ECU HONDA INTEGRA 1994 4.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 1020 of 1413

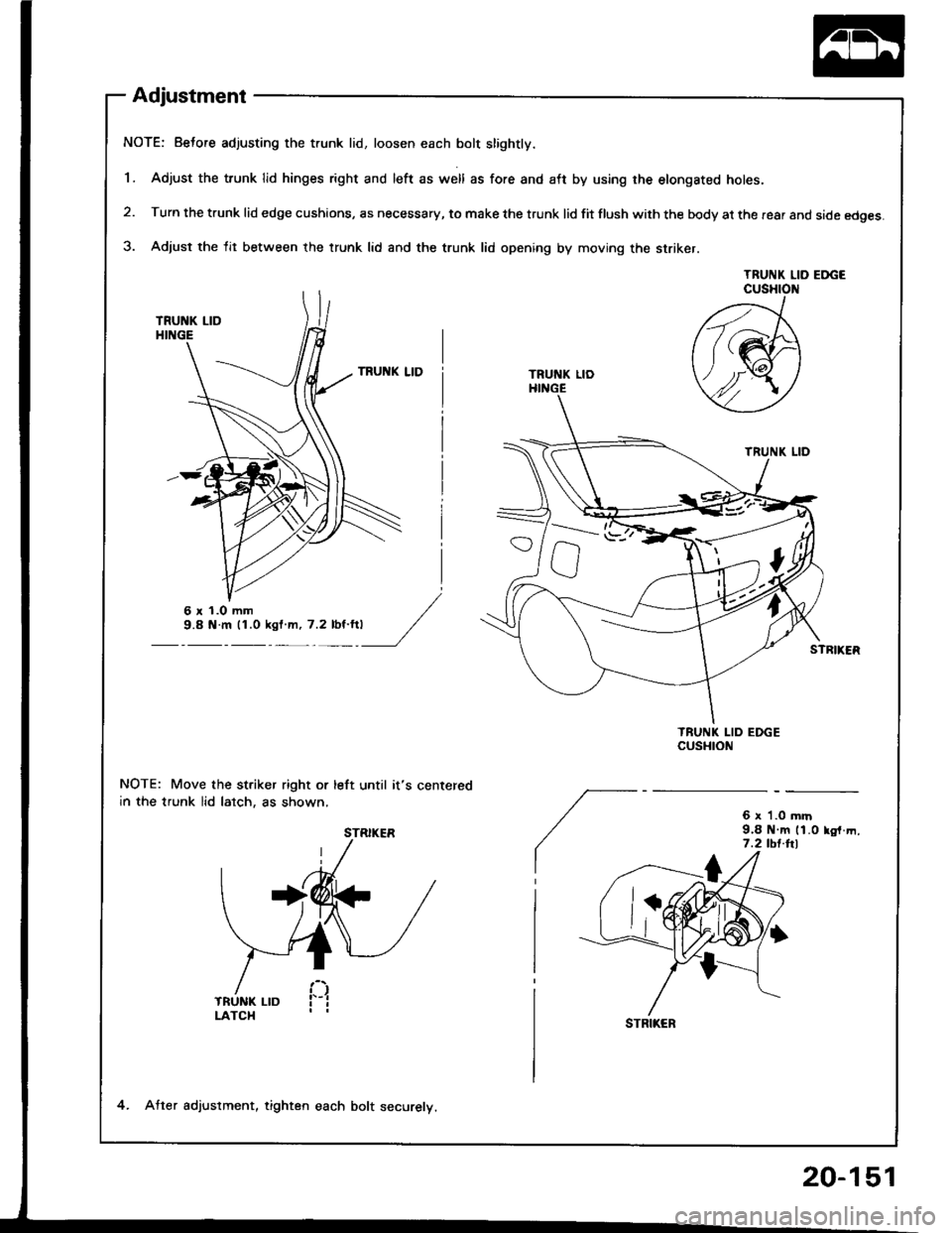

Adjustment

NOTE: Beto.e adjusting the trunk lid, loosen each bolt slightly.

1. Adjust the trunk lid hinges right and left as well as fore and aft by using rhe etongated holes.

2. Turn the trunk lid edge cushions, as necessary, to make the trunk lid fit flush with the body at the rear and side edges.

