engine HONDA INTEGRA 1994 4.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 146 of 1413

lllustrated IndexF

(cont'd)

NOTE: New rod bearings must be selected by

connecting rod and crankshaft identification

(see pages 7-8,9)

matching

marKrngs

Lubricate all internal parts with engine oil during

reassemorv.

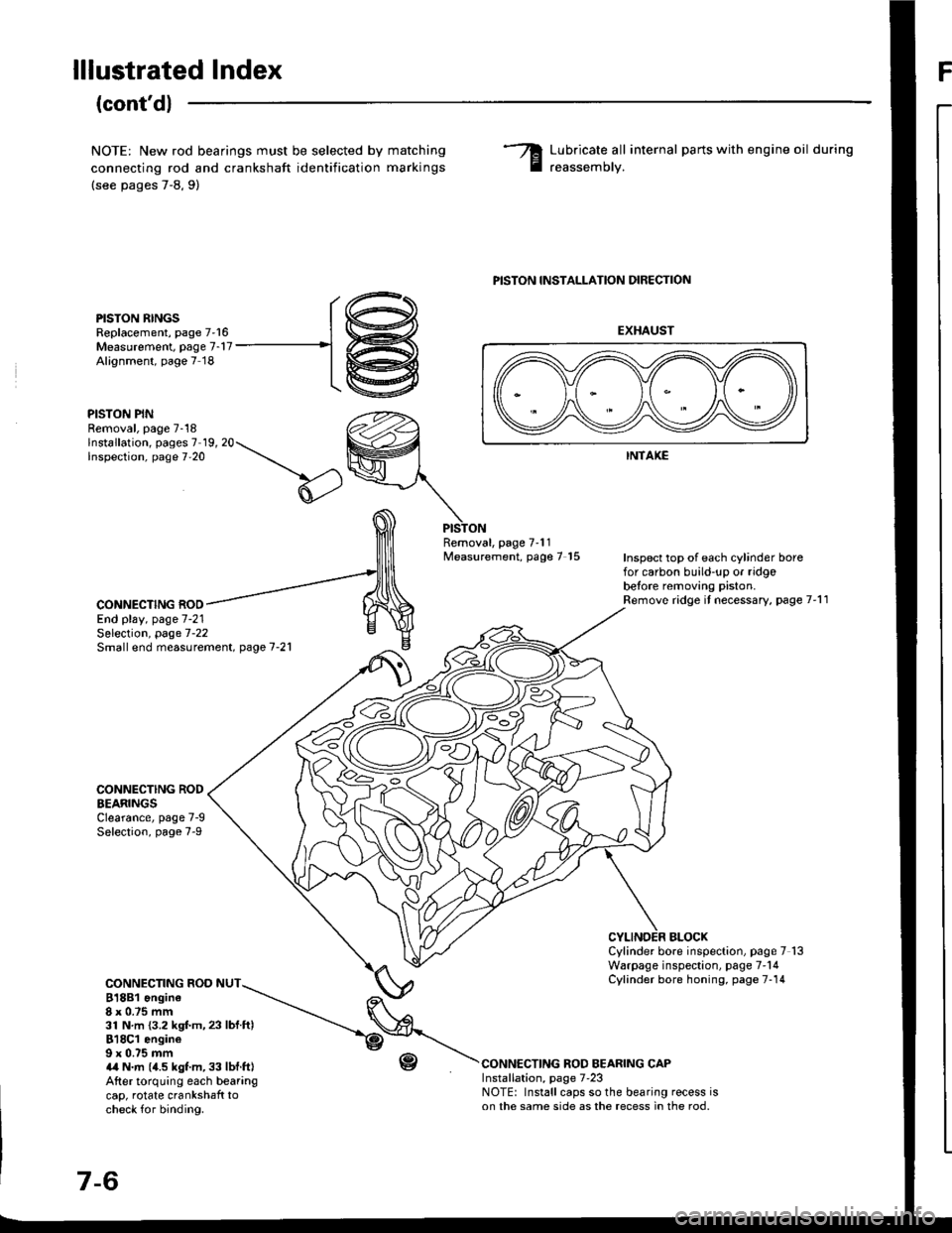

PISTON RINGSReplacement, page 7'16Measurement. page 7-17Alignment, page 7 18

PISTON PINRemoval, page 7-18lnstallation, pages 7 19, 20Inspection, page 7'20

PISTON INSTALLATION DIRECTION

EXHAUST

INTAKE

Removal, page 7'11Measurement, page 7 15Inspect top of each cylinder borefor carbon build-up or ridgobetore removing piston.Remove ridge it necessary, page 7'11CONNECTING ROOEnd play, page 7-21

CONNECTING RODEEARINGSClearance, page 7-9Selection, page 7-9

CONNECTING ROD NUT818B1 ongine8x 0.75 mm31 N.m {3.2 kgf.m,23 lbf ftl818C1 engine9 x 0.75 mma,a N.m (4.5 kgt m, 33 lbf.ft|After torquing each bearangcap, rotate crankshaft tocheck for binding.

r-(,

Selection, page 7-22Small end measurement. page 7-21

BLOCXCylinder bore inspection, page 7 13Warpage inspection, page 7'14Cylinder bore honing, page 7-14

CONNECTING ROD BEARING CAPInstallation, page 7'23NOTE: Install caps so the bearing recess ison the same side as the recess in the rod.

