cks HONDA INTEGRA 1994 4.G Manual PDF

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 1190 of 1413

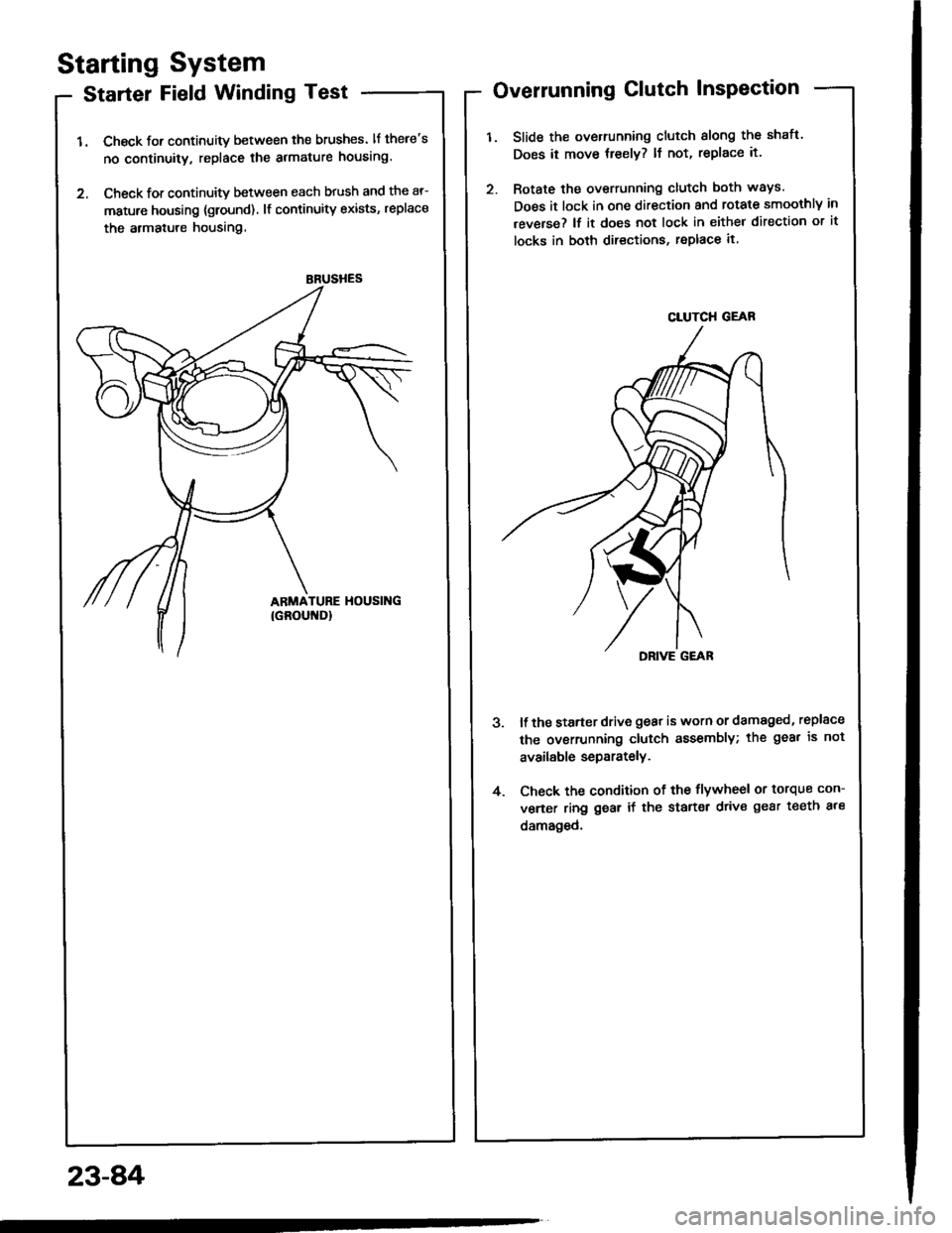

BRUSHES

Starting System

Starter Field Winding Test

1. Check for continuity between the brushes. lf there's

no continuity, replace the armature housing.

2. Check for continuity between each brush and the ar-

mature housing {ground) lf continuity exists, replace

the armatule housing.

Overrunning Clutch InsPection

Slide the overrunning clutch slong the shatt.

Does it move treely? ll not, replace it.

Rotate the overrunning clutch both ways.

Does it lock in one direction and rotate smoothly in

reverse? lf it does not lock in either direction or it

locks in both directions, replace it.

DRIVE G€AR

ll the starter drive gear is worn or damaged, replsce

the ovsrrunning clutch assembly; the gea. is not

available separately.

Check the condition of the flywheel or torque con-

verter ring gear if the starter drive gear teeth ale

damaged.

4.