3. Adjust the lit between the trunk lid and the trunk lid opening by moving the striker.

TRUNK LID EDGECUSHION

NOTE: Move the st.iker right or left until it's centered

in the trunk lid lalch, as shown,6 x '1.0 mrn9.8 N m 11.0 lo,f.m,7.2 tbt.hl

/21

ft(M

Y4Y

TRUNI( LID

TRUNK LIDHINGE

6r1.Omm9.8 N.m 11.0 ksl m, 7.2 lbt'ft|

STRIKER

STRIKER

4. Atter adjuslment, tighten each bolt securelv.

20-151

Page 1023 of 1413

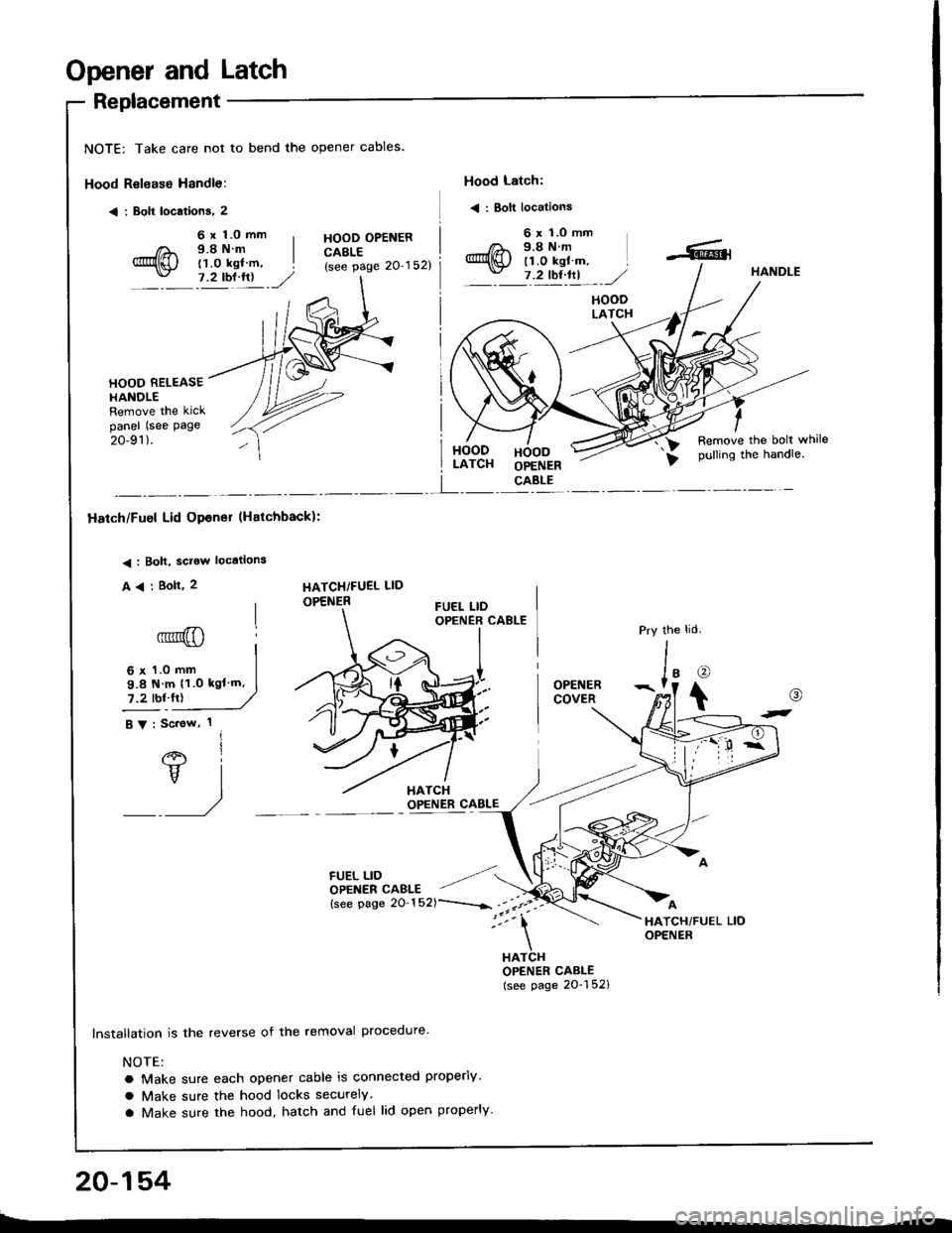

Opener and Latch

Replacement

NOTE: Take care not to bend the opener cables.

Hood Relsase Handle:

< i Bolt locations, 2

Hood Latch:

< : Bolt locations

6 x 1.0 mm9.8Nm(1.0 kgl m,7.2 tbl.lrl

HOOD OPENERCABLE(see page 20'152)

6 x 'l.O mm9.8Nm11.0 kgl m,7 .2 tbt ftl,/HANDLE

HOODLATCH

HOOD RELEASEHANOLERemove the kickpanel (see page

20-91).HOODLATCHHOODOPENERCABLE

Remove the bolt whilepulling the handle.

I

Hatch/Fuel Lid Opener lHatchback):

< : Bolt, sclow locations

A

6' I

vl

/

HATCHiFUEL LID

OPENER

6 x 1.0 mm

9.8 N m 11.0 kgl'm,

7.2 tbl.fr)

FUEL LIDOPENER CAELE

lnstallation is the reverse of the removal procedure'

NOTE:

a Make sure each opener cable is connected properly

a Make sure the hood locks securely

a Make sure the hood, hatch and fuel lid open properly.

the

J'o

t

OPENERCOVER

HATCHOPENER CABLE(see page 20-152)

