cks HONDA INTEGRA 1994 4.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 1102 of 1413

A/C Compressor Belt

Adjustment

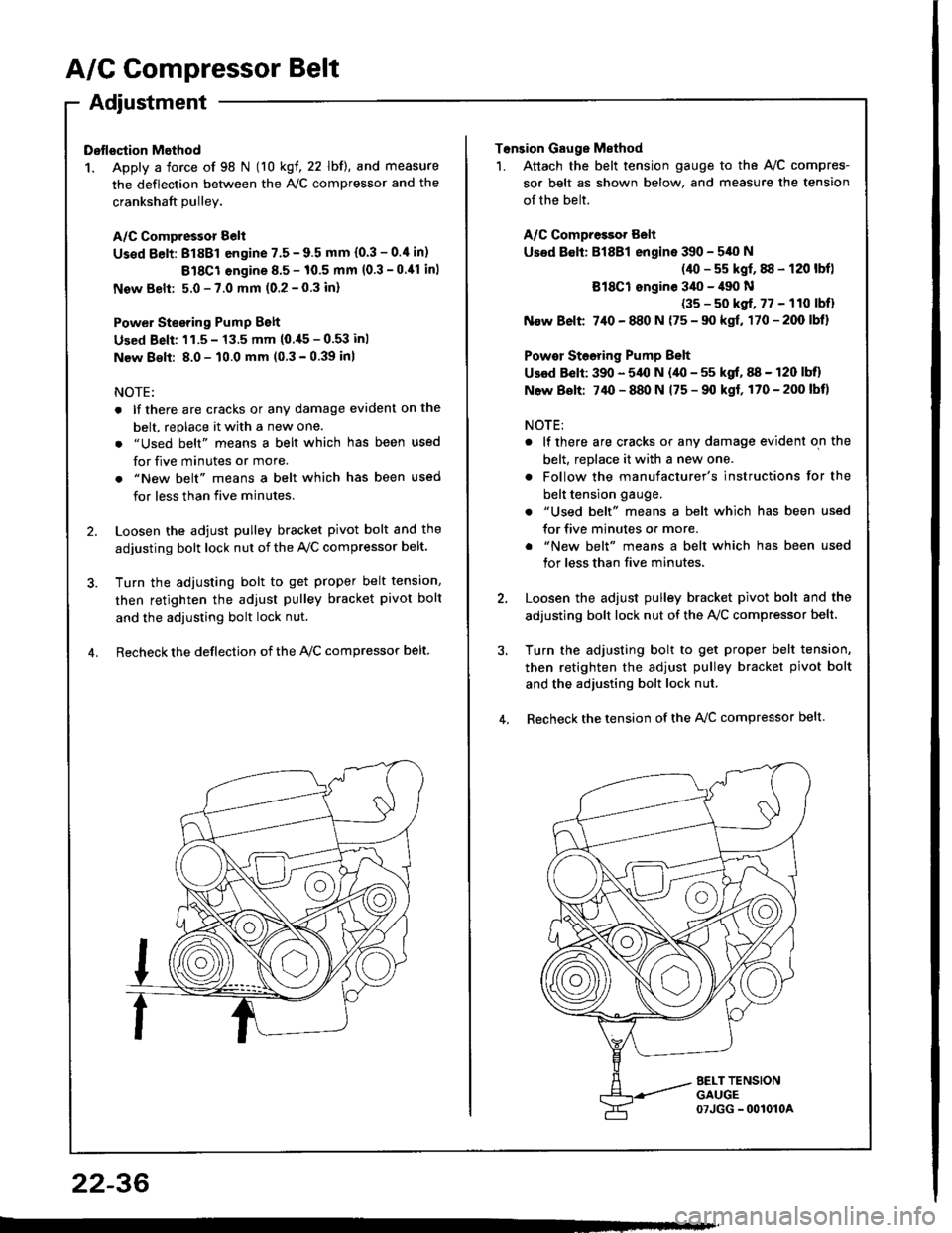

Dstlsqtion Method

1. Apply a force of 98 N (10 kgf, 22 lbf), and measure

the deflection between the A,/C compressor and the

crankshaft Dullev.

A/C Compressor Belt

Us€d Eelt: 81881 engine 7.5 - 9.5 mm (0.3 - 0.4 in)

Bl8Cl engine 8.5 - 10.5 mm (0.3 -0.11 inl

New Belt: 5.0 - 7.0 mm (0.2 - 0.3 inl

Power Stesring Pump Belt

Used Beli: 'l1.5 - 13.5 mm (0.,[5 - 0.53 inl

New 8€lt: 8.0 - 10.0 mm (0 3 - 0.39 inl

NOTE:

. lf there are cracks or any damage evident on the

belt, replace it with a new one.

. "Used belt" means a belt which has been used

for five minutes or more.

. "New belt" means a belt which has been used

for less than five minutes.

2. Loosen the adjust pulley bracket pivot bolt and the

adjusting bolt lock nut of the Ay'C compressor belt.

3. Turn the adiusting bolt to get proper belt tension,

then retighten the adjust pulley bracket pivot bolt

and the adjusting bolt lock nut.

4. Recheck the deflection of the lvc compressor belt

22-36

Tonsion Gauge Method

1. Attach the belt tension gauge to the Ay'C compres-

sor belt as shown below, and measure the tension

of the belt.