23-8,4

CLUTCH GEAR

Page 1192 of 1413

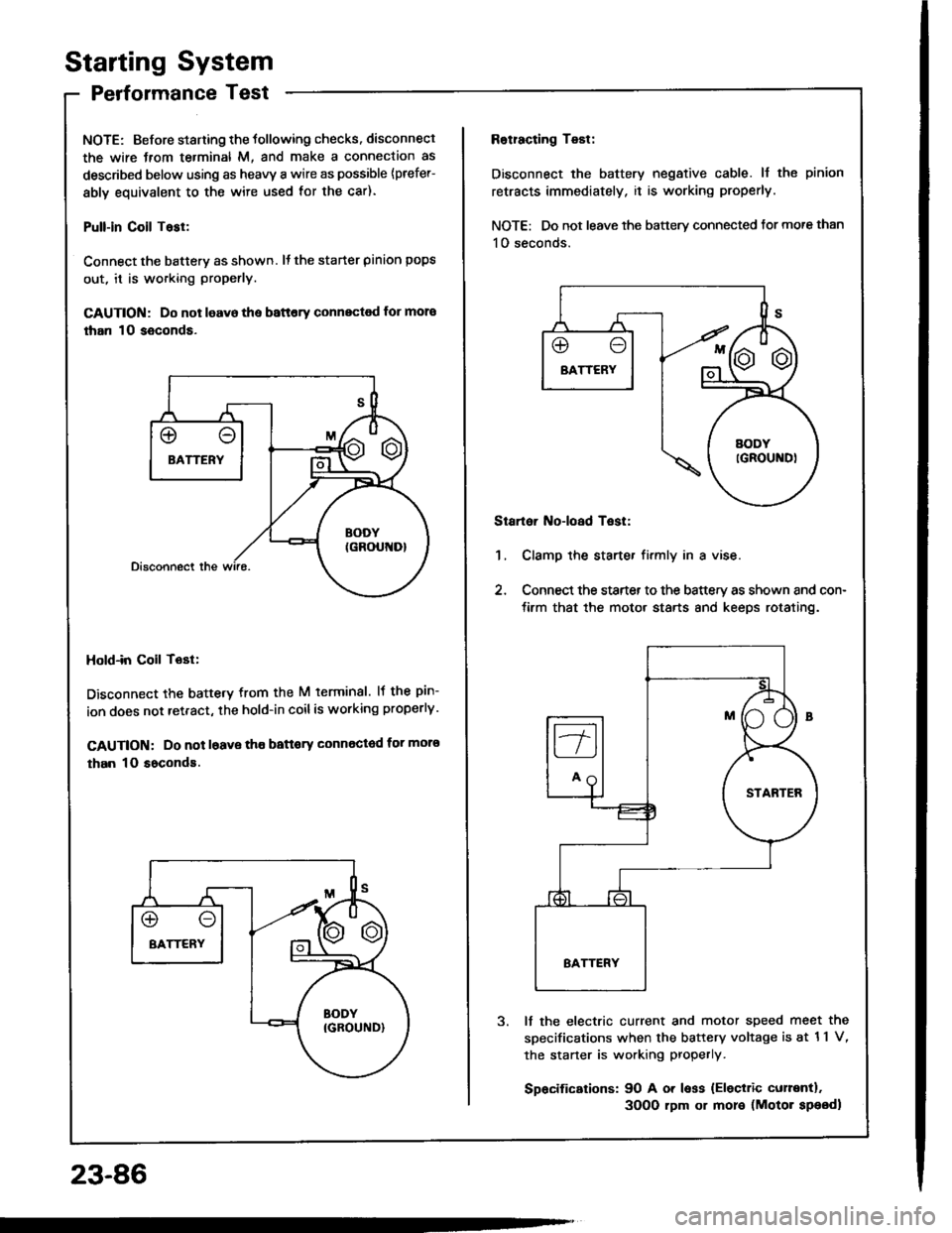

Starting System

Performance Test

NOTE: Before staning the tollowing checks. disconnect

the wire Jrom te.minal M, and make a connection as

described below using as heavy a wire as possible {prefer-

ably equivalent to the wire used for the car).

Pull-in Coil Tasl:

Connect the batterv as shown. It the starter pinion pops

out, it is working properly.

GAUTION: Do not leavo the battery connectod for mora

than 10 seconds.

Hold-in Coil Tost:

Disconnect the battetv from the M terminal. lf the pin-

ion does not retract, the hold-in coilis working properly.

CAUTION: Do not l6ave tho battory Gonnected for moro

than 10 soconds.

23-86

Rotracting Test:

Disconnect the battery negative cable. ll the pinion

retracts immediately, it is working properly.

NOTE: Do not leave the battery connected tor more than

1O seconds.

Startoi Noioad Test:

1, Clamp the starte. firmly in a vise.

2, Connect the starter to the battery as shown and con-

tirm that the motor starts 8nd keeps rotating.

It the electric current and motor speed meet the

sDecifications when the battery voltage is at 11 V,

the staner is working properly.

Spacifications: 90 A or less {Eleciric curentl.

