harness HONDA INTEGRA 1994 4.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 460 of 1413

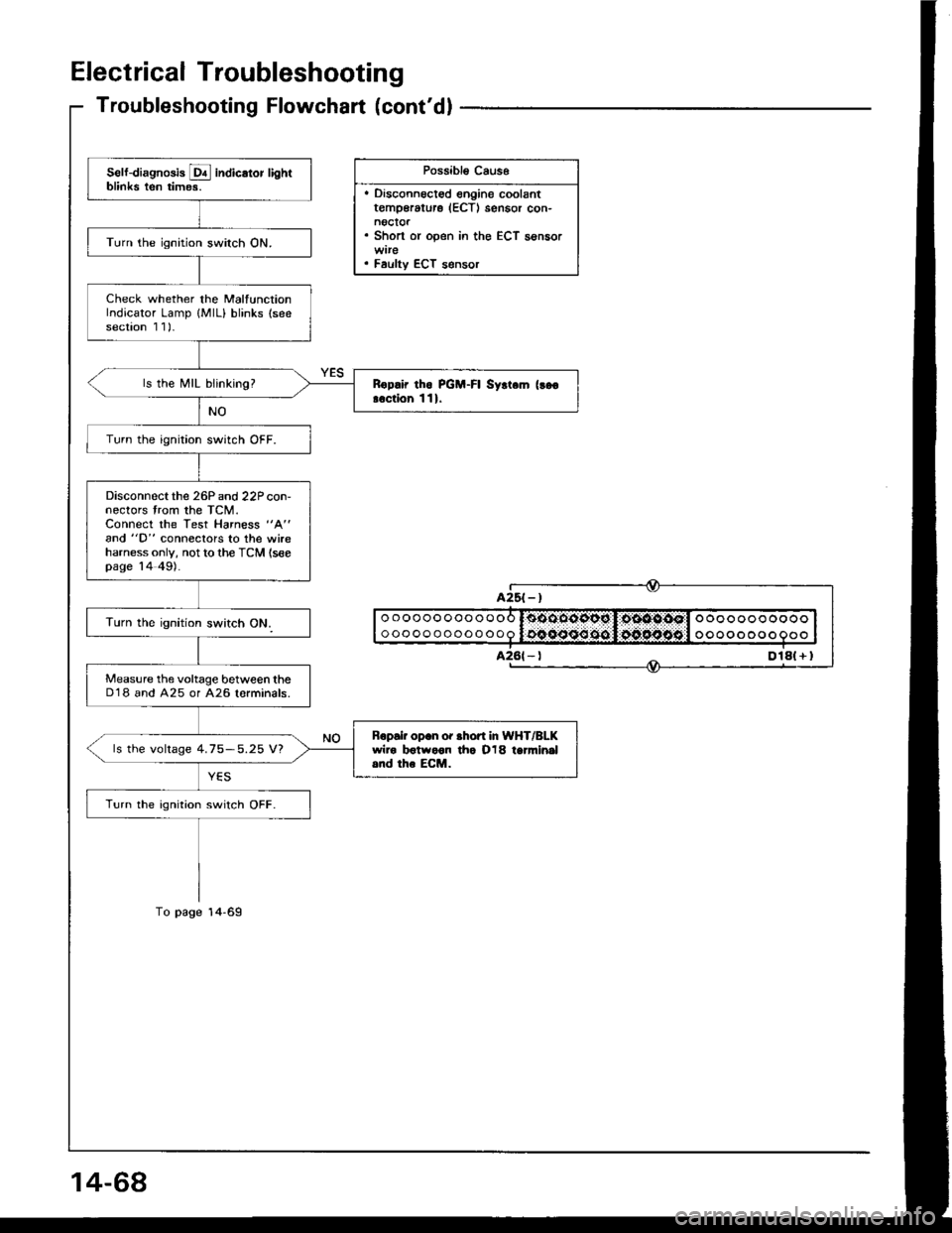

Electrical Troubleshooting

Troubleshooting Flowchart (cont'dl

Possibl€ Caus6

. Disconnoct€d engine coolantt€mp€rature (ECTI sensor con-noctor. Short or open in the ECT sensor

. Faulty ECT s€nsor

Self-diagnosis E indicator lightblinks ten times.

Turn the ignition switch ON.

Check whether the MalfunctionIndicator Lamp {MlL} blinks (seesection 1 1)-

ls the MIL blinking?Rop.ir tho PGM-FI Syrt.m (!go

!.ction 111.

Turn the ignition switch OFF.

Disconnectthe 26P and 22P con-nectors trom the TCM.Connect the Test Harness "A"

and "D" conneclors to the wireharness only, not to the TCM (seepage 14 49).

Measure the voltage between theD'18 and A25 or A26 lorminals.

Bopair op.n or .hofi In WHT/BLKwiro botwoon tho O18 tanni.|al.nd the ECM.ls the voltage 4.75-5.25 V?

Turn the ignition switch OFF.

oooooooooooo

ooooooooooooooooooooooo

oooo o oo o

Dlal + I

Page 463 of 1413

Disconnect lhe 26Pand 22P con-nectors trom the TCMConnect the Test Hahess "A"

and "D" connectors to the wireharness only, not to th€ TCM {seepare'14-49).