A/C Compressot Belt

Used 8€lt: Bl8Bl engine 390 - 540 N

(40 - s5 kgf, 88 - 120 lbfl

Bl8Cl ongine 3il0 - il90 N

(35 - s0 kgf, 77 - 110 lbfl

N€w Belt 7,10 - 880 N {75 - 90 kgf, 170-200lbl}

Powor Steoring Pump Belt

Used Belt: 390 - 5,{l N (40 - 55 kgf, 88 - 120 lbll

N6w Bolt: 74O - 880 N 175 - 90 kgf, 170-200lbt)

NOTE:

. lf there are cracks or any damage evident on the

belt, replace it with a new one.

. Follow the manufacturer's instructions for the

belt tension gauge.

. "Used belt" means a belt which has been used

for five minutes or more.

. "New belt" means a belt which has been used

tor less than five minutes,

2. Loosen the adjust pulley bracket pivot bolt and the

adjusting bolt lock nut of the AVC compressor belt.

3, Turn the adjusting bolt to get proper belt tension,

then retighten the adjust pulley bracket pivot bolt

and the adjusting bolt lock nut.

4. Recheck the tension of the A{/C compressor belt.

Page 1107 of 1413

Electrical

Special Tools

Troubleshooting

Tips and Precautions ................................ 23-3Five-stop Tloubleshooting ..............,...-..-... Z3-sSchematic Symbols ................................_. 23-6wire Color Cod€s ..................................... 23-6Relay and Control Unit Locations

Engine Compartment .........,............ ... --. 23-7Dsshboard and Door ..,,......................... 23-gDashboard and Floor ............................. 23-t OOuaner Panel .....-.....23-12Connector ldentification and WireHarness Routing ........ 23-i 3

Index to Circuits and Systems

Airbag ............... ...-..-... 2g-26sAir Conditioning ....,.. Section 2lAltelnator ......_.............. 23-99Anti-lock Brake Systsm (ABS) Section 19Automatic Transmission Section 14Battery .............. .......... 23-66Chafging System ........... 23-98rCigalstte Lighter .....................-...-......-..-.. Z3-2O4Cfock ................. ..........23-197rcruise Controf .......--..-... 23-242Distributor .................... 23-87Fan Controls ................. 23-1ogFuel and Emissions ... Section 1i*Fuses

Under-dash Fuse/Relay Box ................... 23-48Undor-hood ABS Fuse/Retay Box ............ 23-51Under-hood Fuse/Relay Box,.................. 23-52rGauges

Engine Coolant Temperature {ECT)Gauge ................ ..23-126Fuef cauge ............... 2g-123'Gauge Assembly ....--.23-113Speedometer .....-...,,. 23-114Tachometer .....,.....-.. 23-114Ground Distribution ........ 23-60Heater ,,,........,.... ..... Section 2lrHorn ................. ........... 23-199*fgnition Switch ............. 23-70fgnition Syst6m .......-..-.. 23-A7lgnition Timing .............. 23-89Indicator Lights"A/T Gear Position .............. ................... 23-1 32B1ak6 System ...,..,..-.23-127Engine Oil Pressura .............................. _ 23-1 51Low Fuel ............ ......23-125Malfunction Indicator Lamp {MlL} ...,,. Section I l

tfnteglated Control Unit ...29-144*lnterlock System ...................................... 23-1 3gLights, Exteriol

Back-up Lights ........... 23-179Brake Lights .............. 23-t8ltDaytime Running Lights {Csnada} ........... 23-156Front Palking Lights ............................. 23-1 65Flont Side Marker Lights ....................... 23-165Front Turn Signal Lights ........................ 23-1 65*Hazard Warning Lights .........................- 2g-1A4Headlights ................. 23-t6tLicense Plate Lights .............................. 23-1 69Taillights(Harchback) .......... 23-166

{Sedan) .............. .. 23-167Lights. Inteliol

Cargo Area Light {Hatchback) ...... -.. -.. -... 23-177Ceifing Light ........-..-.23-175

Dash Lights Blightness Controt .............. 23-t70Glove Box Lighr ................................... 23-1 69Spotfighr ............ ....-.23-174Trunk Light (Sedanl ............... .............. - 23.-177*Lighting Sysrem .......-.-... 23-152:Moonroof ,,.,.......,..,,,,,.-.23-211PGM-FI Systom ........ S€crion 11Power Distribution .,.-..--..23-54Power Door Locks .............,,..................... 23-233Power Mirors ..,..,....-...- 23-216Power Relays ...........,..... 23-68Power Windows ............ 29-222*Rear Window Defogger ........,... ..........,..... - 23-20,6Reminder Systems

Key-in Remindel System ....,.............,.... 23-1 50Lights-on Reminder System ................... 23-l 5f*Maintenance Reminder system ..,,.... -.. - -. 23-.1 2gSeat Belt Reminder System ..................- 23-125*Side Markel/Turn Signal/Hazard

Ffasher System .,..,..-.23.-1A4Spark Pfugs .........-...-..... 23-97Starting System ....,,.....-. 23-73*Stereo Sound System ...,.......................,,.. 23-l gg

Supplemental Restraint System {SRS} ......... 23-265Vehicfe Speed Sensor {VSS) .............--..-.... 23-122*Wiper/Washer Systom ...............--.........-..- Zg-254

rRead SRS pi€cautions on Page 23-271 betore workingin these areas.

-+

Page 1109 of 1413

Troubleshooting

Tips and Precautions

Before Troubloshooting

a Check applicable fuses in the appropriate fuse/relay

DOX.

a Check the battery for damage, state of charge, and

clean and tight connections.a Check the alternator belt tension.