3OO0 rpm or more (Motor speodl

Page 1197 of 1413

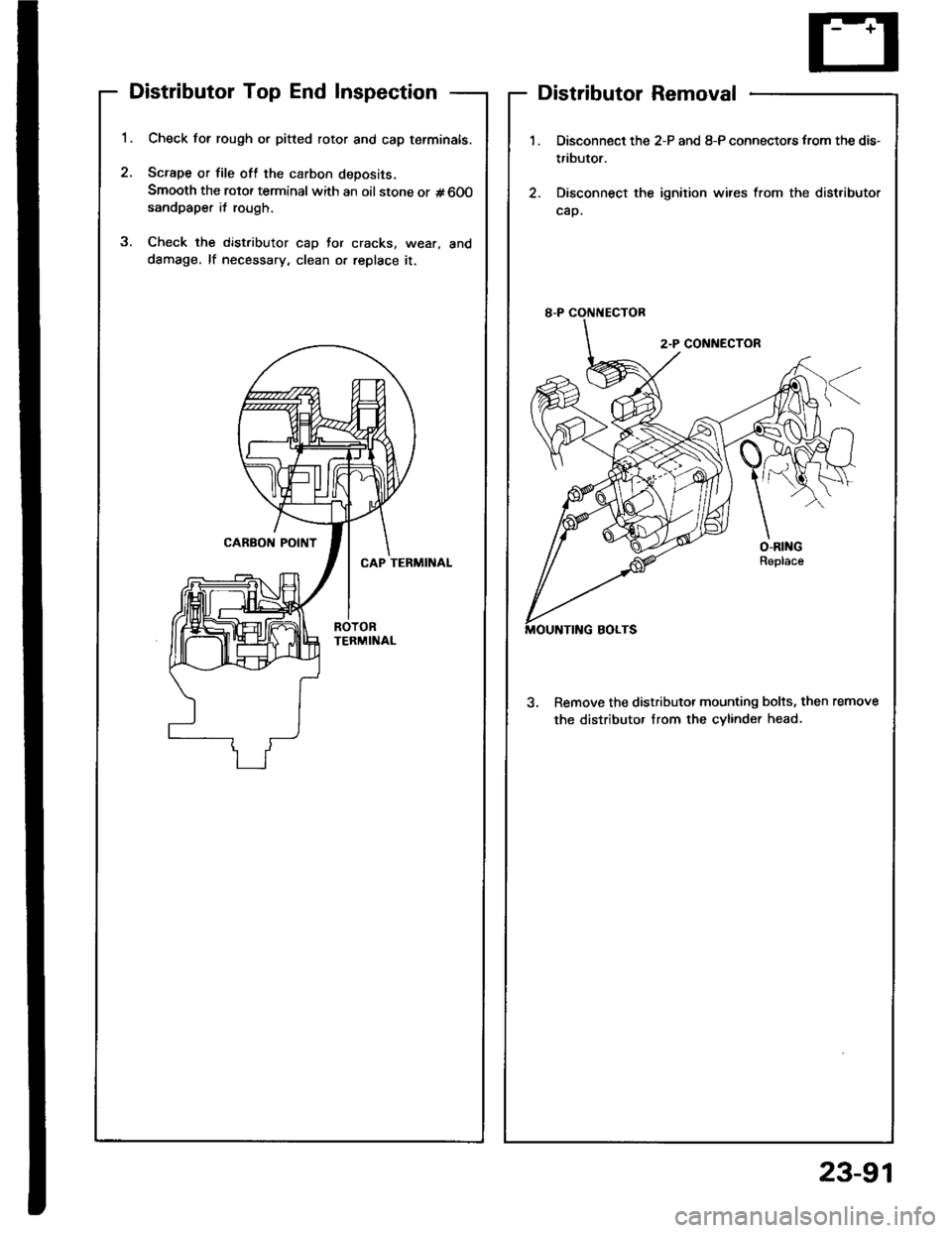

Distributor Top End Inspection

1.

2.

Check for rough or pitted rotor and cap tefminals.

Scrape or file oft the carbon deposits.

Smooth the rotor terminal with an oil stone or #600sandpaper i{ rough.

Check the distributor cap Jor cracks, wear, and

dSmage, lf necessary, clean or replace it.

2

Distributor Removal

1.

2.

Disconnect the 2-P and 8-P connectors from the dis-

tributor.

Disconnect the ignition wires from the distributor

cap.

3. Remove the distributor mounting bolts, then remove

the distributor Irom the cvlinder head.

23-91

Page 1199 of 1413

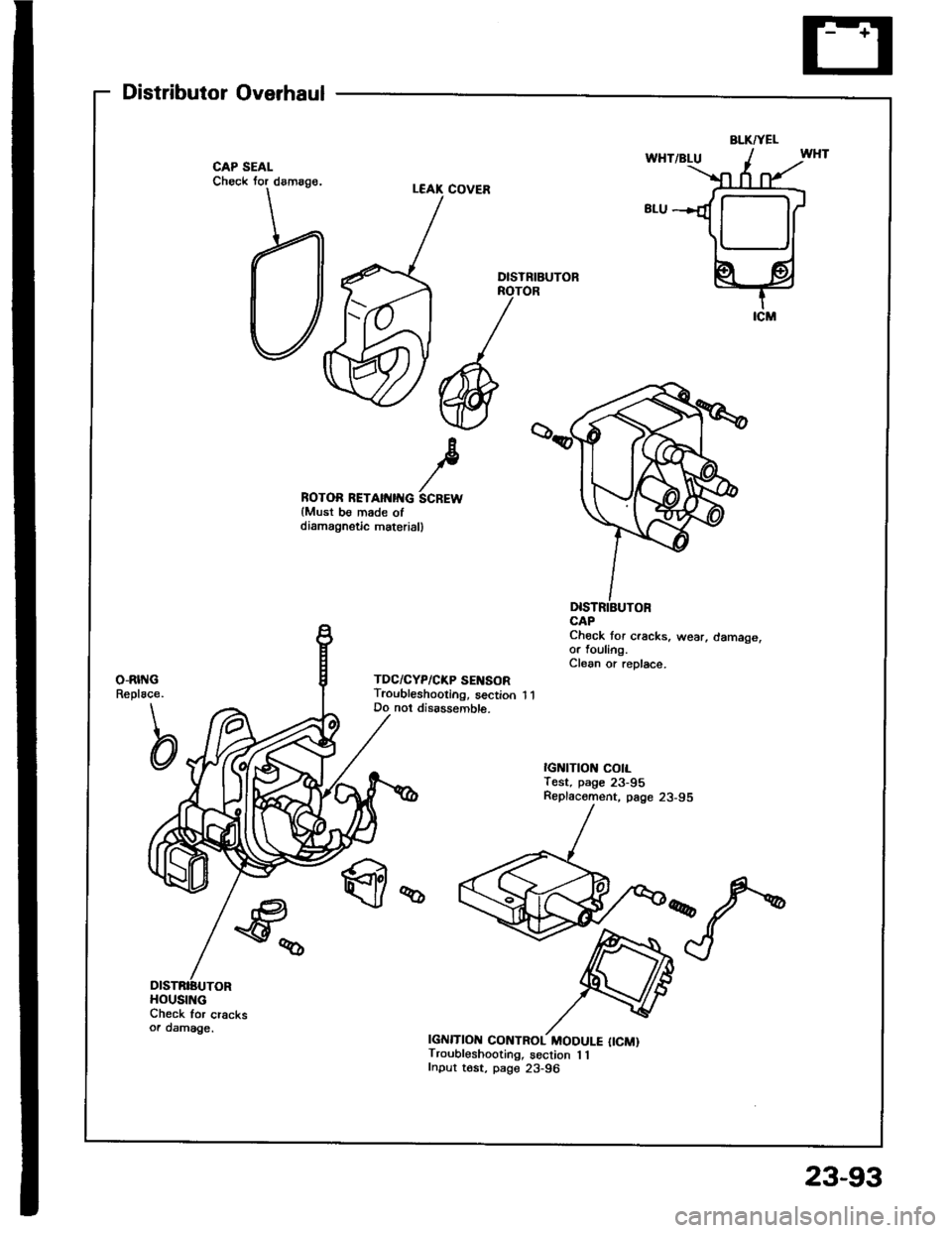

Distributor Overhaul

Check for cracksoa damage.

ROTOR RETAII{IITG SCREWlMust be made ofdiamagnstic materiall

DlsTNIBUTOR

Chock tor cracks, wear, damage,or fouling.Clean or replace.

