v-_fl

ICLUTCH

12-3

Page 337 of 1413

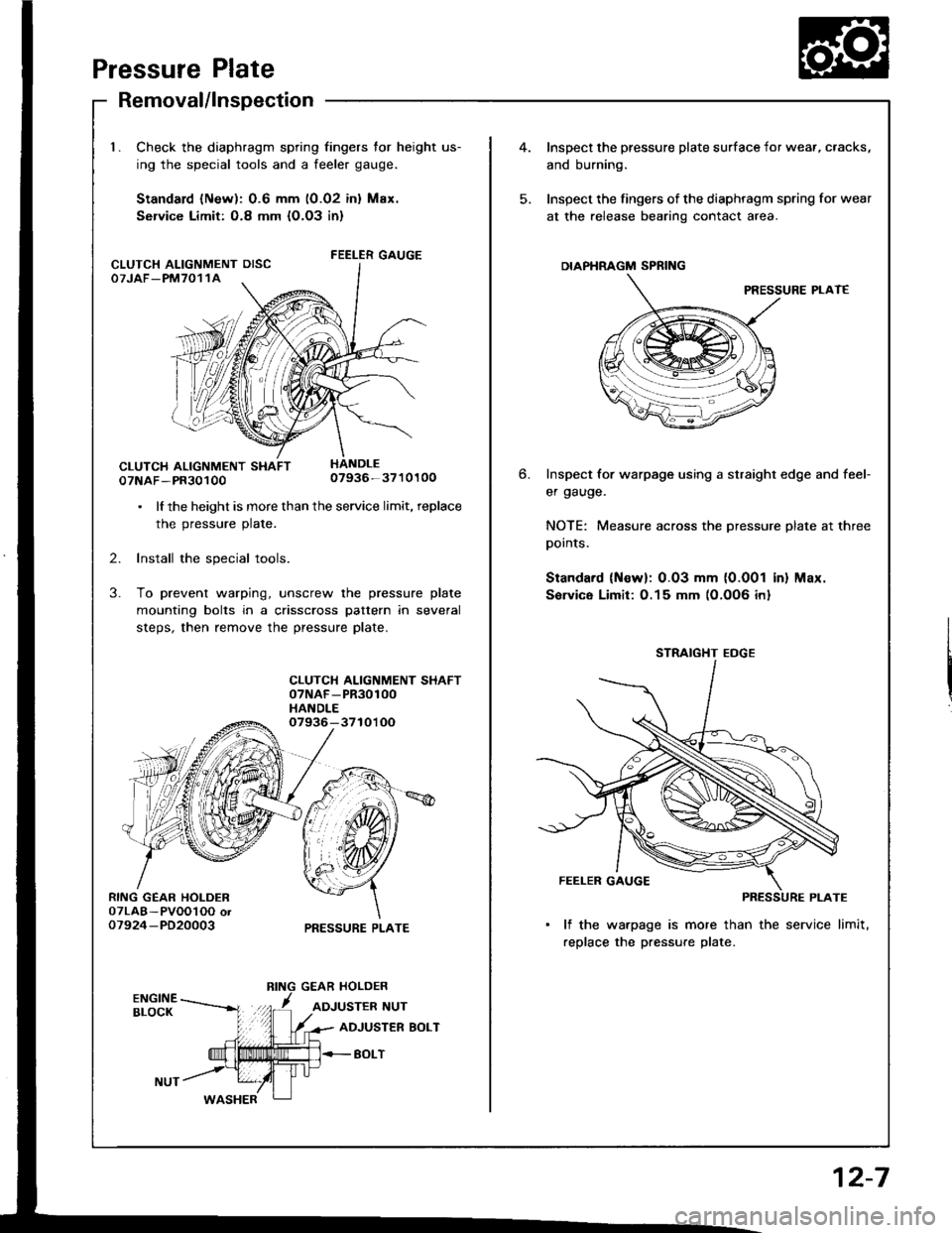

Pressure Plate

RING GEAR HOLDER07LAB-PVOOl OO or07924-PD20003

Removal/lnspection

Check the diaphragm spring fingers for height us-

ing the special tools and a feeler gauge.

Standard lNew): 0.6 mm (0.02 inl Max.

Service Limit: O.8 mm {O.O3 in}

FEELER GAUGE

07NAF-PR3010007936-3710100

. lf the height is more than the service limit, replace

the pressure plate.

2. Install the special tools.

3. To prevent warping, unscrew the pressure plate

mounting bolts in a crisscross pattern in several

steps, then remove the pressure plate.

CLUTCH ALIGNMENT SHAFT07NAF-PR30100HANDLE07936-3710'l OO

PRESSURE PLATE

CLUTCH ALIGNMENT OISCOTJAF_PM7011A

4.Inspect the pressure plate surface

and burning.

Inspect the fingers of the diaphrag

at the release bearing contact ar

DIAPHRAGM SPRING

Inspect for warpage using a stru

er gauge.

NOTE: Measure across the prer

pornls.

Standard (Newl: 0.03 mm (0.0

Sorvice Limit:0.15 mm (0.0O6

STRAIGHT EOGE

FEELER GAUGE

PI

lf the warpage is more than

replace the pressure plate.