CAUTION:

a Do not quick-charg€ a battery unless the batteryground cabla has be€n disconnoctsd. oth€rwisoyou will damage the alternator diodss.a Do not att6mpt to crank the engine with the bat-tery ground cable loosely connectsd or you will se-vorsly damag€ tho widng.

a The original radio has a codod thatt plotection ci.-cuit. Be sul€ to got tho customor's code numbet

before- disconnecting th€ battery.- lomoving tho No. 32 (7.5 Al tuso f.om the

under-hood tuse/lelay box.- removing tho radio.

Aflor s€lvic€. reconn€ct powet to tho radio and

turn it on. Whon the word "CODE" is displayed,

€nt€l the customer'E s-digit codo to .astore ladio

operation.

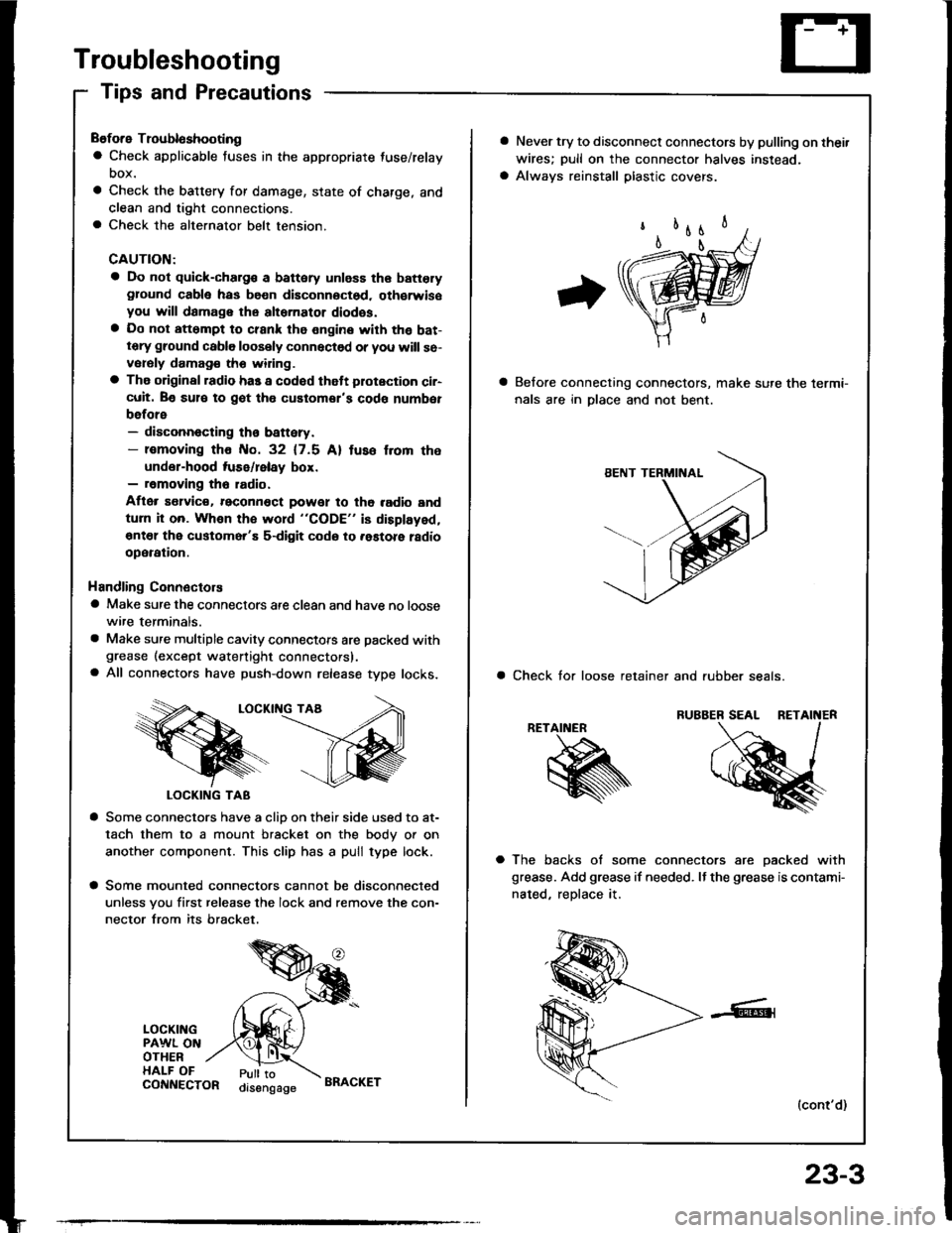

Handling Connectors

a Make sure the connectors are clean and have no loose

wire terminals.

a Make sure multiple cavity connectots are packed withgrease (except watertight connectors).a All connectors have push-down release type locks.

LOCKII{G TAA

LOCKING TAB

a Some connectors have a clio on their side used to at-

tach them to a mount bracket on the body or on

another component. This clip has a pull type lock.

a Some mounted connectors cannot be disconnected

unless you first release the lock and remove the con-

nector from its bracket.

LOCKINGPAWL ONOTHERHALF OFPull toorsengageCONNECTORBRACKET

23-3

a Never try to disconnect connectors by pulling on thei.

wires; pull on the connector halves instead.

a Always reinstall plastic covers.

Belore connecting connectors, make sure the lermi-

nals are in Dlace and not bent.

a Check tor loose retainer and rubber seals.