IGNITION CONTROL MODULE {ICM)Troubleshooting, section 1 1Input tost, page 23-96

BLKTYEL

HOUSING

23-93

Page 1212 of 1413

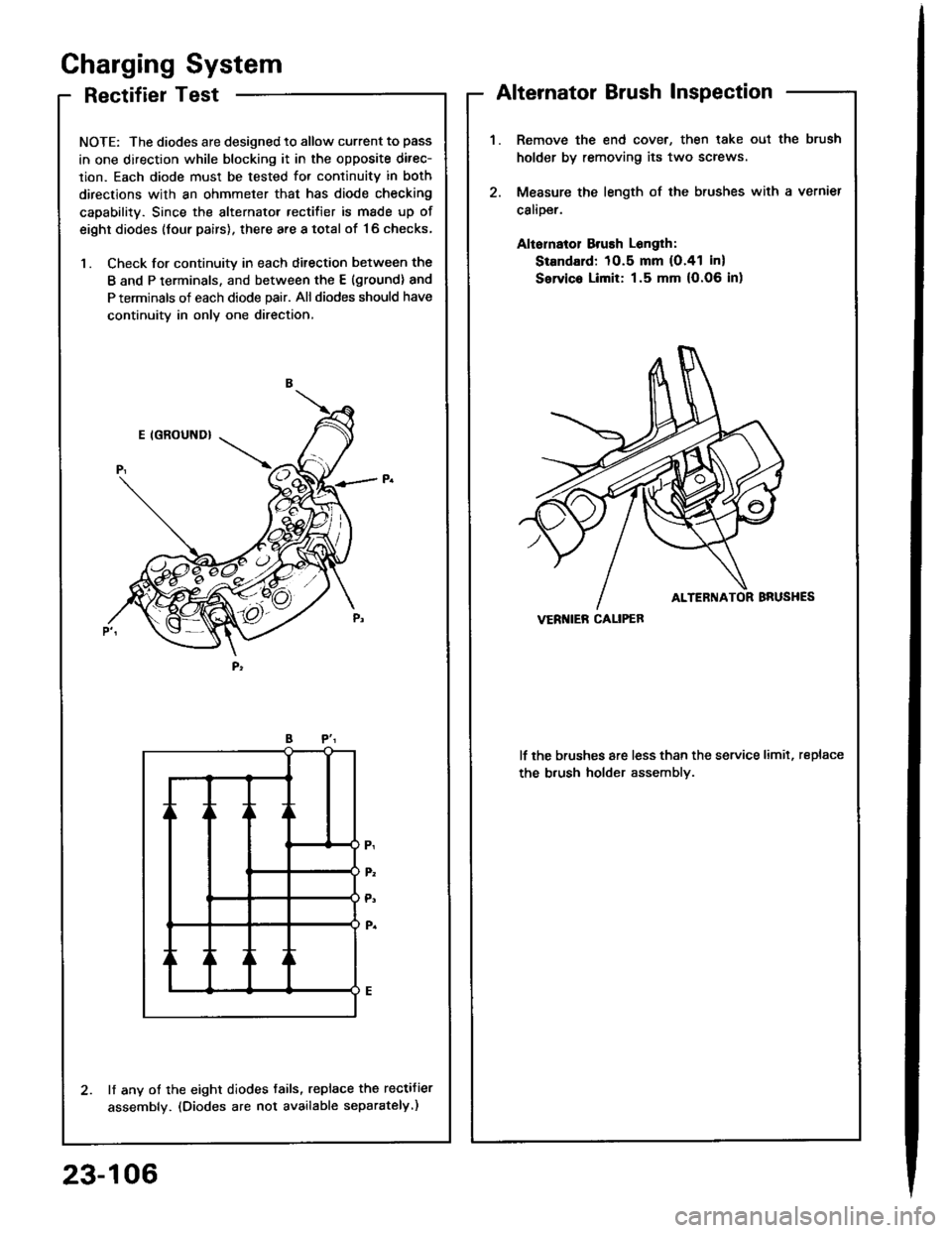

RectifierTest

NOTE: The diodes are designed to allow current to pass

in one direction while blocking it in the opposite direc-

lion. Each diode must be tested for continuitv in both

directions with an ohmmeter that has diode checking

capability. Since the alternator rectifier is made up of

eight diodes (four pairs), there are a total of '16 checks,

1. Check for continuity in each ditection between the

B and P terminals, and between the E (ground) and

P terminals of each diode pair. All diodes should have

continuity in only one direction,

lf any of the eight diodes tails, replace the rectifier

assembly. (Diodes are not available separately.)

Gharging System

Alternator Brush Inspection

Remove the end cover, then lake oul the brush

holder by removing its two screws

Measure the length of the brushes with a vernier

calioer.

Aliornatol Brush Longlh:

Standard: 10.5 mm (O.41 in)

Servic. Limit: 1.5 mm (O.06 in)

lf the brushes are less than the service limit, replace

the b.ush holder assemblv.

