torque HONDA INTEGRA 1994 4.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 505 of 1413

![HONDA INTEGRA 1994 4.G Repair Manual Torque Gonverter Housing/Valve Body

Removal

\LOCK-UP VALVE llB.DY\u

Bolts, 7

DOWEL PIN

otLFEEDPIPES

A

Ll

ll|i

|]V

OII- FEED PIPES

LOCK-UP SEPARATORPI.ATE

TOR COVER

OIL FEEO PIPE

8oll3.3

ATF STRAINER

S HONDA INTEGRA 1994 4.G Repair Manual Torque Gonverter Housing/Valve Body

Removal

\LOCK-UP VALVE llB.DY\u

Bolts, 7

DOWEL PIN

otLFEEDPIPES

A

Ll

ll|i

|]V

OII- FEED PIPES

LOCK-UP SEPARATORPI.ATE

TOR COVER

OIL FEEO PIPE

8oll3.3

ATF STRAINER

S](/img/13/6067/w960_6067-504.png)

Torque Gonverter Housing/Valve Body

Removal

\LOCK-UP VALVE llB.DY\u

Bolts, 7

DOWEL PIN

otLFEEDPIPES

A

Ll

ll|i

|]V

OII- FEED PIPES

LOCK-UP SEPARATORPI.ATE

TOR COVER

OIL FEEO PIPE

8oll3.3

ATF STRAINER

SERVO DETENTBASEREGULATOR VALVEAODY

OIL FEED PIPES

DOWEL PIN

OIL PUMP DRIVEN GEAR SHAFT

OIL PUMP DRIVEN

SECONDARY VALVEBODY

DOWEL PIN

SECONDARY SEPARATORPLATE

SUCTION PIPECOLLAR

MAIN S€PARATORPLATE

ft-- rrr urcler

TOROUE CONVERTERHOUSING

8olts, 4 Boll

MAIII VALVEBODY

14-114

Page 506 of 1413

NOTE:

a Clean all parts thoroughly in solvent or carbuetor

cleaner and dry with compressed air.a Blow out all passages.

a When removing the valve body replace the following:. O-rings. Lock wsshers

1 . Remove the oil feed pipes from the servo body, s€r-

vo detent base, accumulatof cover, lock-uD valve

body and main valve body.

2, Remove the three bolts securing the ATF strainer and

servo detent base, then remove them.

3. Remove the three bolts securing the accumulator

cover. then remove the accumulator cover.

4. Remove the six bolts secu.ing the servo body, then

remove the servo body and separator plate.

5. Remove the bolt securing the secondary valve body,

then remove the secondary valve body and separa-

tor plate.

6. Remove the eight bolts securing the lubricator plate

and lock-up valve body, then remove the lubricatorplate, lock-up valve body and separator plate.

7. Femove the bolt securing the.egulator valve body,

then.emove the regulator valve body.

8. Remove the stator shaft and stopper shaft.

9. Remove the detent spring t,om the detent arm. thenremove the control shaft from the torque convenerhousing.

1O. Remove the detent arm and detent afm shaft t.om

the main valve bodv.

1 1 . Remove the four bolts secu.ing the main valve body,then remove the main valve body.

12. Remove the oil pump driven gear shaft, then remove

the oil pump gears.

'13. Remove the main separator plate with two dowelDtns.

14, Remove and clean the ATF magnet.