@

t-

20-154

Page 1024 of 1413

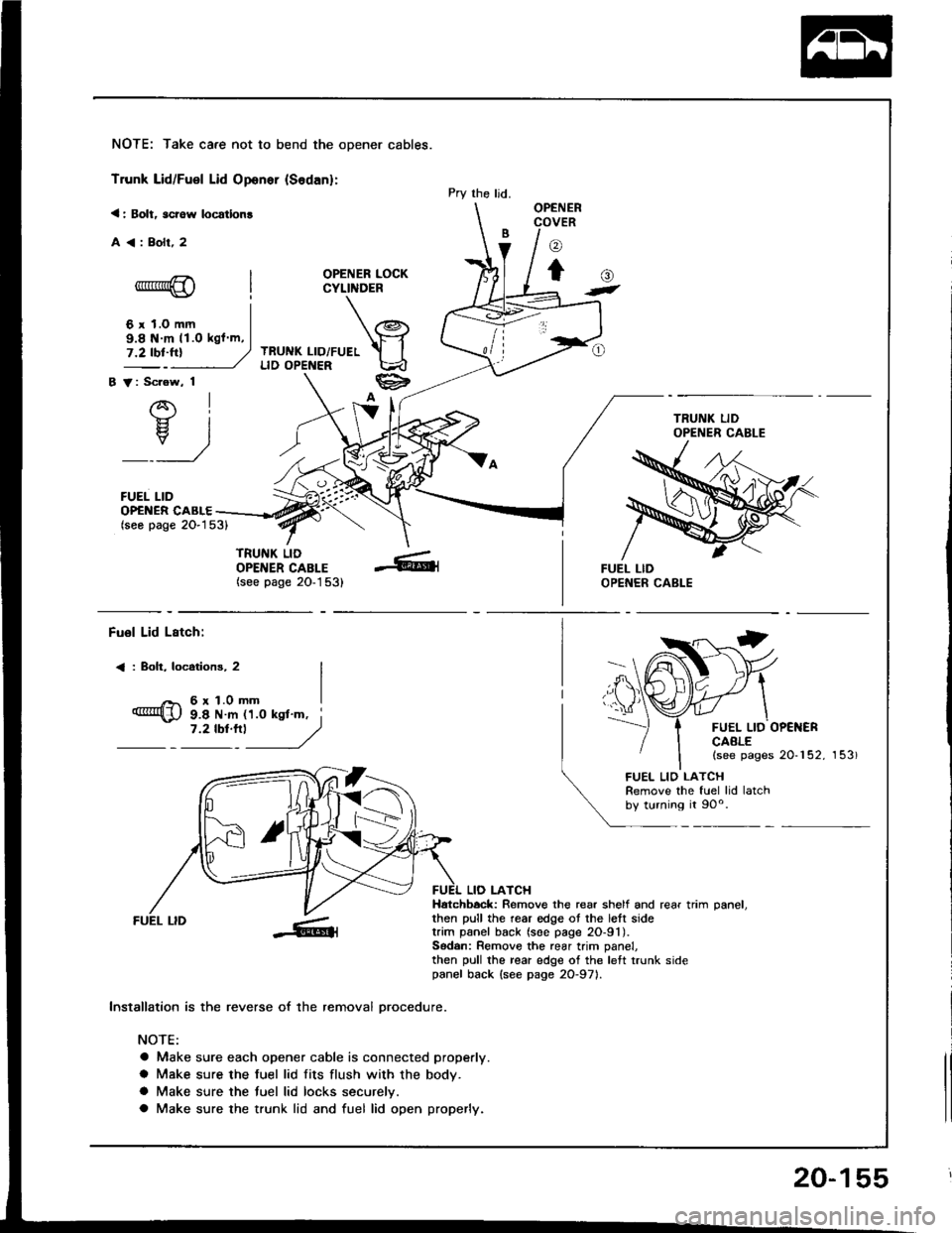

NOTE: Take care not to bend the opener cables.

Trunk Lid/Fuel Lid Oponer {Sodan}:

< : Bolt, scrow locatlon!

A<:Bolr,2

OPENER LOCKCYLINDER

TRUNK LID/FUELLID OPENER

B V: Scrow, 1

AI-}{- IH. I

_:_)

FUEL LID

Pry the ljd.OPENERCOVER

o

to-*rr*@

6 r 1.0 mm

()t

OP€NER CABLE(seo page 2O-153)

TRUNK LIDOPENER CABLE(see page 20-1 53)

9.8 N m 11.O kgl m,

Fuol Lid Lstch:

< : Boh, locotions, 2

6r1.0mm

FUEL LID OP€NERCAALE(see pages 20-152, 153)

9.8 N m 11.0 ksl'm, i7 '2 tbt'''l

------,//

FUEL LID

lnstallation is the reverse of the removal orocedure.

NOTE:

a Make sure each opener cable is connected properly.

a Make sure the fuel lid fits flush with the body.

a Make sure the tuel lid locks securelv.

a Make sure the trunk lid and fuel lid open properly.

LIO LATCHHatchbock: Remove the rear shelf and rear trim oanel.then pull the rear edge ot the lett sidetrim panel back (soe page 2O-91).Sodan: Remove the rear trim panel,then pull the rear edge of the left trunk sidepanel back {see page 2O-971.

FUEL LIO LATCHRemove the fuel lid latchby turning it 90o.