r@

-1@

Page 147 of 1413

Flywheel and Drive Plate

Replacement

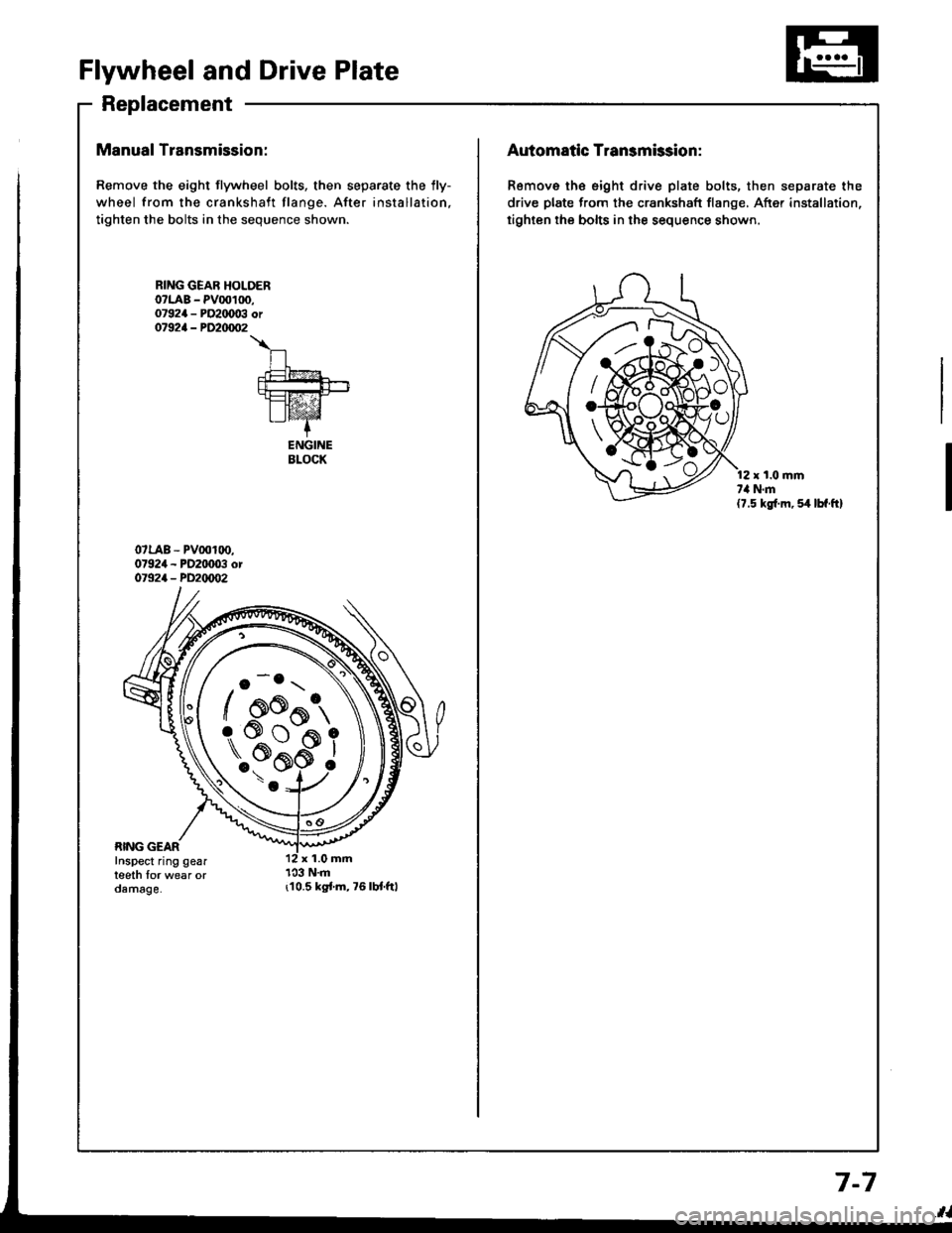

Manual Transmission:

Remove the eight flywheel bolts, then separate the lly-

wheel from the crankshaft flange. After installation,

tighten the bolts in the sequence shown.

r10.5 kgi.m,76lbt.ftl

RING GEAR HOLOERo?LAB - PV00100,07924 - PO2IX)03 or07924 - PD20/m�2

\

n.t=?4

fut!!-+-rt=tz-21I lvaz'Z-+

ENGINEBLOCK

o -o.r \

/ oo^t,

\..?bi

/ AK{:{AAo

rs#*ffi_9

Automatic Transmission:

Remove th€ eight drive plate bolts, then separate the

drive plate from the crankshaft flange, After installation,

tighten the bolts in the sequence shown.

r t.0 mmt,l N.m(7.5 kg{.m, 54 lbf.ft}

7-7

Page 148 of 1413

Main Bearings

Clearance

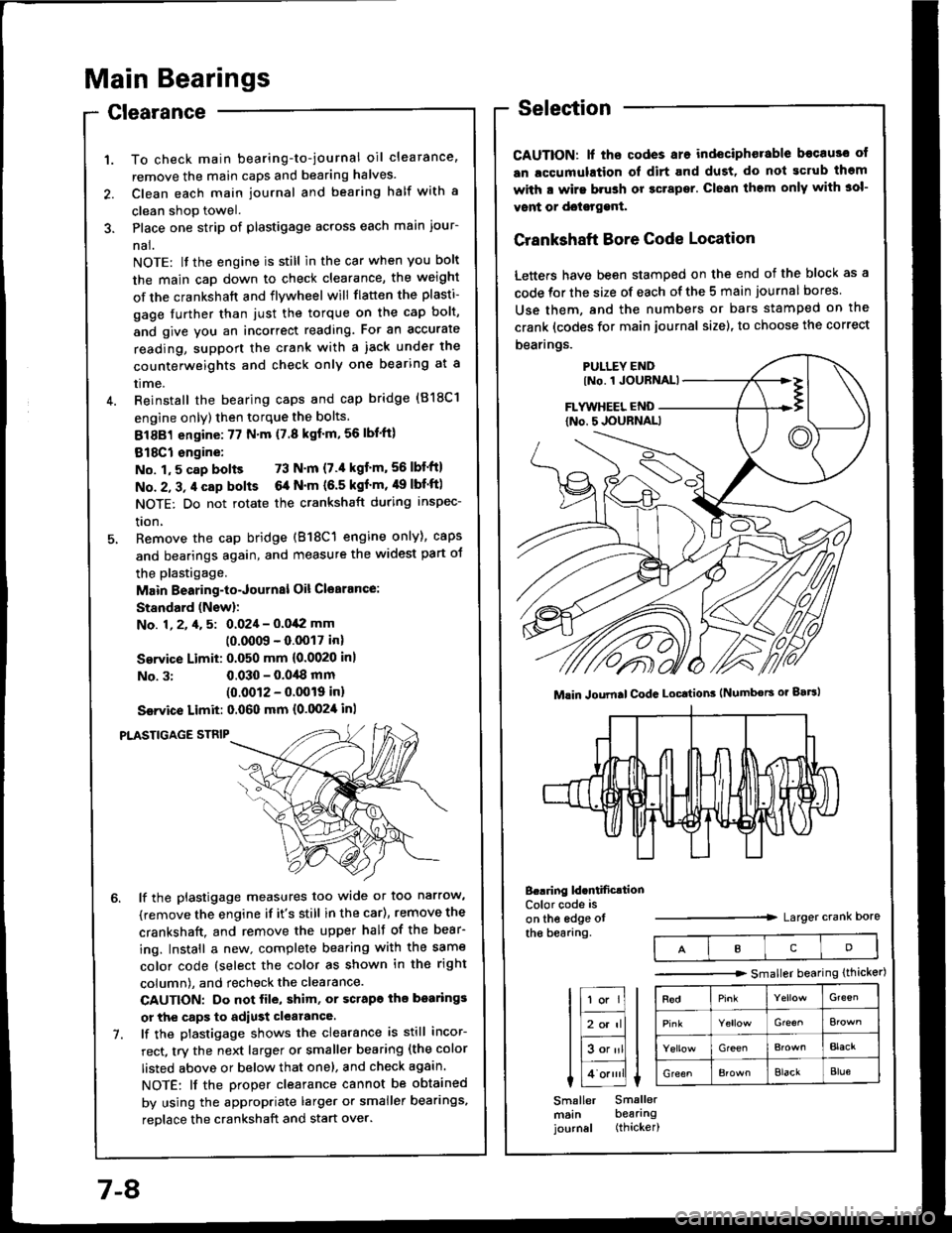

To check main bearing-to-journal oil clearance,

remove the main caps and bearing halves.