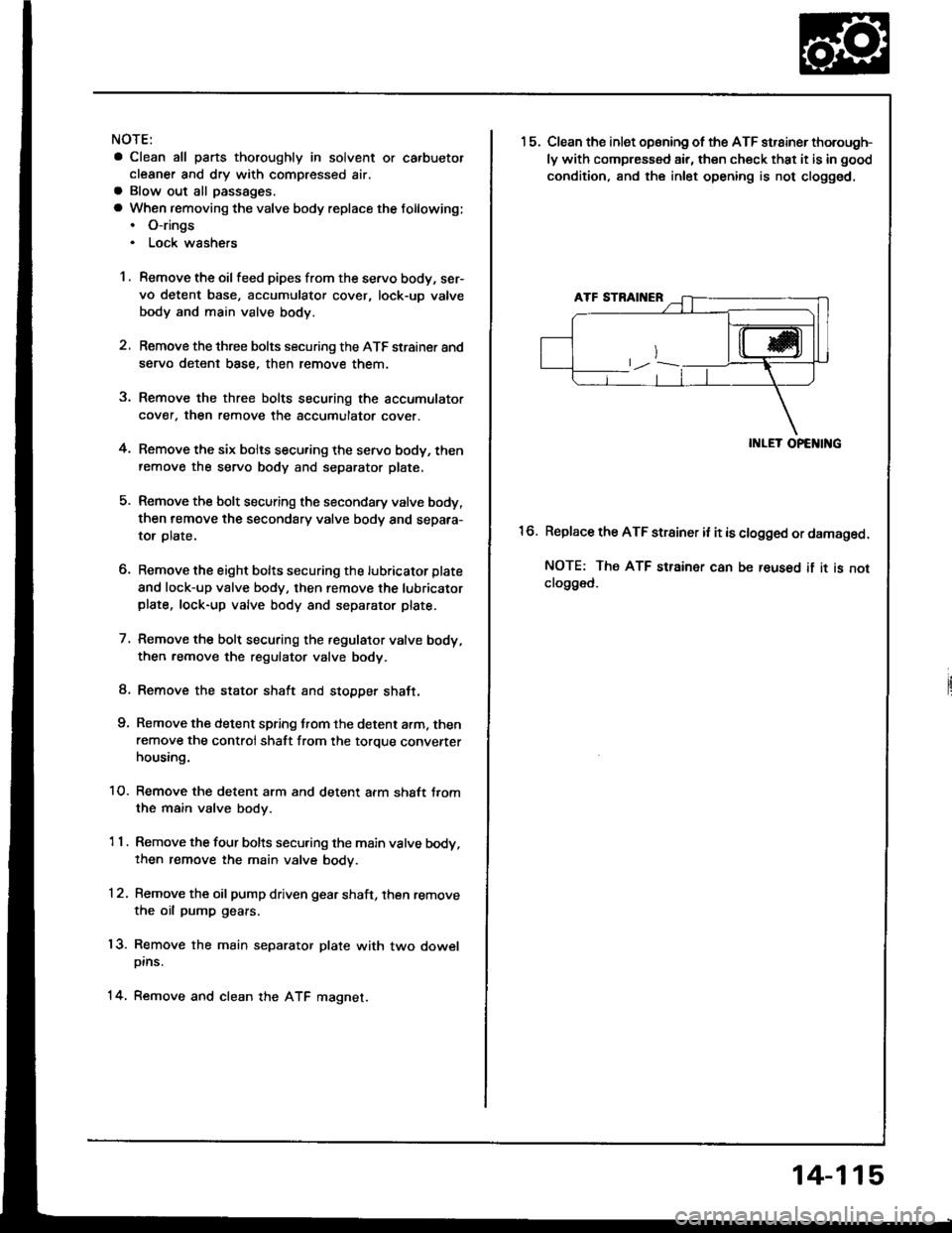

15.Clean the inlet opsning of the ATF strainer thorough-

ly with compressed air, then check that it is in good

condition, and the inlet opening is not clogged.

II{LET OPENING

Replace the ATF strainer it it is clogged or damaged.

NOTE: The ATF strainer can be reused if it is notclo9ged.

16.

14-115

Page 513 of 1413

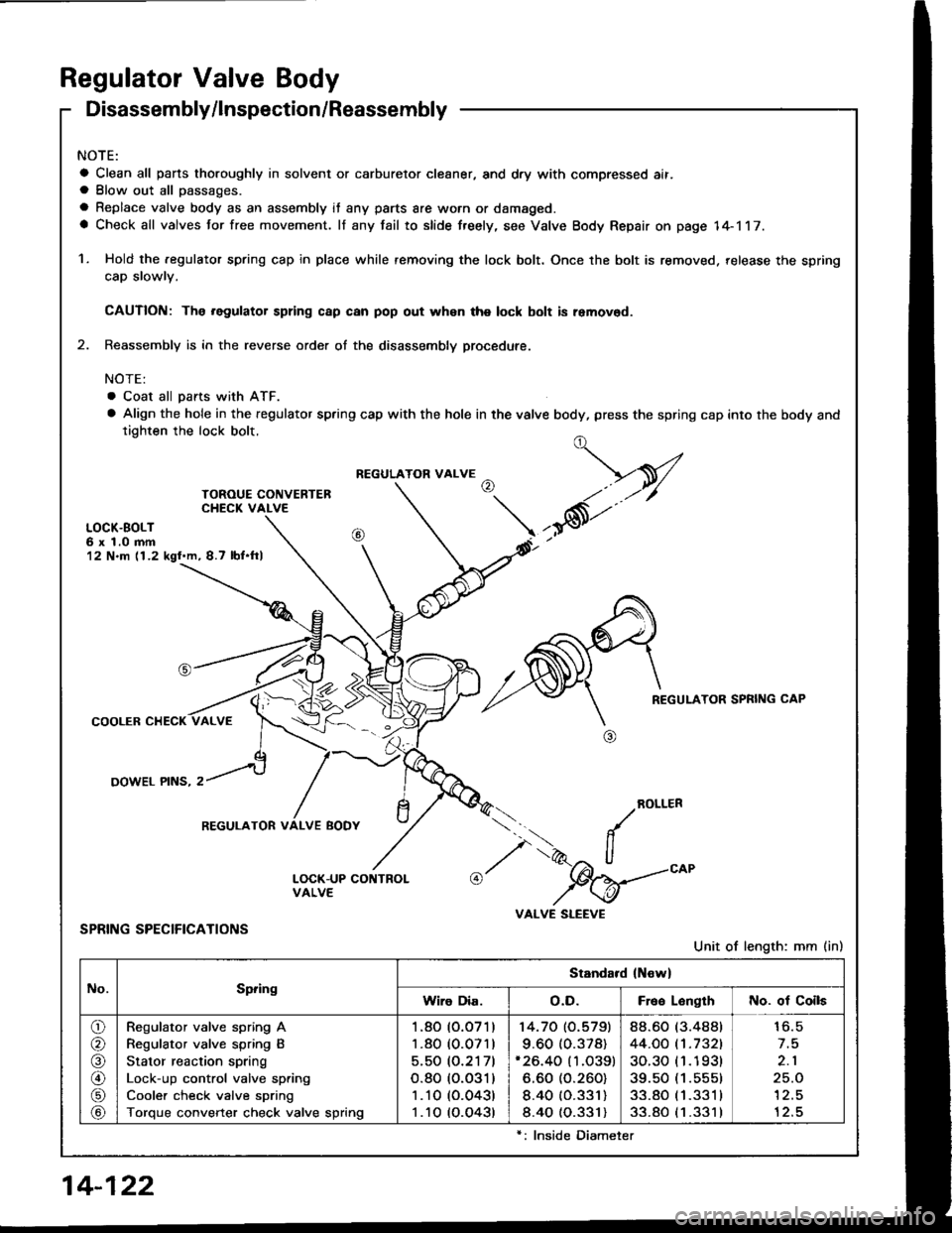

Regulator Valve Body

Disassembly/lnspection/Reassembly

NOTE:

a Clean all pans thoroughly in solvent or carburetor cleaner, and dry with compressed ait.a Blow out all passages.

a Replace valve body as an assembly it any parts are worn or damaged.a Check all valves for free movement. lf any fail to slide freely, see Valve Body Repair on page 14-117.

1. Hold the .egulator spring cap in place while removing the lock bolt. Once the bolt is removed. release the spring

cap slowlv.

CAUTION: The .egulator spring c8p can pop out whsn the lock bolt is removod.

2. Reassembly is in the reverse order of the disassembly procedute.

NOTE:

. Coat all pans with ATF.

a Align the hole in the regulator spring cap with the hole in the valve body, press the spring cap into the body andtighten the lock bolt.