6.

I surface for wear, cracks,

diaphragm spring for wear

nracr area.

PRESSURE PLAT€

straight edge and feef

pressure plate at three

0.001 in) Max.

)O6 inl

12-7

Page 339 of 1413

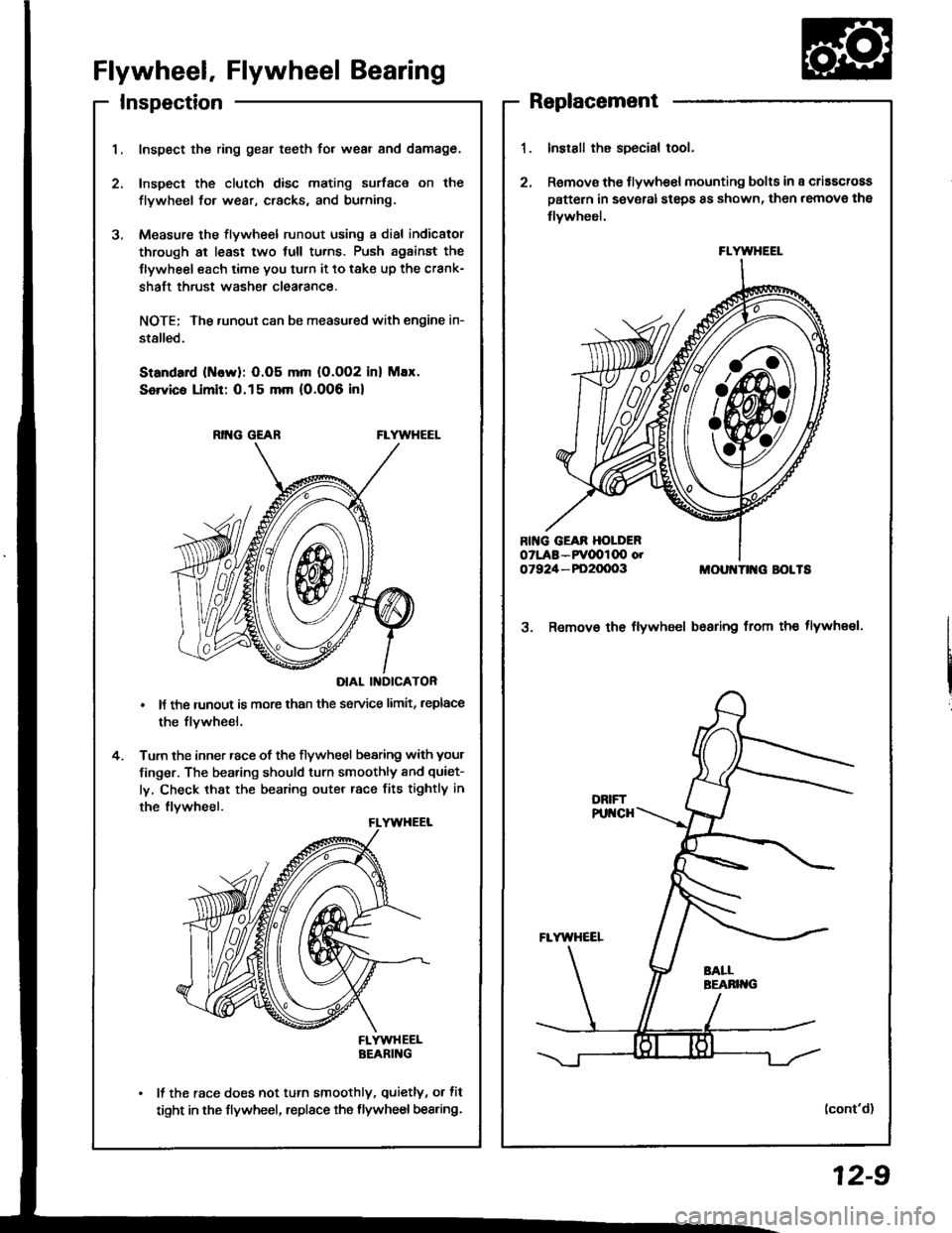

InspectionReplacement

Flywheel, Flywheel Bearing

Inspect the ring gear teeth for wear and damage.

Inspect the clutch disc mating surface on the

flywheel fo. wear, cracks, and burning.

Measure the flywheel runout using a dial indicator

through at least two full tu.ns. Push against the

Ilywheel each time you turn it to take up the crank-

shaft thrust washe. clearance.

NOTE; The runout can be measu.ed with engine in-

stalled.

Standard (ttlervl: O.O5 mm (O.002 inl Max.

Service Limit: 0.15 mm 10.006 inl

RING GEABFLYWHEEL

DIAL II{DICATOR

It the runout is more than the service limit, leplace

the flvwheel.

Turn the inner race of the flywheel bearing with your

finger. The bearing should turn smoothly and quiet-

ly, Check that the bearing outer race fits tightly in

the flvwheel.

FLYWHEELBEARING

It the race does not turn smoothly, quietly, or fit

tight in the flywheel, replace the flywheel bearing.

Install the special tool.

Remov€ the flywhe€l mounting bolts in a criascross

pattern in several steps 8s shown, then remove the

tlywheel.