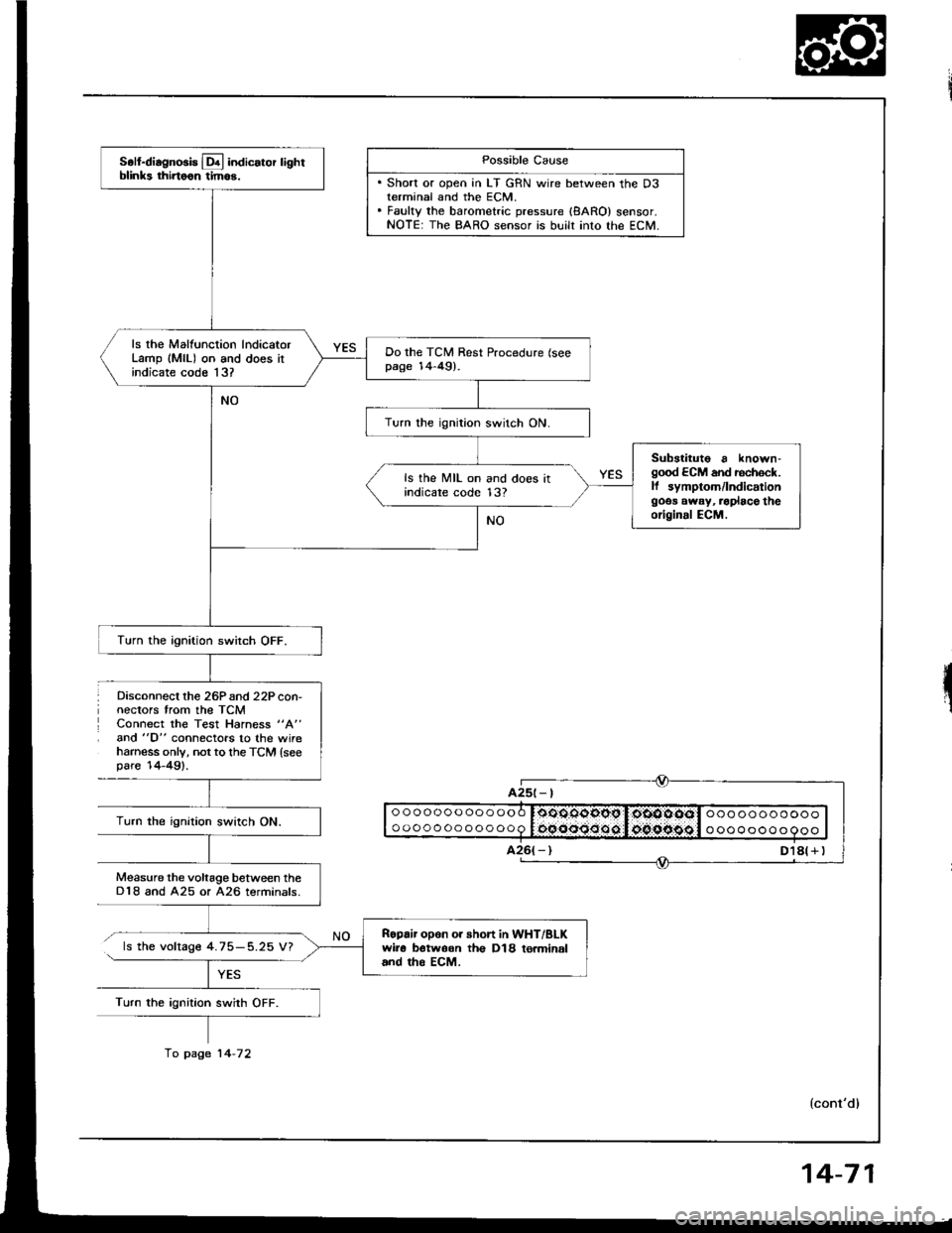

Possible Cause

. Short or open in LT GRN wire between the D3terminal and the ECM.. Fauky the barometric pressure {8ARO} sensor.NOTE: The BARO sensor is built into lhe ECM.

ooooooooooooo

oooooooooooo0oOOqgopg I,oiOOOOol ooo ooooooooooocqooo:Joo.oipggl o oooooo o 9ooTurn the ignition swirch ON.

Measure the voltage between theD18 and A25 or A26 terminals.

ls the voltage 4.75-5.25 V?

Turn the ignition swith OFF.

A25t- |

Soll-diagnosis Lq! indicator lightblinks thirtoon tim6.

ls rhe Malfunction lndicatorLamp (MlL) on and does itindicate code 13?

Do the TCM Rest Procedure (seepage 14-49).

Turn the ignition switch ON.

Substituto a known-good ECM and rechock.ll symptom/lndicationgoos away, .oplace theoriginal ECM.

ls the MIL on and does itindicare code 13?

Turn the ignition switch OFF.

Ropair opon or short in WHT/BLKwir6 botwoon th€ D18 to.minaland tho EcM.