RETAINER

a The backs of some connectors are oacked with

grease. Add grease if needed. It the grease is contami-

nated, reDlace it.

(cont'd)

Page 1110 of 1413

Troubleshooting

Tips and Precautions (cont'dl

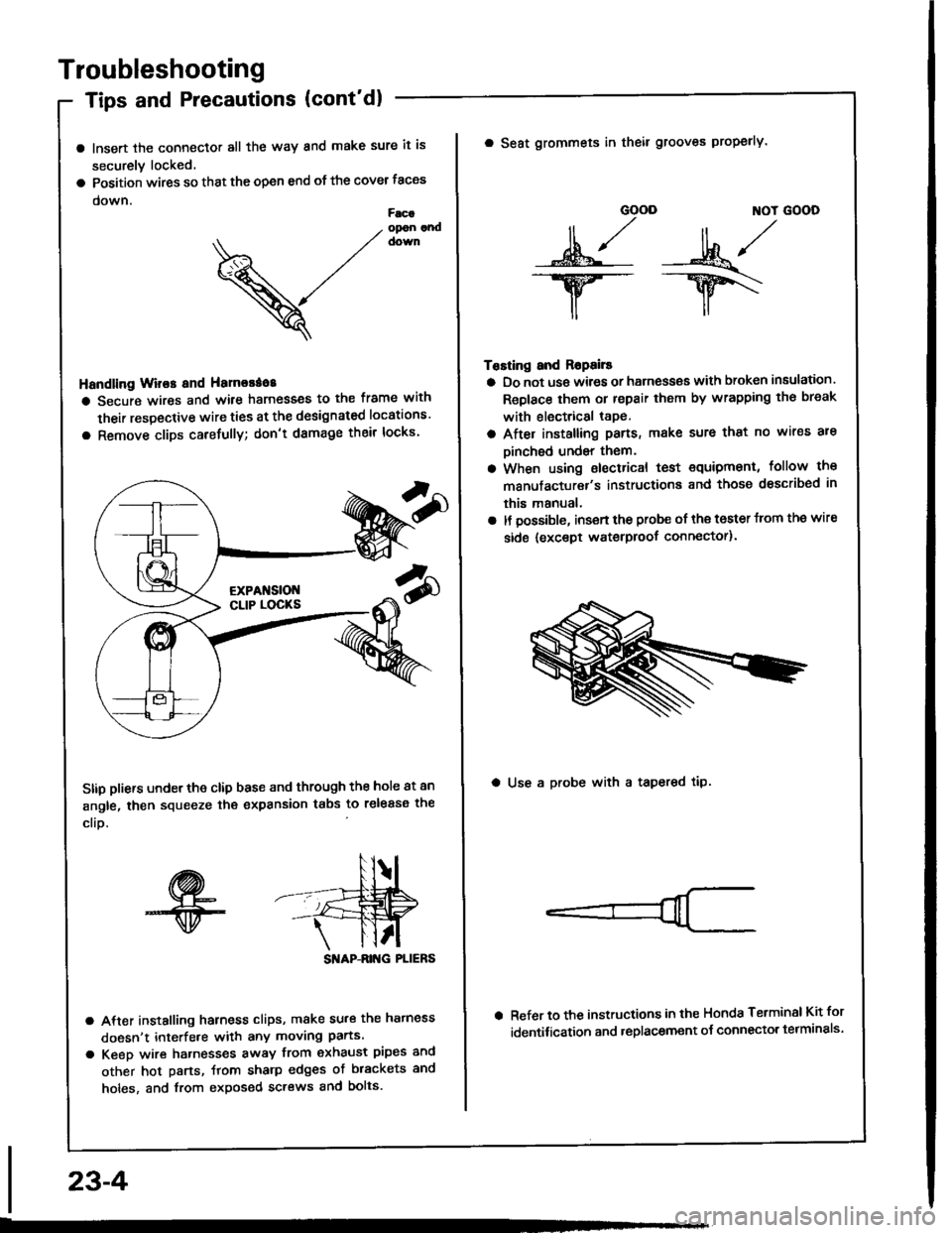

a lnsert the connector all the way and make sure it is

securely locked.

a Position wires so that the open end of the cover taces

down.Facaopon andcown

V

Handling Wir€s and Hamorao8

a Secure wires and wile harnesses to the frame with

their respective wire ties at the designated locations'

a Remove clips carefully; don't damage their locks'

Stip pliers under the clip base and through the hole at an

angle, then squeeze the expansion tabs to release the

clio.

SI'IAP-ANG PLIERS

a After installing harness clips, make su.€ the hatness

doesn't interfe.e with any moving parts.

a Keeo wire hatnesses away from exhaust pipes and

other hot parts, ftom sharp edges of brackets and

holes, and from exposed screws and bolts.

23-4

GOOD ]TOT GOOD

n,/r/ll ,,' ll ,,

s*j -:ut*/-.w-- --ry\

il,,

Tosting and Ropails

a Do not us€ wires or harness€s with broken insulation.

Replace them or repair them by wrapping th€ break

with electrical tape.

a After installing pans, make sure that no wir€s are

Dinched undsr them.

a When using electrical test €quipment, follow the

manufacturer's instructiona and those dsscribed in

this manual,

a It possible, insert the probe of the toster from the wire

side {except waterproof connector).

a Seat grommets in theil grooves properly.

a Use a probe with a tapered tip.