LOCK.BOLT6 x 1.0 mm12 N.m (1.2 kgl.m, 8.7 lbf.ftl

REGULATOR SPRING CAP

COOLER CHECK

OOWEL PINS, 2

ROLLER

SPRING SPECIFICATIONS

Unit of length: mm (in)

../

I',.-2" ll"%=

VALVE SLEEVE

t,-V

,*6t'"

REGULATOR VALVE

REGULATOR VALVE BODY

No.Spring

Standard (New)

Wiro Dia.o.D.Free LonglhNo. of Coils

o/a

@

\9/

Regulator valve spring A

Regulator valve spring B

Stator reaction spring

Lock-up control valve spring

Cooler check valve spring

Torque converter check valve spring

1.80 (O.O71)

1.80 (0.071)

5.50 (O.2171

o.80 (o.o31)

1 .10 (0.043)

1 .10 (O.O43t

14.70 (O.5791

9.60 (0.378)'26.40 (1.O39)

6.60 (O.260)

8.40 (O.331)

8.40 (0.331)

88.60 (3.488t

44.OO t't.7321

30.30 (1 .1 93t

39.50 (1.555)

33.80 (1 .331 I

33.80 (1 .331 )

16.5

2.1

25.O'l2.5

12.5

14-122

lnside Diameter

Page 521 of 1413

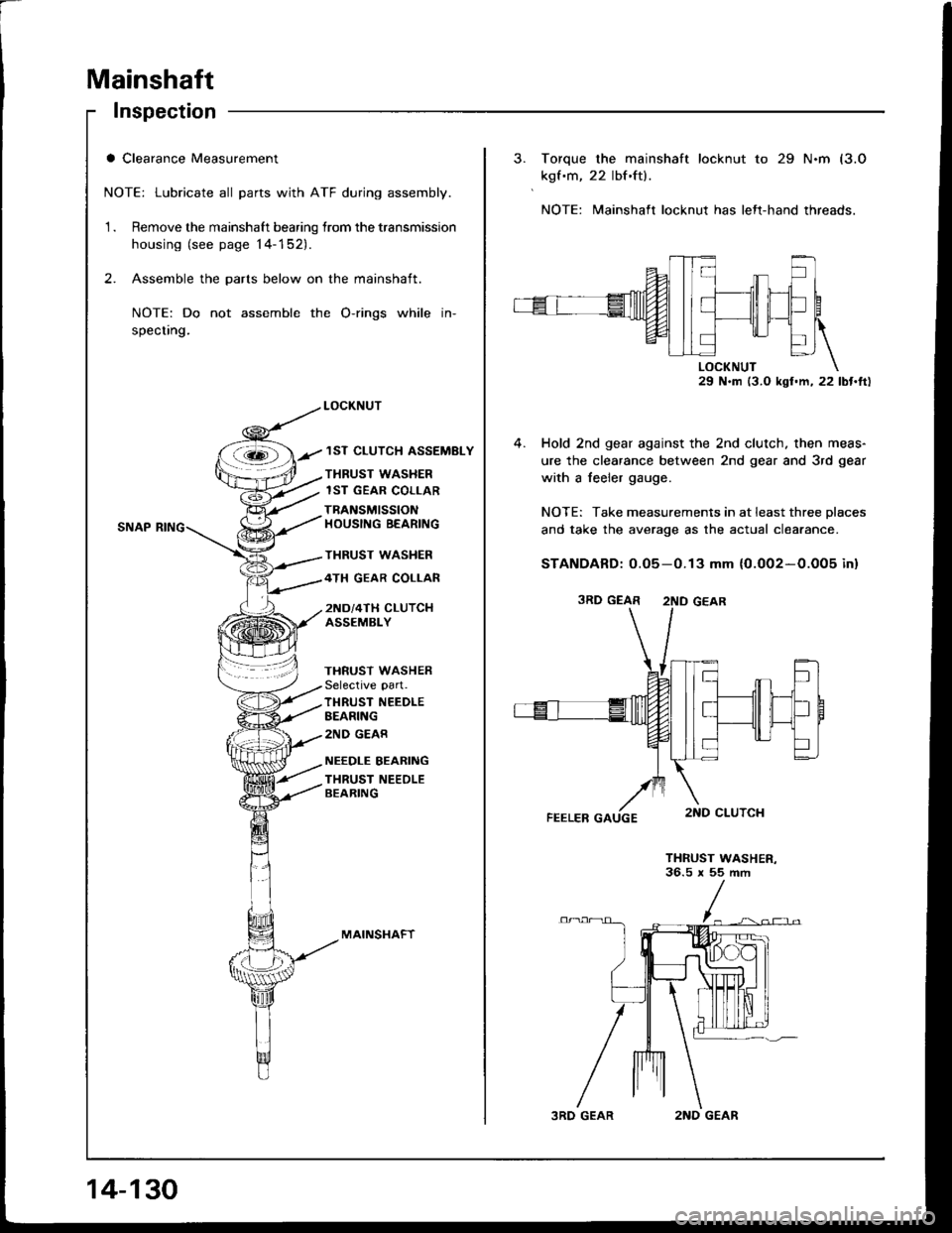

Mainshaft

Inspection

a Clearance Measurement

NOTE: Lubricate all parts with ATF during assembly.

1 . Remove the mainshaft bearing lrom the transmission

housing (see page 14-152).

2. Assemble the parts below on the mainshaft.

NOTE: Do not assemble the O-rings while in-

specting.

LOCKNUT

/ 1ST CLUTCH ASSEMBLY

THRUST WASHER

lST GEAR COLLAR

TBANSMISSIONHOUSING BEARING

THRUST WASHER

4TH GEAR COLLAR

2ND/4TH CLUTCHASSEMBLY

THRUST WASHERSelective part.

TI{RUST NEEDLEBEARING

2ND GEAR

NEEDLE BEARING

THRUST NEEOLEBEARING

MAINSI.IAFT

14-130

3RD GEAR2ND GEAR

Torque the mainshaft locknut to 29 N.m (3.0

kgf .m, 22 lbf.ft).

NOTE: Mainshaft locknut has lett-hand threads.

29 N.m (3.0 kgl.m, 22 lbt.ft)

4. Hold 2nd gear against the 2nd clutch. then meas-

ure the clearance between 2nd gear and 3rd gear

with a feeler gauge.

NOTE: Take measurements in at least three Dlaces

and take the average as the actual clea.ance.