Clean each main journal and bearing half with a

clean shop towel.

Place one strip of plastigage across each main iour-

nal.

NOTE: lf the engine is still in the car when you bolt

the main caD down to check clearance, the weight

of the crankshaft and flywheel will flatten the plasti-

gage further than just the torque on the cap bolt,

and give you an incorrect reading. Fot an accurate

reading, support the crank with a iack under the

counterweights and check only one bearing at a

trme.

Reinstall the bearing caps and cap bridge (818C1

engine only) then torque the bolts.

81881 engine:77 N'm (7.8 kgf'm,56lbl'ft)

818C1 engine:

No. 1,5 cap bolts 73 N'm (7.'l kgt'm,56lbf'ftl

No. 2, 3, 4 cap bolts 6a N'm (6.5 kgf'm, 49 lbf'ftl

NOTE: Do not rotate the crankshaft during inspec-

tron,

Remove the cap bridge (818C1 engine only), caps

and bearings again, and measure the widest part oJ

the plastigage.

Main Bearing-to-Journal Oil Cl€arance:

Standard (Newl:

No. 1, 2, 4, 5: 0.024 - 0.042 mm

10.0009 - 0.0017 inl

Service Limit: 0.050 mm {0.0020 inl

No. 3:0.030 - 0.0,18 mm(0.0012 - 0.0019 inl

Ssrvice Limit: 0.060 mm {0.0024 inl

PLASTIGAGE STNIP

lf the plastigage measures too wide or too narrow,

(remove the engine if it's still in the car), remove the

crankshaft. and remove the upper half of the bear-

ing. Install a new. complete bearing with the same

color code (select the color as shown in the right

column), and recheck the clearance.

CAUTION: Do not file, shim, or scrapo ihe bo.rings

or the caps to adiust clearance.

lf the plastigage shows the clearance is still incor-

rect, try the next larger or smaller bearing (the color

listed above or below that one), and check again.

NOTE: lf the Droper clearance cannot be obtained

by using the appropriate larger or smaller bearings,

reolace the crankshaft and start over.

Selection

CAUTION: lf ths codes are indeciphorable becau3o ot

an lccumulation ol dirt and dust, do not gcrub thgm

with a wirs brush or gcrapsr. Clean them only with 3ol-

vont or doisrggnt.

Crankshaft Bore Code Location

Letters have been stamped on the end of the block as a

code for the size of each of the 5 main journal bores

Use them, and the numbers or bars stamped on the

crank (codes for main journal size), to choose the correct

bearings.

B..ring ld.ntificrtionColor code is

on the edge otthe bearang.Larger crank Dore

Mlin Joumal CodG Locttion3 (Numbors or gaBl

IcD

tr;;lIl

Itr-tl

lE;tl I tlHlt

I Lo.""li L

Smaller Smallermsin bearingjournal (thicker)

-------.r> smaller bearing (thicker)

G'een

Gre€^

GreenBlacr

GreenElackBlue

7-8

Page 150 of 1413

Crankshaft

Removal

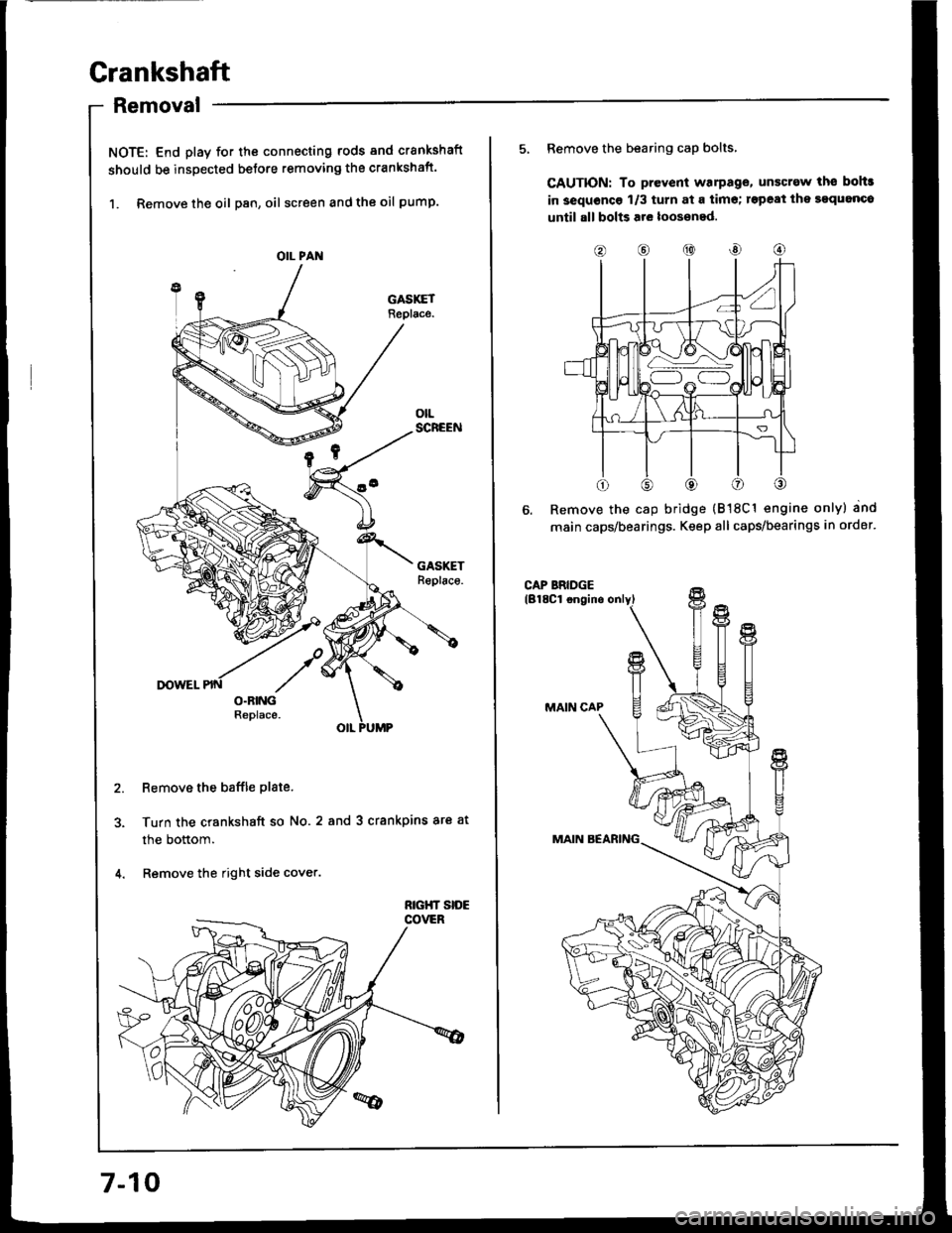

NOTE: End play for th€ connecting rods and crankshaft

should be inspected betore removing the crankshaft.