fo page 14-72

14-71

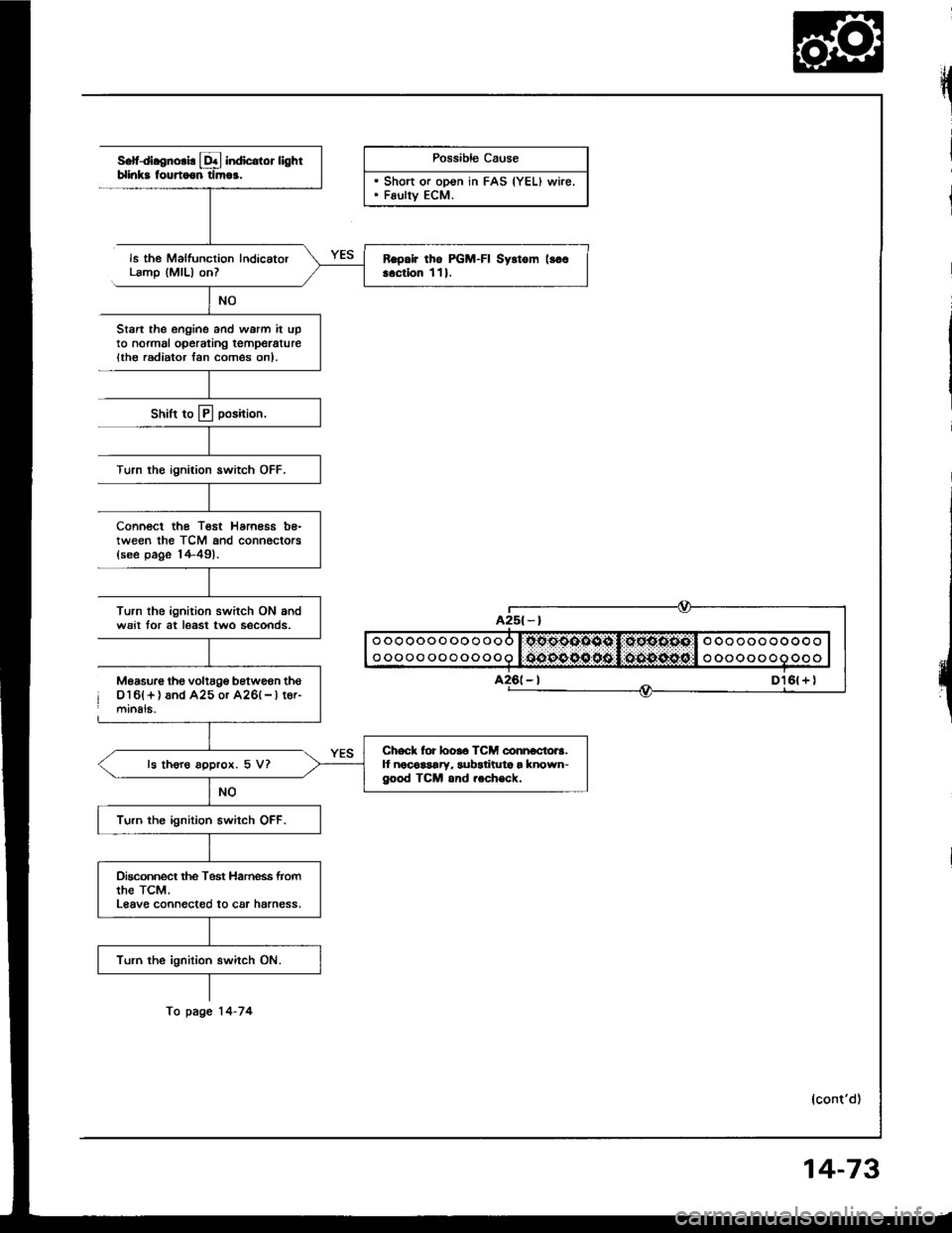

Page 465 of 1413

S.fdl.enorl! L&l indicdor lighlblinks fourtoon tlmoa.

ls the Malfunction IndicatorLamp (MlL) onl

Stan the ongine and warm it upto normal operating temperature{th€ radiator lan com€s on).

Shift to E position,

Turn rhe ignition switch OFF.

Possible Cause

. Sh"rt ". "e"" i" FAS |YEU ,"rirt. Fsulty ECM.

Connect the Test Harness be-tween the TCM and connociors{see page 14-491.

Turn the ignition switch ON andwsit for at least two seconds.

o oooooo ooo ooo l.tto.oodooo l:,gEoo.ottl o ooooo oooo o

o oooo oooooooo l:OOOO OO 60 l.,OO{tO.O6,'l o oooooooooo

Measure lhe voltage betwgan thso16l+ ) and A25 or A26(- | tor-mrnals.

lcont'd)

Ropair tho PGM-FI Syrtom lloo..ctlon 111.

Chock for looro TCM connoctora.lf noco$ary, subatituta a known-good TCM and .ech€ck.ls thoro approx. 5 V?

Turn the ignition switch OFF.

Dkconnect the Test Harness fromthe TcM.Leave connect€d to car harness.

Turn the ignition switch ON.

fo page 14-74

14-73

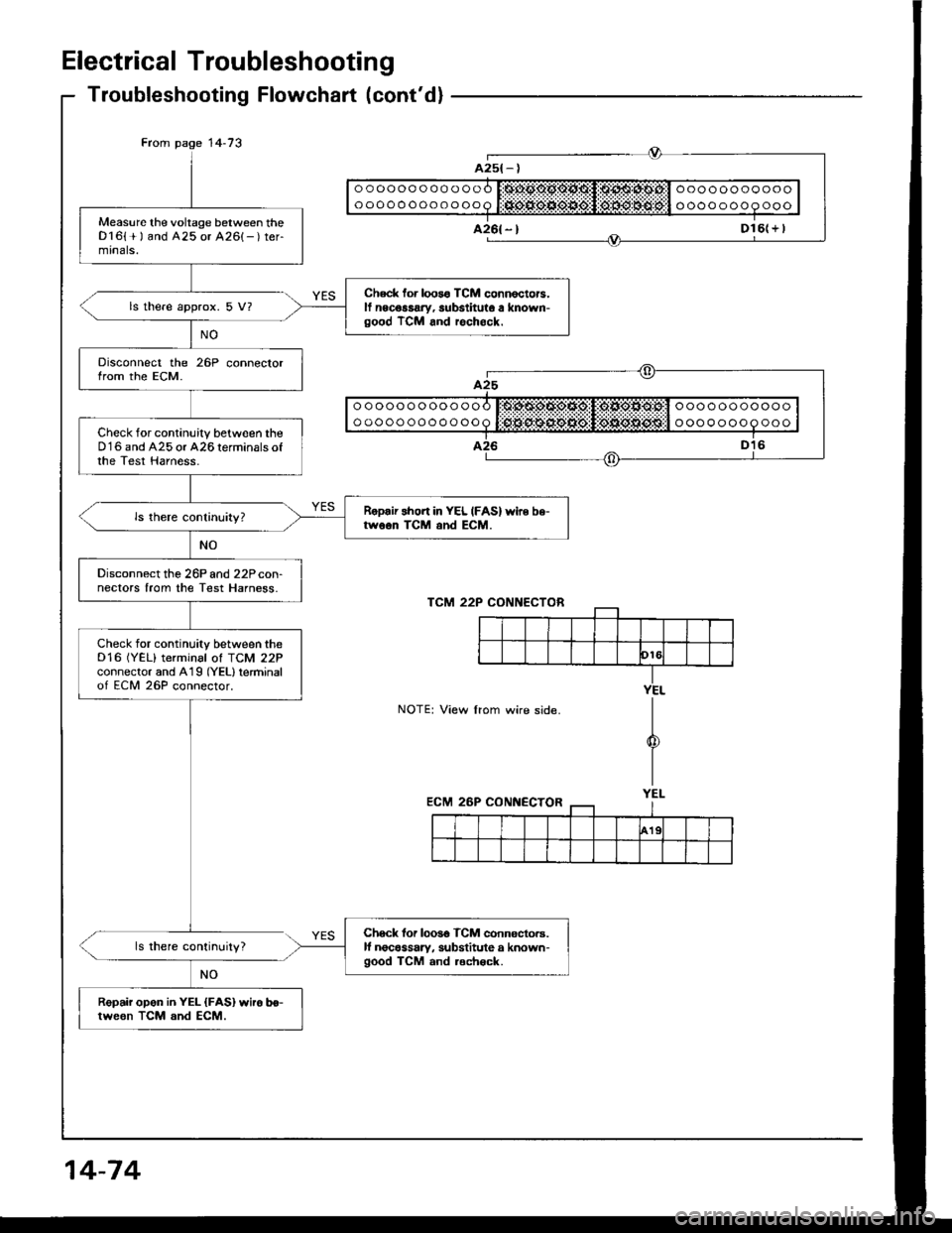

Page 466 of 1413

Electrical Troubleshooting

Troubleshooting Flowchart (cont'd)

ls there continuity?

o o o o o o o o O o O o O $:O.COOtt9O$:l:OtO:CtOiOi:l O o O O O O o O o o Oo o o o o o o o o o o o O I:f(O.{iltltO{t{t:I:OFA:F:d:O:l o o o o o o o O o o o

NOTE: View lrom wire side.