MOUI{TII{G BOLTS

3. Remov€ the flywheel bsaring from th€ tlywheel.

(cont'd)

FLYWHEEL

12-9

Page 340 of 1413

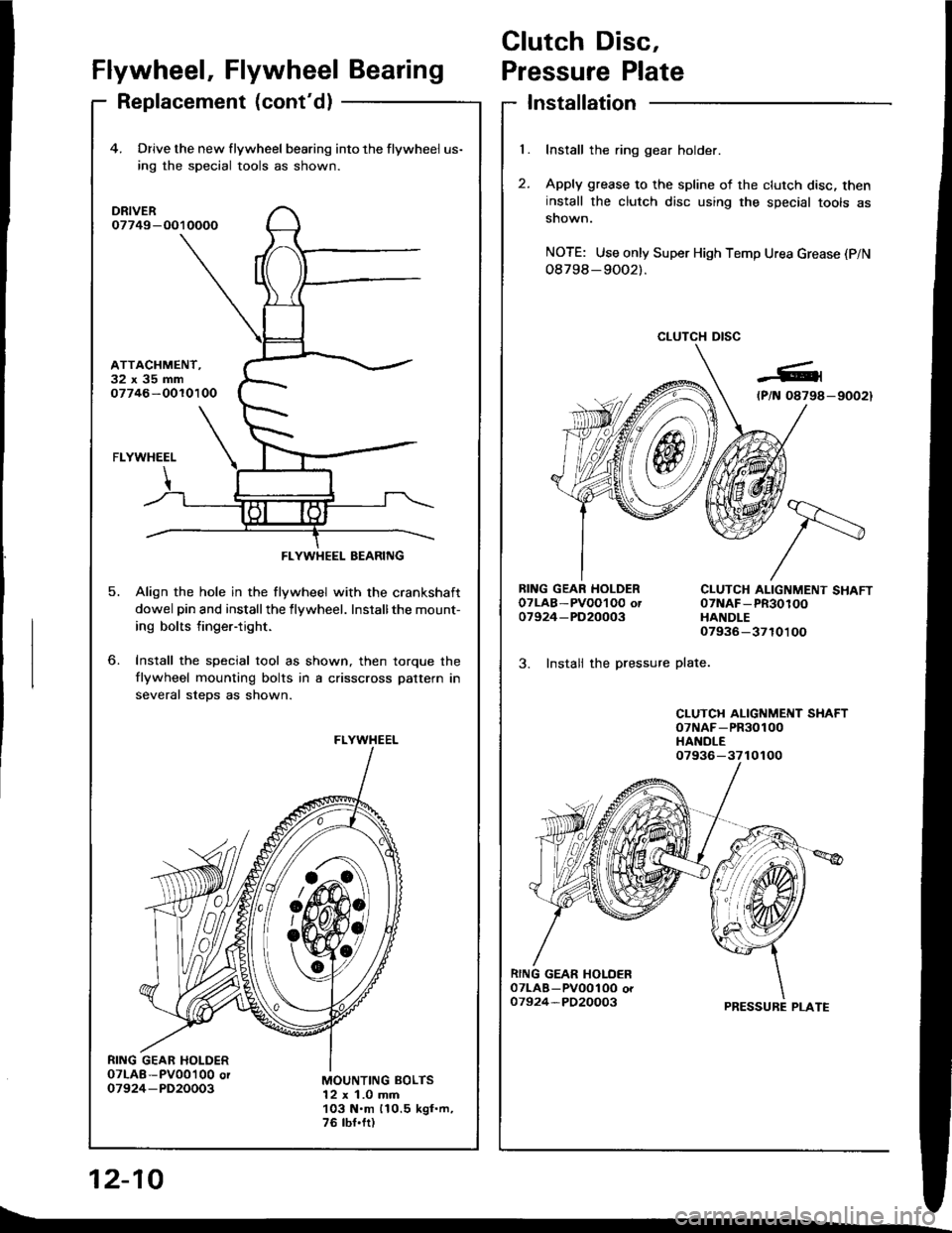

Clutch Disc,

l.

t

Flywheel, Flywheel BearingPressure Plate

Replacement (cont'd)Installation

Install the ring gear holder.

Apply grease to the spline of the clutch disc, theninstall the clutch disc using the special tools assnown.

NOTE: Use only Super High Temp Urea Grease (P/N

08798-9OO2).

CLUTCH DISC

RING GEAR HOLDEROTLAB-PVOOI O0 ot07924-PD20003

3. Instali the pressure

CLUTCH ALIGNMENT SHAFT07NAF-PR30100HANDLE07936-3710100

plate.

CLUTCH ALIGNMENT SHAFToTNAF-PR30100HANDLE

PRESSURE PLATE

12-10

4. Drive the new flywheel bearing into the flywheel us-

ing rhe special tools as shown.

DRIVER07749-O010000

ATTACHMENT.32x35mm07746-OOlO100

o.

5.

FLYWHEEL

Align the hole in the flywheel with the crankshaft

dowel pin and installthe flywheel. Installthe mount-

ing bolts finger-tight.

Install the special tool as shown, then torque the

flywheel mounting bolts in a crisscross pattern in

several steDs as shown.