1. Remove the oil Dan, oil screen and the oil pump.

Remove the baffle plate.

Turn the crankshaft so No.2 and 3 crankpins ar€ at

the bottom.

Remove the right side cover.

OIL PAN

7-10

o@@

5, Remove the bearing cap bolts,

CAUTION: To prevent warPag€, unscrew ths bohr

in 3equoncg 1/3 turn at a tim€; rspeat ihe sgquanco

until all bolts are loos€ned.

Remove the cap bridge {818C1 engine only} and

main caps/bearings. Keep all caps/bearings in order.

Page 151 of 1413

7.

8.

11.

9.

10.

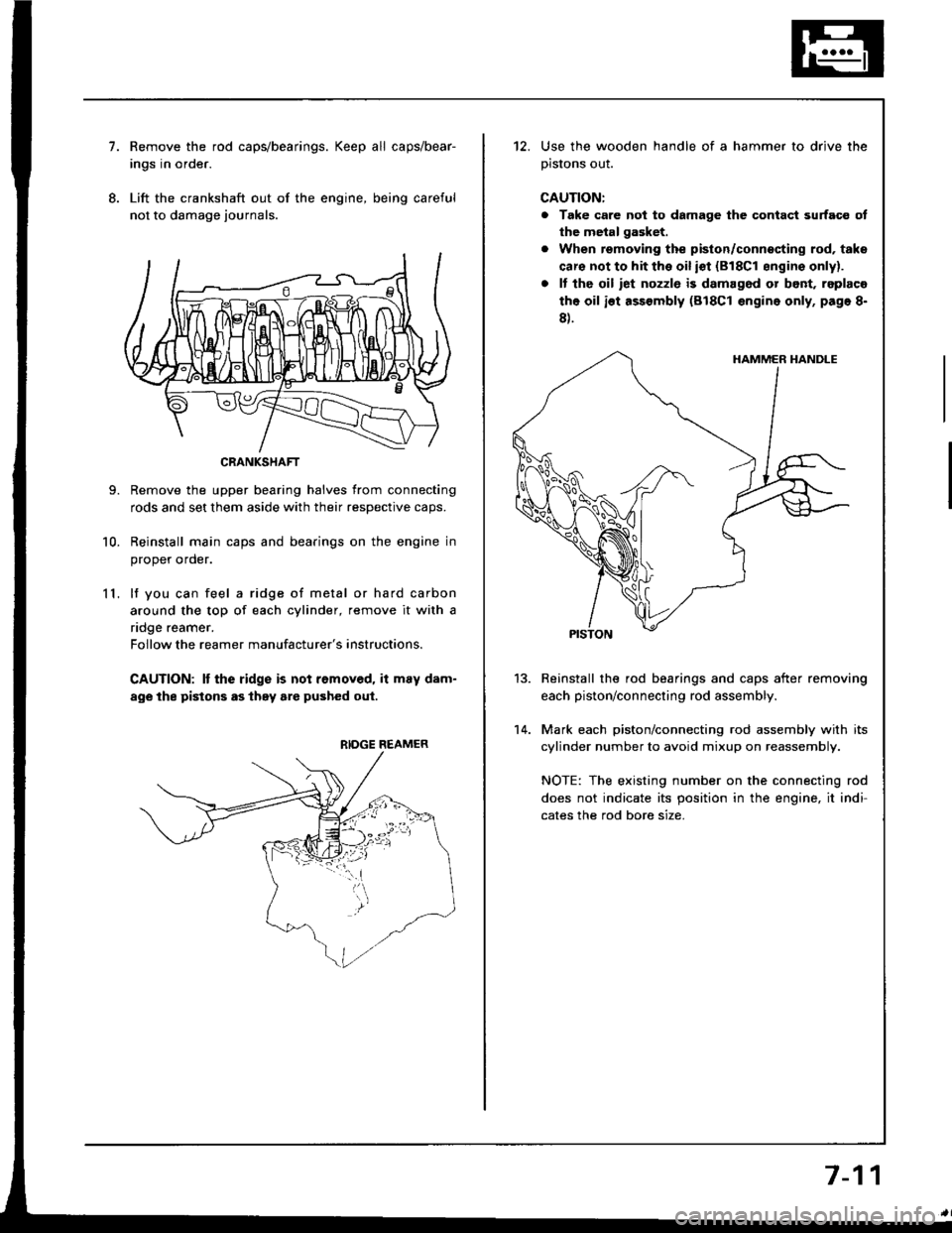

Remove the rod caps/bearings. Keep all caps/bear-

ings in order.

Lift the crankshaft out of the engine, being careful

not to damage journals.

Remove the upper bearing halves from connecting

rods and set them aside with their resDective caDs.

Reinstall main caps and bearings on the engine in

oroDer order.

lf you can feel a ridge of metal or hard carbon

around the top of each cylinder, remove it with a

ndge reamer.

Follow the reamer manufacturer's instructions.

CAUTION: It the ridge is not removed, it may dam-

age the pistons as they are pushed oul.

CRANKSHAFT

RIDGE REAMER

12. Use the wooden handle of a hammer to drive the

prslons ouI.

CAUTION:

a Take care not to damage the contact surfaco ot

the metal gasket.

. When removing the piston/connecting rod, taks

caro not to hit the oil iot {818C1 sngins onlyl.

. It tho oil iet nozzlo is damag6d or bont, replaco

the oil ist assembly (818C1 engine only, page 8-

8).

Reinstall the rod bearings and caps after removing

each piston/connecting rod assembly.

Mark each piston/connecting rod assembly with its

cylinder number to avoid mixup on reassembly.

NOTE: The existing number on the connecting rod

does not indicate its position in the engine, it indi-

cates the rod bore size.

13.

14.