NO

From page 14-73

Measure the voltage between theD 16{+ ) and A25 or A26{- ) ter-mtnals.

Check for loos€ TCM connoctors.ll ngcossary, substituto a known-good TCM and rechock.

ls there approx. 5 V?

Disconnect the 26P connectorfrom the ECM.

Check for continuitv between theD16 and A25 or A26 rerminals ofthe Test Harness.

Ropairshort in YEL IFAS) wire be-tw6on TCM and ECM.

Disconnect the 26P and 22P con-nectors from the Test Harness.

Check for continuity between theD16 (YEL) terminal ot fCM 22Pconnector and A19 (YEL) terminalof ECM 26P connector.

Chgck tor loos€ TCM connoctofs.lf nocassary, substitute o known-good TCM and rech6ck.

Ropair opon in YEL {FAS} wiro bo-trve€n TCM and ECM.

oooooooooooo

oooooooooooo

ooooooooooo

ooooooooooo

22P CONNECTOB

Page 467 of 1413

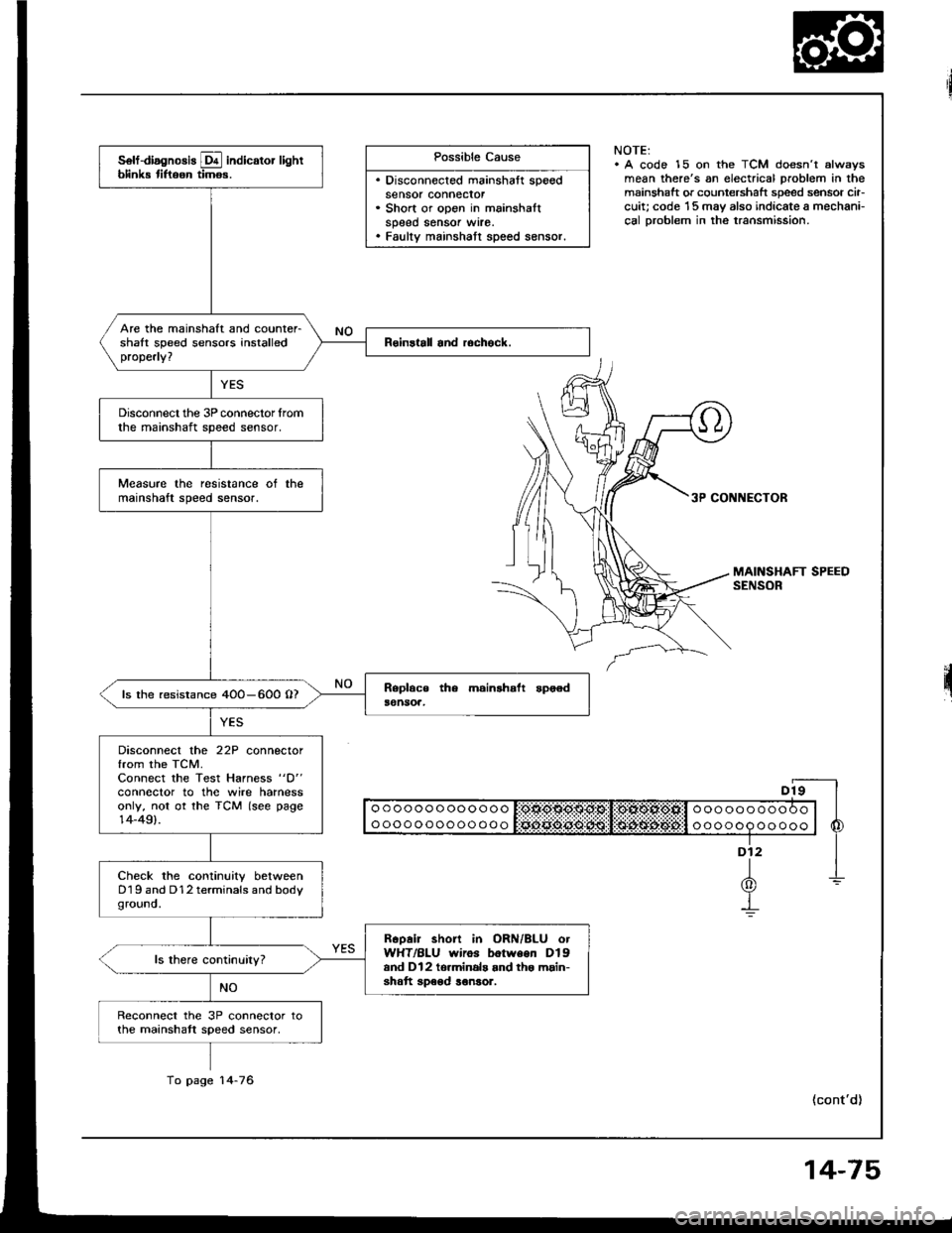

Possible Cause

. Disconnected mainshaft speedsensor connecror. Short or open in mainshaltspeed sensor wrre.. Faulty mainshatt speed sensor.

NOTE:. A code 15 on the TCM doesn't alwsysmean there's an electrical problem in themainshaft or countershaft speed sensor cir-cuit; code '15 may also indicate a mechani-cal Droblem in the transmission.

3P CONNECTOR

II o o o o o o o oo o o o o I:OtlO$O$g:Sl!:OlXOl*Ofill o o o o o o o o o O o | |

I ooooooooooooo l Sciii:ddii:ijii:l:i$idi$;d6#:l o oooop oo ooo | 6

"-f

1-L(0)Y-!

(cont'd)

solf-diagnosis E indicator lightblink tiftoon timos.

Are the mainshaft and counter-shalt speed sensors installedproperly?