MOUNTING BOLTS12 x 1.0 mm103 N.m 110.5 kgf.m,76 tbf.fr)

FLYWHEEL BEARING

FLYWHEEL

07936-3710100

t\_

Page 341 of 1413

spection

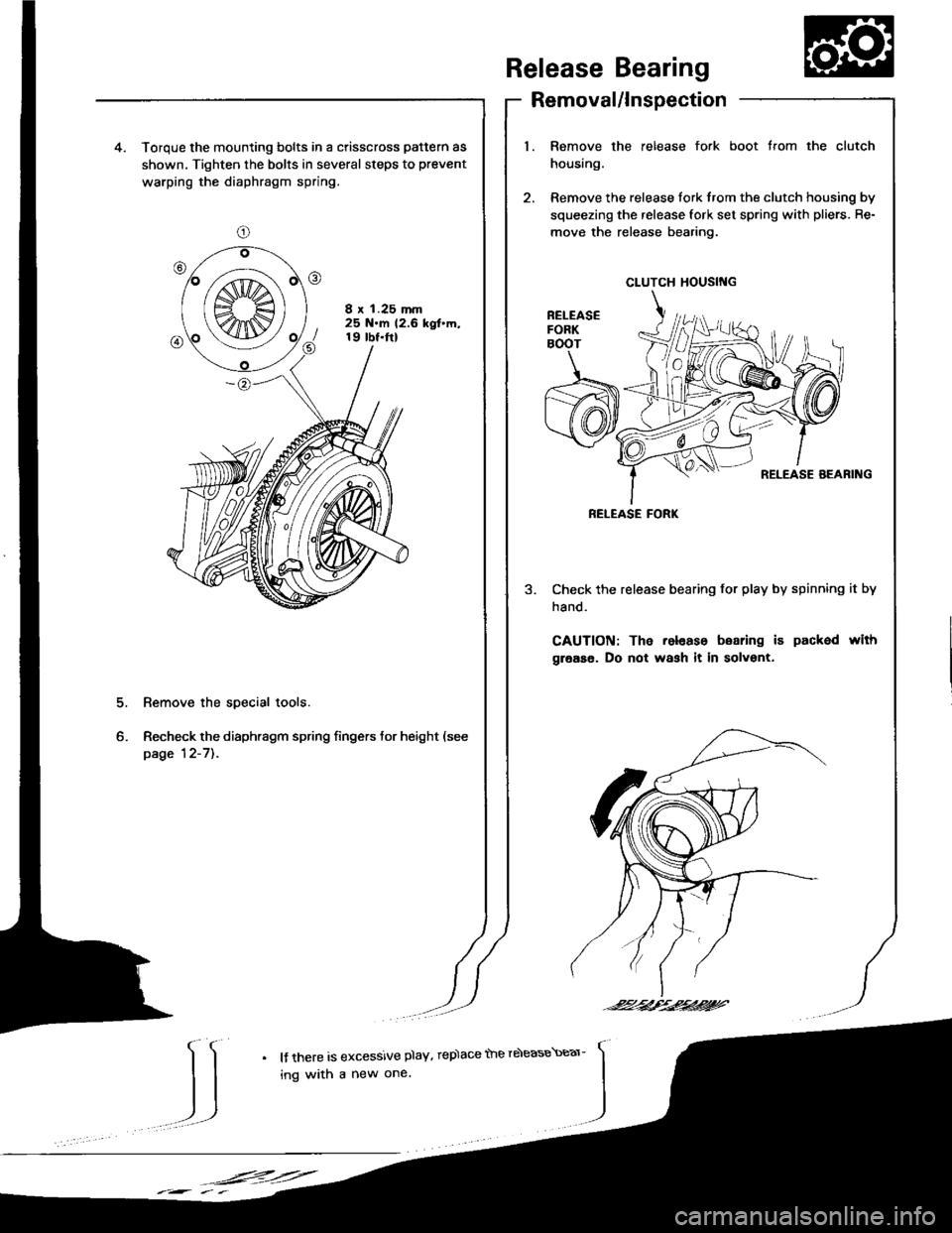

release fork boot trom the clutch4. Torque the mounting bolts in a crisscross pattern as

shown. Tighten the bolts in several steps to prevent

warping the diaphragm spring.

8 x 1.25 mm25 N.m 12.6 kgt'm,19 tbt.ftl

2. Remove the release tork trom the clutch housing by

squeezing the release fork set spring with pliers. Re-

move the release bearing.

Check the release bearing for play by spinning it by

hand.

CAUTION: The release boaring i6 packed with

grease. Do not wash it in solvent.

Remove the special tools.

Recheck the diaphragm spring fingers tor height (see

page 12-7]..

Release Bearing

Removal/ln

1. Remove the

housing.

CLUTCH HOUSING

RELEASE FORK

-24/--2,t'.2424?'

IJ

l{ there is excessive plaY, rep)ace the rdease\Ear-

ing with a new one.