7-11

Page 154 of 1413

Cylinder Block

Inspection (cont'dl

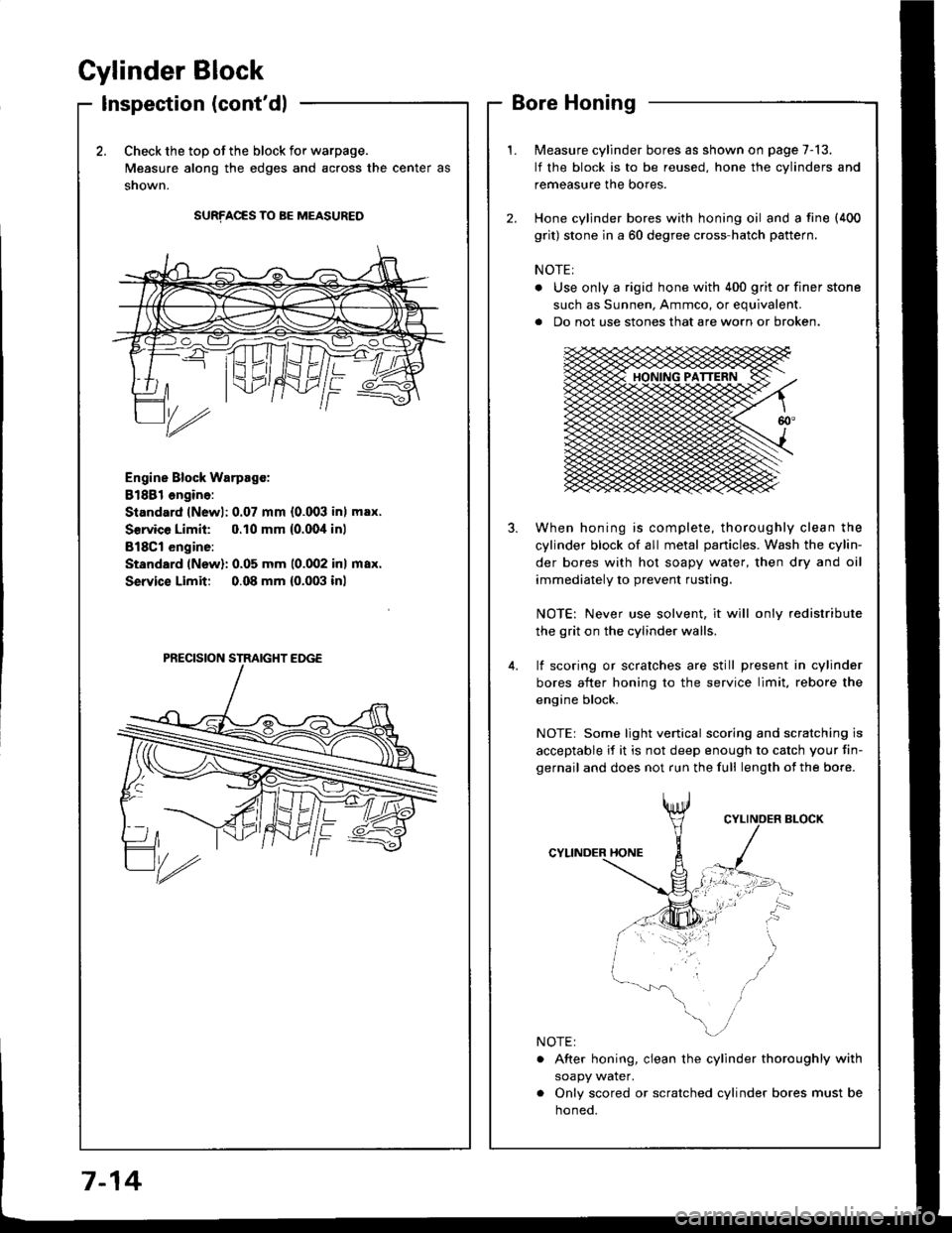

2.Check the top of the block for warpage.

Measure along the edges and across the center as

snown.

SURFACES TO BE MEASURED

Engine Block Warpsgc:

81881 ongine:

Standard lNewl: 0.07 mm {0.003 inl max.

Service Limil: 0.10 mm {0.00,1inl

B18Cl engine:

Standard (New): 0.05 mm 10.002 inl max.

Service Limit 0.08 mm {0.003 inl

Measure cylinder bores as shown on page 7-13.

lf the block is to be reused, hone the cylinders and

remeasure the bores.

Hone cylinder bores with honing oil and a fine (400

grit) stone in a 60 degree cross-hatch pattern.

NOTE:

. Use only a rigid hone with 400 grit or finer stone

such as Sunnen, Ammco, or equivalent.

a Do not use stones that are worn or broken.

When honing is complete, thoroughly clean the

cylinder block of all metal panicles. Wash the cylin-

der bores with hot soapy water, then dry and oil

immediately to prevent rusting.

NOTE: Never use solvent, it will only redistribute

the grit on the cylinder walls.

lf scoring or scralches are still present in cylinder

bores after honing to the service limit, rebore the

engine block.

NOTEr Some light venical scoring and scratching is

acceptable if it is not deep enough to catch your fin-

gernail and does not run the full length of the bore.

CYLINDER HONE

. After honing, clean the cylinder thoroughly with

soapy water.

. Only scored or scratched cylinder bores must be

noneo.