Disconnect the 3P connector lromthe mainshaft speed sensor.

Measure the resistance ot themainshaft speed sensor.

ls the resistance 4OO-600 O?

Disconnect the 22P connectorfrom the TCM.Connect the Test Harness "D"

conneclor to the wire harnessonly, not ot the TCM (see page14-49).

Check the continuity betweenD19 and D12 terminals and bodyground.

Rcoair short in ORN/BLU otWHT/BLU wiros botween Dlgand Dl2 to.minals and tho main-shatt speod ronsor.

Reconnect the 3P connector tothe mainshatt speed sensor,

To page 14-76

14-75

Page 469 of 1413

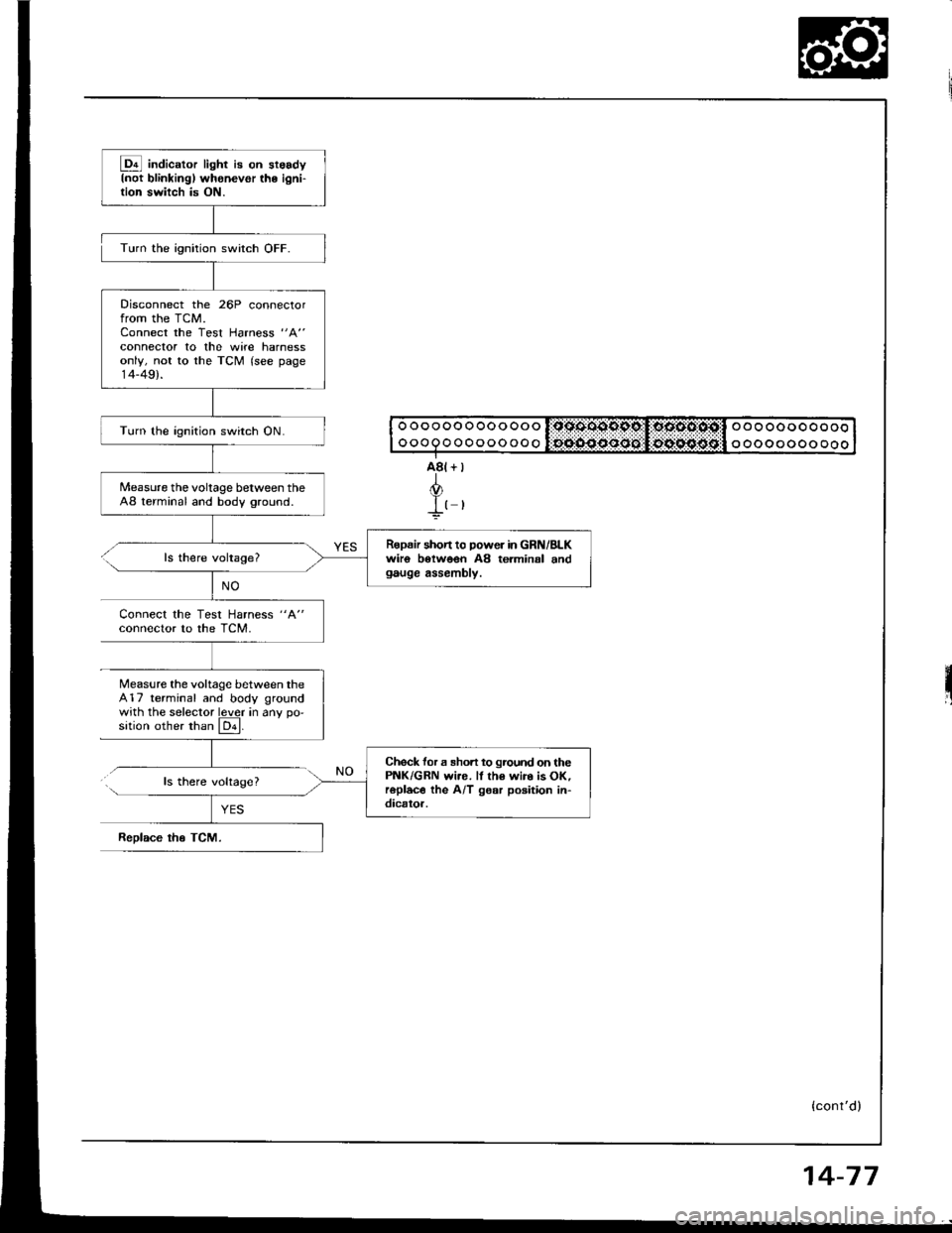

@ indic"to, light i8 on st6sdyInot blinkingl whenevor the ioni-tion switch is ON.

Disconnect the 26P connectorfrom the TCM.Connect the Test Harness "A"

connector to the wite harnessonly, not to the TCM (see page14-49).

Turn the ignition switch ON.

Measure the voltage between theA8 terminal and body ground.

Ropair shon to power in GRN/BLKwiro botwoen A8 terminal andgauge assembly.

Check for a sho.t to ground on thePNK/GRN wi.e. ll th€ wir. is OK,roplac€ the A/T gear poaition in-dicator.

Turn the ignition switch OFF.

ls there voltage?

Connect the Test Harness "A"

conneclor to the TCM.

Measure the voltage between the417 terminal and body groundwith the selector lever in anv oo'sition other than El.

ls there volrage?

ReDlace tho TCM.

o o o o oo o oo o oo o l:qssoo9pc,I:oocto:osil o o o oo o o o o oooooQoooooooooo oo o oooo ooo

{cont'd)