20-155

Page 1025 of 1413

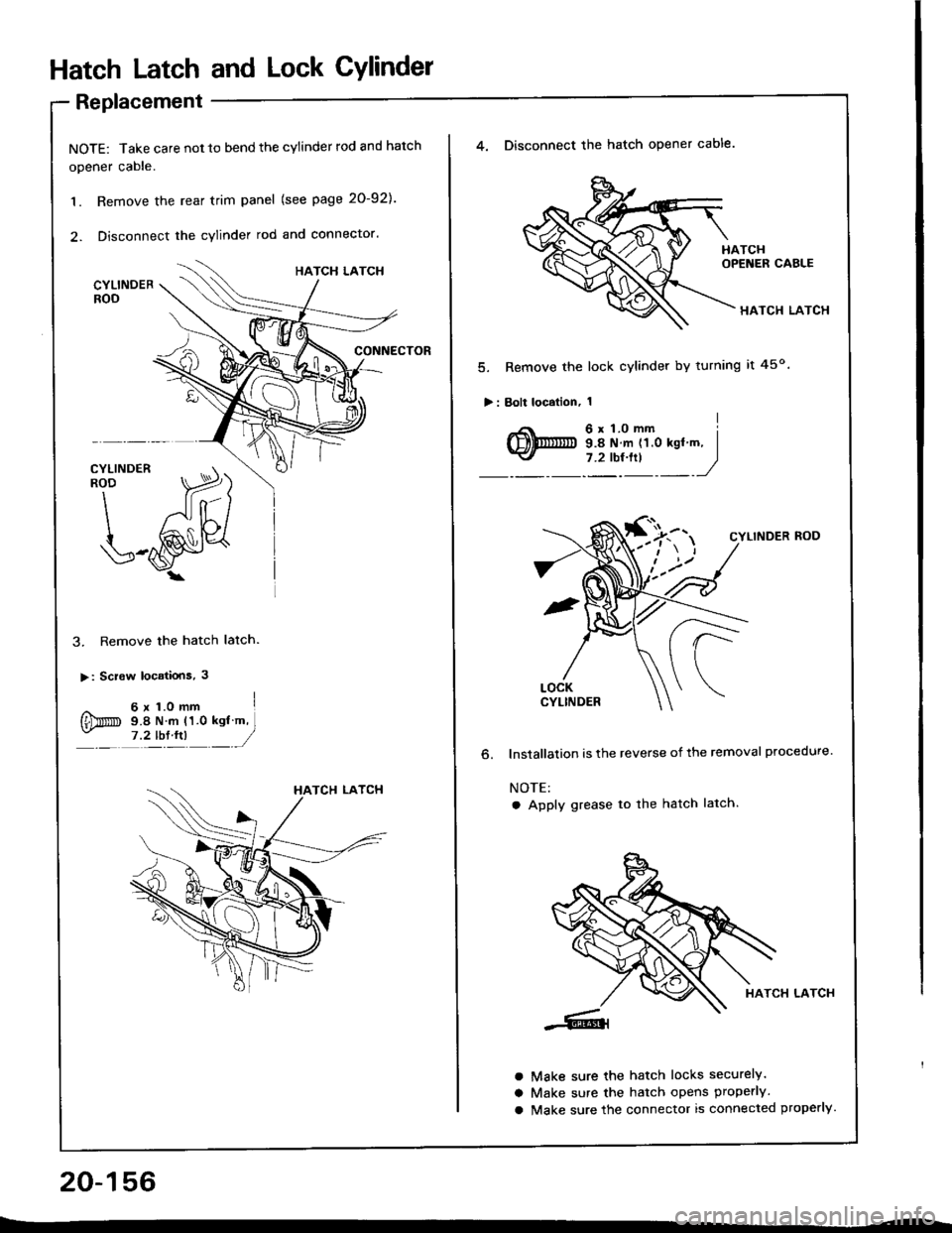

Hatch Latch and Lock CYlindet

Replacement

NOTE: Take care not 10 bend the cylinder rod and hatch

opener cable.

1. Remove the rear trim panel (see page 20-921.

2. Disconnect the cylinder rod and connector.

3. Remove the hatch latch.

>: Screw locatiois, 3

^ 6x1.omm I

{Dm s.e N m (1.0 ksl m,- ,?tb:tn __/

20-156

4. Disconnect the hatch opener cable.

HATCH LATCH

5. Remove the lock cylinder by turning it 45o

>: Bolt localion, 1

o.

CYLINDER ROD

lnstallalion is the reverse of the removal procedure.

NOTE:

a Apply grease to the hatch latch.

HATCH LATCH

Make sure the hatch locks securely.

Make sure the hatch opens properly.

Make sure the connector is connected properly.

a

a

a

Page 1026 of 1413

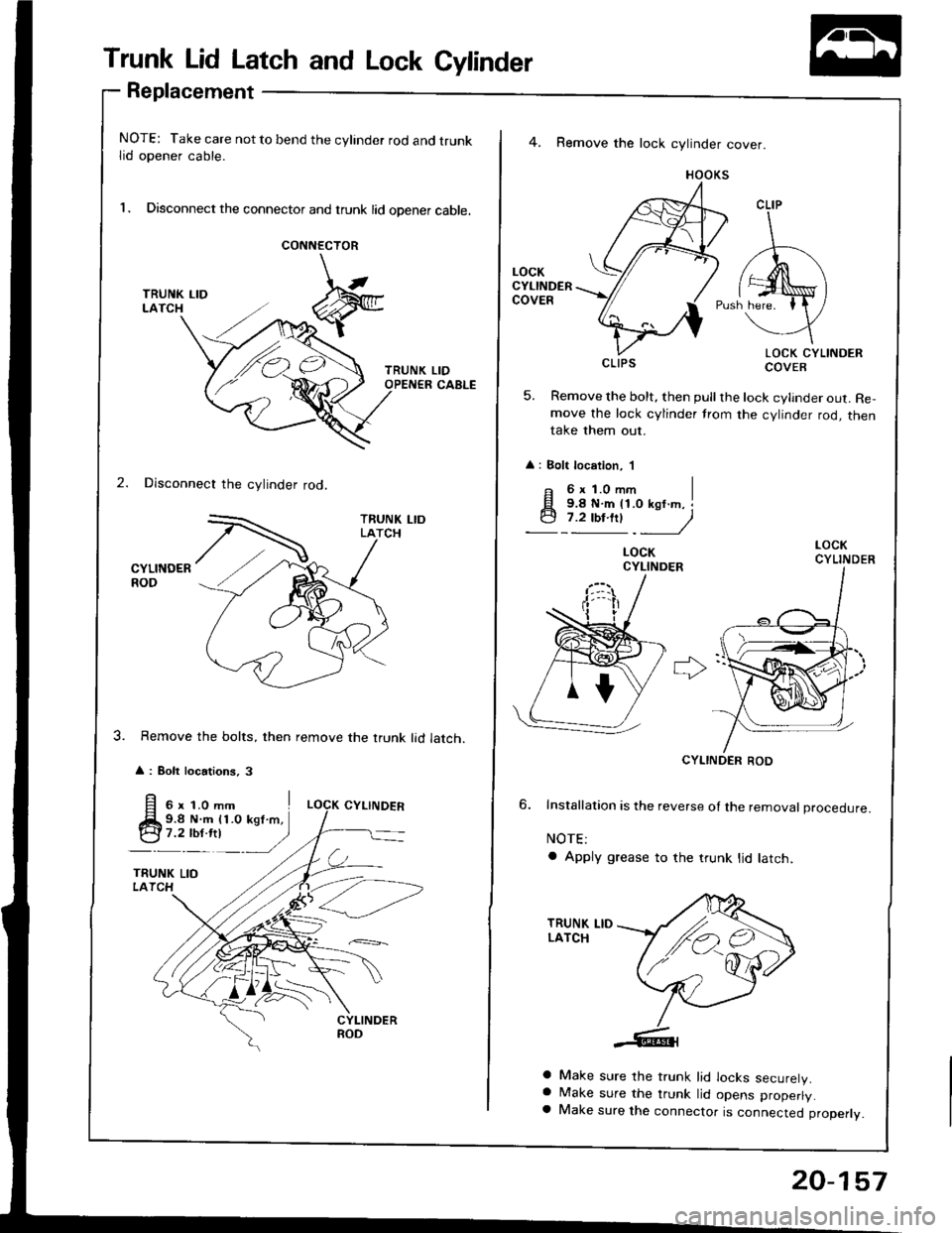

Trunk Lid Latch and Lock Cylinder

Replacement

NOTE: Take care not to bend the cylinder rod and trunklid opener cable.

l. Disconnect the connector and trunk lid opener cable.