,F=:=

Page 342 of 1413

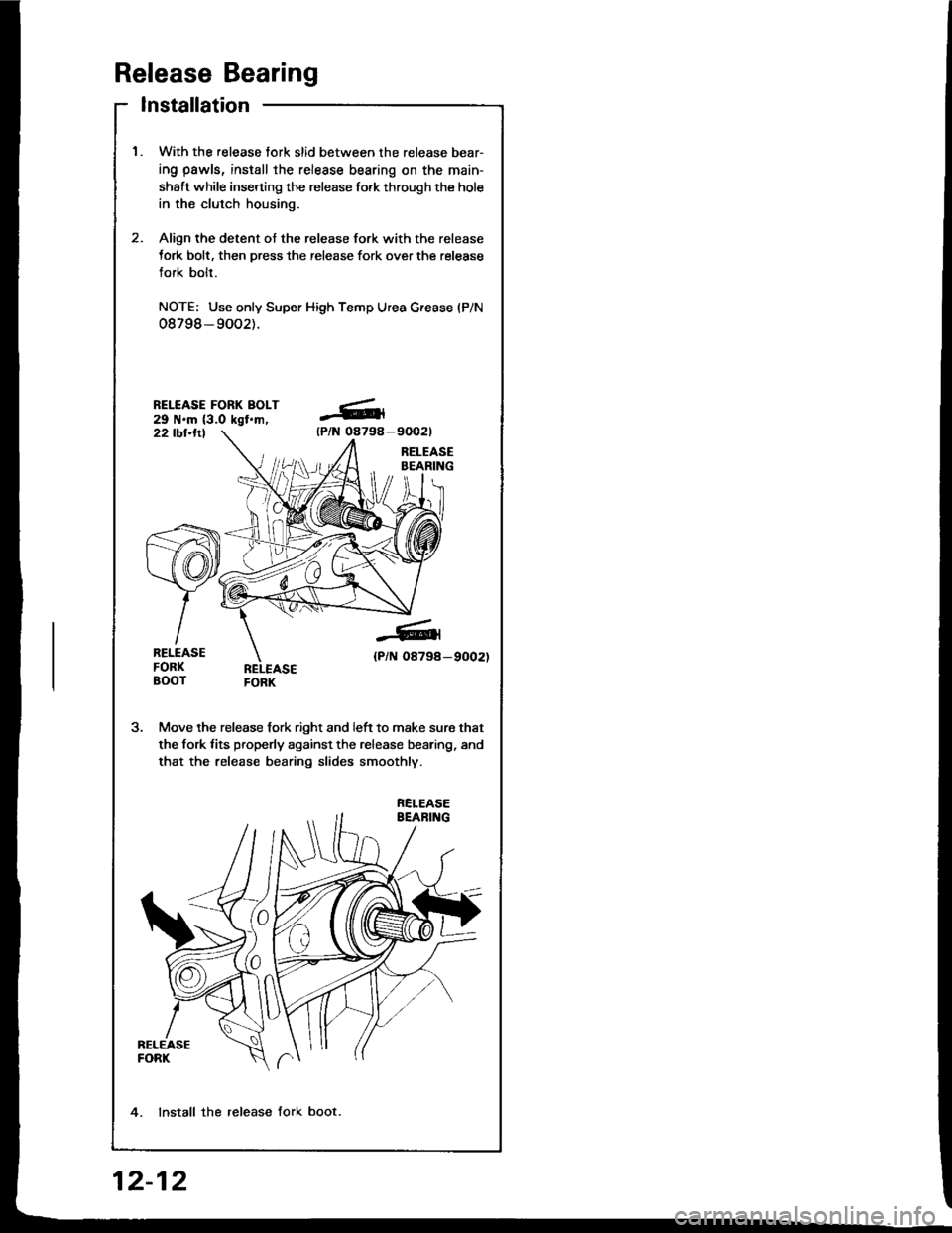

Release Bearing

Installation

1.With the release tork slid between the release bear-

ing pawls, install the release bearing on the main-

shaft while inserting the release fo.k through the hole

in the clutch housing.

Align the detent ot the release fork with the release

tork bolt, then press the release fork over the release

fork bolt.

NOTE; Use only Super High Temp Urea G.ease (P/N

08798- 9002).

2.

-611

lPlN 08798-

-6

{P/N 0879a-9002)

Move the release fork right and left to make sure that

the fork tits properly against the release bearing, and

that the release bearing slides smoothly.

4. lnstall the release fork boot.