14-77

Page 470 of 1413

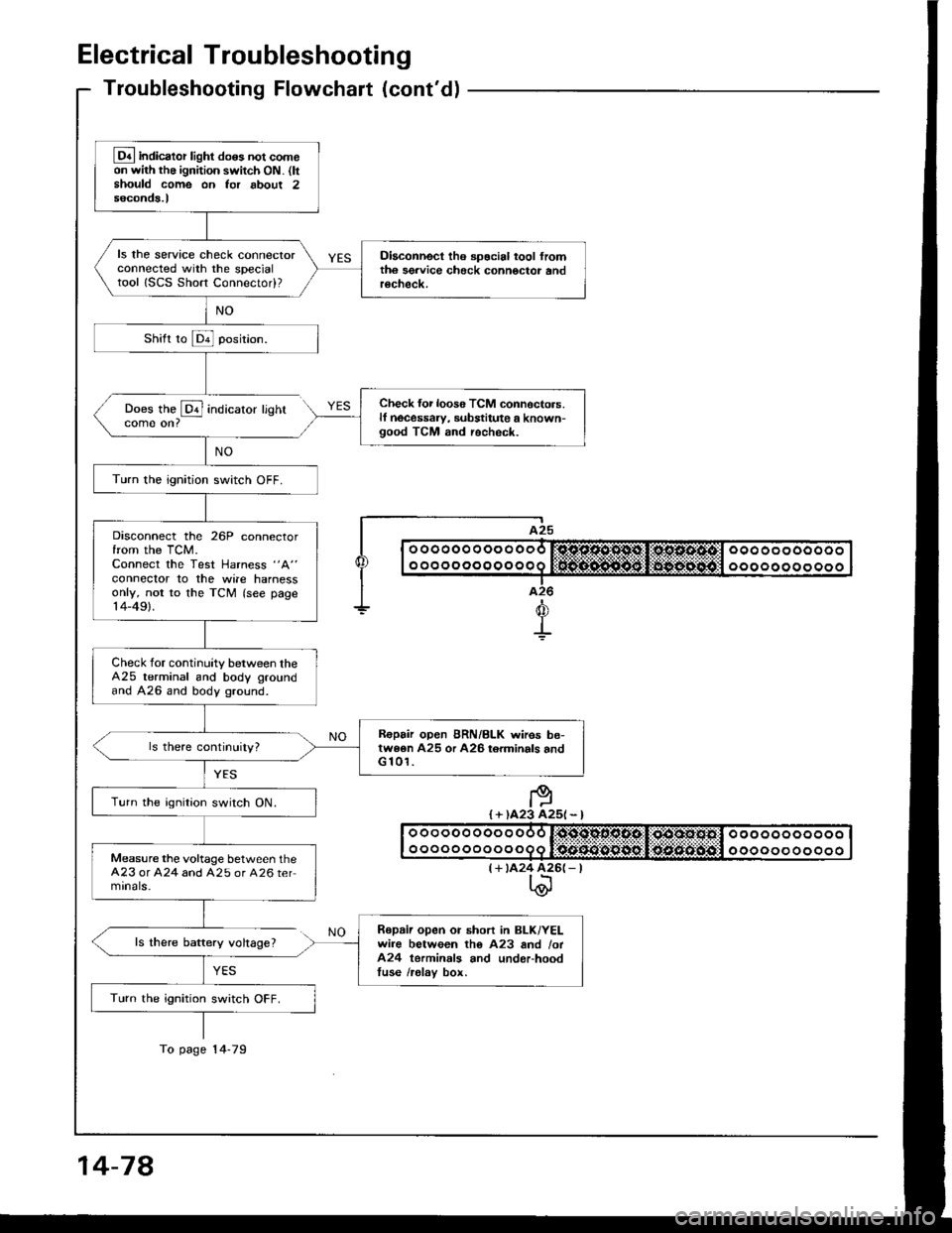

Electrical Troubleshooting

Troubleshooting Flowchaft (cont'dl

Does the @ indicatorcome on?

ls there baftery voltage?

YES

lighr

I A25

| | o ooooo o oo o ooo r:sjc.o.sl'1*st,li*os.s.4tcl ooo oo oooooo I

I I o o o o o o o o o o o o q lifrif.S..n${5git:li$gg-:aiiigitll o o o o o o o o o o o I|--.-T..-I a26

+d

+

I + )A23 A25l - l

(+ tA24 426(- |t\@

Lq4 indicator light do6s not comeon with the ignition switch ON. (ltshould come on Ior about 2seconds.l

ls the service check connectorconnected with the specialtool ISCS Short Connectod?

Diaconnect tho spocial tool fromth6 sgrvice check connoctor andrecheck.

Check {or loos6 TCM connoctors.lf necessaw, substitute a known-good TCM and recheck.

Turn the ignition switch OFF.

Disconnect the 26P connectorfrom the TCM.Connect the Test Harness "A"

conneclor to the wile harnessonly, not to the TCM (see page14-49).

Check for continuity between theA25 terminal and body groundand A26 and body ground.

R€pair open BRN/BLK wires be-twe6n A25 or A26 torminals andG 101.

Turn the ignition switch ON.

Measure the voltage between theA23 or A24 and A25 or A26 termrnals-

Repaii open or short in BLK/YELwire between tho A23 and /ot424 terminals and underhoodtuse /relav box.

Turn the ignition switch OFF.