VERI{IEB CALIPEB

23-106

Page 1247 of 1413

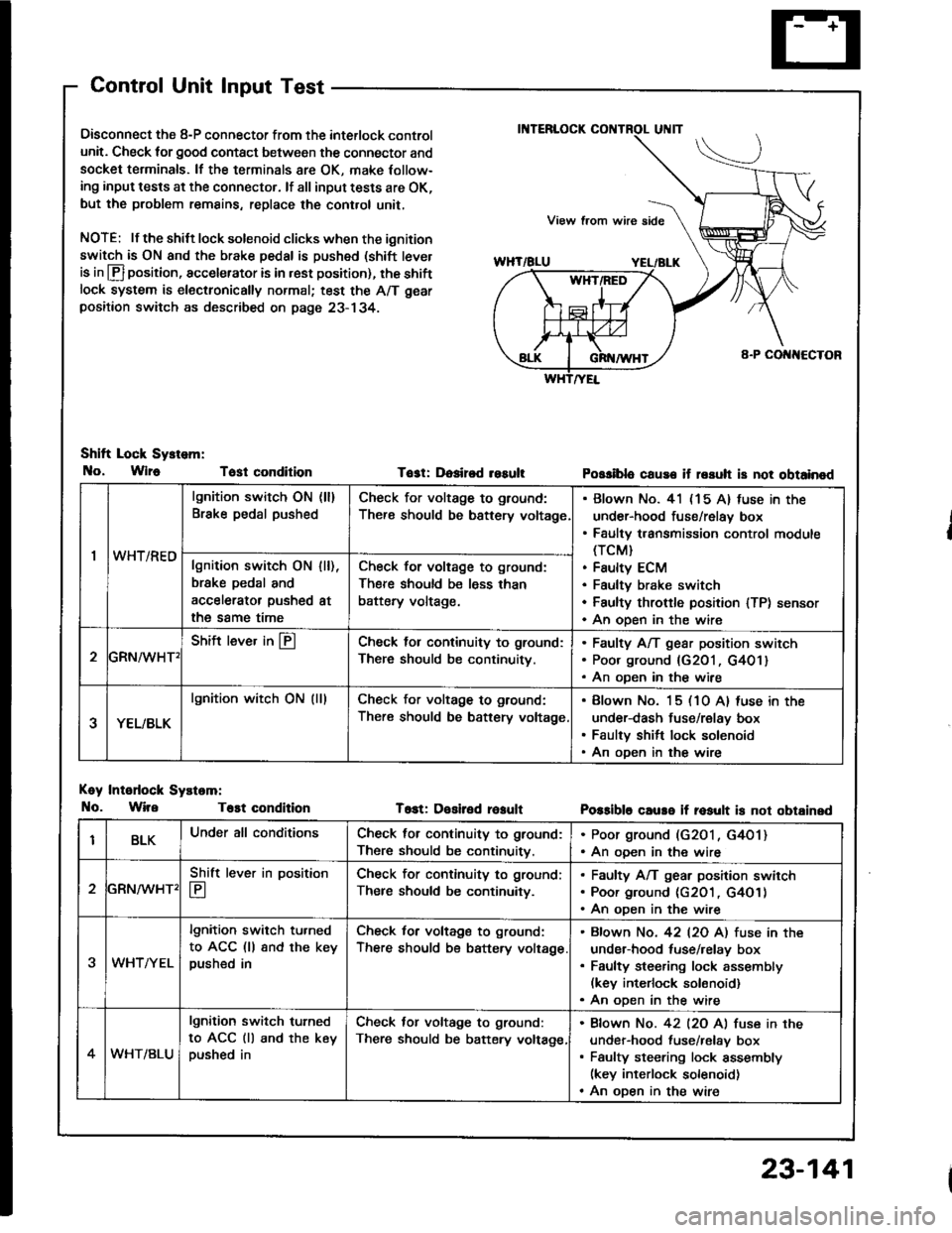

Control Unit Input Test

Oisconnect the 8-P connector from the interlock control

unit. Check for good contact between the connector and

socket terminals. lf the terminals 8re OK, make Iollow-

ing input tests at the connector. lf all input tests are OK,

but the problem remains, replace the cont.ol unit,

NOTE: lf the shilt lock solenoid clicks when the ignition

switch is ON and the brake pedal is pushed (shift tever

is in lfl position, accelerator is in rest position), the shiftlock system is electronically normal; test the A/T gear

positaon switch as described on page 23- 134.

Shift Lock Sy.tem:

No, Wlr6 Tost condition

Koy Intodock Systam:

No. WireT6st condition

Tost: Dosired resultPossiblo cause if rssuh is not obtainod

T6st: Desiled reaultPossible caure if rosult is not obtainsd

'I

lgnition switch ON (ll)

Brake pedal pushedCheck for voltage to ground:

There should be bsttery voltage

Blown No. 41 (15 A) fuse in the

under-hood fuse/relay box

Faulty transmission control module(TCM}

Faulty ECM

Faultv brake switch

Faulty throftle position lTP) sensor

An oDen in the wire

wn t/hEulgnition switch ON

brske pedal and

accelerator pushed

the same time

I [),

at

Check for voltage to ground:

There should be less than

battery voltage.

GRN^/vHT'

Shift lever in @Check lol continuity to ground:

There should be continuity.

Faulty A/T gear position switch

Poor ground {G201, G401}

An oDen in the wire

YEL/BLK

lgnition witch ON (lllCheck for voltage to ground:

There should be battery voltage

Blown No. 15 (10 A) luse in the

under-dash fuse/relay box

Faulty shift lock solenoid

An oDen in the wire

BLKUnder all conditionsCheck for continuity to ground:

There should be continuitv.

. Poor ground (G2O1, G4O1). An ooen in the wire

2

Shift lever in position

E

Check for continuity to ground;

Ther€ should be continuity.

Faulty A/T gear position swirch

Poor ground (c2O1 , G4O1)

An oDen in the wire

3WHTAYEL

lgnition switch tu.ned

to ACC (ll 8nd the keypushed in

Check for voltage to ground:

There should be battery voltage

Bfown No. 42 l2O Al fuse in the

under-hood tuse/relay box

Faulty steering lock assembly(kev interlock solonoid)

An oDen in the wire

4WHT/BLU

lgnition switch turned

to ACC (ll and the keypushed in

Check tor voltage to ground:

There should be batery voltage,

Bfown No. 42 l2O Al fuse in the

under-hood fuse/relav box

Faulty steering lock assembly(key interlock solenoid)