CONNECTOR

2. Disconnect the cylinder rod.

CYLINDERROD

Remove the bolts, then remove the trunk lid latch.

A : Bolt locations, 3

LIDCABLE

4. Remove the lock cylinder cover.

HOOKS

LOCK CYLINDERCOVER

5. Remove the bolt, then pull the lock cylinder out. Re,move the lock cylinder trom the cylinder rod, thentake them out.

: Bolt location, 'l

CLIP

CLIPS

F 6xl.Omm I

q;i!!"jy

LOCKCYLINDER

CYLINDER ROD

6. Installation is the reverse ol the removat proceoure.

NOTE:

a Apply grease to the trunk lid latch,

a Make sure the trunk lid locks securelV.a Make sure the trunk lid opens properly.a Make sure the connector is connected properly.

/ ./,.,

,/'e4

20-157

Page 1030 of 1413

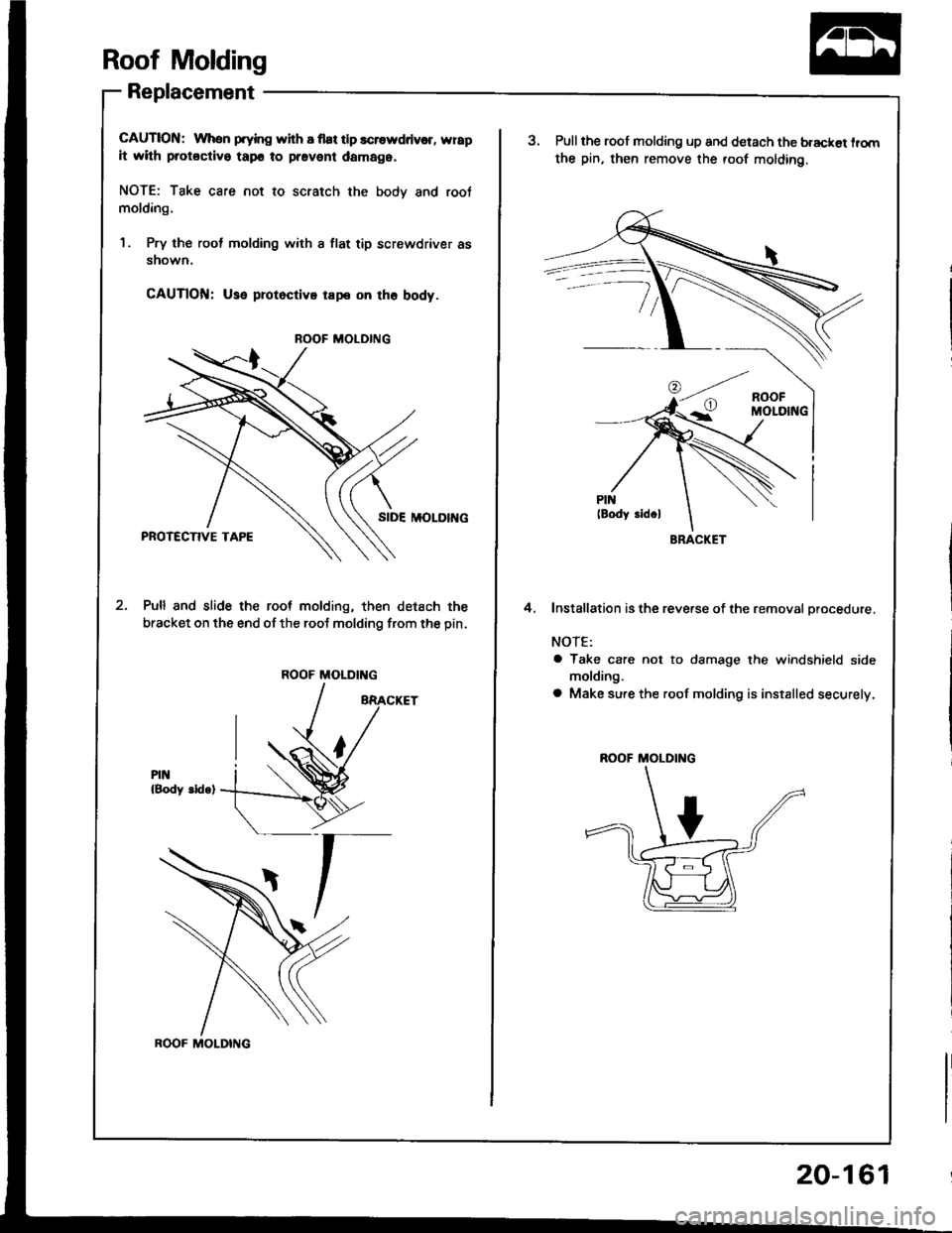

Roof Molding

Replacement

CAUTION: When prying with I flat tlp scrowddv€r, wrap

it with protoctivo tapo to pravent damag6.

NOTE: Take care not to scratch the bodv and root

molding.

1 . Pry the rool molding with a flat tip screwdriver as

snown.

CAUTlOfil: Use protoctivo rape on tho body.

SIDE MOLOII{G

Pull and slide the root molding, then detach the

bracket on the end of the roof molding from the pin.

PIN{Body ddq)

ROOF MOLDING

ROOF MOLDING

ROOF MOLDING

20-161

BRACKET

aPull the roof molding up and detach the bracket lrom

the pin, then remove the roof molding.

Installation is the reverse of the removal orocedure.

NOTE:

a Take care not to damage the windshield side

molding.

a Make sure the roof molding is installed securely.

4.