To page 14-79

14-78

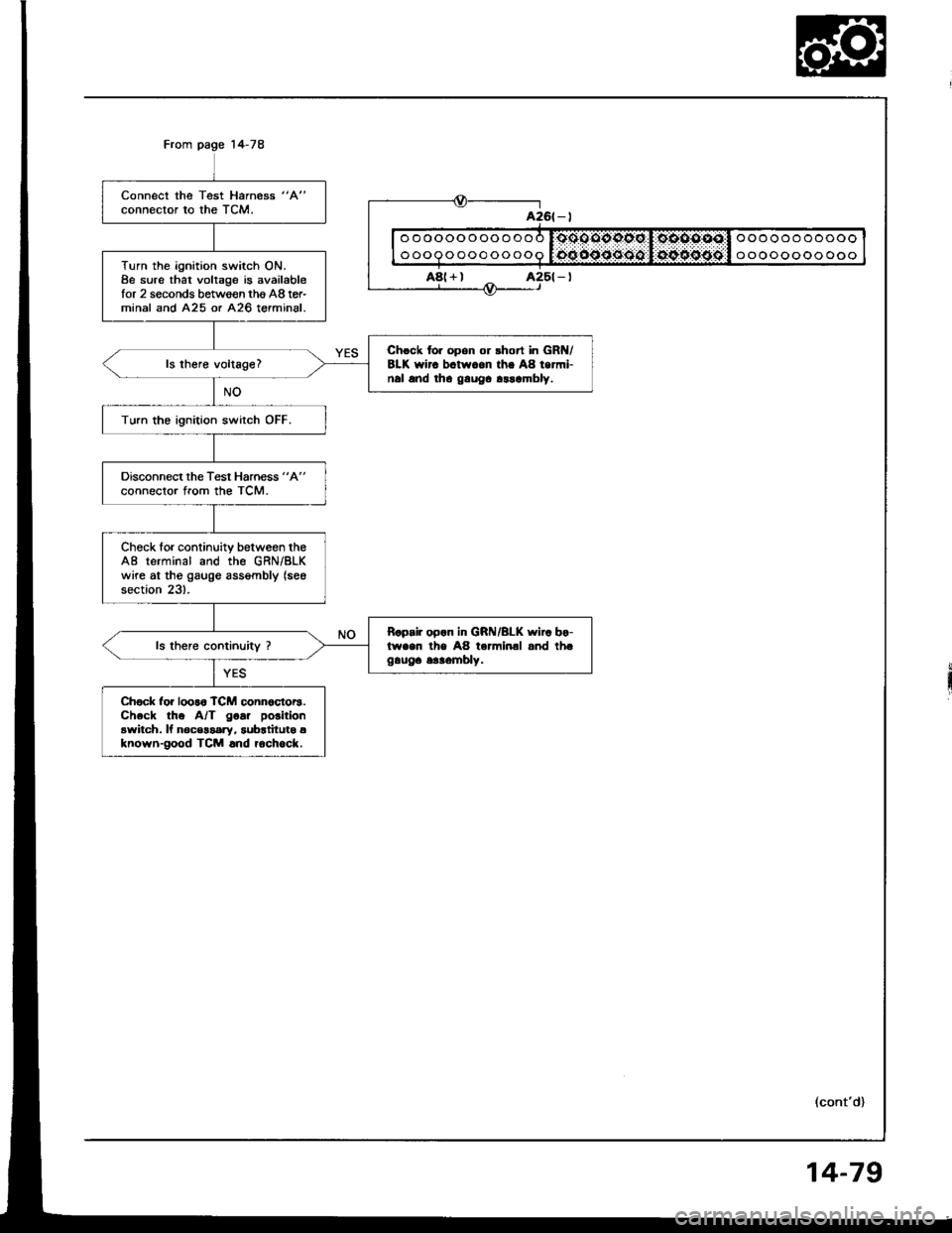

Page 471 of 1413

Connect the Test Harness "A"

connector to the TCM.

Turn the ignition switch ON.8e sure that voltage is availablefor 2 seconds between thg A8 tor-minal and A25 or A26 terminal.

Chrck for opon or rhort in GR /8LK wirc bctw.on th. A8 termi-nal and tha gauOa arrambly.

Turn the ignition switch OFF.

Disconnect the Test Harness "A"

connector from the TCM.

Check for continuity between theA8 terminal and the GRN/BLKwire at tho gaugo assgmbly (see

section 23).

B.p.ir op.n in GRI{/BLK wi.. bo-lwaen the A8 terminal and th.gauga 6aaombly.

Ch€ck for loor6 TCM conn6ctor3.Check the A/T goa. polition

awitch. ll noc€$ary, subrtitutg aknown-good TCM .nd rochock.

ooooooooooo

ooooooooooo

oooooooooooo

oooooooooooo

a26t - |

A8(+)

(cont'd)

14-79

Page 473 of 1413

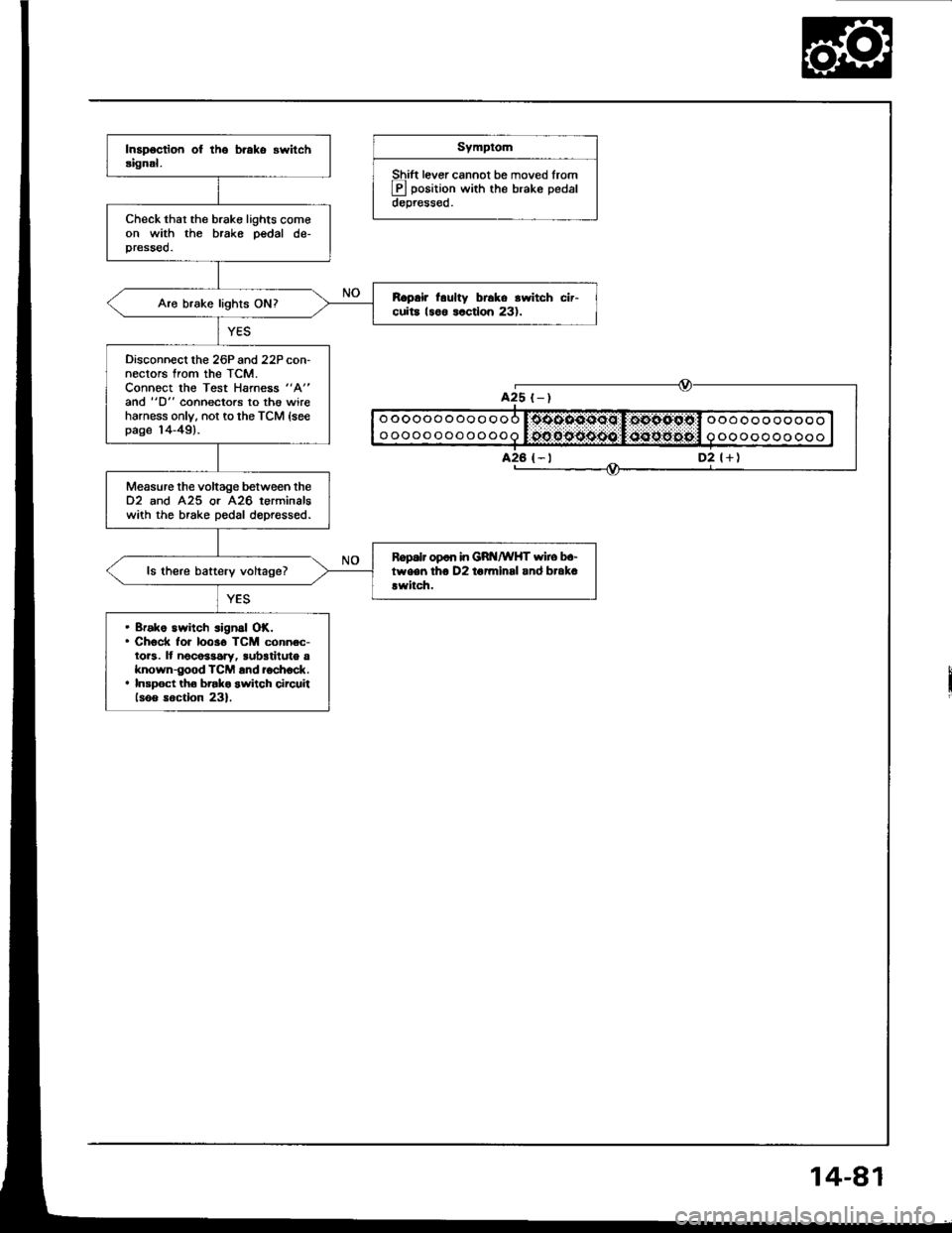

Symptom

Shift lever cannot be moved lrom

E position with the brake pedaldepressed.