7-14

Page 156 of 1413

Piston

lnstallation

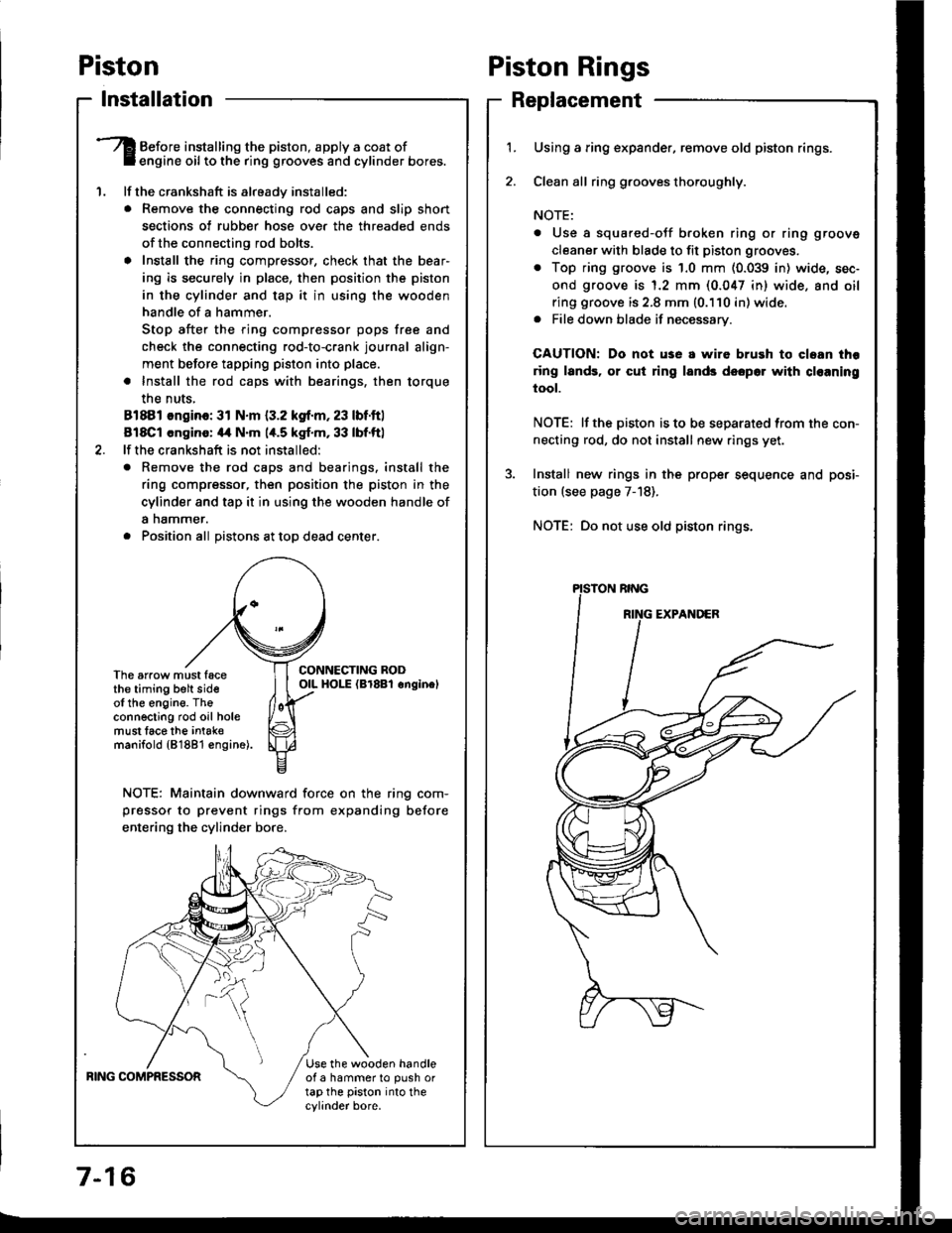

'1.

Before installing the piston, apply a coat ofengine oil to the ring grooves and cylinder bores.

lf the crankshaft is already installed:

. Remove the connecting rod caps and slip short

sections of rubber hose ove. the threaded ends

of the connecting rod bolts.

a Install the ring compressor, check that the bear'

ing is securely in place, then position the piston

in the cylinder and tap it in using the wooden

handle of a hammer.

Stop after the ring compressor pops free and

check the connecting rod-to-crank journal align-

ment before tapping piston into place.

. Install the rod caps with bearings, then torque

the nuts,

81881 ongino: 31 N.m {3.2 kgf.m, 23 lbf.ftl

818C1 cngino: 44 N'm 1,t.5 kgf.m, 33 lbf.ftl

lf the crankshaft is not installed:

o Remove the rod caps and bearings. install the

ring compressor, then position the piston in the

cylinder and tap it in using the wooden handle of

a nammer.

. Position all Distons at toD dead center.

CONNECTING RODOIL HOI-E (Br8Bl onginelThe arrow must facethe timing belt sideof the engine. Theconnecting rod oil holemust lace the intak€manifold {81881 €ngine).

NOTE: Maintain downward force on the ring com-

pressor to prevent rings from expanding before

entering the cylinder bore,

BING COMPRESSORUse the wooden handleof a hammer to push ortap the piston into thecylinder bore.

Piston Rings

Replacement

1.Using a ring expander, remove old piston rings.

Clean all ring g.ooves thoroughly.

NOTE:

. Use a squared-oJf broken ring or ring groove

cleaner with blade to fit piston grooves.

. Top ring groove is 1.0 mm (0.039 in) wide, sec-

ond groove is 1.2 mm (0.047 in) wide. and oil

ring groove is 2.8 mm (0.110 in) wide.. File down blade if necessary.

CAUTION: Do not use a wire brush to cloan thr

ring lands, or cut ring lands dsopo. with cl€aning

tool.

NOTE: lf the piston is to be separated from the con-

necting rod, do not install new rings yet.

Install new rings in the prope. sequence and posi-

tion (see page 7-18).

NOTE: Do not use old piston rings.