An oDen in the wire

23-141

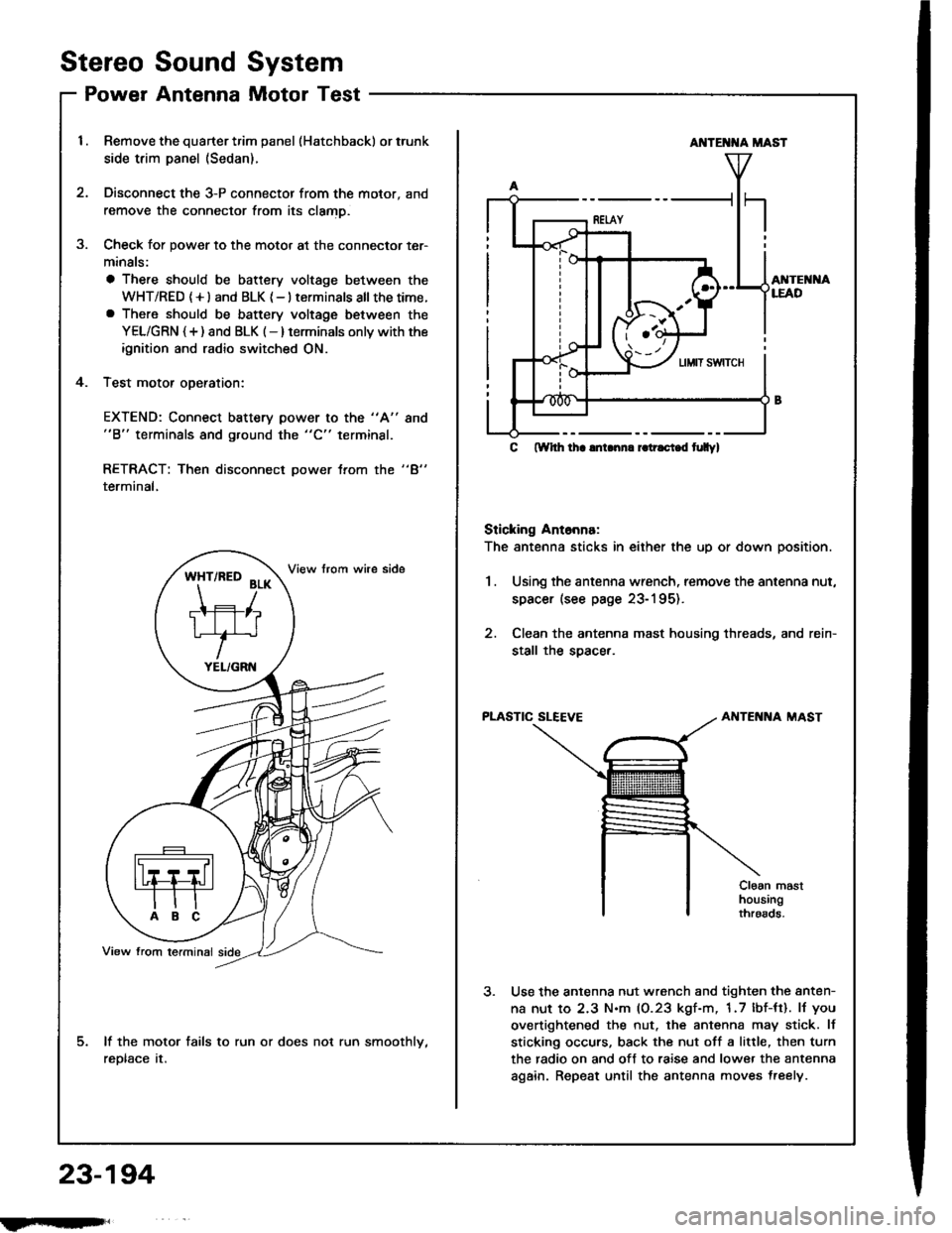

Page 1300 of 1413

Stereo

Power

Sound

Antenna

System

Motor Test

Remove the quarter trim panel (Hatchback) or trunk

side trim panel (Sedan).

Disconnect the 3-P connector from the motor, and

remove the connector from its clamD.

Check for power to the motor at the connector ter-

minals:

a There should be battery voltage between the

WHT/RED (+l and BLK {-} terminals all thetime.a There should be battery voltage between the

YEL/GRN {+) and BLK (-} terminals onlv with the

ignition and radio switched ON.

Test motor oDeration:

3.

4.

EXTEND: Connect battery power to the "A"

"B" terminals and ground the "C" terminal.

8no

"4"RETRACT: Then disconnect power trom the

terminal,

lf the motor fails to run or does not run smoothlv,

reDtace tr.

*ft'^to

?r*

TIFIT*r'

YEL/GRN

AI{TE T{A MAST

AI{TEI{I{ALEAD

C ftYhh lha lnLnn. r.tr.ci.d t|Ilyl

Sticking Ant6nna:

The antenna sticks in either the up or down position.

1.Using the antenna wrench, remove the antenna nut,

spacer (see page 23-195).

Clean the antenna mast housing threads, and rein-

stall the soacer.

PLASTIC SLEEVEAIITENNA MAST

Cloan masthousingthroads.

Use the antenna nut wrench and tighten the anten-

na nut to 2.3 N.m (0.23 kgf-m, 1.7 lbf-tt). lJ you

overtightened the nut. the antenna may stick. lf

sticking occurs, back the nut off a little, then turn

the radio on and off to raise and lower the antenna

again. Repeat until the antenna moves treely.