12-12

Page 343 of 1413

Manual Transmission

Special Toofs ............. 13-2

Maintenance

Transmission Oi1,...,........,........,.,..... 13-3

Back-up Light Switch

Replacement ......... 13-3

Transmission Assembly

Removal ..,.......,...... 13-4

lllustrated Index ................................... 13-8

Transmission Housing

Removal ...........,..... 13-10

Reverse Change Holder, Reverse ldler Gear

Glearance lnspestion ....................... 13-1 1

Removaf ................. 13-12

Change Holder Assembly

Clearance Inspection ....................... 1 3-1 3

Removal ................. 13-15

Disassembly/Reassembly ............... 13-16

Mainshaft, Gountershaft, Shift Fork

Removal ...,............. 13-17

Shift Rod

Removal ................. 13-18

Shift Fork Assembly

Index ................ ...... 13-19

Clearance Inspection ....................... 13-20

Mainshaft Assembly

Index ................ ...... 13-21

Clearance f nspection ....................... 13-22

Disassembly .......... 13-25

Inspection .............. 13-26

Reassembly ........... 13-21

Countershaft Assembly

Index ................ ...... 13-28

Clearance Inspection ....................... 13-29

Disassembly .......... 13-30

Inspection .............. 13-31

Reassembly ........... 13-32

Synchro Sleeve, Synchro Hub

Inspection .............. 13-34

Installation ............. 13-34

Synchro Ring, Gear

lnspection .............. 13-35

Clutch Housing Bearing

Replacement ......... 13-36

Mainshaft Thrust Clearance

Adiustment ............ 13-38

Transmission

Reassembly ........... 13-tl1

Transmission Assembly

lnstallation ............. 13-46

Gearshift Mechanism

Overhaul ................ 13-50

Page 344 of 1413

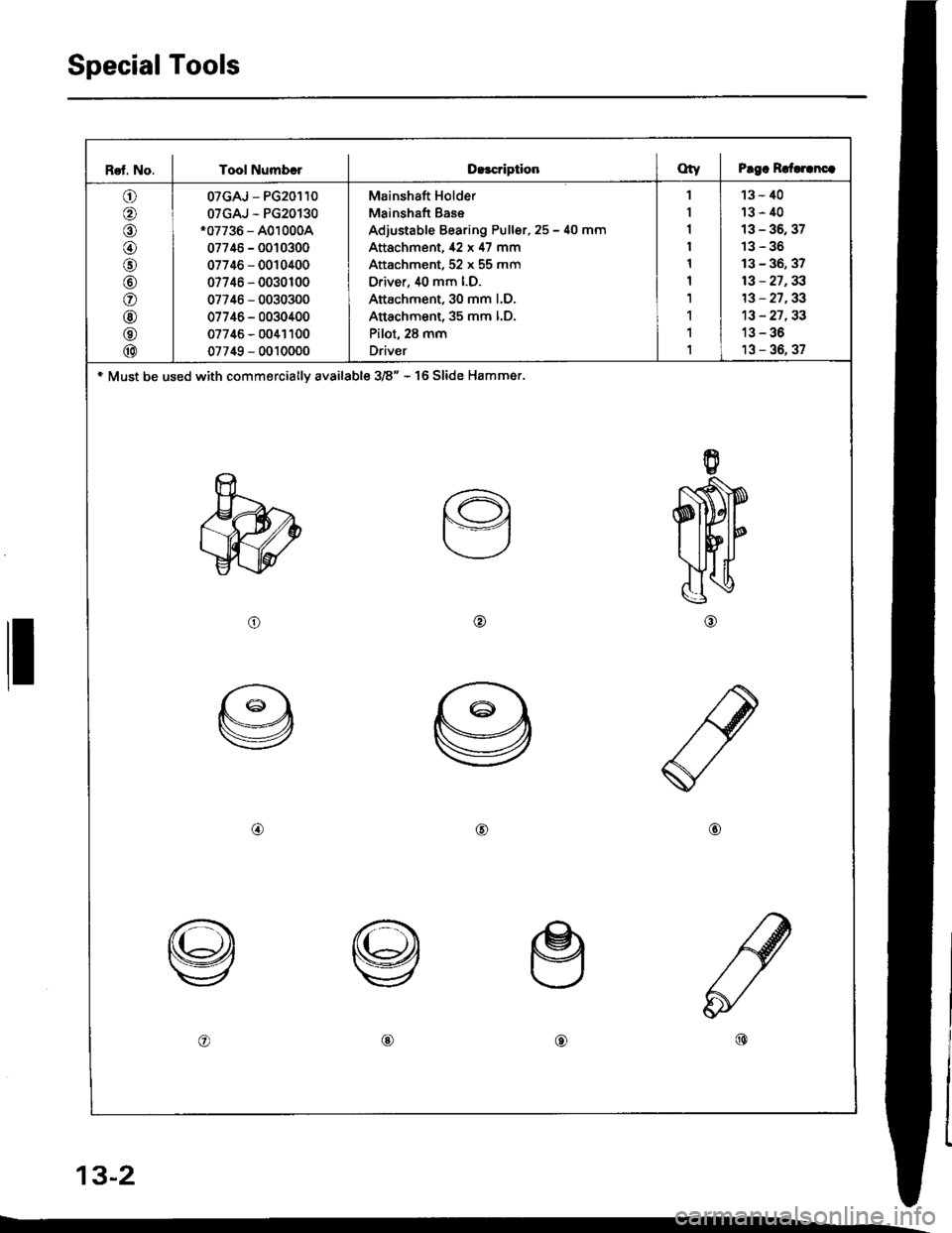

Special Tools

Rsf. No. I Tool NumbrrD!3criptionOty I Prgc R.{.rcnc.

o

o

o

o

@

@

@

@

@

07GAJ - PG20110

07GAJ - PG20130.07736 - A010004

07746 - 0010300

07746 - 0010400

07746 - 0030r00

07746 - 0030300

07746 - 0030400

07745 - 0041100

07749 - 0010000

Mainshaft Holder

Mainshaft Bas€

Adjustable Bearing Puller, 25 - 40 mm

Attachment, 42 x 47 mm

Attachment, 52 x 55 mm

Oriver, 40 mm l.D.