Refer to the instructions in the Honda Terminsl Kit for

identification and .eplacement o{ connector telminals'

Page 1156 of 1413

![HONDA INTEGRA 1994 4.G Repair Manual Fuses

Under-dash Fuse/Relay Box (contd)

NOTE: View from the backside of the under-dash tuse/relay box

c916[To m.in wlro h.rnr.t lol39]l

cgt5tTo ..r wftt hJtr.r (CsOrDl

c9r4[To Int grrtad control unhl HONDA INTEGRA 1994 4.G Repair Manual Fuses

Under-dash Fuse/Relay Box (contd)

NOTE: View from the backside of the under-dash tuse/relay box

c916[To m.in wlro h.rnr.t lol39]l

cgt5tTo ..r wftt hJtr.r (CsOrDl

c9r4[To Int grrtad control unhl](/img/13/6067/w960_6067-1155.png)

Fuses

Under-dash Fuse/Relay Box (cont'd)

NOTE: View from the backside of the under-dash tuse/relay box

c916[To m.in wlro h.rnr.t lol39]l

cgt5tTo ..r wftt hJtr.r (CsOrDl

c9r4[To Int grrtad control unhlc917[To mrin wh.

c913c91

lTo m.in wlro hlni.rr (qt38)ltTo r..r w|? hrt|.|t (C6O3ll

23-50

Page 1159 of 1413

![HONDA INTEGRA 1994 4.G Repair Manual NOTE; View from the backside of the under-hood fuse/relav box

c907lTo m.ln wiro h.mo$ (C214)l

[To msin wlro hEmoss lc215l]

c911lTo ftain wiro hamers (C218)l: USA

lTo mlln wlr. hlmct. (C216li

lTo mrin HONDA INTEGRA 1994 4.G Repair Manual NOTE; View from the backside of the under-hood fuse/relav box

c907lTo m.ln wiro h.mo$ (C214)l

[To msin wlro hEmoss lc215l]

c911lTo ftain wiro hamers (C218)l: USA

lTo mlln wlr. hlmct. (C216li

lTo mrin](/img/13/6067/w960_6067-1158.png)

NOTE; View from the backside of the under-hood fuse/relav box

c907lTo m.ln wiro h.mo$ (C214)l

[To msin wlro hEmoss lc215l]