STANDARD: 0.05-0.13 mm {0.002-0.005 inl

THRUST WASHER-36.5 x 55 ftm

3RD GEAR 2ND GEAR

Page 526 of 1413

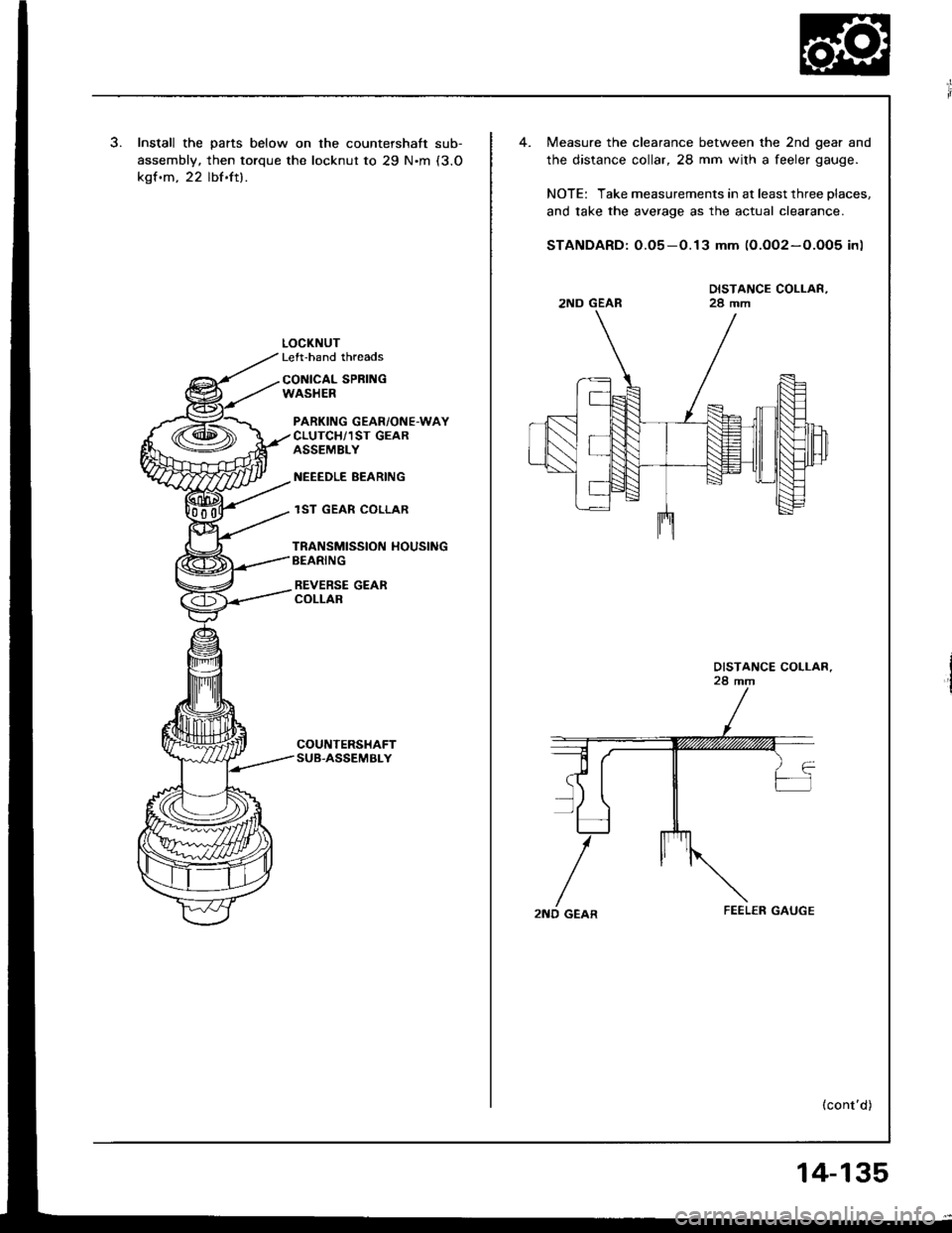

Install the parts below on the countershaft sub-

assembly, then torque the locknut to 29 N'm (3.O

kgf.m, 22 lbf.ft).

LOCKNUTLeft-hand threads

CONICAL SPRI GWASHER

PARKING GEAR/ONE-WAYCLUTCH/1ST GEARASSEMBLY

NEEEDLE BEARING

lST GEAR COLLAR

TRANSMISSION HOUSINGBEARING

REVERSE GEARCOLLAR

Measure the clearance between the 2nd gear and

the distance collar, 28 mm wilh a feeler gauge.

NOTE: Take measurements in at least three places.

and take the average as the actual clearance.

STANDARD: O.O5-0.13 mm (0.OO2-O.O05 in)

DISTANCE COLLAR,28 mm2ND GEAR

2ND GEAR

(cont'd)