Attachment, 30 mm l.D.

Attachment, 35 mm l.D,

Pilot, 28 mm

Driver

1

1

1

1

1

1

1

1

1

1

'13 - 40

13-40

13 - 36, 37

13-36

13 - 36, 37

13 - 27,33

13 - 27,33

13 - 27,33

13-36

13 - 36, 37

* Must be used with commerciallv available 3/�8" - 16 Slide Hammer.

o@

@@@

o@@

ll

13-2

Page 350 of 1413

lllustrated Index

Refer to the drawing below for the transmission disassembly/reassembly.

Clean all the parts thoroughly in solvent and dry with compressed air.

I ruurlcate att the parts with oil before reassembly.

NOTE:

. This transmission uses no gaskets between the major housings; use liquid gasket (P/N 08718-0001)

{see page 13-43).

a

a

Alwavs clean the magnet @ whenever the transmission housing is disassembled.

Inspect all the bearings for wear and operation.

(9

@

@

tqqlnl^'1ult I Ej

nl

11-4fi

,\|j Uh

o

@

o

@@

@

@

(3

(,

@

@

@

a

@

@

@

@

B

tg

Y

o

@

@

@

*N

13-8

[@.--oaF5i,--@:7

Page 351 of 1413

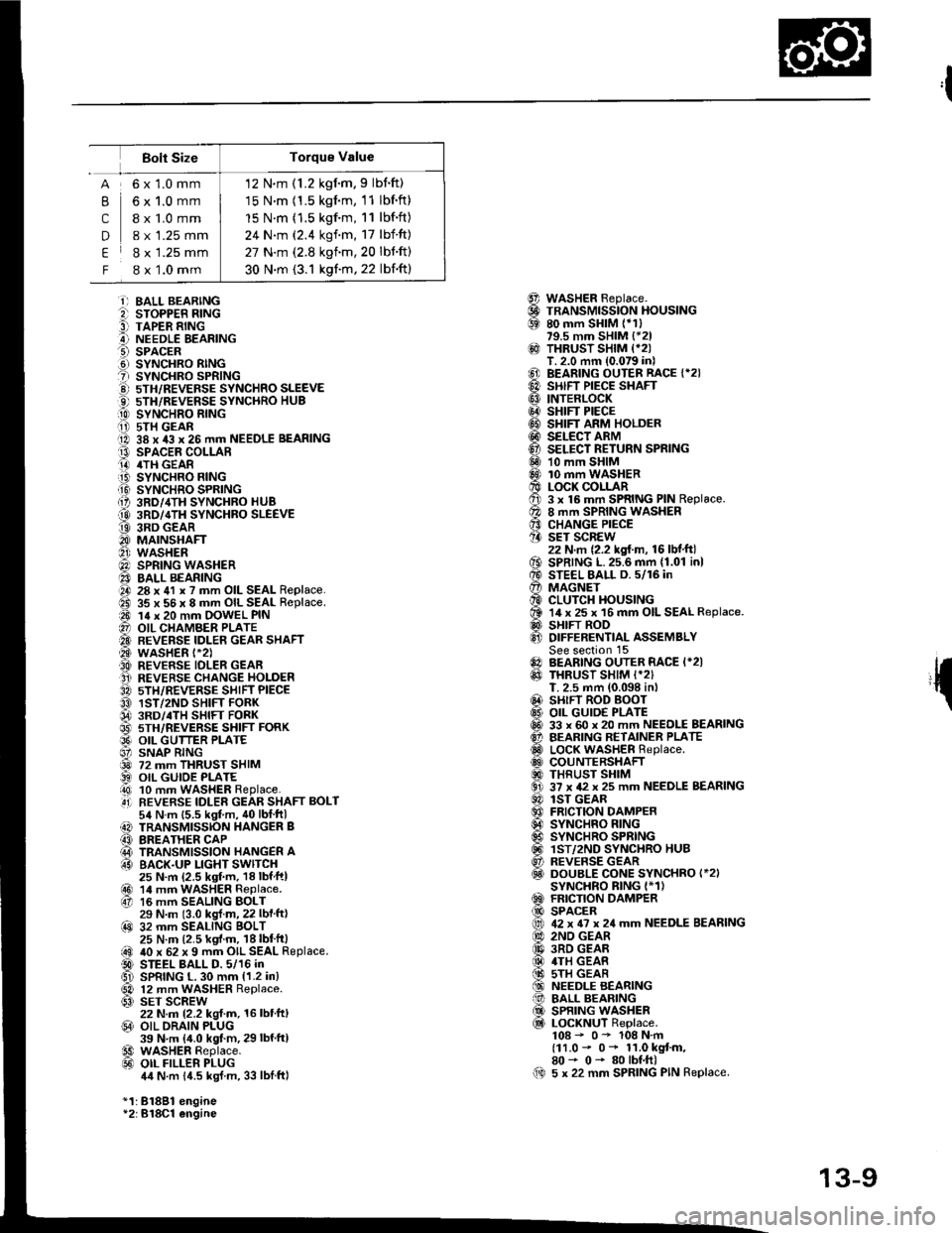

12 N.m (1.2 kgim,9 lbnft)

15 N.m (1.5 kgnm, 11 lbf.ft)

15 N.m (1.5 kgf.m, 11 lbf.ft)

24 N.m (2.4 kgf.m, 17 lbf'ft)

27 N.m (2.8 kgnm,20 lbnft)

30 N.m (3.1 kgf.m, 22 lbf'ft)

Bolt Size

,l

{

@@69

@

@@@@@@@@6Dq0

o€xv0@

@0!@@@@al

61@

B

c

D

E

F

6x1.0mm

6x1.0mm

I x 1.0 mm

8 x 1.25 mm

8 x 1.25 mm

8 x 1.0 mm

i) BALL BEARINGe sroPPER R|NG9 TAPER RINGA NEEDLE EEARINGO SPACER.d SYNCHRO RINGt sYNcHRo SPR|NG!) 5TH/REVEFSE sYNcHRo SLEEVEO 5TH/REVERSE SYNCHRO HUB[0 sYrucxao nlrucii i) 5TH GEARO 38 x 43 x 26 mm NEEDLE BEARINGt3 SPACEE COLLARO 4TH GEAR.iB SYNCHRO FING.Ii9 SYNCHRO SPRING{, 3RD/,ITH SYNCHRO HUB