R(X)F MOLDING

Page 1060 of 1413

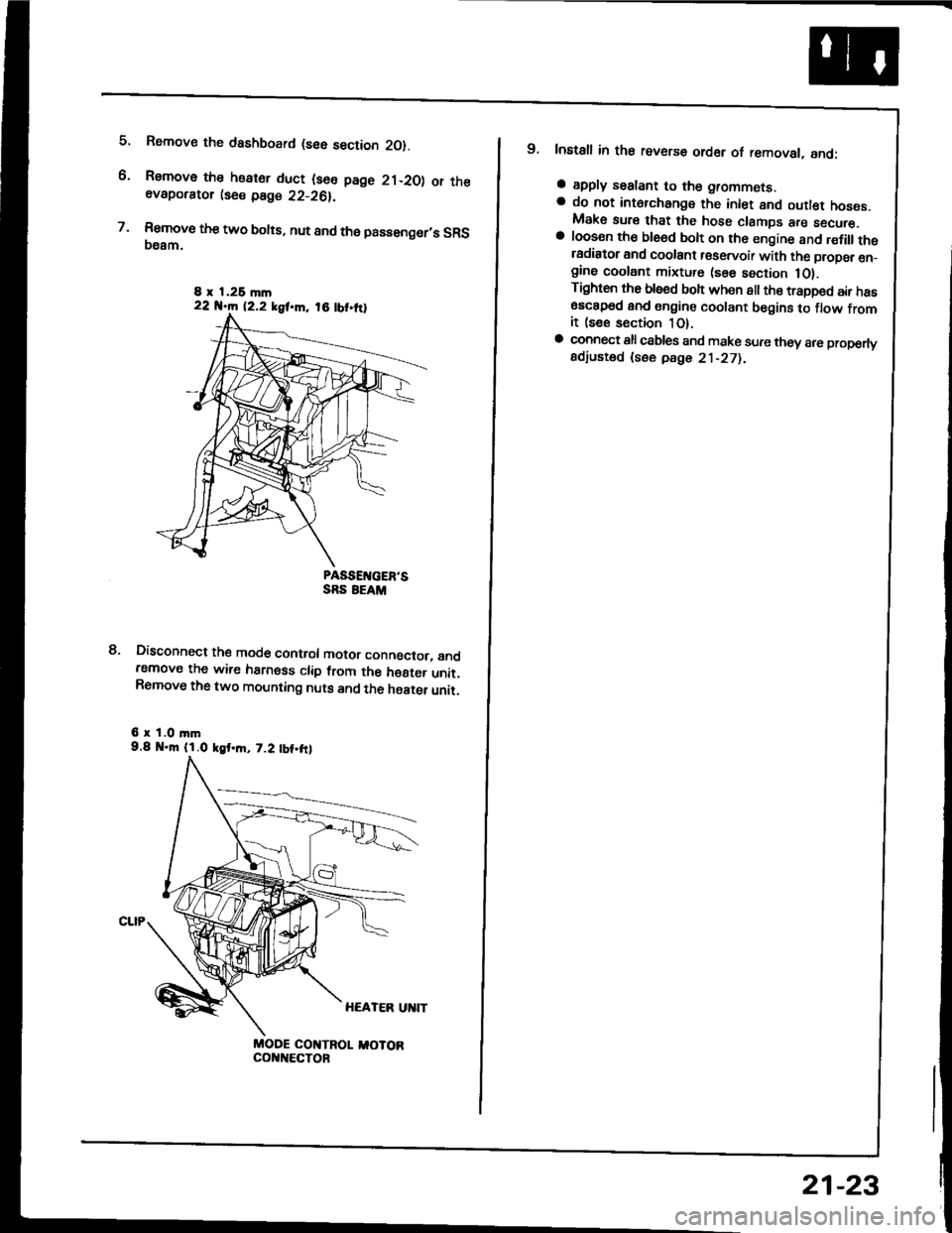

5.

6.

7.

Rsmove the dashboard (see section 2O).

Remove the heater duct (see page 21-20) or theevaporator lse€ page 22-26).

Rsmove the two bolts, nut and the passenger,s SRS(}eam.

PASSEIVGER'SSRS EEAM

Disconnect the mode control motor conngctor, andremove the wire harness clip from the h€8ter unit.Remove the two mounting nuts and the haater unit.

6 r 1.0 mm9.8 .m (l.O kgt.m, 7.2 tbt.frl

MODE COI{TROL I,IOTORcol{t{€cToF

8.

8 x 1,26 mln22 N.m 12.2 kgf.m, 18 tbt.ttl

9. Install in the reverse order of removal, and:

a apply sealant to the grommets.a do not int6rchange the inlet and outl€t hoses.Make sure that the hose clamps are secure.a loosen th€ ble6d bolt on th6 engine and r€fillthetadiator and coolant r€servoir with the propsr en_gine coolant mixture (sse section 1O).Tighten the blsed boh when all the trapped air has6sc8p6d and engine coolant begins to flow fromit (see section 1O).a connect all csbles and make sure they 8re properlyadiusted (see pdge 21-271.