14-135

Page 541 of 1413

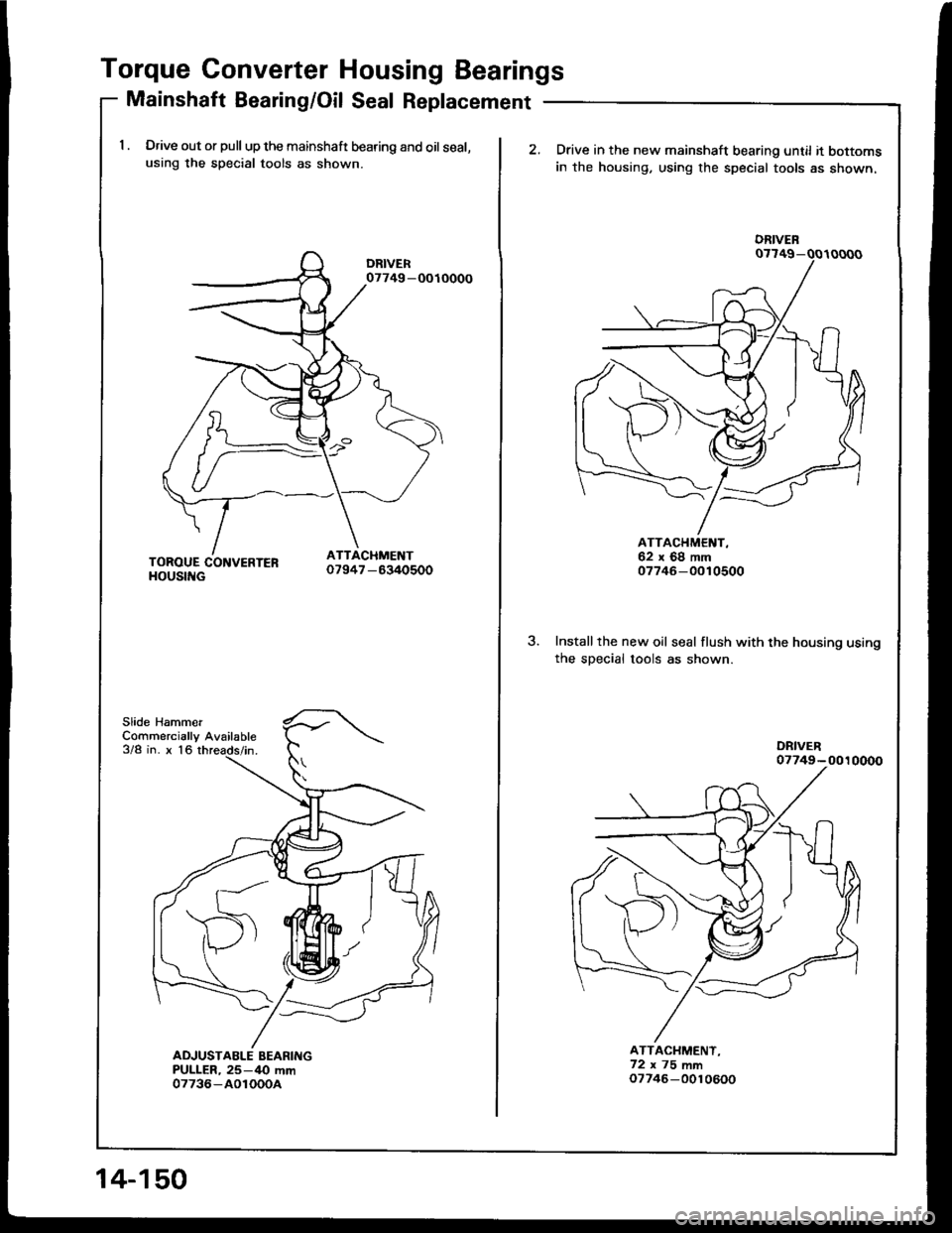

Torque Converter Housing Bearings

Mainshaft Beadng/Oil Seal Replacement

1 . Drive out or pull up the mainshaft bearing and oil seal,using the special tools as shown.

Slide HammerCommercially Available3/8 in. x 16

07749 -OOIOOOO

14-150

2.Drive in the new mainshaft bearing until it bottomsin the housing, using the special tools as shown.

3.Installthe new oil seal flush with the housing usingthe sDecial tools as shown.

ATTACHMENT,62x68mm07746-0010500

ATTACHMENT,72x75mm07746-0010600

DRIVEN

Page 547 of 1413

2.

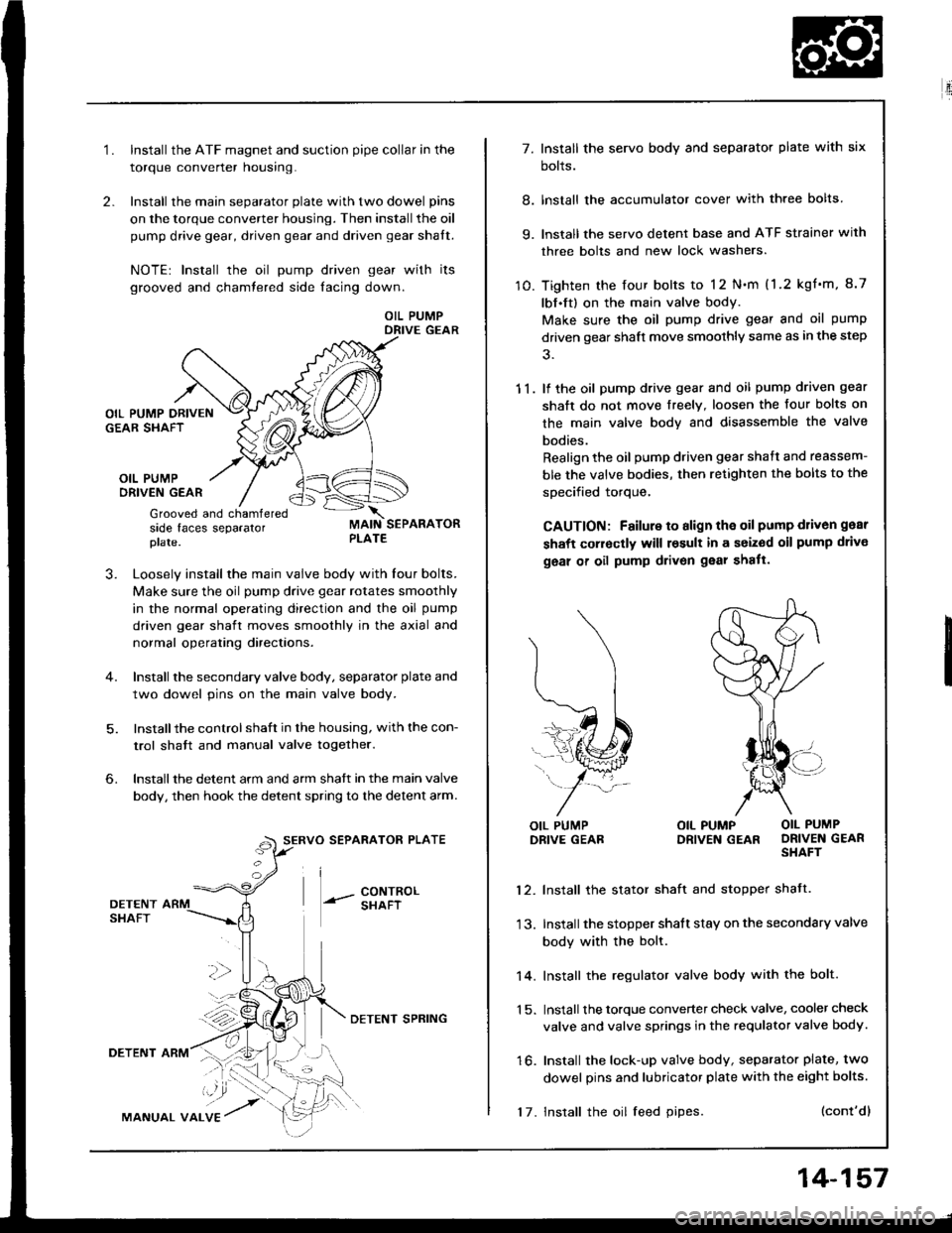

1.Install the ATF magnet and suction pipe collar in the

torque converter nousrng.