23-194

fmft,

Page 1339 of 1413

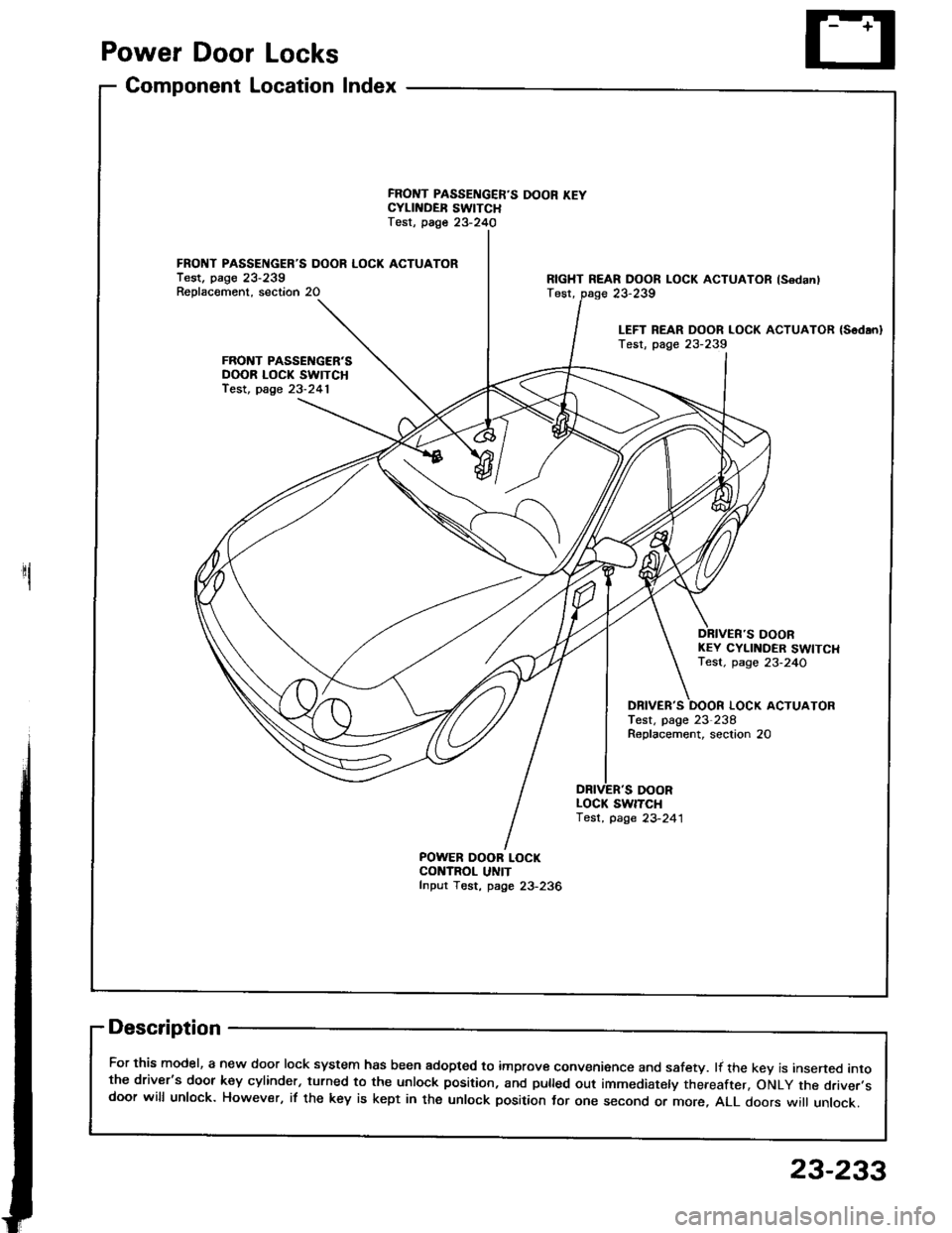

Power Door Locks

Component Location Index

1

FRONT PASSENGER'S DOOR LOCK ACTUATORTest. pago 23-239Reolacement. section 20

FRONT PASSENGER'SDOOR LOCK SWITCHfest, page 23-241

FRONT PASSENGER'S DOOR KEYCYLII{DER SWITCHTest, page 23-240

POWER OOOR LOCKCONTROL UNITfnput Tost, page 23-236

RIGHT REAR DOOR LOCK ACTUATOR lsodanlTest,

DOORKEY CYLINDER SWITCHTest. page 23-24O

DBIVER'S

DOOR

LOCK ACTUATORTest, page 23-238Roplacement, seclion 20

LOCK SWITCH'lest, page 23-241

Description

For this model, a new door lock system has been adopted to improve convenience and safety. lf the kev is insened intothe driver's door key cylinder, turned to the unlock position, and pulled out immediately thereafter, oNLy the driver.sdoor will unlock. However, if the key is kept in the unlock position tor one second or more, ALL doors wi

unlock.