c911lTo ftain wiro hamers (C218)l: USA

lTo mlln wlr. hlmct. (C216li

lTo mrin wiro hameq lC217ll

23-53

Page 1162 of 1413

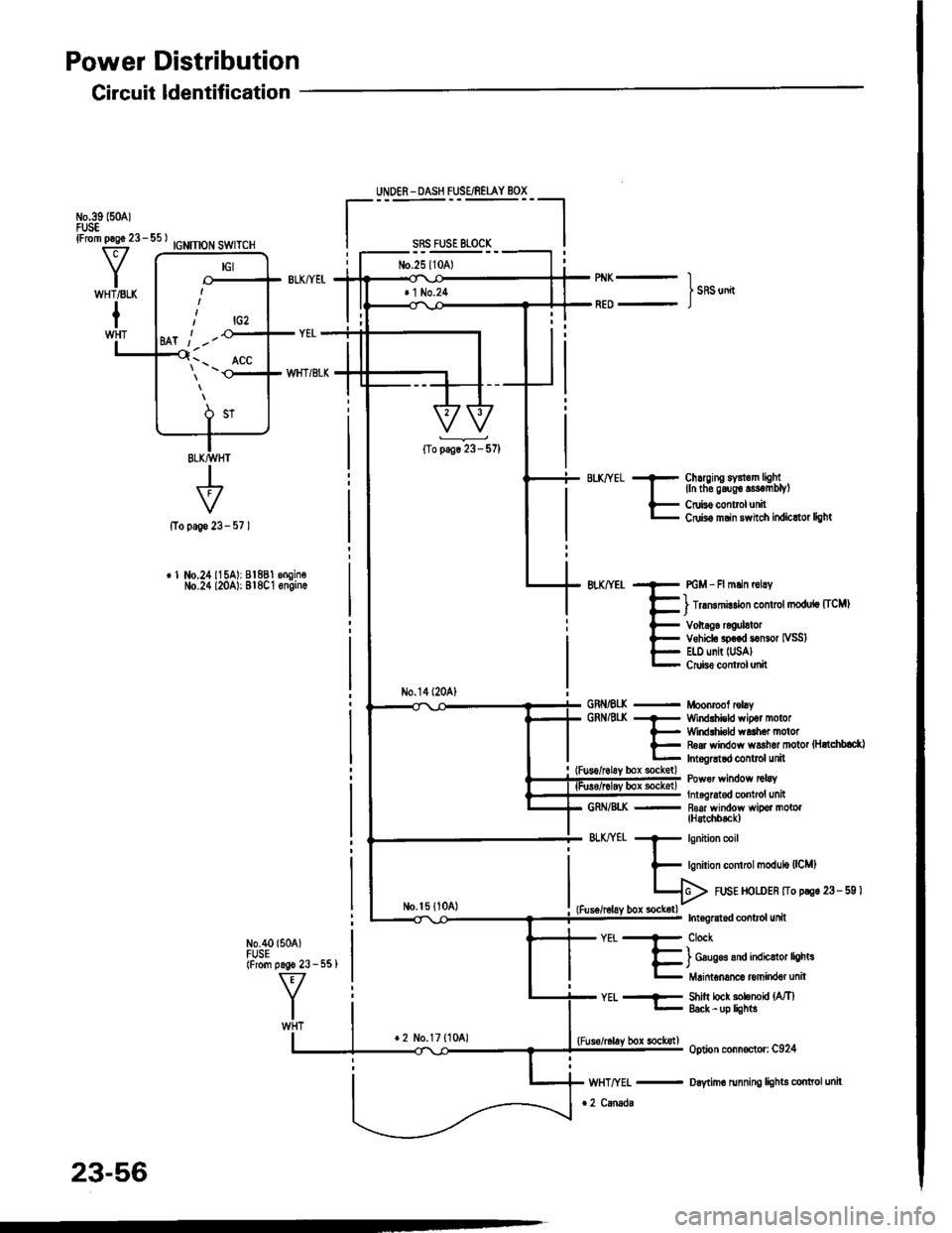

Power Distribution

Circuit ldentification

IGNITION SWITCH

+page 23-

r 1 No.24115A): 81881 engin€No.24 l20A): Bl8C1 6ngin.

N0.40 {504)FUSE(From pago 23 - 551

UNDER - DASH FUSE/REIAY BOX

sRs FusE 81-0cK

No.25l10Al

No.14l20A)

No.l5 {1041

Chuging sY3l.m lightlln tho g6ug€ s3€mblyl

Cruis€ controlunitCdis6 msin 3whch itdicttor light

PGM - Fl mlin r6lry

) lrrmmirdon control modulo [ICM)

Vohag6 rcoulatorVehiclo sp.€d somor IVSS)E|.l) unit IUSA)Crube conttol unit

Moonrcof rclayWind.hicld wipot motorWirdlhi€ld waah6. motorR6ar window ws3hor motot {HrtchblctlInt.gGtod control unit

Power wirdow tclaY

Int6lrat€d contrcl unit- R6af window wipor motol(H3tchbtck)

571

GRNiEI(GRNAt(

GRN/8I..K

BLKffEt

-EiT"h#,H#J:r"