Install the main separator plate with two dowel pins

on the torque converter housing. Then install the oil

pump drive gear, driven gear and driven gear shalt.

NOTE| Install the oil pump driven gear with its

grooved and chamtered side facing down.

OIL PUMPDRIVE GEAR

OIL PUMPORIVEN GEAR

Grooved and chamferedside faces separatorplate.

J.Loosely install the main valve body with Iour bolts.

Make sure the oil pump drive gear rotates smoothly

in the normal operating direction and the oil pump

driven gear shaft moves smoothly in the axial and

normal operating directaons.

Install the secondary valve body, separator plate and

two dowel pins on the main valve body.

Installthe control shaft in the housing, with the con-

trol shatt and manual valve togelher.

Install the detent arm and arm shatt in the main valve

body, then hook the detent spring to the detent arm.

SERVO SEPARATOR PLATE

--- 8ixli"'

6.

36

DETENTSHAFT

DETENT ARM

MANUAL VALVE

DETENI SPRING

17. Install the oil feed pipes.

14-157

E'.:

7. Install the servo body and separator plate with six

bolts.

8. lnstall the accumulator cover with three bolts

9. lnstall the servo detent base and ATF strainer with

three bolts and new lock washers.

10. Tighten the four bolts to 12 N.m (1.2 kgf'm, 8.7

lbf.ft) on the main valve body.

Make sure the oil pump drive gear and oil pump

driven gear shaft move smoothly same as in the step

11. lf the oil pump drive gear and oil pump driven gear

shaft do not move freelY. loosen the four bolts on

the main valve body and disassemble the valve

bodies.

Realign the oil pump driven gear shaft and reassem-

ble the valve bodies, then retighten the bolts to the

specified torque,

CAUTION: Failure to align the oil pump d1iv6n gear

shaft corroctly will result in a seized oil pump drivo

geal of oil pump drivon gear shatt.

l\

(...l

=..�N

L,1ffi#

j-*/:

OIL PUMPDRIVE GEABOIL PUMP OIL PUMPDRIVEN GEAR DRIVEN GEARSHAFT

12. Install the stator shaft and stopper shatt.

13. Install the stopper shatt stay on the secondary valve

body with the bolt.

14. Install the regulator valve body with the bolt.

1 5. Install the torque converter check valve, cooler check

valve and valve springs in the requlator valve body.

16. Install the lock-up valve body, separator plate, two

dowel pins and lubricator plate with the eight bolts.

(cont'dl

Page 549 of 1413

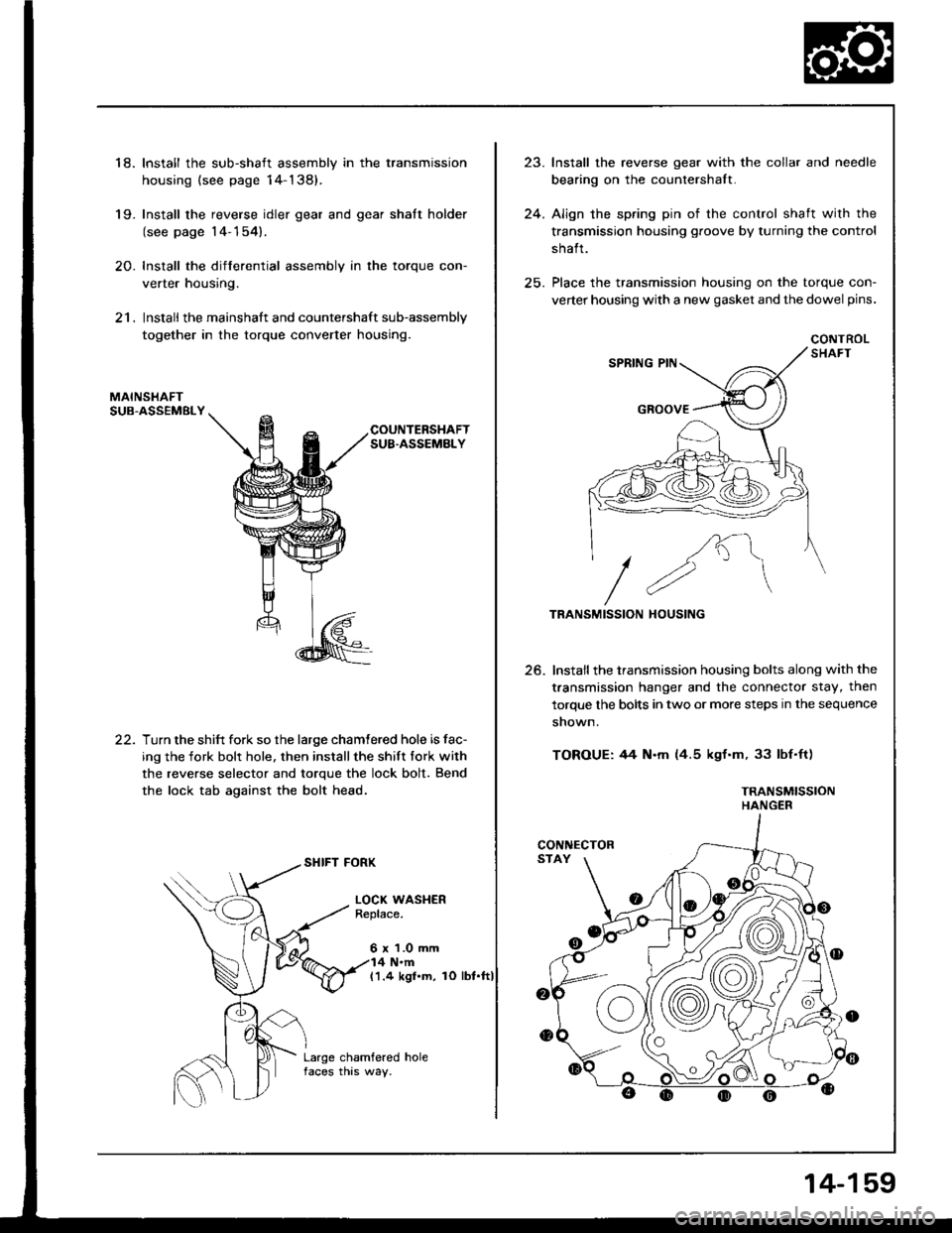

18. Install the sub-shaft assembly in the transmission

housing {see page 14-138).