23-239

LEFT REAR DOOR LOCK ACTUATOR {Sodan}Test, page 23-239

23-233

Page 1340 of 1413

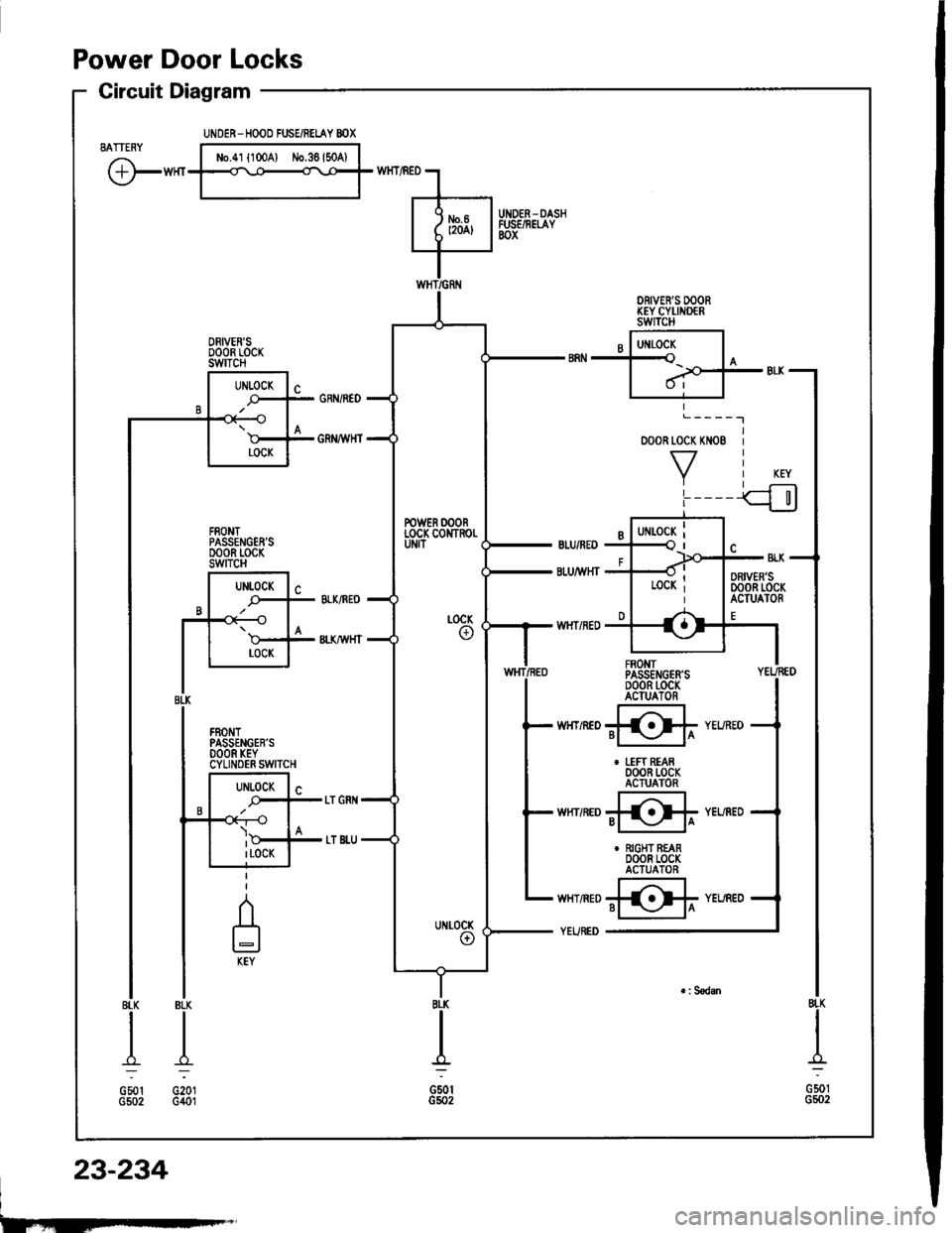

Power Door Locks

Circuit Diagram

BATTENY

@'"t

BLK

.&;

G201G401

o00R toc( KN08

VL____I

FROMTPASSENGER'SoooR t-ocKACIUATOR

@r

I uFt REAR000R LocKACTUATOR

@"

r RIGHT REAR000R LocKACTUATOR

@'

8LK

A=

G501G5o2

I

G501G5o2

UiIDER- HOOD FUSE/RELAY BOX

No.41 l100Al iJo,36l50A)

DRIVER'S OOOBKEY CYI,INDERswITcH

DRIVER'SoooR rocKswtTcH

FRONTPASSENGEN'SDOOR LOCKswncH

POWER OOORLOCK CONTROI.

8rl(

A-l

GSotG502

23-234

I

Page 1342 of 1413

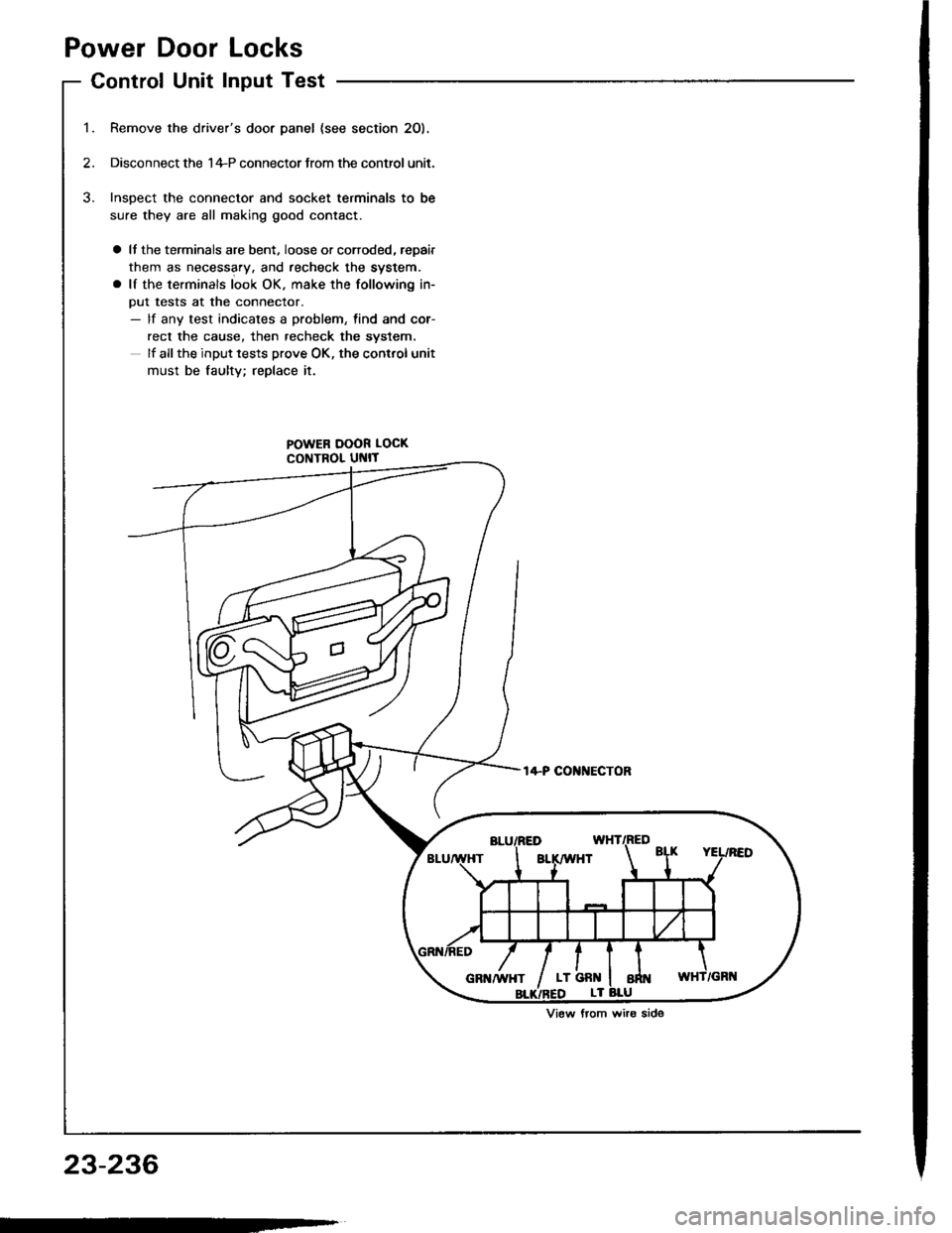

Power Door Locks

Control Unit Input Test

Remove the driver's door panel {see section 2O).

Disconnect the 1+P connector Jrom the control unit.

Inspect the connector and socket terminals to be

sure they are all making good contact.

a It the terminals are bent. loose or corroded, repair

them as necessary. and recheck the system.

a lf the terminals look OK. make the following in-

put tests at the connector.- lf any test indicates a problem, find and cor-

rect the cause, then recheck the syslem.

lf all the input tests prove OK, the control unit

must be faultv; replace it.

POWER DOOR LOCK

CONTROL UNIT

t4-P COI{NECTOR

View from wiro side

23-236