Shitt lock solenoU {MlEack -up lights

option conn€ctor: C924

Daytimo running lights conttol unit

YEt..--

lrcz

Ml t -'-

\'- _ ^ACC

23-56

*2 No.17 {1041bor sockstl

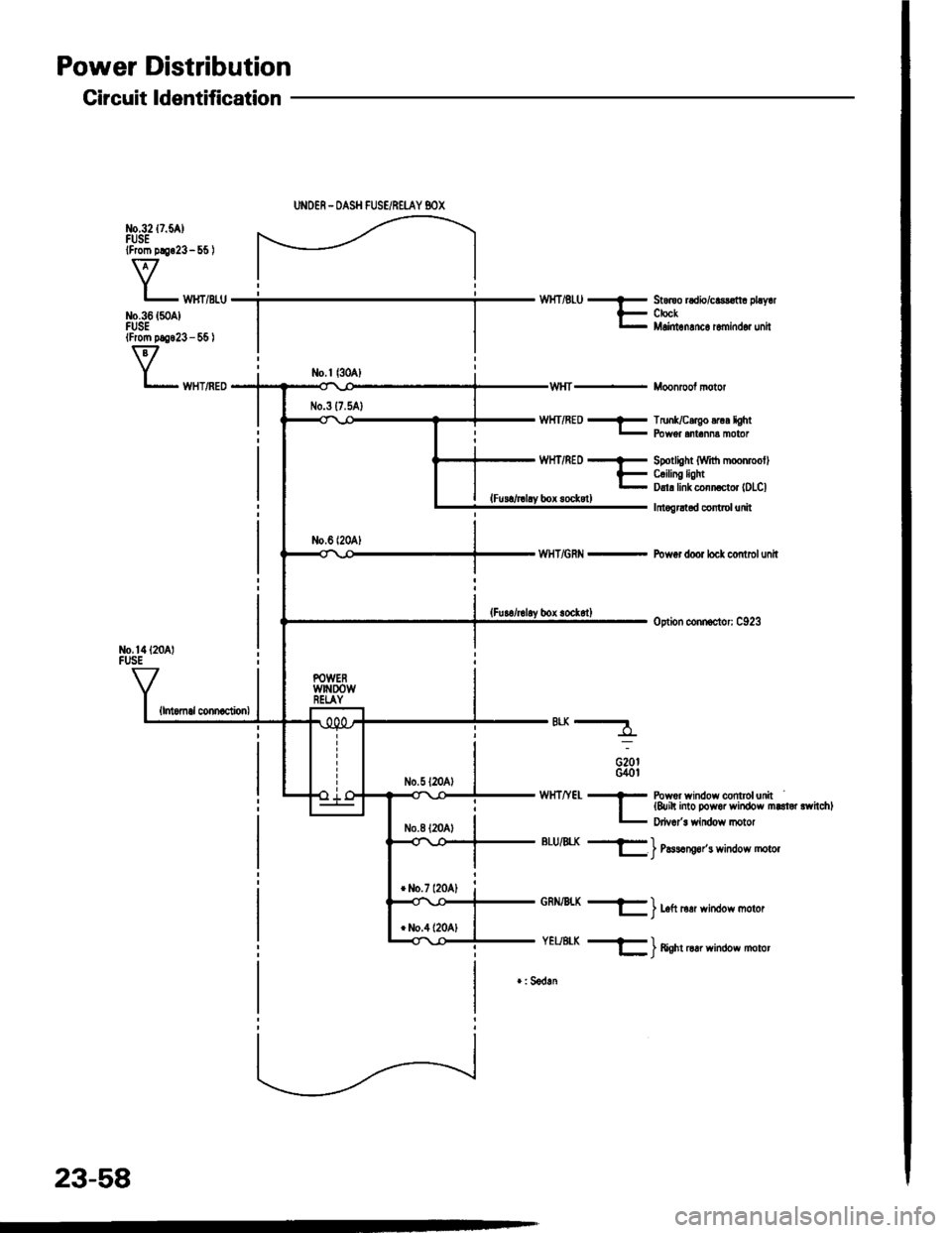

Page 1164 of 1413

Power Distribution

Circuit ldentification

No,14l20 lFUSE

{lntomal connaclionl

UNOER - OASH FUSE/REI-AY BOX

WHT/RED - TrunUcergo .rur lght- Fbwer .nr.nn! moror

WHT/REof

Ebox sockstl

WHT/GRN -

*-

G20tG40l

Spotlight (Wrt'h moonmollC.ilin! lightDrl! link conn ctor lDLCl

Irtogrltad control unit

Pow6r door locl control unit

option connoclor: C923

WHTIYEL * Powor window conttolunrt| {&ih into Dowor window marloi rwhchll- p,i""1" *;n6o* n o1o,

BLU/4X +ll_ | l,lssrng6r's wndow motor

GRN/BLX -

YEUE|-K -

) Left rerr window moror

) ftenr oar winoow motor

r: Sedln

23-58

Page 1176 of 1413

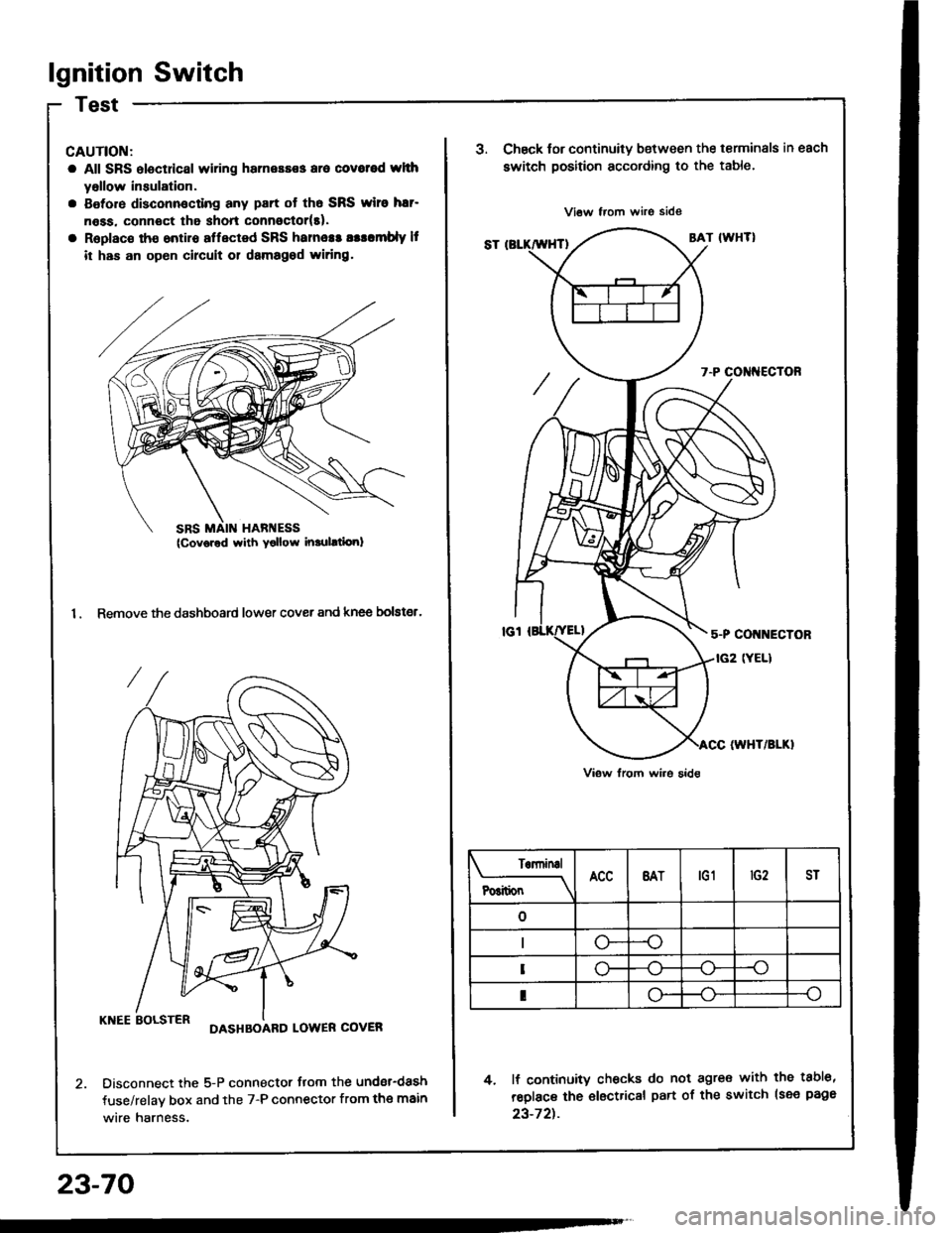

lgnition Switch

CAUTION:

a All SRS electdcal wiring harnessss aro covotod whh

yollow insulation.

a Botore disconnocting any part ot th6 SRS wiro har-

n6ss. connoct tha shon connoctor(t).

a Replac€ tho ontiro affected SRS hames! asllmbly It

it has an op6n circuit 01 damagod widng.