19- Install the reverse idler gear and gear shatt holder

(see page 14-154).

20. Install the differential assembly in the torque con-

verter housing.

21. Install the mainshaft and countershaft sub-assembly

together in the torque converter housing.

MAINSHAFTSUB.ASSEMBLY

COUNTERSHAFTSUB.ASSEMBLY

22.Turn the shift fork so the large chamtered hole is fac-

ing the fork bolr hole. then installthe shift fork with

the reverse selector and torque the lock bolt. Bend

the lock tab against the bolt head.

SHIFT FORK

LOCI( WASHERReplace.

6 x 1.0 mm4 N.m(1.4 kgl.m, rO lbt.ft)

Large chamfered holefaces this way.

,,1

24.

lnstall the reverse gear with the collar and needle

bearing on the countershalt.

Align the spring pin of the control shaft with the

transmission housing groove by turning the control

shalt.

Place the transmission housing on the torque con-

verter housing with a new gasket and the dowel pins.

CONTROL

/K"\

//2"\TRANSMISSION HOUSING

Install the transmission housing bolts along with the

t.ansmission hanger and the connector stay, then

torque the bolts in two or more steps in the sequence

shown.

TOROUE: 44 N.m (4.5 kgf.m, 33 lbf'ft)

TRANSMISSIONHANGER

25.

CONNECTOR

14-159

Page 550 of 1413

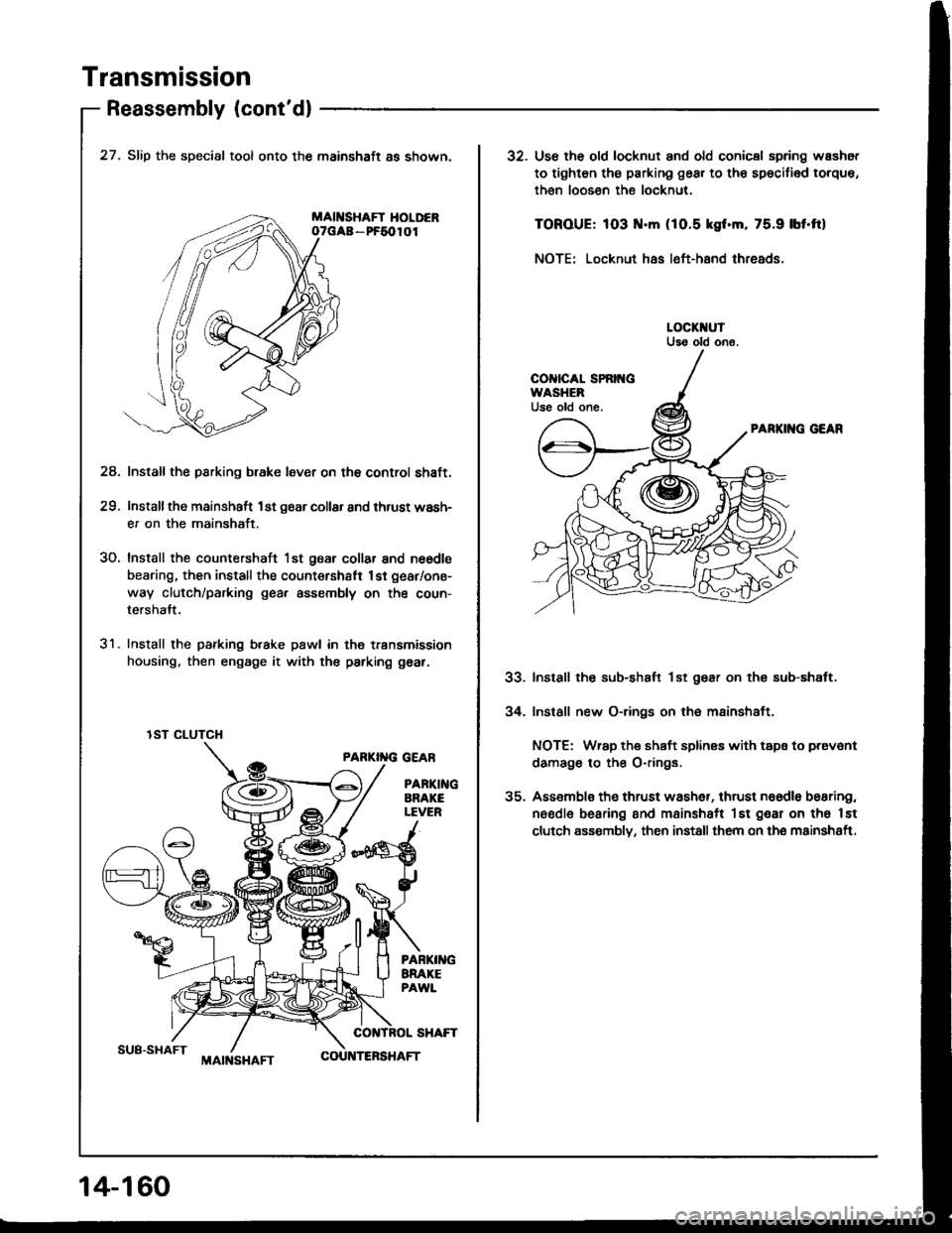

Transmission

Reassembly (cont'dl

SUB-SHAFT

27. Slip the special tool onto the mainshaft as shown.

MAII{SHAFT HOLDERoTGAa - PF5010I

Install the parking b.ake lever on the control shaft.