21-23

Page 1100 of 1413

and com

it with a

a

a

a

a

4t l\-N

r-

-l/

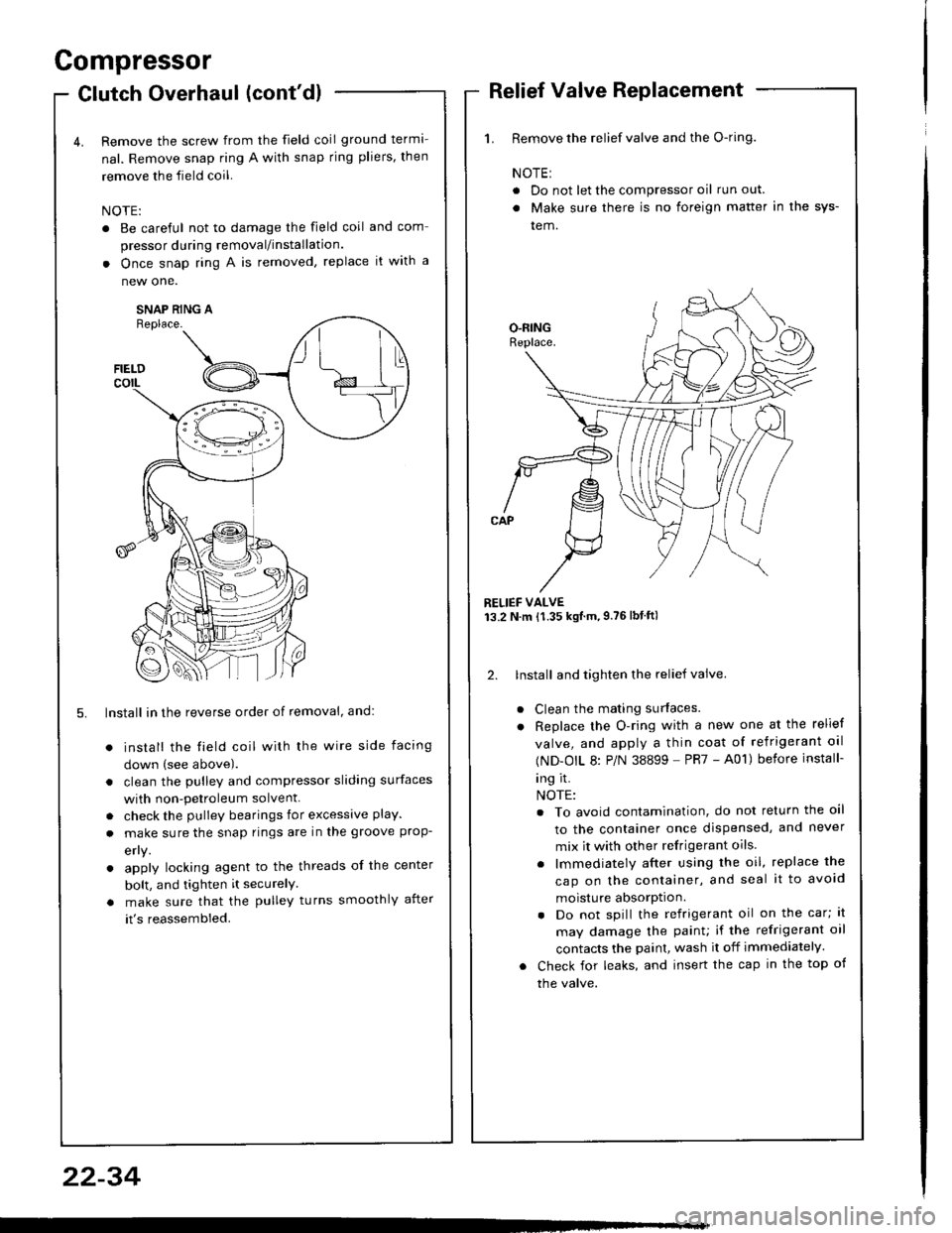

Compressor

Clutch Overhaul (cont'dl

Remove the screw from the field coil ground terma-

nal. Remove snap ring A with snap rjng pliers, then

remove the field coil.

NOTE:

. Be careful not to damage the field coil

pressor during removal/installation.

. Once snap ring A is removed, replace

new one.

SNAP RING AReplace.

FIELDcorL

5. lnstall in the reverse order of removal, and:

install the field coil with the wire side facing

down (see above).

clean the pulley and compressor sliding surfaces

with non-petroleum solvent.

check the pulley bearings for excessive play.

make sure the snap rings are in the groove prop-

efly.

apply locking agent to the threads of the center

bolt, and tighten it securelY

make sure that the pulley turns smoothly after

it's reassembled.

1. Remove the relief valve and the O-ring.

NOTE:

. Do not let the compressor oil run out.

. Make sure there is no foreign matter in the sys-

tem.

RELIEF VALVE13.2 N.m {1.35 kgtm,9.76lbtftl

2. lnstall and tighten the relief valve.

Clean the mating surfaces.

Replace the O-ring with a new one at the relief

valve, and apply a thin coat of refrigerant oal

(ND-OIL 8: P/N 38899 - PR7 - A01) before install-

ing it.

NOTE:

. To avoid contamination, do not return the oil

to the container once dispensed, and never

mix it with other refrigerant oils.

. lmmediately after using the oil, replace the

cap on the container, and seal it to avoid

moisture absorption.

. Do not spill the refrigerant oil on the car; lt

may damage the painu if the refrigerant oil

contacts the paint, wash it off immediately.

Check for leaks, and insert the cap in the top of

the valve.

22-34

Page 1103 of 1413

Condenser

Replacement

RAOIATOR UPPENMOUNT BRACKETS

Recover the relrigerant with a Becovery/Recycling/

Charging System (see page 22-221.

Remove the coolant reservoir,

NOTE: Do not disconnect the reservoir hose from

the coolant reservoir and the radiator.

COOLANT RESERVOIR

Remo.ve the bolts and the radiator upper mount

brackets, and remove the bolt from thg suction hose

bracket.

9.8 N.m {1.0 kgf.m.7.2 lbtftl

'1Iffi

22-37

6x1.0mm9.8 N.m (1.0 kgl.m,7.2 lbt.ft)

......-.....

CONOENSER LINE

Remove the bolts. and disconnect the discharge line

and the condenser line from the condenser.

NOTE: Plug or cap the lines immediately after dis-

connecting to avoid moisture and dust contamina-

tion into the system.

DISCHARGE LINE

Remove the two mounting bolts, then lift out the

condenser as shown.

NOTE: Do not damage the radiator and condenser

fins when removing the condenser.

6x1.0mm9.8 N.m (1.0 kgf.m, 7.2 lbl.tt)

Install in the reverse order of removal. and:

. if you're installing a new condenser, add refriger-

ant oil (ND-OIL 8: P/N 38899 - PR7 - A01) (see

page 22-21t,.