Check thar the brake lights comeon with the brake pedal de-pressed.

R.prir l.ulty br6ko rwitch cir-cuita 18o6 lactlon 231.Aro brake lights ON?

Disconnecl lhe 26P and 22P con-nectors from the TCM.Connoct the Test Harness "A"

and "D" coonectors to th€ wireharness only, not to the TCM {seepage 14-49).

Measure the voltage between the02 and 425 or A26 terminalswith the brake pedal dopressed.

Ropalr op6n in GRt{/wHT wiro b.-tween tho D2 to7minsl and brak.!witch.ls there battery voltage?

. Bfako switch signal OK.. Check for 10036 TCM connec-tors. It noco$ary, sub3tiluto aknown-good TCM and ioch6ck.. Insp6ct tho brako switch circuiilsoo soction 23).

oooooooooooo

oooooooooooo

ooooooooooo

oooooooooo

A25 t-)

D2 l+)

Page 476 of 1413

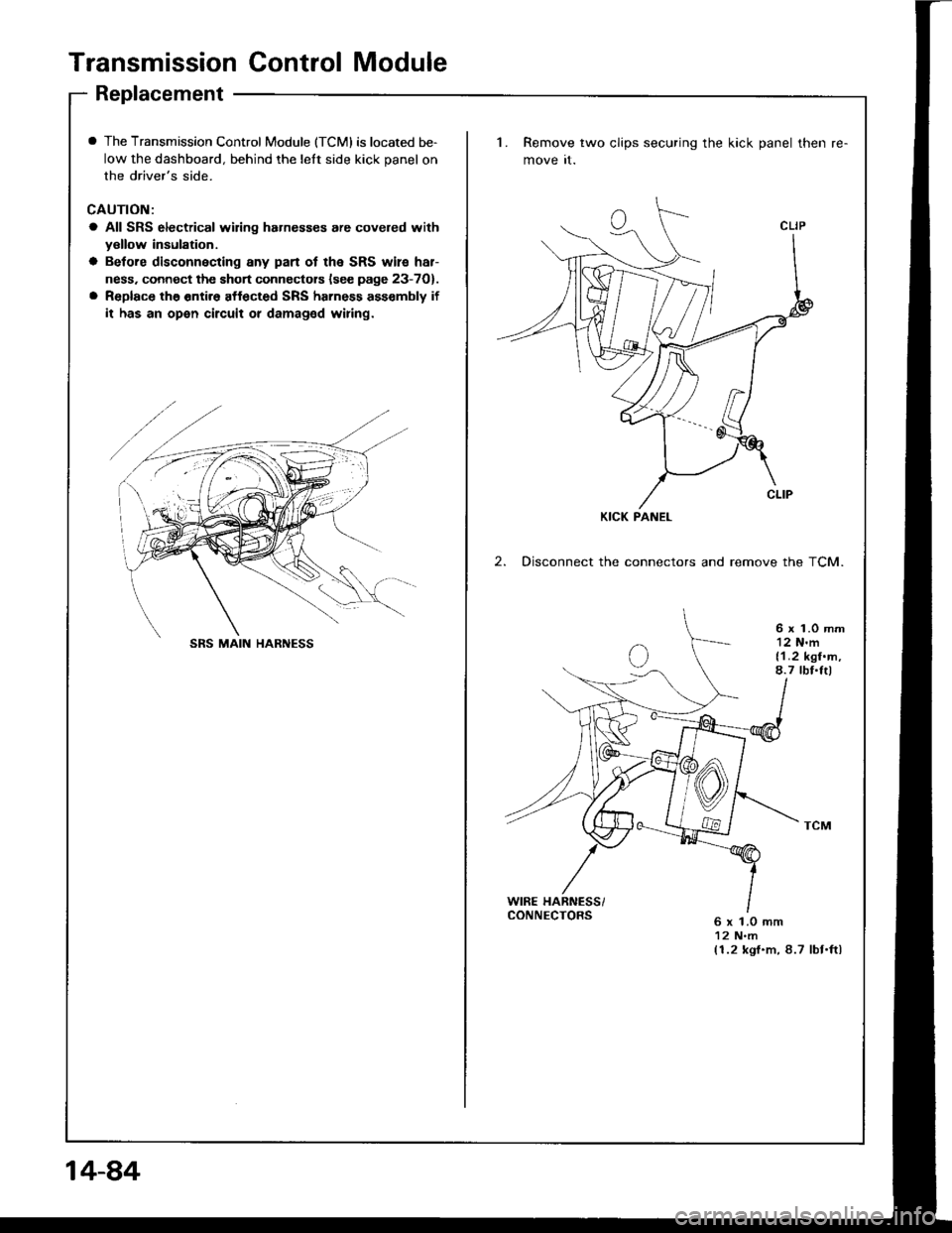

Transmission Control Module

Replacement

I The Transmission Control Module (TCMI is located be-

low the dashboard, behind the lelt side kick panel on

the driver's side.

CAUTION:

a All SRS electrical wiring hahesses are covered withyellow insulation.

a Betore disconnecting any pan ot the SRS wile har-

ness. connect the short connectors lsee page 23-7O).

a Replace the entir6 affected SRS harness ass€mbly if

it has an open circuit or damaged wiring.

1. Remove two clips securing the kick panel then

move it.

2. Disconnect the connectors and remove the TCM.

6 x 1.0 mm12 N'm{1.2 kgf.m,8.7 tbf.Itl

WIRE HARNESS/CONNECTORS6 x 1.0 mm12 N.m(1.2 kgf.m, 8.7 lbt.ftl

KICK PANEL

SRS MAIN HARNESS

14-84