Installthe mainshaft 1st g6ar collar and thrust wash-

er on the mainshaft.

Install the countershaft 1st gear collar and n6€dls

bearing, then install the count€rshatt 1st gear/one-

way clutch/parking gea, assembly on the coun-

tershalt.

Install the parking b.ake pawl in th€ transmission

housing, then engage it with the parking gear.

PARKI''IG GEAR

PARTI GARAKELEVER

24.

29.

30.

31.

lST CLUTCH

14-1 60

MAIt{SHAFTCOU TERSHAFT

32. Use th6 old locknut and old conicsl spring washot

to tighten th€ parking gear to th€ sp€cifi€d torque,

then loosen the locknut.

TOROUE: 103 .m (1O.5 kgf.m, 75.9 lbf'ftl

NOTE: Locknut has left-hand threads.

PARKII{G GEAR

Install the sub-shaft lst gear on thg sub-shaft.

Install new O-rings on the mainshaft.

NOTE: Wrap the shaft splines with tspa to prevont

damago to the O-rings.

Assemblo th€ thrust wash6r, thrust naedle bearing,

needle bearing and msinshsft lst gear on tho lst

clutch assombly, then install them on the mainshaft.

33.

34.

Page 551 of 1413

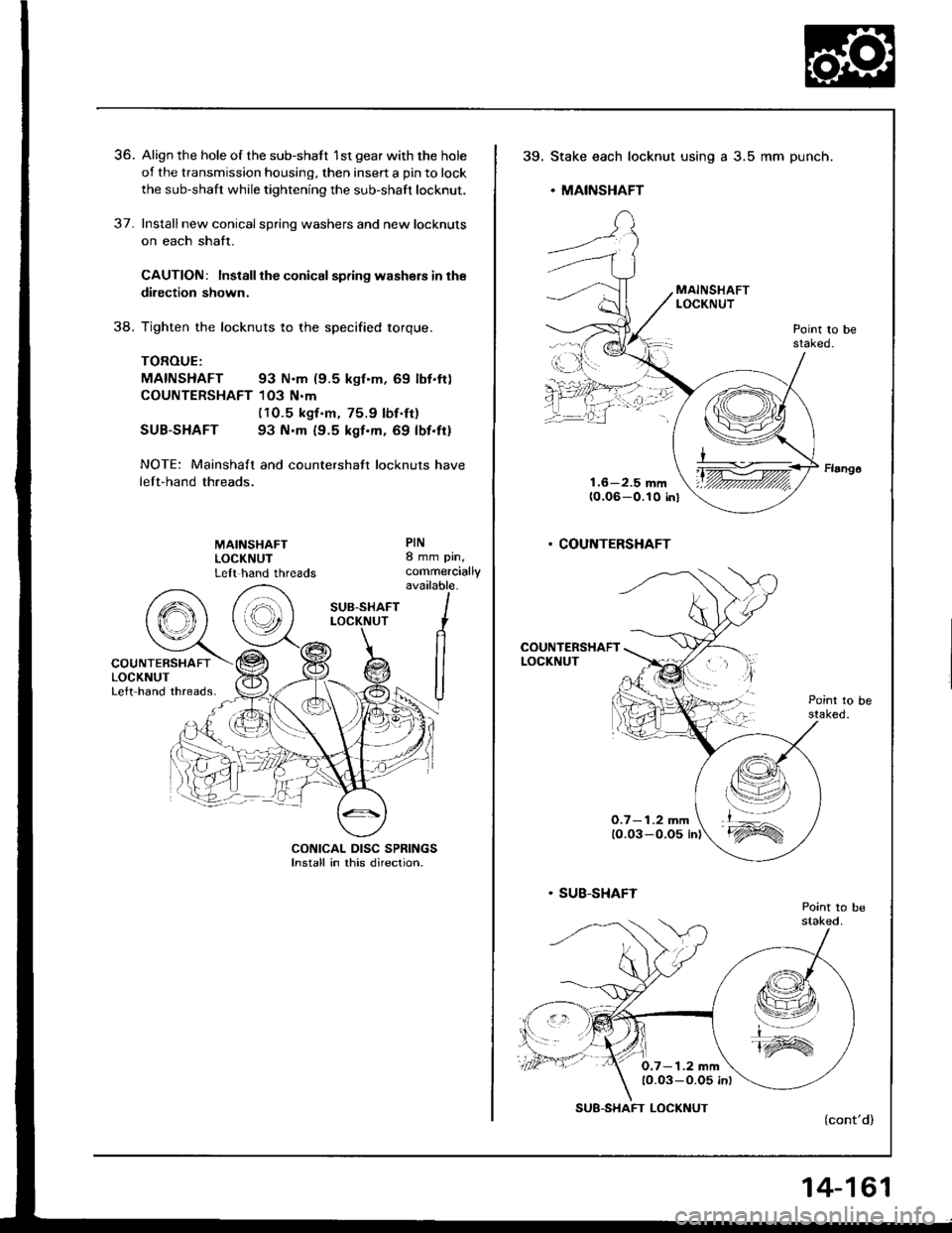

36. Align the hole of the sub-shaft 1st gear with the hole

of the transmission housing, then insert a pin to lock

the sub-shaft while tightening the sub-shaft locknut.

37. Installnew conicalspring washers and new locknuts

on each shaft.

CAUTION: Install the conical spdng washers in the

dilection shown.

38. Tighten the locknuts to the specified torque.

TOROUE:

MAINSHAFT 93 N.m (9.5 kgf'm, 69 lbf.ft)

COUNTERSHAFT 103 N.m(1O.5 kgf.m, 75.9 lbf.ft)

SUB-SHAFT 93 N.m (9.5 kgf.m. 69 lbf.fi)

NOTE: Mainshalt and countershaft locknuts have

left-hand threads.

CONICAL DISC SPRINGSlnstall in rhis direcrion.

39.Stake each locknut using

. MAINSHAFT

a 3.5 mm punch.

. COUNTERSHAFT

O,7- 1.2 mm

0.7- 1.2 mm1O.03-O.05 in)

SUB-SHAFT LOCKNUT

14-161