. replace the O-rings with new ones at each fitting,

and apply a thin coat of refrigerant oil {ND-OIL 8:

P/N 38899 - PR7 - A01) before installing them.

NOTE: Be sure to use the right O-rings for HFC-

134a (R-134a) to avoid leakage.

a do not damage the radiator and condenser fins

when installing the condenser,

. be sure to install the condenser mount cushions

securely into the holes.

. charge the system (see page 22-39) and test its

performance (see page 22 24!�.

Page 1110 of 1413

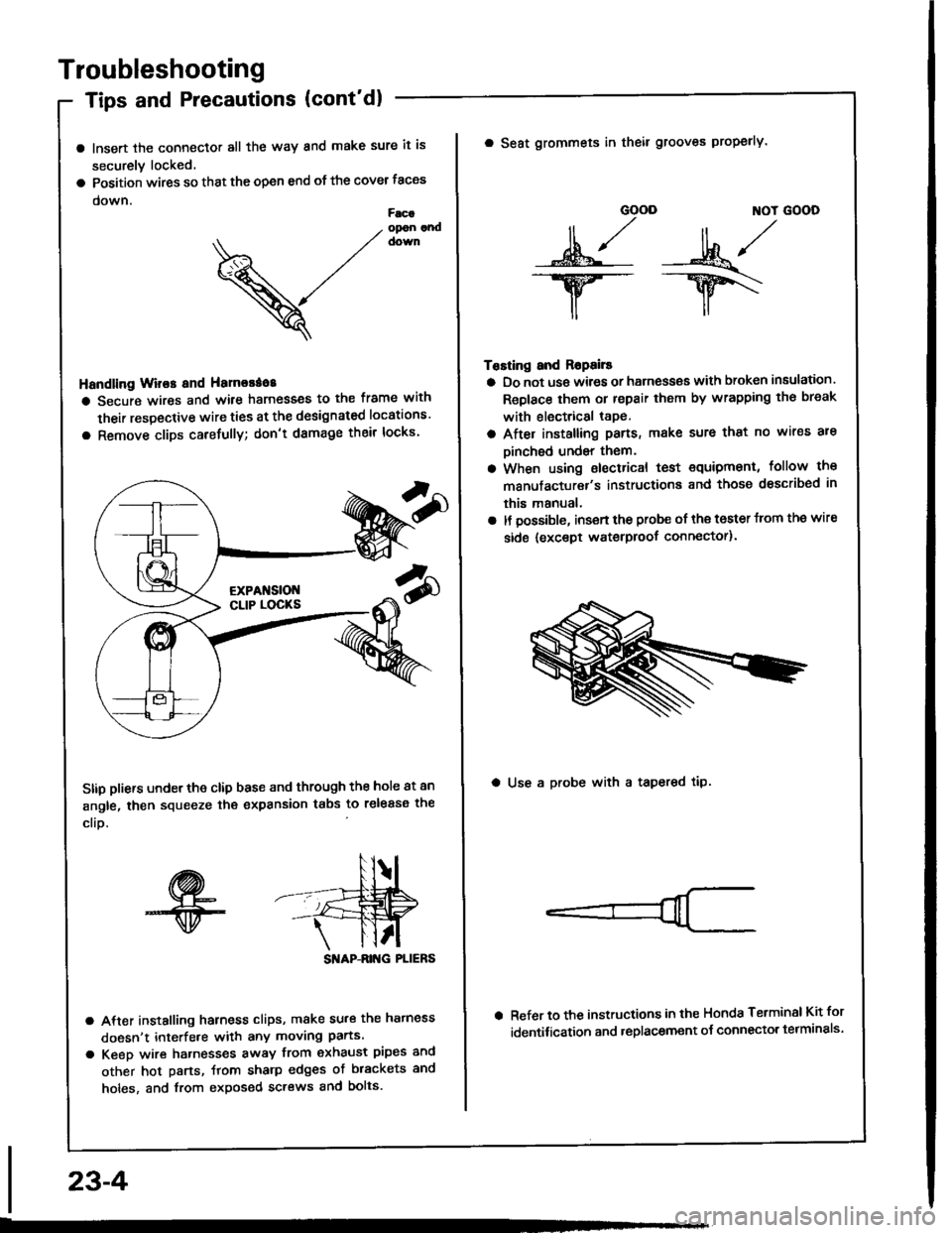

Troubleshooting

Tips and Precautions (cont'dl

a lnsert the connector all the way and make sure it is

securely locked.

a Position wires so that the open end of the cover taces

down.Facaopon andcown

V

Handling Wir€s and Hamorao8

a Secure wires and wile harnesses to the frame with

their respective wire ties at the designated locations'

a Remove clips carefully; don't damage their locks'

Stip pliers under the clip base and through the hole at an

angle, then squeeze the expansion tabs to release the

clio.

SI'IAP-ANG PLIERS

a After installing harness clips, make su.€ the hatness

doesn't interfe.e with any moving parts.

a Keeo wire hatnesses away from exhaust pipes and

other hot parts, ftom sharp edges of brackets and

holes, and from exposed screws and bolts.

23-4

GOOD ]TOT GOOD

n,/r/ll ,,' ll ,,

s*j -:ut*/-.w-- --ry\

il,,

Tosting and Ropails

a Do not us€ wires or harness€s with broken insulation.

Replace them or repair them by wrapping th€ break

with electrical tape.

a After installing pans, make sure that no wir€s are

Dinched undsr them.

a When using electrical test €quipment, follow the

manufacturer's instructiona and those dsscribed in

this manual,

a It possible, insert the probe of the toster from the wire

side {except waterproof connector).

a Seat grommets in theil grooves properly.

a Use a probe with a tapered tip.

Refer to the instructions in the Honda Terminsl Kit for

identification and .eplacement o{ connector telminals'