@ 3RD/4TH SYNCHBO SLEEVEt9 3RD GEARO MAINSHAFTO wasHER@) SPRING WASHER40 BALL BEARINGO 28 x 41 x ? mm OIL SEAL Replace.ad 35 x 56 x 8 mm OIL SEAL Replace.a0 14 x 20 mm OOWEL PIN@ OIL CHAMBER PLATE'A BEVERSE IDLEN GEAR SHAFT@ wasHER t-2).A REVERSE IDLER GEAFO REVERSE CHANGE HOLDER3A sTH/REVERSE SHIFT PIECEO 1ST/2ND SHIFT FORK04 3RD/.TH sHlFr FoRK@ 5TH/REVERSE SHIFT FORKO9' OIL GUTTER PLATE6' SNAP RING@ 72 mm THRUST SHIM) OIL GUIOE PLATEi!0 10 mm WASHER Replace..4i] REVERSE IDLER GEAR SHAFT BOLT54 N.m {5.5 kgt m, 40lblftl) TRANSMISSION HANGER B(3 BREATHER CAP@ TRANSMISSION HANGER A63 BACK.UP LIGHT SWITCH25 N.m (2.5 ksf.m, 18lbfftl@r 14 mrn waSHER Replace.67 16 mm SEALING BOLT29 N.m (3.0 kgl.m, 22 lbf ft)@ 32 mm SEALING BOLT25 N.m (2.5 kgf.m. 18lbt'ft|@ 40 x 62 x 9 mm OIL SEAL Replace.D STEEL BALL D. 5/16 inGl SPRING L. 30 mm {1.2 in}

@ 12 mm WASHER Replace.63) SET SCREW22 N.m 12.2 kgl.m, 16 lbt'ft,@ OIL ORAIN PLUG39 N.m {4.0 kgt.m, 29 lbf'ftl€9 WASHER Replace.@ oIL FILLER PLUG4,1N.m 14.5 kgJ m, 33 lblftl

*1:81881 engine*2:B18Cl engine

WASHER Beplace.TRANSMISSION HOUSING80 mm SHIM (*1)79.5 mm SHIM {*21THRUST SHIM {*2IT. 2.0 mm (0.079 in)BEARING OUTER RACE {*2}SHIFT PIECE SHAFTINTERLOCKSHIFT PIECESHIFT ARM HOLDERSELECT ARMSELECT RETURN SPRING10 mm SHIM10 mm WASHERLOCK COLLAR3 x 16 mm SPRING PIN Replace.8 mm SPRING WASHERCHANGE PIECESET SCREW22 N.m {2.2 kgf.m, 16 lbf.ft}SPRING L.25.6 mm {1.01 inlSTEEL BALL D. 5/16 inMAGNETCLUTCH HOUSING14 x 25 x 16 mm OIL SEAL Replace.SHIFT RODDIFFERENTIAL ASSEMBLYSee section 15BEARING OUTER RACE I*2ITHRUST SHIM I*2)T. 2.5 mm (0.098 in,SHIFT ROD BOOTOIL GUID€ PLATE33 x 60 x 20 mm NEEDLE BEARINGBEARING RETAINER PLATELOCK WASHER Replace.COUNTERSHAFTTHRUST SHIM37 x 42 x 25 mm NEEDLE BEARINGlST GEARFRICTION DAMPERSYNCHRO RINGSYNCHRO SPRINGlST/2ND SYNCHRO HUBREVERSE GEARDOUBLE CONE SYNCHRO I*2ISYNCHRO BING I*1)FRICTION DAMPERSPACER42 x 6? x 24 mm NEEDLE BEARING2ND GEAR3RD GEAR4TH GEAS5TH GEARNEEDLE BEARINGBALL BEARINGSPRING WASHERLOCKNUT Replace.108 - 0- 108 N.m(11.0 - 0* 11.0 kgt m,80- 0- 80lbf.ft)5 x 22 mm SPRING PIN Replace.00

13-9