Page 157 of 1413

I

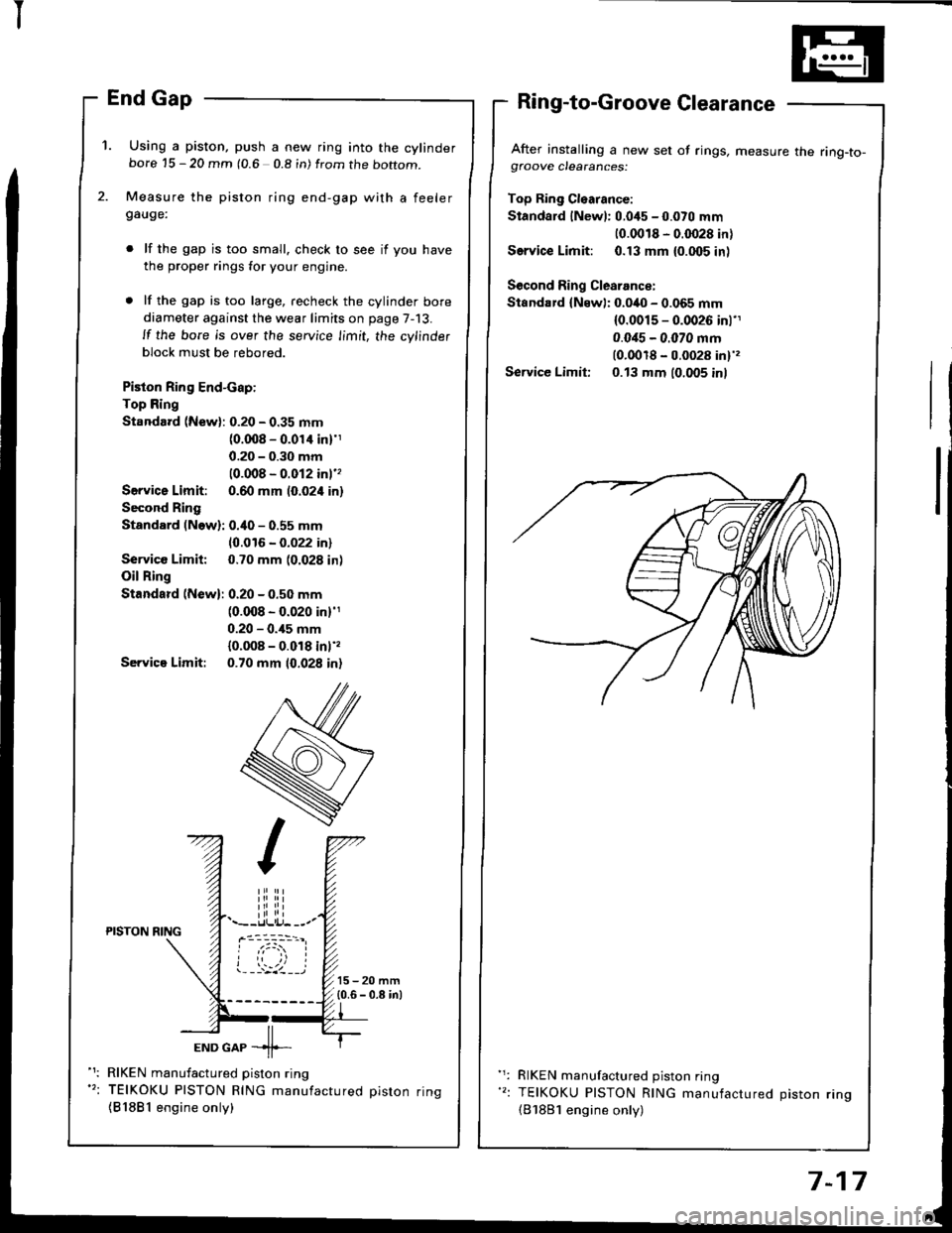

'1. Using a piston, push a new ring into the cylinderbore 15 - 20 mm (0.6 0.8 in) from the boftom.

Measure the piston ring end-gap with a feelergauge:

lf the gap is too small. check to see if you have

the proper rings for your engine.

lf the gap is too large, recheck the cylinder bore

diameter against the wear limits on page 7-13.

ll the bore is over the service limit, the cylinder

block must be rebored.

Piston Ring End-cap:

Top Ring

Standard (New): 0.20 - 0.35 mm(0.008 - 0.01'l inl'1

0.20 - 0.30 mm

10.008 - 0.012 inl''

Servica Limit: 0.60 mm (0.024 in)

Second Ring

Standard (Now): 0.40 - 0.55 mm

10.016 - 0.022 in)

Service Limit: 0.70 mm (0.028 in)

Oil Ring

Standard (New): 0.20 - 0.50 mm(0.008 - 0.020 in)'1

0.20 - 0.,15 mm

{0.008 - 0.018 inl',

Servica Limit: 0.70 mm 10.028 in)

After installing a new set of rings, measure the ring-to-gfoove clearances:

Top Ring Cl€arance:

Standard lNewl: 0.045 - 0.070 mm

10.0018 - 0.0028 in)

Service Limit: 0.13 mm {0.005 inl

Second Ring Clearance:

Standard {Newl: 0.040 - 0.065 mm(0.0015 - 0.0026 inl'1

0.0i15 - 0.070 mm(0.0018 - 0.0028 in)',

Service Limit: 0.13 mm (0.005 inl

iliiii.--r.llli.j- --.-PISTON NING

ioi

---'z llEND GAP -11--

RIKEN manufactured piston ring

TEIKOKU PISTON RING manufactured oiston rinq

{81881 engine only)

RIKEN manufactured piston ring

TEIKOKU PISTON RING manufactured Diston rino(B'1881 engine only)

7-17

Page 159 of 1413

Installation (B18Bl engine)

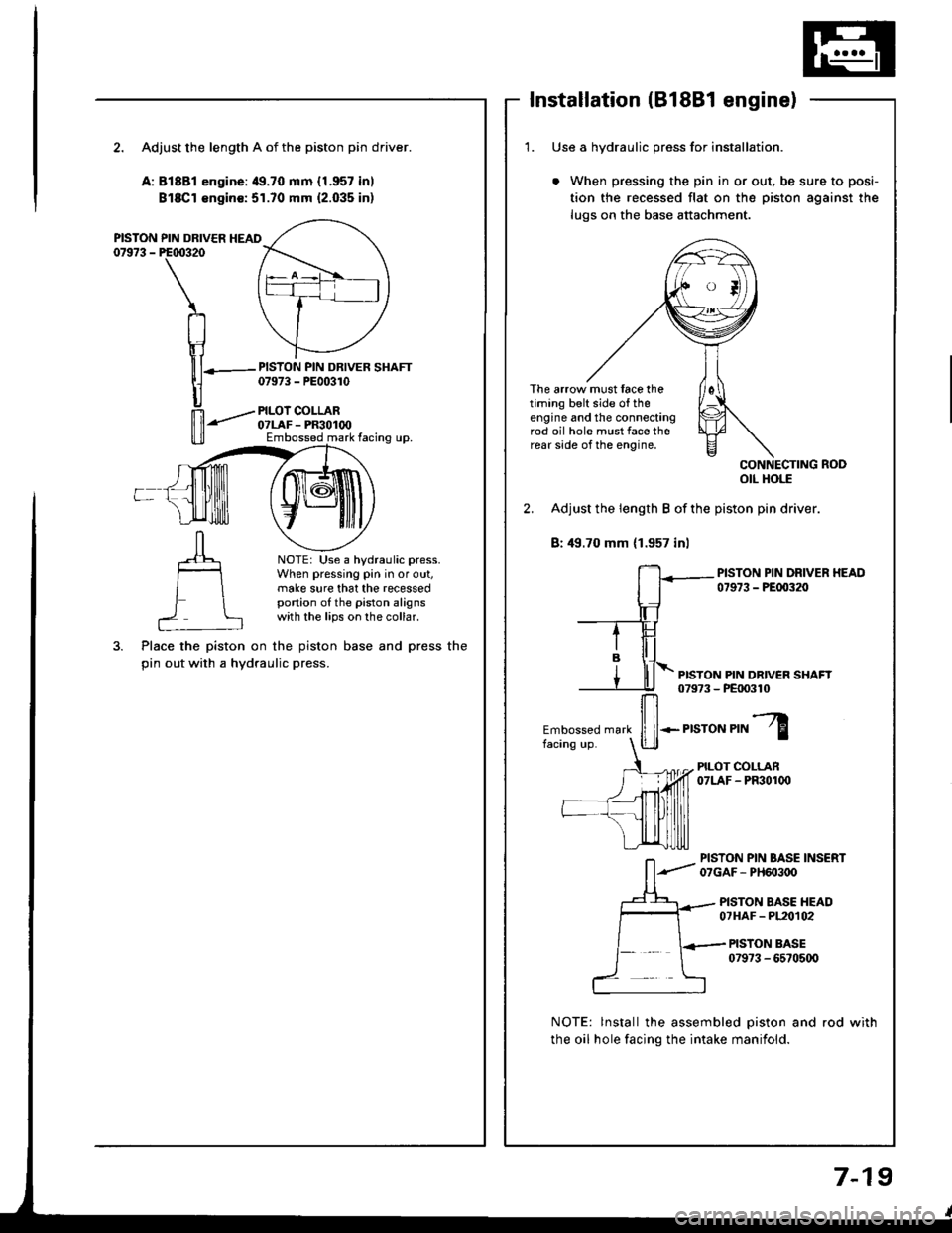

2. Adjust the length A of the piston pin driver.

A:81881 engine:49.70 mm {1.957 inl

Bl8Cl €ngin€:51.70 mm {2.035 inl

PISTON PIN DRIVER HEAD07973 - PE00320

PISTON PIN DRIVER SHAFT07973 - PE00310

PILOI COLLAR07LAF - PR30100Embossed mark facing up.