1. Remove the dashboard lower cover and knee bolster.

KNEE BOLSTERDASHBOARD LOWER COVER

Disconnect the 5-P connector flom the undsr-dash

fuse/relav box and the 7-P connector from the main

wire harness.

23-70

SRS MAIN HARI{ESS(Cov6red with Yollow inrulltiori)

J.Chsck tor continuity b€tween the terminals in each

switch position according to the table.

4. lf continuity checks do not agre€ with the tabl6,

reolace the €lectrical part of the switch lsee page

23-72t.

Terninal

P6itionBATtG1ST

--o

o-

I

Page 1189 of 1413

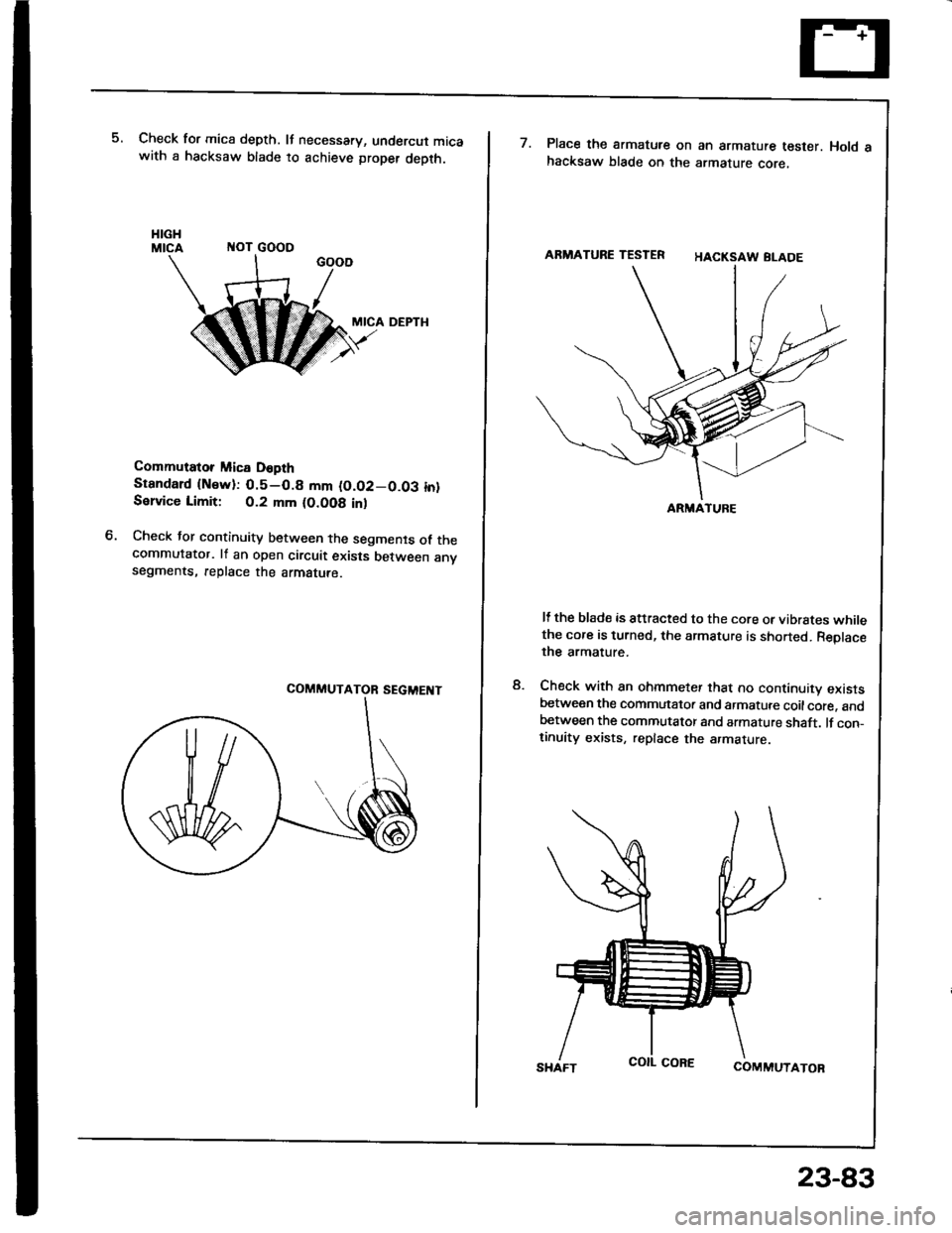

Check for mica depth. It necessary, undercut micawith a hacksaw blade to achieve proper depth.

ITOT GOOO

MICA DEPTH

Commutator Mica D6pth

Stsndard {Nsw):0.5-0.8 mm (O.O2-0.03 in}Sslvice Limit: 0.2 mm (O.OO8 inl

Check tor continuity between the segments of thecommutator. lf an open circuit exists between anvsegments, replace the armatute.

M

ARMATURE TESTER

ARMATUFE

Place the armatute on an armature tester. Hold ahacksaw blade on the armature core,

HACKSAW BLADE

It the blade is attracted to the core or vibrstes whilethe core is turned, the armature is shorted. Reolacethe armature.

Check with an ohmmeter that no continuity existsbetween the commutator and armatute coilcore. andbetween the commutator and armature shaft. lf con_tinuity exists, replace the armature

COMMUTATOR

8.

SHAFT

23-83