NOTE: Use a hydraulic press.When pressing pin in or out,make sure that the recessedportion of the piston alignswith the lips on the collar.

Place the piston on the piston base and press the

pin out with a hydraulic press.

1. Use a hvdraulic oress for installation.

When pressing the pin in or out, be sure to posi-

tion the recessed flat on the piston against the

lugs on the base attachment.

The arrow must face thetiming belt side o{ theengine and the connectingrod oil hole must face therear side of the engine,

otl Hols

2. Adjust the length B of the piston pin driver.

B: 49.70 mm (1.957 inl

PISTON PIN DRIVER HEAD07973 - PEfl)320

PISTON PIN DR|VEN SHAFT079?3 - PE|X)310

Embossed mark

ffi*.r,"ror","l

PILOT COLLAN07LAF - PF301(x)

PISTON PIN BASE INSERT07GAF- PH603oO

PISTON BASE HEAD07HAF - PL20t02

PISTON BASE079?3 - 6570500

NOTE: lnstall the assembled piston and rod with

the oil hole facing the intake manifold.

7-19

Page 160 of 1413

Piston Pins

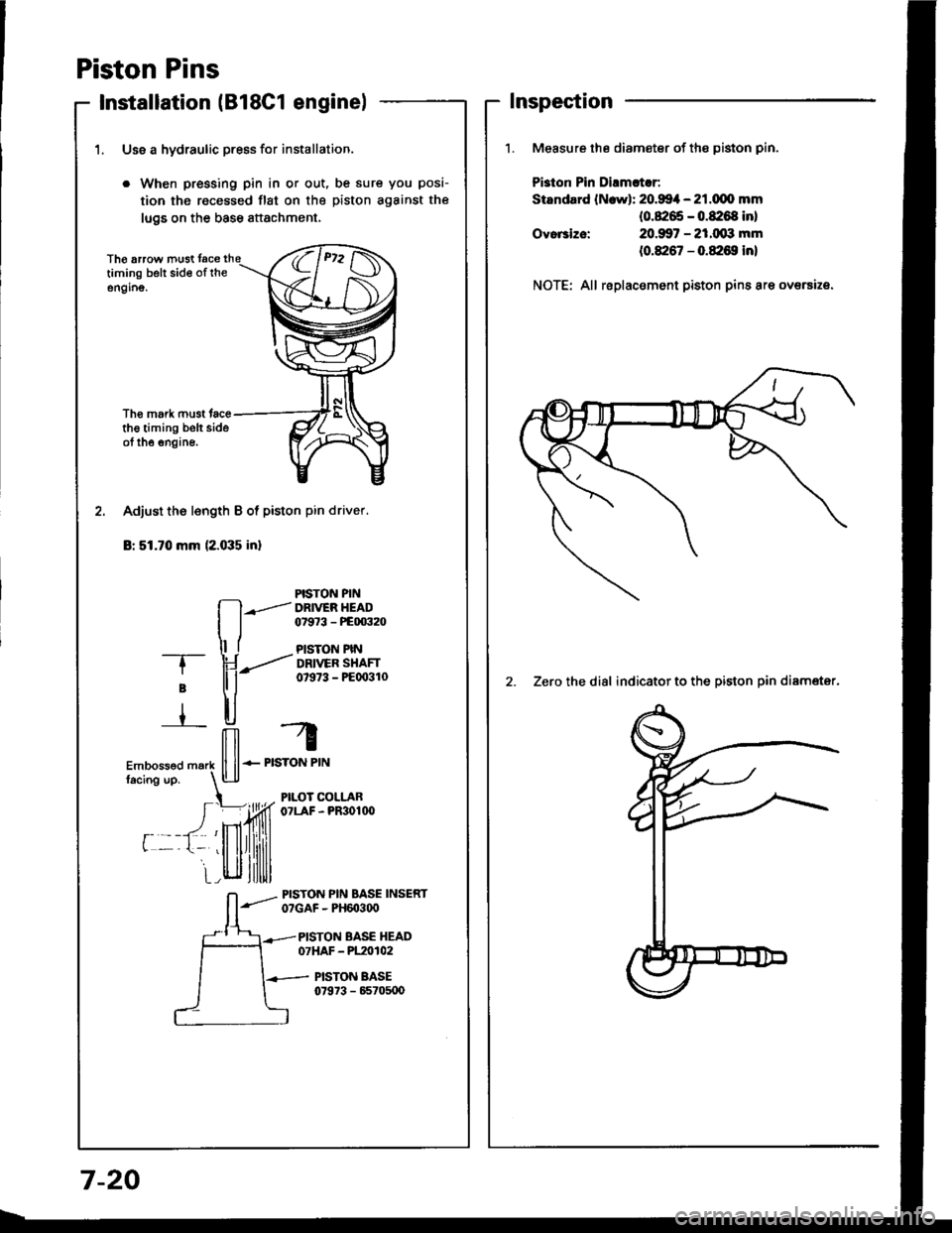

Installation lB18C1 enginel

1. Use a hydraulic press for installation.

. When pressing pin in or out, be sure you posi-

tion the recessed flst on the piston against the

lugs on the base attachment,

Th€ arrow must tacetiming belt sid€ of rheengino.

Tho mork must tacethe timing belt sideot the engine.

PISTON PIN

fl--.l DRr

ER HEAD

I j 07e73 - PEm32o

ll t PlsroN PtN-T- \J ---..'' DRtvER sHAFr

; tl i- 07s73 - PEoo3lo

r ll-,H, -4

ilil r

Embossed m.rk ll ll-- PISTON PIN

facins up. l!-lJ

t PILOT COLLAR

I =)ffi o?LAF-PR3o1n'

r --t- 'llllrllilill

i_r_,llll,ltlllll

L-lt|lllltlll

Adjust the l€ngth B of piston pin driver.

Br 51.70 mm (2.035 inl

_- PrsroN PIN BASE INSERTO?GAF - PH6O3q)

PISTON BASE HEAD07HAF - P120102

PISTON BASE07973 - 65705U)

Inspection

Measure the diameter of the piston pin.

Pi3ton Pin Dirmltlr:

Standard lN.wl: 20.994 - 21.dlo mm(0.8265 - 0.8:168 inl

20.907 - 21.(xxt mm

(0.8267 - 0.&16S in)

Ovo.3ize:

NOTE: All replacement piston pins are oversize.

2. Zero the dial indicator to the piston oin diamater.

7-20